Engineering Project: The Method to Solve Practical Problems for the Monitoring and Control of Driver-Less Electric Transport Vehicles in the Underground Mines

Abstract

:1. Introduction and Background

1.1. Retrospective: The Development of Driver-Less Technology

1.2. Retrospective: Literature Recommendations for the Readers

1.3. Retrospective: Driver-Less Technology in the Industrial Transportation

1.4. Retrospective: Driver-Less Technology in the Underground Transportation

2. Idea and Design

2.1. The Comparison of ZigBee WSN Technology and Other Technologies

2.2. The Comparison of Communication-Based Train Control (CBTC) System and Other Technologies

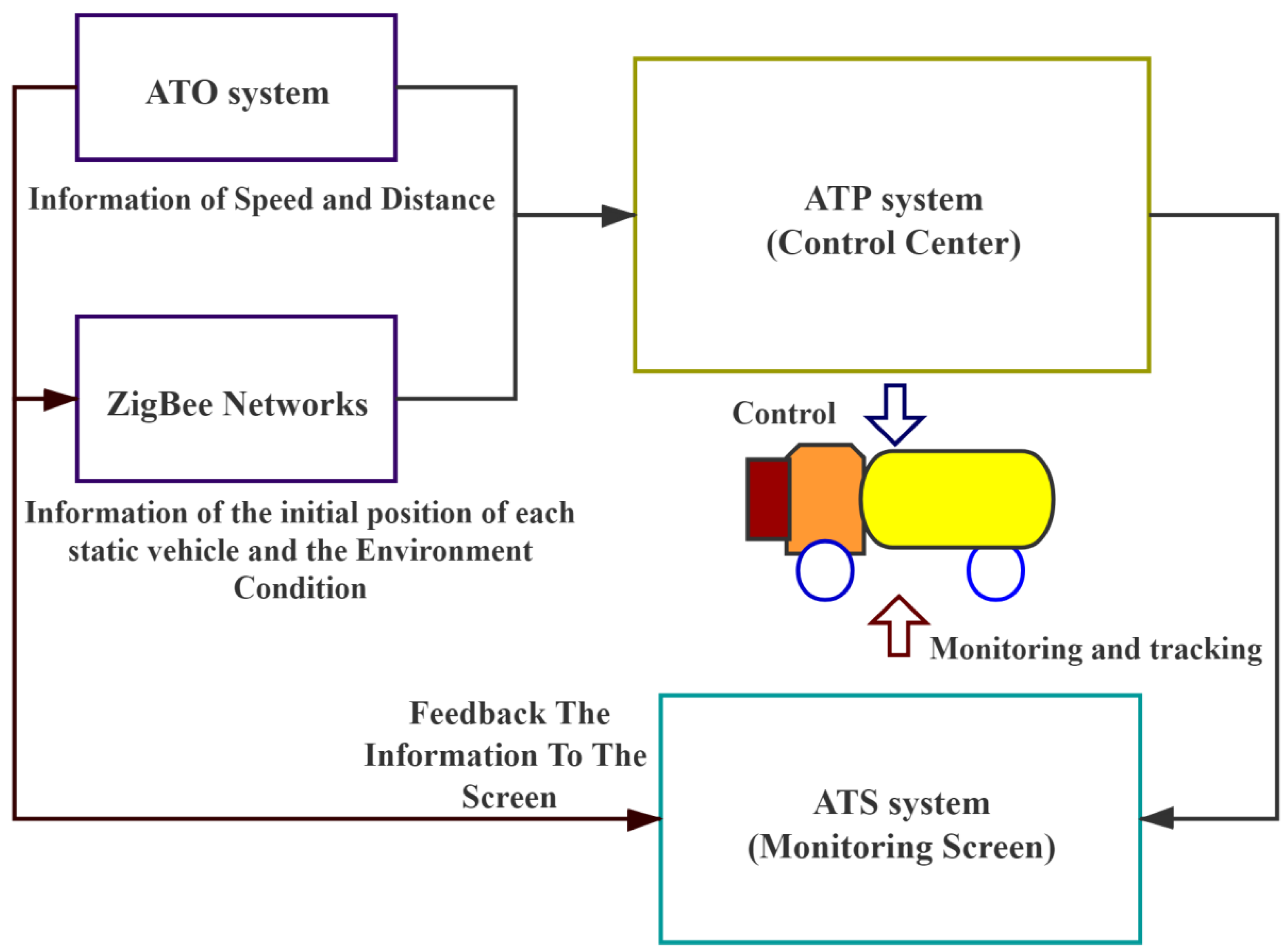

2.3. Idea: System Integration

- The information transmission function from the ATO system and ZigBee WSN.

- The control function from the ATP system.

