Experimental Study on Effects of Triggering Modes on Thermal Runaway Characteristics of Lithium-Ion Battery

Abstract

:1. Introduction

2. Thermal Abuse Experiments under Different Triggering Methods

2.1. Experimental Systems

2.2. Experiment Content

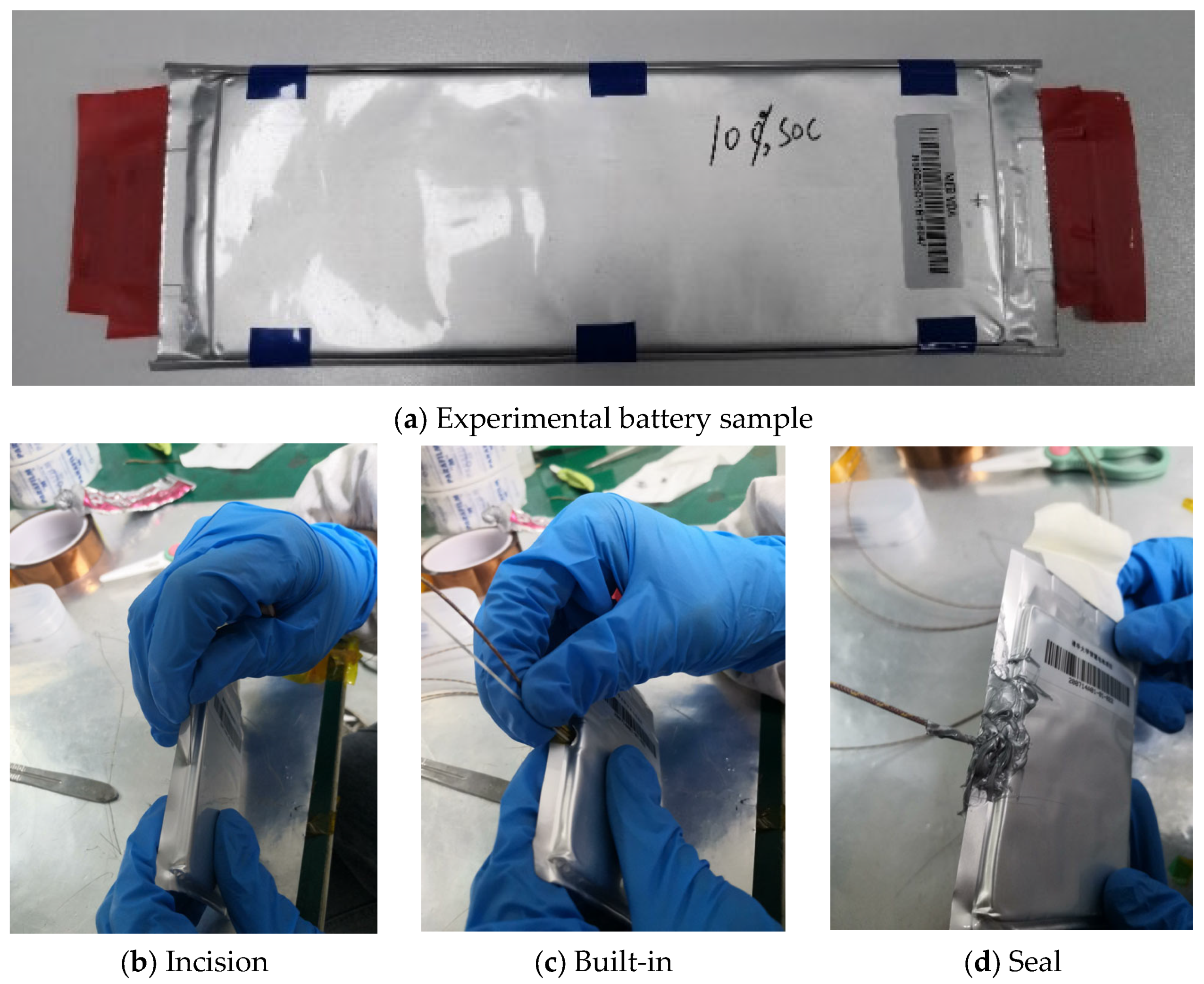

2.2.1. Lateral Nail Penetration Experiment

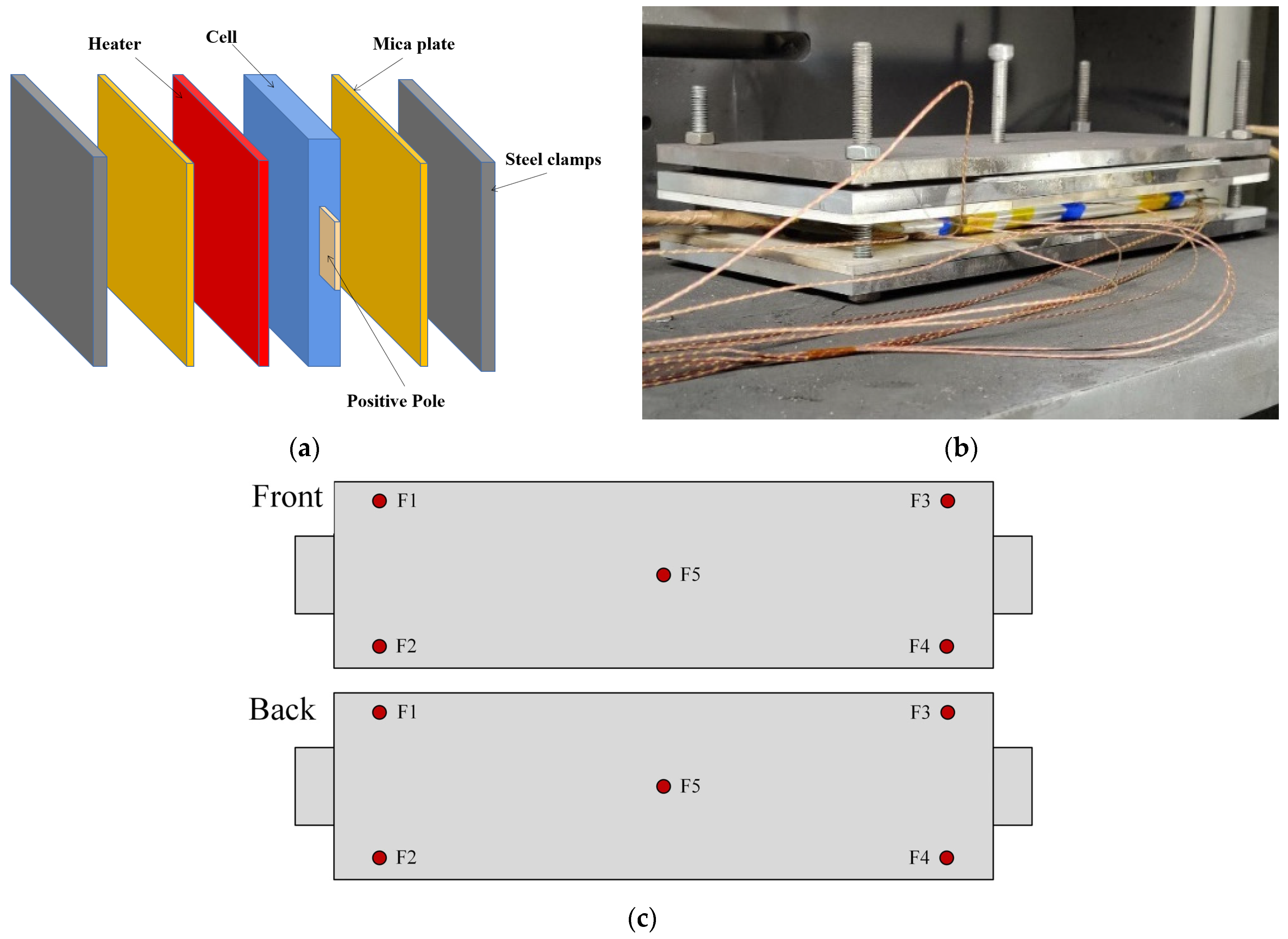

