Research on Regenerative Braking of Pure Electric Mining Dump Truck

Abstract

:1. Introduction

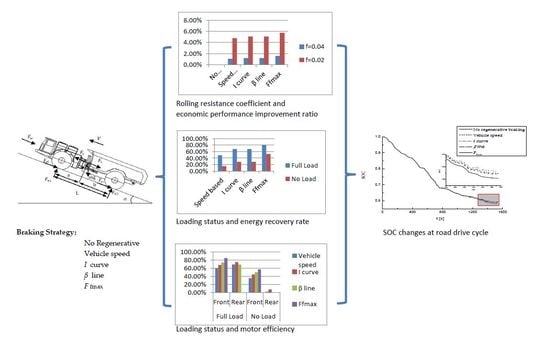

2. Principle Analysis of Regenerative Braking Control System

3. System Model and Control Strategy

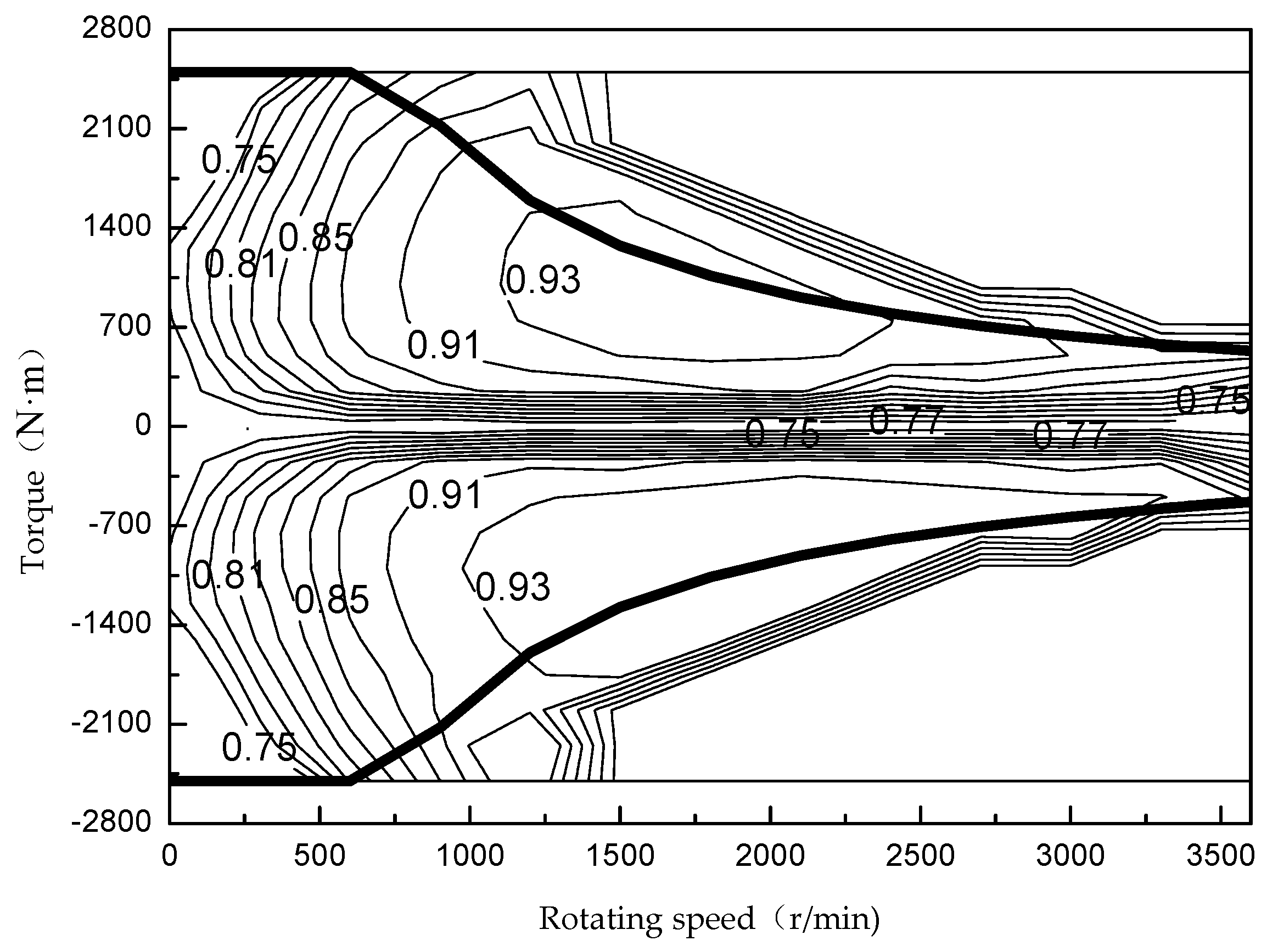

3.1. Drive Motor, Battery and Regenerative Braking Force Model

3.1.1. Drive Motor Mechanics Model

3.1.2. Battery Model

3.1.3. Regenerative Braking Force Model

3.2. Vehicle Dynamics Model

3.2.1. Normal Reaction Force on the Front and Rear Wheels of the Vehicle when Braking

3.2.2. Front and Rear Axle Braking Force Distribution

- (1)

- The front and rear wheels are both locked and dragged.

- (2)

- The front wheels are locked and dragged first, and then the rear wheels are locked and dragged.

- (3)

- The rear wheels are locked and dragged first, and then the front wheels are locked and dragged.

