Neural Network PID-Based Preheating Control and Optimization for a Li-Ion Battery Module at Low Temperatures

Abstract

:1. Introduction

1.1. Review of Battery Thermal Management Methods at Low Temperatures

1.2. Motivation and Contributions of This Paper

1.3. Paper Organization

2. Preheating System and Simulation Analysis

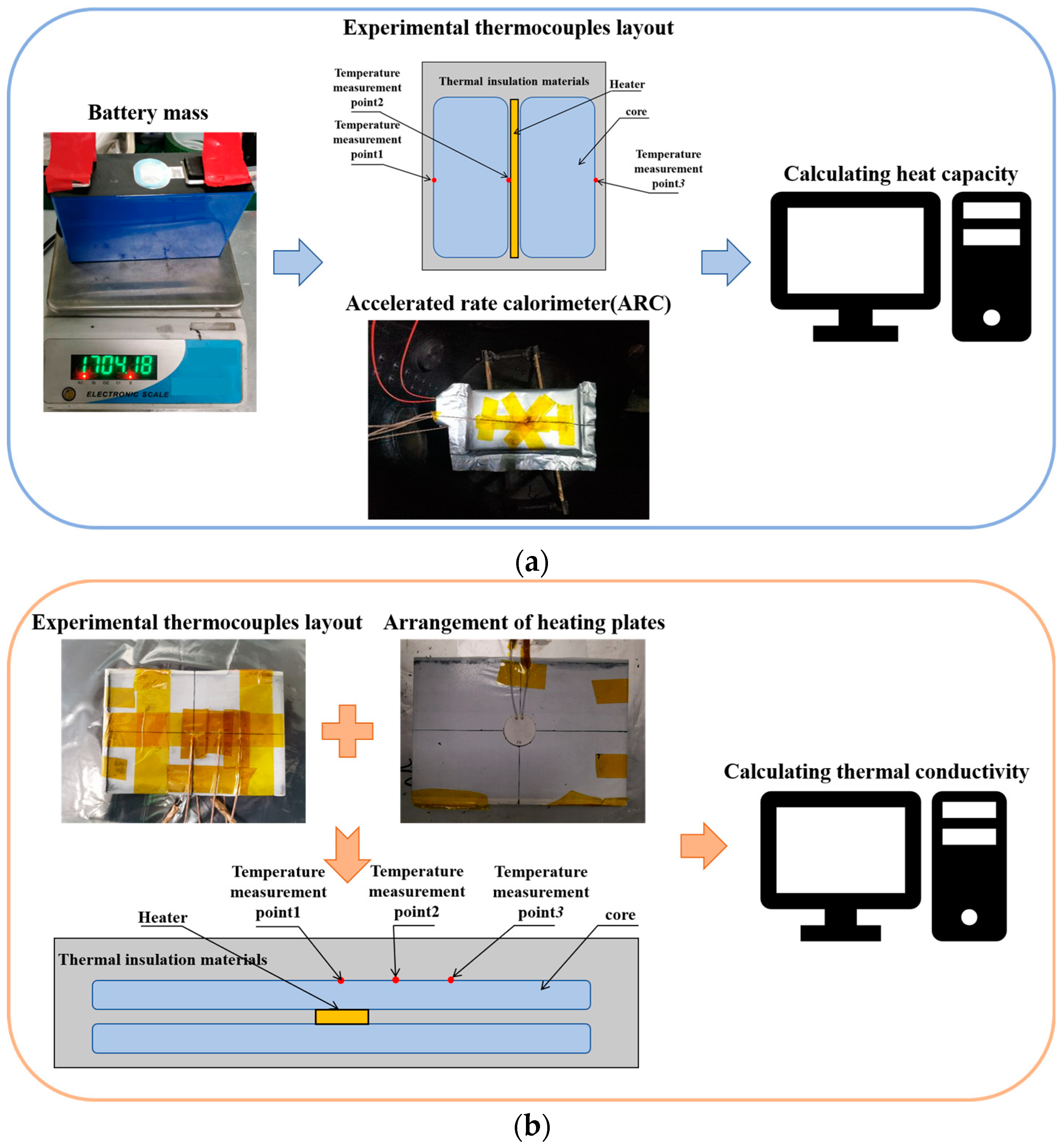

2.1. Experiment and Structure of the Preheating System

2.2. Grid Independence Test

2.3. Numerical Model

2.4. Simulation Analysis

3. Temperature Balancing Strategy and Result Analysis

3.1. Balancing Strategy

3.2. Neural Network PID Controller

4. Multi-Objective Optimization

4.1. Optimization Principle

4.2. Weight Coefficient Determination

4.3. Optimization Solution

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qin, P.; Sun, J.; Yang, X.; Wang, Q. Battery thermal management system based on the forced-air convection: A review. Etransportation 2021, 7, 100097. [Google Scholar] [CrossRef]

- Gehringer, D.; Kuthada, T.; Wagner, A. Thermal Management System of the UNICARagil Vehicles—A Comprehensive Overview. World Electr. Veh. J. 2023, 14, 6. [Google Scholar] [CrossRef]

- Kizilel, R.; Sabbah, R.; Selman, J.R.; Al-Hallaj, S. An alternative cooling system to enhance the safety of Li-ion battery packs. J. Power Sources 2009, 194, 1105–1112. [Google Scholar] [CrossRef]

- Pesaran, A.A.J.B.M. Battery thermal management in EV and HEVs: Issues and solutions. In Proceedings of the Advanced Automotive Battery Conference, Las Vegas, NV, USA, 6–8 February 2001. [Google Scholar]

- Pesaran, A.A.; Vlahinos, A.; Burch, S. Thermal Performance of EV and HEV Battery Modules and Packs; National Renewable Energy Laboratory: Golden, CO, USA, 1997. [Google Scholar]

