Assessment of the Modulus of Rupture and Modulus of Elasticity in Static Bending of Yellow Pine Earlywood and Latewood

Abstract

:1. Introduction

2. Materials and Methods

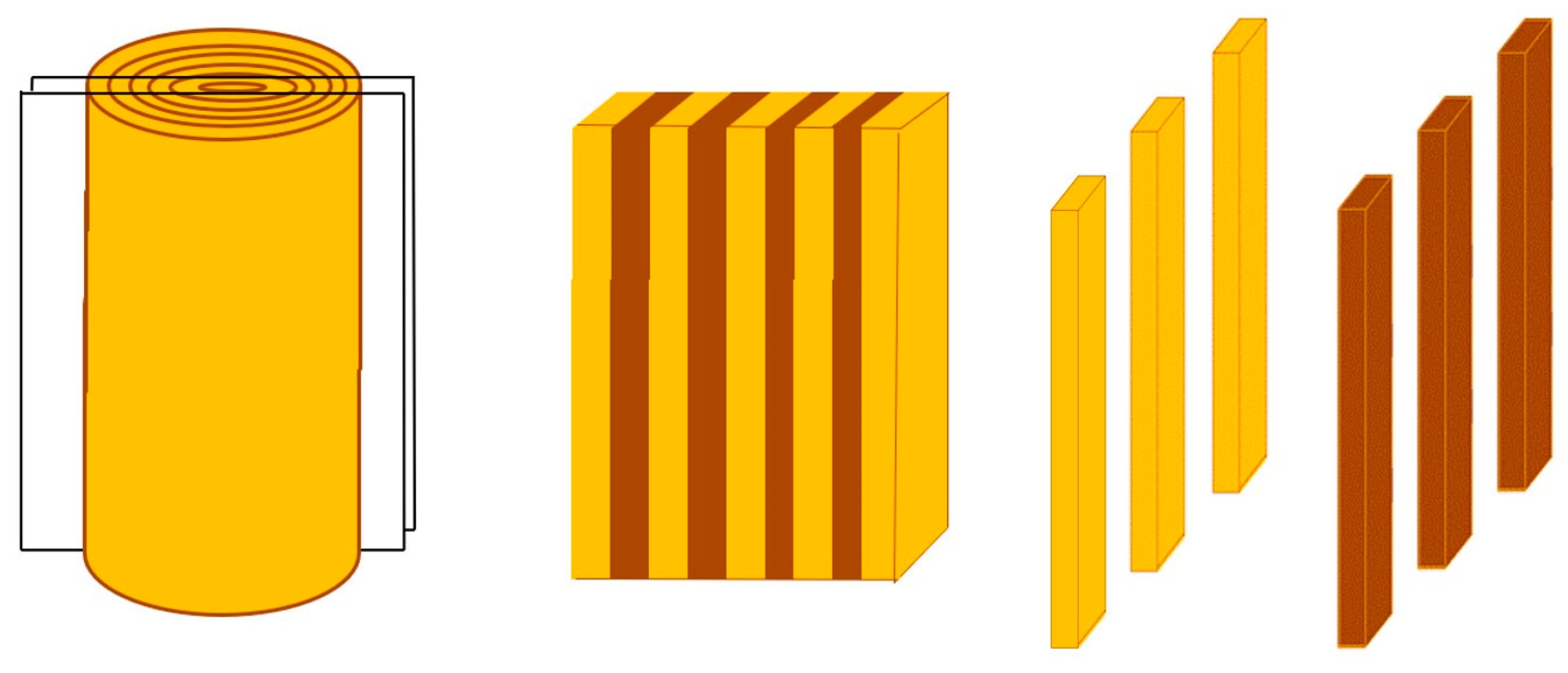

2.1. Yellow Pine Wood Samples

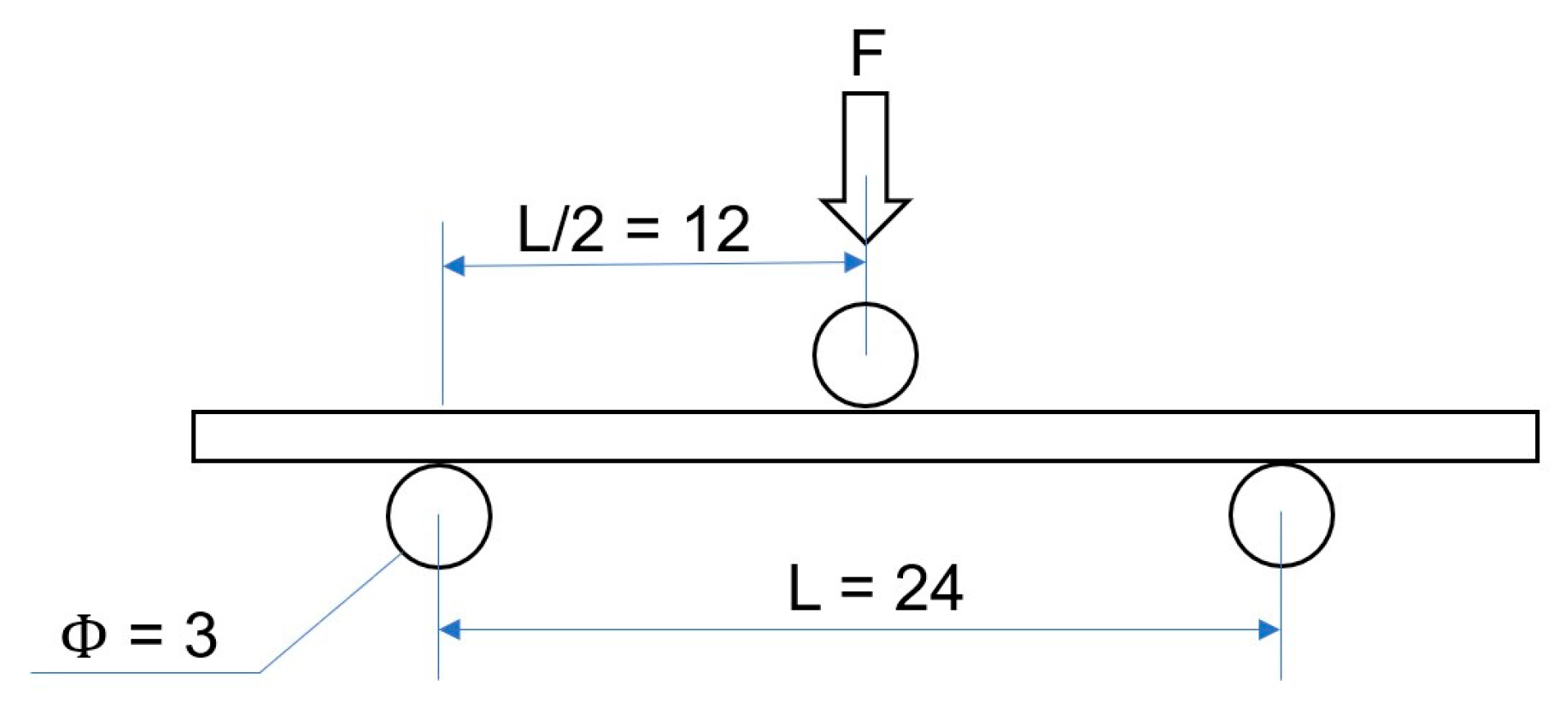

2.2. Determination of Modulus of Rupture and Modulus of Elasticity in Static Bending Using Standard Wood Samples

2.3. Determination of Modulus of Rupture and Modulus of Elasticity in Static Bending of Earlywood (EW) and Latewood (LW) from the Yellow Pine Sapwood Area

