Engineered Bamboo Building Materials: Types, Production, and Applications

Abstract

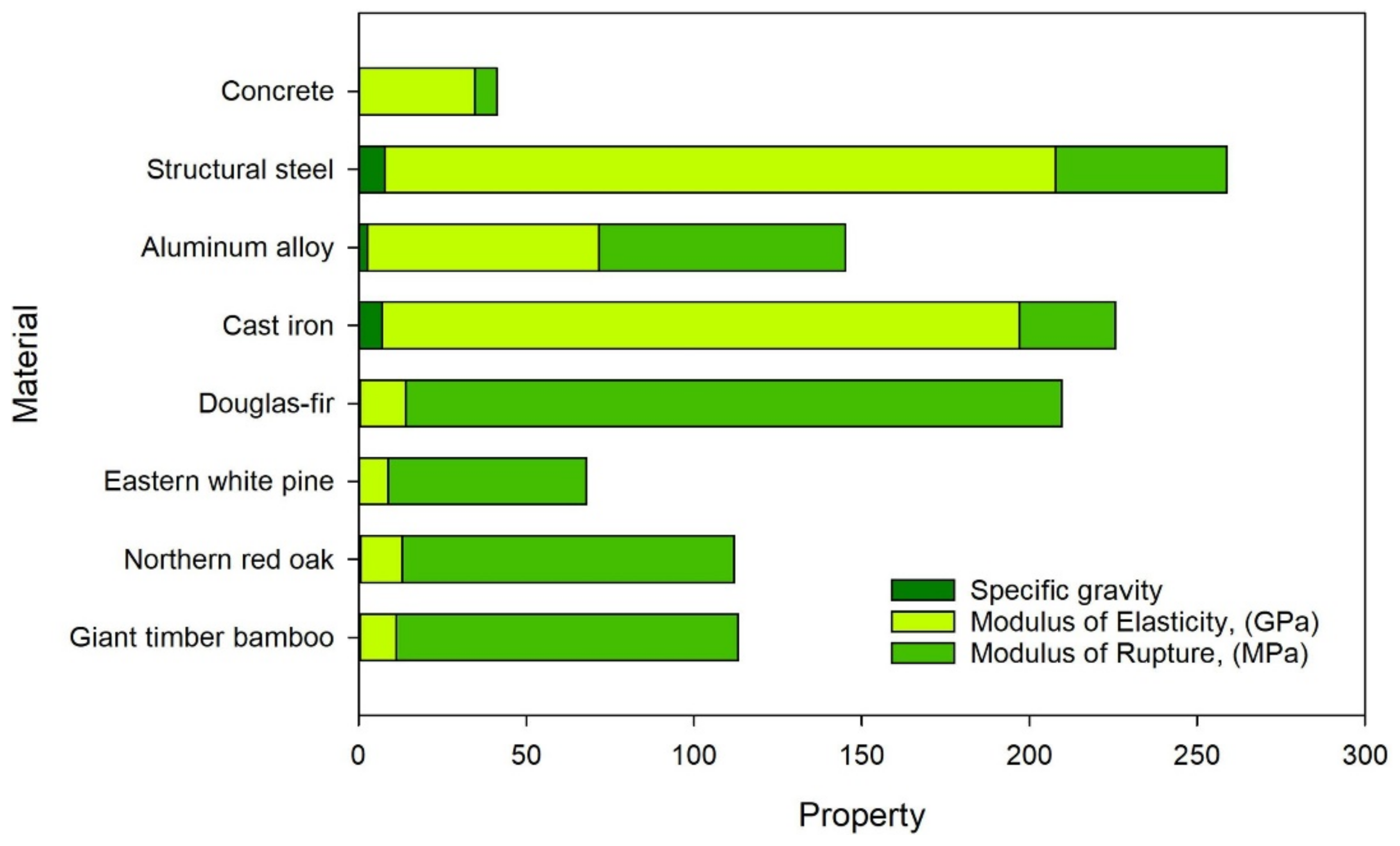

:1. Introduction

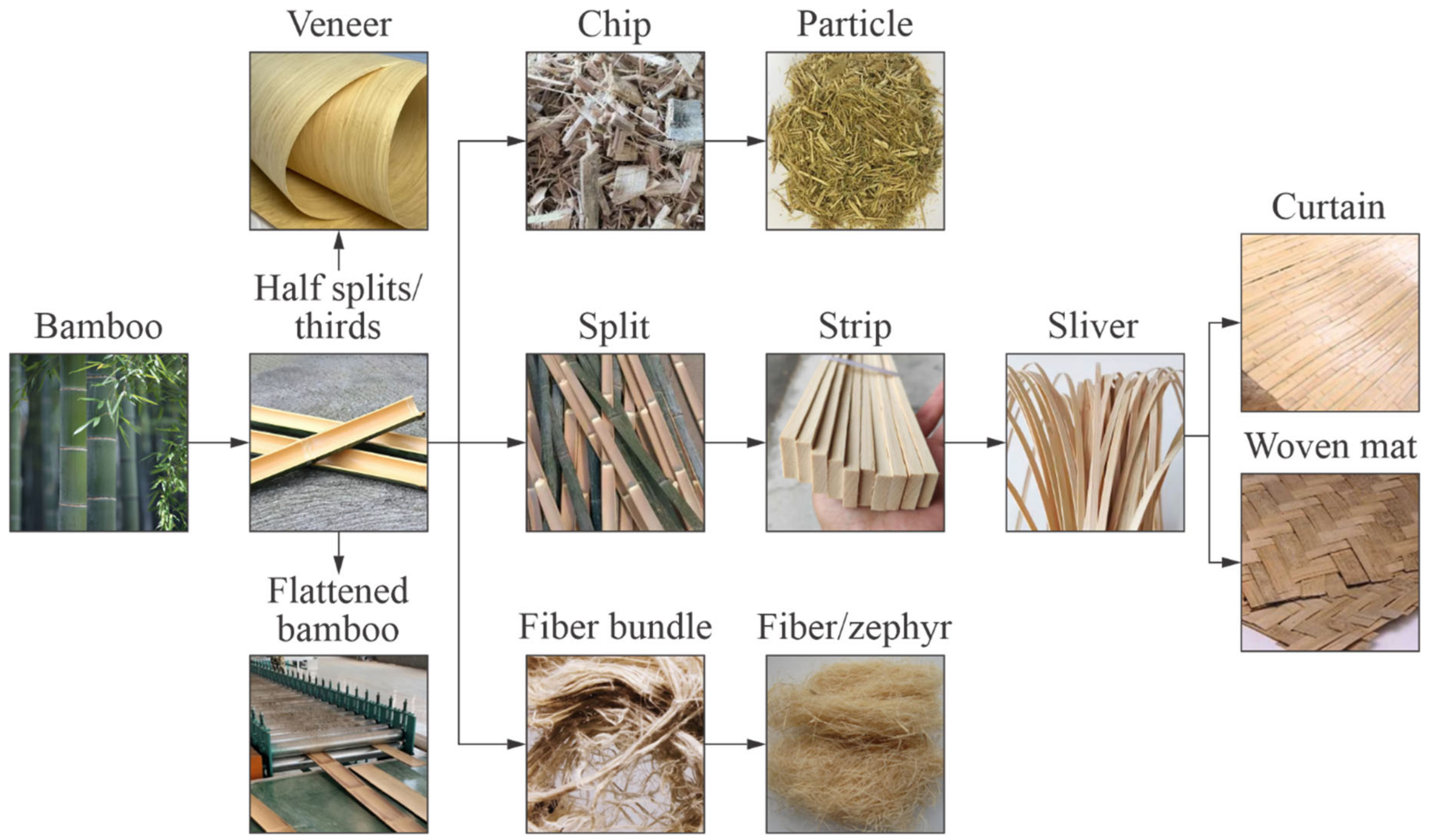

2. Selected Types of Engineered Bamboo Materials

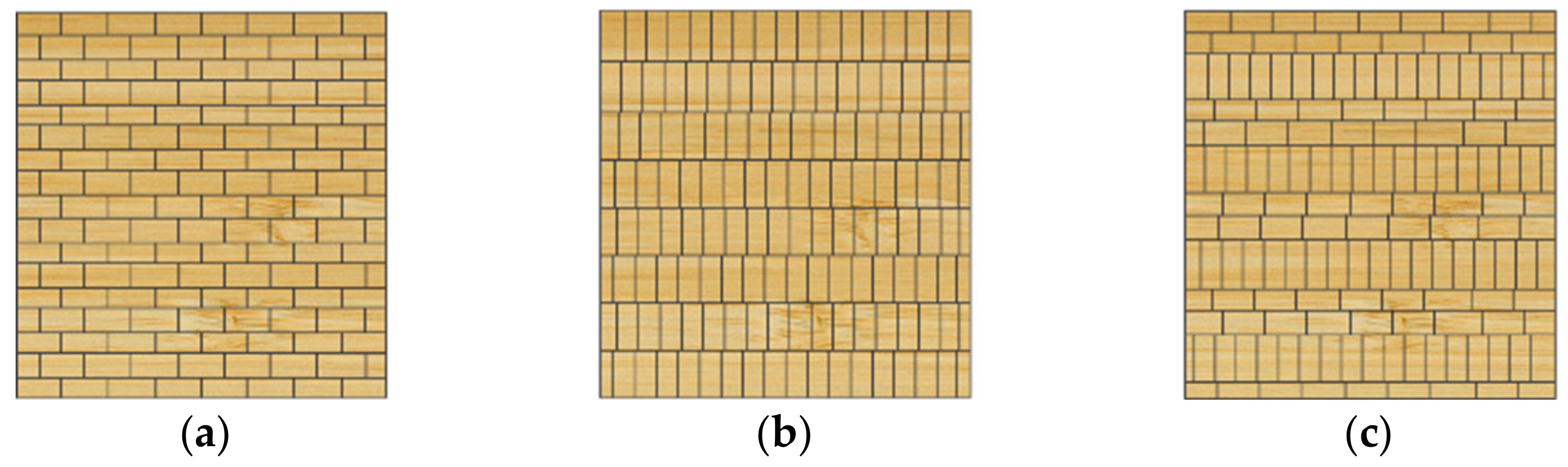

