This section proposes an optimized energy management strategy of the E-REV based on driving characteristics. AVL Cruise is used to establish the vehicle model of E-REV and energy management strategy. With the goal of minimum energy consumption and emissions, off-line optimization calculation is performed for the five typical driving conditions selected above. Then the extreme learning machine is used to classify the actual driving cycles into five typical driving conditions, and the off-line optimization results are used for real-time energy management. Compared with the results of traditional energy management strategies, analyzing the energy-saving effect of this optimized energy management strategy.

3.1. Multi-Objective Optimization for Typical Driving Conditions

The basic parameters of the E-REV built in this paper shown in

Table 6. According to the engine test data, the engine external characteristic curve and the brake specific fuel consumption (BSFC) map is shown in

Figure 14a.

Figure 14b is the efficiency map and maximum torque curve of the motor.

Common rule-based EMS of E-REV includes the thermostat control strategy, power following control strategy, and multi-workpoints control strategy.

Thermostat control: when the State of Charge (SOC) of battery is between and , the engine maintains the working state; when is more than , the engine is turned off and runs on pure electric power; when SOC is less than , the engine works at the highest efficiency point, and the excess energy charges the battery. This strategy can effectively avoid engine start and stop frequently, but batteries often charge and discharge with a large current which is extremely bad for battery life.

Power following control: this strategy determines the working state of the engine according to the power demand of the vehicle and SOC of the battery. Only when SOC more than and the power demand is less than , the engine will turn off. Under this control strategy, the battery can maintain the best performance state, but frequent engine fluctuations are detrimental to the economy and fuel consumption.

Multi-workpoints control: the strategy is to make the engine work at different working points according to the vehicle’s power demand and battery SOC. Too many working points will cause the engine fluctuation to become larger, and too few working points will not avoid the power battery work with large current. This strategy can not only ensure the life of the power battery but also reduce the fluctuation of the engine.

The dynamics, economy, and emissions of the vehicle are important performance indexes for evaluating EMS, but they are contradictory. Therefore, the optimization of EMS for E-REV is not a simple single-objective optimization problem, but a multi-objective optimization problem.

The simulated annealing algorithm is a heuristic search algorithm, which simulates the solid annealing process. Ingber [

39] improved simulated annealing algorithm and proposed an adaptive simulated annealing (ASA) algorithm, which improved the performance and calculation speed of the algorithm. In this paper, the ASA is selected to optimize the control parameters of the EMS.

In the ASA algorithm, the solution

generated at the

-th iteration is shown in Equation (

14),

s is the

s-th term of the solution vector.

where

,

are the upper and lower limits of

.

can be calculated as Equation (

15) and

obeys uniform distribution on [0, 1].

The feature of using this method to generate new solutions is that the search interval is large when the temperature is high, and the search interval is small when the temperature is low, which greatly improves the speed of the algorithm to search for the optimal solution.

Cooling function in adaptive simulated annealing algorithm is shown in Equation (

16).

is the temperature at the

k-th iteration of the outer loop and

is the initial temperature.

S is the dimension of solution vector and

C is a constant.

The greater the initial temperature or the greater the number of iterations is, the higher the probability of obtaining the optimal solution is, but the longer the calculation time requires. Therefore, the choice of initial temperature and iteration number needs to balance both optimization time and optimization effect. The flow of ASA is shown in

Figure 15.

This work selects control parameters in multi-workpoints control strategy with three working speed of the engine to optimize, which switch according to the battery SOC and the vehicle speed. Then, the control parameters selected for optimization and their upper and lower limits are shown in

Table 7.

Economy is one of the most important indexes to measure the performance of the vehicle. The economic evaluation parameters are commonly used for fuel consumption per hundred kilometers. Compared with traditional internal combustion engine vehicles, E-REV has an additional energy source from the battery. The conversion relationship between the fuel consumption per hundred kilometers of the extended-range engine and the battery consumption per hundred kilometers is shown in Equation (

17).

where

represents the fuel consumption per hundred kilometers after equivalent conversion, the unit is

.

E represents power consumption per hundred kilometers, the unit is

.

is the fuel density, the unit is

.

q is the calorific value of fuel in J/g.

and

represent the average efficiency of the engine and generator, respectively.

The purpose of this work is to improve the economy and emissions of E-REV. The economic evaluation indexes include fuel consumption and electricity consumption per hundred kilometers. Emissions include nitrogen oxides, CO, and hydrocarbons. So the objective function is shown as Equation (

18).

where

and

represent fuel consumption and electricity consumption per hundred kilometers.

,

and

represent emissions of nitrogen oxides, CO, and hydrocarbons.

respectively represent the weight values of fuel consumption, electricity consumption and emissions, which can be determined according to actual requirement. In this paper, weight is selected as [0.35, 0.35, 0.1, 0.1, 0.1].