2.4. Statistical Analysis

3. Results

4. Conclusions

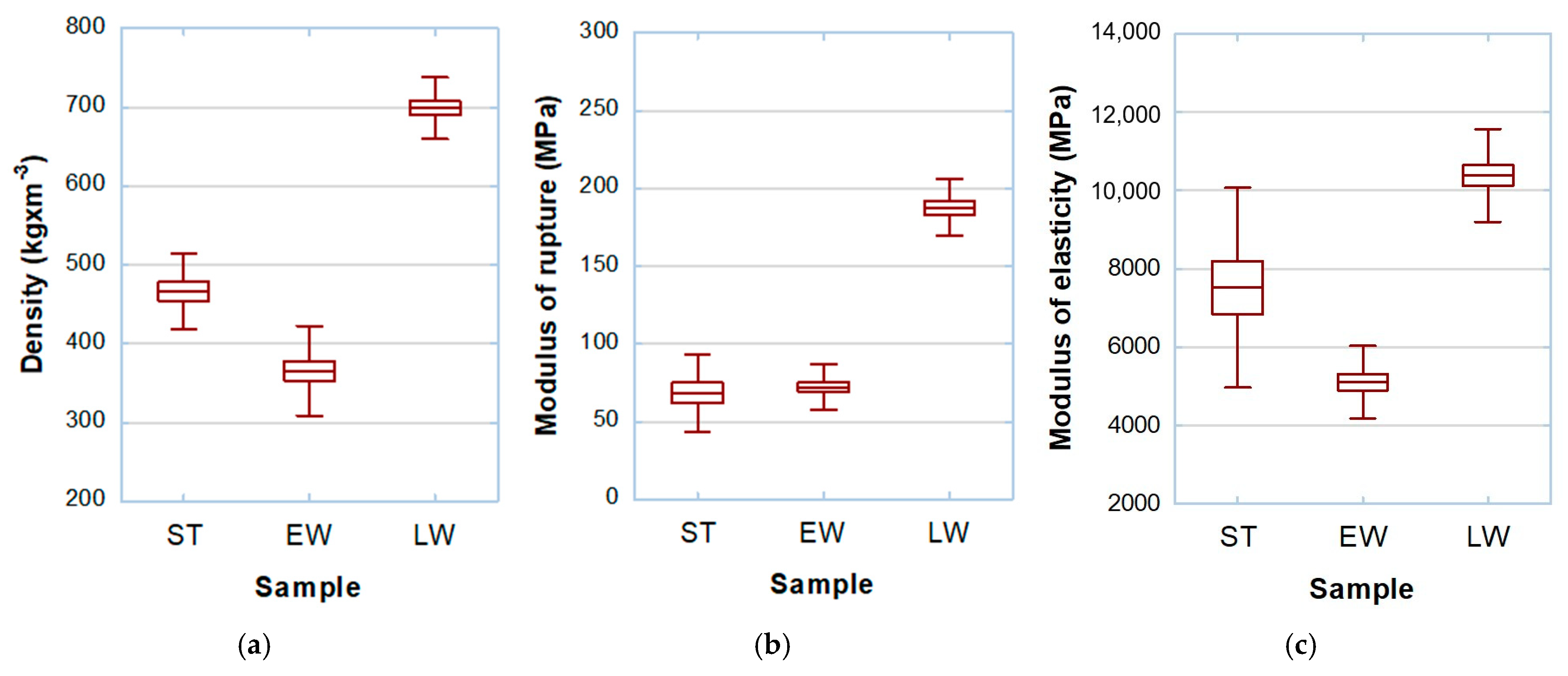

- The density of the yellow pine earlywood was 22% lower than the density of sapwood. The density of the latewood was 50% higher than the density of the sapwood. In general, it should be stated that the density of the latewood was twice as high as the density of the earlywood of yellow pine.

