Comparative Life Cycle Assessment of Heat-Treated Radiata Pine Lumber: Evaluating Two Heat Supply Scenarios in China

Abstract

:1. Introduction

2. Methodology

2.1. Goal and Scope

2.1.1. Goal Definition

2.1.2. System Boundary

2.1.3. Declared Unit

2.1.4. Allocation Procedure

2.2. Inventory Approach

2.2.1. Forest Management and Wood Harvesting

2.2.2. Transportation

2.2.3. Log Sawing

2.2.4. Lumber Drying

2.2.5. Lumber Heat Treatment

2.2.6. Heat Supply

2.3. Impact Assessment Method

3. Results and Discussion

3.1. Inventory Analysis for Wood-Fired Boiler Heat Supply Scenario

3.2. Inventory Analysis for Power Plant Heat Supply Scenario

3.3. Life Cycle Impact Assessment Results

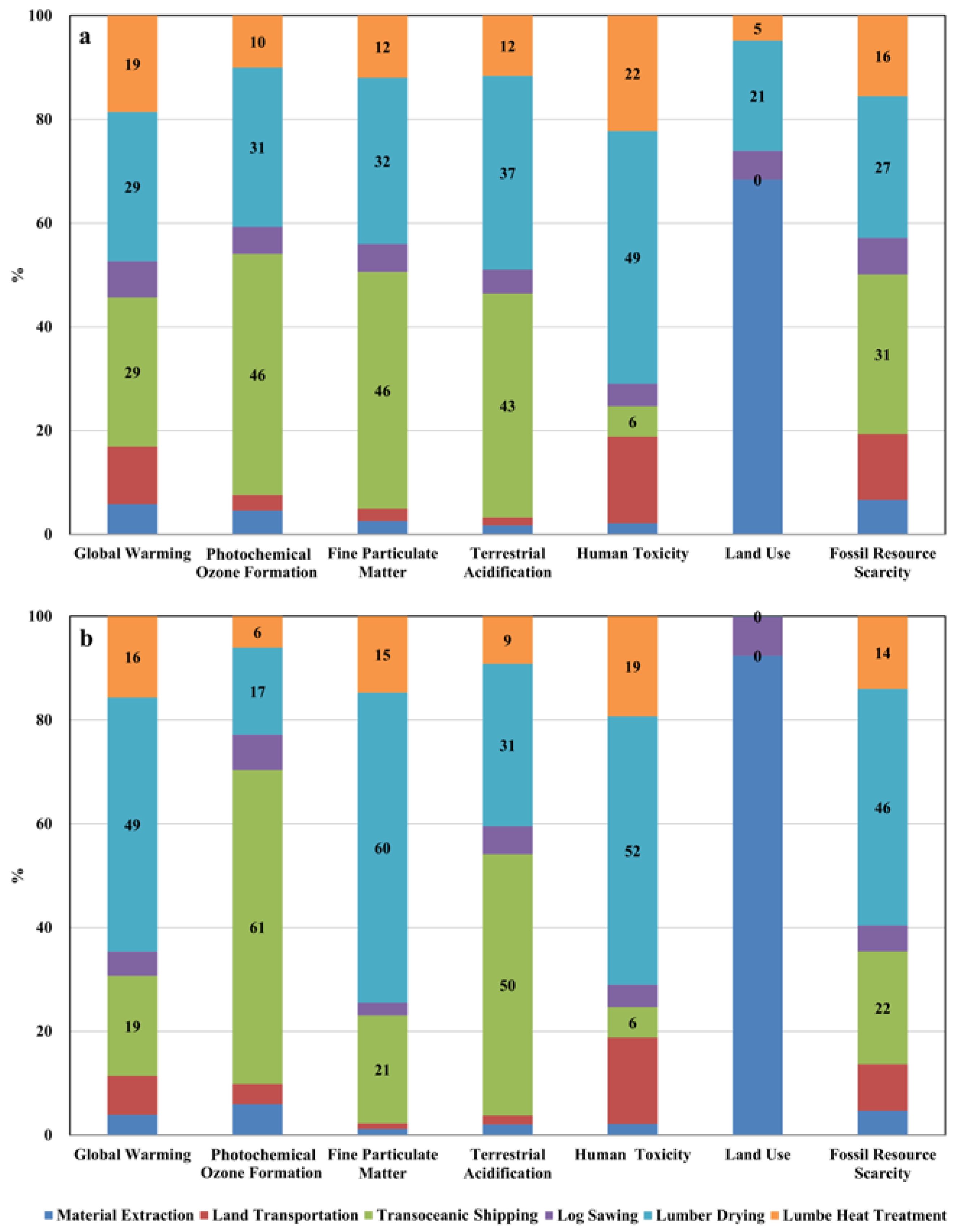

