Encouraging Invasive Acacia Control Strategies by Repurposing Their Wood Biomass Waste for Pulp and Paper Production

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sampling

2.2. Wood Properties

2.3. Kraft Pulping

2.3.1. Experimental Design and Statistical Analysis

2.3.2. Scale-Up

2.3.3. Kraft Pulp Characterization

2.3.4. Bleaching

2.4. Papermaking Potential

3. Results and Discussion

3.1. Wood Chemical Composition

3.2. Kraft Pulping Experimental Design and Optimization

3.3. Papermaking Potential

3.3.1. Fiber Properties

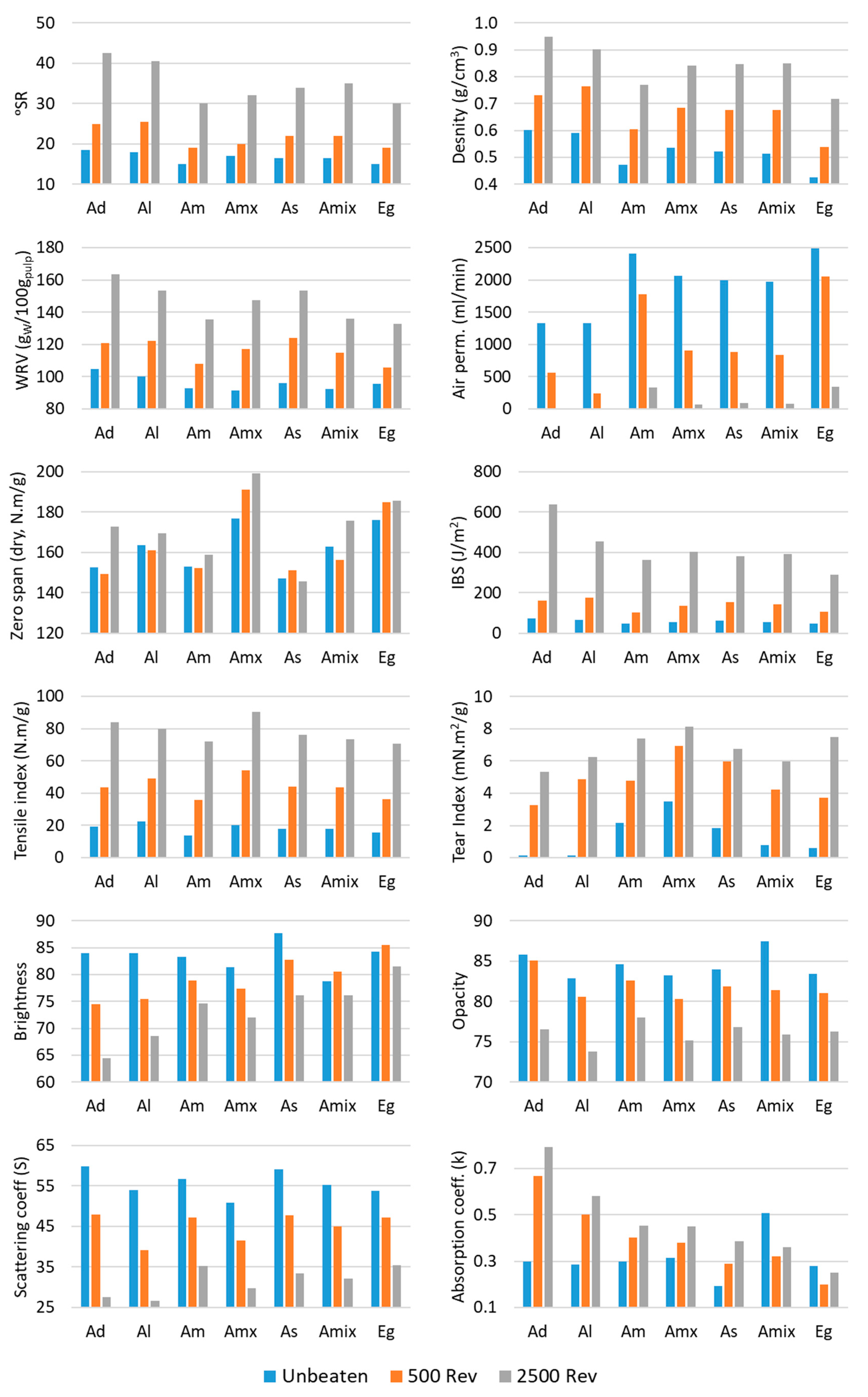

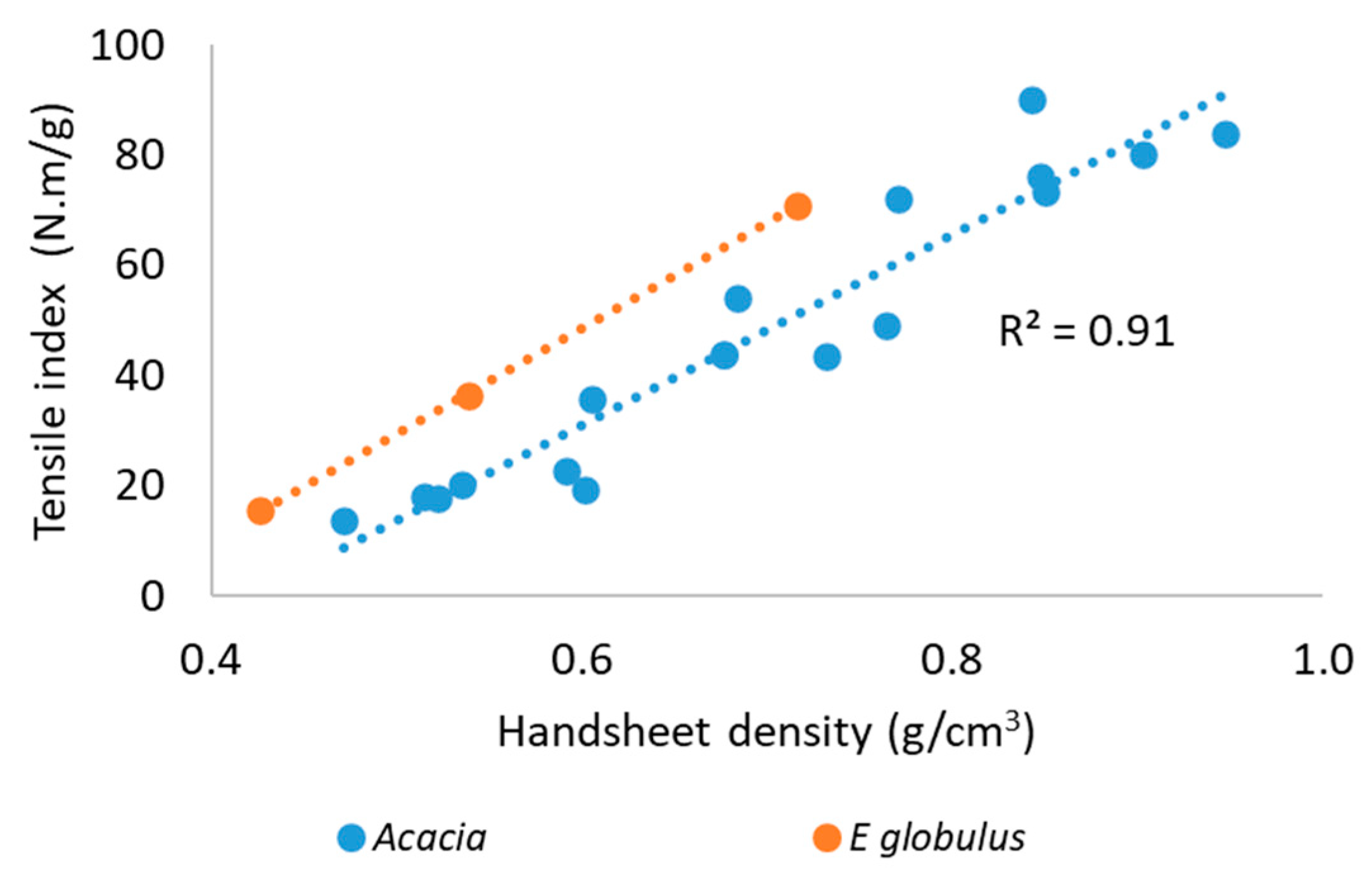

3.3.2. Pulp and Handsheet Properties

3.3.3. Handsheet at 30 °SR

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lorenzo, P.; González, L.; Reigosa, M.J. The genus Acacia as invader: The characteristic case of Acacia dealbata Link in Europe. Ann. For. Sci. 2010, 67, 101. [Google Scholar] [CrossRef]

