Effect of Polyethylene Glycol with Different Molecular Weights on the Properties of Mytilaria laosensis Timber

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

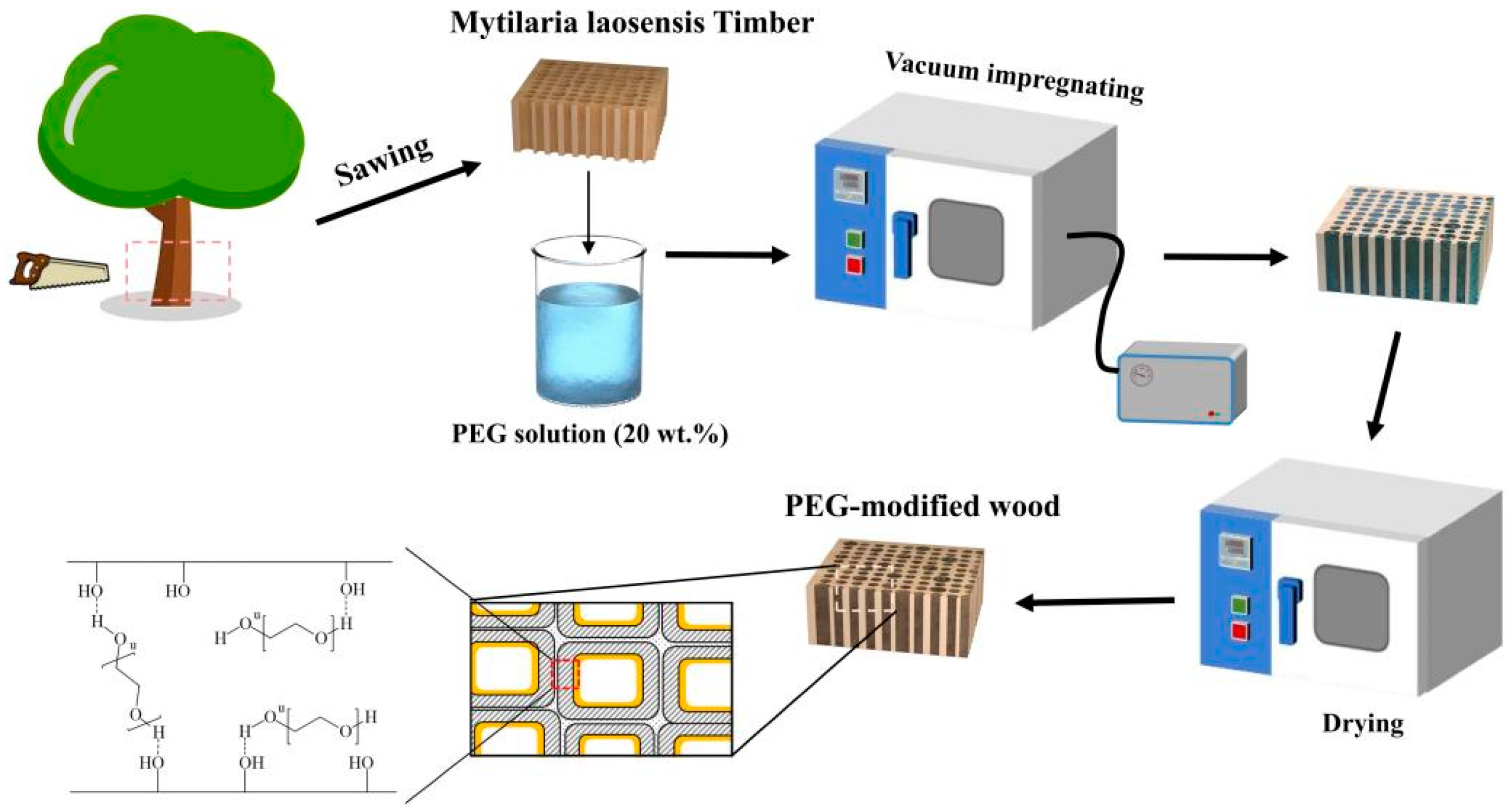

2.2. Preparation of PEG-Modified M. laosensis Wood

2.3. Characterization

2.3.1. Weight Gain Ratio

2.3.2. Dimensional Stability

2.3.3. Water Absorption Rate

2.3.4. Mechanical Properties

2.3.5. Thermal Stability Analysis

2.3.6. Structural Characterization and Performance Testing

2.3.7. Data Analysis

3. Results and Discussion

3.1. Physical Performance Analysis

3.1.1. Weight Gain Ratio

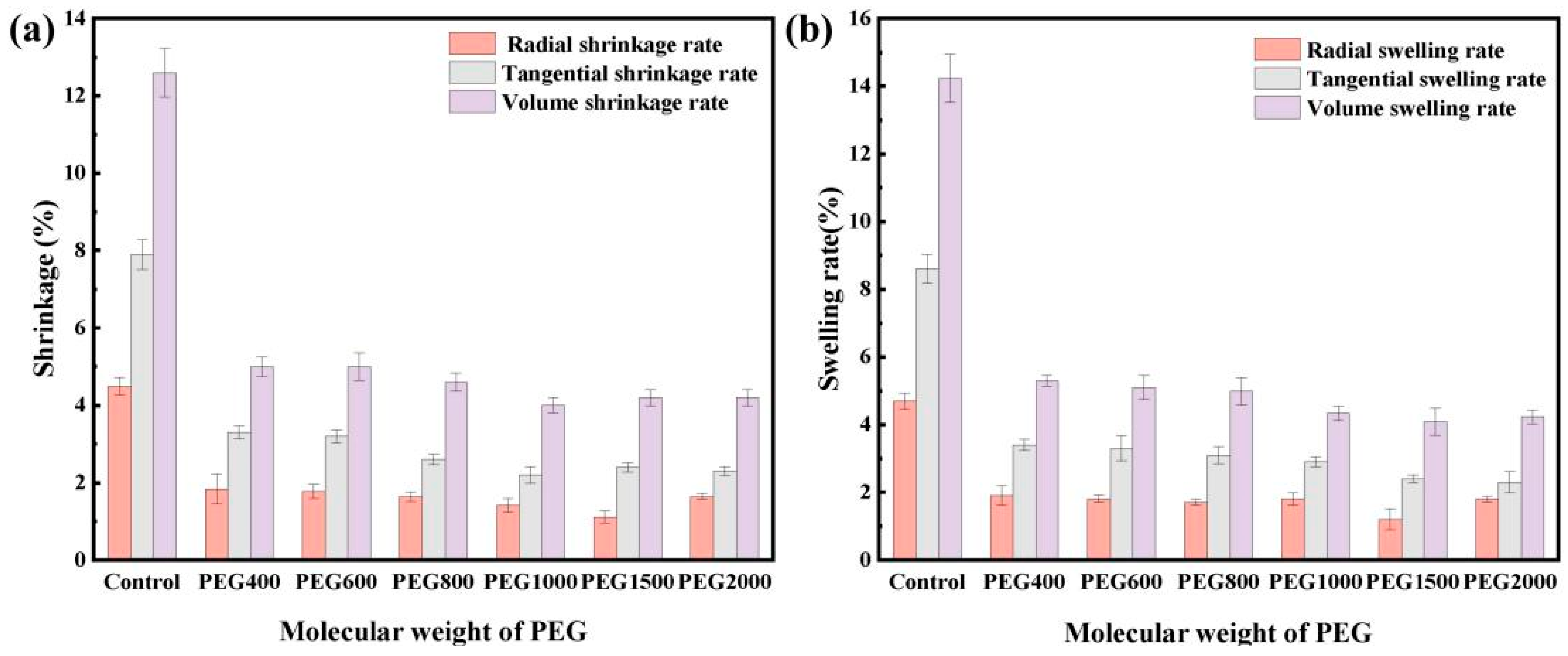

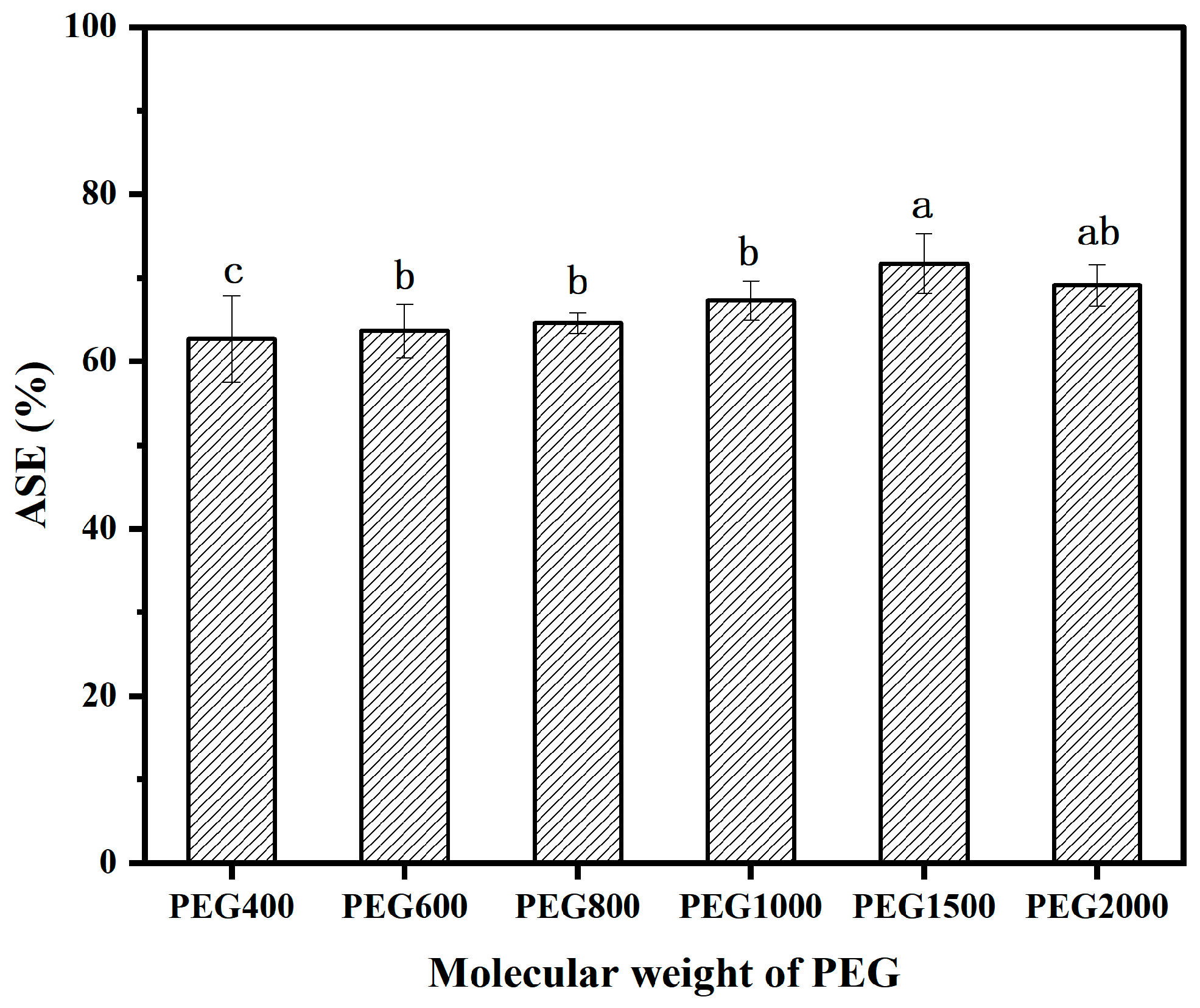

3.1.2. Dimensional Stability