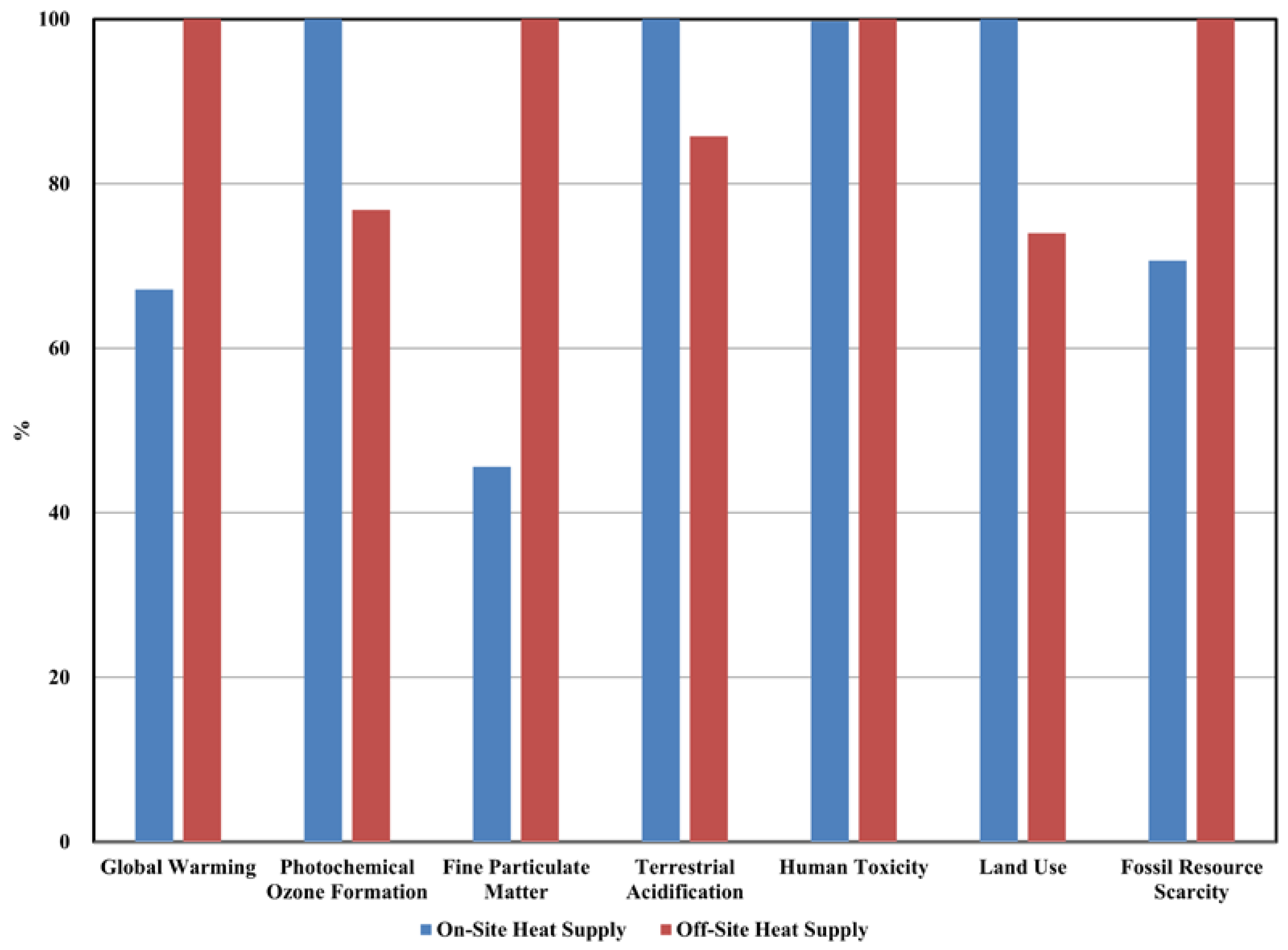

3.3.1. Midpoint Impacts

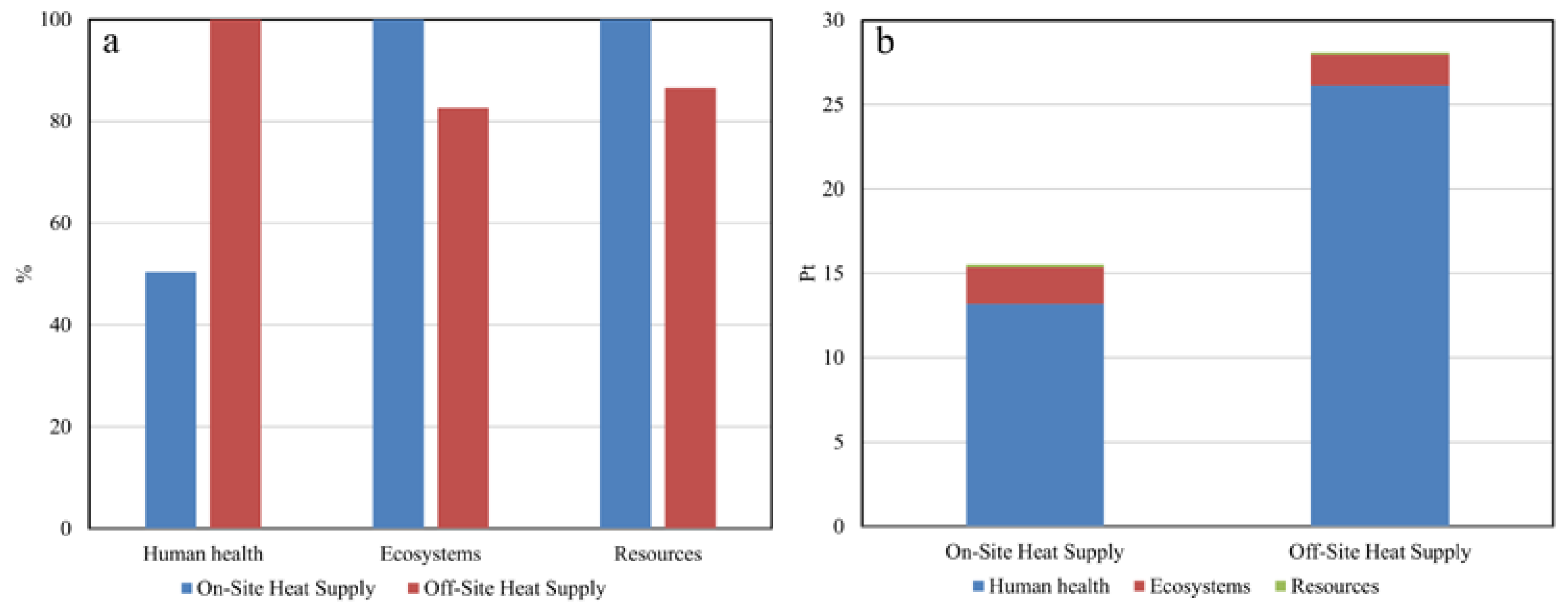

3.3.2. Endpoint Impacts

3.3.3. Limitations and Challenges

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hill, C.; Altgen, M.; Rautkari, L. Thermal Modification of Wood-A Review: Chemical Changes and Hygroscopicity. J. Mater. Sci. 2021, 56, 6581–6614. [Google Scholar] [CrossRef]