- Celesti-Grapow, L.; Bass, L.; Brundu, G.; Camarda, I.; Carli, E.; D’Auria, G.; Del Guacchip, E.; Domina, G.; Ferretti, G.; Foggi, C.; et al. Plant invasions on small Mediterranean islands: An overview. Plant Biosyst. 2016, 150, 1119–1133. [Google Scholar] [CrossRef]

- Morris, T.L.; Esler, K.J.; Barger, N.N.; Jacobs, S.M.; Cramer, M.D. Ecophysiological traits associated with the competitive ability of invasive Australian acacias. Divers. Distrib. 2011, 17, 898–910. [Google Scholar] [CrossRef]

- Le Maitre, D.C.; Gaertner, M.; Marchante, E.; Ens, E.J.; Holmes, P.M.; Pauchard, A.; O’Farrell, P.J.; Rogers, A.M.; Blanchard, R.; Blignaut, J.; et al. Impacts of invasive Australian acacias: Implications for management and restoration. Divers. Distrib. 2011, 17, 1015–1029. [Google Scholar] [CrossRef]

- Marchante, E.; Kjøller, A.; Struwe, S.; Freitas, H. Short- and long-term impacts of Acacia longifolia invasion on the belowground processes of a Mediterranean coastal dune ecosystem. Appl. Soil. Ecol. 2008, 40, 210–217. [Google Scholar] [CrossRef]

- Correia, R.; Quintela, J.C.; Duarte, M.P.; Gonçalves, M. Insights for the valorization of biomass from portuguese invasive acacia spp. in a biorefinery perspective. Forests 2020, 11, 1342. [Google Scholar] [CrossRef]

- Del Vecchio, S.; Acosta, A.; Stanisci, A. The impact of Acacia saligna invasion on Italian coastal dune EC habitats. Comptes Rendus Biol. 2013, 336, 364–369. [Google Scholar] [CrossRef] [PubMed]

- Colaço, M.C.; Sequeira, A.C.; Skulska, I. Genus Acacia in Mainland Portugal: Knowledge and Experience of Stakeholders in Their Management. Land 2023, 12, 2026. [Google Scholar] [CrossRef]

- Invasoras.pt, Invasive Species in Portugal, INVADER-B e INVADER-IV. Universidade de Coimbra. 2020. Available online: https://invasoras.pt/en/invasive-species-in-portugal (accessed on 30 May 2023).

- ICNF, 6 Inventário Florestal Nacional IFN6—Final Report, ICNF, Lisboa. 2019. Available online: https://www.icnf.pt/api/file/doc/c8cc40b3b7ec8541 (accessed on 30 May 2023).