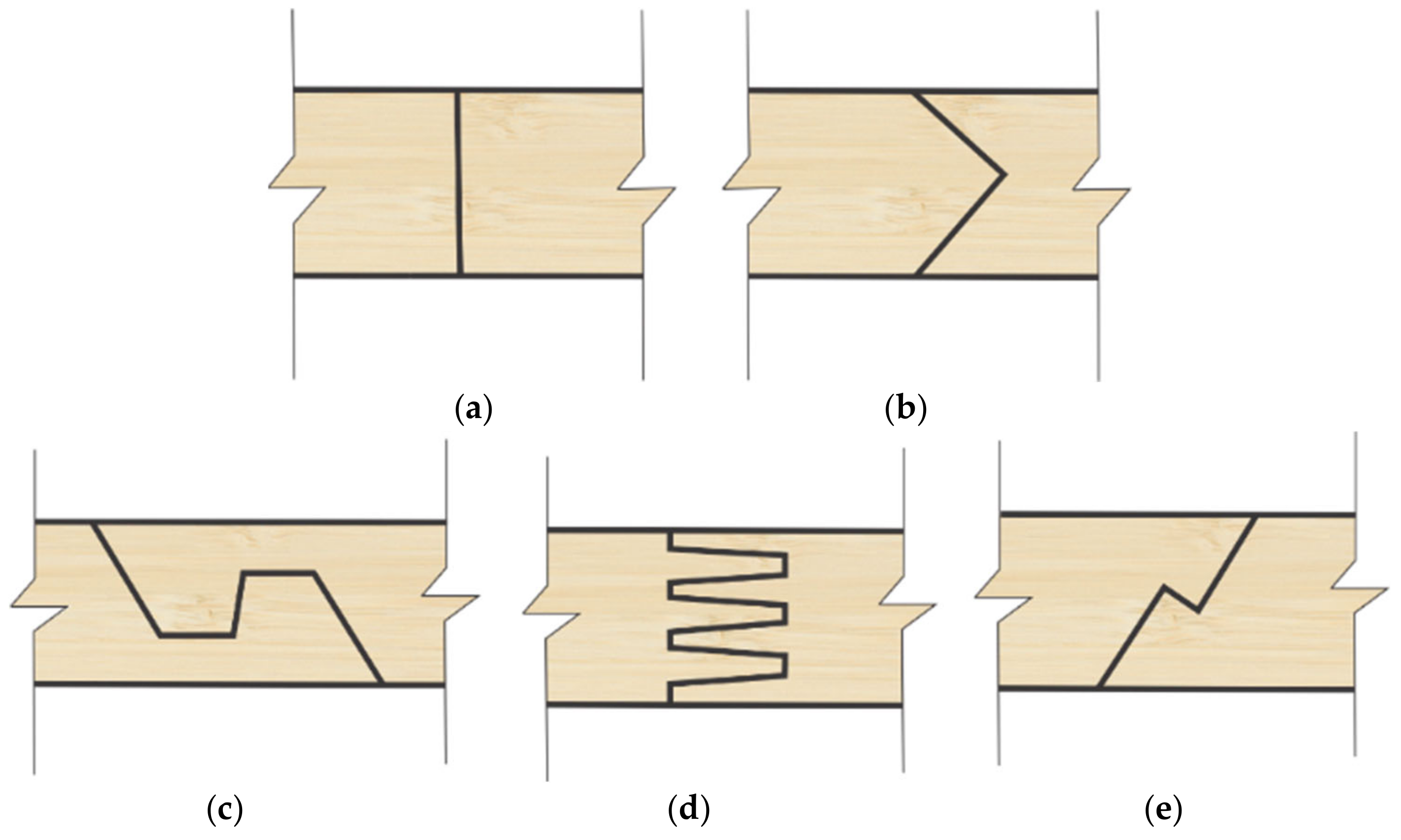

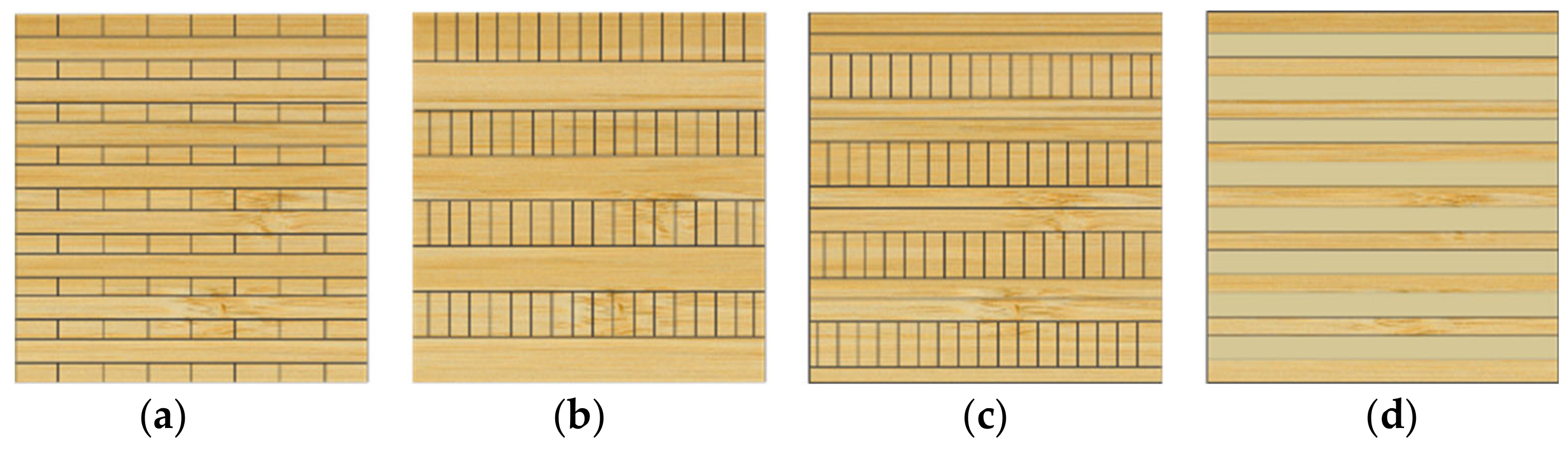

2.1. LBL

2.2. LBS

2.3. PSB

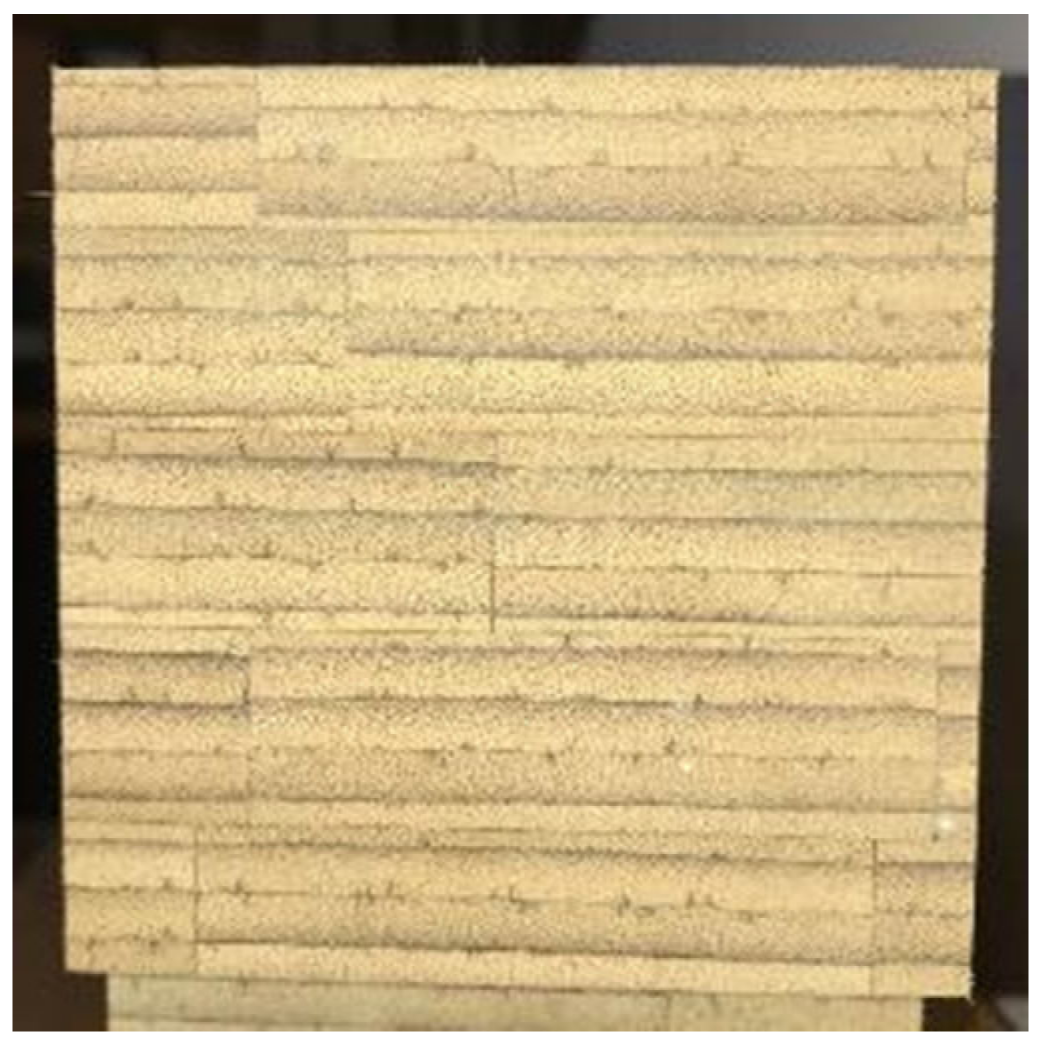

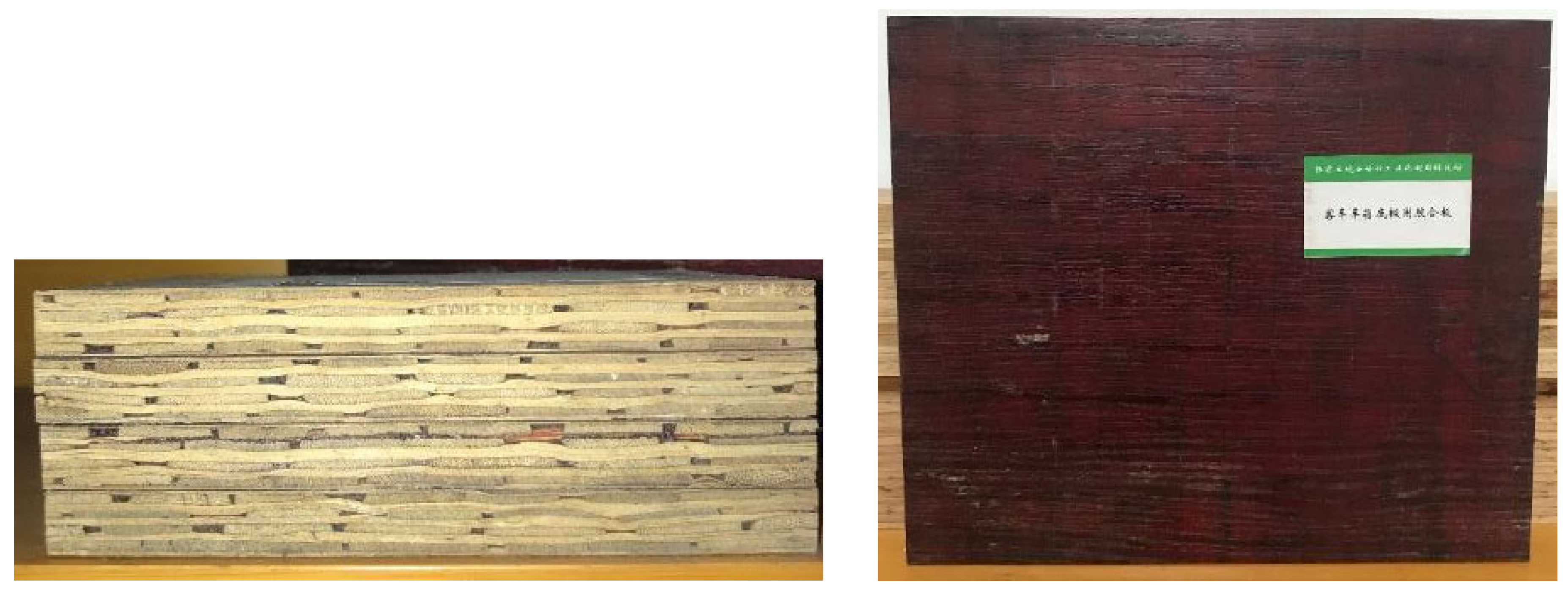

2.4. BMB

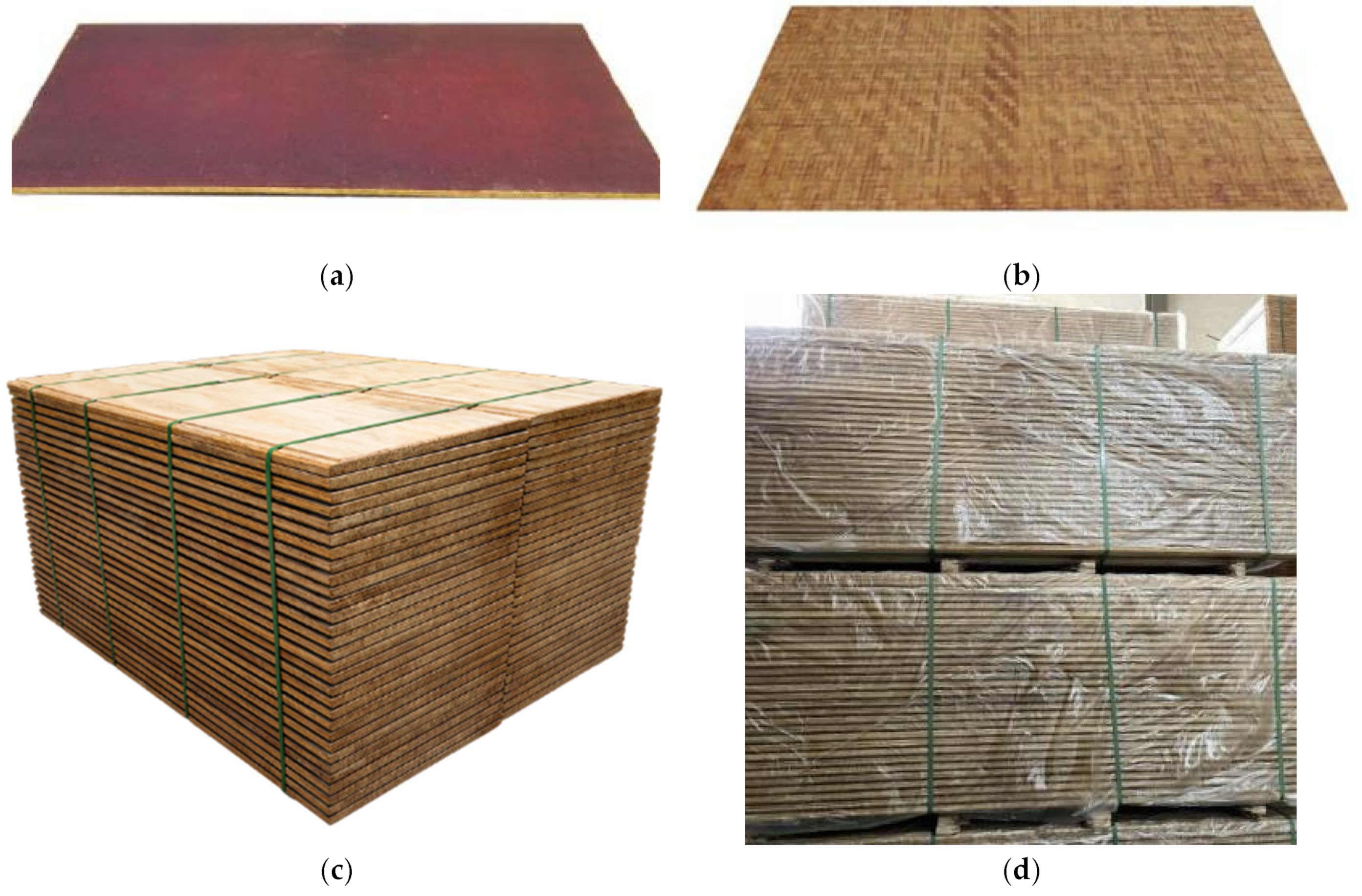

2.5. BP

