1. Introduction

With the development of the social economy, vehicle ownership has increased significantly year by year, and problems such as traffic congestion and accidents have intensified rapidly [

1]. Under the severe road traffic safety situation, autonomous emergency braking (AEB), as a key technology of vehicle active safety, can automatically control the vehicle in an emergency state to achieve effective collision avoidance or reduce collision intensity. It has become one of the popular topics grabbing scholars’ attention [

2,

3,

4]. In the current technical range, the two variables of safety distance and safety time are usually used as the main considerations in the control strategy of an automatic emergency braking system to judge the safety state of the vehicle [

5].

The safety distance model is based on the dynamics of the vehicle braking process. The early control strategy based on the safety distance model is generally two levels, the first level of early warning, and the second level of braking. When the relative distance between the self-vehicle and the target vehicle measured by the information acquisition module reaches the critical distance of early warning, the system prompts the driver to brake through a sound warning. If the driver has not taken braking measures, and the relative distance between the two vehicles reaches the critical braking distance, the system avoids collision by automatic braking. The Mazda [

6,

7], Honda [

8], SeungwukMoon model proposed by Seoul University in South Korea and the Berkeley model [

9] proposed by Berkeley University are the more classic safety distance models. The Mazda model considers many extreme conditions, and the braking strategy is more conservative, which means it is easy to cause interference to the driver. The Honda model achieves hierarchical control of early warning and active braking by comparing the relative motion parameters of the two vehicles. The SeungwukMoon model considers the road condition and combines the road adhesion coefficient estimation method to improve the safety distance model. The Berkeley model considers the problem that the reserved braking safety distance is too large or too small, and the Mazda model and Honda model are optimized.

In addition to the above classical safety distance models, many researchers have actively tried to study the AEB control strategy based on safety distance. Teng F. et al. [

10] proposed an automobile anti-collision safety early warning algorithm based on an improved Berkeley model, preprocessed the reaction time and braking onset time and dynamically selected the calculation formula of safety early warning distance to meet the dynamic demand of safety early warning distance under different braking deceleration speeds. Gounis K. et al. [

11] simulates a three-layer AEB control system based on safety distance. Collision risk is compared according to the relative distance from the vehicle in front and the relative distance threshold based on adaptive speed. The results are fed back to the rule-based monitoring module, which determines the required deceleration command and then provides the command to the low-level control module through a switching algorithm. In view of the collision avoidance problem of the vehicle fleet, Sidorenko G. et al. [

12] pay attention to collision avoidance in the emergency braking scene and queue, and deduce the minimum safety workshop distance or lower bound to ensure no rear-end collision, and also design a two-layer emergency braking strategy of the vehicle fleet based on vehicle-to-vehicle (V2V) communication. Kim H. et al. [

13] developed a pure distance-based AEB control algorithm that defined discrete minimum braking and stopping distance formulas based on a variety of different vehicle driving conditions in each case. Park J. et al. [

14] proposed an emergency crash-avoidance system that includes not only braking but also steering control. Based on the relative motion with surrounding vehicles and lane information obtained through vision sensors, the minimum distance to avoid collision during braking and steering is calculated, respectively. In particular, in order to avoid lane change collision, the maximum lateral acceleration and angle of the trajectory are considered. In view of the low early-warning accuracy of vehicles during a lane change in different lanes, He X. et al. [

15] proposed a safety distance model for the vehicle running side on curves, taking the angle between two vehicles and the speed as the main parameters to ensure that there was no collision risk after the lane change vehicle and self-driven vehicle were run for t time.

The safety time model uses time-to-collision (TTC), the remaining time when the self-vehicle and the front vehicle simultaneously maintain the current motion state until the collision occurs, as the indicator to judge the dangerous state of the driving, and compares it with the pre-set TTC threshold of early warning and emergency braking in the control strategy, so as to determine the AEB system to execute the early warning or braking function.

