Exploring Sustainable Innovation Level, Spatial Inequities, and Convergence Trends in China’s Wood Industry

Abstract

:1. Introduction

2. Literature Review

2.1. Sustainable Innovation Theory

2.2. Research on Wood Industry Innovation

3. Materials and Methods

3.1. Construction of Sustainable Innovation Index for Wood Industry

3.1.1. Internal Logic of Sustainable Innovation

3.1.2. Selection and Explanation of Basic Indicators

3.1.3. Construction of Index by Projection Pursuit Method

- (1)

- Standardization of sample index values

- (2)

- Construct the projected eigenvalue function Zi

- (3)

- Construct the projection indicator function Q(a).

- (4)

- Solving the optimal projection direction

- (5)

- Solving the value of sustainable innovation index of the wood industry

3.2. Analysis Method of Dynamic Evolution and Regional Difference Characteristics

3.2.1. Kernel Density Estimation Method

3.2.2. Dagum Gini Coefficient and Its Decomposition

3.3. Convergence Characteristic Analysis Method

3.3.1. σ Convergence

3.3.2. Spatial Correlation

- (1)

- Global Moran’s I

- (2)

- Local Moran’s I

3.3.3. β Convergence

3.4. Data Sources

4. Results

4.1. Measurement Results of Sustainable Innovation Index of Wood Industry

4.2. Regional Distribution of Sustainable Innovation Index

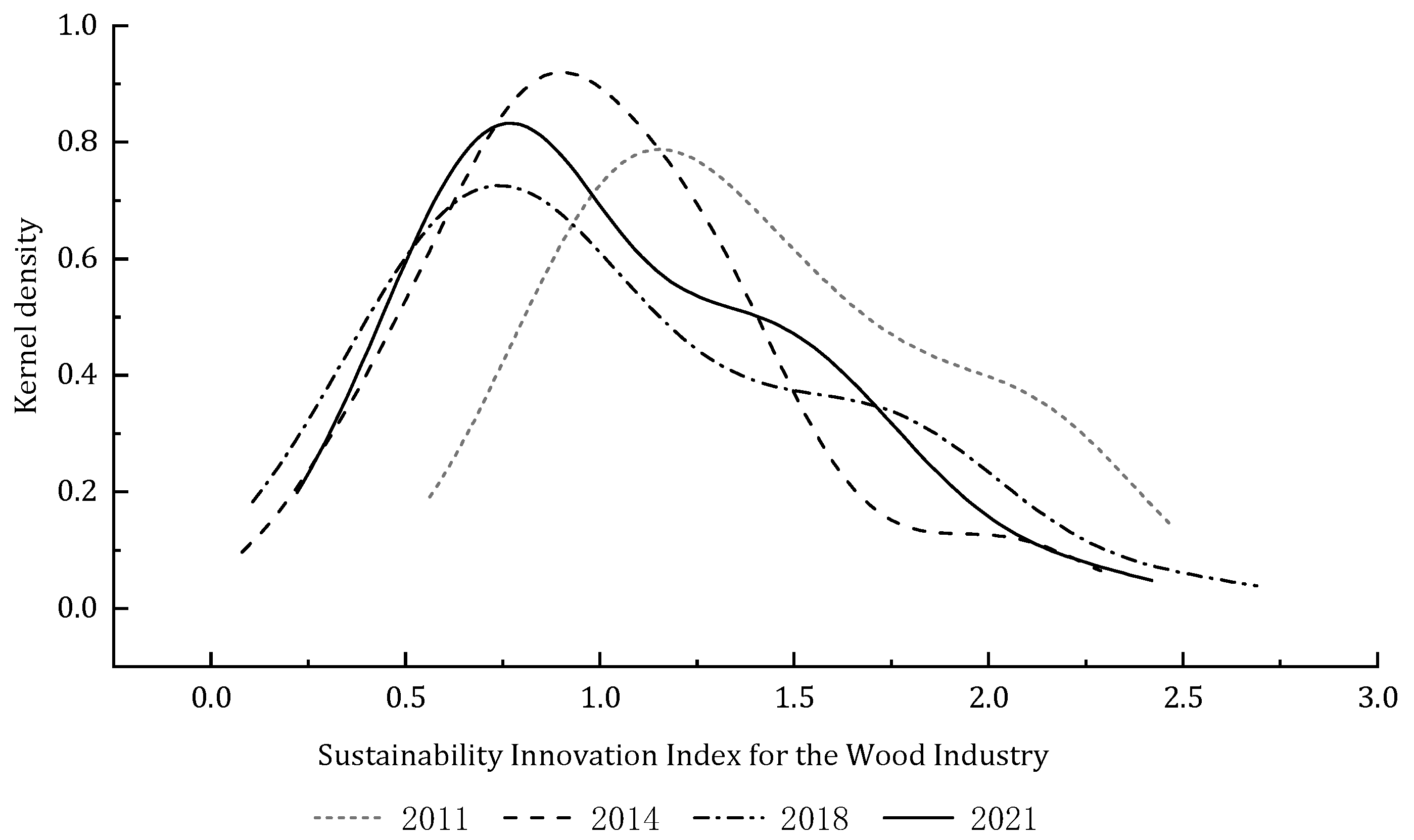

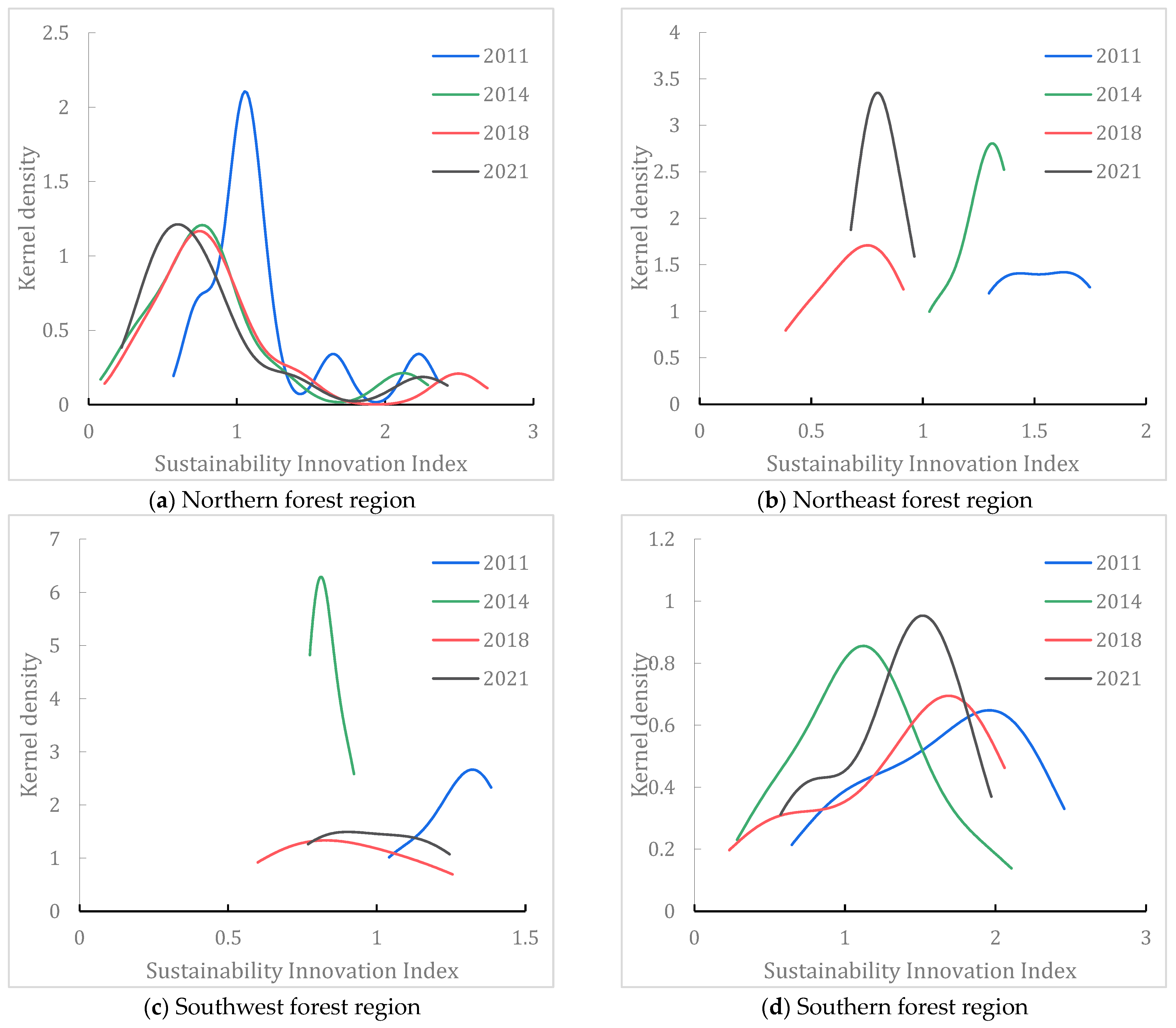

4.3. Distribution Dynamics and Evolution Characteristics

4.4. Regional Differences and Their Sources

4.5. Convergence Characteristics of Sustainable Innovation Index of China’s Wood Industry