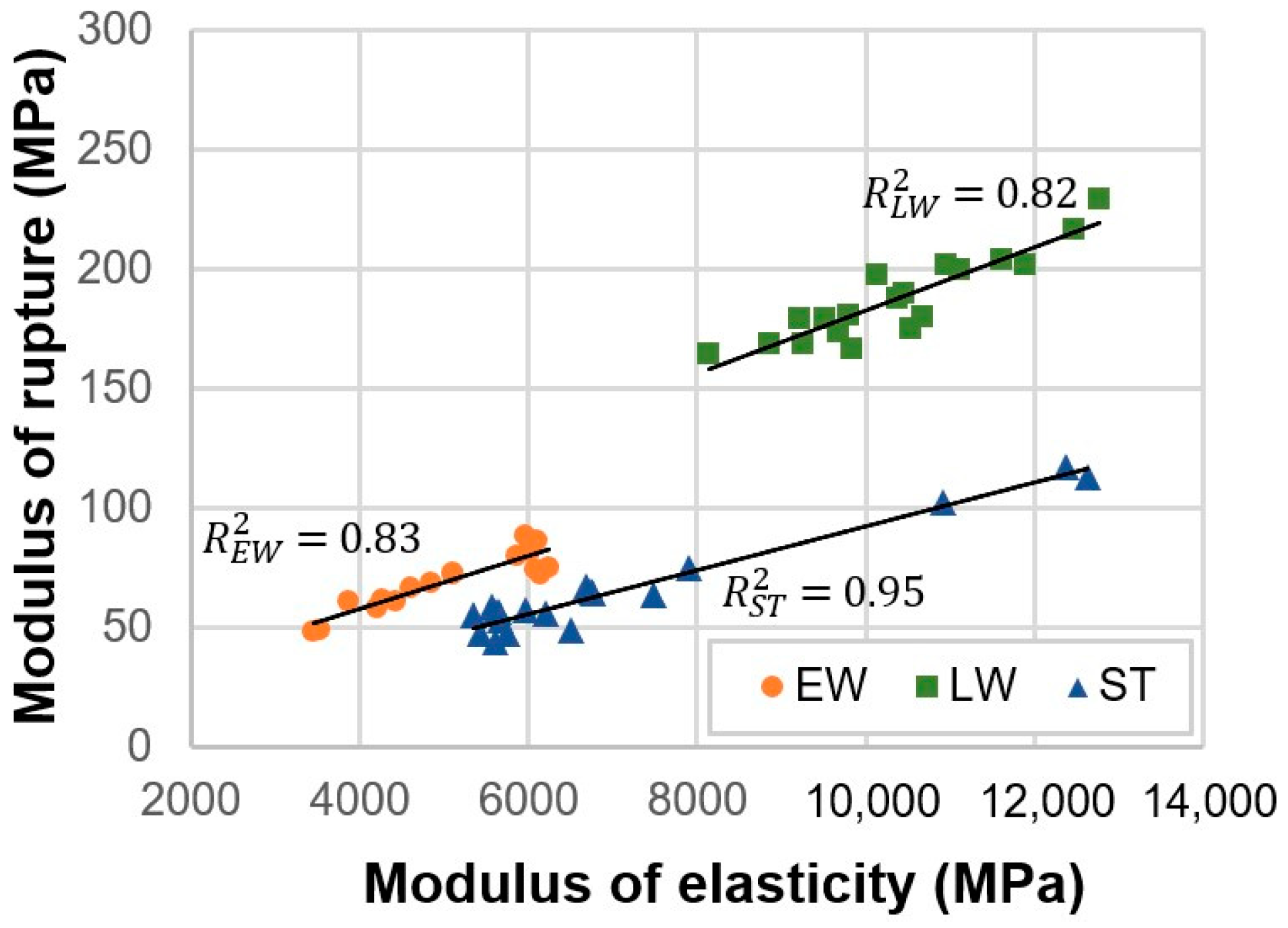

- The modulus of rupture of the yellow pine earlywood was about 6% higher than the modulus of rupture of the pine wood, determined using standard samples, and these differences were not statistically significant. The modulus of rupture of the latewood was approximately three times higher than the modulus of rupture of the pine wood determined using standard samples, and these differences were statistically significant. The modulus of rupture of latewood was 2.5 times higher than the modulus of rupture of the earlywood.

- The modulus of elasticity of the earlywood was about 32% lower than the modulus of elasticity of the pine wood determined using standard samples, and these differences were statistically significant. The modulus of elasticity of the latewood was about 38% higher than the modulus of elasticity of the pine wood determined using standard samples, and these differences were statistically significant. The modulus of elasticity of the latewood was found to be two times higher than the modulus of elasticity of the earlywood.