3. Application

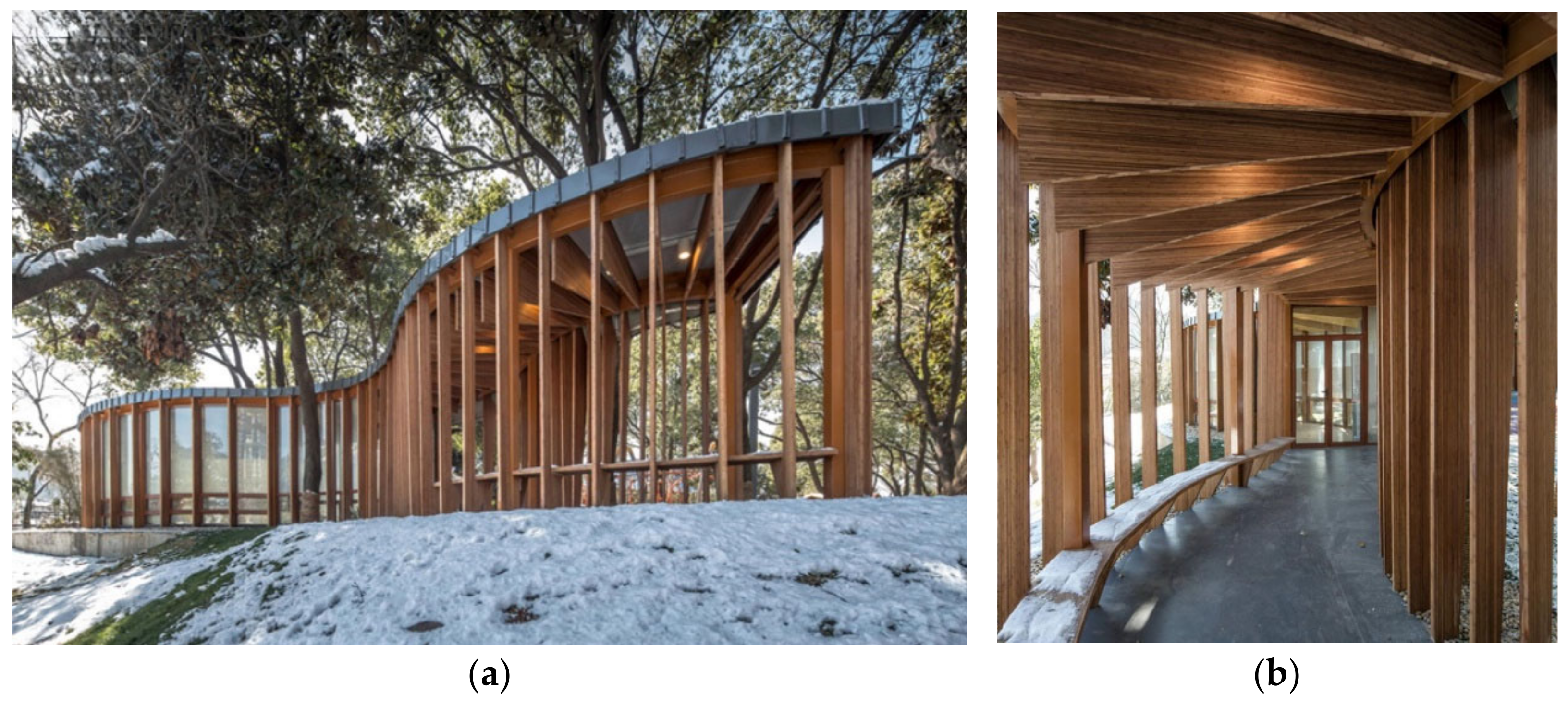

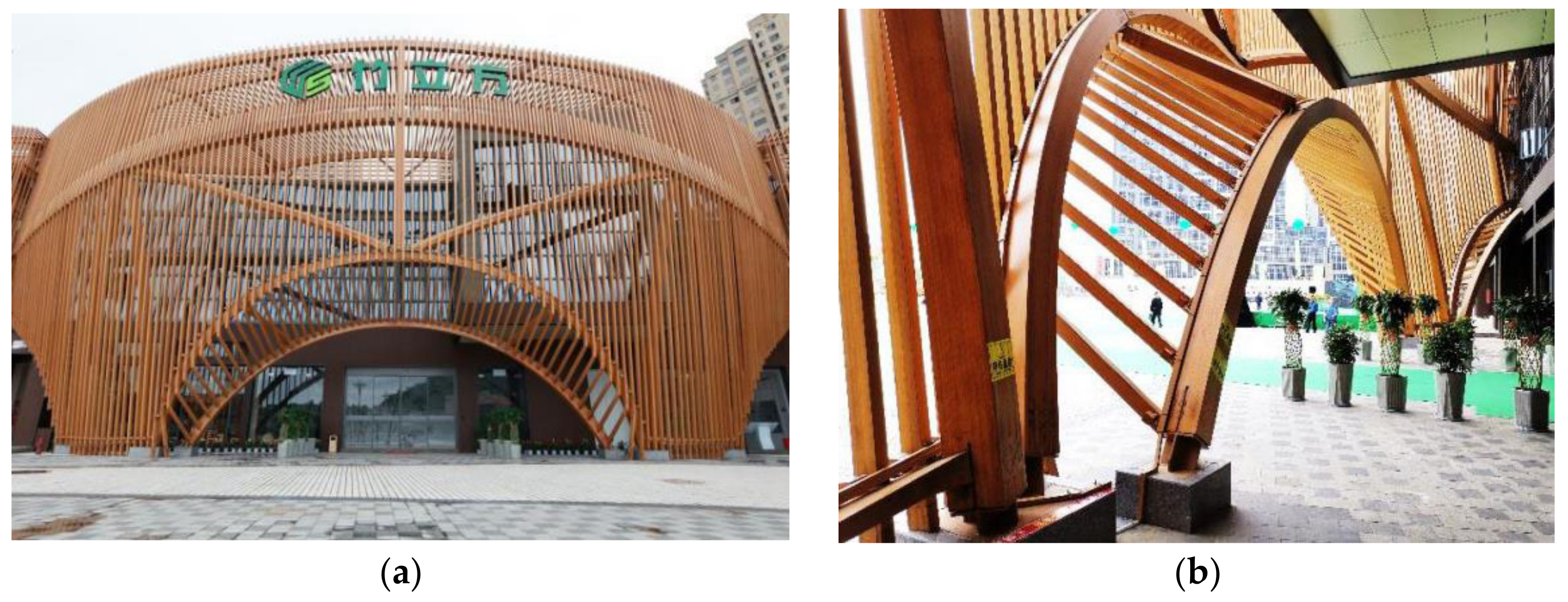

3.1. Application of LBL

3.2. Application of PSB

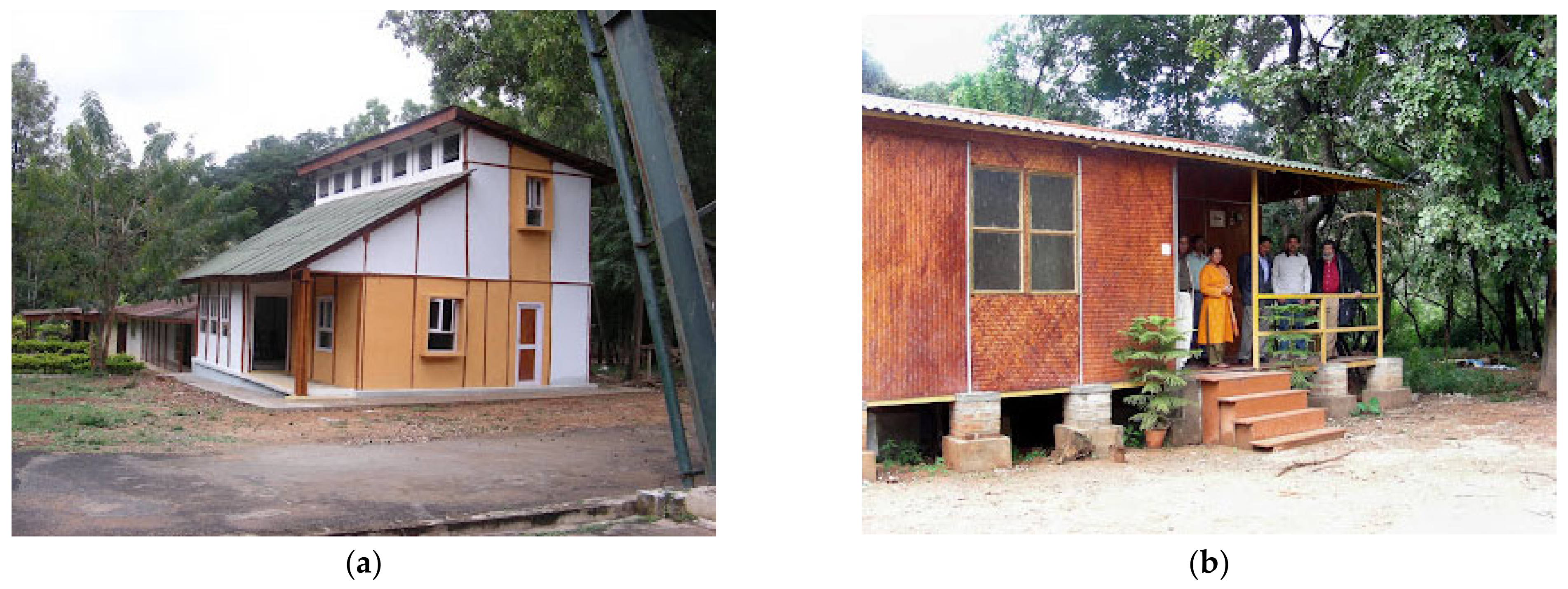

3.3. Application of BMBs and BP

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- COP29 Presidency Holds Round Table on Sustainable Built Environment in Azerbaijan. Available online: https://cop29.az/en/media-hub/news/cop29-presidency-holds-round-table-on-sustainable-built-environment-in-azerbaijan (accessed on 19 January 2025).

