Fault Diagnosis Method of DC Charging Points for EVs Based on Deep Belief Network

Abstract

:1. Introduction

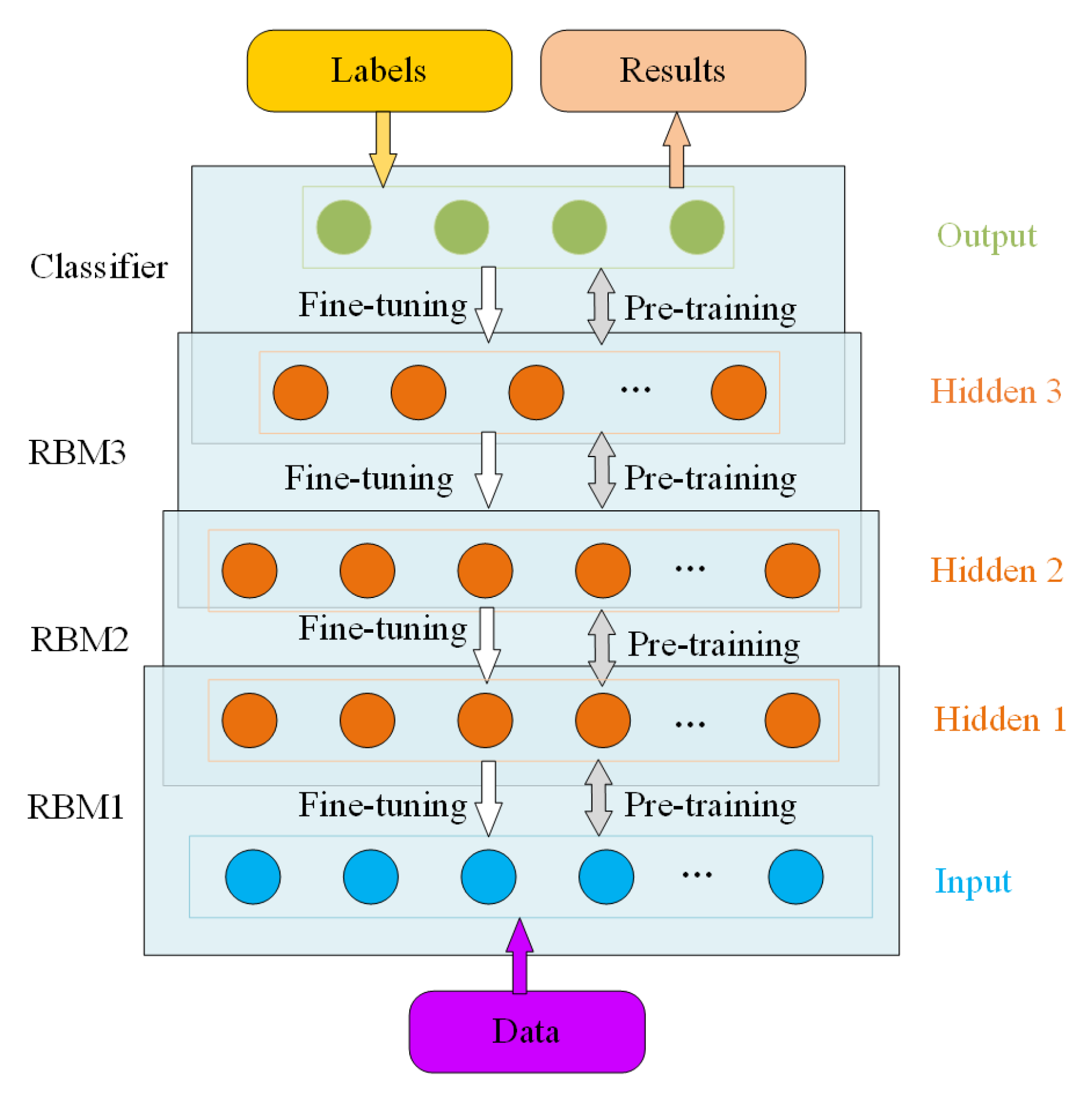

2. Principle of DBN