At the same time, in order to ensure the dynamics of the vehicle, dynamic constraints are shown in

Table 8 need to be added.

The five typical driving cycles constructed above are imported into AVL Cruise software respectively, and optimized by the ASA algorithm.

Figure 16 shows the iterative optimization process of some control parameters, including low, middle and high engine working speed, under the Type 2 typical driving cycle. It can be seen from the figure that after 100 iterations, the parameters have stabilized.

The optimization results of control parameters obtained by the ASA algorithm for five types of typical driving cycles are shown in

Table 9. It can be seen from the table that the optimal control parameters under different driving cycles are quite different, which also shows the necessity of control parameter optimization.

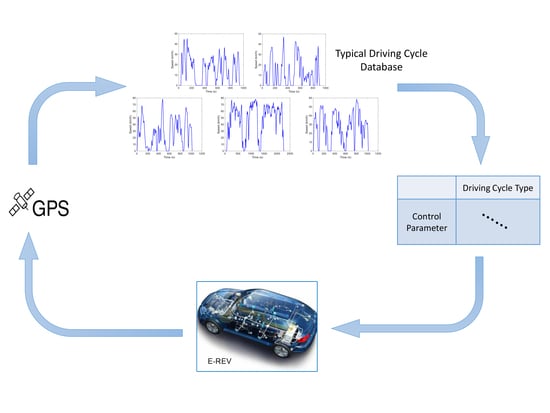

3.2. Real-Time Energy Management Strategy Based on Driving Cycle Recognition

The control parameters of five typical working conditions have been optimized by ASA algorithm. However, the actual driving conditions of the vehicle are various. In order to let E-REV adapt to complex driving conditions and achieve the purpose of improving the fuel economy and emissions of the vehicle, an adaptive multi-workpoint energy management strategy based on offline parameter optimization and online driving cycle recognition (A-MEMS) has been proposed. Its control principle diagram is shown in

Figure 17.

The actual driving condition needs to be divided into driving fragments for recognition according to a fixed step size, and the step length of the driving cycle recognition is selected to be 100 s. The characteristics in each step length are calculated separately, and principal components composed of these characteristics are input to the trained ELM. Select a section of actual driving condition, whose cycle time is 2100 s and total mileage is 19.73 km. The final recognition result of ELM is shown in

Figure 18.

Respectively, simulation with three common rule-based energy management strategies including thermostat control strategy, power following control strategy, and multi-workpoints control strategy, and A-MEMS based on driving cycle recognition. There is only one engine workpoint in thermostat control, which works or not depending on SOC. The distributions of engine working points of the other three strategies are shown in the

Figure 19.

During thermostat control, the working point is set in the high-efficiency zone and the engine power is selected to be 37.5 kW with a target speed of 4000 rpm and a target torque of 90 Nm. As is shown in

Figure 19, working points of the power following strategy are concentrated near the minimum fuel consumption curve. The engine works at certain specified speeds of the multi-workpoints and A-MEMS. Compared with multi-workpoints control, the engine working range of low and medium speeds in A-MEMS has expanded, while the high-speed working range has slightly reduced. Meanwhile, working points of the engine in the optimized control are more biased towards the low fuel consumption area.

The A-MEMS categorizes actual driving fragments into the five typical driving cycles. It can be seen in

Figure 20 that SOC limit of A-MEMS varies with driving cycle type. In 150–200 s, the recognition result is Type 2 where the vehicle speed fluctuates greatly and the average vehicle speed is low. Then, the upper limit of SOC is increased to improve the engine load, which means that the engine will work in a higher efficient region. Each driving cycle has its own optimal working speed of engine and limit of SOC, which can make engine mainly work at high-efficiency area with low and medium speed.

The equivalent fuel consumption per hundred kilometers, emissions and dynamics of the four energy management strategies are shown in

Table 10. Compared with the other two rule-based control strategies, the multi-workpoints control strategy has lower fuel consumption and emissions. Under the power-following control strategy, although the engine works on the minimum fuel consumption curve, the engine runs for a long time, and the engine’s working state changes frequently, so the fuel consumption is greater than other strategies.

The equivalent fuel consumption of the A-MEMS based on driving cycle recognition is 8.9% lower than multi-workpoints control without driving cycle recognition, and 17.6% lower than that of the thermostat control strategy. The emissions of HC compounds, carbon monoxide, and nitrogen oxides in the exhaust gas were also reduced by 7.9%, 14.0%, and 13.4%, respectively, compared with multi-workpoints control, although the dynamics have been reduced slightly, though they still meet vehicle dynamic targets.