4.5.1. Results of σ Convergence

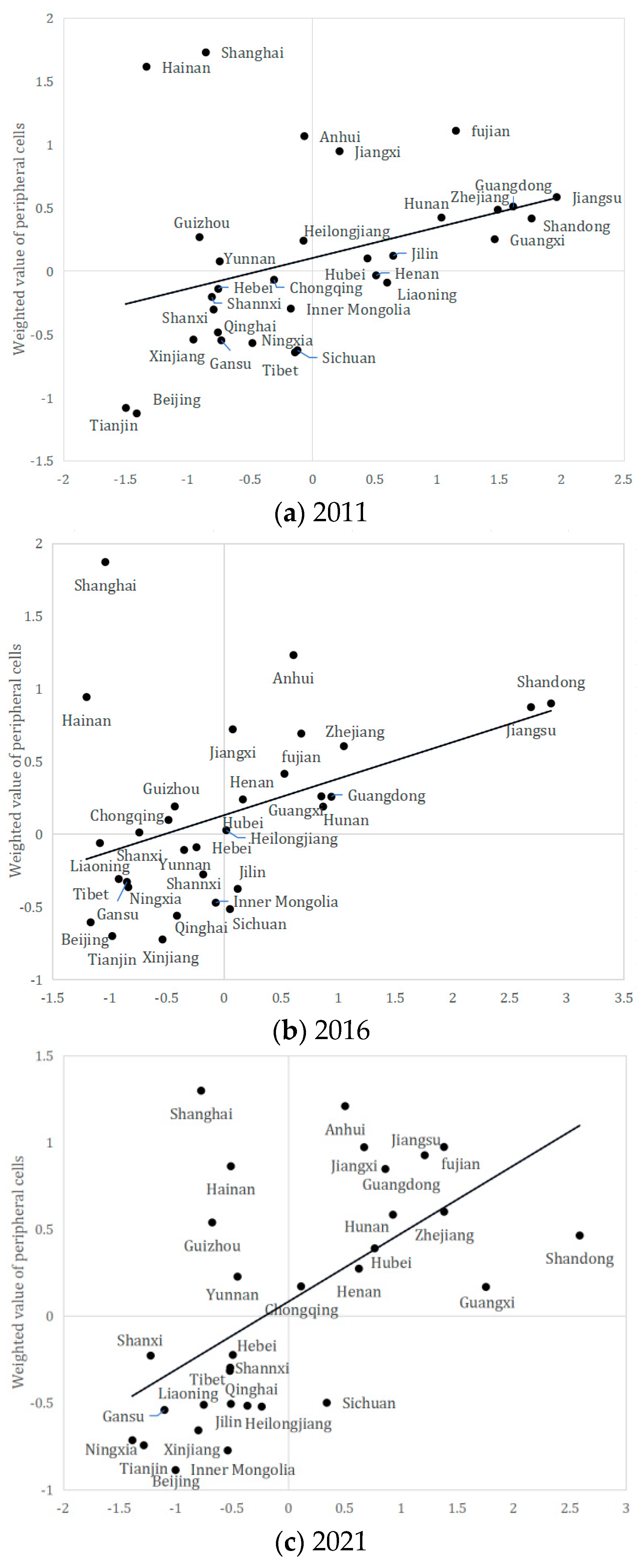

4.5.2. Spatial Correlation Analysis

- Global Moran’s I

- 2.

- Local Moran’s I

4.5.3. Trend of β Convergence

- Absolute β convergence analysis

- 2.

- Conditional β convergence analysis

5. Discussion

5.1. Regional Imbalance in Sustainable Innovation Hinders Wood Industry Progress and Fair Benefit Allocation

5.2. Differential Impact of Regional Differences on β Convergence of Wood Industry Conditions and Sustainable Innovation

6. Conclusions and Recommendations

6.1. Conclusions

6.2. Policy Recommendations

- Strengthen the innovation leadership of advantageous forest areas and deepen cooperation and exchange

- 2.

- Strengthen the support of elements to enhance the overall efficiency of the industry

- 3.

- Increase support to promote the rapid development of backward forest areas

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dahlander, L.; Gann, D.M.; Wallin, M.W. How open is innovation? A retrospective and ideas forward. Res. Policy 2021, 50, 104218. [Google Scholar] [CrossRef]

- Cui, R.; Song, H.; Li, D. Global value chain embeddedness, technology spillover and enterprise innovation. Int. Rev. Econ. Financ. 2024, 93, 758–771. [Google Scholar] [CrossRef]

- Fabrizio, K.R.; Poczter, S.; Zelner, B.A. Does innovation policy attract international competition? Evidence from energy storage. Res. Policy 2017, 46, 1106–1117. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, X.; Kong, F. The dynamic impact of digital economy on the green development of traditional manufacturing industry: Evidence from China. Econ. Anal. Policy 2023, 80, 143–160. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, H.; Li, S. Future social change of manufacturing and service industries: Service-oriented manufacturing under the integration of innovation-flows drive. Technol. Forecast. Soc. Chang. 2023, 196, 122808. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, Y.; Yu, C.; Qi, J.; Yang, C.; Cheng, B.; Liang, S. Global timber harvest footprints of nations and virtual timber trade flows. J. Clean. Prod. 2020, 250, 119503. [Google Scholar] [CrossRef]

- Chen, C.; Duan, C.; Li, J.; Liu, Y.; Ma, X.; Zheng, L.; Stavik, J.; Ni, Y. Cellulose (dissolving pulp) manufacturing processes and properties: A mini-review. BioResources 2016, 11, 5553–5564. [Google Scholar] [CrossRef]

- Hasan, S.S.; Zhang, Y.; Chu, X.; Teng, Y. The role of big data in China’s sustainable forest management. For. Econ. Rev. 2019, 1, 96–105. [Google Scholar] [CrossRef]

- Calik, E.; Bardudeen, F. A measurement scale to evaluate sustainable innovation performance in manufacturing organizations. Procedia CIRP 2016, 40, 449–454. [Google Scholar] [CrossRef]

- Alfranca, O.; Voces, R.; Herruzo, A.C.; Diaz-Balteiro, L. Effects of innovation on the European wood industry market structure. For. Policy Econ. 2014, 40, 40–47. [Google Scholar] [CrossRef]

- Ng, B.; Thiruchelvam, K. The dynamics of innovation in Malaysia’s wooden furniture industry: Innovation actors and linkages. For. Policy Econ. 2012, 14, 107–118. [Google Scholar] [CrossRef]