2.1. RBM Model

2.2. Structure and Training Process of DBN

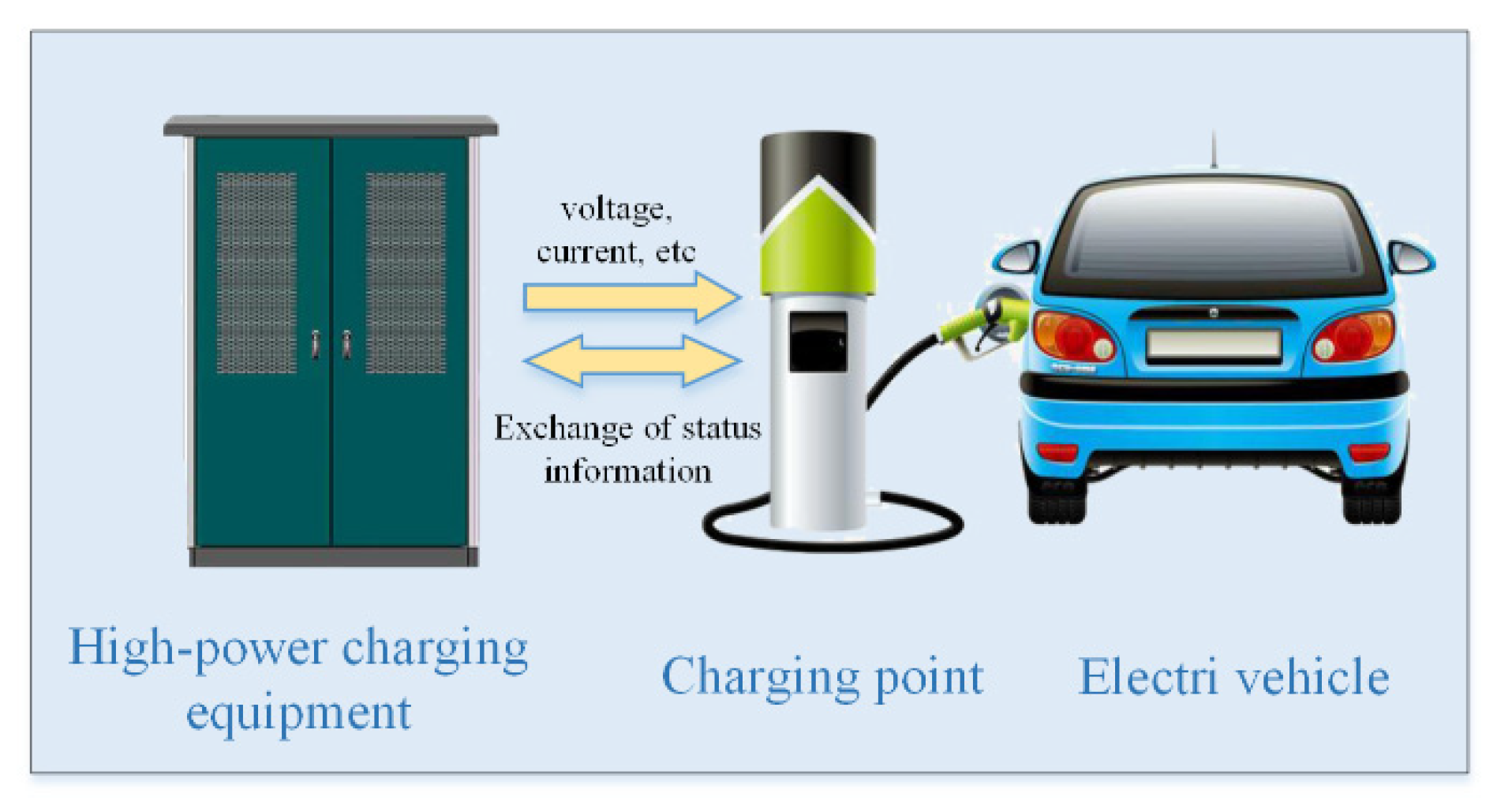

3. Design of Charging Points Fault Diagnosis

3.1. Fault Characteristics of Charging Points