- Yang, H.; Wang, P.; An, Y.; Shi, C.; Sun, X.; Wang, K.; Zhang, X.; Wei, T.; Ma, Y. Remaining useful life prediction based on denoising technique and deep neural network for lithium-ion capacitors. Etransportation 2020, 5, 100078. [Google Scholar] [CrossRef]

- Han, X.; Lu, L.; Zheng, Y.; Feng, X.; Li, Z.; Li, J.; Ouyang, M. A review on the key issues of the lithium ion battery degradation among the whole life cycle. Etransportation 2019, 1, 100005. [Google Scholar] [CrossRef]

- Dondelewski, O.; O’Connor, T.S.; Zhao, Y.; Hunt, I.A.; Holland, A.; Hales, A.; Offer, G.J.; Patel, Y. The role of cell geometry when selecting tab or surface cooling to minimise cell degradation. Etransportation 2020, 5, 100073. [Google Scholar] [CrossRef]

- Hales, A.; Prosser, R.; Diaz, L.B.; White, G.; Patel, Y.; Offer, G. The Cell Cooling Coefficient as a design tool to optimise thermal management of lithium-ion cells in battery packs. Etransportation 2020, 6, 100089. [Google Scholar] [CrossRef]

- Piao, N.; Gao, X.; Yang, H.; Guo, Z.; Hu, G.; Cheng, H.-M.; Li, F. Challenges and development of lithium-ion batteries for low temperature environments. Etransportation 2022, 11, 100145. [Google Scholar] [CrossRef]

- Li, Z.; Huang, J.; Liaw, B.Y.; Metzler, V.; Zhang, J. A review of lithium deposition in lithium-ion and lithium metal secondary batteries. J. Power Sources 2014, 254, 168–182. [Google Scholar] [CrossRef]

- Jaguemont, J.; Boulon, L.; Dubé, Y. A comprehensive review of lithium-ion batteries used in hybrid and electric vehicles at cold temperatures. Appl. Energy 2016, 164, 99–114. [Google Scholar] [CrossRef]

