A Review on Predictive Control Technology for Switched Reluctance Motor System

Abstract

:1. Introduction

2. Composition of SRM Drive System

2.1. Mathematical Model of SRMs

2.2. Power Converter Topology

3. Predictive Control Basics

3.1. Generalized Predictive Control

3.2. Hysteresis Predictive Control

3.3. Deadbeat Predictive Control

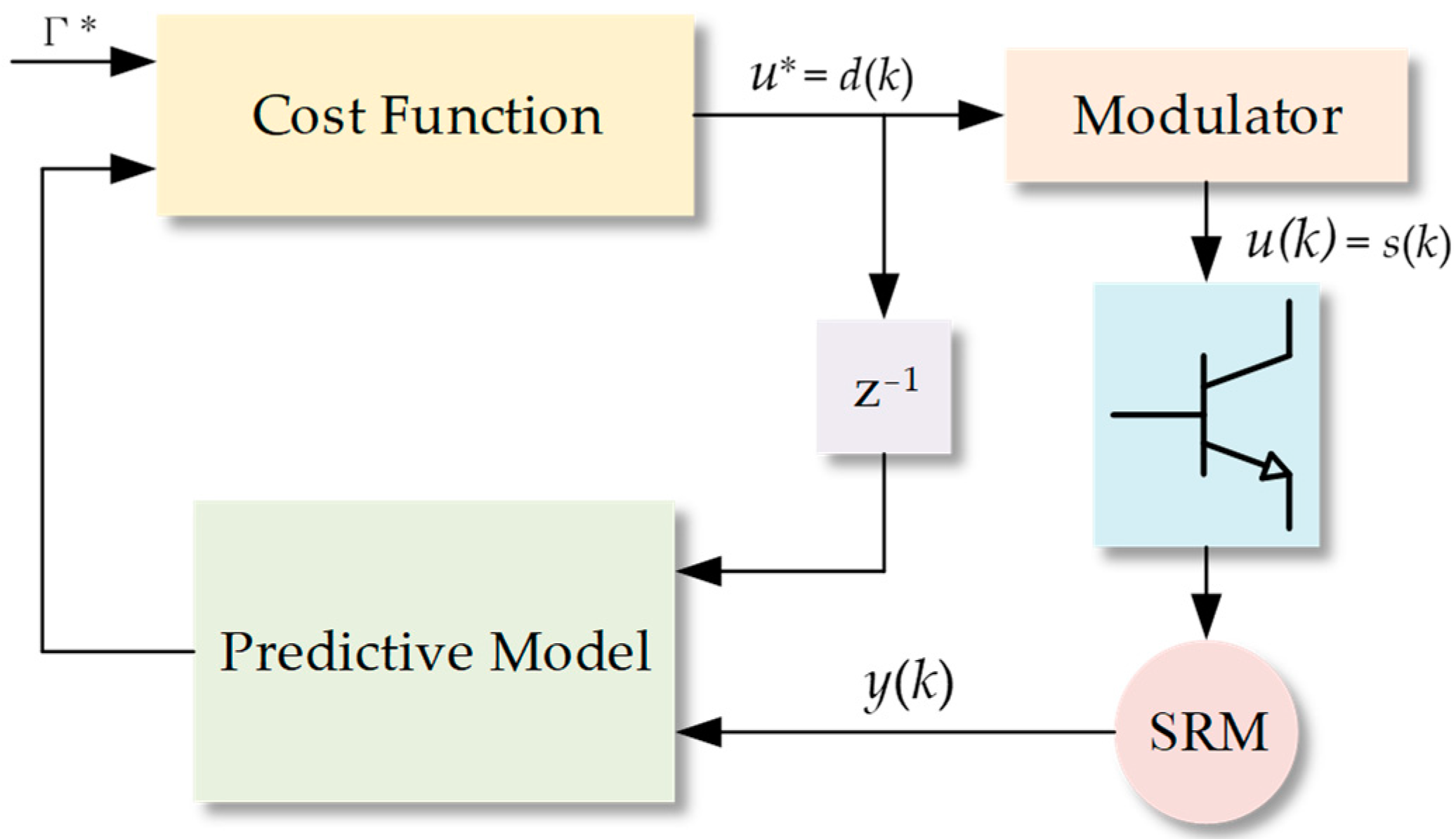

3.4. Model Predictive Control

4. A Summary of the Recent Development in Predictive Control Techniques for SRMs

4.1. Predictive Current Control

4.1.1. Predictive Model

4.1.2. Switching Behavior

4.1.3. Other Predictive Current Control

4.2. Predictive Torque Control

4.2.1. Torque Distribution

4.2.2. Predictive Model

4.2.3. Candidate Voltage Vector Optimization

4.2.4. Error Compensation

4.3. Other Predictive Control Applications

5. Future Directions

5.1. Rated Power and Topology of SRM

5.2. Application in Electrified Powertrain

5.3. Control Strategies

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ahn, J.-W.; Lukman, G.F. Switched reluctance motor: Research trends and overview. CES Trans. Electr. Mach. Syst. 2018, 2, 339–347. [Google Scholar]

- Han, S.; Liu, C.; Sun, X.; Diao, K. An effective method of verifying poles polarities in switched reluctance motors. Int. J. Comput. Math. Electr. Electron. Eng. 2019, 38, 927–938. [Google Scholar] [CrossRef]

- Mohanraj, D.; Gopalakrishnan, J.; Chokkalingam, B.; Mihet-Popa, L. Critical Aspects of Electric Motor Drive Controllers and Mitigation of Torque Ripple—Review. IEEE Access 2022, 10, 73635–73674. [Google Scholar] [CrossRef]