- Neiva, D.M.; Luís, Â.; Gominho, J.; Domingues, F.; Duarte, A.P.; Pereira, H. Bark residues valorization potential regarding antioxidant and antimicrobial extracts. Wood Sci. Technol. 2020, 54, 559–585. [Google Scholar] [CrossRef]

- Pedro, S.I.; Rosado, T.; Barroca, C.; Neiva, D.; Alonso-Herranz, V.; Gradillas, A.; García, A.; Gominho, J.; Gallardo, E.; Anjos, O. Characterisation of the Phenolic Profile of Acacia retinodes and Acacia mearnsii Flowers’ Extracts. Plants 2022, 11, 1442. [Google Scholar] [CrossRef]

- Santos, A.J.A.; Anjos, O.M.S.; Simões, R.M.S. Papermaking potential of Acacia dealbata and Acacia melanoxylon. Appita Technol. Innov. Manuf. Environ. 2006, 59, 58–64. [Google Scholar]

- Subhan, N.; Burrows, G.E.; Kerr, P.G.; Obied, H.K. Phytochemistry, Ethnomedicine, and Pharmacology of Acacia Studies. In Studies in Natural Products Chemistry; Atta-ur-Rahman, F.R.S., Ed.; Elsevier: Amsterdam, The Netherland, 2018; Volume 57, pp. 247–326. [Google Scholar] [CrossRef]

- Griffin, A.R.; Midgley, S.J.; Bush, D.; Cunningham, P.J.; Rinaudo, A.T. Global uses of Australian acacias—Recent trends and future prospects. Divers. Distrib. 2011, 17, 837–847. [Google Scholar] [CrossRef]

- Chan, J.M.; Day, P.; Feely, J.; Thompson, R.; Little, K.M.; Norris, C.H. Acacia mearnsii industry overview: Current status, key research and development issues. South For. 2015, 77, 19–30. [Google Scholar] [CrossRef]

- Nambiar, E.K.S.; Harwood, C.E.; Mendham, D.S. Paths to sustainable wood supply to the pulp and paper industry in Indonesia after diseases have forced a change of species from acacia to eucalypts. Aust. For. 2018, 81, 148–161. [Google Scholar] [CrossRef]

- Anjos, O.M.S.; Santos, A.J.A.; Simões, R.M.S. Effect of Acacia melanoxylon fibre morphology on papermaking potential. Appita Technol. Innov. Manuf. Environ. 2011, 64, 185–191. [Google Scholar]

- Lourenço, A.; Baptista, I.; Gominho, J.; Pereira, H. The influence of heartwood on the pulping properties of Acacia melanoxylon wood. J. Wood Sci. 2008, 54, 464–469. [Google Scholar] [CrossRef]

- Santos, A.; Anjos, O.; Amaral, M.E.; Gil, N.; Pereira, H.; Simões, R. Influence on pulping yield and pulp properties of wood density of Acacia melanoxylon. J. Wood Sci. 2012, 58, 479–486. [Google Scholar] [CrossRef]

- ASTM D2395; Standard Test Methods for Density and Specific Gravity (Relative Density) of Wood and Wood-Based Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- TAPPI Standards, Technical Information Papers, and Useful Methods, Atlanta, GA, USA.

- Neiva, D.M.; Araújo, S.; Gominho, J.; Carneiro, A.C.; Pereira, H. Potential of Eucalyptus globulus feedstock: Chemical and fuel characterization. Ind. Crop Pro. 2018, 123, 262–270. [Google Scholar] [CrossRef]

- SCAN—Test Methods. Scandinavian Pulp and Paper and Board Testing Committee, Stockholm, Sweden.

- Li, J.; Gellerstedt, G. The contribution to Kappa number from hexeneuronic acid groups in pulp xylan. Carbohydr. Res. 1997, 302, 213–218. [Google Scholar] [CrossRef]

- ISO- Standard Catalogue ICS 85- Paper Technology, Geneva, Switzerland. Available online: https://www.iso.org/ics/85/x/ (accessed on 5 May 2023).