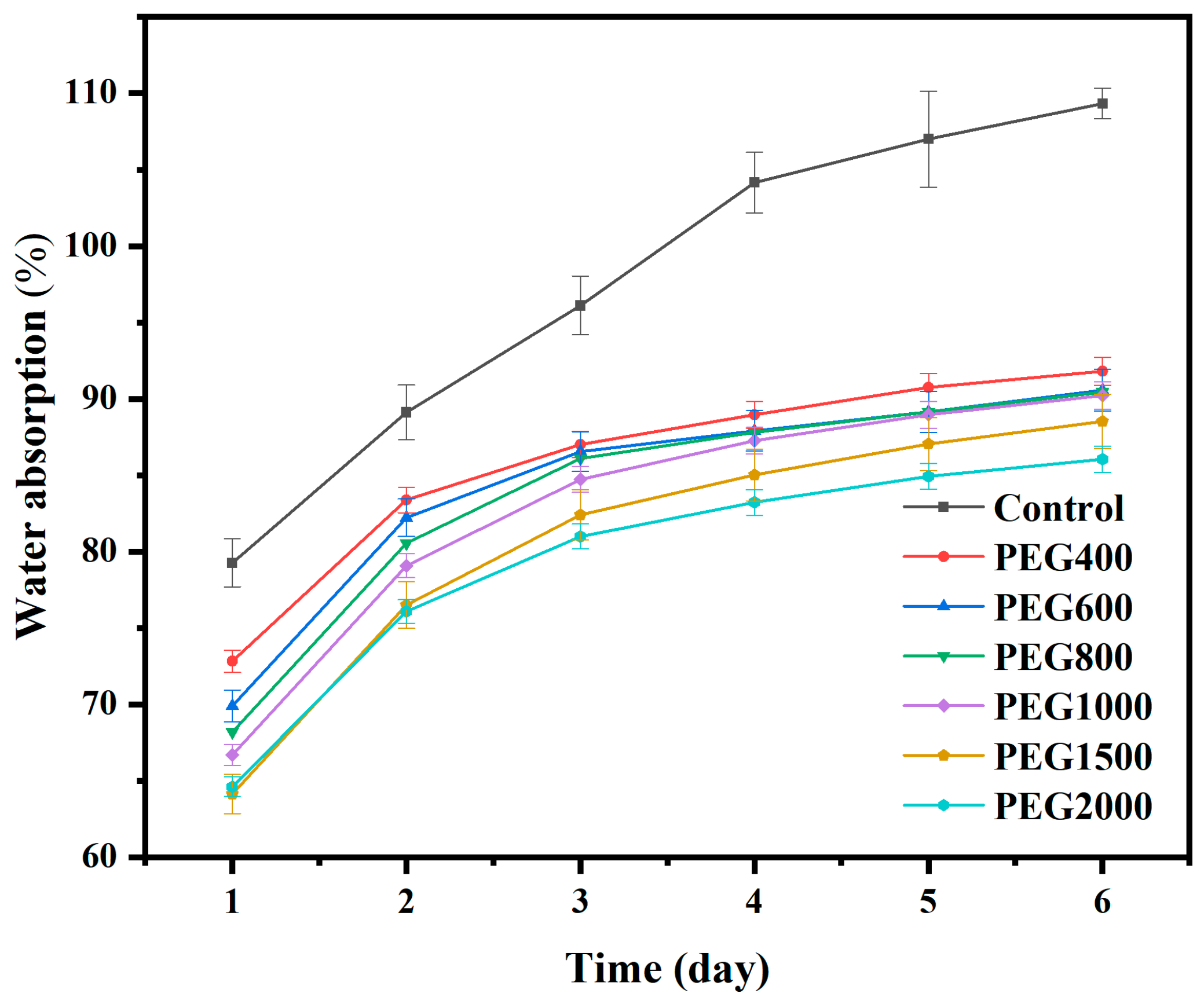

3.1.3. Water Absorption

3.2. Mechanical Performance Analysis

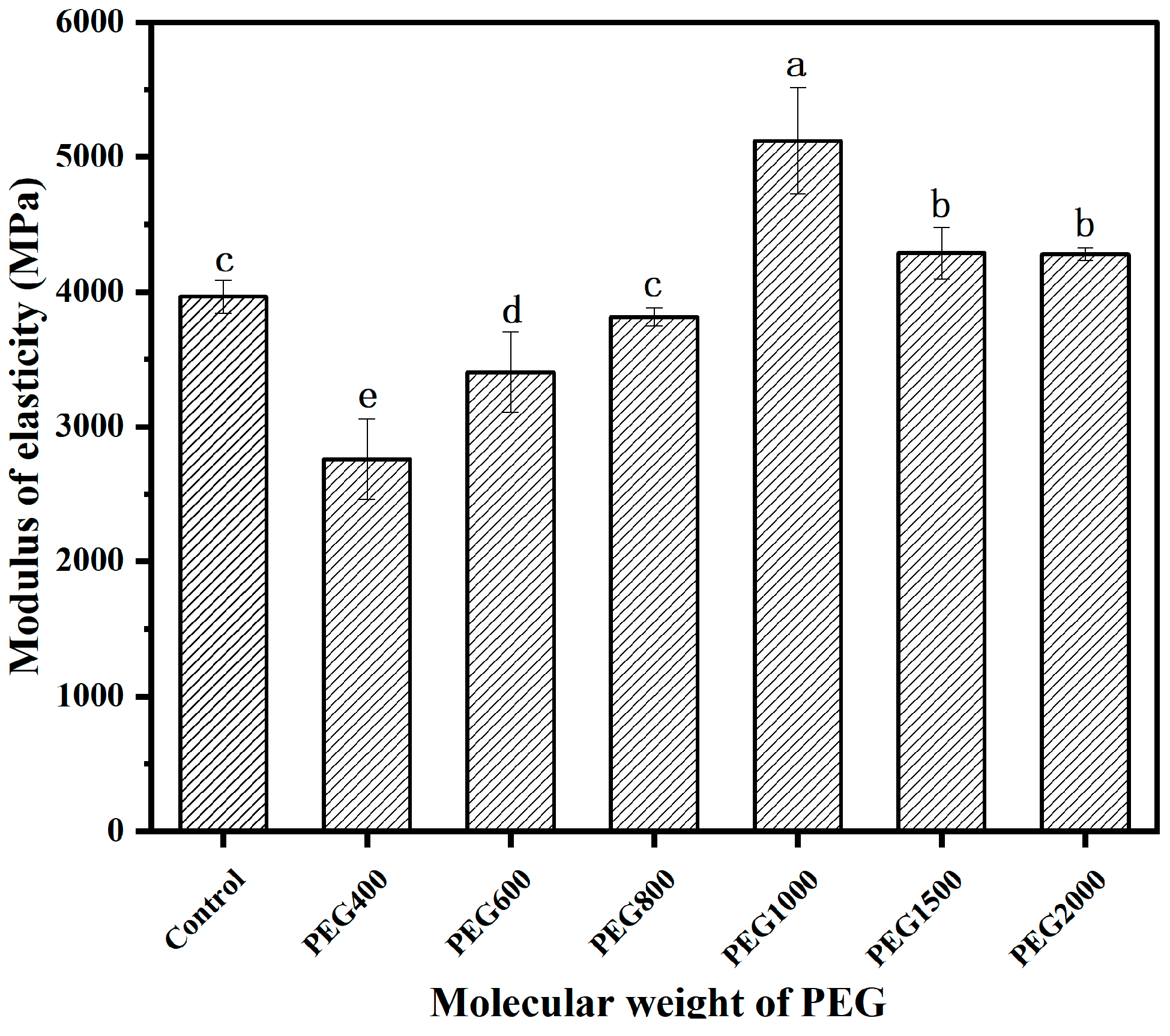

3.2.1. Flexural Modulus of Elasticity

3.2.2. Flexural Strength

3.3. Thermal Stability Analysis

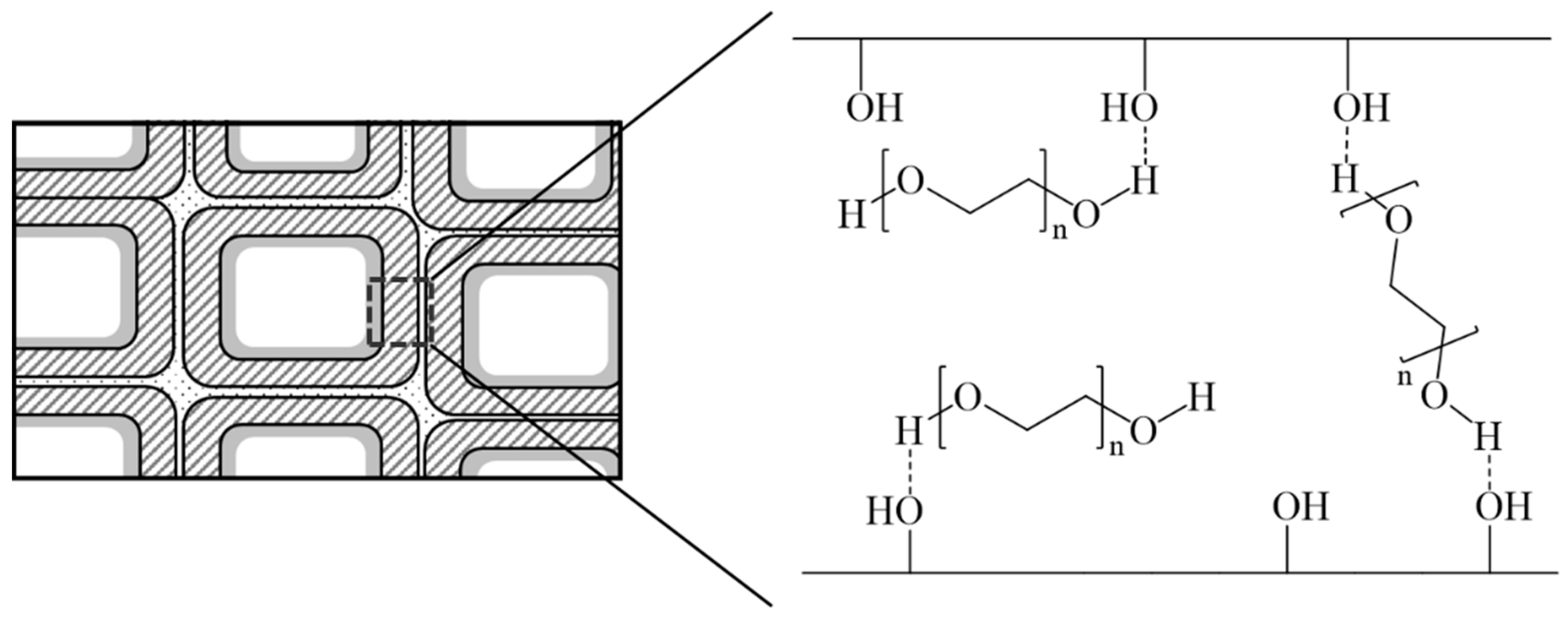

3.4. Mechanism of Modification

3.4.1. FTIR Analysis

3.4.2. XRD Analysis

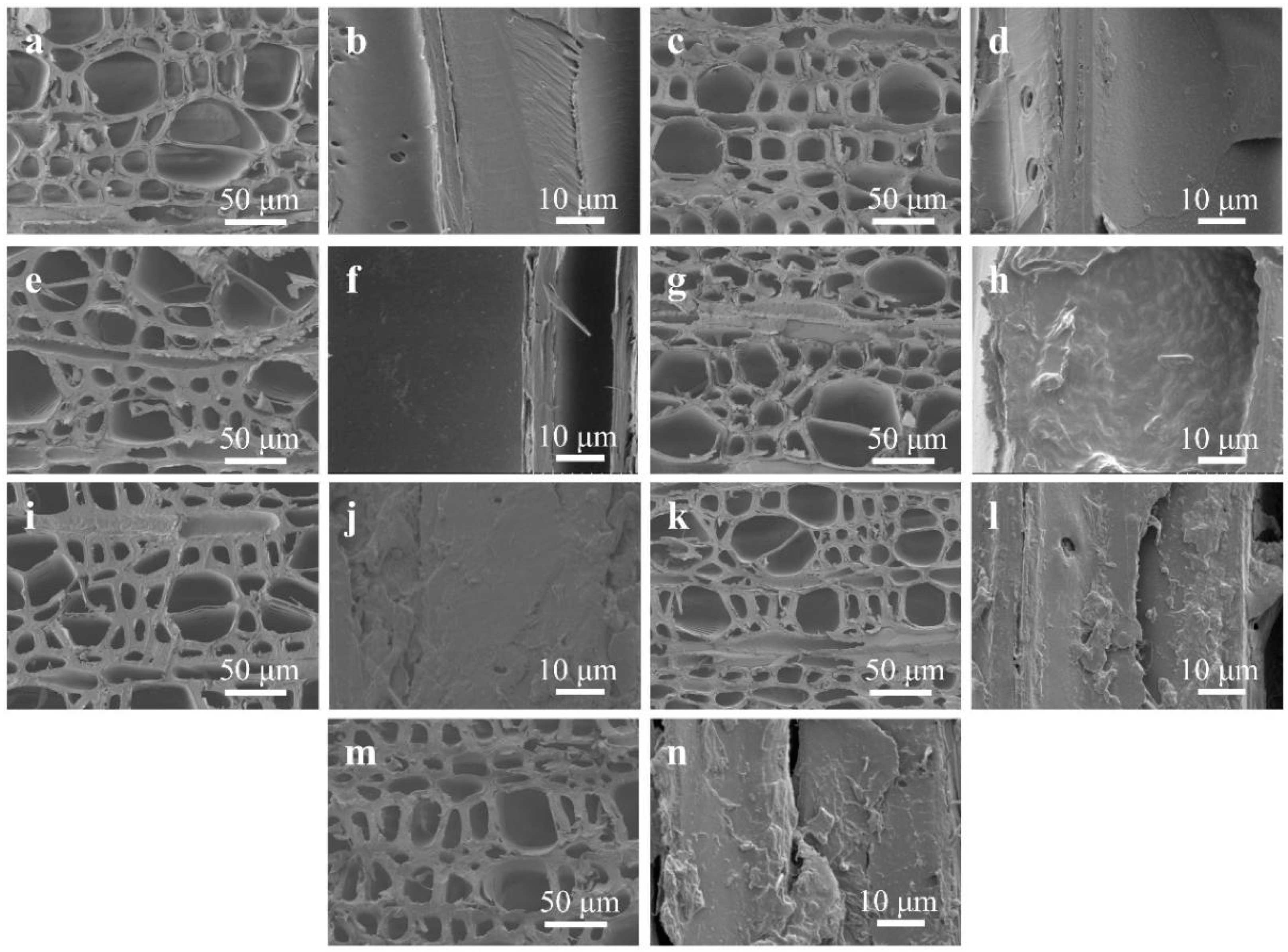

3.4.3. SEM Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bazli, M.; Heitzmann, M.; Ashrafi, H. Long-span timber flooring systems: A systematic review from structural performance and design considerations to constructability and sustainability aspects. J. Build. Eng. 2022, 48, 103981. [Google Scholar] [CrossRef]