- COP29: Why Nature and Preservation? Available online: https://www.sgs.com/en-kz/news/2024/11/cop29-why-nature-and-preservation (accessed on 19 January 2025).

- COP29: Key Outcomes for Food, Forests, Land and Nature at the UN Climate Talks in Baku. Available online: https://www.carbonbrief.org/cop29-key-outcomes-for-food-forests-land-and-nature-at-the-un-climate-talks-in-baku/ (accessed on 19 January 2025).

- Röck, M.; Hollberg, A.; Habert, G.; Passer, A. LCA and BIM: Visualization of environmental potentials in building construction at early design stages. Build. Environ. 2018, 140, 153–161. [Google Scholar] [CrossRef]

- Kaan, H.; De Boer, B.J. Passive houses: Achievable concepts for low CO2 housing. Proceedings of 15th ISES Conference, Guelph, ON, Canada, 19–22 August 2019; pp. 2–5. [Google Scholar]

- Lin, B.; Liu, H. CO2 emissions of China’s commercial and residential buildings: Evidence and reduction policy. Build. Environ. 2015, 92, 418–431. [Google Scholar] [CrossRef]

- Ma, J.; Qian, Q.K.; Visscher, H.; Song, K. Reluctance to Adopt Energy Efficiency Renovation in Chinese Households—A Behavioural Perspective. In Proceedings of the Proceedings of the 40th IAEE International Conference, Singapore, 16–21 June 2017. [Google Scholar]

- D&R International, Ltd. 2011 Buildings Energy Data Book; United States Department of Energy: Washington, DC, USA, 2012; pp. 21–61.

- Hausfather, Z. Analysis: Fossil-Fuel Emissions in 2018 Increasing at Fastest Rate for Seven Years. Available online: https://www.carbonbrief.org/analysis-fossil-fuel-emissions-in-2018-increasing-at-fastest-rate-for-seven-years (accessed on 17 March 2025).

- Dauletbek, A.; Zhou, P. BIM-based LCA as a comprehensive method for the refurbishment of existing dwellings considering environmental compatibility, energy efficiency, and profitability: A case study in China. J. Build. Eng. 2022, 46, 103852. [Google Scholar] [CrossRef]

- Le Quéré, C.; Andrew, R.M.; Friedlingstein, P.; Sitch, S.; Hauck, J.; Pongratz, J.; Pickers, P.A.; Korsbakken, J.I.; Peters, G.P.; Canadell, J.G.; et al. Global Carbon Budget 2018. Earth System Science Data 2018, 10, 2141–2194. [Google Scholar] [CrossRef]

- United Nations. The Emissions Gap Report 2018; United Nations Environment Programme: Nairobi, Kenya, 2018; pp. 14–122. [Google Scholar]

- United Nations. Global Status Report 2018; The United Nations Environment Programme: Nairobi, Kenya, 2018; pp. 8–48. [Google Scholar]

- Soust-Verdaguer, B.; Llatas, C.; García-Martínez, A. Critical review of bim-based LCA method to buildings. Energy Build. 2017, 136, 110–120. [Google Scholar] [CrossRef]

- The World Business Council. Energy Efficiency in Buildings; The World Business Council for Sustainable Development: Geneva, Switzerland, 2009; pp. 3–72. [Google Scholar]

- Communique. From Baku to Belem: Forests for Climate, People and the Planet. Available online: https://www.un.org/esa/forests/wp-content/uploads/2024/12/Communique_Forest-Pavilion_UNFCCC-COP29.pdf (accessed on 19 January 2025).

- COP29: Climate Finance In The Built Environment. Available online: https://www.architecture2030.org/cop29-climate-finance-in-the-built-environment/ (accessed on 19 January 2025).

- The Role of COP29 in Low-Carbon Construction Practices. Available online: https://neuroject.com/cop29-in-low-carbon-construction/#The_Emphasis_on_Sustainable_Materials_at_COP29 (accessed on 19 January 2025).

- COP29 Highlights: Key Takeaways for Cities and the Built Environment. Available online: https://www.archdaily.com/1024140/cop29-highlights-key-takeaways-for-cities-and-the-built-environment (accessed on 19 January 2025).

- Wang, T.; Wang, Y.; Crocetti, R.; Wålinder, M. Influence of face grain angle, size, and moisture content on the edgewise bending strength and stiffness of birch plywood. Mater. Des. 2022, 223, 111227. [Google Scholar] [CrossRef]

- Mahdavi, M.; Clouston, P.L.; Arwade, S.R. Development of Laminated Bamboo Lumber: Review of Processing, Performance, and Economical Considerations. J. Mater. Civ. Eng. 2011, 23, 1036–1042. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, T.; Ringaby, J.; Crocetti, R.; Debertolis, M.; Wålinder, M. Testing and analysis of screw-connected moment joints consisting of glued-laminated timbers and birch plywood plates. Eng. Struct. 2023, 290, 116356. [Google Scholar] [CrossRef]

- Lee, A.W.C.; Chen, G.; Tainter, F.H. Comparative treatability of Moso bamboo and Southern pine with CCA preservative using a commercial schedule. Bioresour. Technol. 2001, 77, 87–88. [Google Scholar] [CrossRef]

- Fang, C.-H.; Jiang, Z.-H.; Sun, Z.-J.; Liu, H.-R.; Zhang, X.-B.; Zhang, R.; Fei, B.-H. An overview on bamboo culm flattening. Constr. Build. Mater. 2018, 171, 65–74. [Google Scholar] [CrossRef]

- Khoshbakht, N.; Clouston, P.L.; Arwade, S.R.; Schreyer, A.C. Computational Modeling of Laminated Veneer Bamboo Dowel Connections. J. Mater. Civ. Eng. 2018, 30, e1906308. [Google Scholar] [CrossRef]

- Li, Z.; Chen, C.; Mi, R.; Gan, W.; Dai, J.; Jiao, M.; Xie, H.; Yao, Y.; Xiao, S.; Hu, L. A Strong, Tough, and Scalable Structural Material from Fast-Growing Bamboo. Adv. Mater. 2020, 32, 1906308. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.R.; Chen, Z.F.; Huang, D.S.; Zhou, A.P. The ultimate load-carrying capacity and deformation of laminated bamboo hollow decks: Experimental investigation and inelastic analysis. Constr. Build. Mater. 2016, 117, 190–197. [Google Scholar] [CrossRef]

- Jin, X.B.; Jiang, Z.H.; Wen, X.W.; Zhang, R.; Qin, D.C. Flame Retardant Properties of Laminated Bamboo Lumber Treated with Monoammonium Phosphate (MAP) and Boric acid/Borax (SBX) Compounds. Bioresources 2017, 12, 5071–5085. [Google Scholar] [CrossRef]

- Yu, H.Q.; Jiang, Z.H.; Hse, C.Y.; Shupe, T.F. Selected Physical and Mechanical Properties of Moso Bamboo (Phyllostachys Pubescens). J. Trop. Sci. 2008, 20, 258–263. [Google Scholar]

- Chung, K.F.; Yu, W.K. Mechanical properties of structural bamboo for bamboo scaffoldings. Eng. Struct. 2002, 24, 429–442. [Google Scholar] [CrossRef]

- Lorenzo, R.; Godina, M.; Mimendi, L. Determination of the physical and mechanical properties of moso, guadua and oldhamii bamboo assisted by robotic fabrication. J. Wood Sci. 2020, 66, 20. [Google Scholar] [CrossRef]

- Dixon, P.G.; Gibson, L.J. The structure and mechanics of Moso bamboo material. J. R. Soc. Interface 2014, 11, 20140321. [Google Scholar] [CrossRef]

- Vilanova, A.; Fernández-Gómez, J.; Landsberger, G.A. Evaluation of the mechanical properties of self compacting concrete using current estimating models Estimating the modulus of elasticity, tensile strength, and modulus of rupture of self compacting concrete. Constr. Build. Mater. 2011, 25, 3417–3426. [Google Scholar] [CrossRef]

- Dauletbek, A.; Li, H.; Lorenzo, R. A review on mechanical behavior of laminated bamboo lumber connections. Compos. Struct. 2023, 313, 116898. [Google Scholar] [CrossRef]

- Guo, A. Structural analysis of a Guadua bamboo bridge in Colombia. Sustain. Struct. 2022, 2, 000020. [Google Scholar] [CrossRef]

- Guo, A. “Bamboo: A Very Sustainable Construction Material”—2021 International Online Seminar summary report. Sustain. Struct. 2022, 2, 000015. [Google Scholar] [CrossRef]

- Appiah-Kubi, E.; Awotwe-Mensah, M.; Mitchual, S. Assessment of physical and mechanical properties of juvenile and matured Bambusa vulgaris glue-laminated bamboo for structural applications in Ghana. Sustain. Struct. 2023, 3, 000026. [Google Scholar] [CrossRef]