- Häärä, M.; Sundberg, A.; Willför, S. Calcium oxalate—A source of “hickey” problems– a literature review on oxalate formation, analysis and scale control. Nord. Pulp Pap. Res. J. 2011, 26, 263–282. [Google Scholar] [CrossRef]

- Oliveira, G.R.A.; Grasel, F.S.; de Pinho, G.P.; Silvério, F.O. Characterizing the Chemical composition of lipophilic extracts from Acacia mearnsii wood. J. Braz. Chem. Soc. 2020, 31, 341–350. [Google Scholar] [CrossRef]

- Allen, L.H. Pitch control in pulp mills. In Pitch Control, Wood Resin and Deresination; Back, E.L., Allen, L.H., Eds.; Tappi Press: Atlanta, GA, USA, 2000; Chapter 11. [Google Scholar]

- Patil, R.M.; Genco, J.; Pendse, H.; van Heiningen, A. Cleavage of acetyl groups from northeast hardwood for acetic acid production in kraft pulp mills. Tappi J. 2013, 12, 57–67. [Google Scholar] [CrossRef]

- Giesbrecht, B.M.; Coldebella, R.; Gentil, M.; Nunes, G.R.S.; Finger, M.R.; Jardim, J.M.; Pedrazzi, C.; Cardoso, G.V. The performance of Acacia mearnsii De Wild for kraft pulping. Cienc. Florest. 2022, 32, 266–286. [Google Scholar] [CrossRef]

- Rosli, W.D.W.; Mazlan, I.; Law, K.N. Effects of kraft pulping variables on pulp and paper properties of Acacia mangium kraft pulp. Cellul. Chem. Technol. 2009, 43, 9–15. [Google Scholar]

- Haque, M.D.; Uddin, M.N.; Quaiyyum, M.A.; Nayeem, J.; Alam, M.Z.; Jahan, M.S. Pulpwood quality of the second generation Acacia auriculiformis. J. Bioresour. Bioprod. 2019, 4, 73–79. [Google Scholar] [CrossRef]

- Buchert, J.; Bergnor, E.; Lindblad, G.; Viikari, L.; Ek, M. Significance of xylan and glucomannan in the brightness reversion of kraft pulps. Tappi J. 1997, 80, 165–171. [Google Scholar]

- Searle, S.D.; Owen, J.V. Variation in basic wood density and percentage heartwood in temperate Australian Acacia species. Aust. For. 2005, 68, 126–136. [Google Scholar] [CrossRef]

- Mmolotsi, R.M.; Chisupo, O.; Mojeremane, W.; Rampart, M.; Kopong, I.; Monekwe, D. Dimensional relations and physical properties of wood of Acacia saligna, an invasive tree species growing in Botswana. Res. J. Agric. Forest Sci. 2013, 1, 12–15. [Google Scholar]

- Cremonez, V.G.; Junior, E.A.B.; de Andrade, A.S.; da Silva, E.L.; Klitzke, R.J.; Klock, U. Wood basic density effect of Eucalyptus grandis in the paper making. Rev. Matéria 2019, 23, e12420. [Google Scholar] [CrossRef]

- Magaton, A.S.; Colodette, J.L.; Gouvêa, A.F.G.; Gomide, J.L.; Muguet, M.C.S.; Pedrazzi, C. Eucalyptus wood quality and its impact on kraft pulp production and use. Tappi J. 2009, 8, 32–39. [Google Scholar] [CrossRef]

- Ferdous, T.; Ni, Y.; Quaiyyum, M.A.; Uddin, M.N.; Jahan, M.S. Non-wood fibers: Relationships of fiber properties with pulp properties. ACS Omega 2021, 6, 21613–21622. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.; Zhong, X.C.; Sun, R.C.; Lu, Q. Anatomy, ultrastructure and lignin distribution in cell wall of Caragana korshinskii. Ind. Crop. Prod. 2006, 24, 186–193. [Google Scholar] [CrossRef]

- Foelkel, C. The Eucalyptus Fibers and the Kraft Pulp Quality Requirements for Paper Manufacturing. 2007 Eucalyptus Online Book & Newsletter. Available online: https://www.eucalyptus.com.br/capitulos/ENG03fibers.pdf (accessed on 24 April 2023).