Among the studies on safety time models, the most representative one is the TTC model proposed by Tokyo A&M University. If the TTC value obtained through real-time calculation is less than the set value, the system automatically intervenes in the braking. Otherwise, the current driving state is safe by default. In addition, Seyedi M. et al. [

16] selected four real-world rear-end collision scenarios with different collision characteristics, defined different forward collision warning (FCW)/AEB safety algorithms, and simulated important input parameters that affect collision results, such as speed, braking strength and driver reaction time. Bae J.J. et al. [

17] designed a hierarchical braking control strategy based on collision time, and developed an autonomous braking algorithm that can satisfy both vehicle safety and riding comfort, which consists of a two-step braking strategy dependent on collision time. The first step is the partial braking strategy, which can provide both speed reduction and good ride comfort under normal braking conditions. The second step is the full braking strategy to avoid a forward collision during an emergency braking situation. In order to effectively improve vehicle safety on mountainous areas and other curved roads and reduce braking distance and time, Wu G. et al. [

18] designed a DCT shifting strategy suitable for different drivers. In order to reflect the active safety protection of the automotive AEB system for vulnerable road users, many researchers have conducted more studies on the pedestrian AEB system. Park M.K. et al. [

19] proposed a pedestrian target selection method based on a funnel plot for the pedestrian AEB system. By comparing the predicted position and current position of pedestrians, the speed before the accident can be inferred. The fusion information of vehicles and sensors can be used to calculate the alarm time and estimate the collision probability. Based on this, the effective collision avoidance between vehicles and pedestrians is realized under the condition that the vehicle speed is not higher than 40 km/h. Rosado A.L. et al. [

20] proposed an AEB analysis model, which can predict the collision speed, stopping distance and time with high accuracy, and it can complete the decision-making process by analyzing the lateral movement behavior of pedestrians and searching for the deterministic calculation of pedestrians entering the collision area. Yang W. et al. [

21] proposed a pedestrian collision avoidance control strategy based on fuzzy neural network control at the upper level and PID control at the lower level, introduced a genetic algorithm to optimize the fuzzy neural network model and verified the effectiveness of the strategy by using the pedestrian crossing test scene in C-NCAP.

At present, the control strategy of an automatic emergency braking system is generally based on the safety distance and safety time to judge the safety state of the vehicle. Each control strategy considers different emphases. Under the premise of not interfering with the driver’s normal driving, the longitudinal collision avoidance algorithm considering the pre-collision time has the best performance [

22]. However, the safety time model cannot clearly define the braking deceleration speed and the safety time threshold, and it lacks the consideration of occupant comfort, which cannot guarantee the reliability of the control strategy [

23]. Therefore, in order to simplify the control system and improve the reliability and efficiency of the control strategy, aiming at the problem that the decision-making braking of the system needs to switch between different states in real time, the safety distance and time model can be combined to establish the hierarchical braking strategy on the premise of giving full consideration to occupant comfort and safety. The upper control model considers the pre-collision time to make decisions on braking deceleration, and the lower controller uses PID to control the vehicle braking pressure, so as to achieve control accuracy and efficiency.