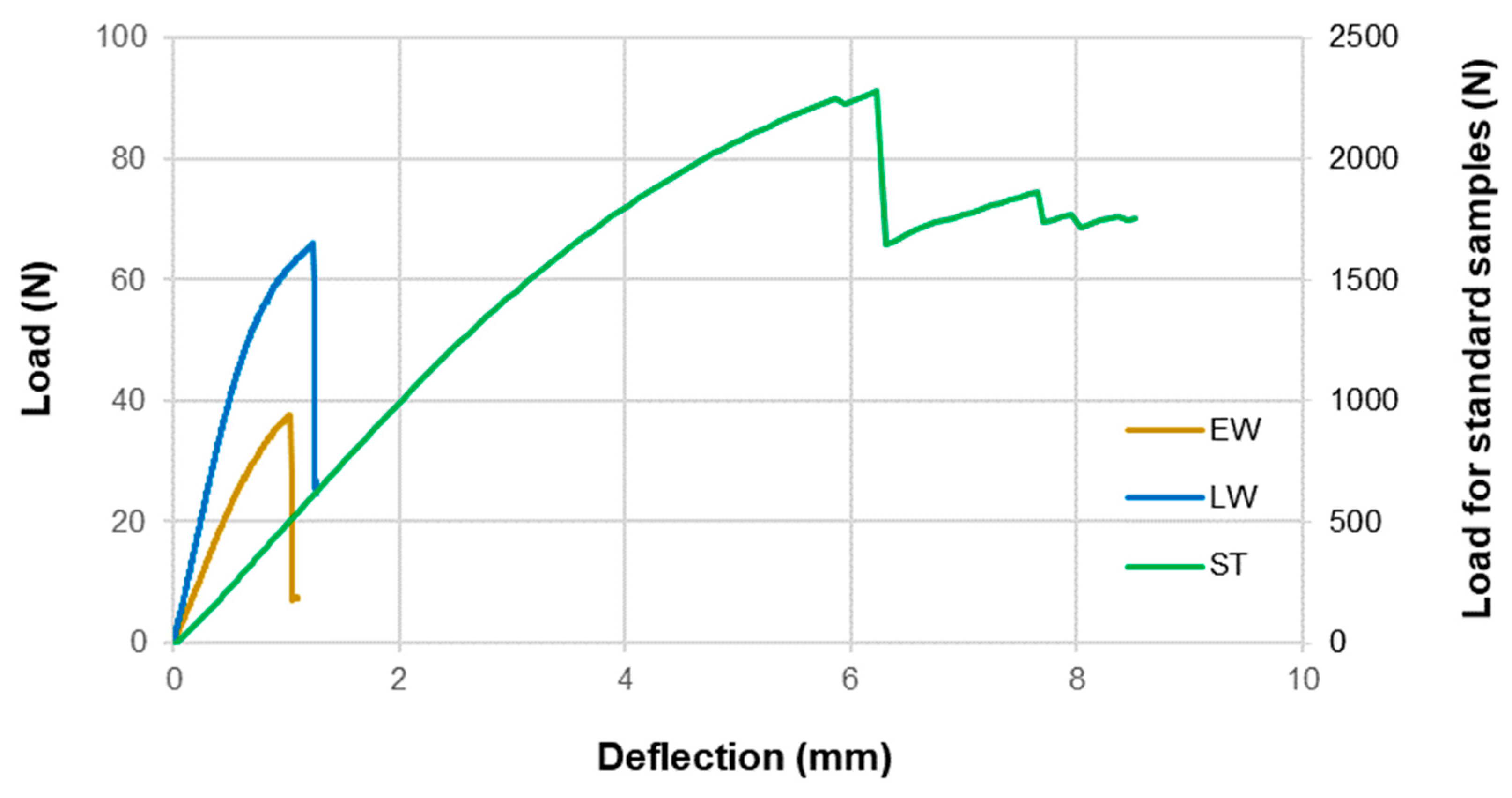

- The maximum load transferred by latewood zones was four times higher than the maximum load transferred by earlywood zones. The deflection at the maximum load of earlywood zones was 20% smaller than the deflection at the maximum load of latewood zones.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Goodman, J.R.; Bodig, J. Orthotropic elastic properties of wood. J. Struct. Div. 1970, 96, 2301–2319. [Google Scholar] [CrossRef]

- Wilczyński, A.; Gogolin, M. Badanie Właściwości Sprężystych Drewna Sosny, Buka i Dębu [Investigation of the Elastic Properties of Pine, Beech and Oak Wood]; Zeszyty Naukowe Wyższej Szkoły Pedagogicznej w Bydgoszczy: Studia Techniczne, 15; Biblioteka Uniwersytetu Kazimierza Wielkiego: Bydgoszcz, Poland, 1989. [Google Scholar]

- Bergander, A.; Salmén, L. Variations in transverse fibre wall properties: Relations between elastic properties and structure. Holzforschung 2000, 54, 654–660. [Google Scholar] [CrossRef]

- Andersson, F.A. (Ed.) Coniferous Forests, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2005; Volume 6, ISBN 9780444816276. [Google Scholar]

- Mańkowski, P.; Laskowska, A. Compressive strength parallel to grain of earlywood and latewood of yellow pine. Maderas-Cienc. Tecnol. 2021, 23, 1–12. [Google Scholar] [CrossRef]

- Paschalis-Jakubowicz, P.; Kulik, P.; Lachowicz, H. Kształtowanie cen oraz metody sprzedaży surowca cennego w Polsce [Prices and sales methods of the valuable timber in Poland]. Sylwan 2015, 159, 267–277. [Google Scholar]

- Mikołajczak, E.; Wieruszewski, M.; Wanat, L. A sustainable roundwood pricing strategy as an opportunity or a threat for the development of wood-based industry in Poland. In Proceedings of the 13th International Scientific Conference WoodEMA 2020 and the 31st International Scientfic Conference ICWST 2020, Vinkovci, Croatia, 28–30 September 2020; pp. 245–250. [Google Scholar]

- Zastocki, D.; Oktaba, J.; Lachowicz, H. Changes in the Market of Precious Wood: A Case Study of Submission System in Poland. Forests 2021, 12, 421. [Google Scholar] [CrossRef]

- Kollmann, F.; Côté, W. Principles of Wood Science and Technology; Springer: Berlin/Heidelberg, Germany, 1968; Volume 1: Solid Wood. [Google Scholar]

- Burawska-Kupniewska, I.; Mańkowski, P.; Krzosek, S. Mechanical Properties of Machine Stress Graded Sawn Timber Depending on the Log Type. Forests 2021, 12, 532. [Google Scholar] [CrossRef]

- Wagenführ, R. Holzatlas [The Atlas of Wood]; Fachbuchverlag Leipzig: München, Germany, 2007. [Google Scholar]

- EN 408:2010+A1:2012; Timber Structures—Structural Timber and Glued Laminated Timber—Determination of Some Physical and Mechanical Properties. European Committee for Standardization: Brussels, Belgium, 2012.

- EN 384:2016+A2:2022; Structural Timber—Determination of Characteristic Values of Mechanical Properties and Density. European Committee for Standardization: Brussels, Belgium, 2022.