- Molinaro, M.; Orzes, G. From forest to finished products: The contribution of Industry 4.0 technologies to the wood sector. Comput. Ind. 2022, 138, 103637. [Google Scholar] [CrossRef]

- Purkus, A.; Hagemann, N.; Bedtke, N.; Gawel, E. Towards a sustainable innovation system for the German wood-based bioeconomy: Implications for policy design. J. Clean. Prod. 2018, 172, 3955–3968. [Google Scholar] [CrossRef]

- Li, N.; Toppinen, A.; Lantta, M. Managerial perceptions of SMEs in the wood industry supply chain on corporate responsibility and competitive advantage: Evidence from China and Finland. J. Small Bus. Manag. 2016, 54, 162–186. [Google Scholar] [CrossRef]

- Tao, C.; Gao, Z.; Cheng, B.; Chen, F.; Yu, C. Enhancing wood resource efficiency through spatial agglomeration: Insights from China’s wood-processing industry. Resour. Conserv. Recycl. 2024, 203, 107453. [Google Scholar] [CrossRef]

- Degler, T.; Agarwal, N.; Nylund, P.A.; Brem, A. Sustainable innovation types: A bibliometric review. Int. J. Innov. Manag. 2021, 25, 2150096. [Google Scholar] [CrossRef]

- Shakeel, J.; Mardani, A.; Chofreh, A.G.; Goni, F.A.; Klemeš, J.J. Anatomy of sustainable business model innovation. J. Clean. Prod. 2020, 261, 121201. [Google Scholar] [CrossRef]

- Ruggerio, C.A. Sustainability and sustainable development: A review of principles and definitions. Sci. Total Environ. 2021, 786, 147481. [Google Scholar] [CrossRef]

- Silvestre, B.S.; Ţîrcă, D.M. Innovations for sustainable development: Moving toward a sustainable future. J. Clean. Prod. 2019, 208, 325–332. [Google Scholar] [CrossRef]

- Zeng, D.; Hu, J.; Ouyang, T. Managing innovation paradox in the sustainable innovation ecosystem: A case study of ambidextrous capability in a focal firm. Sustainability 2017, 9, 2091. [Google Scholar] [CrossRef]

- Ilic, S.; Petrovic, T.; Djukic, G. Eco-innovation and sustainable development. Probl. Ekorozwoju 2022, 17, 197–203. [Google Scholar] [CrossRef]

- Bakhtina, V.A. Innovation and its potential in the context of the ecological component of sustainable development. Sustain. Account. Manag. Policy J. 2011, 2, 248–262. [Google Scholar]

- Dyck, B.; Silvestre, B.S. Enhancing socio-ecological value creation through sustainable innovation 2.0: Moving away from maximizing financial value capture. J. Clean. Prod. 2018, 171, 1593–1604. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, L.; Zhang, H. A sustainable innovation strategy oriented toward complex product Servitization. Sustainability 2022, 14, 4290. [Google Scholar] [CrossRef]

- Escobar, A.; Luna, J.; Caraballo, A. Barriers to sustainable green innovation in meeting the challenges of the global economy of firms. Glob. J. Environ. Sci. Manag. 2023, 9, 219–232. [Google Scholar]

- Hermundsdottir, F.; Aspelund, A. Competitive sustainable manufacturing-Sustainability strategies, environmental and social innovations, and their effects on firm performance. J. Clean. Prod. 2022, 370, 133474. [Google Scholar] [CrossRef]

- Schaltegger, S.; Wagner, M. Sustainable entrepreneurship and sustainability innovation: Categories and interactions. Bus. Strategy Environ. 2011, 20, 222–237. [Google Scholar] [CrossRef]

- Johnsson, S.; Andersson, E.; Thollander, P.; Karlsson, M. Energy savings and greenhouse gas mitigation potential in the Swedish wood industry. Energy 2019, 187, 115919. [Google Scholar] [CrossRef]

- Zhan, W.; Yang, Z.; Xu, H.; Xue, S.; Lin, J.; Guan, X. Exploring the potential of StyleGAN for modeling high-quality and diverse digital wood textures: Towards advancements in the wood industry. Ind. Crops Prod. 2024, 209, 117880. [Google Scholar] [CrossRef]

- Evans, S.; Vladimirova, D.; Holgado, M.; Van Fossen, K.; Yang, M.; Silva, E.A.; Barlow, C.Y. Business model innovation for sustainability: Towards a unified perspective for creation of sustainable business models. Bus. Strategy Environ. 2017, 26, 597–608. [Google Scholar] [CrossRef]

- Stojčić, N.; Anić, I.; Aralica, Z. Do firms in clusters perform better? Lessons from wood-processing industries in new EU member states. For. Policy Econ. 2019, 109, 102043. [Google Scholar] [CrossRef]

- Scordato, L.; Klitkou, A.; Tartiu, V.E.; Coenen, L. Policy mixes for the sustainability transition of the pulp and paper industry in Sweden. J. Clean. Prod. 2018, 183, 1216–1227. [Google Scholar] [CrossRef]

- Schulte, M.; Jonsson, R.; Eggers, J.; Hammar, T.; Stendahl, J.; Hansson, P. Demand-driven climate change mitigation and trade-offs from wood product substitution: The case of Swedish multi-family housing construction. J. Clean. Prod. 2023, 421, 138487. [Google Scholar] [CrossRef]