- Qu, L.; Wang, Z.; Qian, J.; He, Z.; Yi, S. Effect of Combined Aluminum-Silicon Synergistic Impregnation and Heat Treatment on the Thermal Stability, Chemical Components, and Morphology of Wood. Bioresources 2019, 14, 349–362. [Google Scholar] [CrossRef]

- Búryová, D.; Sedlák, P. Life Cycle Assessment of Coated and Thermally Modified Wood Façades. Coatings 2021, 11, 1487. [Google Scholar] [CrossRef]

- Kuka, E.; Cirule, D.; Andersone, I.; Andersons, B.; Kurnosova, N.; Verovkins, A.; Puke, M. Environmental Performance of Combined Treated Wood. Wood Mater. Sci. Eng. 2023, 18, 88–96. [Google Scholar] [CrossRef]

- Ferreira, J.; Herrera, R.; Labidi, J.; Esteves, B.; Domingos, I. Energy and Environmental Profile Comparison of TMT Production from Two Different Companies—A Spanish/Portuguese Case Study. iForest 2018, 11, 155–161. [Google Scholar] [CrossRef]

- Candelier, K.; Dibdiakova, J. A Review on Life Cycle Assessments of Thermally Modified Wood. Holzforschung 2020, 75, 199–224. [Google Scholar] [CrossRef]

- Bjørn, A.; Owsianiak, M.; Molin, C.; Laurent, A. Main Characteristics of LCA. In Life Cycle Assessment: Theory and Practice; Hauschild, M.Z., Rosenbaum, R.K., Olsen, S.I., Eds.; Springer: Cham, Switzerland, 2018; pp. 9–16. [Google Scholar]

- Hill, C.; Hughes, M.; Gudsell, D. Environmental Impact of Wood Modification. Coatings 2021, 11, 366. [Google Scholar] [CrossRef]

- Aro, M.D. Life-Cycle Assessment of Thermally-Modified Southern Pine Decking. Master’s Thesis, University of Minnesota, Minneapolis, MN, USA, 2018. [Google Scholar]

- Finnish Thermowood Association. Executive Summary–ThermoWood®: Life Cycle Assessment (LCA) of Finnish Thermally Modified Wood Cladding; Publishing House Koivuniemi: Espoo, Finland, 2008. [Google Scholar]

- Marra, M.; Allegre, O.; Guercini, S. Life Cycle Assessment of ThermoVacuum Treated Softwood Timber with Comparison to Untreated and Preserved Cladding. In Proceedings of the COST Action FP1407 1st Conference “Life Cycle Assessment, EPDs, and Modified Wood”, Koper, Slovenia, 25–26 August 2015; University of Primorska Press: Koper, Slovenia, 2015. [Google Scholar]

- Ferreira, J.; Jones, D.; Esteves, B.; Cruz-Lopes, L.; Pereira, H.; Domingos, I. Life Cycle Assessment of Maritime Pine Wood: A Portuguese Case Study. J. Sustain. For. 2021, 40, 431–445. [Google Scholar] [CrossRef]

- Lewis, G.M.; Eastin, I.; Keoleian, G.A. Life Cycle Carbon Accounting of Thermally Modified Wood in the US Inland Northwest. ACS Sustain. Chem. Eng. 2022, 10, 10252–10259. [Google Scholar] [CrossRef]

- Jones, D.; Sandberg, D. A Review of Wood Modification Globally–Updated Findings from COST FP1407. Interdiscip. Perspect. Built Env. 2020, 1, 1–31. [Google Scholar] [CrossRef]

- Elustondo, D.; Oliveira, L. Opportunities to Reduce Energy Consumption in Softwood Lumber Drying. Dry. Technol. 2006, 24, 653–662. [Google Scholar]

- Zhang, B.G.; Zhou, Y.D.; Yi, S.L. Preliminary Analysis of Energy-Saving and Emission-Reduction Path in Conventional Wood Drying. China For. Prod. Ind. 2014, 41, 3–6. (In Chinese) [Google Scholar]

- GB 24500-2020; Minimum Allowable Values of Energy Efficiency and Energy Efficiency Grades of Industrial Boilers. China National Standardization Administration: Beijing, China, 2020.