- Nagraik, P.; Shukla, S.R.; Kelkar, B.U.; Paul, B.N. Wood modification with nanoparticles fortified polymeric resins for producing nano-wood composites: A review. J. Indian Acad. Wood Sci. 2023, 20, 1–11. [Google Scholar] [CrossRef]

- Qin, G.; Hao, J.; Yang, J.; Li, R.; Yin, G. Branch Occlusion and Discoloration under the Natural Pruning of Mytilaria laosensis. Forests 2019, 10, 892. [Google Scholar] [CrossRef]

- Shen, W.; Zhang, C.; Wang, G.; Li, Y.; Zhang, X.; Cui, Y.; Hu, Z.; Shen, S.; Xu, X.; Cao, Y.; et al. Variation pattern in the macromolecular (cellulose, hemicelluloses, lignin) composition of cell walls in Pinus tabulaeformis tree trunks at different ages as revealed using multiple techniques. Int. J. Biol. Macromol. 2024, 268, 131619. [Google Scholar] [CrossRef] [PubMed]

- Salmén, L.; Stevanic, J.S.; Holmqvist, C.; Yu, S. Moisture induced straining of the cellulosic microfibril. Cellulose 2021, 28, 3347–3357. [Google Scholar] [CrossRef]

- Hou, S.; Wang, J.; Yin, F.; Qi, C.; Mu, J. Moisture sorption isotherms and hysteresis of cellulose, hemicelluloses and lignin isolated from birch wood and their effects on wood hygroscopicity. Wood Sci. Technol. 2022, 56, 1087–1102. [Google Scholar] [CrossRef]

- Yang, T.; Mei, C. Effects of hemicellulose removal combined with polyethylene glycol impregnation on dimensional stability of wood. Wood Mater. Sci. Eng. 2023, 18, 933–942. [Google Scholar] [CrossRef]

- Hu, Y.-P.; Li, W.-B.; Wu, S.; Wang, Y.-J.; Zhong, W.-Z.; Zhang, H. Experimental Study of the Anisotropic Thermal Conductivity of Spruce Wood. Int. J. Thermophys. 2023, 44, 131. [Google Scholar] [CrossRef]

- Ye, X.; Liang, Y.; Liao, B.; Ni, C.; Lu, H.; He, R.; Zhang, C.; Xu, H.; Yang, J. Chemical constituents from Mytilaria laosensis Lec. leaves and branches. Biochem. Syst. Ecol. 2023, 111, 104742. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Shen, L.; Wu, Z.; Li, H.; Hu, M.; Liu, Q.; Chen, C.; Hu, X.; Zhong, Y. Evaluation of Wood Anatomical Properties from 18 Tree Species in the Subtropical Region of China. Forests 2023, 14, 2344. [Google Scholar] [CrossRef]