- Khoaele, K.K.; Gbadeyan, O.J.; Chunilall, V.; Sithole, B. A review on waste wood reinforced polymer composites and their processing for construction materials. Int. J. Sustain. Eng. 2023, 16, 104–116. [Google Scholar] [CrossRef]

- Zanchini, R.; Blanc, S.; Pippinato, L.; Poratelli, F.; Bruzzese, S.; Brun, F. Enhancing wood products through ENplus, FSC and PEFC certifications: Which attributes do consumers value the most? For. Policy Econ. 2022, 142, 102782. [Google Scholar] [CrossRef]

- Vergarechea, M.; Astrup, R.; Fischer, C.; Øistad, K.; Blattert, C.; Hartikainen, M.; Eyvindson, K.; Di Fulvio, F.; Forsell, N.; Burgas, D. Future wood demands and ecosystem services trade-offs: A policy analysis in Norway. For. Policy Econ. 2023, 147, 102899. [Google Scholar] [CrossRef]

- Cai, Z.; Aguilar, F.X. Consumer stated purchasing preferences and corporate social responsibility in the wood products industry: A conjoint analysis in the US and China. Ecol. Econ. 2013, 95, 118–127. [Google Scholar] [CrossRef]

- Sachs, J.D. The Age of Sustainable Development; Columbia University Press: New York, NY, USA, 2015; ISBN 0231173148. [Google Scholar]

- Khorshidi, K.; Choukolaei, H.A.; Ghasemi, P. Sustainable solutions for the wood and paper industry: A comprehensive assessment of the rural environment impact. J. Eng. Res. 2023, in press. [Google Scholar] [CrossRef]

- Nijnik, M.; Nijnik, A.; Sarkki, S.; Muñoz-Rojas, J.; Miller, D.; Kopiy, S. Is forest related decision-making in European treeline areas socially innovative? A Q-methodology enquiry into the perspectives of international experts. For. Policy Econ. 2018, 92, 210–219. [Google Scholar] [CrossRef]

- Ziemnowicz, C.; Joseph, A. Schumpeter and innovation. In Encyclopedia of Creativity, Invention, Innovation and Entrepreneurship; Springer: Berlin/Heidelberg, Germany, 2020; pp. 1517–1522. [Google Scholar]

- Moore, J.E.; Mascarenhas, A.; Bain, J.; Straus, S.E. Developing a comprehensive definition of sustainability. Implement. Sci. 2017, 12, 110. [Google Scholar] [CrossRef]

- Domljan, I.; Domljan, V. Enterprise-based Support to Innovative Activities. In International Conference “New Technologies, Development and Applications; Springer: Cham, Switzerland, 2021; pp. 1166–1172. [Google Scholar]

- Le, T.T.; Vo, X.V.; Venkatesh, V.G. Role of green innovation and supply chain management in driving sustainable corporate performance. J. Clean. Prod. 2022, 374, 133875. [Google Scholar] [CrossRef]

- Zhang, F.; Zhu, L. Enhancing corporate sustainable development: Stakeholder pressures, organizational learning, and green innovation. Bus. Strategy Environ. 2019, 28, 1012–1026. [Google Scholar] [CrossRef]

- Wang, W.; Feng, Y.J.; Chen, W.F.; Li, F.L. An Evaluation Method of Water Resources Carrying Capacity Based on Projection Pursuit Model. Adv. Mater. Res. 2013, 652, 1710–1716. [Google Scholar] [CrossRef]

- Ge, M.; Lin, H. Evaluation of China’s regional innovation capability based on simulated annealing projection pursuit model and nested fuzzy evaluation model. Expert Syst. 2023, 40, e13179. [Google Scholar] [CrossRef]

- Anselin, L.; Rey, S. Properties of tests for spatial dependence in linear regression models. Geogr. Anal. 1991, 23, 112–131. [Google Scholar] [CrossRef]

- Xue, L.; Luo, X.; Wu, X. Carbon sequestration efficiency in four major forest regions in China: Measurement, drivers and convergence. J. Nat. Resour. 2016, 31, 1351–1363. (In Chinese) [Google Scholar]

- Zheng, C.; Deng, F.; Li, C.; Yang, Z. The impact of China’s western development strategy on energy conservation and emission reduction. Environ. Impact Assess. Rev. 2022, 94, 106743. [Google Scholar] [CrossRef]

- Ren, W.; Xue, B.; Yang, J.; Lu, C. Effects of the Northeast China revitalization strategy on regional economic growth and social development. Chin. Geogr. Sci. 2020, 30, 791–809. [Google Scholar] [CrossRef]

- Wan, M.; Lähtinen, K.; Toppinen, A. Strategic transformation in the value-added wood products companies: Case study evidence from China. Int. J. Emerg. Mark. 2015, 10, 224–242. [Google Scholar] [CrossRef]

- Luo, Y.; Chen, Y.; Tao, C.; Yang, C.; Xiang, F.; Xu, C.; Lin, F. The Impact of the Digital Economy on Supply Chain Security: Evidence from China’s Wooden Furniture Industry. Forests 2024, 15, 879. [Google Scholar] [CrossRef]

- Tan, Q.; Imamura, K.; Nagasaka, K.; Inoue, M. Consumer price premiums for FSC-labeled wood flooring: A comparison of five Chinese cities. BioProducts Bus. 2020, 5, 13–24. [Google Scholar]