- Ouyang, M.; Chu, Z.; Lu, L.; Li, J.; Han, X.; Feng, X.; Liu, G. Low temperature aging mechanism identification and lithium deposition in a large format lithium iron phosphate battery for different charge profiles. J. Power Sources 2015, 286, 309–320. [Google Scholar] [CrossRef]

- Liu, H.; Wei, Z.; He, W.; Zhao, J. Thermal issues about Li-ion batteries and recent progress in battery thermal management systems: A review. Energy Convers. Manag. 2017, 150, 304–330. [Google Scholar] [CrossRef]

- Pesaran, A.A. Battery thermal models for hybrid vehicle simulations. J. Power Sources 2002, 110, 377–382. [Google Scholar] [CrossRef]

- Du, J.; Liu, Y.; Mo, X.; Li, Y.; Li, J.; Wu, X.; Ouyang, M. Impact of high-power charging on the durability and safety of lithium batteries used in long-range battery electric vehicles. Appl. Energy 2019, 255, 113793. [Google Scholar] [CrossRef]

- Tomaszewska, A.; Chu, Z.; Feng, X.; O’Kane, S.; Liu, X.; Chen, J.; Ji, C.; Endler, E.; Li, R.; Liu, L.; et al. Lithium-ion battery fast charging: A review. eTransportation 2019, 1, 100011. [Google Scholar] [CrossRef]

- Wu, S.; Xiong, R.; Li, H.; Nian, V.; Ma, S. The state of the art on preheating lithium-ion batteries in cold weather. J. Energy Storage 2019, 27, 101059. [Google Scholar] [CrossRef]

- Teng, H.; Ma, Y.; Yeow, K.; Thelliez, M. An Analysis of a Lithium-ion Battery System with Indirect Air Cooling and Warm-Up. SAE Int. J. Passeng. Cars-Mech. Syst. 2011, 4, 1343–1357. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, X.; Meng, H.; Guo, L.; Zhang, Z. Numerical analysis of the thermal performance of a liquid cooling battery module based on the gradient ratio flow velocity and gradient increment tube diameter. Int. J. Heat Mass Transf. 2021, 175, 121338. [Google Scholar] [CrossRef]

- Lee, D.-Y.; Cho, C.-W.; Won, J.-P.; Park, Y.C.; Lee, M.-Y. Performance characteristics of mobile heat pump for a large passenger electric vehicle. Appl. Therm. Eng. 2013, 50, 660–669. [Google Scholar] [CrossRef]

- Zhang, C.; Huang, J.; Sun, W.; Xu, X.; Li, Y. Research on the Influence of Liquid on Heat Dissipation and Heating Characteristics of Lithium-Ion Battery Thermal Management System. World Electr. Veh. J. 2022, 13, 68. [Google Scholar] [CrossRef]

- Hu, X.; Zheng, Y.; Howey, D.A.; Perez, H.; Foley, A.; Pecht, M. Battery warm-up methodologies at subzero temperatures for automotive applications: Recent advances and perspectives. Prog. Energy Combust. Sci. 2020, 77, 100806. [Google Scholar] [CrossRef]

- Salunkhe, P.B.; Shembekar, P.S. A review on effect of phase change material encapsulation on the thermal performance of a system. Renew. Sustain. Energy Rev. 2012, 16, 5603–5616. [Google Scholar] [CrossRef]

- Huang, D.; Chen, Z.; Zhou, S. Model prediction-based battery-powered heating method for series-connected lithium-ion battery pack working at extremely cold temperatures. Energy 2021, 216, 119236. [Google Scholar] [CrossRef]

- Moria, H.; Pourhedayat, S.; Dizaji, H.S.; Abusorrah, A.M.; Abu-Hamdeh, N.H.; Wae-Hayee, M. Exergoeconomic analysis of a Peltier effect air cooler using experimental data. Appl. Therm. Eng. 2021, 186, 116513. [Google Scholar] [CrossRef]

