1. Introduction

A large number of wood-based products are encountered in everyday life. These products are used for extended periods of time and are often damaged by environmental changes [

1], which greatly affects both the appearance and function of the material. Restorers use old wood of the same quality and color as the original wood to replace damaged heritage pieces [

2]. Research has shown that this approach is not only feasible [

3], but it is almost impossible to distinguish the repaired section from the original wood in restored heritage pieces with the naked eye. Unfortunately, this restoration approach cannot be used to repair furniture still used in everyday life, because the restoration of antique wooden furniture requires the selection of suitable wood for replacement from a large amount of old wood, and the disassembly and assembly of furniture requires a clear understanding of the mortise and tenon structure of the furniture. Instead, these defects are often filled with a material that resembles the original shape and color. However, wood is not naturally adhesive, and therefore, binders are needed to construct wood-repair composites.

As noted by Fulcher [

4], the performance of wood-repair composites depends on both the properties of the binder and the filler, and hence, the binder and filler need to be treated and studied as a system. Current binders for wood restoration are classified according to the source materials, such as animal glues, waxes, oils, and natural resins [

5,

6,

7], as well as synthetic resins including acrylics [

8] and epoxies [

9]. Current natural fillers include natural wood shavings [

10], cellulose [

4], lignin [

11] derived from wood, calcium carbonate, wollastonite, soapstone [

12], and plaster [

13] of mineral origin, and there are also several synthetic fillers such as microballoons [

10,

14], fibers, and polymers [

6]. Despite the wide range of available binders and fillers, no one system has been shown to combine all the ideal properties of wood-repair composites. Therefore, Walsh-Korbs [

15] et al. have suggested that future research in wood protection should focus on multi-phase treatments and responsive technologies.