3.3. Regenerative Braking Strategy

3.3.1. Vehicle Speed based Braking Strategy

3.3.2. I Curve based Braking Strategy

3.3.3. Regeneration Braking Strategy based on β Line

3.3.4. Maximizing Front Axle Braking Force Strategy

4. Simulation Analysis

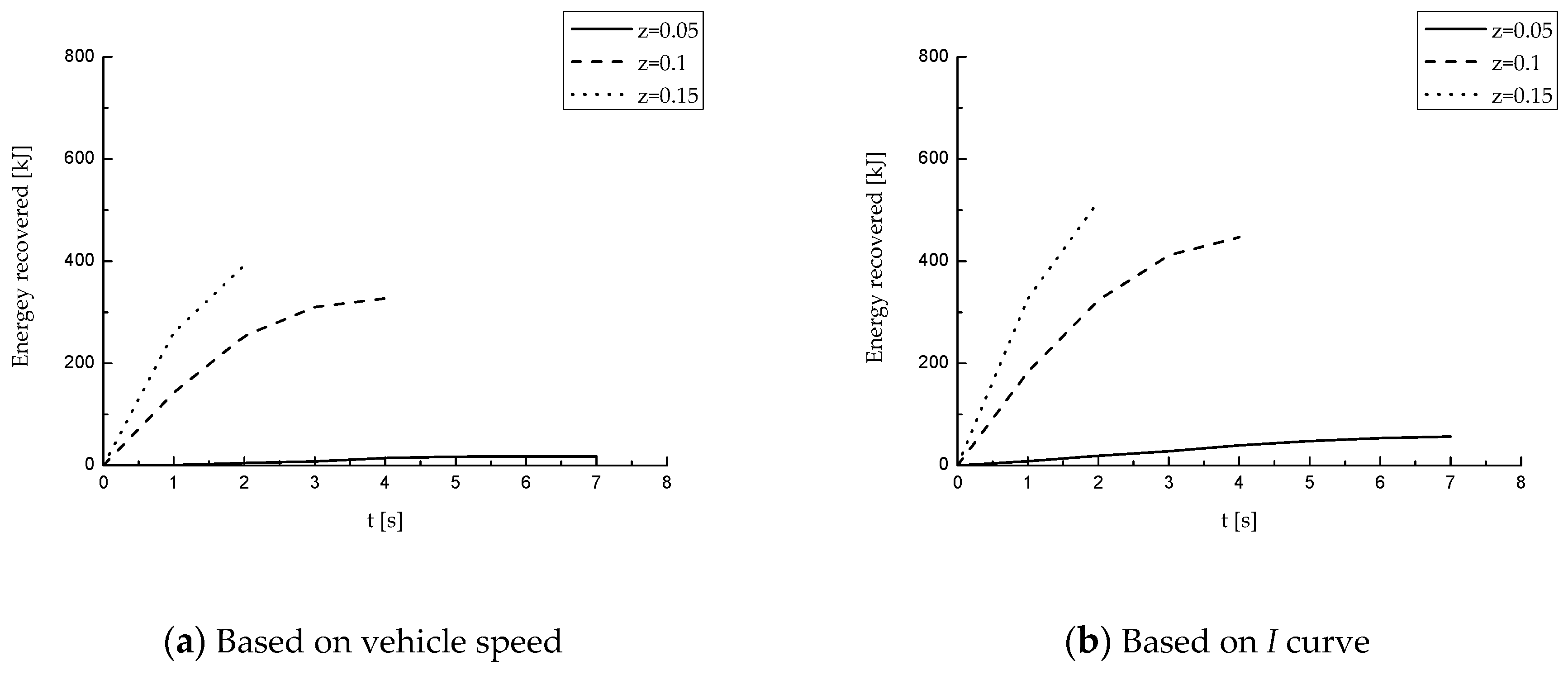