2.2.2. Lateral Heating Experiment

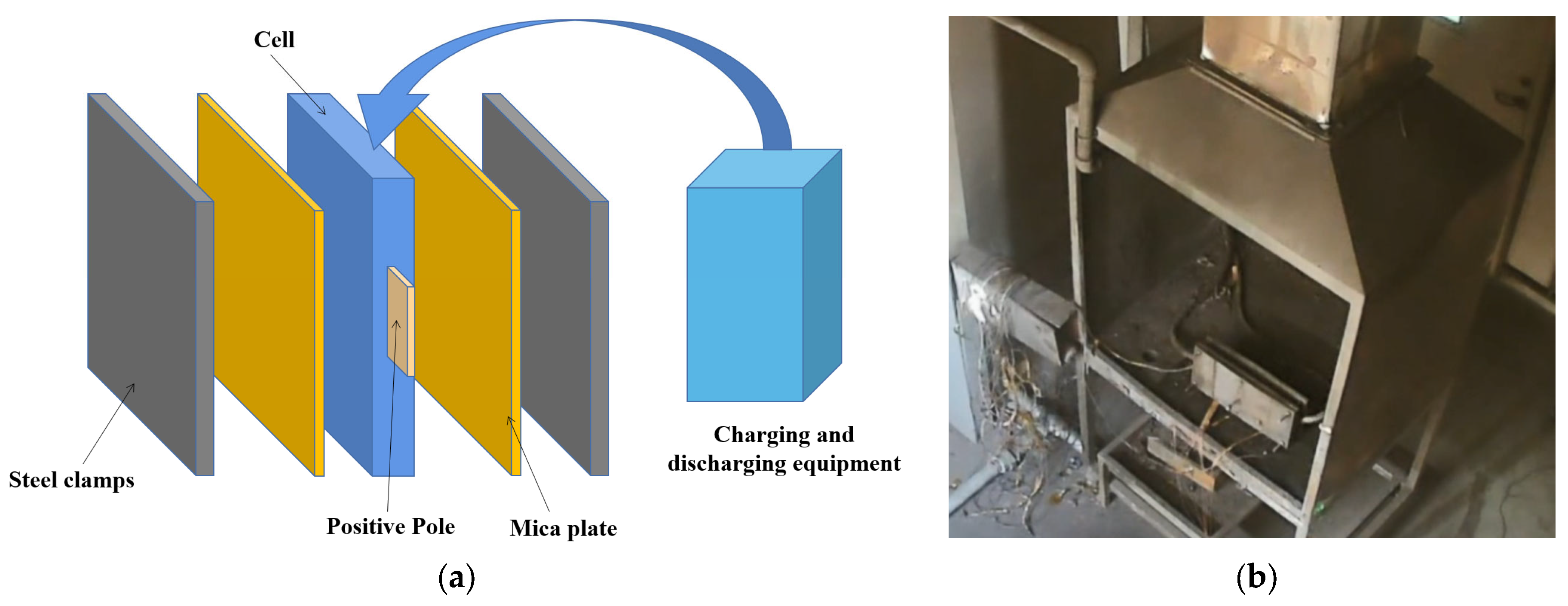

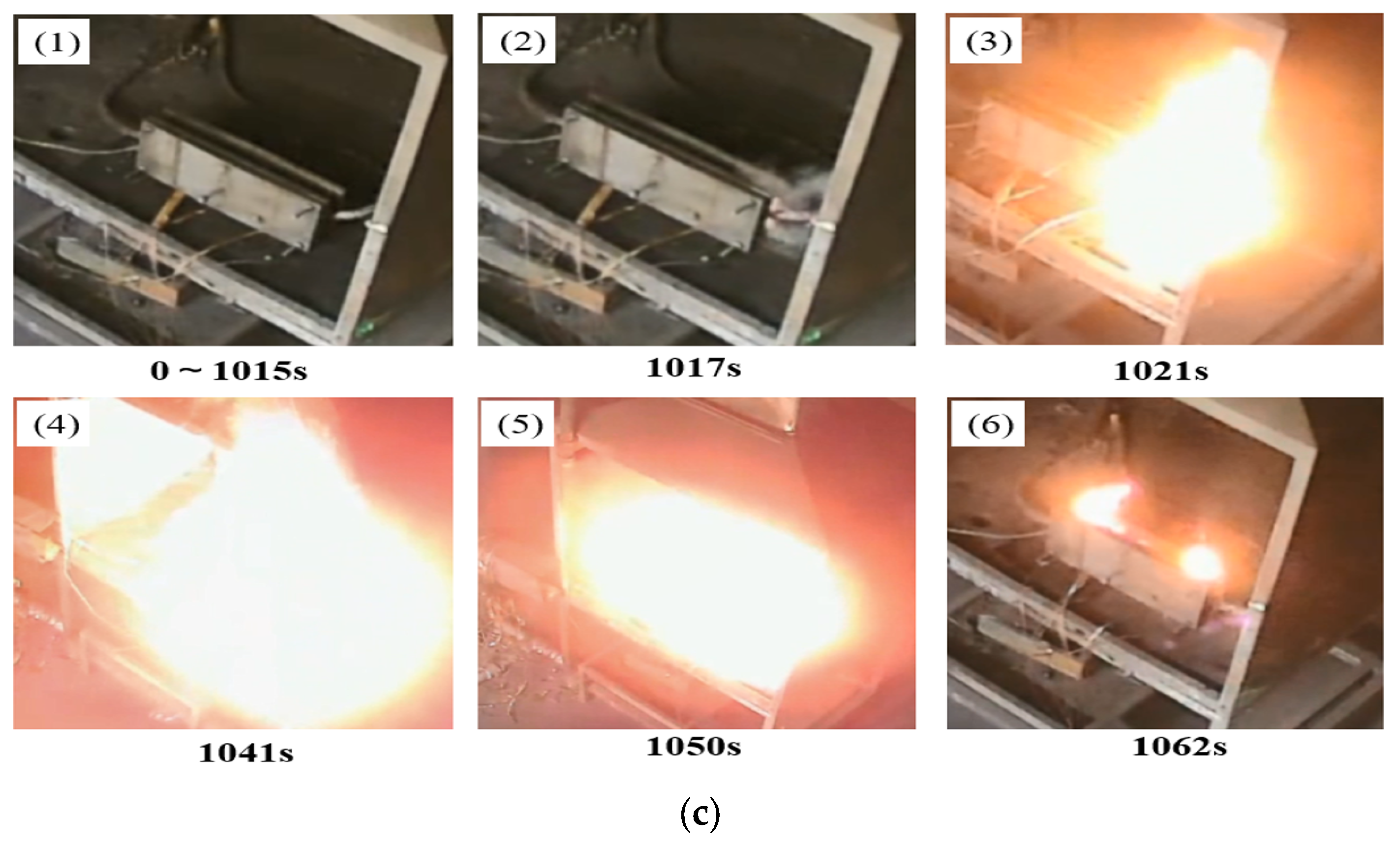

2.2.3. Overcharge Experiment

2.3. Experimental Evaluation Index