- Fang, G.; Scalcon, F.P.; Xiao, D.; Vieira, R.P.; Gründling, H.A.; Emadi, A. Advanced Control of Switched Reluctance Motors (SRMs): A Review on Current Regulation, Torque Control and Vibration Suppression. IEEE Open J. Ind. Electron. Soc. 2021, 2, 280–301. [Google Scholar] [CrossRef]

- Banerjee, R.; Sensarma, P. Digital Peak Current Program Mode Controller for Switched Reluctance Machines. IEEE Trans. Power Electron. 2023, 38, 5230–5239. [Google Scholar] [CrossRef]

- Qin, Y.; Tang, X.; Jia, T.; Duan, Z.; Zhang, J.; Li, Y.; Zheng, L. Noise and vibration suppression in hybrid electric vehicles: State of the art and challenges. Renew. Sustain. Energy Rev. 2020, 124, 109782. [Google Scholar] [CrossRef]

- Diao, K.; Sun, X.; Bramerdorfer, G.; Cai, Y.; Lei, G.; Chen, L. Design optimization of switched reluctance machines for performance and reliability enhancements: A review. Renew. Sustain. Energy Rev. 2022, 168, 112785. [Google Scholar] [CrossRef]

- Bilgin, B.; Jiang, J.W.; Emadi, A. Switched Reluctance Motor Drives: Fundamentals to Applications; Taylor & Francis: New York, NY, USA, 2018. [Google Scholar]

- Diao, K.; Sun, X.; Lei, G.; Guo, Y.; Zhu, J. Application-oriented system level optimization method for switched reluctance motor drive systems. In Proceedings of the IPEMC 2020-ECCE Asia, Nanjing, China, 31 May–3 June 2020. [Google Scholar]

- Sun, X.; Diao, K.; Yang, Z. Performance improvement of a switched reluctance machine with segmental rotors for hybrid electric vehicles. Comput. Electr. Eng. 2019, 77, 244–259. [Google Scholar]