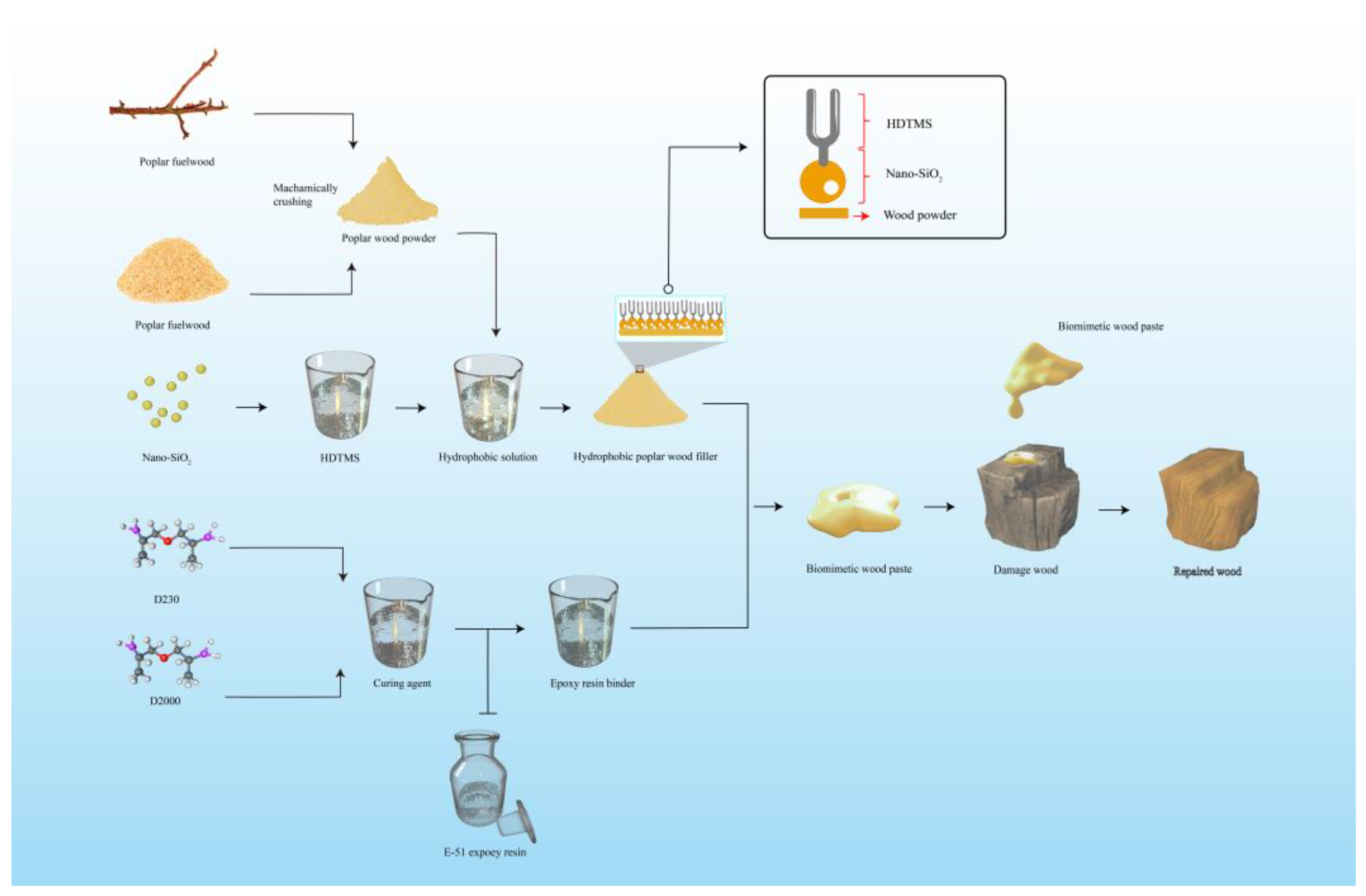

To further enhance the restorative properties, here, hydrophobic poplar wood fillers inspired by nature are proposed. For example, to enhance the interactions between the filler and binder and to increase the hydrophobicity of the wood-repair composite, the surface of the poplar filler was subjected to a hydrophobic modification treatment to mimic the papilla structure on the surface of lotus leaves. Also, binders were selected to mimic the high adhesion of mussel proteins, providing structural support and preventing further damage.

The focus of this study is the design of new wood composites for the efficient and effective repair of wood damaged by insects and splitting, which are the two most frequently encountered damages in daily life. The effects of the wood composites on the performance and interaction mechanisms are investigated using various testing methods. Notably, specially designed repair experiments showed a new method to characterize the mechanical properties of wood composites effectively and demonstrated the feasibility of the new approach for the repair of wooden artifacts, exposed outdoor wooden buildings, and household materials.

3. Results and Discussion

3.1. Contact-Angle Measurement

As seen in

Figure 3, the surface of the untreated poplar wood filler was hydrophilic and quickly absorbed water droplets placed on the surface, with a corresponding water contact angle of 0°. It showed very strong hydrophilicity, which is mainly due to the main component of poplar containing cellulose; each structural unit of the molecule has three hydroxyl groups, a kind of hydrophilic group. However, the surface of the modified poplar wood filler prepared via this method was highly hydrophobic. Water droplets placed on the surface of the hydrophobic poplar wood filler were spherical in shape, and the water contact angle was as high as 149.3°. The average value after removing the maximum and minimum contact angles was still 147.5°, showing that the samples were highly and uniformly hydrophobic. The hydrophobic modification is attributed to altering the surface properties of a material to make it repel water. This can be achieved by introducing hydrophobic silica to modify the surface chemistry of the material, which improves surface roughness [

16]. Additionally, the addition of HDTMS reduced the surface energy, and the synergistic effect with silicon dioxide improved the surface hydrophobicity of the materials. Specifically, the presence of micro- and nano-scale structures on the surface trapped air and reduced the contact area between water droplets and the surface. The successful hydrophobic modification of the filler particles was especially important in creating the wood composites, as the properties of the hydrophobic poplar filler are more similar to those of the hydrophobic chain segments of the epoxy resin, which will improve the binding between the filler and epoxy.

3.2. Mechanical Test

From

Figure 4, it can be seen that the elongation at the break and elastic modulus of the wood composites samples prepared with both the D-230 and D-2000 epoxies increased with an increase in the cure temperature. Increasing the cure temperature resulted in a more significant increase in the tensile strength of D-230 wood composite samples compared with the D-2000 wood composite samples. The different trends in the two samples were because, as the reaction temperature increased, the mesh structure formed by the epoxy resins was less uniform, and the material was more easily deformed. In particular, the tensile strength of the D-2000 samples was lower because these samples contained more flexible ether bonds that prevented the formation and propagation of cracks in the matrix when the resin was stretched. Therefore, the formation of an irregular mesh structure at higher curing temperatures did not significantly affect the tensile strength of the D-2000 samples.