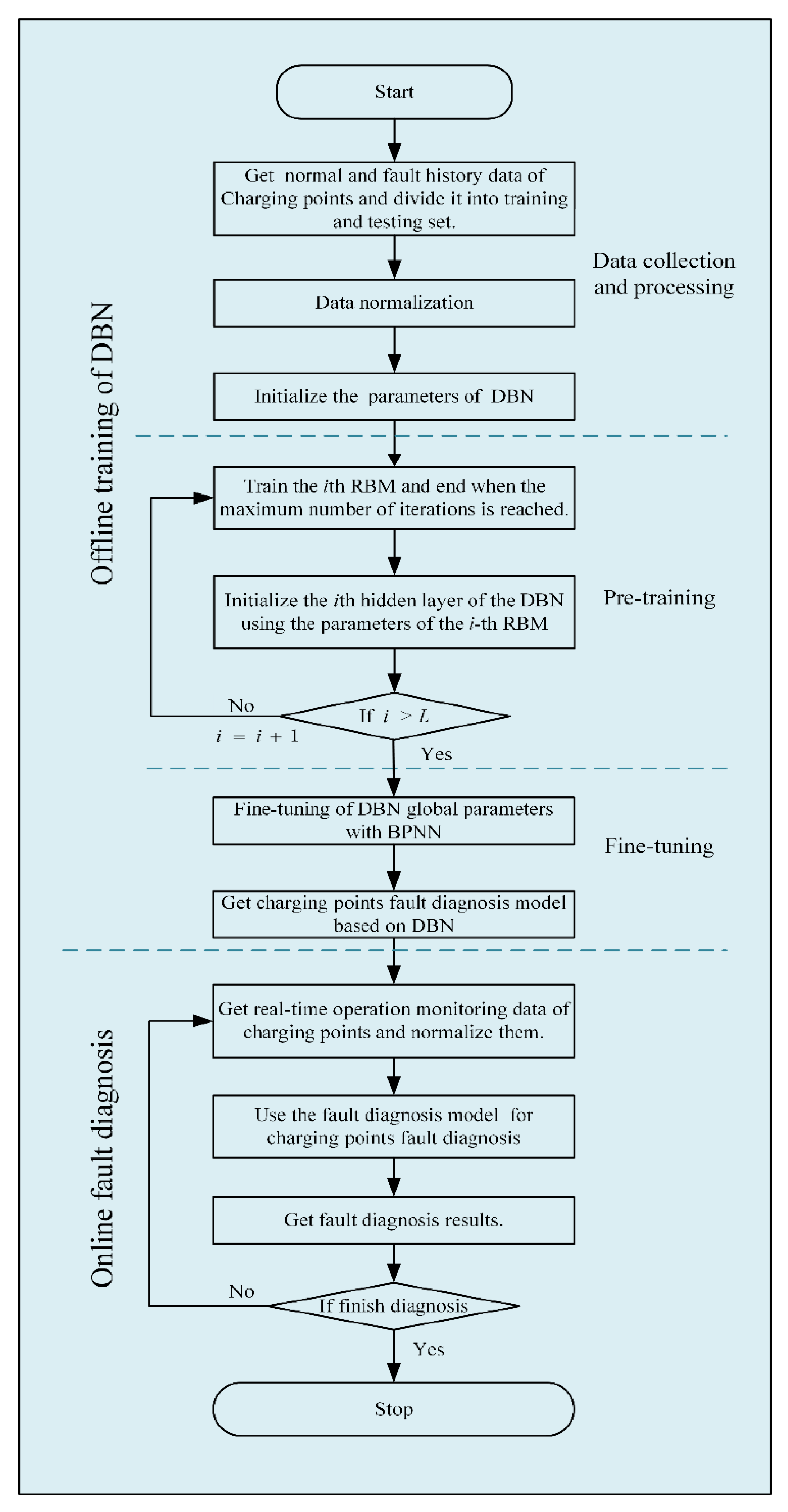

3.2. Design of Fault Diagnosis Flow

- Organize the historical status data of charging points and build a data set.