- The monitoring function from the ATS system.

- The ATO system of the CBTC system collects the speed and distance information and sends it to the ATP system.

- The ATP system of the CBTC system controls each vehicle in the underground mine according to the information provided by the ATO system.

- The ZigBee WSN collects the initial position of each static vehicle and monitors the temperature, humidity, and concentration of harmful gases in the underground environment.

- The information of the speed, distance, temperature, humidity, and concentration of harmful gases will be fed back to the screen of the ATS system, and the running process of the vehicles will be also fed back to the screen.

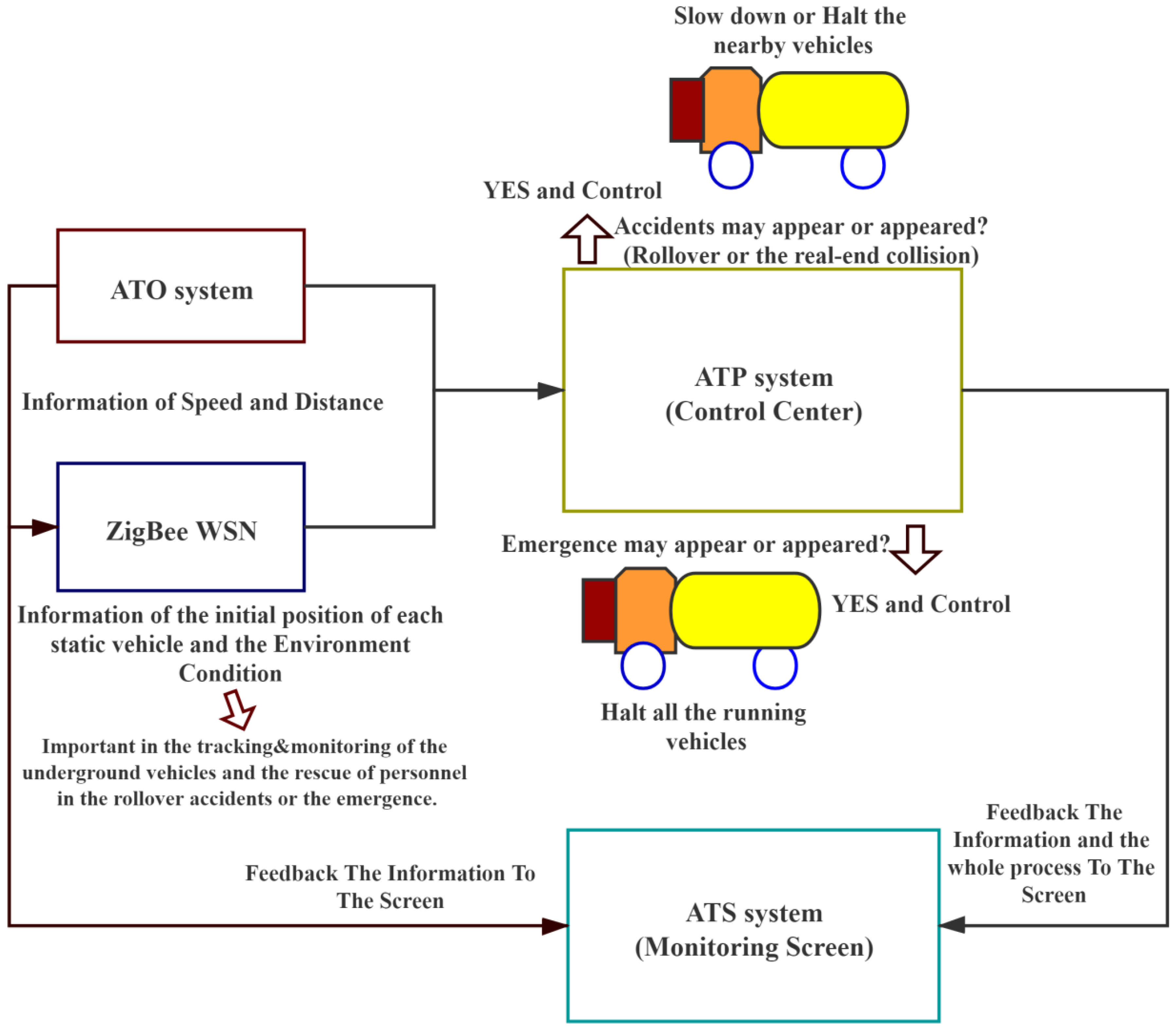

3. Concept: The Methods to Solve the Practical Problems in the Mining Engineering Projects

3.1. Vehicle Safety Problems

3.2. Vehicle Scheduling Problems

4. The Work for the Next Step

5. Discussion and Outlook

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cheon, S. An Overview of Automated Highway Systems (AHS) and the Social and Institutional Challenges They Face; University of California Transportation Center Working Papers; Springer: Berkeley, CA, USA, 2003. [Google Scholar]