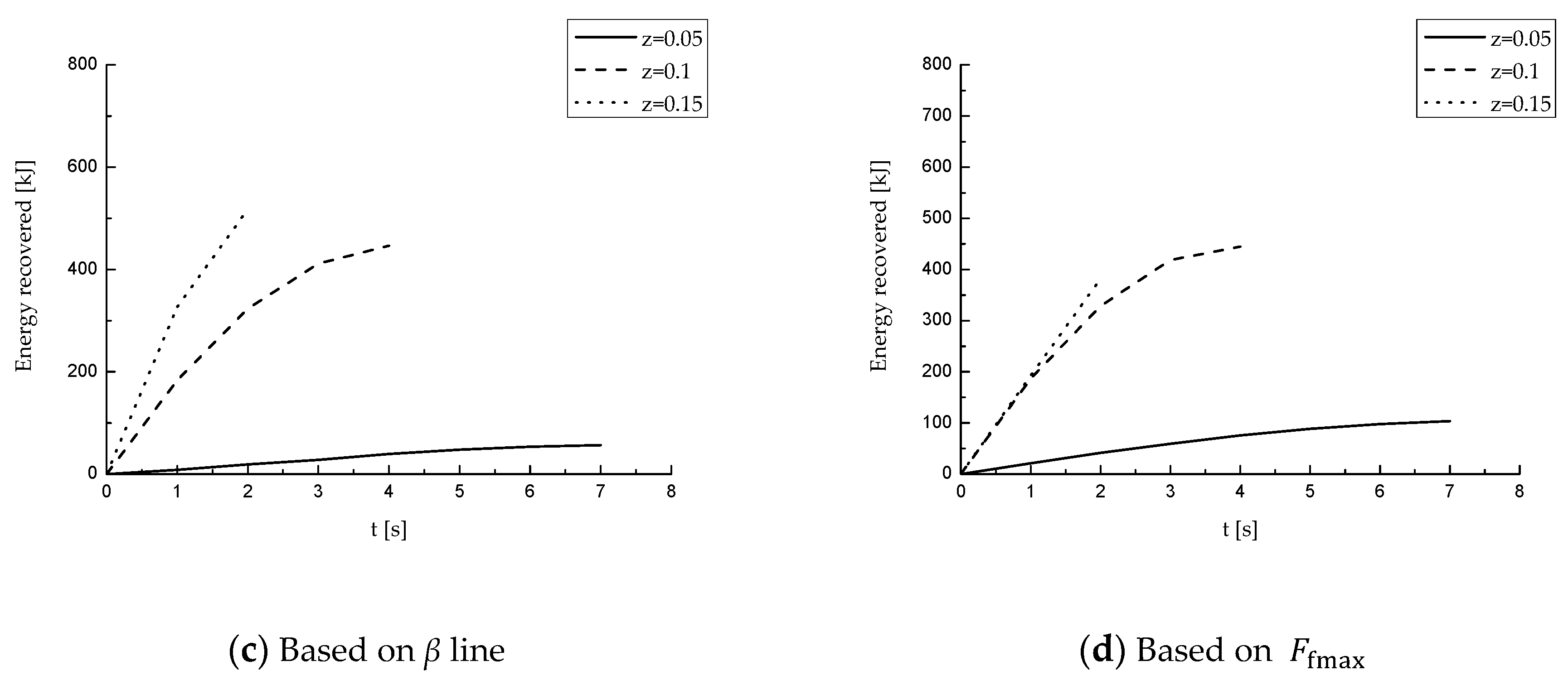

4.1. Simulation of Different Braking Strength on Horizontal Road at Maximum Vehicle Speed

4.1.1. Comparison of Braking Energy Recovery

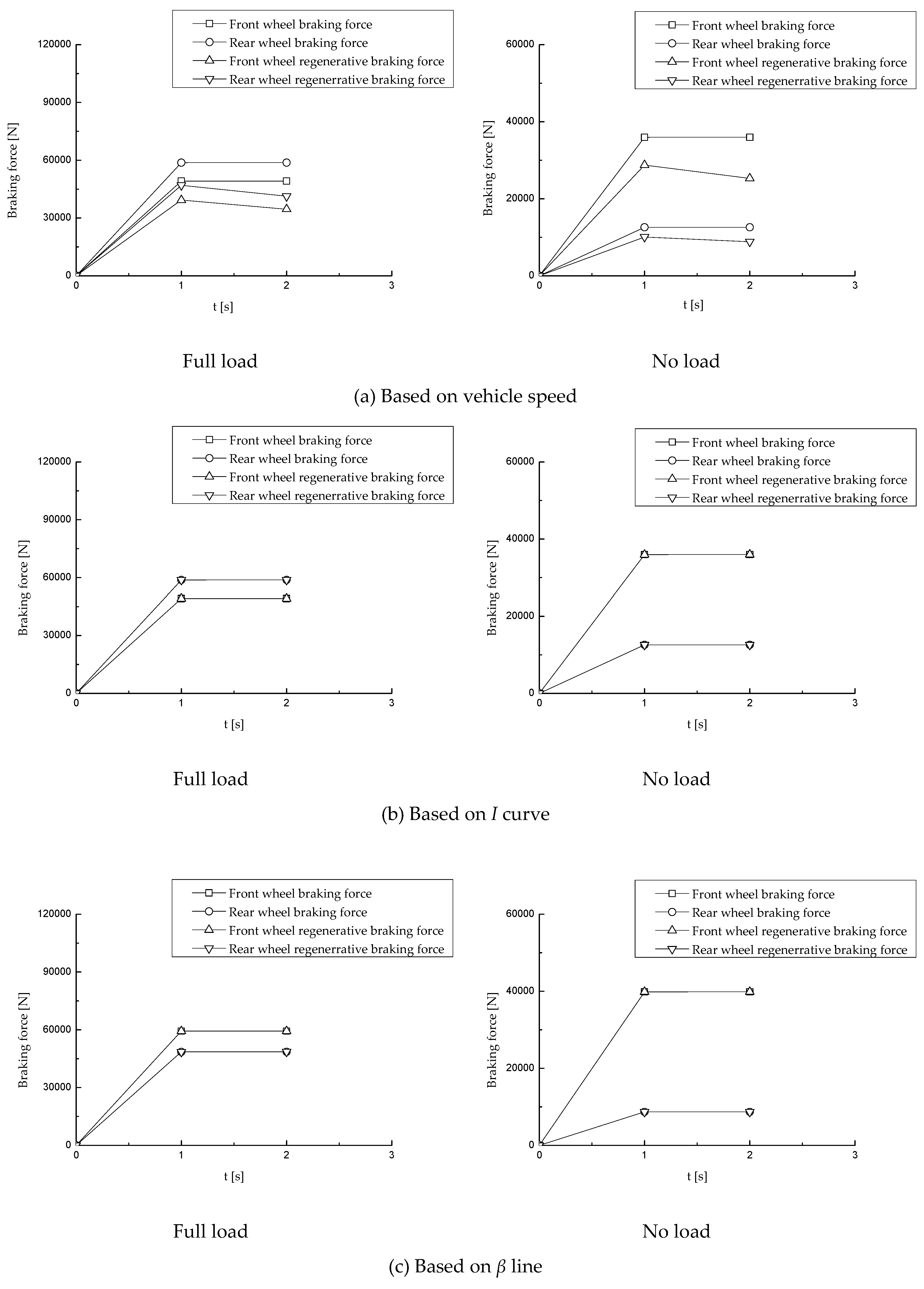

4.1.2. Comparison of Braking Force Distribution

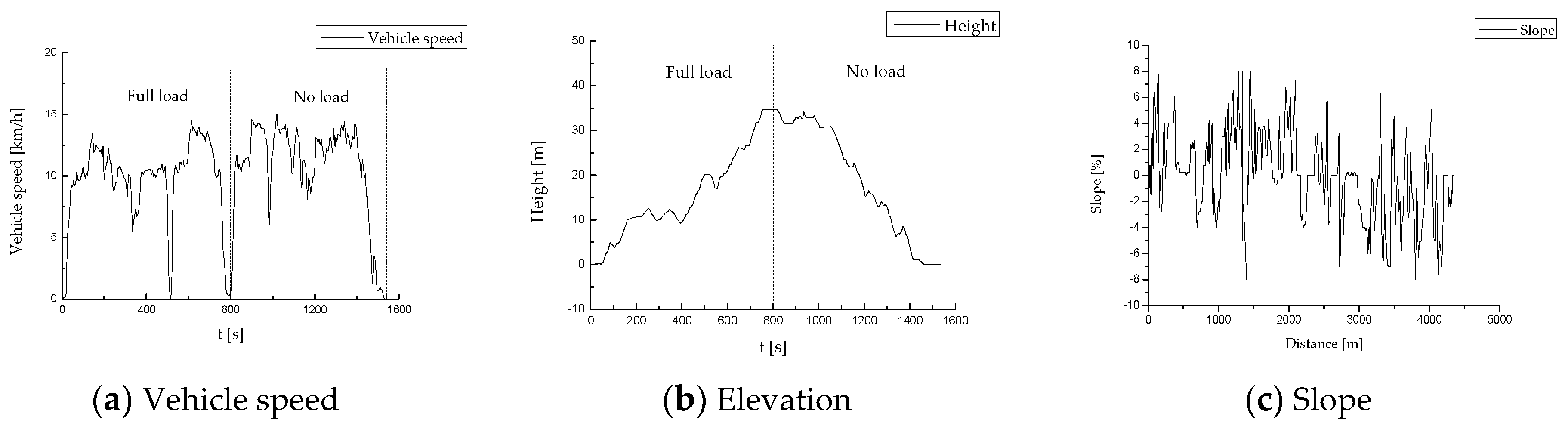

4.2. Simulation of Road Drive Cycle

4.2.1. Comparison of Braking Energy Recovery

4.2.2. Vehicle Energy Consumption and Battery SOC Changes

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Feng, Y. Performance Cost-Benefit Analysis of a Series Hybrid. Electric Mining Truck; University of Science and Technology: Beijing, China, 2017. [Google Scholar]

- Zhou, M.; Gao, Z.; Zhang, H. Research on regenerative braking control strategy of hybrid electric vehicle. In Proceedings of the 6th International Forum on Strategic Technology, Harbin, China, 22–24 August 2011; pp. 300–303. [Google Scholar]