- Barbu, M.C.; Tudor, E.M. State of the art of the Chinese forestry, wood industry and its markets. Wood Mater. Sci. Eng. 2022, 17, 1030–1039. [Google Scholar] [CrossRef]

- Zhang, M.; Song, G.; Ma, N. A mechanism for upgrading the global value chain of China’s wood industries based on sustainable green growth. J. Clean. Prod. 2024, 449, 141717. [Google Scholar] [CrossRef]

- Schubert, M.; Panzarasa, G.; Burgert, I. Sustainability in wood products: A new perspective for handling natural diversity. Chem. Rev. 2022, 123, 1889–1924. [Google Scholar] [CrossRef]

- Dong, X.; Gan, W.; Shang, Y.; Tang, J.; Wang, Y.; Cao, Z.; Xie, Y.; Liu, J.; Bai, L.; Li, J. Low-value wood for sustainable high-performance structural materials. Nat. Sustain. 2022, 5, 628–635. [Google Scholar] [CrossRef]

- Mi, X.; Feng, G.; Hu, Y.; Zhang, J.; Chen, L.; Corlett, R.T.; Hughes, A.C.; Pimm, S.; Schmid, B.; Shi, S. The global significance of biodiversity science in China: An overview. Natl. Sci. Rev. 2021, 8, b32. [Google Scholar] [CrossRef]

- Chen, N.; Qin, F.; Zhai, Y.; Cao, H.; Zhang, R.; Cao, F. Evaluation of coordinated development of forestry management efficiency and forest ecological security: A spatiotemporal empirical study based on China’s provinces. J. Clean. Prod. 2020, 260, 121042. [Google Scholar] [CrossRef]

| First Level Indicators | Second Level Indicators | Third Level Indicators | Type |

|---|---|---|---|

| Sustainable innovation level | Factors support sustainability | Number of enterprise units | Positive |

| Fixed assets investment | Positive | ||

| Average number of employees | Positive | ||

| Industrial benefits sustainability | Net profit margin | Positive | |

| Asset liability ratio | Positive | ||

| Total asset contribution rate | Positive | ||

| Operating revenue realized per 100 CNY of assets | Positive | ||

| Current asset turnover rate | Positive | ||

| Operating costs per 100 CNY of operating revenue | Negative | ||

| Operating revenue profit margin | Positive | ||

| Average wage | Positive | ||

| Carbon emissions | Negative | ||

| Innovative research and development sustainability | Technology funding investment | Positive | |

| Number of R&D in science and technology | Positive | ||

| Number of research institutions | Positive | ||

| Application promotion sustainability | Sales expense ratio | Positive | |

| Administrative/management expense ratio | Positive | ||

| Number of key forestry leading enterprises | Positive | ||

| Industrial agglomeration level | Positive | ||

| International cooperation sustainability | Customs export value | Positive | |

| Foreign capital dependence | Interval |

| Region | Province |

|---|---|

| Northern Forest Region | Beijing, Tianjin, Hebei, Shanxi, Shandong, Henan, Shaanxi, Gansu, Qinghai, Ningxia, Xinjiang |

| Northeast Forest Region | Inner Mongolia, Liaoning, Jilin, Heilongjiang |

| Southwest Forest Region | Sichuan, Yunnan, Tibet |

| Southern Forest Region | Shanghai, Jiangsu, Zhejiang, Fujian, Anhui, Jiangxi, Hubei, Hunan, Guangdong, Guangxi, Hainan, Guizhou |

| Region | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Northern Forest Region | 1.165 | 0.929 | 0.962 | 0.849 | 1.109 | 1.049 | 0.889 | 0.928 | 0.829 | 0.855 | 0.841 |

| Northeast Forest Region | 1.530 | 1.404 | 1.244 | 1.251 | 1.037 | 1.037 | 0.744 | 0.684 | 0.656 | 0.639 | 0.814 |

| Southwest Forest Region | 1.263 | 0.964 | 1.033 | 0.835 | 1.021 | 0.946 | 0.717 | 0.901 | 0.854 | 1.033 | 0.990 |

| Southern Forest Region | 1.653 | 1.324 | 1.341 | 1.112 | 1.309 | 1.404 | 1.272 | 1.361 | 1.266 | 1.340 | 1.341 |

| Countrywide | 1.414 | 1.148 | 1.154 | 1.001 | 1.166 | 1.171 | 0.996 | 1.061 | 0.979 | 1.038 | 1.050 |

| Level | Southern Forest Region | Northern Forest Region | Northeast Forest Region | Southwest Forest Region |

|---|---|---|---|---|

| high level | Jiangsu, Zhejiang, Fujian, Hunan, Guangdong, Guangxi | Shandong, Henan | ||

| medium-high level | Anhui, Jiangxi, Hubei | Jilin | Sichuan | |

| medium-low level | Hebei, Shaanxi, Qinghai | Inner Mongolia, Heilongjiang | Chongqing | |

| low level | Shanghai, Hainan, Guizhou | Beijing, Tianjin, Shanxi, Gansu, Ningxia, Xinjiang | Liaoning | Yunnan, Tibet |