- He, L.; Zhang, T.; Zhao, X.; Zhao, Y.; Xu, K.; He, Z.; Yi, S. Synergistic effect of tung oil and heat treatment on surface characteristics and dimensional stability of wood. Colloids Surf. A 2023, 665, 131233. [Google Scholar] [CrossRef]

- Marbun, S.D.; Dwianto, W.; Meliala, S.B.P.S.; Widyorini, R.; Augustina, S.; Hiziroglu, S. Dimensional stability mechanisms of binderless boards by heat or steam treatment: A review. Cellulose 2023, 30, 8571–8593. [Google Scholar] [CrossRef]

- Ma, P.; An, X.; Wang, F.; Huang, H.; Chen, Z.; Wang, S.; Gong, M.; Que, Z. Effects of pre-heating treatment parameters on dimensional stability and mechanical properties of densified Chinese fir. Constr. Build. Mater. 2023, 407, 133484. [Google Scholar] [CrossRef]

- Kuribayashi, T.; Ogawa, Y.; Morfin, I.; Matsumoto, Y.; Nishiyama, Y. Mesostructural changes in cellulose within wood cell wall upon hydrothermal treatment at 200 °C. Cellulose 2023, 30, 8405–8413. [Google Scholar] [CrossRef]

- Fodor, F.; Bak, M.; Németh, R. Photostability of Oil-Coated and Stain-Coated Acetylated Hornbeam Wood against Natural Weather and Artificial Aging. Coatings 2022, 12, 817. [Google Scholar] [CrossRef]

- Slabohm, M.; Mayer, A.K.; Militz, H. Compression of Acetylated Beech (Fagus sylvatica L.) Laminated Veneer Lumber (LVL). Forests 2022, 13, 1122. [Google Scholar] [CrossRef]

- Wang, K.; Dong, Y.; Yan, Y.; Zhang, W.; Qi, C.; Han, C.; Li, J.; Zhang, S. Highly hydrophobic and self-cleaning bulk wood prepared by grafting long-chain alkyl onto wood cell walls. Wood Sci. Technol. 2016, 51, 395–411. [Google Scholar] [CrossRef]

- Soni, J.; Sahiba, N.; Sethiya, A.; Agarwal, S. Polyethylene glycol: A promising approach for sustainable organic synthesis. J. Mol. Liq. 2020, 315, 113766. [Google Scholar] [CrossRef]

- Jiang, J.; Zhou, Y.; Mei, C.; Cao, J. Polyethylene glycol and silica sol penetration improves hydrophobicity and dimensional stability of wood after a short-time treatment. Eur. J. Wood Wood Prod. 2021, 79, 1395–1404. [Google Scholar] [CrossRef]

- Xu, J.; Yang, T.; Xu, X.; Guo, X.; Cao, J. Processing solid wood into a composite phase change material for thermal energy storage by introducing silica-stabilized polyethylene glycol. Compos. Part A 2020, 139, 106098. [Google Scholar] [CrossRef]

- Puttmann, S.; Burian, B.; Müller, L.; Müller, M. Impact of different polyethylene glycol wood treatments on the adhesive properties of beech wood. Int. Wood Prod. J. 2023, 14, 34–41. [Google Scholar] [CrossRef]

- Fortino, S.; Metsäjoki, J.; Ronkainen, H.; Bjurhager, I.; Heinemann, S.; Salminen, L.I. Scratch resistance of PEG-impregnated green wood: A method for evaluation of swollen wood properties. Wood Sci. Technol. 2020, 54, 715–735. [Google Scholar] [CrossRef]

- Bjurhager, I.; Ljungdahl, J.; Wallström, L.; Gamstedt, E.K.; Berglund, L.A. Towards improved understanding of PEG-impregnated waterlogged archaeological wood: A model study on recent oak. Holzforschung 2010, 64, 243–250. [Google Scholar] [CrossRef]

- Mortensen, M.N.; Egsgaard, H.; Hvilsted, S.; Shashoua, Y.; Glastrup, J. Characterisation of the polyethylene glycol impregnation of the Swedish warship Vasa and one of the Danish Skuldelev Viking ships. J. Archaeol. Sci. 2007, 34, 1211–1218. [Google Scholar] [CrossRef]

- Fejfer, M.; Majka, J.; Zborowska, M. Dimensional Stability of Waterlogged Scots Pine Wood Treated with PEG and Dried Using an Alternative Approach. Forests 2020, 11, 1254. [Google Scholar] [CrossRef]

- Augustina, S.; Dwianto, W.; Wahyudi, I.; Darmawan, W.; Malik, J.; Maulana, S.; Gérardin, P. Treatability and dimensional stability of three hardwood species using different types of water-soluble impregnating agent. Eur. J. Wood Wood Prod. 2024, 1–13. [Google Scholar] [CrossRef]

- GB/T 1927.8-2021; Test Methods for Physical and Mechanical Properties of Wood with Small Clear Specimens—Part 8: Determination of Swelling. GB Standards: Beijing, China, 2021.

- GB/T 1927.6-2021; Test Methods for Physical and Mechanical Properties of Wood with Small Clear Specimens—Part 6: Determination of Shrinkage. GB Standards: Beijing, China, 2021.

- GB/T 1927.7-2021; Test Methods for Physical and Mechanical Properties of Wood with Small Clear Specimens—Part 7: Determination of Water Absorption. GB Standards: Beijing, China, 2021.

- GB/T 1927.10-2021; Test Methods for Physical and Mechanical Properties of Wood with Small Clear Specimens—Part 10: Determination of Modulus of Elasticity in Bending. GB Standards: Beijing, China, 2021.

- GB/T 1927.9-2021; Test Methods for Physical and Mechanical Properties of Wood with Small Clear Specimens—Part 9: Determination of Bending Strength. GB Standards: Beijing, China, 2021.