- Harmon, T.; Cahn, J.; Logan, M. Measurement of Thermal Conductivity by Utilization of the Peltier Effect. J. Appl. Phys. 1959, 30, 1351–1359. [Google Scholar] [CrossRef]

- Enescu, D.; Virjoghe, E.O. A review on thermoelectric cooling parameters and performance. Renew. Sustain. Energy Rev. 2014, 38, 903–916. [Google Scholar] [CrossRef]

- Yang, X.-G.; Liu, T.; Wang, C.-Y. Innovative heating of large-size automotive Li-ion cells. J. Power Sources 2017, 342, 598–604. [Google Scholar] [CrossRef]

- Zhang, G.; Ge, S.; Xu, T.; Yang, X.-G.; Tian, H.; Wang, C.-Y. Rapid self-heating and internal temperature sensing of lithium-ion batteries at low temperatures. Electrochim. Acta 2016, 218, 149–155. [Google Scholar] [CrossRef]

- Ning, G.; Haran, B.; Popov, B.N. Capacity fade study of lithium-ion batteries cycled at high discharge rates. J. Power Sources 2003, 117, 160–169. [Google Scholar] [CrossRef]

- Ruan, H.; Jiang, J.; Sun, B.; Su, X.; He, X.; Zhao, K. An optimal internal-heating strategy for lithium-ion batteries at low temperature considering both heating time and lifetime reduction. Appl. Energy 2019, 256, 113797. [Google Scholar] [CrossRef]

- Stuart, T.; Hande, A. HEV battery heating using AC currents. J. Power Sources 2004, 129, 368–378. [Google Scholar] [CrossRef]

- Zhang, J.; Ge, H.; Li, Z.; Ding, Z. Internal heating of lithium-ion batteries using alternating current based on the heat generation model in frequency domain. J. Power Sources 2015, 273, 1030–1037. [Google Scholar] [CrossRef]

- Qin, Y.; Du, J.; Lu, L.; Gao, M.; Haase, F.; Li, J.; Ouyang, M. A rapid lithium-ion battery heating method based on bidirectional pulsed current: Heating effect and impact on battery life. Appl. Energy 2020, 280, 115957. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, X.; Chen, Z. Low temperature preheating techniques for Lithium-ion batteries: Recent advances and future challenges. Appl. Energy 2022, 313, 118832. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, F.; Wang, Z. Heating Character of a LiMn2O4 Battery Pack at Low Temperature Based on PTC and Metallic Resistance Material. Energy Procedia 2017, 105, 2131–2138. [Google Scholar] [CrossRef]

- Lei, Z.; Zhang, Y.; Lei, X. Improving temperature uniformity of a lithium-ion battery by intermittent heating method in cold climate. Int. J. Heat Mass Transf. 2018, 121, 275–281. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, G.; Wu, C.; Huang, W.; Xu, C.; Jin, C.; Wu, Y.; Jiang, Z.; Dai, H.; Feng, X.; et al. Multi-objective optimization design for a double-direction liquid heating system-based Cell-to-Chassis battery module. Int. J. Heat Mass Transf. 2022, 183, 122184. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, G.; Zhu, J.; Feng, X.; Wei, X.; Ouyang, M.; Dai, H. Multi-objective optimization design and experimental investigation for a parallel liquid cooling-based Lithium-ion battery module under fast charging. Appl. Therm. Eng. 2022, 211, 118503. [Google Scholar] [CrossRef]

- Xie, B.; Zhang, G.; Jiang, Y.; Wang, R.; Sheng, X.; Xi, F.; Zhao, Z.; Chen, W.; Zhu, Y.; Wang, Y.; et al. “3D+1D” modeling approach toward large-scale PEM fuel cell simulation and partitioned optimization study on flow field. Etransportation 2020, 6, 100090. [Google Scholar] [CrossRef]