- Goto, Y.; Stentz, A. The CMU system for mobile robot navigation. In Proceedings of the 1987 IEEE International Conference on Robotics and Automation, Raleigh, NC, USA, 31 March–3 April 1987; IEEE: Montreal, QC, Canada, 1987; pp. 99–105. [Google Scholar]

- Goto, Y.; Stentz, A. Mobile Robot Navigation: The CMU System. IEEE Expert 1987, 2, 44–54. [Google Scholar] [CrossRef] [Green Version]

- Parker, A.; Thomas, D.; Siewiorek, D.; Barbacci, M.; Hafer, L. The CMU Design Automation System: An Example of Automated Data Path Design. In Twenty-five years of electronic design automation; Association for Computing Machinery: New York, NY, USA, 1988; pp. 531–538. [Google Scholar] [CrossRef] [Green Version]

- Stouffer, R. Happy Motoring?: CMU Developing New Propulsion System. Pittsburgh Bus. Times-J. 1989, 8, 1. [Google Scholar]

- Carley, L.; Garrod, D.; Harjani, R.; Kelly, J.; Lim, T.; Ochotta, E.; Rutenbar, R. ACACIA: The CMU analog design system. In Proceedings of the 1989 IEEE Custom Integrated Circuits Conference, San Diego, CA, USA, 15–18 May 1989; pp. 4.3/1–4.3/5. [Google Scholar]

- Anonymous. SICK laser sensors guide driverless vehicles. Mater. Handl. Manag. 2005, 60, 9. [Google Scholar]

- Zhang, T.; Liu, X.; Mei, T.; Tang, G.; Li, B.; Wang, X. A novel platform for simulation and evaluation of intelligent behavior of driverless vehicle. In Proceedings of the 2008 IEEE International Conference on Vehicular Electronics and Safety, Blackwell Inn, OI, USA, 22–24 September 2008; pp. 237–240. [Google Scholar]

- Womack, B. Google Unveils Driverless Vehicle Prototypes. Mint (New Delhi, India), 28 May 2014. [Google Scholar]

- Anonymous. The other driverless VEHICLE: Trials of autonomous cars by Uber and Waymo are grabbing the headlines, but this kind of technology also promises to transform industrial machinery. Eng. Des. 2020, 46, 20. [Google Scholar]

- Anonymous. Waymo Plans to Offer Completely Driverless Vehicles. Auto Business News, 11 October 2019. [Google Scholar]

- Leggett, D. Ford and Baidu Announce Joint Autonomous Vehicle Testing. Just-Auto.Com, 2 November 2018. [Google Scholar]

- Legacy, C.; Ashmore, D.; Scheurer, J.; Stone, J.; Curtis, C. Planning the driverless city. Transp. Rev. 2019, 39, 84–102. [Google Scholar] [CrossRef]

- Levy, A. Go green, go driverless. Nature (London) 2015. [Google Scholar] [CrossRef]

- McGee, P. Driverless Car Groups Look Past the Engineering Challenge. Financial Time, 24 November 2019. [Google Scholar]

- Anonymous. DRIVERLESS. States News Service, 14 March 2019. [Google Scholar]

- Anonymous. Driverless car coming. Eng. Rev. 2014, 39, 18. [Google Scholar]

- Anonymous. Driverless CARRIAGES. Eng. Des. 2020, 46, 20. [Google Scholar]

- Salonen, A.; Haavisto, N. Towards Autonomous Transportation. Passengers’ Experiences, Perceptions and Feelings in a Driverless Shuttle Bus in Finland. Sustainability 2019, 11, 588. [Google Scholar] [CrossRef] [Green Version]

- Anonymous. Could Driverless Cars Improve Life for People with Disabilities? -BYLN- Ashley Halsey III The Washington Post. Daily Herald, 3 December 2017. [Google Scholar]

- Blau, M.; Akar, G.; Nasar, J. Driverless vehicles’ potential influence on bicyclist facility preferences. Int. J. Sustain. Transp. 2018, 12, 665–674. [Google Scholar] [CrossRef]

- Allan, D. Driverless Cars. Herald (Glasgow Scotland), 1 January 2020. [Google Scholar]

- Bissell, D.; Birtchnell, T.; Elliott, A.; Hsu, E.L. Autonomous automobilities: The social impacts of driverless vehicles. Curr. Sociol. 2018, 68, 116–134. [Google Scholar] [CrossRef]