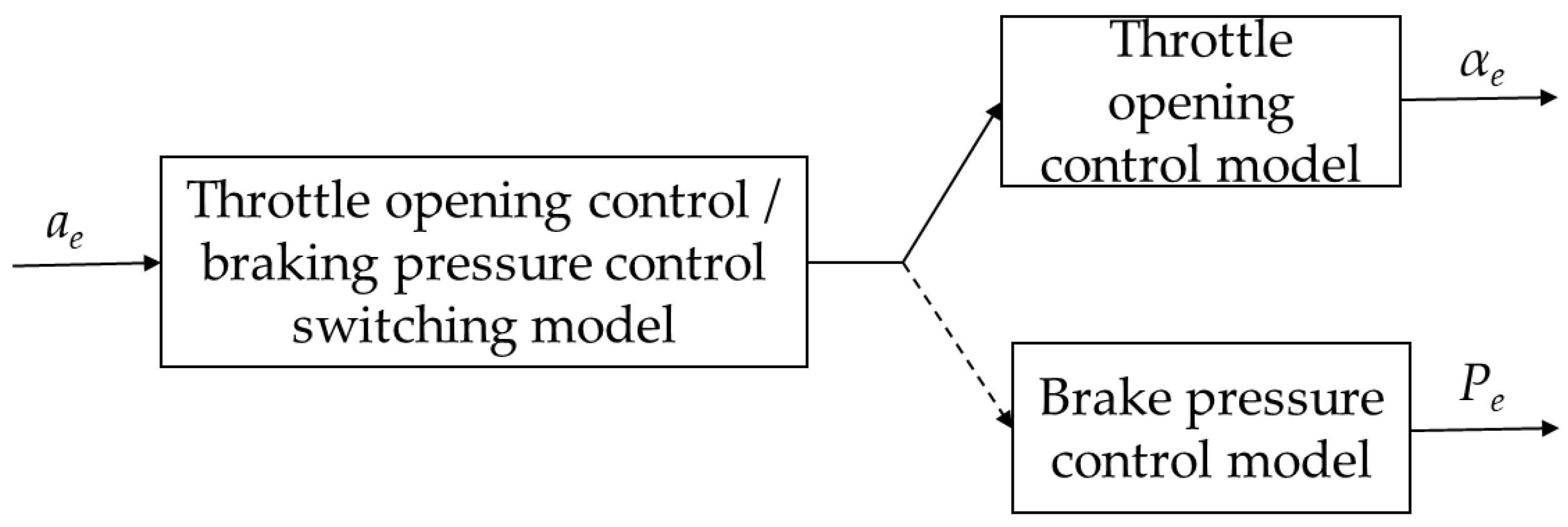

In this paper, a hierarchical control strategy based on safety time logic is studied. Firstly, the actual working condition requirements and the basic architecture of the AEB system are analyzed, and the control strategy and basic algorithm logic that meet the requirements are selected, that is, the hierarchical control strategy under the safety time logic. After that, according to the needs of the control strategy, the vehicle dynamics model and the inverse dynamics model of the matching vehicle upper system are established to obtain the necessary dynamic parameters of the algorithm. According to the known parameters, the AEB hierarchical control algorithm was built in Simulink. The upper layer adopts fuzzy control and the lower layer adopts PID control. The lower PID adjusts the speed by controlling the throttle opening and the brake pipeline pressure. Finally, in the CarSim and Simulink environment, the joint simulation proves that the control strategy can meet the actual needs under the E-NCAP standard and is feasible.

4. Simulation Results and Analysis

In order to reduce rear-end traffic accidents caused by braking problems, automobile evaluation agencies such as Euro-NCAP, NHTSA, J-NCAP and C-NCAP have incorporated automatic emergency braking system into the rules of new vehicle evaluation, and they are constantly improving the corresponding test scenarios and requirements. Among numerous test and evaluation regulations, Euro-NCAP has the most comprehensive test for intelligent driving functions. It has developed three test scenarios for the AEB function: car-to-car rear stationary (CCRs), car-to-car rear moving (CCRm) and car-to-car rear braking (CCRb) [

30]. In this paper, which relies on the joint simulation of CarSim and Simulink, the hierarchical control strategy algorithm under hierarchical early warning was simulated and tested, respectively, in these three typical test scenarios to verify the effectiveness of the control strategy.

4.1. CCRs Test

The test conditions are shown in

Table 5 (the target vehicle is always in front of the self-vehicle), and the simulation results are shown in

Figure 8 and

Figure 9.

It can be seen from

Figure 8 that the initial distance between the two vehicles is 40 m, and the self-vehicle is close to the front vehicle in a stationary state at a relative speed of 50 km/h at 40 m from the front vehicle. As the simulation progresses, the relative distance between the two vehicles gradually decreases. At 3.7 s, the distance between the two vehicles reaches the minimum value, and then the relative distance between the two vehicles remains unchanged at 2.22 m.