3. Analysis of Experimental Phenomenon and Results

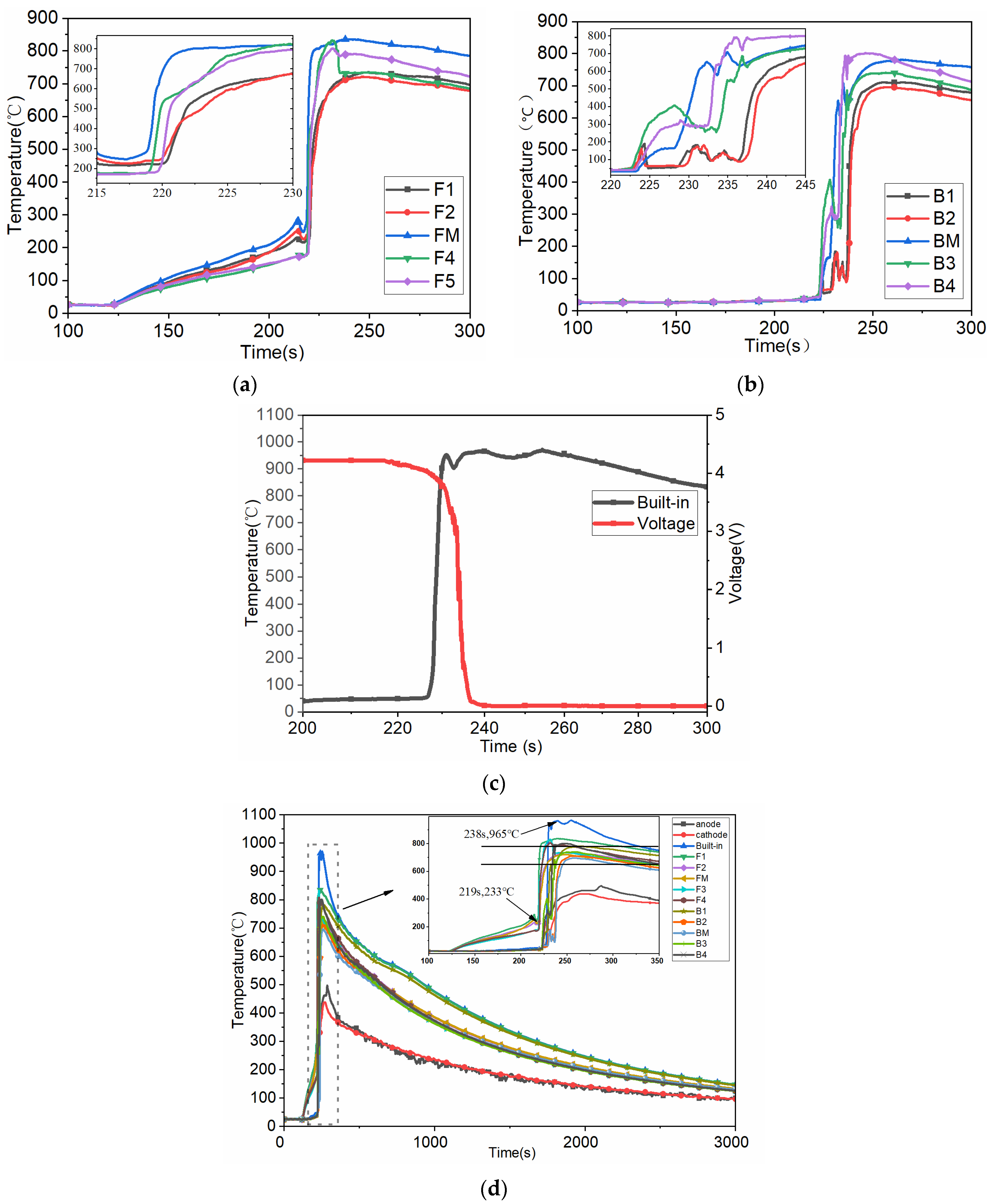

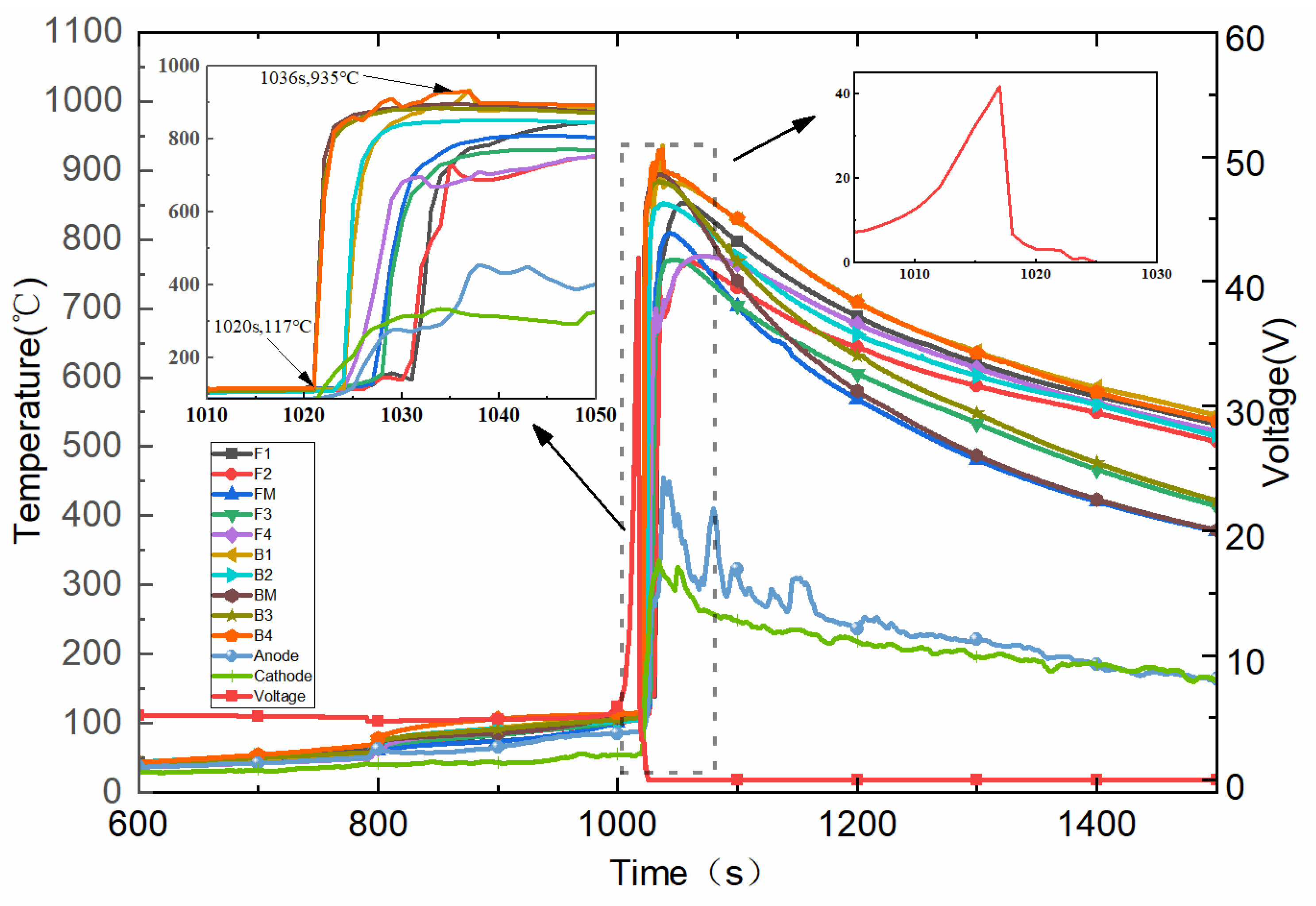

3.1. Phenomena under Different Abuse Methods

3.2. Analysis of Spreading Tendency under Different Abuse Methods

4. Comparison and Analysis of Battery Abuse with Different Triggering Methods

5. Conclusions

- (1)