- Sanguinetti, E.R. Planning for the Driverless Future: As roads dominated by driverless cars become an increasing reality, plaintiff auto attorneys should prepare now for likely changes to their practices and their clients’ needs. Trial 2018, 54, 50. [Google Scholar]

- Talley, E.L. Is the Future of Law a Driverless Car? Assessing How the Data Analytics Revolution Will Transform Legal Practice. Ssrn Electron. J. 2017, 174, 183–205. [Google Scholar] [CrossRef] [Green Version]

- Forlano, L. Stabilizing/Destabilizing the Driverless City: Speculative Futures and Autonomous Vehicles. Int. J. Commun. (Online) 2019, 13, 2811. [Google Scholar]

- Wu, B.; Tang, Y.; Yan, X.; Soares, C.G. Bayesian Network modelling for safety management of electric vehicles transported in RoPax ships. Reliab. Eng. Syst. Saf. 2021, 209, 107466. [Google Scholar] [CrossRef]

- Ferrandino, E.; Capillo, A.; Mascioli, F.; Rizzi, A. Nanogrids: A Smart Way to Integrate Public Transportation Electric Vehicles into Smart Grids. In Proceedings of the 12th International Joint Conference on Computational Intelligence—IJCCI 2020, Budapest, Hungary, 2–4 November 2020; Volume 2020, pp. 512–520. [Google Scholar] [CrossRef]

- Hoff, E.B.; Sarker, B.R. An overview of path design and dispatching methods for automated guided vehicles. Integr. Manuf. Syst. 1998, 9, 296–307. [Google Scholar] [CrossRef]

- Barshick, C.M.; Helms, M.M. Automated guided vehicles drive aluminum manufacturing into the future. Prod. Inventory Manag. J. 2001, 42, 22. [Google Scholar]

- Bellamy, D.; Pravica, L. Assessing the impact of driverless haul trucks in Australian surface mining. Resour. Policy 2011, 36, 149–158. [Google Scholar] [CrossRef]

- Bartley, R. Trucking Industry, Military Test Driverless Vehicles. Fiercemobileit, 17 June 2014. [Google Scholar]

- Ohashi, F.; Kaminishi, K.; Heredia, J.D.F.; Kato, H.; Ogata, T.; Hara, T.; Ota, J. Realization of heavy object transportation by mobile robots using handcarts and outrigger. ROBOMECH J. 2016, 3, 27. [Google Scholar] [CrossRef]

- Sakuyama, T.; Heredia, J.D.F.; Ogata, T.; Hara, T.; Ota, J. Object Transportation by Two Mobile Robots with Hand Carts. Int. Sch. Res. Not. 2014, 2014, 1–15. [Google Scholar] [CrossRef]

- Brown, E. Driverless Forklifts. NASA Tech. Briefs 2019, 43, A16–A19. [Google Scholar]

- Burke, K. Plants become wall-e world; Self-driving vehicles ferry parts around factory floors. Automot. News 2017, 91, 16. [Google Scholar]

- Hjalmarsson-Jordanius, A.; Edvardsson, M.; Romell, M.; Isacson, J.; Aldén, C.; Sundin, N. Autonomous Transport: Transforming Logistics through Driverless Intelligent Transportation. Transp. Res. Rec. 2018, 2672, 24–33. [Google Scholar] [CrossRef]

- Benter, A.; Antolovich, M.; Moore, W. Determining bulk density of mine rock piles using ground penetrating radar frequency downshift. In Proceedings of the 2011 6th International Workshop on Advanced Ground Penetrating Radar (IWAGPR), Aachen, Germany, 22–24 June 2011; pp. 1–6. [Google Scholar] [CrossRef]

- Meech, J.; Parreira, J. An interactive simulation model of human drivers to study autonomous haulage trucks. Procedia Comput. Sci. 2011, 6, 118–123. [Google Scholar] [CrossRef] [Green Version]

- Korane, K.J. Drones come down to Earth: Driverless trucks foretell the future of mining. Mach. Des. 2013, 85, 58. [Google Scholar]

- Murden, S. Autonomous Vehicles Lead Rio Tinto and BHP Billiton into Cruise Control. Australian Mining, 5 November 2015. [Google Scholar]

- Anonymous. Plugging-in for Productivity. Eng. Mining J. (1926) 2016, 217, 52. [Google Scholar]

- Shiers, W.; Barnett, C. Automatic for the people: Driverless trucks is a hot topic among manufacturers at the moment, and while some believe it won’t be long before drivers are replaced, others are more conservative. Commercial Motor. 2016, 225, 38–41. [Google Scholar]

- Cheng, X. Application of SINS/DGPS integrated navigation technology in unmanned mining vehicles. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 569, p. 42001. [Google Scholar]