- Rosli, W.D.W.; Mazlan, I.; Law, K.N. Effect of lignin on Acacia mangium kraft pulp refining behaviour. Cellul. Chem. Technol. 2011, 45, 643–648. [Google Scholar]

| Ad | Al | Am | Amx | As | Eg [23] | |

|---|---|---|---|---|---|---|

| Ashes | 0.4 ± 0.03 | 0.4 ± 0.01 | 0.3 ± 0.01 | 0.3 ± 0.01 | 1.1 ± 0.22 | 0.8 |

| Extractives | 5.0 ± 0.1 | 5.0 ± 0.1 | 6.6 ± 0.2 | 8.0 ± 0.2 | 4.0 ± 0.1 | 4.4 |

| n-Hexane | 0.2 ± 0.0 | 0.1 ± 0.0 | 0.1 ± 0.0 | 0.2 ± 0.0 | 0.2 ± 0.0 | 0.3 |

| EtOH | 3.2 ± 0.1 | 3.8 ± 0.0 | 4.6 ± 0.1 | 7.1 ± 0.2 | 2.4 ± 0.0 | 1.4 |

| Water | 1.6 ± 0.1 | 1.1 ± 0.0 | 1.8 ± 0.2 | 0.7 ± 0.1 | 1.4 ± 0.1 | 2.7 |

| Lignin | 23.0 ± 0.1 | 23.7 ± 0.2 | 20.8 ± 0.1 | 20.8 ± 0.1 | 23.5 ± 0.1 | 24.3 |

| Klason | 19.7 ± 0.1 | 20.6 ± 0.2 | 18.3 ± 0.1 | 18.1 ± 0.0 | 20.6 ± 0.1 | 19.9 |

| Soluble | 3.2 ± 0.1 | 3.2 ± 0.0 | 2.5 ± 0.0 | 2.7 ± 0.1 | 2.9 ± 0.1 | 4.4 |

| Polysaccharides | 71.1 ± 0.9 | 67.5 ± 2.6 | 71.6 ± 0.8 | 68.7 ± 1.5 | 68.7 ± 0.6 | 63.3 |

| Cellulose | 41.8 ± 1.1 | 44.2 ± 2.3 | 45.0 ± 0.4 | 43.1 ± 1.1 | 41.0 ± 0.6 | 40.0 |

| Hemicelluloses | 29.3 ± 2.0 | 23.3 ± 0.3 | 26.6 ± 0.5 | 25.6 ± 0.8 | 27.7 ± 0.9 | 23.3 |

| Monosaccharides and acetyl groups | 79.7 ± 1.0 | 75.5 ± 2.8 | 80.2 ± 0.8 | 77.0 ± 1.7 | 77.1 ± 0.7 | 70.8 |

| Ramnose | 0.2 ± 0.0 | 0.1 ± 0.0 | 0.2 ± 0.0 | 0.2 ± 0.0 | 0.2 ± 0.0 | 0.3 |

| Arabinose | 0.1 ± 0.0 | 0.1 ± 0.0 | 0.1 ± 0.0 | 0.1 ± 0.0 | 0.2 ± 0.0 | 0.6 |

| Galactose | 0.2 ± 0.0 | 0.1 ± 0.0 | 0.3 ± 0.0 | 0.1 ± 0.0 | 0.2 ± 0.0 | 1.6 |

| Glucose | 46.4 ± 1.2 | 49.1 ± 2.6 | 50.1 ± 0.4 | 47.8 ± 1.2 | 45.6 ± 0.6 | 44.4 |

| Xylose | 23.6 ± 0.5 | 19.1 ± 1.6 | 23.5 ± 0.4 | 20.9 ± 0.7 | 22.0 ± 0.1 | 18.0 |

| Mannose | * | * | * | * | * | 0.9 |

| Galacturonic acid | 0.4 ± 0.0 | 0.3 ± 0.0 | 0.3 ± 0.0 | 0.3 ± 0.0 | 0.5 ± 0.0 | 0.9 |

| Glucuronic acid | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.1 |

| Acetates | 8.8 ± 2.7 | 6.7 ± 1.4 | 5.8 ± 0.2 | 7.6 ± 0.8 | 8.5 ± 0.9 | 4.0 |

| T (°C) | AA (%) | Ad | Al | Am | Amx | As | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Y (%) | K | Y (%) | K | Y (%) | K | Y (%) | K | Y (%) | K | ||