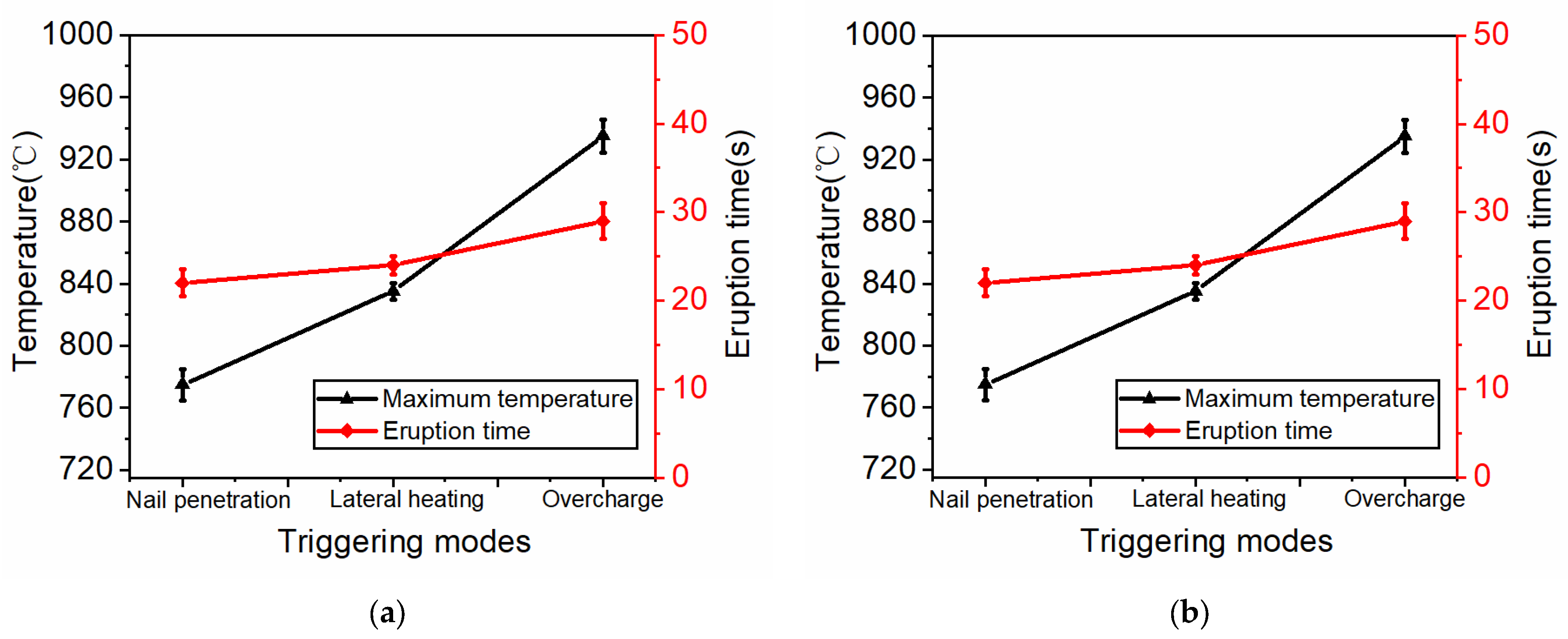

- The injection time and the maximum surface temperature are positively correlated with the energy input before thermal runaway. It is found that there is no additional energy input in the needle-triggering method. The peak temperature of the surface in the nail-triggering experiment is 774 °C, and the injection time is shorter when there is thermal runaway. Lateral heating will input energy to the battery in the form of thermal energy. The input energy is related to the heating time, and the maximum temperature of the battery surface reaches 835 °C. The overcharged battery thermal runaway trigger mode inputs energy into the battery in the form of electric energy, and the input energy is the most. Therefore, the eruption time is up to 29 s after thermal runaway, and the maximum temperature of the surface reaches 935 °C. Considering that the surface temperature of the battery is in direct contact with the adjacent battery during the battery-grouping process, when any position on the surface of the adjacent battery reaches the thermal runaway trigger temperature, it will cause thermal runaway spread. The maximum surface temperature of the battery in the most extreme cases should be considered, and corresponding thermal spread suppression measures should be taken. Under the same conditions, the intensity and destructiveness of the battery overcharge thermal runaway behavior are greater than the internal short-circuit thermal runaway caused by acupuncture and the overtemperature thermal runaway caused by thermal abuse. It shows that before the battery triggers thermal runaway, the more total energy stored inside the battery, the higher the degree of damage to the surrounding battery system.

- (2)

- The time of thermal runaway triggered by acupuncture is the shortest, the triggering temperature of thermal runaway is 42 °C, the thermal runaway triggered by overcharge needs 1020 s, the triggering temperature is 117 °C, and the triggering temperature of lateral heating thermal runaway is 233 °C. In the process of using a power battery, it is necessary to pay attention to the harm of battery thermal runaway caused by collision and extrusion in a short time.