- Shen, W.; Yang, J.; Xiao, Z.; Liu, Z. Analysis of New Zealand Radiata Pine Wood Imports and Application. Int. Wood Ind. 2020, 6, 38–42. (In Chinese) [Google Scholar]

- ISO 14040:2006; Environmental Management-Life Cycle Assessment-Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management-Life Cycle Assessment-Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Jungmeier, G.; Werner, F.; Jarnehammar, A.; Hohenthal, C.; Richter, K. Allocation in LCA of wood-based products, Experiences of cost action E9, Part I, Methodology. Int. J. Life Cycle Assess. 2002, 7, 290–294. [Google Scholar]

- Hill, C.; Dibdiakova, J. The Environmental Impact of Wood Compared to Other Building Materials. Int. Wood Prod. J. 2016, 7, 215–219. [Google Scholar]

- Shmulsky, R.; Jones, P.D. Forest Products and Wood Science, An Introduction, 6th ed.; Wiley-Blackwell: Chichester, UK, 2011; p. 431. [Google Scholar]

- Ministry of Ecology and Environment of China. Handbook on Methods and Coefficients for Accounting for Emissions and Discharges from Statistical Surveys of Emission Sources; Ministry of Ecology and Environment of China: Beijing, China, 2021. (In Chinese) [Google Scholar]

- Calvo Buendia, E.; Tanabe, K.; Kranjc, A.; Baasansuren, J.; Fukuda, M.; Ngarize, S.; Osako, A.; Pyrozhenko, Y.; Shermanau, P.; Federici, S. 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2019. [Google Scholar]

- International Energy Agency. Energy System of China. 2021. Available online: https://www.iea.org/countries/china (accessed on 15 May 2024).

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar]

- Sahoo, K.; Bergman, R.; Runge, T. Life-Cycle Assessment of Redwood Lumber Products in the US. Int. J. Life Cycle Assess. 2021, 26, 1702–1720. [Google Scholar]

- PE International. Life Cycle Assessment of Rough-Sawn Kiln-Dried Hardwood Lumber. A Report for American Hardwood Export Council; PE International: Leinfelden-Echterdingen, Germany, 2012. [Google Scholar]

- Milota, M.R.; West, C.D.; Hartley, I.D. Gate-to-Gate Life-Cycle Inventory of Softwood Lumber Production. Wood Fiber Sci. 2005, 37, 47–57. [Google Scholar]

- Pang, S.S. Emissions from Kiln Drying of Pinus radiata Timber: Analysis, Recovery, and Treatment. Dry. Technol. 2012, 30, 1099–1104. [Google Scholar]

- Alen, R.; Kotilainen, R.; Zaman, A. Thermochemical Behavior of Norway Spruce (Picea abies) at 180–225 °C. Wood Sci. Technol. 2002, 36, 163–171. [Google Scholar]

- Chu, D.M.; Zhang, X.Y.; Mu, J.; Avramidis, S.; Xue, L.; Li, Y. A Greener Approach to Byproducts from the Production of Heat-Treated Poplar Wood: Analysis of Volatile Organic Compound Emissions and Antimicrobial Activities of Its Condensate. J. Clean. Prod. 2019, 213, 521–527. [Google Scholar] [CrossRef]

- Labat, G.; Bucket, E.; Legay, S.; Yriex, C.; Marchal, P.; Raphalen, E.; Deroubaix, G.; Guyonnet, R.; Besset, H.; Fredon, E.; et al. Environmental Characterisation of Retification Process By-Products (Liquid and Gaseous Wastes). In Proceedings of the 6th International Symposium “Environment and Wood Preservation”, Cannes-Mandelieu, France, 7–8 February 2005. [Google Scholar]

- Ananias, R.A.; Ulloa, J.; Elustondo, D.M.; Salinas, C.; Rebolledo, P.; Fuentes, C. Energy Consumption in Industrial Drying of Radiata Pine. Dry. Technol. 2012, 30, 774–779. [Google Scholar]

- International Thermowood Association. Thermowood-Environmental Aspects. 2023. Available online: https://www.thermowood.fi/ymparisto (accessed on 14 May 2024).