From

Figure 9, it can be seen that under this simulation condition, the initial speed of the two vehicles is quite different. The AEB system detects the risk of collision when the simulation time is 1.3 s, and the calculated TTC value is less than the threshold of the first-level braking. Therefore, the deceleration of the self-vehicle begins to decrease from 0 until it brakes at a deceleration of −0.4 m/s

2. The deceleration is stable at about −0.4 m/s

2 in 1.3 s to 2.7 s. As the real-time distance between the two vehicles decreases, the collision risk level increases. In 2.7 s, the TTC value calculated by the AEB system is less than the secondary braking threshold. After receiving the secondary braking request, the braking system brakes, so that the vehicle acceleration rises to −0.8 m/s

2. Finally, the self-vehicle stops at a distance of 2.22 m from the target vehicle, avoiding the occurrence of collision.

In the simulation time of 2.7 s to 3.7 s, the actual deceleration following state of the self-vehicle is better. After 3.7 s of simulation time, the actual deceleration oscillation is due to the fluctuation in the self-vehicle deceleration detected by the sensor due to the braking of the self-vehicle. In general, the simulation results show that the designed control strategy can effectively avoid collision under the condition of a close-to-stationary target.

4.2. CCRm Test

The test conditions are shown in

Table 6 (the target vehicle is always in front of the self-driving vehicle), and the simulation results are shown in

Figure 10 and

Figure 11.

It can be seen from

Figure 10 that the initial distance between the two vehicles is 40 m, and the self-vehicle is approaching the front vehicle at a relative speed of 30 km/h at 40 m from the front vehicle. As the simulation progresses, the relative distance between the two vehicles gradually decreases. At 4.4 s, the distance between the two vehicles reaches a minimum of 2.11 m, and then the relative distance between the two vehicles gradually increases.

From

Figure 11, it can be seen that within the first 2 s of the simulation time, the distance between the self-driving and the target vehicle that is far away and the calculated TTC value do not reach the set thresholds. The self-vehicle maintains a uniform speed and the acceleration is stable at 0. In 2 s, the TTC value calculated by the AEB system reaches the first braking threshold, and the vehicle brakes at a deceleration of −0.4 m/s

2. In 4.4 s, the speed of the self-vehicle is equal to that of the target vehicle. The TTC value calculated by the vehicle is greater than the threshold set by the system. The AEB system issues an instruction to stop braking and restore the normal driving state of the self-vehicle. Under this condition, the nearest distance between the vehicles is 2.11 m.

In the simulation time of 2 s to 4.4 s, the actual deceleration of the self-driving basically reached −0.4 m/s2, but due to the ground adhesion limit it will produce shock, resulting in unstable deceleration, even more than −0.4 m/s2. After 4.4 s of simulation time, the actual deceleration oscillation was due to the fluctuation in self-vehicle deceleration detected by the sensor due to the braking of the self-vehicle. In general, the simulation results show that the designed control strategy can effectively avoid collision under the condition of being close to the uniform braking target vehicle.

4.3. CCRb Test

The test conditions are shown in

Table 7 (the target vehicle is always in front of the self-driving vehicle), and the simulation results are shown in

Figure 12 and

Figure 13.

From

Figure 12, it can be seen that the initial distance between the two vehicles is 12 m, and the self-vehicle is close to the front vehicle at a relative speed of 50 km/h at a distance of 12 m from the front vehicle. Because the front vehicle travels at a constant speed of 50 km/h for 4 s and then decelerates at −4 m/s

2, as the simulation progresses, the relative distance between the two vehicles gradually decreases. The distance between the two vehicles reaches the minimum value at 6.8 s, and then the relative distance between the two vehicles remains unchanged at 1.56 m.