- Divide the data set into the training set and test set according to a certain ratio, and normalize them.

- Construct the DBN model through two stages of pre-training and fine-tuning, and optimize the parameters of the DBN model.

- Test the performance of the DBN fault diagnosis model using test data.

- Apply the DBN model that meets the needs of the fault diagnosis of charging points.

4. Implementation of Charging Points Fault Diagnosis

4.1. Data Acquisition and Processing

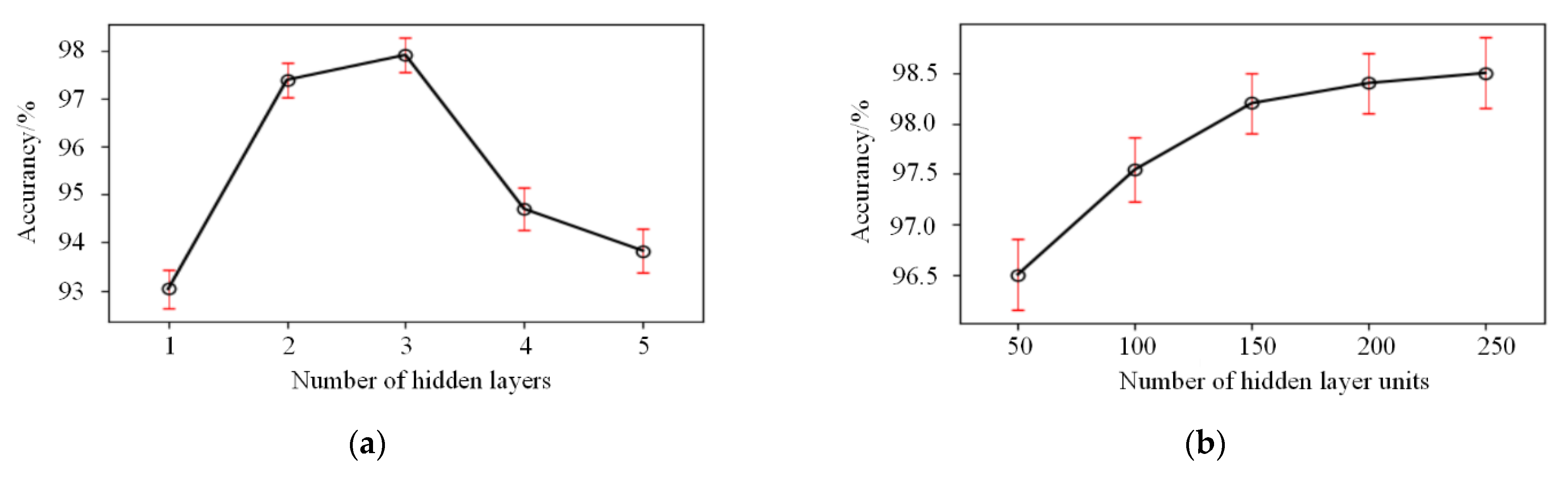

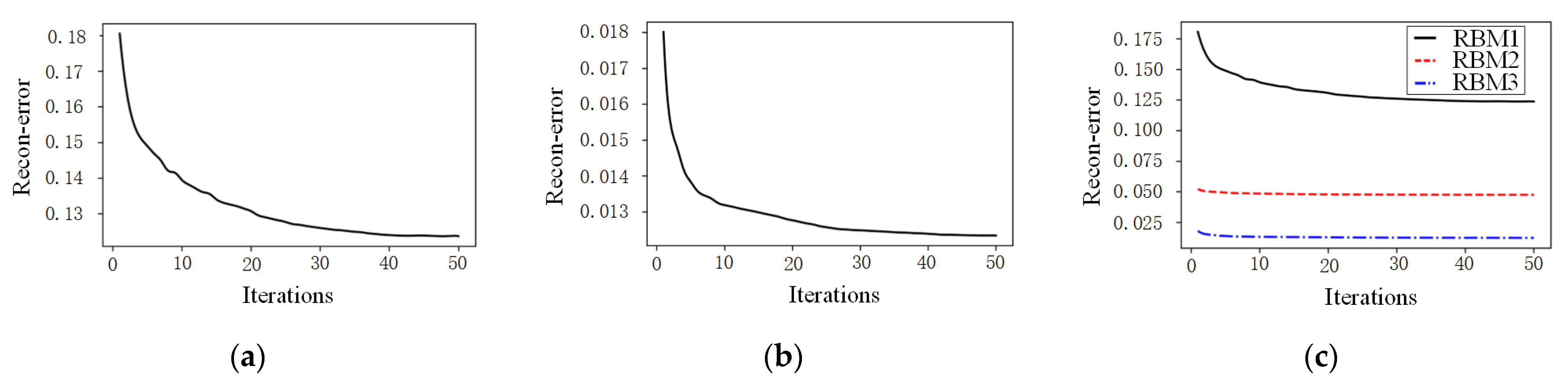

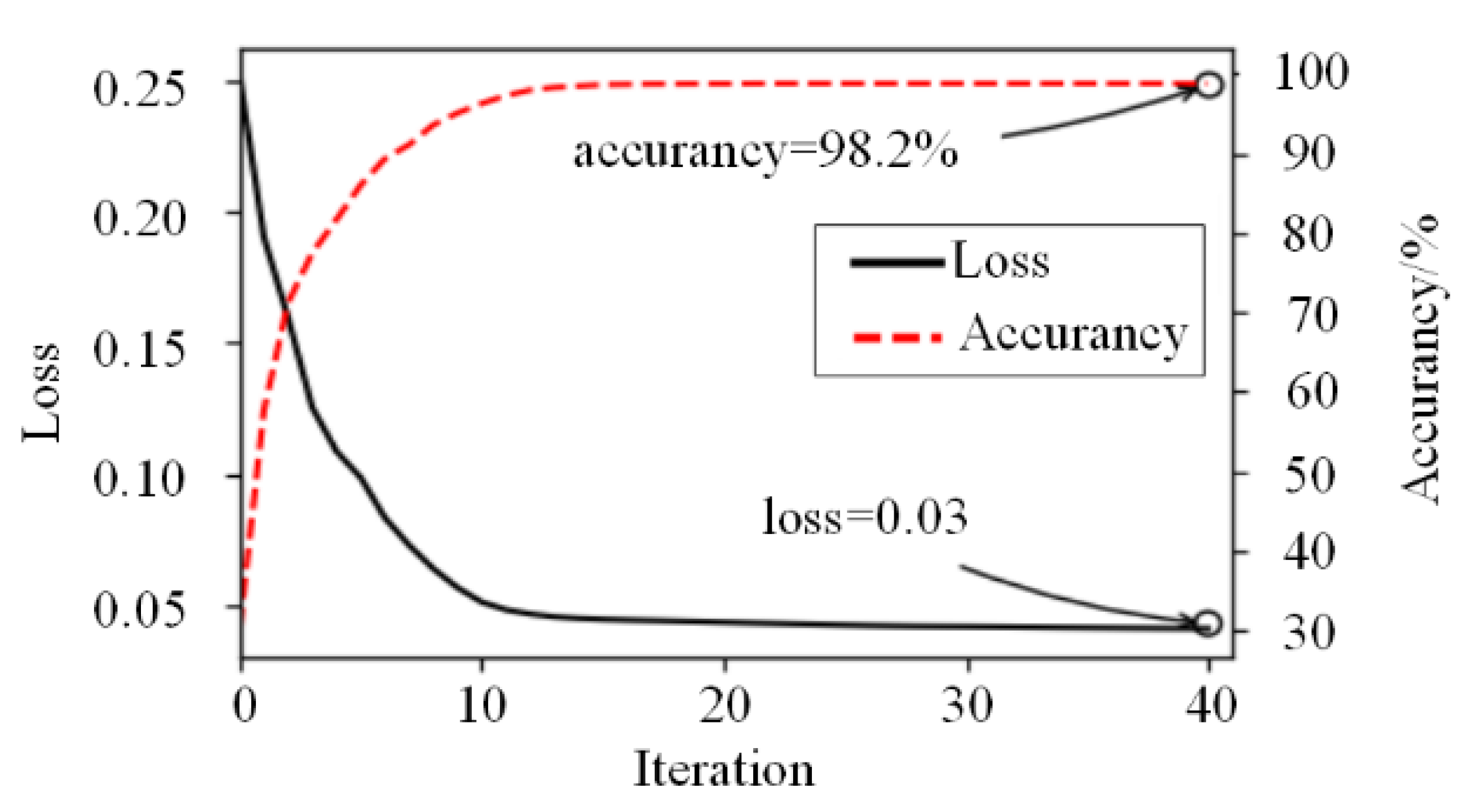

4.2. Experiment and Analysis

- Only the reconstruction errors of the top RBM can reach the preset needs, while the reconstruction errors of the preceding L-1 RBMs are degraded in accuracy by accumulation.

- An increase in the number of hidden layers L leads to excessive error accumulation in the reverse gradient descent algorithm.