- (3)

- According to the temperature curve, in the acupuncture experiment, the thermal diffuses from the nail position to other places. The trend of thermal runaway spread is an irregular semicircle. In the side-heating experiment, under the action of the side heating of the heater, the internal material near the heater first undergoes thermal runaway. In the overcharge experiment, according to the voltage curve, abnormal changes in voltage can be used as a judgment condition for overcharge thermal runaway. It is worth noting that there will be a voltage drop before thermal runaway occurs under different trigger conditions. There is a time difference between voltage anomaly and thermal runaway. Therefore, abnormal voltage can be regarded as an early warning to determine whether thermal runaway occurs. One should make full use of the reaction time and take corresponding thermal runaway blocking protective measures in time to avoid further diffusion of thermal runaway.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mallick, S.; Gayen, D. Thermal behaviour and thermal runaway propagation in lithium-ion battery systems—A critical review. J. Energy Storage 2023, 62, 106894. [Google Scholar] [CrossRef]

- Li, Y.; Liu, G.; Li, Z. Numerical modeling of thermal runaway in high-energy lithium-ion battery packs induced by multipoint heating. Case Stud. Therm. Eng. 2022, 38, 102335. [Google Scholar] [CrossRef]

- Yu, W.; Guo, Y.; Xu, S.; Yang, Y.; Zhao, Y.; Zhang, J. Comprehensive recycling of lithium-ion batteries: Fundamentals, pretreatment, and perspectives. Energy Storage Mater. 2022, 54, 172–220. [Google Scholar] [CrossRef]

- Lai, X.; Yi, W.; Cui, Y.; Qin, C.; Han, X.; Sun, T.; Zhou, L.; Zheng, Y. Capacity estimation of lithium-ion cells by combining model-based and da-ta-driven methods based on a sequential extended Kalman filter. Energy 2021, 216, 119233. [Google Scholar] [CrossRef]

- Liu, L.; Xu, J.; Wang, S.; Wu, F.; Li, H.; Chen, L. Practical evaluation of energy densities for sulfide solid-state batteries. eTransportation 2019, 1, 100010. [Google Scholar] [CrossRef]

- Michaelides, E.E.; Nguyen, V.N.; Michaelides, D.N. The effect of electric vehicle energy storage on the transition to renewable energy. Green Energy Intell. Transp. 2023, 2, 100042. [Google Scholar] [CrossRef]

- Chombo, P.V.; Laoonual, Y. A review of safety strategies of a Li-ion battery. J. Power Sources 2020, 478, 228649. [Google Scholar] [CrossRef]

- Sun, J.; Mao, B.; Wang, Q. Progress on the research of fire behavior and fire protection of lithium ion battery. Fire Saf. J. 2021, 120, 103119. [Google Scholar] [CrossRef]

- Brescia, V.; Degregori, G.; Maggi, D.; Hadro, D. An integrated vision of electric vehicles’ consumer behaviour: Mapping the practitioners to consolidate the research agenda. J. Clean. Prod. 2023, 410, 137210. [Google Scholar] [CrossRef]

- Feng, X.; Ren, D.; He, X.; Ouyang, M. Mitigating Thermal Runaway of Lithium-Ion Batteries. Joule 2020, 4, 743–770. [Google Scholar] [CrossRef]

- Lai, X.; Jin, C.; Yi, W.; Han, X.; Feng, X.; Zheng, Y.; Ouyang, M. Mechanism, modeling, detection, and prevention of the internal short circuit in lithium-ion batteries: Recent advances and perspectives. Energy Storage Mater. 2021, 35, 470–499. [Google Scholar] [CrossRef]

- Xiao, Y.; Yang, F.; Gao, Z.; Liu, M.; Wang, J.; Kou, Z.; Lin, Y.; Li, Y.; Gao, L.; Chen, Y.; et al. Review of mechanical abuse related thermal runaway models of lith-ium-ion batteries at different scales. J. Energy Storage 2023, 64, 107145. [Google Scholar] [CrossRef]

- Feng, X.; Ouyang, M.; Liu, X.; Lu, L.; Xia, Y.; He, X. Thermal runaway mechanism of lithium ion battery for electric vehicles: A review. Energy Storage Mater. 2018, 10, 246–267. [Google Scholar] [CrossRef]

- Fu, Y.; Lu, S.; Li, K.; Liu, C.; Cheng, X.; Zhang, H. An experimental study on burning behaviors of 18650 lithium ion batteries using a cone calorimeter. J. Power Sources 2015, 273, 216–222. [Google Scholar] [CrossRef]

- Lopez, C.F.; Jeevarajan, J.A.; Mukherjee, P.P. Characterization of Lithium-Ion Battery Thermal Abuse Behavior Using Experimental and Computational Analysis. J. Electrochem. Soc. 2015, 162, A2163–A2173. [Google Scholar] [CrossRef]