- Doran, B.; Lopez, M. Autonomous vehicles and msha. Pit Quarry 2019, 111, 72. [Google Scholar]

- Dong, L.; Sun, D.; Han, G.; Li, X.; Hu, Q.; Shu, L. Velocity-Free Localization of Autonomous Driverless Vehicles in Underground Intelligent Mines. IEEE Trans. Veh. Technol. 2020, 69, 9292–9303. [Google Scholar] [CrossRef]

- Dash, A.K.; Bhattcharjee, R.; Paul, P.; Tikader, M. Study and Analysis of Accidents Due to Wheeled Trackless Transportation Machinery in Indian Coal Mines—Identification of Gap in Current Investigation System. Procedia Earth Planet. Sci. 2015, 11, 539–547. [Google Scholar] [CrossRef] [Green Version]

- Ghaddar, M.; Ben Mabrouk, I.; Nedil, M.; Hettak, K.; Talbi, L. Deterministic Modeling of 5G Millimeter-Wave Communication in an Underground Mine Tunnel. IEEE Access 2019, 7, 116519–116528. [Google Scholar] [CrossRef]

- Ma, L. Study on Intelligent Mine Based on the Application of 5G Wireless Communication System. In Proceedings of the IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2020; Volume 558, p. 32050. [Google Scholar]

- Kulich, J.; Bleibinhaus, F. Fault Detection with Crosshole and Reflection Geo-Radar for Underground Mine Safety. Geosciences 2020, 10, 456. [Google Scholar] [CrossRef]

- Hargrave, C.; Munday, L.; Kennedy, G.; De Kock, A. Mine Machine Radar Sensor for Emergency Escape. Resources 2020, 9, 16. [Google Scholar] [CrossRef] [Green Version]

- Ikeda, H.; Kawamura, Y.; Tungol, Z.P.; Moridi, M.A. Implementation and Verification of a Wi-Fi Ad Hoc Communication System in an Underground Mine Environment. J. Min. Sci. 2019, 55, 505–514. [Google Scholar] [CrossRef]

- Min, C.; Jinhao, Z. The Application of WiFi 6 Technology in Underground Mine. In Proceedings of the IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 687, p. 12153. [Google Scholar]

- Moridi, M.A.; Kawamuraa, Y.; Sharifzadeha, M.; Chandab, E.K.; Jang, H. An investigation of underground monitoring and communication system based on radio waves attenua-tion using ZigBee. Tunn. Undergr. Space Technol. 2014, 43, 362–369. [Google Scholar] [CrossRef]

- Moridi, M.A.; Sharifzadeh, M.; Kawamura, Y.; Jang, H.D. Development of wireless sensor networks for underground communication and monitoring systems (the cases of underground mine environments). Tunn. Undergr. Space Technol. 2018, 73, 127–138. [Google Scholar] [CrossRef] [Green Version]

- Anonymous. Helicomm and Venture Design Services Announced Text Messaging Mobile Communicator. Business Wire, 6 December 2007. [Google Scholar]

- Chen, S.; Yao, J.; Wu, Y. Analysis of the Power Consumption for Wireless Sensor Network Node Based on Zigbee. Procedia Eng. 2012, 29, 1994–1998. [Google Scholar] [CrossRef] [Green Version]

- Uradzinski, M.; Guo, H.; Liu, X.; Yu, M. Advanced Indoor Positioning Using Zigbee Wireless Technology. Wirel. Pers. Commun. 2017, 97, 6509–6518. [Google Scholar] [CrossRef]

- Mohammad, M.; Kawamura, A.; Sharifzadeh, Y.; Chanda, M.; Knox, E.; Markus, W.; Hyongdoo, J.; Hirokazu, O. Development of underground mine monitoring and communication system integrated ZigBee and GIS. Int. J. Min. Sci. Technol. 2015, 25, 811–818. [Google Scholar]

- Li-Min, Y.; Anqi, L.; Zheng, S.; Hui, L. Design of Monitoring System for Coal Mine Safety Based on Wireless Sensor Network. In Proceedings of the 2008 IEEE/ASME International Conference on Mechtronic and Embedded Systems and Applications, Beijing, China, 12–15 October 2008; pp. 409–414. [Google Scholar]

- Hongjiang, H.; Shuangyou, W. The Application of ARM and ZigBee Technology Wireless Networks in Monitoring Mine Safety System. In Proceedings of the 2008 ISECS International Colloquium on Computing, Communication, Control, and Management, Guangzhou, China, 3–4 August 2008; Volume 2, pp. 430–433. [Google Scholar] [CrossRef]