- Wang, H.; Chen, L.; Sun, X.; Cai, Y.; Diao, K. Design optimization and analysis of a segmented-rotor switched reluctance machine for BSG application in HEVs. Int. J. Appl. Electromagn. Mech. 2020, 63, 529–550. [Google Scholar]

- Sun, X.; Shen, Y.; Wang, S.; Lei, G.; Yang, Z.; Han, S. Core Losses Analysis of a Novel 16/10 Segmented Rotor Switched Reluctance BSG Motor for HEVs Using Nonlinear Lumped Parameter Equivalent Circuit Model. IEEE/ASME Trans. Mechatron. 2018, 23, 747–757. [Google Scholar] [CrossRef]

- Diao, K.; Sun, X.; Lei, G.; Guo, Y.; Zhu, J. Multimode Optimization of Switched Reluctance Machines in Hybrid Electric Vehicles. IEEE Trans. Energy Convers. 2021, 36, 2217–2226. [Google Scholar] [CrossRef]

- Zhou, Z.; Sun, X.; Chen, L.; Yang, Z.; Han, S.; Li, K.; Zhu, J.; Guo, Y. A segmented rotor type switched reluctance machine for BSGs of hybrid electric vehicles: Concept, design and analysis. In Proceedings of the 20th International Conference on Electrical Machines and Systems (ICEMS2017), Sydney, NSW, Australia, 11–14 August 2017. [Google Scholar]

- Sun, X.; Diao, K.; Lei, G.; Guo, Y.; Zhu, J. Direct Torque Control Based on a Fast Modeling Method for a Segmented-Rotor Switched Reluctance Motor in HEV Application. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 9, 232–241. [Google Scholar] [CrossRef]

- Diao, K.; Sun, X.; Chen, L.; Cai, Y.; Wang, H.; Wu, J. Direct torque control of a segmented switched reluctance motor for BSG in HEVs. In Proceedings of the 3rd Conference on Vehicle Control and Intelligence (CVCI 2019), Hefei, China, 21–22 September 2019. [Google Scholar]

- Sun, X.; Zhou, Z.; Chen, L.; Yang, Z.; Han, S. Performance analysis of segmented rotor switched reluctance motors with three types of winding connections for belt-driven starter generators of hybrid electric vehicles. Int. J. Comput. Math. Electr. Electron. Eng. 2018, 37, 1258–1270. [Google Scholar]

- Chen, L.; Wang, H.; Sun, X.; Cai, Y.; Li, K.; Diao, K.; Wu, J. Development of digital control system for a belt-driven starter generator SSRM for HEVs. Proc. Inst. Mech. Eng. Part I J. Syst. Control. Eng. 2020, 234, 975–984. [Google Scholar]

- Sun, X.; Diao, K.; Lei, G.; Guo, Y.; Zhu, J. Study on Segmented-Rotor Switched Reluctance Motors with Different Rotor Pole Numbers for BSG System of Hybrid Electric Vehicles. IEEE Trans. Veh. Technol. 2019, 68, 5537–5547. [Google Scholar] [CrossRef]

- Sun, X.; Xue, Z.; Han, S.; Xu, X.; Yang, Z.; Chen, L. Design and analysis of a novel 16/10 segmented rotor SRM for 60 V belt-driven starter generator. J. Magn. 2016, 21, 393–398. [Google Scholar] [CrossRef] [Green Version]

- McCann, R.; Le, A.T.; Traore, D. Model Predictive Control for Time-Delay Compensation of a Switched Reluctance Motor Drive in Smart Building Applications. In Proceedings of the 2008 IEEE Industry Applications Society Annual Meeting, Edmonton, AB, Canada, 5–9 October 2008. [Google Scholar]

- Abdel-Fadil, R.; Szamel, L. Predictive Control of Switched Reluctance Motors for Aircraft Electrical Actuators Applications. Acta Polytech. Hung. 2020, 17, 209–227. [Google Scholar] [CrossRef]