- Zhao, R.; Liu, J.; Gu, J. Simulation and experimental study on lithium ion battery short circuit. Appl. Energy 2016, 173, 29–39. [Google Scholar] [CrossRef]

- Guo, L.; Wang, Z.; Wang, J.; Luo, Q.; Liu, J. Effects of the environmental temperature and heat dissipation condition on the thermal runaway of lithium ion batteries during the charge-discharge process. J. Loss Prev. Process. Ind. 2017, 49, 953–960. [Google Scholar] [CrossRef]

- Wilke, S.; Schweitzer, B.; Khateeb, S.; Al-Hallaj, S. Preventing thermal runaway propagation in lithium ion battery packs using a phase change composite material: An experimental study. J. Power Sources 2017, 340, 51–59. [Google Scholar] [CrossRef]

- Shah, K.; Chalise, D.; Jain, A. Experimental and theoretical analysis of a method to predict thermal runaway in Li-ion cells. J. Power Sources 2016, 330, 167–174. [Google Scholar] [CrossRef]

- Chen, M.; Bai, F.; Song, W.; Lv, J.; Lin, S.; Feng, Z.; Li, Y.; Ding, Y. A multilayer electro-thermal model of pouch battery during normal discharge and internal short circuit process. Appl. Therm. Eng. 2017, 120, 506–516. [Google Scholar] [CrossRef]

- Lai, X.; Wang, S.; Wang, H.; Zheng, Y.; Feng, X. Investigation of thermal runaway propagation characteristics of lithium-ion battery modules under different trigger modes. Int. J. Heat Mass Transf. 2021, 171, 121080. [Google Scholar] [CrossRef]

- Feng, X.; Fang, M.; He, X.; Ouyang, M.; Lu, L.; Wang, H.; Zhang, M. Thermal runaway features of large format prismatic lithium ion battery using extended volume accelerating rate calorimetry. J. Power Sources 2014, 255, 294–301. [Google Scholar] [CrossRef]

- Wang, Q.; Sun, Q.; Ping, P.; Zhao, X.; Sun, J.; Lin, Z. Heat transfer in the dynamic cycling of lithium–titanate batteries. Int. J. Heat Mass Transf. 2016, 93, 896–905. [Google Scholar] [CrossRef]

- Huang, P.; Wang, Q.; Li, K.; Ping, P.; Sun, J. The combustion behavior of large scale lithium titanate battery. Sci. Rep. 2015, 5, 7788. [Google Scholar] [CrossRef]

- Ashok, B.; Kannan, C.; Mason, B.; Ashok, S.D.; Indragandhi, V.; Patel, D.; Wagh, A.S.; Jain, A.; Kavitha, C. Towards Safer and Smarter Design for Lithium-Ion-Battery-Powered Electric Vehicles: A Comprehensive Review on Control Strategy Architecture of Battery Management System. Energies 2022, 15, 4227. [Google Scholar] [CrossRef]

- Xu, C.; Feng, X.; Huang, W.; Duan, Y.; Chen, T.; Gao, S.; Lu, L.; Jiang, F.; Ouyang, M. Internal temperature detection of thermal runaway in lithium-ion cells tested by extend-ed-volume accelerating rate calorimetry. J. Energy Storage 2020, 31, 101670. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, Y.; Meng, J.; Sun, X.; Zhao, P.; Sun, P.; Zheng, B. Experimental Study on Effects of Triggering Modes on Thermal Runaway Characteristics of Lithium-Ion Battery. World Electr. Veh. J. 2023, 14, 270. https://doi.org/10.3390/wevj14100270

Dong Y, Meng J, Sun X, Zhao P, Sun P, Zheng B. Experimental Study on Effects of Triggering Modes on Thermal Runaway Characteristics of Lithium-Ion Battery. World Electric Vehicle Journal. 2023; 14(10):270. https://doi.org/10.3390/wevj14100270

Chicago/Turabian StyleDong, Yuanjin, Jian Meng, Xiaomei Sun, Peidong Zhao, Peng Sun, and Bin Zheng. 2023. "Experimental Study on Effects of Triggering Modes on Thermal Runaway Characteristics of Lithium-Ion Battery" World Electric Vehicle Journal 14, no. 10: 270. https://doi.org/10.3390/wevj14100270

APA StyleDong, Y., Meng, J., Sun, X., Zhao, P., Sun, P., & Zheng, B. (2023). Experimental Study on Effects of Triggering Modes on Thermal Runaway Characteristics of Lithium-Ion Battery. World Electric Vehicle Journal, 14(10), 270. https://doi.org/10.3390/wevj14100270