- Wang, X.; Zhao, W.; Zhang, Y.; Shi, J.; Shan, S.; Cai, L. Exploring wood micromechanical structure: Impact of microfibril angle and crystallinity on cell wall strength. J. Build. Eng. 2024, 90, 109452. [Google Scholar] [CrossRef]

- Dorvel, B.; Boopalachandran, P.; Chen, I.; Bowling, A.; Williams, K.; King, S. Probing the effect of polymer molecular weight on penetration into the wood cell wall using polyethylenimine (PEI) as a model compound. J. Microsc. 2018, 270, 121–128. [Google Scholar] [CrossRef] [PubMed]

- Grinins, J.; Biziks, V.; Rizikovs, J.; Irbe, I.; Militz, H. Evaluation of water related properties of birch wood products modified with different molecular weight phenol-formaldehyde oligomers. Holzforschung 2021, 75, 908–916. [Google Scholar] [CrossRef]

- Gao, Y.; Li, Y.; Ren, R.; Li, L.; Chen, Y. Enhanced mechanical and humidity resistance properties of heat-treated wood by impregnation of low-molecular-weight lignin. Wood Sci. Technol. 2022, 56, 1551–1565. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, Y. Studies on pre-treatment by compression for wood impregnation III: Effects of the solid content of low-molecular-weight phenol formaldehyde resin on the impregnation. J. Wood Sci. 2022, 68, 28. [Google Scholar] [CrossRef]

- Jeremic, D.; Cooper, P.; Brodersen, P. Penetration of poly (ethylene glycol) into wood cell walls of red pine. Holzforschung 2007, 61, 272–278. [Google Scholar] [CrossRef]

- Kim, M.; Park, B.-D. Effects of molecular weight of urea–formaldehyde resins on wettability and adhesion at wood surface, interphase, and plywood. Wood Sci. Technol. 2022, 56, 1675–1703. [Google Scholar] [CrossRef]

- Rosca, I.; Bergmann, I.; Tanczos, I. Penetrability of resins and polyethylene glycols in ammonia treated spruce wood. Holz Roh Werkst. 2005, 63, 403–407. [Google Scholar] [CrossRef]

- Jeremic, D.; Cooper, P. PEG quantification and examination of molecular weight distribution in wood cell walls. Wood Sci. Technol. 2008, 43, 317–329. [Google Scholar] [CrossRef]

- Liang, B.; Lu, X.; Li, R.; Tu, W.; Yang, Z.; Yuan, T. Solvent-free preparation of bio-based polyethylene glycol/wood flour composites as novel shape-stabilized phase change materials for solar thermal energy storage. Sol. Energy Mater. Sol. Cells 2019, 200, 110037. [Google Scholar] [CrossRef]

- Martha, R.; Mubarok, M.; Batubara, I.; Rahayu, I.S.; Setiono, L.; Darmawan, W.; Akong, F.O.; George, B.; Gérardin, C.; Gérardin, P. Effect of furfurylation treatment on technological properties of short rotation teak wood. J. Mater. Res. Technol. 2021, 12, 1689–1699. [Google Scholar] [CrossRef]

- Cao, Y.; Li, X.; Liu, L.; Xie, G.; Lai, M.; Gao, J. Increased dimensional stability of Eucalyptus grandis × Eucalyptus urophylla ‘GLGU9’ wood through palm oil thermal treatment. BioResources 2023, 18, 3471–3478. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, T.; He, L.; Zhang, T.; Gao, J.; He, Z.; Yi, S. Hygroscopicity and dimensional stability of wood thermally treated with moist air or low point metal alloy: A comparative study. Holzforschung 2023, 77, 28–37. [Google Scholar] [CrossRef]

- Nagarajappa, G.B.; Pandey, K.K. UV resistance and dimensional stability of wood modified with isopropenyl acetate. J. Photochem. Photobiol. B 2016, 155, 20–27. [Google Scholar] [CrossRef]

- Shen, X.; Yang, S.; Li, G.; Liu, S.; Chu, F. The contribution mechanism of furfuryl alcohol treatment on the dimensional stability of plantation wood. Ind. Crops Prod. 2022, 186, 115143. [Google Scholar] [CrossRef]

- Ohmae, K.; Minato, K.; Norimoto, M. The Analysis of Dimensional Changes Due to Chemical Treatments and Water Soaking for Hinoki (Chamaecyparis obtusa) Wood. Holzforschung 2002, 56, 98–102. [Google Scholar] [CrossRef]

- Lai, C.C.; Chung, C.K. Hydrophilicity and optic property of polyethylene glycol coating on polydimethylsiloxane for fast prototyping and its application to backlight microfluidic chip. Surf. Coat. Technol. 2020, 389, 125606. [Google Scholar] [CrossRef]

- Srinivas, K.; Pandey, K.K. Effect of heat treatment on color changes, dimensional stability, and mechanical properties of wood. J. Wood Chem. Technol. 2012, 32, 304–316. [Google Scholar] [CrossRef]

- Bessala, L.F.B.; Gao, J.; He, Z.; Wang, Z.; Yi, S. Effects of different heat treatment media on odorous constituents, chemical decomposition and mechanical properties of two hardwoods. RSC Adv. 2024, 14, 7414–7429. [Google Scholar] [CrossRef] [PubMed]

- Ping, L.; Chai, Y.; Sun, B.; Liu, J. Assessment of the physico-mechanical, thermal, and morphological properties of rubber wood modified with silica sol in combination with GU/GMU resins. BioResources 2020, 15, 8051. [Google Scholar] [CrossRef]

- Jiang, T.; Gao, H.; Sun, J.; Xie, Y.; Li, X. Impact of DMDHEU resin treatment on the mechanical properties of poplar. Polym. Polym. Compos. 2014, 22, 669–674. [Google Scholar] [CrossRef]

- Acosta, A.P.; Barbosa, K.T.; Amico, S.C.; Missio, A.L.; de Avila Delucis, R.; Gatto, D.A. Improvement in mechanical, physical and biological properties of eucalyptus and pine woods by raw pine resin in situ polymerization. Ind. Crops Prod. 2021, 166, 113495. [Google Scholar] [CrossRef]