As seen in

Figure 5, the elongation at the break showed a non-monotonic trend with the number-average molecular weight of the polyetheramines at a given cure temperature. In particular, the sample prepared with D-500 had the highest elongation at the break, and the elongation at the break then decreased significantly in the sample with D-1000 before increasing gradually with a further increase in molecular weight. Meanwhile, both the tensile strength and elastic modulus decreased with increasing molecular weight. The maximum in the elongation at the break of the D-500 sample was likely because the addition of a small amount of the long, flexible chain segments from D-2000 toughened the material. As the samples were deformed, either yielding or slip needed to occur to maintain the overall mesh structure. However, as the amount of D-2000 added increased, the D-230 chains were unable to form a compact network structure to fill the entire wood composites, and therefore, any cracks formed rapidly spread through the material until being stopped by a D-2000 entanglement. Because of these competing phenomena, there was an optimal amount of D-2000 where a minimum elongation at the break was observed. As the amount of D-2000 added increased, the resin became more homogenous, and the mechanical properties gradually approached those of the D-2000 wood composites. During tensile stress, the force was more uniformly distributed throughout these samples, and as a result, the elongation at the break increased. Meanwhile, the decrease in both the tensile strength and elastic modulus was directly related to the large number of flexible D-2000 chain segments in the samples with the higher number of average molecular weights.

The mechanical property measurements showed that a higher curing temperature and a moderate amount of D-2000 addition increased the elongation at the break of the wood composites samples. Successful wood composites will need to be both highly elastic and tough at room temperature to ensure that the filler remains bonded with the wood and does not crack when the repaired wood undergoes wet expansion and dry contraction. Based on the results presented above, the filler prepared with the D-500 and cured at 80 °C was selected as the optimal formulation and further characterized.

3.3. Rotational Rheology Measurement Results

The rheological properties of D-500 biomimetic wood paste at 80 °C in air were investigated and the results are presented in

Figure 6. The samples exhibited shear thinning behavior, indicating that their viscosity decreased with the increasing shear rate. When the samples were not subjected to any stress, the storage modulus (G′) was found to be higher than the loss modulus (G″), which is characteristic of a viscoelastic solid. At a strain of approximately 0.1%, the storage modulus and loss modulus intersected, suggesting a transition from a viscoelastic solid to a viscoelastic fluid. At higher shear rates, the modulus exceeded the storage modulus, indicating that the samples behaved predominantly as a viscoelastic fluid. This implies that under the applied shear, the D-500 biomimetic wood paste underwent rapid deformation and could easily flow and conform to the shape of defects in damaged wood.

When the external force was removed, the D-500 biomimetic wood paste reverted to behaving as a viscoelastic solid. This means that it would retain its solid form in the defect site, providing structural support and preventing further damage. The ability of the biomimetic wood paste to transition between a solid and a fluid state under different shear conditions makes it an ideal material for filling and repairing damaged wood.

These rheological properties of the D-500 biomimetic wood paste at elevated temperatures suggest that it has the potential to be used in various applications, such as wood restoration and preservation. Its ability to flow and conform to irregular surfaces, combined with its solid-like behavior after deformation, makes it a promising material for repairing and reinforcing damaged wood structures. Further research and development are needed to optimize the formulation and application of this biomimetic wood paste for practical use.

3.4. Scanning Electron Microscopy (SEM)

It can be seen from

Figure 7 that there was no obvious interface between the hydrophobic poplar filler and the epoxy resin binder, and the epoxy resin binder evenly coated the poplar filler surfaces. This good compatibility confirmed that the hydrophobic modification strategy was an effective way to improve the compatibility of the filler and binder. In the cross-sectional images of the stretched samples, the folds formed by the pulling of the hydrophobic poplar filler could be seen, but no holes in the resin matrix from the pulled-out filler particles or fractured filler particles could be seen [

17]. Together with the folds and cracks in the resin matrix seen in

Figure 7b,c, these images show that the majority of the fractures occurred in the resin matrix, and the hydrophobic poplar filler prevented extensive slip of the matrix and crack propagation. These results highlight that the D-500 wood composites prepared here had good mechanical properties that are ideal for a wood-repair composite.

As shown in

Figure 7, the interface between the hydrophobic poplar filler and the epoxy resin binder was not clearly visible, indicating strong compatibility between the two materials. The epoxy resin binder was observed to uniformly coat the surfaces of the poplar filler, demonstrating the effectiveness of the hydrophobic modification strategy in enhancing the compatibility between the filler and binder in the artificial adhesive.

In the cross-sectional images of the stretched samples, it was evident that the hydrophobic poplar filler was pulled out of the resin, but no holes or voids caused by the pulled-out filler particles or fractured filler particles were observed in the resin matrix. This observation, combined with the presence of folds and cracks in the resin matrix, as shown in

Figure 7b,c, suggests that most of the fractures occurred within the resin matrix, while the hydrophobic poplar filler effectively prevented extensive slippage and crack propagation in the matrix.