- Pei, Z.; Deng, Z.; Xu, S.; Xu, X. Anchor-Free Localization Method for Mobile Targets in Coal Mine Wireless Sensor Networks. Sensors 2009, 9, 2836–2850. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chehri, A.; Mouftah, H.; Fortier, P.; Aniss, H. Experimental Testing of IEEE801.15.4/ZigBee Sensor Networks in Confined Area. In Proceedings of the 2010 8th Annual Communication Networks and Services Research Conference, Montreal, QC, Canada, 11–14 May 2010; pp. 244–247. [Google Scholar]

- Bian, J. Application of the wireless sensor network based on ZigBee technology in monitoring system for coal mine safety. In Proceedings of the 2010 International Conference on Computer, Mechatronics, Control and Electronic Engineering, Changchun, China, 24–26 August 2010; Volume 5, pp. 204–206. [Google Scholar]

- Li, Q.; Zhao, H.; Liu, P. Research on Robot Network Communication System in Underground Coal Mine Based on ZigBee. In Proceedings of the 2010 Third International Symposium on Information Processing, Qingdao, China, 15–17 October 2010; pp. 22–24. [Google Scholar] [CrossRef]

- Cao, Z.; Lu, H.; He, Q. Research of underground staff positioning system based on wireless sensor network. In Proceedings of the 2011 International Conference on Computer Science and Service System (CSSS), Nanjing, China, 13 April 2011; pp. 600–603. [Google Scholar]

- Jiang, W.; Yang, F. Positioning Algorithm of Underground Personnel Based on ZigBee Technology. Appl. Mech. Mater. 2014, 532, 121–125. [Google Scholar] [CrossRef]

- Wang, D.H.; Zhang, Q.Q.; Sun, Y.F. Design of Wireless Voice Communication System in Underground Coal Mine Based on ZigBee. Appl. Mech. Mater. 2014, 548–549, 1402–1406. [Google Scholar] [CrossRef]

- Liu, Q.; Chu, Y.Q.; Han, X. Research on MCL for Mobile Underground Miner Location System Based on ZigBee. Appl. Mech. Mater. 2015, 713–715, 2325–2328. [Google Scholar] [CrossRef]

- Ge, B.; Wang, K.; Han, J.; Zhao, B. Improved RSSI Positioning Algorithm for Coal Mine Underground Locomotive. J. Electr. Comput. Eng. 2015, 2015, 1–8. [Google Scholar] [CrossRef]

- Abane, A.; Daoui, M.; Bouzefrane, S.; Muhlethaler, P. NDN-over-ZigBee: A ZigBee support for Named Data Networking. Futur. Gener. Comput. Syst. 2019, 93, 792–798. [Google Scholar] [CrossRef]

- Chi, Z.; Li, Y.; Huang, Z.; Sun, H.; Zhu, T. Simultaneous Bi-Directional Communications and Data Forwarding Using a Single ZigBee Data Stream. In Proceedings of the IEEE/ACM Transactions on Networking, Paris, France, 29 April–2 May 2021; pp. 1–13. [Google Scholar]

- Shariff, F.; Rahim, N.A.; Hew, W.P. Zigbee-based data acquisition system for online monitoring of grid-connected pho-tovoltaic system. Expert Syst. Appl. 2015, 42, 1730–1742. [Google Scholar] [CrossRef]

- Zhu, L.; Li, Y.; Yu, F.R.; Ning, B.; Tang, T.; Wang, X. Cross-Layer Defense Methods for Jamming-Resistant CBTC Systems. IEEE Trans. Intell. Transp. Syst. 2020, 1–13. [Google Scholar] [CrossRef]

- Wang, H.; Yu, F.R.; Zhu, L.; Tang, T.; Ning, B. Finite-State Markov Modeling of Leaky Waveguide Channels in Communication-Based Train Control (CBTC) Systems. IEEE Commun. Lett. 2013, 17, 1408–1411. [Google Scholar] [CrossRef]

- Bantin, C.; Siu, J. Radio CBTC for the Las Vegas Monorail. Wit Trans. Built Environ. 2005, 77, 9. [Google Scholar]

- Bin, N.; Tao, T.; Min, Q.K.; Hai, G.C. CBTC (Communication Based Train Control): System and development. In Geo-Environment and Landscape Evolution III; WIT Press: Southampton, UK, 2006; Volume 88. [Google Scholar]

- Wang, H.; Yu, F.R.; Zhu, L.; Tang, T.; Ning, B. Finite-state Markov modeling of tunnel channels in communication-based train control (CBTC) systems. In Proceedings of the 2013 IEEE International Conference on Communications (ICC), Budapest, Hungary, 9–13 June 2013; pp. 5047–5051. [Google Scholar]