| 155 | 17 | 57 | 45 | 58 | 46 | 58 | 43 | 58 | 38 | 57 | 57 |

| 155 | 23 | 52 | 22 | 52 | 26 | 53 | 22 | 53 | 20 | 51 | 39 |

| 175 | 17 | 52 | 10 | 52 | 13 | 53 | 12 | 52 | 14 | 51 | 14 |

| 175 | 23 | 47 | 7 | 48 | 8 | 49 | 8 | 48 | 10 | 46 | 11 |

| 151 | 20 | 56 | 46 | 56 | 49 | 57 | 43 | 56 | 36 | 57 | 60 |

| 179 | 20 | 49 | 7 | 49 | 6 | 49 | 9 | 49 | 9 | 48 | 10 |

| 165 | 16 | 56 | 13 | 56 | 24 | 57 | 23 | 55 | 25 | 56 | 31 |

| 165 | 24 | 49 | 9 | 50 | 12 | 51 | 11 | 50 | 12 | 48 | 18 |

| 165 | 20 | 51 | 13 | 51 | 13 | 53 | 14 | 52 | 14 | 51 | 20 |

| 165 | 20 | 52 | 13 | 52 | 13 | 52 | 14 | 52 | 14 | 51 | 21 |

| Optimum Factor Values | Optimum Point RSM (Small Digesters) | Optimum Point Scale-Up | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Theoretic | Experimental | Unbleached | Bleached | ||||||||||||

| T (°C) | AA (%) | Y (%) | K | Y (%) | K | HexA | DP | Y (%) | K | HexA | DP | Y (%) | HexA | DP | |

| Ad | 165 | 17 | 54.5 | 16.8 | 55.0 | 18.3 | 3.8 | 4402 | 53.5 | 16.4 | 3.6 | 3514 | 95.9 | 0.2 | 3203 |

| Al | 169 | 16 | 54.2 | 16.6 | 54.3 | 17.4 | 4.6 | 4152 | 52.6 | 19.1 | 4.3 | 3490 | 95.6 | 0.2 | 3086 |

| Am | 166 | 18 | 54.1 | 16.8 | 53.2 | 17.1 | 3.8 | 3811 | 52.8 | 15.4 | 3.4 | 3305 | 94.9 | 0.2 | 2956 |

| Amx | 172 | 16 | 53.3 | 17.5 | 53.6 | 14.7 | 4.1 | 4850 | 52.3 | 17.4 | 3.8 | 4215 | 95.6 | 0.2 | 3690 |

| As | 173 | 16 | 52.9 | 16.8 | 52.5 | 16.6 | 4.3 | 3728 | 52.9 | 17.5 | 4.1 | 3211 | 95.1 | 0.2 | 2867 |

| Amix | 170 | 17 | 52.6 | 17.0 | 3.7 | 3526 | 95.3 | 0.2 | 3085 | ||||||

| Eg | 170 | 17 | 51.4 | 15.5 | 4.1 | 3242 | 95.8 | 0.1 | 2835 | ||||||

| Rev | Fibers (millions/g) | Width (µm) | Length (µm) | Coarseness (mg/100 m) | Fine Elements % in Area | |