- Jartek. Tekmaheat-Technology for Thermal Modification of Wood. 2022. Available online: https://www.jartek.fi/application/files/7414/9457/7116/jartek_thermal_modification_of_wood_en.pdf (accessed on 14 May 2024).

- Gu, L.; Ding, T.; Jiang, N. Development of Wood Heat Treatment Research and Industrialization. J. For. Eng. 2019, 4, 1–11. (In Chinese) [Google Scholar]

- Chen, C.X.; Pierobon, F.; Granguly, I. Life Cycle Assessment (LCA) of Cross-Laminated Timber (CLT) Produced in Western Washington: The Role of Logistics and Wood Species Mix. Sustainability 2019, 11, 1278. [Google Scholar] [CrossRef]

- Roberts, G.; Skinner, C.; Ormondroyd, G.A. The Environmental and Social Impacts of Modified Wood Production: Effect of Timber Sourcing. Int. Wood Prod. J. 2022, 13, 236–254. [Google Scholar]

- Vedachalam, S.; Baquerizo, N.; Dalai, A.K. Review on Impacts of Low Sulfur Regulations on Marine Fuels and Compliance Options. Fuel 2022, 310, 122243. [Google Scholar] [CrossRef]

- Rohner, C. Daily Fuel Consumption and Greenhouse Gas Emissions by Bulk Carriers Anchoring in the Southern Gulf Islands. A Report Prepared for the Salt Spring Island Climate Action Council; Centre for Marine Affairs: Southern Gulf Islands, BC, Canada, 2020. [Google Scholar]

- Haque, N.; Jangam, S.V.; Mujumdar, A.S. Life Cycle Assessment of Drying Systems. In Handbook of Industrial Drying, 4th ed.; Mujumdar, A.S., Ed.; CRC Press: Boca Raton, FL, USA, 2015; pp. 1229–1238. [Google Scholar]

- Forest Research. Carbon Emissions of Different Fuels. 2024. Available online: https://www.forestresearch.gov.uk/tools-and-resources/fthr/biomass-energy-resources/reference-biomass/facts-figures/carbon-emissions-of-different-fuels/ (accessed on 15 May 2024).

- Riley, S.; Sargent, R. Optimizing Radiata Pine Drying Schedules. Wood Mater. Sci. Eng. 2011, 6, 7–14. [Google Scholar] [CrossRef]

- International Energy Agency. World Energy Outlook 2024; International Energy Agency: Paris, France, 2024; pp. 314+319. [Google Scholar]

- Ren, Y.; Li, G.; Wang, H.; Bie, Z. China’s Zero-Coal Power System Future. Int. J. Electr. Power Energy Syst. 2024, 156, 109748. [Google Scholar]

| Process | Data Source | Equivalent Process |

|---|---|---|

| Forest management and wood harvesting (material extraction) | Ecoinvent | Sawlog and veneer log, softwood, debarked, measured as solid wood {RoW}|debarking, softwood, in forest|Cut-off, U |

| Transoceanic shipping | Ecoinvent | Transport, freight, sea, bulk carrier for dry goods {GLO}|market for transport, freight, sea, bulk carrier for dry goods|Cut-off, U |

| Land transport | Ecoinvent | Transport, freight, lorry >32 metric ton, EURO5 {RoW}|market for transport, freight, lorry >32 metric ton, EURO5|Cut-off, U |

| Electricity in China | Ecoinvent | Electricity, high voltage {CN-ECGC}|electricity, high voltage, production mix|Cut-off, U |

| Off-site heat supply | Ecoinvent | Heat, district or industrial, other than natural gas {RoW}|heat and power co-generation, lignite|Cut-off, U Heat, district or industrial, natural gas {RoW}|heat and power co-generation, natural gas, combined cycle power plant, 400 MW electrical|Cut-off, U |