- Guo, J.; Wang, J.; Cao, B. Brake-force distribution strategy for electric vehicle based on maximum energy recovery. J. Xi’an Jiaotong Univ. 2008, 5, 607–611. [Google Scholar]

- Wei, Z.; Xu, J.; Halim, D. Braking force control strategy for electric vehicles with load variation and wheel slip considerations. IET Electr. Syst. Transp. 2017, 7, 41–47. [Google Scholar] [CrossRef]

- Liu, L.; Ji, F.; Yang, S.; Xu, B. Control strategy for electro-mechanical braking based on curves of ECE regulations and ideal braking force. J. Beijing Univ. Aeronaut. Astronaut. 2013, 39, 138–142. [Google Scholar]

- Liu, Z.; Guo, X. Electronic-hydraulic-compound regenerative braking control for electric vehicles. J. Cent. South. Univ. (Sci. Technol.) 2011, 42, 2687–2691. [Google Scholar]

- Lv, C.; Zhang, J.; Li, Y.; Yuan, Y. Mechanism analysis and evaluation methodology of regenerative braking contribution to energy efficiency improvement of electrified vehicles. Energy Convers. Manag. 2015, 92, 469–482. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Y.; Chen, L.; Ye, Y. New regenerative braking control strategy for rear-driven electrified minivans. Energy Convers. Manag. 2014, 92, 469–482. [Google Scholar]

- Qiu, C.; Wang, G.; Meng, M.; Shen, Y. A novel control strategy of regenerative braking system for electric vehicles under safety critical driving situations. Energy 2018, 149, 329–340. [Google Scholar] [CrossRef]

- Guo, Z.J.; Yue, D.D.; Wu, J.B. Optimization of Regenerative Braking Control Strategy for Pure Electric Vehicle. Appl. Mech. Mater. 2017, 872. [Google Scholar] [CrossRef]

- Zhang, X.; Göhlich, D.; Li, J. Energy-Efficient Toque Allocation Design of Traction and Regenerative Braking for Distributed Drive Electric Vehicles. IEEE Trans. Veh. Technol. 2017, 99, 1. [Google Scholar] [CrossRef]

- Yu, H.; Wood, A.S.; Huang, M.; Qi, H. Optimal Braking Control for an Independent four Wheel-Motor-Driven Electric Vehicle. In Proceedings of the Hybrid & Electric Vehicles Conference, Prague, Czech Republic, 23–24 March 2017. [Google Scholar]

- Zhang, J.; Song, B.; Niu, X. Optimization of Parallel Regenerative Braking Control Strategy. In Proceedings of the IEEE Vehicle Power & Propulsion Conference, Harbin, China, 3–5 September 2008; pp. 1–4. [Google Scholar]

- Chu, L.; Shang, M.; Fang, Y.; Guo, J.; Zhou, F. Braking Force Distribution Strategy for HEV Based on Braking Strength. In Proceedings of the International Conference on Measuring Technology and Mechatronics Automation, Changsha, China, 13–14 March 2010. [Google Scholar]

- Li, P. Regenerative braking control strategy for a mild HEV. Automot. Eng. 2005, 5, 67–103. [Google Scholar]

- Zhao, X.; Ma, J.; Wang, G.P. Composite braking control strategy of pure electric bus based on brake driving intention recognition. J. Traffic Transp. Eng. 2014, 4, 64–75. [Google Scholar]

- Cai, J.W.; Chu, L.; Fu, Z.C.; Ren, L.P. Regenerative Braking System for a Pure Electric Bus. Appl. Mech. Mater. 2014, 543, 1405–1408. [Google Scholar] [CrossRef]

- Song, B.L.; Zhou, X.S.; Li, J.; Wang, X.; Chen, C.; Sun, S.L. Modeling and simulation of regenerative braking system for pure electric light truck. J. Automot. Saf. Energy 2015, 6, 85–89. [Google Scholar]