- Liu, S.; Wu, H.; Du, Y.; Lu, X.; Qu, J. Shape-stable composite phase change materials encapsulated by bio-based balsa wood for thermal energy storage. Sol. Energy Mater. Sol. Cells 2021, 230, 111187. [Google Scholar] [CrossRef]

- Apaydın Varol, E.; Mutlu, Ü. TGA-FTIR Analysis of Biomass Samples Based on the Thermal Decomposition Behavior of Hemicellulose, Cellulose, and Lignin. Energies 2023, 16, 3674. [Google Scholar] [CrossRef]

- Ochieng, R.; Cerón, A.L.; Konist, A.; Sarker, S. A combined analysis of the drying and decomposition kinetics of wood pyrolysis using non-isothermal thermogravimetric methods. Energy Convers. Manag. X 2023, 20, 100424. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, Y.; Deng, M.; Liang, G.; Ju, H.; Xiao, Y. An intrinsic antistatic polyethylene glycol-based solid–solid phase change material for thermal energy storage and thermal management. Polym. Adv. Technol. 2024, 35, e6347. [Google Scholar] [CrossRef]

- Meng, Y.; Majoinen, J.; Zhao, B.; Rojas, O.J. Form-stable phase change materials from mesoporous balsa after selective removal of lignin. Compos. Part B 2020, 199, 108296. [Google Scholar] [CrossRef]

- He, L.; Wang, M.; Zhang, X.; Liu, X.; Luo, Y.; Chen, Y.; Fan, Y. The confinement effect on phase change materials by physicochemical structure of wood-based materials. Ind. Crops Prod. 2024, 212, 118299. [Google Scholar] [CrossRef]

- Jiang, L.; Lei, Y.; Liu, Q.; Wang, Y.; Zhao, Y.; Lei, J. Facile preparation of polyethylene glycol/wood-flour composites as form-stable phase change materials for thermal energy storage. J. Therm. Anal. Calorim. 2019, 139, 137–146. [Google Scholar] [CrossRef]

- Ma, L.; Wang, Q.; Li, L. Delignified wood/capric acid-palmitic acid mixture stable-form phase change material for thermal storage. Sol. Energy Mater. Sol. Cells 2019, 194, 215–221. [Google Scholar] [CrossRef]

- Liu, X.; Xu, X.; Tu, X.; Ma, W.; Huang, H.; Varodi, A.M. Characteristics of Ancient Ship Wood from Taicang of the Yuan Dynasty. Materials 2022, 16, 104. [Google Scholar] [CrossRef]

- Guo, C.; Chen, Y.; Li, L. Investigation on interfacial interaction and thermal properties of flame retarded wood-plastic form-stable phase change material. Compos. Interfaces 2018, 26, 597–610. [Google Scholar] [CrossRef]

- Flaig, N.; Christ, M.; Müller, M. Influence of wood modification with polyethylene glycol and various carboxylic acids on the dimensional stability of beech wood (Fagus sylvatica). Int. Wood Prod. J. 2023, 14, 120–134. [Google Scholar] [CrossRef]

| Species | Modification Method | ASE (%) | Refs |

|---|---|---|---|

| Teak wood (Tectona grandis Linn. F.) | Furfurylation treatment | 64.17 | [42] |

| Eucalyptus grandis × Eucalyptus urophylla “GLGU9” | Palm oil thermal treatment | 56.6 | [43] |

| Silver birch (Betula pendula) | Phenol-formaldehyde resin treatment | 65.0 | [29] |

| Ailanthus altissima (Mill.) Swingle | Low point metal alloy treatment | 56.0 | [44] |

| Rubberwood (Hevea brasiliensis Müll.Arg) | Isopropenyl acetate treatment | 60.6 | [45] |

| Mytilaria laosensis | PEG treatment | 71.22 | This work |

| Species | Modification Method | Change Ratio of MOE | Change Ratio of MOR | Refs |

|---|---|---|---|---|

| Teak wood (Tectona grandis Linn. F.) | Furfurylation treatment | −14.0% | −20.0% | [42] |

| Silver oak (Grevillea robusta) | Vacuum heat treatment | −21% | −60% | [49] |

| Afrormosia (Pericopsis elata Van Meeuwen) | Air heat treatment | −18% | −24.2% | [50] |

| Rubber wood (Hevea brasiliensis) | Silica sol and glyoxal melamine urea treatment | +3.4% | +25.2% | [51] |

| Poplar (Populus) | Dimethylol dihydroxy ethylene urea treatment | +46.6% | −16.9% | [52] |

| Pinus elliottii Engelm | Raw pine resin treatment | +70.0% | +50.0% | [53] |

| Mytilaria laosensis | PEG treatment | +29% | +5% | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, L.; Liu, X.; Kuang, Y.; Wang, L.; Chen, S.; Luo, Y.; Chen, Y. Effect of Polyethylene Glycol with Different Molecular Weights on the Properties of Mytilaria laosensis Timber. Forests 2024, 15, 1401. https://doi.org/10.3390/f15081401

He L, Liu X, Kuang Y, Wang L, Chen S, Luo Y, Chen Y. Effect of Polyethylene Glycol with Different Molecular Weights on the Properties of Mytilaria laosensis Timber. Forests. 2024; 15(8):1401. https://doi.org/10.3390/f15081401

Chicago/Turabian StyleHe, Linhan, Xiaoling Liu, Yin Kuang, Liuliu Wang, Songwu Chen, Yufen Luo, and Yao Chen. 2024. "Effect of Polyethylene Glycol with Different Molecular Weights on the Properties of Mytilaria laosensis Timber" Forests 15, no. 8: 1401. https://doi.org/10.3390/f15081401

APA StyleHe, L., Liu, X., Kuang, Y., Wang, L., Chen, S., Luo, Y., & Chen, Y. (2024). Effect of Polyethylene Glycol with Different Molecular Weights on the Properties of Mytilaria laosensis Timber. Forests, 15(8), 1401. https://doi.org/10.3390/f15081401