These findings highlight the excellent mechanical properties of the D-500 wood composites, making them an ideal material for wood-repair composites.

3.5. Fourier Transform Infrared-Raman (FT-IR) Results

Fourier infrared spectroscopy was used to identify the functional groups in the hydrophobic poplar filler, D-500 epoxy resin binder, and D-500 wood composites. The peaks seen at 1608 cm

−1,1509 cm

−1, and 827 cm

−1 in the spectrum in

Figure 8 were characteristic of aromatic rings, and the peaks at 1460 cm

−1 were characteristic of C-H deformations and CH3 asymmetric bending vibrations. Peaks characteristic of C-H bending vibrations at 1374 cm

−1, ether groups at 1249 cm

−1, C-N stretching vibrations at 1182 cm

−1, and C-O-C stretching vibrations at 1034 cm

−1 were all present in the D-500 wood composites and corresponding blank specimens. However, the intensities of these peaks were significantly reduced compared with those of the unpolymerized groups [

18], indicating that a significant number of the oxirane groups had reacted to form the mesh structure. The functional groups present in the D-500 wood composite spectrum were more similar to those of the blank wood than the treated hydrophobic filler and were consistent with the expected composition based on the added epoxy resin binder and hydrophobic poplar filler. In addition, the D-500 wood composite sample contained the same functional groups seen in the epoxy resin binder and hydrophobic poplar filler, except the oxirane group. Moreover, the spectra were unchanged after the molding process, indicating that the epoxy resin binder did not chemically react with the filler. These results showed that the resin acted as a physical adhesive, like mussel proteins, which would help protect the surface of the damaged wood and could facilitate the cleaning of the caulk when the wood is repaired.

3.6. Synchronous Thermal Analysis (TG-DSC) Results

Thermal analysis of the hydrophobic poplar filler, D-500 epoxy resin binder, and D-500 wood composites was conducted, and the results are shown in

Figure 9. From

Figure 9, it can be seen that the mass loss of the samples was less than 4% below 220 °C, and no significant weight loss was observed. There were no heat flow peaks in the DSC curves of the epoxy resin binder or the wood composites below 220 °C, indicating that the epoxy resin binder was completely cured and the wood composites did not have a glass transition temperature. As a result, the mechanical properties of the wood composites would be stable below 220 °C.

These findings are significant, as they demonstrate the thermal stability of the wood composites. The absence of weight loss and heat flow peaks below 220 °C indicates that the composite materials can withstand elevated temperatures without undergoing significant degradation or structural changes. This is crucial for applications where the wood composites may be exposed to high temperatures, such as in outdoor environments or near heat sources.

The thermal stability of the wood composites also ensures the longevity and durability of the repaired or reinforced wood structures. By maintaining its mechanical properties below 220 °C, the composite can effectively provide structural support and prevent further damage, even in challenging thermal conditions.

Overall, the thermal analysis results confirm the suitability of the hydrophobic poplar filler, D-500 epoxy resin binder, and D-500 wood composites for applications that require thermal stability. Further research and testing are necessary to explore the behavior of the wood composites at higher temperatures and to optimize their formulation for specific applications.

3.7. X-ray Photoelectron Spectroscopy (XPS) Results

XPS is a surface-sensitive analytical technique that provides information about the chemical composition and electronic structure of the material. From the XPS analysis spectrum presented in

Figure 10 of this research paper, it can be observed that the wood composite sample contained 2s and 2p peaks of Si and 1s absorption peaks of C, O, and F. The presence of the Si peaks confirms the successful incorporation of hydrophobic SiO

2 and cetyltrimethoxysilane into the poplar wood powder. This modification imparted hydrophobic properties to the wood powder, making it resistant to moisture and water. The hydrophobic properties of the wood composites make them ideal for outdoor applications where they may be exposed to moisture or rain. The hydrophobic modification also improves the durability and longevity of the composite material, thus making it more resistant to decay and insect damage.

In addition to the Si peaks, the XPS analysis spectrum also showed the presence of F, which was attributed to the defoamer and other additives present in the composite material. The defoamer was added to the epoxy resin binder to prevent air bubbles from forming during the curing process, which may weaken the material’s mechanical properties.

Overall, the XPS analysis confirmed the successful incorporation of hydrophobic SiO2 and cetyltrimethoxysilane into the poplar wood powder, resulting in wood composites with improved hydrophobic properties. The presence of other elements such as F was also identified, indicating the composition complexity of the composite material. The results of the XPS analysis provide valuable information for optimizing the formulation of wood composites for various applications.