|---|---|---|---|---|---|---|

| Ad | 0 | 34 | 17.3 | 650 | 5.8 | 4.4 |

| 500 | 36 | 17.5 | 640 | 5.6 | 4.7 | |

| 2500 | 37 | 18.3 | 631 | 5.5 | 5.5 | |

| Al | 0 | 24 | 21.9 | 662 | 7.9 | 4.2 |

| 500 | 25 | 22.2 | 661 | 7.8 | 4.5 | |

| 2500 | 25 | 22.8 | 650 | 7.8 | 4.7 | |

| Am | 0 | 28 | 15.6 | 731 | 6.3 | 3.4 |

| 500 | 30 | 16.1 | 731 | 6.1 | 3.3 | |

| 2500 | 29 | 17.1 | 720 | 6.2 | 4.1 | |

| Amx | 0 | 22 | 17.5 | 918 | 6.7 | 2.3 |

| 500 | 22 | 18.3 | 916 | 6.7 | 2.5 | |

| 2500 | 23 | 19.6 | 904 | 6.7 | 2.6 | |

| As | 0 | 29 | 15.9 | 794 | 5.6 | 3.4 |

| 500 | 30 | 16.3 | 794 | 5.5 | 3.5 | |

| 2500 | 32 | 17.0 | 775 | 5.4 | 3.7 | |

| Amix | 0 | 27 | 17.5 | 753 | 6.4 | 3.4 |

| 500 | 29 | 18.0 | 759 | 6.2 | 3.4 | |

| 2500 | 30 | 18.9 | 743 | 6.1 | 3.6 | |

| Eg | 0 | 24 | 15.6 | 849 | 6.4 | 2.7 |

| 500 | 26 | 16.2 | 851 | 6.2 | 2.8 | |

| 2500 | 26 | 17.3 | 835 | 6.4 | 3.4 |

| Ad | Al | Am | Amx | As | Amix | Eg | |

|---|---|---|---|---|---|---|---|

| Rev required | 1070 | 1100 | 2500 | 2167 | 1835 | 1730 | 2500 |

| Density (g/cm3) | 0.78 | 0.80 | 0.77 | 0.81 | 0.78 | 0.78 | 0.73 |

| WRV (gW/100 gpulp) | 133 | 132 | 136 | 142 | 144 | 128 | 133 |

| Air permeability (mL/min) | 410 | 170 | 330 | 210 | 350 | 370 | 350 |

| Internal bond strength (J/m2) | 298 | 260 | 362 | 360 | 306 | 296 | 290 |

| Zero span (N·m/g) | 156 | 164 | 159 | 198 | 147 | 168 | 185 |

| Tensile index (N·m/g) | 55 | 58 | 72 | 84 | 65 | 62 | 70 |

| Tear index (mN·m2/g) | 3.8 | 5.3 | 7.4 | 7.9 | 6.5 | 5.3 | 7.5 |

| Brightness (%) | 71.5 | 73.5 | 74.5 | 73 | 78.5 | 78.0 | 81.5 |

| Opacity (%) | 82.5 | 78.5 | 78 | 76 | 78.5 | 78 | 81.5 |

| Transparency (%) | 27.5 | 31 | 31 | 33 | 29.5 | 30 | 31 |

| Scattering coefficient (S) | 42 | 35.5 | 35.5 | 32 | 38 | 37 | 35.5 |

| Absorption coefficient (k) | 0.73 | 0.54 | 0.45 | 0.43 | 0.34 | 0.34 | 0.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Neiva, D.M.; Godinho, M.C.; Simões, R.M.S.; Gominho, J. Encouraging Invasive Acacia Control Strategies by Repurposing Their Wood Biomass Waste for Pulp and Paper Production. Forests 2024, 15, 822. https://doi.org/10.3390/f15050822

Neiva DM, Godinho MC, Simões RMS, Gominho J. Encouraging Invasive Acacia Control Strategies by Repurposing Their Wood Biomass Waste for Pulp and Paper Production. Forests. 2024; 15(5):822. https://doi.org/10.3390/f15050822

Chicago/Turabian StyleNeiva, Duarte M., Maria C. Godinho, Rogério M. S. Simões, and Jorge Gominho. 2024. "Encouraging Invasive Acacia Control Strategies by Repurposing Their Wood Biomass Waste for Pulp and Paper Production" Forests 15, no. 5: 822. https://doi.org/10.3390/f15050822

APA StyleNeiva, D. M., Godinho, M. C., Simões, R. M. S., & Gominho, J. (2024). Encouraging Invasive Acacia Control Strategies by Repurposing Their Wood Biomass Waste for Pulp and Paper Production. Forests, 15(5), 822. https://doi.org/10.3390/f15050822