- Dauletbek, A.; Xue, X.; Shen, X.; Li, H.; Feng, Z.; Lorenzo, R.; Liu, K.; Escamilla, E.Z.; Zheng, X.; Yao, L. Lightweight bamboo structures—Report on 2021 International Collaboration on Bamboo Construction. Sustain. Struct. 2023, 3, 000025. [Google Scholar] [CrossRef]

- Mimendi, L.; Lorenzo, R. An innovative digital workflow to design, build and manage bamboo structures. Sustain. Struct. 2022, 2, 000011. [Google Scholar] [CrossRef]

- Wei, Y.; Chen, S.; Tang, S.; Peng, D.; Zhao, K. Mechanical response of timber beams strengthened with variable amounts of CFRP and bamboo scrimber layers. J. Compos. Constr. 2022, 26, 04022038. [Google Scholar] [CrossRef]

- Deng, J.C.; Chen, F.M.; Li, H.D.; Wang, G.; Shi, S.Q. The effect of PF/PVAC weight ratio and ambient temperature on moisture absorption performance of bamboo-bundle laminated veneer lumber. Polym. Compos 2016, 37, 955–962. [Google Scholar] [CrossRef]

- Chen, S.; Wei, Y.; Wang, G.; Zhao, K.; Ding, M. Mechanical behavior of laminated bamboo-timber composite columns under axial compression. Arch. Civ. Mech. Eng. 2023, 23, 72. [Google Scholar] [CrossRef]

- Chen, G.; Yu, Y.F.; Li, X.; He, B. Mechanical behavior of laminated bamboo lumber for structural application: An experimental investigation. Eur. J. Wood Wood Prod. 2020, 78, 53–63. [Google Scholar] [CrossRef]

- Sharma, B.; Bauer, H.; Schickhofer, G.; Ramage, M.H. Mechanical characterisation of structural laminated bamboo. PI Civil Eng. Str. B 2017, 170, 250–264. [Google Scholar] [CrossRef]

- Yu, Y.; Huang, X.; Yu, W. A novel process to improve yield and mechanical performance of bamboo fiber reinforced composite via mechanical treatments. Compos. Part B Eng. 2014, 56, 48–53. [Google Scholar] [CrossRef]

- Chen, S.; Wei, Y.; Mingmin, D.; Zhao, K.; Zheng, K. Combinatorial design and flexural behavior of laminated bamboo-timber composite beams. Thin-Walled Struct. 2022, 181, 109993. [Google Scholar] [CrossRef]

- Li, Y.; Lou, Z. Progress of bamboo flatten technology research. J. For. Eng. 2021, 6, 14–23. [Google Scholar] [CrossRef]

- Dauletbek, A.; Li, H.; Lorenzo, R.; Corbi, I.; Corbi, O.; Ashraf, M. A Review of Basic Mechanical Behavior of Laminated Bamboo Lumber. J. Renew. Mater. 2022, 10, 273–300. [Google Scholar] [CrossRef]

- Dauletbek, A.; Li, H.; Xiong, Z.; Lorenzo, R. A review of mechanical behavior of structural laminated bamboo lumber. Sustain. Struct. 2021, 1, 000004. [Google Scholar] [CrossRef]

- Li, H.T.; Wu, G.; Xiong, Z.H.; Corbi, I.; Corbi, O.; Xiong, X.H.; Zhang, H.Z.; Qiu, Z.Y. Length and orientation direction effect on static bending properties of laminated Moso bamboo. Eur. J. Wood Wood Prod. 2019, 77, 547–557. [Google Scholar] [CrossRef]

- Li, H.T.; Deeks, A.J.; Zhang, Q.S.; Wu, G. Flexural Performance of Laminated Bamboo Lumber Beams. Bioresources 2016, 11, 929–943. [Google Scholar] [CrossRef]

- Jorissen, A.J.M.; Voermans, J.; Jansen, M.H. Glued-laminated bamboo: Node and joint failure in bamboo laminations in tension. IJBAR 2007, 6, 137–144. [Google Scholar]

- Ni, L.; Zhang, X.B.; Liu, H.R.; Sun, Z.J.; Song, G.N.; Yang, L.M.; Jiang, Z.H. Manufacture and Mechanical Properties of Glued Bamboo Laminates. Bioresources 2016, 11, 4459–4471. [Google Scholar] [CrossRef]

- Sharma, B.; Gatoo, A.; Ramage, M.H. Effect of processing methods on the mechanical properties of engineered bamboo. Constr. Build. Mater. 2015, 83, 95–101. [Google Scholar] [CrossRef]

- Zhou, A.; Bian, Y. Experimental Study on the Flexural Performance of Parallel Strand Bamboo Beams. Sci. World J. 2014, 2014, 181627. [Google Scholar] [CrossRef] [PubMed]

- Huang, D.S.; Bian, Y.L.; Zhou, A.P.; Sheng, B.L. Experimental study on stress-strain relationships and failure mechanisms of parallel strand bamboo made from phyllostachys. Constr. Build. Mater. 2015, 77, 130–138. [Google Scholar] [CrossRef]

- Dongsheng, H.; Aiping, Z.; Yuling, B. Experimental and analytical study on the nonlinear bending of parallel strand bamboo beams. Constr. Build. Mater. 2013, 44, 585–592. [Google Scholar] [CrossRef]

- Ross, R.J. Forest Products Laboratory USDA Forest Service. Wood Handbook, Wood as an Engineering Material; Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010; p. 508. [Google Scholar]

- Zhang, X.L.; Que, Y.L.; Wang, X.M.; Li, Z.R.; Zhang, L.L.; Que, Z.L.; Komatsu, K. Experimental Behavior of Laminated Veneer Lumber with Round Holes, with and without Reinforcement. Bioresources 2018, 13, 8899–8910. [Google Scholar] [CrossRef]

- Huang, Y.X.; Ji, Y.H.; Yu, W.J. Development of bamboo scrimber: A literature review. J. Wood Sci. 2019, 65. [Google Scholar] [CrossRef]

- Marx, C.; Moody, R. Bending strength of shallow glued-laminated beams of a uniform grade. For. Prod. Lab. 1981, 380, 19. [Google Scholar] [CrossRef]

- Sousa, H.S.; Branco, J.M.; Lourenco, P.B. Glulam Mechanical Characterization. Mater. Sci. Forum 2013, 730–732, 994–999. [Google Scholar] [CrossRef]

- Hugot, F.; Cazaurang, G. Mechanical properties of an extruded wood plastic composite. Mec. Ind. 2009, 10, 519–524. [Google Scholar] [CrossRef]

- Verma, C.S.; Chariar, V.M. Development of layered laminate bamboo composite and their mechanical properties. Compos. Part B Eng. 2012, 43, 1063–1069. [Google Scholar] [CrossRef]

- Wei, X.; Chen, F.; Wang, G. Flexibility characterization of bamboo slivers through winding-based bending stiffenss method. J. For. Eng. 2020, 5, 48–53. [Google Scholar] [CrossRef]

- Kelkar, B.U.; Shukla, S.R.; Nagraik, P.; Paul, B.N. Structural bamboo composites: A review of processing, factors affecting properties and recent advances. Adv. Bamboo Sci. 2023, 3, 100026. [Google Scholar] [CrossRef]

- Zhu, J.; Tan, Y.; Chen, K.; Peng, H.; Li, Z.; Jiang, J.; Lyu, J.; Zhan, T. Evaluation of transverse shrinking and swelling of bamboo using digital image correlation technique. Ind. Crops Prod. 2024, 211, 118274. [Google Scholar] [CrossRef]

- Xie, J.; Huang, X.; Qi, J.; Hse, C.-Y.; Shupe, T. Effect of Anatomical Characteristics and Chemical Components on Microwave-assisted Liquefaction of Bamboo Wastes. Bioresources 2013, 9, 231–240. [Google Scholar] [CrossRef]

- Zhu, J.; Fan, Y.; Chen, K.; Tan, Y.; Peng, H.; Li, Z.; Jiang, J.; Lyu, J.; Zhan, T. Shrinking and swelling of moso bamboo with different gradient variations: Effects of culm height and presence of pith. Ind. Crops Prod. 2024, 222, 120052. [Google Scholar] [CrossRef]

- Xue, X.; Li, H.; Lorenzo, R. A Review of Basic Mechanical Properties of Bamboo Scrimber Based on Small-Scale Specimens. J. Renew. Mater. 2024, 12, 869–894. [Google Scholar] [CrossRef]

- Xu, P.; Tam, V.W.Y.; Li, H.; Zhu, J.; Xu, X. A critical review of bamboo construction materials for sustainability. Renew. Sust. Energ. Rev. 2025, 210, 115230. [Google Scholar] [CrossRef]

- Bamigboye, G.; Davis, I.; Nwankwo, C.; Michaels, T.; Adeyemi, G.; Ozuor, O. Innovation in Construction Materials—A Review. IOP Conf. Ser. Mater. Sci. Eng. 2019, 640, 012070. [Google Scholar] [CrossRef]