- Liu, Z. Simulation of Cell to Cell Variations and Thermal Management in Lithium-Ion Battery Packs; Tianjin University: Tianjin, China, 2014. [Google Scholar]

- Kang, J.; Meng, W.; Abraham, A.; Liu, H. An adaptive PID neural network for complex nonlinear system control. Neurocomputing 2014, 135, 79–85. [Google Scholar] [CrossRef] [Green Version]

- Chao, R.-J.; Chen, Y.-H. Evaluation of the criteria and effectiveness of distance e-learning with consistent fuzzy preference relations. Expert Syst. Appl. 2009, 36, 10657–10662. [Google Scholar] [CrossRef]

- Lam, K.C.; Hu, T.S.; Ng, S.T. Using the principal component analysis method as a tool in contractor pre-qualification. Constr. Manag. Econ. 2005, 23, 673–684. [Google Scholar] [CrossRef]

- Huang, J. Combining entropy weight and TOPSIS method for information system selection. In 2008 IEEE Conference on Cybernetics and Intelligent Systems; IEEE: New York, NY, USA, 2008; pp. 1281–1284. [Google Scholar] [CrossRef]

| Items | Value |

|---|---|

| Working voltage | 2.5~4.2 V |

| Nominal capacity | 101.2 Ah |

| Heat capacity | 1001.8 J/Kg/°C |

| Various thermal conductivity | 22.4 W/(m·K) (x direction) |

| 22.4 W/(m·K) (y direction) | |

| 1.15 W/(m·K) (z direction) | |

| Battery density | 2418.2 Kg/m3 |

| Battery mass | 1.7 Kg |

| Preheating Time (s) | Temperature Difference (°C) |

|---|---|

| 3660 | 0 |

| 3465 | 1 |

| 3330 | 2 |

| 3090 | 3 |

| 2910 | 4 |

| 2775 | 5 |

| 2640 | 6 |

| 2565 | 7 |

| 2445 | 8 |

| 2325 | 9 |

| 2236 | 10 |

| 1 | 0 |

| 0.860215 | 0.1 |

| 0.763441 | 0.2 |

| 0.591398 | 0.3 |

| 0.462366 | 0.4 |

| 0.365591 | 0.5 |

| 0.268817 | 0.6 |

| 0.215054 | 0.7 |

| 0.129032 | 0.8 |

| 0.043011 | 0.9 |

| 0 | 1 |

| 0.183024468 | 0 |

| 0.162434255 | 0.018083183 |

| 0.125829362 | 0.036166365 |

| 0.098375745 | 0.054249548 |

| 0.077785319 | 0.072332731 |

| 0.057195106 | 0.090415913 |

| 0.04575617 | 0.108499096 |

| 0.027453617 | 0.126582278 |

| 0.009151277 | 0.144665461 |

| 0 | 0.162748644 |

| 1 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, S.; Zheng, Y.; Lu, L.; Shen, K.; Chen, S. Neural Network PID-Based Preheating Control and Optimization for a Li-Ion Battery Module at Low Temperatures. World Electr. Veh. J. 2023, 14, 83. https://doi.org/10.3390/wevj14040083

Pan S, Zheng Y, Lu L, Shen K, Chen S. Neural Network PID-Based Preheating Control and Optimization for a Li-Ion Battery Module at Low Temperatures. World Electric Vehicle Journal. 2023; 14(4):83. https://doi.org/10.3390/wevj14040083

Chicago/Turabian StylePan, Song, Yuejiu Zheng, Languang Lu, Kai Shen, and Siqi Chen. 2023. "Neural Network PID-Based Preheating Control and Optimization for a Li-Ion Battery Module at Low Temperatures" World Electric Vehicle Journal 14, no. 4: 83. https://doi.org/10.3390/wevj14040083