- An increase in the number of hidden layers L leads to an effect of increasing the complexity of the running time and decreasing the efficiency.

4.3. Comparison of Methods

- CNN has a more complex structure and training process than other models, and therefore has a significantly longer convergence time.

- RBFNN is a local approximation network, thus the convergence speed is faster.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhou, D.; Hu, Y. Fault diagnosis techniques for dynamic systems. Acta Autom. Sin. 2009, 35, 748–758. [Google Scholar] [CrossRef]

- Tidriri, K.; Chatti, N.; Verron, S.; Tiplica, T. Bridging data-driven and model-based approaches for process fault diagnosis and health monitoring: A review of researches and future challenges. Annu. Rev. Control 2016, 42, 63–81. [Google Scholar] [CrossRef]

- Wu, Y.; Jiang, B.; Shi, P. Incipient fault diagnosis for T–S fuzzy systems with application to high-speed railway traction devices. IET Control Theory Appl. 2016, 10, 2286–2297. [Google Scholar] [CrossRef]

- Gao, D.; Hou, J.; Liang, K.; Yang, Q. Fault diagnosis system for electric vehicle charging devices based on fault tree analysis. In Proceedings of the 2018 37th Chinese Control Conference (CCC), Wuhan, China, 25–27 July 2018; pp. 5055–5059. [Google Scholar]

- Liu, X.; Han, J.; Wei, X.; Zhang, H.; Hu, X. Distributed fault detection for non-linear multi-agent systems: An adjustable dimension observer design method. IET Control Theory Appl. 2019, 13, 2407–2415. [Google Scholar] [CrossRef]

- Zhong, Y.; Zhang, W.; Zhang, Y.; Zuo, J.; Zhan, H. Sensor fault detection and diagnosis for an unmanned quadrotor helicopter. J. Intell. Robot. Syst. 2019, 96, 555–572. [Google Scholar] [CrossRef]

- Rahimi, A.; Kumar, K.D.; Alighanbari, H. Fault estimation of satellite reaction wheels using covariance based adaptive unscented Kalman filter. Acta Astronaut. 2017, 134, 159–169. [Google Scholar] [CrossRef]