- Sun, F.; Liu, W.; He, H.; Guo, H. An integrated control strategy for the composite braking system of an electric vehicle with independently driven axles. Veh. Syst. Dyn. 2016, 54, 22. [Google Scholar] [CrossRef]

- Wang, M.; Sun, Z.; Zhuo, G.; Cheng, P. Maximum braking energy recovery of electric vehicles and its influencing factors. J. Tongji Univ. (Nat. Sci.) 2012, 40, 583–588. [Google Scholar]

- Guo, J.; Wang, J.; Cao, B. Regenerative Braking Strategy for Electric Vehicles. In Proceedings of the 2009 IEEE Intelligent Vehicles Symposium, Xi’an, China, 3–5 June 2009. [Google Scholar]

- Zhang, W. Automotive Theory, 2nd ed.; China Machine Press: Beijing, China, 2010. [Google Scholar]

- Yu, Z. Automotive Theory, 5th ed.; China Machine Press: Beijing, China, 2009. [Google Scholar]

- Philipp, S.; Tim, B.; Constantinos, S. Comparison of Electric Vehicles with Single Drive and Four Wheel Drive System Concerning Regenerative Braking. In Proceedings of the Twelfth International Conference on Ecological Vehicles & Renewable Energies, Monte-Carlo, Monaco, 11–13 April 2017. [Google Scholar]

- Sun, D.; Lan, F.; Chen, J. A study on the braking energy recovery strategy for a 4WD battery electric vehicle based on ideal braking force distribution (Curve I). Automot. Eng. 2013, 35, 1057–1061. [Google Scholar]

- Yao, L.; Chu, L.; Zhou, F.K.; Liu, M.H.; Zhang, Y.S.; Wei, W.R. Simulation and analysis of potential of energy-saving from braking energy recovery of electric vehicle. J. Jilin Univ. (Eng. Technol. Ed.) 2013, 43, 6–11. [Google Scholar]