- Šilinskas, B.; Varnagiryte-Kabašinskiene, I.; Aleinikovas, M.; Beniušiene, L.; Aleinikoviene, J.; Škema, M. Scots pine and Norway spruce wood properties at sites with different stand densities. Forests 2020, 11, 587. [Google Scholar] [CrossRef]

- Vega, M.; Hamilton, M.; Downes, G.; Harrison, P.A.; Potts, B. Radial variation in modulus of elasticity, microfibril angle and wood density of veneer logs from plantation-grown Eucalyptus nitens. Ann. For. Sci. 2020, 77, 65. [Google Scholar] [CrossRef]

- Alteyrac, J.; Cloutier, A.; Zhang, S.Y. Characterization of juvenile wood to mature wood transition age in black spruce (Picea mariana (Mill.) B.S.P.) at different stand densities and sampling heights. Wood Sci. Technol. 2006, 40, 124–138. [Google Scholar] [CrossRef]

- Krauss, A.; Moliński, W.; Kúdela, J.; Čunderlík, I. Differences in the mechanical properties of early and latewood within individual annual rings in dominant pine tree (Pinus sylvestris L.). Wood Res. 2011, 56, 1–12. [Google Scholar]

- Huang, Y.; Fei, B.; Yu, Y.; Wang, S.; Shi, Z.; Zhao, R. Modulus of elasticity and hardness of compression and opposite wood cell walls of masson pine. BioResources 2012, 7, 3028–3037. [Google Scholar] [CrossRef]

- Moya, L.; Laguarda, M.F.; Cagno, M.; Cardoso, A.; Gatto, F.; O’Neill, H. Physical and Mechanical Properties of Loblolly and Slash Pine Wood from Uruguayan Plantations. For. Prod. J. 2013, 63, 128–137. [Google Scholar] [CrossRef]

- Mania, P.; Nowicki, M. Nanohardness and elasticity of cell walls of Scots pine (Pinus sylvestris L.) juvenile and mature wood. Bull. Pol. Acad. Sci. Tech. Sci. 2020, 68, 1237–1241. [Google Scholar] [CrossRef]

- Prosiński, S. Chemia Drewna [Chemistry of Wood]; PWRiL: Warsaw, Poland, 1984. [Google Scholar]

- Kacik, F.; Solár, R. Analyticka Chemia Dreva [Analitical Chemistry of Wood]; Technicka Univerzita vo Zwolene: Zwolen, Slowak, 1999. [Google Scholar]

- Solár, R. Chémia Dreva [Chemistry of Wood]; Technicka Univerzita vo Zwolene: Zwolen, Slowak, 2004. [Google Scholar]

- Grotta, A.T.; Leichti, R.J.; Gartner, B.L.; Johnson, G.R. Effect of growth ring orientation and placement of earlywood and latewood on MOE and MOR of very-small clear Douglas-Fir beams. Wood Fiber Sci. 2005, 37, 207–212. [Google Scholar]

- Kretschmann, D.E.; Cramer, S.M. The role of earlywood and latewood properties on dimensional stability of loblolly pine. In Proceedings of the Compromised Wood Workshop, Christchurch, New Zealand, 29–30 January 2007; Wood Technology Research Centre, School of Forestry, University of Canterbury: Christchurch, New Zealand, 2007; pp. 215–236, ISBN 978-0-473-12768-8. [Google Scholar]

- Moliński, W.; Krauss, A. Radial gradient of modulus of elasticity of wood and tracheid cell walls in dominant pine trees (Pinus sylvestris L.). Folia Forestalia Polonica. Ser. B Drzew. 2008, 39, 19–29. [Google Scholar]

- Rocha, M.F.V.; Costa, L.R.; Costa, L.J.; De Araújo, A.C.C.; Soares, B.C.D.; Hein, P.R.G. Wood knots influence the modulus of elasticity and resistance to compression. Floresta e Ambiente 2018, 25, e20170906. [Google Scholar] [CrossRef]

- Ruel, J.J.; Ayres, M.P.; Lorio, P.L. Loblolly pine responds to mechanical wounding with increased resin flow. Can. J. Bot. 1998, 28, 596–602. [Google Scholar] [CrossRef]

- Wieruszewski, M.; Trociński, A.; Kawalerczyk, J.; Derkowski, A.; Mirski, R. The Strength of Pine (Pinus sylvestris L.) Sawn Timber in Correlation with Selected Wood Defects. Materials 2022, 15, 3974. [Google Scholar] [CrossRef] [PubMed]

- Green, D.W.; Gorman, T.M.; Murphy, J.F.; Wheeler, M.B. Moisture Content and the Properties of Lodgepole Pine Logs in Bending and Compression Parallel to the Grain; Research Paper FPL-RP-639; Forest Products Laboratory, U.S. Department of Agriculture, Forest Service: Madison, WI, USA, 2007. [Google Scholar] [CrossRef]