| Gini Coefficient | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 | Average |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Countrywide | 0.181 | 0.220 | 0.216 | 0.229 | 0.195 | 0.236 | 0.270 | 0.282 | 0.258 | 0.272 | 0.241 | 0.236 |

| Northern Forest Region | 0.168 | 0.208 | 0.254 | 0.281 | 0.212 | 0.248 | 0.234 | 0.294 | 0.258 | 0.303 | 0.290 | 0.250 |

| Northeast Forest Region | 0.059 | 0.098 | 0.037 | 0.044 | 0.132 | 0.119 | 0.190 | 0.133 | 0.093 | 0.094 | 0.056 | 0.096 |

| Southwest Forest Region | 0.047 | 0.076 | 0.044 | 0.030 | 0.073 | 0.107 | 0.161 | 0.127 | 0.152 | 0.065 | 0.092 | 0.089 |

| Southern Forestry Region | 0.168 | 0.208 | 0.207 | 0.210 | 0.182 | 0.203 | 0.231 | 0.209 | 0.179 | 0.201 | 0.154 | 0.195 |

| 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 | Average | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| South~North interregional | 0.239 | 0.272 | 0.277 | 0.285 | 0.225 | 0.286 | 0.303 | 0.335 | 0.310 | 0.328 | 0.324 | 0.289 |

| South-North~East interregional | 0.147 | 0.167 | 0.156 | 0.152 | 0.201 | 0.226 | 0.329 | 0.375 | 0.354 | 0.377 | 0.264 | 0.250 |

| South-South~West interregional | 0.190 | 0.234 | 0.201 | 0.212 | 0.199 | 0.252 | 0.336 | 0.286 | 0.270 | 0.218 | 0.203 | 0.237 |

| North-North~East interregional | 0.192 | 0.253 | 0.222 | 0.271 | 0.185 | 0.22 | 0.229 | 0.253 | 0.212 | 0.253 | 0.216 | 0.228 |

| North-South~West interregional | 0.144 | 0.169 | 0.197 | 0.192 | 0.159 | 0.196 | 0.221 | 0.229 | 0.228 | 0.248 | 0.245 | 0.203 |

| North-East~South-West interregional | 0.098 | 0.191 | 0.096 | 0.199 | 0.117 | 0.139 | 0.183 | 0.171 | 0.188 | 0.236 | 0.114 | 0.157 |

| Year | Countrywide | Intra-Regional Gini Coefficient | Contribution/% | Inter-Regional Gini Contribution | Contribution/% | Hypervariance Density Gini Contribution | Contribution/% |

|---|---|---|---|---|---|---|---|

| 2011 | 0.181 | 0.049 | 26.74 | 0.084 | 46.12 | 0.049 | 27.13 |

| 2012 | 0.220 | 0.060 | 27.42 | 0.093 | 42.46 | 0.066 | 30.12 |

| 2013 | 0.216 | 0.064 | 29.60 | 0.080 | 36.83 | 0.073 | 33.57 |

| 2014 | 0.229 | 0.066 | 28.91 | 0.083 | 36.08 | 0.080 | 35.01 |

| 2015 | 0.195 | 0.059 | 30.18 | 0.054 | 27.69 | 0.082 | 42.13 |

| 2016 | 0.236 | 0.068 | 28.66 | 0.083 | 35.03 | 0.086 | 36.31 |

| 2017 | 0.270 | 0.075 | 27.70 | 0.122 | 45.26 | 0.073 | 27.04 |

| 2018 | 0.282 | 0.076 | 26.91 | 0.125 | 44.32 | 0.081 | 28.78 |

| 2019 | 0.258 | 0.065 | 25.38 | 0.126 | 48.89 | 0.066 | 25.73 |

| 2020 | 0.272 | 0.072 | 26.55 | 0.136 | 50.10 | 0.064 | 23.34 |

| 2021 | 0.241 | 0.061 | 25.26 | 0.118 | 48.78 | 0.063 | 25.96 |

| Region | Northern Forest Region | Northeastern Forest Region | Southwestern Forest Region | Southern Forest Region |