| Parameters | Value |

|---|---|

| Vehicle curb mass () | 45,000 kg (Include batteries) |

| Load capacity () | 55,000 kg |

| Center of mass height () | 1.8 m (Full load), 1.5 m (No load) |

| Wheelbase () | 6 m |

| Front wheelbase () | 2.45 m (Full load), 1.78 m (No load) |

| Rear wheelbase () | 3.55 m (Full load), 4.72 m (No load) |

| Wheel radius () | 0.95 m |

| Rolling resistance coefficient () | 0.04 |

| Ground adhesion coefficient () | 0.6 |

| Motor rated power () | 200 kW |

| Number of motors () | 2 (Four-wheel drive) |

| Strategy | Braking Strength | ||||||

|---|---|---|---|---|---|---|---|

| z = 0.05 | z = 0.1 | z = 0.15 | |||||

| Full Load | No Load | Full Load | No Load | Full Load | No Load | ||

| Speed based | Energy covered | 17.7 | 0.0 | 310.1 | 117.9 | 392.3 | 163.4 |

| Vehicle Kinetic energy * | 868.1 | 390.6 | 868.1 | 390.6 | 868.1 | 390.6 | |

| Proportion [%] | 2.0% | 0.0% | 35.7% | 30.2% | 45.2% | 41.8% | |

| I curve | Energy covered | 56.5 | 0.0 | 411.4 | 165.4 | 517.5 | 221.7 |

| Vehicle Kinetic energy * | 868.1 | 390.6 | 868.1 | 390.6 | 868.1 | 390.6 | |

| Proportion [%] | 6.5% | 0.0% | 47.4% | 42.3% | 59.6% | 56.8% | |

| β line | Energy covered | 56.5 | 0.0 | 411.3 | 165.0 | 517.4 | 221.0 |

| Vehicle Kinetic energy * | 868.1 | 390.6 | 868.1 | 390.6 | 868.1 | 390.6 | |

| Proportion [%] | 6.5% | 0.0% | 47.4% | 42.2% | 59.6% | 56.6% | |

| Energy covered | 105.0 | 21.4 | 445.3 | 199.9 | 383.1 | 232.9 | |

| Vehicle Kinetic energy * | 868.1 | 390.6 | 868.1 | 390.6 | 868.1 | 390.6 | |

| Proportion [%] | 12.1% | 5.5% | 51.3% | 51.2% | 44.1% | 59.6% | |

| Strategy | Working Condition | |||

|---|---|---|---|---|

| Full Load | No Load | Total | ||

| Speed based | Energy covered | 361.4 | 420.7 | 782.1 |

| Vehicle Kinetic | 740.0 | 2778.0 | 3518.0 | |

| Proportion [%] | 48.8% | 15.1% | 22.2% | |

| I curve | Energy covered | 501.6 | 783.5 | 1285.1 |

| Vehicle Kinetic | 740.0 | 2778.0 | 3518.0 | |

| Proportion [%] | 67.8% | 28.2% | 36.5% | |

| β line | Energy covered | 501.6 | 783.0 | 1284.6 |

| Vehicle Kinetic | 740.0 | 2778.0 | 3518.0 | |

| Proportion [%] | 67.8% | 28.2% | 36.5% | |

| Energy covered | 591.8 | 1464.3 | 2056.1 | |

| Vehicle Kinetic | 740.0 | 2778.0 | 3518.0 | |

| Proportion [%] | 80.0% | 52.7% | 58.4% | |

| Strategy | Motor Regenerative Braking Efficiency | |||

|---|---|---|---|---|

| Full Load | No Load | |||

| Front | Rear | Front | Rear | |

| Vehicle speed | 60.76% | 69.79% | 36.02% | 2.41% |

| I curve | 68.16% | 75.42% | 44.95% | 8.11% |

| β line | 74.68% | 69.43% | 50.60% | 0.42% |

| 85.53% | 0.00% | 57.65% | 0.00% | |

| Strategy | Energy Consumed | Improvement Ratio (Compared to No Regeneration)% | ||

|---|---|---|---|---|

| Full Load (Uphill) | No Load (Downhill) | Total | ||

| No Regenerative | 145850 | 42795 | 188645 | 0.00% |

| Vehicle speed | 145630 | 41011 | 186641 | 1.06% |

| I curve | 145630 | 40811 | 186441 | 1.17% |

| β line | 145630 | 40811 | 186441 | 1.17% |

| 145580 | 40128 | 185708 | 1.56% | |

| Strategy | Energy Consumed | Improvement Ratio (Compared to No Regeneration) % | ||

|---|---|---|---|---|

| Full Load (Uphill) | No Load (Downhill) | Total | ||

| No regenerative | 100290 | 28852 | 129142 | 0.00% |

| Vehicle speed | 98902 | 24096 | 122998 | 4.76% |

| I curve | 98812 | 23785 | 122597 | 5.07% |

| β line | 98812 | 23785 | 122597 | 5.07% |

| 98665 | 23078 | 121743 | 5.73% | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Yang, J.; Zhang, W.; Ma, F. Research on Regenerative Braking of Pure Electric Mining Dump Truck. World Electr. Veh. J. 2019, 10, 39. https://doi.org/10.3390/wevj10020039

Zhang W, Yang J, Zhang W, Ma F. Research on Regenerative Braking of Pure Electric Mining Dump Truck. World Electric Vehicle Journal. 2019; 10(2):39. https://doi.org/10.3390/wevj10020039

Chicago/Turabian StyleZhang, Wei, Jue Yang, Wenming Zhang, and Fei Ma. 2019. "Research on Regenerative Braking of Pure Electric Mining Dump Truck" World Electric Vehicle Journal 10, no. 2: 39. https://doi.org/10.3390/wevj10020039

APA StyleZhang, W., Yang, J., Zhang, W., & Ma, F. (2019). Research on Regenerative Braking of Pure Electric Mining Dump Truck. World Electric Vehicle Journal, 10(2), 39. https://doi.org/10.3390/wevj10020039