- Glass, S.V.; Zelinka, S.L. Moisture Relations and Physical Properties of Wood. In Wood Handbook; General Technical Report FPL-GTR-190; Forest Products Laboratory, U.S. Department of Agriculture, Forest Service: Madison, WI, USA, 2010; Chapter 4; pp. 1–19. [Google Scholar]

- Ishimaru, Y.; Arai, K.; Mizutani, M.; Oshima, K.; Iida, I. Physical and mechanical properties of wood after moisture conditioning. J. Wood Sci. 2001, 47, 185–191. [Google Scholar] [CrossRef]

- Li, W.; Zhang, Y.; Wang, X.; Wang, J. Relationship between structural characteristics of growth rings and strain accumulation in thermally modified Douglas fir wood during compressive test. Wood Mater. Sci. Eng. 2024, 1–10. [Google Scholar] [CrossRef]

- Li, W.; Yang, K.; Zhang, Y.; Shi, J.; Van den Buckle, J.; Acker, J.V. The effect of growth-ring orientation on the compressive performance of Douglas fir. Wood Mater. Sci. Eng. 2024, 19, 131–142. [Google Scholar] [CrossRef]

- Zink-Sharp, A.; Price, C. Intra-ring compression strength of low density hardwoods. Maderas-Cienc. Tecnol. 2006, 8, 117–126. [Google Scholar] [CrossRef]

- Auty, D.; Achim, A.; MacDonald, E.; Cameron, A.; Gardiner, B. Models for Predicting Clearwood Mechanical Properties of Scots Pine. For. Sci. 2016, 62, 403–413. [Google Scholar] [CrossRef]

- Verkasalo, E.; Leban, J.M. MOE and MOR in static bending of small clear specimens of Scots pine, Norway spruce and European fir from Finland and France and their prediction for the comparison of wood quality. Pap. Timber J. Finish For. Ind. 2002, 84, 332–340. [Google Scholar]

- Bytner, O.; Drożdżek, M.; Laskowska, A.; Zawadzki, J. Influence of Thermal Modification in Nitrogen Atmosphere on the Selected Mechanical Properties of Black Poplar Wood (Populus nigra L.). Materials 2022, 15, 7949. [Google Scholar] [CrossRef]

- Cramer, S.; Kretschmann, D.; Lakes, R.; Schmidt, T. Earlywood and latewood elastic properties in loblolly pine. Holzforschung 2005, 59, 531–538. [Google Scholar] [CrossRef]

- Lanvermann, C.H.; Hass, P.H.; Wittel, F.K.; Niemz, P. Mechanical Properties of Norway Spruce: Intra-Ring Variation and Generic Behavior of Earlywood and Latewood until Failure. BioResources 2014, 9, 105–119. [Google Scholar] [CrossRef]

- Büyüksarı, Ü.; As, N.; Dündar, T. Mechanical Properties of Earlywood and Latewood Sections of Scots Pine Wood. BioResources 2017, 12, 4004–4012. [Google Scholar] [CrossRef]

- Büyüksarı, Ü.; As, N.; Dündar, T. Intra-Ring Properties of Earlywood and Latewood Sections of Sessile Oak (Quercus petraea). BioResources 2018, 13, 836–845. [Google Scholar] [CrossRef]

- Groom, L.; Shaler, S.; Mott, L. Mechanical properties of individual southern pine fibers. Part III. Global relationships between fiber properties and fiber location within an individual tree. Wood Fiber Sci. 2002, 34, 238–250. [Google Scholar]

- Wimmer, R.; Lucas, B.N.; Tsui, T.Y.; Oliver, W.C. Longitudinal hardness and Young’s modulus of spruce tracheid secondary walls using nanoindentation technique. Wood Sci. Technol. 1997, 31, 131–141. [Google Scholar] [CrossRef]

- Bergander, A.; Salmén, L. Cell wall properties and their effects on the mechanical properties of fibers. J. Mater. Sci. Lett. 2002, 37, 151–156. [Google Scholar] [CrossRef]

- ISO 13061-1:2014; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 1: Determination of Moisture Content for Physical and Mechanical Tests. International Organization of Standardization: Geneva, Switzerland, 2014.

- ISO 13061-2:2014; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 2: Determination of Density for Physical and Mechanical Tests. International Organization of Standardization: Geneva, Switzerland, 2014.

- ISO 13061-3:2014; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 3: Determination of Ultimate Strength in Static Bending. International Organization of Standardization: Geneva, Switzerland, 2014.

- ISO 13061-4:2014; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 4: Determination of Modulus of Elasticity in Static Bending. International Organization of Standardization: Geneva, Switzerland, 2014.