|---|---|---|---|---|

| 2011 | 0.0538 | 0.0064 | 0.0043 | 0.0472 |

| 2012 | 0.0767 | 0.0157 | 0.0096 | 0.0723 |

| 2013 | 0.1062 | 0.0023 | 0.0037 | 0.0731 |

| 2014 | 0.1391 | 0.0043 | 0.0016 | 0.0733 |

| 2015 | 0.0788 | 0.0335 | 0.0089 | 0.0632 |

| 2016 | 0.1177 | 0.0344 | 0.0193 | 0.0737 |

| 2017 | 0.0993 | 0.0631 | 0.0463 | 0.0925 |

| 2018 | 0.1545 | 0.0314 | 0.0260 | 0.0877 |

| 2019 | 0.1180 | 0.0159 | 0.0410 | 0.0699 |

| 2020 | 0.1498 | 0.0150 | 0.0084 | 0.0751 |

| 2021 | 0.1510 | 0.0054 | 0.0148 | 0.0432 |

| Average | 0.1132 | 0.0207 | 0.0167 | 0.0701 |

| Year | Geographic Distance Matrix | Adjacency Matrix | ||||

|---|---|---|---|---|---|---|

| Moran’s I | Z-Value | p-Value | Moran’s I | Z-Value | p-Value | |

| 2011 | 0.064 | 0.970 | 0.178 | 0.191 | 2.043 | 0.041 |

| 2012 | 0.117 | 1.425 | 0.084 | 0.153 | 1.679 | 0.093 |

| 2013 | 0.099 | 1.498 | 0.076 | 0.173 | 1.91 | 0.056 |

| 2014 | 0.103 | 1.446 | 0.084 | 0.156 | 1.73 | 0.084 |

| 2015 | 0.094 | 1.463 | 0.088 | 0.18 | 1.954 | 0.051 |

| 2016 | 0.106 | 1.605 | 0.065 | 0.261 | 2.731 | 0.006 |

| 2017 | 0.119 | 1.454 | 0.085 | 0.259 | 2.667 | 0.008 |

| 2018 | 0.127 | 1.558 | 0.075 | 0.333 | 3.347 | 0.000 |

| 2019 | 0.138 | 1.853 | 0.044 | 0.404 | 3.961 | 0.000 |

| 2020 | 0.132 | 1.796 | 0.047 | 0.353 | 3.495 | 0.000 |

| 2021 | 0.117 | 1.724 | 0.051 | 0.328 | 3.305 | 0.000 |

| Project | Countrywide | Northern Forest Region | Northeastern Forest Region | Southwestern Forest Region | Southern Forest Region |

|---|---|---|---|---|---|

| Model Type | Two-way fixed SLM | Two-way fixed SEM | OLS | Two-way fixed SLM | Two-way fixed SLM |

| β | −0.6024 | −0.7805 | −0.3003 | −0.5855 | −0.7998 |

| 0.0289 | 0.0273 | - | 0.0111 | 0.0138 | |

| 0.0799 | - | - | −0.4813 | −0.1429 | |

| - | −0.2712 | - | - | - | |

| R2 | 0.3756 | 0.4238 | 0.2008 | 0.4194 | 0.5073 |

| Log-L | 109.4391 | 40.6490 | - | 31.2239 | 86.6001 |

| Spatial fixed effect | Yes | Yes | - | Yes | Yes |

| Time fixed effect | Yes | Yes | - | Yes | Yes |

| Hausmantest | 41.25 | 81.68 | - | 84.61 | 42.90 |

| LM-lag | 46.751 | 5.389 | 0.376 | 2.561 | 18.017 |

| R-LM-lag | 0.965 | 0.001 | 1.467 | 1.062 | 25.842 |

| LM-error | 46.019 | 5.452 | 0.044 | 5.148 | 23.466 |

| R-LM-error | 0.233 | 0.064 | 1.136 | 3.649 | 31.291 |

| Convergence rate/% | 8.3853 | 13.7872 | 3.2469 | 8.0057 | 14.6210 |

| Project | Countrywide | Northern Forest Region | Northeastern Forest Region | Southwestern Forest Region | Southern Forest Region |

|---|---|---|---|---|---|

| Model Type | Two-way fixed SLM | Two-way fixed SLM | OLS | Two-way fixed SEM | Two-way fixed SLM |

| β | −0.6252 | −0.7458 | −0.4256 | −0.8136 | −0.7926 |

| 0.0269 | 0.0281 | - | 0.0056 | 0.01267 | |

| 0.0938 | −0.1476 | - | -- | −0.2091 | |

| - | - | - | −0.4555262 | - | |

| R2 | 0.4011 | 0.4294 | 0.7004 | 0.6372 | 0.5169 |

| Log-L | 120.4641 | 39.8413 | - | 44.9872 | 91.1812 |

| Spatial fixed effect | Yes | Yes | - | Yes | Yes |

| Time fixed effect | Yes | Yes | - | Yes | Yes |

| Hausmantest | 100.70 | 77.76 | - | 47.85 | 138.21 |

| LM-lag | 31.778 | 1.473 | 2.381 | 12.090 | 6.613 |

| R-LM-lag | 0.120 | 5.767 | 6.212 | 6.449 | 6.120 |

| LM-error | 38.900 | 4.568 | 0.334 | 5.899 | 15.427 |

| R-LM-error | 7.242 | 8.862 | 4.164 | 0.258 | 14.933 |

| Convergence rate/% | 8.92 | 12.45 | 5.04 | 15.27 | 14.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, M.; Ma, Y.; Lu, W.; Ma, N. Exploring Sustainable Innovation Level, Spatial Inequities, and Convergence Trends in China’s Wood Industry. Forests 2024, 15, 2168. https://doi.org/10.3390/f15122168

Zhang M, Ma Y, Lu W, Ma N. Exploring Sustainable Innovation Level, Spatial Inequities, and Convergence Trends in China’s Wood Industry. Forests. 2024; 15(12):2168. https://doi.org/10.3390/f15122168

Chicago/Turabian StyleZhang, Mengwan, Yifei Ma, Wenyu Lu, and Ning Ma. 2024. "Exploring Sustainable Innovation Level, Spatial Inequities, and Convergence Trends in China’s Wood Industry" Forests 15, no. 12: 2168. https://doi.org/10.3390/f15122168

APA StyleZhang, M., Ma, Y., Lu, W., & Ma, N. (2024). Exploring Sustainable Innovation Level, Spatial Inequities, and Convergence Trends in China’s Wood Industry. Forests, 15(12), 2168. https://doi.org/10.3390/f15122168