- Wang, H.; Yu, F.R.; Zhu, L.; Tang, T.; Ning, B. Finite-State Markov Modeling for Wireless Channels in Tunnel Communication-Based Train Control Systems. In IEEE Trans. Intell. Transp. Syst. 2014, 15, 1083–1090. [Google Scholar] [CrossRef]

- Briginshaw, D. Can CBTC cope with complex rail networks? Int. Railw. J. 2014, 54, 2. [Google Scholar]

- Guo, J.; Du, J.; Xu, D. Navigation and Positioning System Applied in Underground Driverless Vehicle Based on IMU. In Proceedings of the 2018 International Conference on Robots & Intelligent System (ICRIS), Changsha, China, 26–27 May 2018; pp. 13–16. [Google Scholar]

- Czaplewski, K.; Wisniewski, Z.; Specht, C.; Wilk, A.; Koc, W.; Karwowski, K.; Skibicki, J.; Dabrowski, P.; Czaplewski, B.; Specht, M.; et al. Application of Least Squares with Conditional Equations Method for Railway Track Inventory Using GNSS Observations. Sensors 2020, 20, 4948. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Hwang, Y.; Liao, Y.; Ku, Y.; Yu, C. A rail-to-rail ultra-wide bandwidth hybrid supply modulator for 5G applications with envelope tracking techniques. Int. J. Circuit Theory Appl. 2019, 47, 1907–1921. [Google Scholar] [CrossRef]

- Jia, X.; Shi, F.; Guan, Y.; Tang, S.; Tong, M. Zigbee-based wireless gas monitoring sensor alarm system in coal mine. IOP Conf. Ser. Earth Environ. Sci. 2020, 446, 22012. [Google Scholar]

- Dorthi, K.; Bayyapu, N.; Karra, R.C. Zigbee based Wireless Data Acquisition System for monitoring of partition stability above old underground coal workings. Arab. J. Geosci. 2020, 13, 1–11. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.; Zeng, Q.; Yang, Y.; Dai, Z. Research on Optimization Measures of Zigbee Network Connection in an Imitated Mine Fading Channel. Electronics (Basel) 2021, 10, 171. [Google Scholar]

- Celaya-Echarri, M.; Azpilicueta, L.; Lopez-Iturri, P.; Picallo, I.; Aguirre, E.; Astrain, J.J.; Villadangos, J.; Falcone, F. Radio Wave Propagation and WSN Deployment in Complex Utility Tunnel Environments. Sensors 2020, 20, 6710. [Google Scholar] [CrossRef]

- Blanco, J.; García, A.; Morenas, J.L. Design and Implementation of a Wireless Sensor and Actuator Network to Sup-port the Intelligent Control of Efficient Energy Usage. Sensors (Basel Switzerland) 2018, 18, 1892. [Google Scholar] [CrossRef] [Green Version]

- Fraga-Lamas, P.; Fernández-Caramés, T.M.; Castedo, L. Towards the Internet of Smart Trains: A Review on Industrial IoT-Connected Railways. Sensors (Basel Switzerland) 2017, 17, 1457. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X. Advanced Parabolic Equation-Based Propagation Modeling for Train Communication Systems. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 2018. [Google Scholar]

- Gao, P.; Liu, C.; Dong, H.; Zheng, W. A Dynamic Fault Tree Based CBTC Onboard ATP System Safety Analysis Method*. In Proceedings of the 2020 IEEE 23rd International Conference on Intelligent Transportation Systems (ITSC), Rhodes, Greece, 20–23 September 2020; pp. 1–7. [Google Scholar]

- Terblanche, S.; Bley, A. An improved formulation of the underground mine scheduling optimisation problem when considering selective mining. Orion (Johannesbg. South Afr.) 2015, 31, 1. [Google Scholar] [CrossRef]

- Åstrand, M.; Johansson, M.; Greberg, J. Underground mine scheduling modelled as a flow shop: A review of relevant work and future challenges. J. South. Afr. Inst. Min. Metall. 2018, 118, 1265. [Google Scholar] [CrossRef]

- Gamache, M.; Grimard, R.; Cohen, P. A shortest-path algorithm for solving the fleet management problem in under-ground mines. Eur. J. Oper. Res. 2005, 166, 497–506. [Google Scholar] [CrossRef]

- O’Sullivan, D.; Newman, A. Optimization-based heuristics for underground mine scheduling. Eur. J. Oper. Res. 2015, 241, 248–259. [Google Scholar] [CrossRef]

- Manríquez, F.; Pérez, J.; Morales, N. A simulation–Optimization framework for short-term underground mine production scheduling. Optim. Eng. 2020, 21, 939–971. [Google Scholar] [CrossRef]

- Yardimci, A.G.; Karpuz, C. Shortest path optimization of haul road design in underground mines using an evolutionary algorithm. Appl. Soft Comput. 2019, 83, 105668. [Google Scholar] [CrossRef]