| Unit Process | Item | Unit | Value | |

|---|---|---|---|---|

| Log sawing | Inputs | Debarked logs | kg | 1023.80 |

| Electricity | kWh | 11.76 | ||

| Diesel | L | 0.42 | ||

| Outputs | Green rough-sawn lumber | m3 | 1 (716.70 kg) | |

| Wood residues | kg | 307.10 | ||

| Particulate matter | kg | 0.002 | ||

| Lumber drying | Inputs | Green rough-sawn lumber | m3 | 1.08 |

| Heat | GJ | 2.67 | ||

| Diesel | L | 0.13 | ||

| Water | kg | 50 | ||

| Electricity | kWh | 28.8 | ||

| Outputs | Kiln-dried rough -awn lumber | m3 | 1 | |

| VOCs | kg | 0.16 | ||

| Heating by wood-fired steam boiler | Inputs | Wood residues | kg | 83.31 |

| Electricity | kWh | 3.26 | ||

| Water | kg | 173.68 | ||

| Outputs | Heat | GJ | 1 | |

| Ash | kg | 0.25 | ||

| NOx | kg | 0.09 | ||

| SO2 | kg | 0.0003 | ||

| Particulate matter | kg | 0.04 | ||

| COD | kg | 0.003 | ||

| Wood heat treatment | Inputs | Kiln-dried rough-sawn lumber | m3 | 1 |

| Heat | GJ | 0.60 | ||

| Electricity | kWh | 25.10 | ||

| Water | kg | 5000 | ||

| Outputs | Heat-treated lumber | m3 | 1 | |

| VOCs | kg | 35 | ||

| Heating by wood-fired hot oil boiler | Inputs | Wood residues | kg | 83.39 |

| electricity | kWh | 28.24 | ||

| Outputs | Heat | GJ | 1 | |

| Ash | kg | 0.25 | ||

| NOx | kg | 0.08 | ||

| SO2 | kg | 0.0003 | ||

| Particulate matter | kg | 0.05 | ||

| COD | kg | 0.003 |

| Unit Process | Item | Unit | Value | |

|---|---|---|---|---|

| Lumber drying | Inputs | Green rough-sawn lumber | m3 | 1.08 |

| Heat | GJ | 1.86 | ||

| Diesel | L | 0.13 | ||

| Water | kg | 50 | ||

| Electricity | kWh | 28.8 | ||

| Outputs | Kiln-dried rough-sawn lumber | m3 | 1 | |

| VOCs | kg | 0.16 | ||

| Wood heat treatment | Inputs | Kiln-dried rough-sawn lumber | m3 | 1 |

| Heat from steam | GJ | 0.16 | ||

| Heat from electric resistance heater | GJ | 0.28 | ||

| Electricity | kWh | 25.1 | ||

| Water | kg | 5000 | ||

| Outputs | Heat-treated lumber | m3 | 1 | |

| VOCs | kg | 35 |

| Impact Category | Heat Supply Scenario | Life Cycle Stages | ||||||

|---|---|---|---|---|---|---|---|---|

| Material Extraction | Land Transport | Transoceanic Shipping | Log Sawing | Lumber Drying | Lumber Heat Treatment | Total | ||

| GW | On site | 14.16 | 26.95 | 69.77 | 16.88 | 69.86 | 45.08 | 242.71 |

| (kg CO2 eq) | Off site | 14.16 | 26.95 | 69.77 | 16.88 | 177.14 | 56.57 | 361.48 |