- Wang, H.L.; Zhou, G.B. State of charge prediction of supercapacitors via combination of Kalman filtering and backpropagation neural network. IET Electr. Power Appl. 2018, 12, 588–594. [Google Scholar]

- Ahmed, R.; El Sayed, M.; Gadsden, S.A.; Tjong, J.; Habibi, S. Automotive internal-combustion-engine fault detection and classification using artificial neural network Techniques. IEEE Trans. Veh. Technol. 2015, 64, 21–33. [Google Scholar] [CrossRef]

- Ji, Z.; Liu, W. Open-circuit fault detection for three-phase inverter based on backpropagation neural network. Neural Comput. Appl. 2018, 31, 4665–4674. [Google Scholar] [CrossRef]

- Chen, Y.; Ma, H.W.; Dong, M. Automatic classification of welding defects from ultrasonic signals using an SVM-based RBF neural network approach. Insight 2018, 60, 194–199. [Google Scholar] [CrossRef]

- Liu, L.; Ji, Y.F.; Gao, Y.; Kuang, L. Classification of epileptic electroencephalograms signal based on integrated radius-basis-function neural-network. J. Med. Imaging Health Inform. 2018, 8, 1462–1467. [Google Scholar] [CrossRef]

- Zhou, W.; Li, X.; Yi, J.; He, H. A novel UKF-RBF method based on adaptive noise factor for fault diagnosis in pumping unit. IEEE Trans. Ind. Inform. 2019, 15, 1415–1424. [Google Scholar] [CrossRef]

- Wang, Z.H.; Shen, Y.; Zhang, X.L. Actuator fault estimation for a class of nonlinear descriptor systems. Int. J. Syst. Sci. 2014, 45, 487–496. [Google Scholar] [CrossRef]

- Konar, P.; Chattopadhyay, P. Bearing fault detection of induction motor using wavelet and Support Vector Machines (SVMs). Appl. Soft. Comput. 2011, 11, 4203–4211. [Google Scholar] [CrossRef]

- Yan, X.; Jia, M. A novel optimized SVM classification algorithm with multi-domain feature and its application to fault diagnosis of rolling bearing. Neurocomputing 2018, 313, 47–64. [Google Scholar] [CrossRef]

- Zidi, S.; Moulahi, T.; Alaya, B. Fault Detection in wireless sensor networks through SVM classifier. IEEE Sens. J. 2018, 18, 340–347. [Google Scholar] [CrossRef]

- Wen, L.; Li, X.Y.; Gao, L.; Zhang, Y.Y. A new convolutional neural network-based data-driven fault diagnosis Method. IEEE Trans. Ind. Electron. 2018, 65, 5990–5998. [Google Scholar] [CrossRef]

- Du, T.; Zhang, H.; Wang, L. Analogue circuit fault diagnosis based on convolution neural network. Electron. Lett. 2019, 55, 1277–1278. [Google Scholar] [CrossRef]

- Xia, M.; Li, T.; Xu, L.; Liu, L.Z.; de Silva, C.W. Fault diagnosis for rotating machinery using multiple sensors and convolutional neural networks. IEEE-ASME Trans. Mechatron. 2018, 23, 101–110. [Google Scholar] [CrossRef]

- Ren, H.; Qu, J.; Chai, Y.; Tang, Q.; Ye, X. Deep learning for fault diagnosis: The state of the art and challenge. Control Decis. 2017, 32, 1345–1358. [Google Scholar]

- Deng, L.; Hinton, G.E.; Kingsbury, B. New types of deep neural network learning for speech recognition and related applications: An overview. In Proceedings of the IEEE International Conference on Acoustics, Speech, and Signal Processing (ICASSP), Vancouver, BC, Canada, 26–31 May 2013; pp. 8599–8603. [Google Scholar]

- Chen, Z.; Li, W. Multisensor feature fusion for bearing fault diagnosis using sparse autoencoder and deep belief network. IEEE Trans. Instrum. Meas. 2017, 66, 1693–1702. [Google Scholar] [CrossRef]