- Nesbitt, P.; Blake, L.R.; Lamas, P.; Goycoolea, M.; Pagnoncelli, B.K.; Newman, A.; Brickey, A. Underground mine scheduling under uncertainty. Eur. J. Oper. Res. 2021. [Google Scholar] [CrossRef]

- Fathollahzadeh, K.; Asad, M.W.A.; Mardaneh, E.; Cigla, M. Review of Solution Methodologies for Open Pit Mine Production Scheduling Problem. Int. J. Min. Reclam. Env. 2021, 1–36. [Google Scholar] [CrossRef]

- Sotoudeh, F.; Nehring, M.; Kizil, M.; Knights, P. Integrated underground mining and pre-concentration systems; a critical review of technical concepts and developments. Int. J. Min. Reclam. Env. 2021, 35, 153–182. [Google Scholar] [CrossRef]

- Wolff, D. Driving on the Cutting Edge of Autonomous Vehicle Tech. MIT News, 25 February 2021. [Google Scholar]

- Anonymous. Agree on rulebook for testing, developing autonomous vehicles. Automot. News 2021, 95, 10. [Google Scholar]

- Chen, Q.; Xie, Y.; Guo, S.; Bai, J.; Shu, Q. Sensing System of Environmental Perception Technologies for Driverless Vehicle: A Review of State of the Art and Challenges. Sens. Actuators A Phys. 2021, 319, 112566. [Google Scholar] [CrossRef]

- Liu, X.; Yan, Y.; Gan, H. Research on pedestrian detection algorithm in driverless urban traffic environment. Matec Web Conf. 2021, 336, 06002. [Google Scholar] [CrossRef]

- Powell, J.P.; Fraszczyk, A.; Cheong, C.N.; Yeung, H.K. Potential Benefits and Obstacles of Implementing Driverless Train Operation on the Tyne and Wear Metro: A Simulation Exercise. Urban Rail Transit 2016, 2, 114–127. [Google Scholar] [CrossRef] [Green Version]

- Daly, J. Mining Minus the Miners; Forget Cars—The Driverless-Vehicle Revolution Is Happening Deep Underground; (Brief article); The Globe and Mail: Toronto, ON, Canada, 2017; p. 14. [Google Scholar]

- Fitzgerald, B. Driverless Trucks Head Deep Underground. The Australian, 3 December 2015; p. 19. [Google Scholar]

- Bascompta, M.; Castañón, A.M.; Sanmiquel, L.; Oliva, J. A GIS-based approach: Influence of the ventilation layout to the environmental conditions in an under-ground mine. J. Environ. Manag. 2016, 182, 525–530. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Mao, S.; Li, M.; Wang, S. A Tightly Coupled GIS and Spatiotemporal Modeling for Methane Emission Simulation in the Underground Coal Mine System. Appl. Sci. 2019, 9, 1931. [Google Scholar] [CrossRef] [Green Version]

- Zhou, K.; Yu, L.; Long, Z.; Mo, S. Local path planning of driverless car navigation based on jump point search method under urban environment. Future Internet 2017, 9, 51. [Google Scholar] [CrossRef] [Green Version]

- Yu, L.; Kong, D.; Shao, X.; Yan, X. A Path Planning and Navigation Control System Design for Driverless Electric Bus. IEEE Access 2018, 6, 53960–53975. [Google Scholar] [CrossRef]

- Anonymous. Autonomous Volvo Truck Testing in Regular Operations Underground. Just-Auto.Com, 8 September 2016. [Google Scholar]

- Stevenson, S.S. WaveSense Uses Ground-Penetrating Radar to Help Driverless Cars See. Xconomy [BLOG], 25 September 2018. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Wang, G.; Yu, H.; Wang, X. Engineering Project: The Method to Solve Practical Problems for the Monitoring and Control of Driver-Less Electric Transport Vehicles in the Underground Mines. World Electr. Veh. J. 2021, 12, 64. https://doi.org/10.3390/wevj12020064

Li S, Wang G, Yu H, Wang X. Engineering Project: The Method to Solve Practical Problems for the Monitoring and Control of Driver-Less Electric Transport Vehicles in the Underground Mines. World Electric Vehicle Journal. 2021; 12(2):64. https://doi.org/10.3390/wevj12020064

Chicago/Turabian StyleLi, Shuai, Guojun Wang, Haoxuan Yu, and Xinmin Wang. 2021. "Engineering Project: The Method to Solve Practical Problems for the Monitoring and Control of Driver-Less Electric Transport Vehicles in the Underground Mines" World Electric Vehicle Journal 12, no. 2: 64. https://doi.org/10.3390/wevj12020064