- de Oliveira Andrade, J.J.; Possan, E.; Squiavon, J.Z.; Ortolan, T.L.P. Evaluation of mechanical properties and carbonation of mortars produced with construction and demolition waste. Constr. Build. Mater. 2018, 161, 70–83. [Google Scholar] [CrossRef]

- Soliman, A.; Hafeez, G.; Erkmen, E.; Ganesan, R.; Ouf, M.; Hammad, A.; Eicker, U.; Moselhi, O. Innovative construction material technologies for sustainable and resilient civil infrastructure. Mater. Today 2022, 60, 365–372. [Google Scholar] [CrossRef]

- Reyes, M.; Pérez, G.; Coma, J. Sustainability Factor for the Cost–Benefit Analysis of Building-Integrated Greenery Systems. Sustainability 2024, 16, 157. [Google Scholar] [CrossRef]

- Ekins, P.; Zenghelis, D. The costs and benefits of environmental sustainability. Sustain. Sci. 2021, 16, 949–965. [Google Scholar] [CrossRef] [PubMed]

- Bahishti, A. The Importance of Review Articles & its Prospects in Scholarly Literature. Extensive Rev. 2021, 1, 1–6. [Google Scholar] [CrossRef]

- Liu, X.; Smith, G.; Jiang, Z.; Bock, M.; Boeck, F.; Frith, O.; Gatóo, A.; Liu, K.; Mulligan, H.; Semple, K.; et al. Nomenclature for Engineered Bamboo. Bioresources 2016, 11, 1141–1161. [Google Scholar] [CrossRef]

- GB/T 36394-2018; Terminology of bamboo products. State Forestry and Grassland Administration: Beijing, China, 2018.

- Ramage, M.; Sharma, B.; Bock, M.; Gatóo, A.; Mulligan, H. Engineered bamboo: State of the art. Proc. Inst. Civ. Eng. Constr. Mater. 2015, 168, 57–67. [Google Scholar] [CrossRef]

- Harries, K.; Sharma, B.; Richard, M. Structural Use of Full Culm Bamboo: The Path to Standardization. Int. J. Archit. Eng. Constr. 2012, 1, 66–75. [Google Scholar] [CrossRef]

- Gatóo, A.; Sharma, B.; Bock, M.; Mulligan, H.; Ramage, M. Sustainable structures: Bamboo standards and building codes. Proc. Inst. Civ. Eng. Eng. Sustain. 2014, 167, 189–196. [Google Scholar] [CrossRef]

- Hong, C.; Li, H.; Xiong, Z.; Lorenzo, R.; Corbi, I.; Corbi, O.; Wei, D.; Yuan, C.; Yang, D.; Zhang, H. Review of connections for engineered bamboo structures. J. Build. Eng. 2020, 30, 101324. [Google Scholar] [CrossRef]

- Kumar, D.; Mandal, A. Review on manufacturing and fundamental aspects of laminated bamboo products for structural applications. Constr. Build. Mater. 2022, 348, 128691. [Google Scholar] [CrossRef]

- Li, L.; Huang, C.; Guo, N. Flexural behaviour of bamboo scrimber beams with different composite and reinforced technology: A literature review. Case Stud. Constr. Mater. 2024, 20. [Google Scholar] [CrossRef]

- Lou, Z.; Wang, Q.; Sun, W.; Zhao, Y.; Wang, X.; Liu, X.; Li, Y. Bamboo flattening technique: A literature and patent review. Eur. J. Wood Wood Prod. 2021, 79, 1035–1048. [Google Scholar] [CrossRef]

- Khajouei-Nezhad, M.; Semple, K.; Nasir, V.; Hu, Y.a.; Marggraf, G.; Hauptman, J.; Dai, C. Advances in engineered bamboo processing: Material conversion and structure. Adv. Bamboo Sci. 2023, 5, 100045. [Google Scholar] [CrossRef]

- Li, H.Z.X.; Guo, N.; Sheng, Y.; Deng, B. Modern Bamboo Wood Structures; China Construction Industry Press: Beijing, China, 2020. [Google Scholar]

- Huang, Z. Application of Bamboo in Building Envelope; Springer International Publishing: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Bala, A.; Gupta, S. Engineered bamboo and bamboo-reinforced concrete elements as sustainable building materials: A review. Constr. Build. Mater. 2023, 394, 132116. [Google Scholar] [CrossRef]

- Sewar, Y.; Amran, M.; Avudaiappan, S.; Gamil, Y.; Rashid, R.S.M. Bonding strength performance of bamboo-based composite materials: An in-depth insight for sustainable construction applications. Heliyon 2024, 10, e32155. [Google Scholar] [CrossRef] [PubMed]

- Lou, Z.; Zheng, Z.; Yan, N.; Jiang, X.; Zhang, X.; Chen, S.; Xu, R.; Liu, C.; Xu, L. Modification and Application of Bamboo-Based Materials: A Review-Part II: Application of Bamboo-Based Materials. Forests 2023, 14, 2266. [Google Scholar] [CrossRef]

- Sun, X.; He, M.; Li, Z. Novel engineered wood and bamboo composites for structural applications: State-of-art of manufacturing technology and mechanical performance evaluation. Constr. Build. Mater. 2020, 249, 2010–2012. [Google Scholar] [CrossRef]

- Li, H.T.; Chen, G.; Zhang, Q.S.; Ashraf, M.; Xu, B.; Li, Y.J. Mechanical properties of laminated bamboo lumber column under radial eccentric compression. Constr. Build. Mater. 2016, 121, 644–652. [Google Scholar] [CrossRef]

- Luna, P.; Takeuchi, C.; Alvarado, C.; Moreno, I. Glued Laminated Guadua angustifolia Bamboo Columns. Acta. Hortic. 2013, 1003, 125–129. [Google Scholar] [CrossRef]

- Echeverry, J.S.; Correal, J.F. Cyclic behavior of Laminated Guadua Mat sheathing-to-framing connections. Constr. Build. Mater. 2015, 98, 69–79. [Google Scholar] [CrossRef]

- Li, Z.; Xiao, Y.; Wang, R.; Monti, G. Studies of Nail Connectors Used in Wood Frame Shear Walls with Ply-Bamboo Sheathing Panels. J. Mater. Civ. Eng. 2014, 27, 04014216. [Google Scholar] [CrossRef]

- Luna, P.; Takeuchi, C. Experimental Analysis of Frames Made with Glued Laminated Pressed Bamboo Guadua. Key Eng. Mater. 2012, 517, 184–188. [Google Scholar] [CrossRef]

- Ban, Y.; Zhi, W.; Fei, M.; Liu, W.; Yu, D.; Fu, T.; Qiu, R. Preparation and Performance of Cement Mortar Reinforced by Modified Bamboo Fibers. Polymers 2020, 12, 2650. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Zhang, Y.; Yang, X.; Ji, H.; Zhong, T.; Wang, G. A comparative study of the microstructure and water permeability between flattened bamboo and bamboo culm. J. Wood Sci. 2019, 65, 64. [Google Scholar] [CrossRef]

- Li, X.; Liu, R.; Long, L.; Liu, B.; Xu, J. Tensile behavior and water absorption of innovative composites from natural cork granules and bamboo particles. Compos. Struct. 2021, 258, 113376. [Google Scholar] [CrossRef]

- Xiao, Y.; Yang, R.Z.; Shan, B. Production, environmental impact and mechanical properties of glubam. Constr. Build. Mater. 2013, 44, 765–773. [Google Scholar] [CrossRef]

- Shan, B.; Wang, G.; Lei, P.; Li, T.; Xiao, Y.; Qin, S.; Chen, J. Experimental research on formaldehyde emission characteristics from glubam by climate chamber test. Sustain. Struct. 2023, 3, 000027. [Google Scholar] [CrossRef]

- Xia, Y.; Dong, H.; Semple, K.; Huang, J.; Zhang, W.; Dai, C. Drying and heat treatment of bamboo: Cell collapse and restoration. Constr. Build. Mater. 2025, 466, 140314. [Google Scholar] [CrossRef]

- Xing, W.; Hao, J.; Sikora Karol, S. Shear Performance of Adhesive Bonding of Cross-Laminated Bamboo. J. Mater. Civ. Eng. 2019, 31, 04019201. [Google Scholar] [CrossRef]

- Teixeira, D.E.; Bastos, R.P.; Almeida, S.A.D. Characterization of glued laminated panels produced with strips of bamboo (guadua magna) native from the brazilian cerrado. Cerne 2015, 21, 595–600. [Google Scholar] [CrossRef]

- Sinha, A.; Way, D.; Mlasko, S. Structural Performance of Glued Laminated Bamboo Beams. J. Struct. Eng. 2014, 140, 04013021. [Google Scholar] [CrossRef]

- Nugroho, N.; Ando, N. Development of structural composite products made from bamboo II: Fundamental properties of laminated bamboo lumber. J. Wood Sci. 2001, 47, 237–242. [Google Scholar] [CrossRef]

- Xiao, Y.; Shan, B.; Yang, R.Z.; Li, Z.; Chen, J. Glue Laminated Bamboo (GluBam) for Structural Applications. In Materials and Joints in Timber Structures; RILEM Bookseries Volume 9; Springer: Berlin/Heidelberg, Germany, 2014; pp. 589–601. [Google Scholar] [CrossRef]