It can be seen from

Figure 13 that in the first 4 s of the simulation time, the AEB system is not involved because the relative speed between the front vehicle and the self-vehicle is 0. When the simulation time is close to 4.6 s, the TTC value reaches the primary braking threshold. The deceleration of the self-vehicle decreases from 0 to brake at a deceleration close to −0.4 m/s

2. At 5.6 s, the TTC value reaches the secondary braking threshold. At this time, the vehicle performs full braking, and the braking deceleration is close to −0.8 m/s

2 until the vehicle stops moving. At this time, the distance between the self-vehicle and the target vehicle is 1.56 m, which proves that under this condition, this algorithm can ensure that the vehicle does not collide. In this condition, the braking time of the vehicle with primary braking deceleration is shorter. This is because the distance between the self-vehicle and the target vehicle is relatively close, and the front vehicle brakes at a deceleration of −4 m/s

2, resulting in the calculated TTC value rapidly falling to the secondary braking TTC threshold. The AEB system quickly sends out the secondary braking deceleration signal, and the vehicle performs emergency braking.

In the simulation time of 5.6 s to 6.9 s, the actual deceleration following state of the self-vehicle is better. After 3.7 s of simulation time, the actual deceleration oscillation is due to the fluctuation in vehicle deceleration detected by the sensor due to the braking of the self-vehicle. In general, the simulation results show that the designed control strategy can effectively avoid collision when the front vehicle brakes urgently under the condition of close-range stable following.

In addition to the above working conditions, this paper also carried out simulation tests under multiple working conditions, and the simulation results are shown in

Table 8.

When the self-vehicle is close to the static vehicle at 12 m ahead at a relative speed of 10 km/h, the shortest distance between the two vehicles is 3.41 m. When the self-vehicle is close to the stationary vehicle at 40 m ahead at a relative speed of 50 km/h, the shortest distance between the two vehicles is 2.22 m. When the self-vehicle is close to the target vehicle at 12 m ahead at a relative speed of 30 km/h, the target vehicle runs at a constant speed of 20 km/h, and the shortest distance between the two vehicles is 2.95 m. When the self-vehicle is close to the target vehicle at 50 m ahead at a relative speed of 50 km/h, the target vehicle slows down at a speed of −2 m/s2 from 50 km/h, and the shortest distance between the two vehicles is 1.23 m. When the self-vehicle is close to the target vehicle at 12 m ahead at a relative speed of 50 km/h, the target vehicle slows down at a speed of −6 m/s2 from 50 km/h, and the shortest distance between the two vehicles is 1.56 m. When the self-vehicle is close to the target vehicle at 12 m ahead at a relative speed of 50 km/h, the target vehicle slows down at a speed of −2 m/s2 from 50 km/h, and the shortest distance between the two vehicles is 1.05 m. When the self-vehicle is close to the target vehicle at 40 m ahead at a relative speed of 50 km/h, the target vehicle slows down at a speed of −6 m/s2 from 50 km/h, and the shortest distance between the two vehicles is 1.07 m.

It can be seen from the overall simulation results that the vehicle will begin emergency braking when it enters the dangerous state, so that the vehicle will slow down and maintain a safe state, and the minimum relative distance is also reasonable. The automatic emergency braking system based on the safe time logic algorithm built in this paper has a good braking effect in an emergency and can avoid vehicle collision.

5. Conclusions

In this paper, an algorithm based on safety time logic is proposed. The TTC threshold of warning at all levels is calculated. The hierarchical control algorithm based on layered warning is verified by CarSim and Simulink joint simulation. Under typical and various working conditions of CCRs, CCRm and CCRb, the system meets the actual working conditions and operational feasibility, and improves the reliability and accuracy of the control strategy. The automatic emergency braking system based on collision time designed in this paper can meet the requirements of driving safety, and has a certain reference value for the development and design of the AEB system.

For low-speed driving conditions, although the algorithm proposed in this paper can ensure that the vehicle does not collide, because the algorithm only considers the safety event logic and does not consider the actual distance between the vehicles, the AEB system adopts emergency braking. The distance between the vehicle and the target vehicle is relatively large, which will cause some interference to the driver’s normal driving. Therefore, a safe distance model should be introduced into the control algorithm to avoid premature intervention of the system under low-speed driving conditions. In this paper, the simulation test was used to verify the effectiveness of the control strategy of the automatic emergency braking system, but the simulation results can only show the effectiveness of the control strategy to a certain extent. In later work, a hardware-in-the-loop test or real vehicle test can be used for verification.