- Yu, D.; Chen, Z.M.; Xiahou, K.S.; Li, M.S.; Ji, T.Y.; Wu, Q.H. A radically data-driven method for fault detection and diagnosis in wind turbines. Int. J. Electr. Power Energy Syst. 2018, 99, 577–584. [Google Scholar] [CrossRef]

- Li, M.; Yu, D.; Chen, Z.; XiaHou, K.; Li, Y.; Ji, T. Fault diagnosis and isolation method for wind turbines based on deep belief network. Electr. Mach. Control 2019, 23, 114–122. [Google Scholar]

- Zhu, J.; Hu, T.; Jiang, B.; Yang, X. Intelligent bearing fault diagnosis using PCA–DBN framework. Neural Comput. Appl. 2019, 32, 10773–10781. [Google Scholar] [CrossRef]

- Fischer, A.; Igel, C. Training restricted boltzmann machines: An introduction. Pattern Recognit. 2014, 47, 25–39. [Google Scholar] [CrossRef]

- Hinton, G.E. Training products of experts by minimizing contrastive divergence. Neural Comput. 2002, 14, 1771–1800. [Google Scholar] [CrossRef] [PubMed]

- Pan, G.; Chai, W.; Qiao, J. Calculation for depth of deep belief network. Control Decis. 2015, 30, 256–260. [Google Scholar]

| Description | Symbol | Label |

|---|---|---|

| Normal state | d0 | 0000 |

| Communication failure between EVs and charging points | d1 | 0001 |

| Insulation testing faults | d2 | 0010 |

| Charging module output overvoltage | d3 | 0011 |

| Charging module over-temperature fault | d4 | 0100 |

| Charging module input phase loss | d5 | 0101 |

| Battery charging over-current fault | d6 | 0110 |

| DC bus output over-voltage fault | d7 | 0111 |

| DC bus output contactor failure | d8 | 1000 |

| Description | Symbol | Value |

|---|---|---|

| Number of units in input layer | - | 16 |

| Number of units in output layer | - | 4 |

| Number of iterations of pre-training | n1 | 50 |

| Number of pre-training batch samples | s1 | 50 |

| Learning rate of pre-training | a1 | 0.15 |

| Momentum of pre-training | 0.8 | |

| Number of iterations of fine-tuning | n2 | 40 |

| Number of fine-tuning batch samples | s2 | 20 |

| Learning rate of fine-tuning | a2 | 0.6 |

| Methods | Training Accuracy (%) | Testing Accuracy (%) | Average Accuracy (%) | Convergence Time (s) |

|---|---|---|---|---|

| BPNN | 93.6 | 92.5 | 93.05 | 59.12 |

| RBFNN | 95.8 | 94.7 | 95.25 | 24.13 |

| SVM | 94.5 | 93.3 | 93.90 | 35.36 |

| CNN | 96.3 | 96.1 | 96.24 | 245.74 |

| DBM | 98.2 | 98.1 | 98.15 | 206.37 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, D.; Lin, X. Fault Diagnosis Method of DC Charging Points for EVs Based on Deep Belief Network. World Electr. Veh. J. 2021, 12, 47. https://doi.org/10.3390/wevj12010047

Gao D, Lin X. Fault Diagnosis Method of DC Charging Points for EVs Based on Deep Belief Network. World Electric Vehicle Journal. 2021; 12(1):47. https://doi.org/10.3390/wevj12010047

Chicago/Turabian StyleGao, Dexin, and Xihao Lin. 2021. "Fault Diagnosis Method of DC Charging Points for EVs Based on Deep Belief Network" World Electric Vehicle Journal 12, no. 1: 47. https://doi.org/10.3390/wevj12010047

APA StyleGao, D., & Lin, X. (2021). Fault Diagnosis Method of DC Charging Points for EVs Based on Deep Belief Network. World Electric Vehicle Journal, 12(1), 47. https://doi.org/10.3390/wevj12010047