- Yuan, T.; Zhang, T.; Huang, Y.; Wu, Y.; Wang, X.; Li, Y. Study on Bamboo Longitudinal Flattening Technology. Polymers 2022, 14, 816. [Google Scholar] [CrossRef] [PubMed]

- Lou, Z.; Yuan, T.; Wang, Q.; Wu, X.; Hu, S.; Hao, X.; Liu, X.; Li, Y. Fabrication of Crack-Free Flattened Bamboo and Its Macro-/Micro-Morphological and Mechanical Properties. J. Renew. Mater. 2021, 9, 959–977. [Google Scholar] [CrossRef]

- Li, X.; Ashraf, M.; Li, H.; Zheng, X.; Ameri, A.A.H.; Al-Deen, S. Behaviour of Parallel Bamboo Strand Lumber under compression loading—An experimental study. MATEC Web Conf. 2019, 275, 01002. [Google Scholar] [CrossRef]

- Gong, Y.; Zhang, C.; Zhao, R.; Xing, X.; Ren, H. Experimental study on tensile and compressive strength of bamboo scrimber. Bioresources 2016, 11, 7334–7344. [Google Scholar] [CrossRef]

- Sylvayanti, S.P.; Nugroho, N.; Bahtiar, E.T. Bamboo Scrimber’s Physical and Mechanical Properties in Comparison to Four Structural Timber Species. Forests 2023, 14, 146. [Google Scholar] [CrossRef]

- Zeidler, A.; Borůvka, V.; Černý, J.; Baláš, M. Douglas-fir outperforms most commercial European softwoods. Ind. Crops Prod. 2022, 181, 114828. [Google Scholar] [CrossRef]

- Huang, Y.; Qi, Y.; Zhang, Y.; Yu, W. Progress of Bamboo Recombination Technology in China. Adv. Polym. Tech. 2019, 2019, 2723191. [Google Scholar] [CrossRef]

- Adier, M.F.V.; Sevilla, M.E.P.; Valerio, D.N.R.; Ongpeng, J.M.C.; Sadowski, T. Bamboo as Sustainable Building Materials: A Systematic Review of Properties, Treatment Methods, and Standards. Buildings 2023, 13, 2449. [Google Scholar] [CrossRef]

- Hu, Y.; Xiong, L.; Li, Y.; Semple, K.; Nasir, V.; Pineda, H.; He, M.; Dai, C. Manufacturing and Characterization of Wide-Bundle Bamboo Scrimber: A Comparison with Other Engineered Bamboo Composites. Materials 2022, 15, 7518. [Google Scholar] [CrossRef]

- Shu, B.; Xiao, Z.; Hong, L.; Zhang, S.; Li, C.; Fu, N.; Lu, X. Review on the Application of Bamboo-Based Materials in Construction Engineering. J. Renew. Mater. 2020, 8, 1215–1242. [Google Scholar] [CrossRef]

- Gonzalez Beltran, G.E. Plybamboo Wall-Panels for Housing: Structural Design. Ph.D. Thesis, Technische Universiteit Eindhoven, Eindhoven, The Netherlands, 2003. [Google Scholar] [CrossRef]

- Gauss, C.; De Araujo, V.; Gava, M.; Barbosa, J.; Jr, H. Bamboo Particleboards: Recent Developments. Pesqui. Agropecu. Trop. 2019, 49, e55081. [Google Scholar] [CrossRef]

- Barbosa, J.C.; Michelon, A.L.S.; De Araujo, V.A.; Gava, M.; Morales, E.A.M.; Garcia, J.N.; Lahr, F.A.R.; Christoforo, A.L. Medium Density Particleboard Reinforced with Bamboo Laminas. Bioresources 2015, 10, 330–335. [Google Scholar] [CrossRef]

- Cheng, G.; Li, H.; Li, H.; Ashraf, M. Compression resistance of short LBL columns with local damage after retrofitting using basalt fiber reinforced polymer. J. Build. Eng. 2022, 48, 103941. [Google Scholar] [CrossRef]

- Guo, A. Structural design and construction of an office building with laminated bamboo lumber. Sustain. Struct. 2021, 1, 000010. [Google Scholar] [CrossRef]

- Xue, X.; Zhou, W.; Sayed, U.; Feng, Z.; Li, Y.; Huang, Z.; Ashraf, M.; Lorenzo, R. Design and construction of “Bamboo Cubic” facade with laminated bamboo lumber. Sustain. Struct. 2023, 3, 000030. [Google Scholar] [CrossRef]

- Feng, Z.; Shen, X.; Wang, Y.; Xue, X.; Lorenzo, R.; Ashraf, M.; Xiong, Z.; Zhou, C.; Chen, N.; Zhang, J.; et al. Engineered bamboo bridge structure—Report on 3rd International Collaboration on Bamboo Construction. Sustain. Struct. 2024, 4, 000062. [Google Scholar] [CrossRef]

- Kaisen Banye Co., LTD. Product List: Plybamboo Details. Available online: http://www.zjksby.com/produce.html?bd_vid=10370092083323033007. (accessed on 31 December 2024).

- Bamboo Mat Boards from IPIRTI: A Material Waiting for Innovation. Available online: https://design-for-india.blogspot.com/2007/12/bamboo-mat-boards-from-ipirti-material.html (accessed on 21 January 2025).

- Zhang, B.H.; Dong, L.; Zheng, W.; Wang, Z.Q.; Wang, J.; Ling, Z.B.; Shi, B.K. The effect of combined use of plybamboo sheathings and self-tapping screws in enhancing wood-frame shear wall performance. Wood Mater. Sci. Eng. 2024, 20, 394–403. [Google Scholar] [CrossRef]

| Property | LBL [43,50,51,52,53,54] | PSB [55,56,57] | LVL [43,58,59,60] | Glulam [59,61,62] | WPC [63] | Douglas Fir [58] | Teak [58,64] |

|---|---|---|---|---|---|---|---|

| Species type | Phyllostachys pubescens, Dendrocalamus strictus | Phyllostachys pubescens | Douglas-fir | Douglas-fir | Pine | - | - |

| Bending strength parallel to grain (MPa) | 63.87–128.4 | 89.32 ± 4.92 | 54.2–71.7 | 48.74 | 26.1 | 85 | 80 |

| MOE in bending (MPa) | 8320–10,912 | 12,656 ± 763.94 | 15,400–19,300 | 15,370 | 4100 | 13,400 | 9400 |

| Tensile strength parallel to grain (MPa) | 90–124 | 118.40–138 | 88.5 | 16.5–26 | 11.6 | 107.6 | 95–155 |

| MOE in tension parallel to grain (MPa) | 10,700 | 10,296–13,680 | 13,790 | 9400–11,900 | 3000 | 11,600–14,800 | - |

| Compressive strength parallel to grain (MPa) | 29.55–72.60 | 61.76–65.53 | 36 | 24–31 | 28.1 | 49.9 | 41.1 |

| MOE in compression parallel to grain (MPa) | 8396–11,022 | 11,890–12,630 | - | 8600 | 3700 | - | - |

| Shear strength parallel to grain (MPa) | 7.15–17.5 | 23.44 | 7.34 | 2.7–4.3 | 8.1 | 7.8 | 8.9 |

| Material | Species | Density (kg/m3) | Sample Size (mm) | Compression (MPa) | MOE (GPa) |

|---|---|---|---|---|---|

| PSB [57,112,113,114] | Phyllostachys pubescens, Neosincalamus affinis, Gigantachloa | 980–1250 | 105 × 105 × 315 20 × 20 × 30 50 × 50 × 150 | 61.8–104.8 | 5.3–12.63 |

| LBL [43,54] | Phyllostachys pubescens | 644–686 | 50 × 50 × 200 20 × 20 × 60 | 55–72.6 | 8.4–11 |

| LVL [85] | Douglas fir | 520 | 50 × 50 × 200 | 57 | - |

| Agathis [85] | Agathis | - | 2.5 × 2.5 × 10 | 24.75 | - |

| Douglas fir [58,115] | - | 533–561 | - | 49.9 | - |

| Scrimber [85] | Poplar | 885 | 20 × 20 × 80 | 101 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hosseini, M.; Gaff, M.; Wei, Y.; Tu, C. Engineered Bamboo Building Materials: Types, Production, and Applications. Forests 2025, 16, 662. https://doi.org/10.3390/f16040662

Hosseini M, Gaff M, Wei Y, Tu C. Engineered Bamboo Building Materials: Types, Production, and Applications. Forests. 2025; 16(4):662. https://doi.org/10.3390/f16040662

Chicago/Turabian StyleHosseini, Mahdi, Milan Gaff, Yang Wei, and Chaoyu Tu. 2025. "Engineered Bamboo Building Materials: Types, Production, and Applications" Forests 16, no. 4: 662. https://doi.org/10.3390/f16040662

APA StyleHosseini, M., Gaff, M., Wei, Y., & Tu, C. (2025). Engineered Bamboo Building Materials: Types, Production, and Applications. Forests, 16(4), 662. https://doi.org/10.3390/f16040662