3.8. Brunauer-Emmett-Teller (BET) Specific Surface Area Results

From the data presented in

Table 1 of this research paper, it can be observed that the specific surface area, BJH hole volume, and BJH average pore size of the wood composite sample were similar to those of the hydrophobic poplar wood filler and poplar panels. This similarity suggests that the wood composites have a comparable pore structure to both the hydrophobic poplar wood filler and the natural poplar panels.

However, upon closer examination, it was found that the values measured for the wood composites were more similar to those of poplar panels than those of the hydrophobic poplar wood filler. This indicates that the pore structure of the prepared wood composite samples is closer to that of poplar panels than that of the natural poplar.

The similarity in pore structure between the wood composites and poplar panels is significant, as it suggests that the wood composites have properties that closely resemble natural wood. This is important for applications where the appearance and performance of wood are desired, such as in furniture, flooring, and construction materials.

The comparable pore structure also indicates that the wood composites have the potential to exhibit similar moisture absorption and release properties as natural wood. This is advantageous, as it allows the wood composites to maintain their dimensional stability and resist moisture-related issues such as warping, swelling, and decay.

In conclusion, the surface area analysis of the wood composites revealed that their pore structure is more similar to that of poplar panels than that of the hydrophobic poplar wood filler. This finding highlights the potential of the wood composites to mimic the properties of natural wood, making them a promising material for various applications.

3.9. Poplar Panel Restoration

In

Figure 11 and

Figure 12, the comparison of the mechanical properties of the damaged poplar panels containing circular and strip defects with the undamaged poplar panels revealed significant decreases in tensile strength, elastic modulus, and static flexural strength. This indicates that insect and dry crack damage have a detrimental effect on the performance of wood-based products.

These findings emphasize the importance of developing effective wood-repair composites to restore the mechanical properties of damaged wood. In this study, D-500 wood composites were used as a repair material for damaged poplar panels. The results showed a significant improvement in both the tensile and bending properties of the repaired poplar panels.

Notably, the samples with repaired strip defects, which mimic dry crack damage, exhibited the best results. The elastic modulus of the repaired sample was found to be 97% that of the original, undamaged poplar panel. This indicates that the wood composites successfully restored the stiffness and strength of the damaged wood, approaching the performance of the undamaged wood.

The improved mechanical properties of the repaired poplar panels can be attributed to the unique structure and properties of the wood composites. The wood composites are designed to mimic the hierarchical structure and mechanical properties of natural wood, including its high strength and stiffness. This allows the wood composites to effectively reinforce and restore damaged wood, enhancing its overall performance.

The successful repair of the damaged poplar panels using the D-500 wood composites has significant implications for the wood industry. It provides a sustainable and efficient solution for repairing damaged wood-based products, reducing waste, and extending the lifespan of wooden materials. Additionally, the wood composites offer the potential for improved durability and resistance to future damage, ensuring the longevity and reliability of wood-based products.

In conclusion, the tensile and bending properties of the damaged poplar panels were significantly improved by repairing them with the D-500 wood composites. The repaired samples, particularly those with strip defects resembling dry crack damage, exhibited mechanical properties approaching those of the undamaged poplar panels. This highlights the potential of wood composites as an effective repair material for damaged wood-based products, contributing to the sustainability and performance of the wood industry.

4. Conclusions

In this paper, wood composites were prepared using epoxy resin, polyetheramines, and poplar fibers for wood fibers. The wood composites were designed to mimic the papillary structure of the lotus leaf surface, to improve the binding between the filler and epoxy, and the high adhesion of mussel proteins, providing structural support and preventing further damage. Notably, the flow state, microstructure, and surface elemental composition of wood composites with polyetheramines D-500 at 80 °C were analyzed in detail. The epoxy resin binder was shown to be hydrophobic, similar to the hydrophobic poplar wood filler, thereby increasing the compatibility between the filler and matrix. The chemical composition of the wood composites was also similar to the resin binder, and the filler primarily bonded to the wood through physical adhesion. The binding and mechanical properties of the filler remained stable up to 220 °C. Moreover, the biomimetic wood paste behaved as a viscoelastic solid that retained its original shape at rest but easily flowed when deformed, allowing it to easily flow into damaged sections of wood samples. In summary, the wood composites produced in this paper could be used to repair damage commonly seen in wooden materials used in everyday life and provides a new approach to the restoration of wooden artifacts, exposed outdoor wooden buildings, and household materials.