| POF | On site | 0.23 | 0.15 | 2.34 | 0.26 | 1.54 | 0.50 | 5.03 |

| (kg NOx eq) | Off site | 0.23 | 0.15 | 2.34 | 0.26 | 0.65 | 0.23 | 3.87 |

| FPM | On site | 0.02 | 0.02 | 0.40 | 0.05 | 0.28 | 0.10 | 0.87 |

| (kg PM2.5 eq) | Off site | 0.02 | 0.02 | 0.40 | 0.05 | 1.14 | 0.28 | 1.91 |

| TA | On site | 0.05 | 0.04 | 1.25 | 0.13 | 1.08 | 0.34 | 2.90 |

| (kg SO2 eq) | Off site | 0.05 | 0.04 | 1.25 | 0.13 | 0.78 | 0.23 | 2.48 |

| HT | On site | 1.19 | 9.30 | 3.28 | 2.41 | 27.15 | 12.39 | 55.72 |

| (kg 1,4-DCB) | Off site | 1.19 | 9.30 | 3.28 | 2.41 | 28.89 | 10.77 | 55.84 |

| LU | On site | 499.71 | 0.01 | 0.01 | 40.54 | 155.32 | 35.23 | 730.81 |

| (m2a crop eq) | Off site | 499.71 | 0.01 | 0.01 | 40.54 | 0.45 | 0.20 | 540.91 |

| FRS | On site | 4.21 | 8.08 | 19.56 | 4.48 | 17.34 | 9.88 | 63.53 |

| (kg oil eq) | Off site | 4.21 | 8.08 | 19.56 | 4.48 | 40.99 | 12.61 | 89.92 |

| Impact Category | Country | Life Cycle Stages | ||||

|---|---|---|---|---|---|---|

| Land Transport | Transoceanic Shipping | Log Sawing | Lumber Drying | All Stages | ||

| GW (kg CO2 eq) | CN | 26.9 | 69.8 | 16.9 | 69.9 | 241.9 |

| NZ | 11.3 | 27.8 | 25.0 | 32.0 | 152.8 | |

| POF (kg NOx eq) | CN | 0.2 | 2.3 | 0.3 | 1.5 | 5.0 |

| NZ | 0.1 | 0.9 | 0.2 | 1.1 | 3.1 | |

| FPM (kg PM2.5 eq) | CN | 0.021 | 0.398 | 0.047 | 0.280 | 0.9 |

| NZ | 0.009 | 0.159 | 0.048 | 0.215 | 0.6 | |

| TA (kg SO2 eq) | CN | 0.043 | 1.251 | 0.134 | 1.081 | 2.9 |

| NZ | 0.018 | 0.498 | 0.084 | 0.275 | 1.2 | |

| HT (kg 1,4-DCB) | CN | 9.3 | 3.3 | 2.4 | 27.1 | 55.4 |

| NZ | 3.9 | 1.3 | 3.0 | 64.4 | 86.1 | |

| LU (m2a crop eq) | CN | 0.009 | 0.011 | 40.538 | 155.317 | 730.8 |

| NZ | 0.004 | 0.004 | 280.010 | 168.599 | 983.8 | |

| FRS (kg oil eq) | CN | 8.1 | 19.6 | 4.5 | 17.3 | 63.4 |

| NZ | 3.4 | 7.8 | 6.6 | 8.3 | 39.4 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, T.; Luan, R.; Lyu, H.; Cai, L.; Zhao, J.; Chen, M. Comparative Life Cycle Assessment of Heat-Treated Radiata Pine Lumber: Evaluating Two Heat Supply Scenarios in China. Forests 2025, 16, 607. https://doi.org/10.3390/f16040607

Ding T, Luan R, Lyu H, Cai L, Zhao J, Chen M. Comparative Life Cycle Assessment of Heat-Treated Radiata Pine Lumber: Evaluating Two Heat Supply Scenarios in China. Forests. 2025; 16(4):607. https://doi.org/10.3390/f16040607

Chicago/Turabian StyleDing, Tao, Ruotong Luan, He Lyu, Liping Cai, Jiaxuan Zhao, and Meiling Chen. 2025. "Comparative Life Cycle Assessment of Heat-Treated Radiata Pine Lumber: Evaluating Two Heat Supply Scenarios in China" Forests 16, no. 4: 607. https://doi.org/10.3390/f16040607

APA StyleDing, T., Luan, R., Lyu, H., Cai, L., Zhao, J., & Chen, M. (2025). Comparative Life Cycle Assessment of Heat-Treated Radiata Pine Lumber: Evaluating Two Heat Supply Scenarios in China. Forests, 16(4), 607. https://doi.org/10.3390/f16040607