- Kozakiewicz, P.; Życzkowski, W. Physical and mechanical properties and anatomy of common juniper (Juniperus communis L.) wood. Sylwan 2015, 159, 151–159. [Google Scholar] [CrossRef]

- Cave, I.D.; Walker, J.C.F. Stiffness of wood in fast-grown plantation softwoods: The influence of microfibril angle. For. Prod. J. 1994, 44, 43–48. [Google Scholar]

- Peltola, H.; Gort, J.; Pulkkinen, P.; Zubizarreta Gerendiain, A.; Karppinen, J.; Ikonen, V.P. Differences in growth and wood density traits in Scots pine (Pinus sylvestris L.) genetic entries grown at different spacing and sites. Silva Fenn. 2009, 43, 339–354. [Google Scholar] [CrossRef]

- Traoré, M.; Kaal, J.; Martínez Cortizas, A. Differentiation between pine woods according to species and growing location using FTIR-ATR. Wood Sci. Technol. 2018, 52, 487–504. [Google Scholar] [CrossRef]

- Danawade, B.A.; Malagi, R.R.; Patil, B.S.; Hanamapure, R.S. Effect of finger joint on flexural strength of teak wood. Int. J. Eng. Technol. 2014, 5, 4929–4937. [Google Scholar]

- Souppez, J.B.R. Timber construction: An experimental assessment of the strength of scarf joints and the effectiveness of various adhesives for laminated wood. In Historic Ships; The Royal Institution of Naval Architects (RINA): London, UK, 2020; pp. 53–60. [Google Scholar]

- Hu, W.; Yu, R. Mechanical and acoustic characteristics of four wood species subjected to bending load. Maderas. Cienc. Tecnol. 2023, 25, 1–12. [Google Scholar] [CrossRef]

- Sokołowski, P.K.; Kossakowski, P.G. Static Analysis of Wooden Beams Strengthened with FRCM-PBO Composite in Bending. Materials 2023, 16, 1870. [Google Scholar] [CrossRef]

- Bakalarz, M.M. Mechanical Properties of Full-Scale Wooden Beams Strengthened with Carbon-Fibre-Reinforced Polymer Sheets. Materials 2024, 17, 4917. [Google Scholar] [CrossRef]

- Roszyk, E. The effect of ultrastructure and moisture content on mechanical parameters of pine wood (Pinus sylvestris L.) upon tensile stress along the grains. Turk. J. Agric. For. 2014, 38, 413–419. [Google Scholar] [CrossRef]

- Roszyk, E.; Moliński, W.; Kamiński, M. Tensile properties along the grains of earlywood and latewood of Scots pine (Pinus sylvestris L.) in dry and wet state. BioResources 2016, 11, 3027–3037. [Google Scholar] [CrossRef]

- Barnett, J.R.; Bonham, V.A. Cellulose microfibril angle in the cell wall of wood fibres. Biol. Rev. 2004, 79, 461–472. [Google Scholar] [CrossRef] [PubMed]

| Wood Sample | Property | Statistical Parameters | |

|---|---|---|---|

| MOR | F-Value | Significance Level p | |

| EW | MOREW = 0.118 WD + 28.993 | 5.566 | p < 0.050 |

| LW | MORLW = 0.295 WD − 18.819 | 14.265 | p < 0.050 |

| ST | MORST = 0.419 WD − 124.491 | 74.430 | p < 0.050 |

| MOE | F-Value | Significance Level p | |

| EW | MOEEW = 6.343 WD + 2788 | 3.202 | p > 0.050 |

| LW | MOELW = 19.64 WD − 3345 | 12.999 | p < 0.050 |

| ST | MOEST = 46.18 WD − 13,866 | 116.37 | p < 0.050 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mańkowski, P.; Karwat, Z.; Laskowska, A. Assessment of the Modulus of Rupture and Modulus of Elasticity in Static Bending of Yellow Pine Earlywood and Latewood. Forests 2025, 16, 265. https://doi.org/10.3390/f16020265

Mańkowski P, Karwat Z, Laskowska A. Assessment of the Modulus of Rupture and Modulus of Elasticity in Static Bending of Yellow Pine Earlywood and Latewood. Forests. 2025; 16(2):265. https://doi.org/10.3390/f16020265

Chicago/Turabian StyleMańkowski, Piotr, Zbigniew Karwat, and Agnieszka Laskowska. 2025. "Assessment of the Modulus of Rupture and Modulus of Elasticity in Static Bending of Yellow Pine Earlywood and Latewood" Forests 16, no. 2: 265. https://doi.org/10.3390/f16020265

APA StyleMańkowski, P., Karwat, Z., & Laskowska, A. (2025). Assessment of the Modulus of Rupture and Modulus of Elasticity in Static Bending of Yellow Pine Earlywood and Latewood. Forests, 16(2), 265. https://doi.org/10.3390/f16020265