- Sánchez, J.A.; Andrada, P.; Blanqué, B.; Torrent, M. Predictive Maintenance Plan for Switched Reluctance Motor Drives. IEEE Latin Am. Trans. 2020, 18, 67–74. [Google Scholar] [CrossRef]

- Sun, X.; Wu, J.; Wang, S.; Diao, K.; Yang, Z. Analysis of torque ripple and fault-tolerant capability for a 16/10 segmented switched reluctance motor in HEV applications. COMPEL Int. J. Comp. Math. Electr. Electron. Eng. 2019, 38, 1725–1737. [Google Scholar]

- Ralev, I.; Qi, F.; Burkhart, B.; Klein-Hessling, A.; De Doncker, R.W. Impact of Smooth Torque Control on the Efficiency of a High-Speed Automotive Switched Reluctance Drive. IEEE Trans. Ind. Appl. 2017, 53, 5509–5517. [Google Scholar]

- Valencia, D.F.; Tarvirdilu-Asl, R.; Garcia, C.; Rodriguez, J.; Emadi, A. Vision, Challenges, and Future Trends of Model Predictive Control in Switched Reluctance Motor Drives. IEEE Access 2021, 9, 69926–69937. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, X.; Li, J.; Jiang, H.; Zhang, Z. Regenerative braking control method for switched reluctance motor. J. Electron. Meas. Instrum. 2021, 35, 187–194. [Google Scholar]

- Sun, X.; Wu, J.; Lei, G.; Cai, Y.; Chen, X.; Guo, Y. Torque Modeling of a Segmented-Rotor SRM Using Maximum-Correntropy-Criterion-Based LSSVR for Torque Calculation of EVs. IEEE Trans. Emerg. Sel. Top. Power Electron. 2021, 9, 2674–2684. [Google Scholar] [CrossRef]

- Sun, X.; Wan, B.; Lei, G.; Tian, X.; Guo, Y.; Zhu, J. Multiobjective and Multiphysics Design Optimization of a Switched Reluctance Motor for Electric Vehicle Applications. IEEE Trans. Energy Convers. 2021, 36, 3294–3304. [Google Scholar]

- Diao, K.; Sun, X.; Yao, M. Robust-Oriented Optimization of Switched Reluctance Motors Considering Manufacturing Fluctuation. IEEE Trans. Transp. Electrif. 2022, 8, 2853–2861. [Google Scholar] [CrossRef]

- Sun, X.; Xiong, Y.; Yao, M.; Tang, X. A hybrid control strategy for multimode switched reluctance motors. IEEE/ASME Trans. Mechatron. 2022, 27, 5605–5614. [Google Scholar] [CrossRef]

- Diao, K.; Bramerdorfer, G.; Sun, X.; Yang, Z.; Han, S. Multiobjective design optimization of a novel switched reluctance motor with unequal alternating stator yoke segments. IEEE Trans. Transp. Electrif. 2023, 9, 512–521. [Google Scholar] [CrossRef]

- Sun, X.; Feng, L.; Zhu, Z.; Lei, G.; Diao, K.; Guo, Y.; Zhu, J. Optimal Design of Terminal Sliding Mode Controller for Direct Torque Control of SRMs. IEEE Trans. Transp. Electrif. 2022, 8, 1445–1453. [Google Scholar]

- Al-Amyal, F.; Számel, L. Analytical Approach for the Turn-Off Angle in Switched Reluctance Motors. Proceedings of Sixth International Congress on Information and Communication Technology; Lecture Notes in Networks and Systems; Springer: Singapore, 2022; Volume 217, pp. 685–696. [Google Scholar]

- Wadnerkar, V.; Bhaskar, M.; Das, T.; RajKumar, A. A New Fuzzy Logic based Modeling and Simulation of a Switched Reluctance Motor. J. Electr. Eng. Technol. 2010, 5, 276–281. [Google Scholar] [CrossRef]

- Shen, Y.; Sun, X.; Chen, L.; Yang, Z.; Li, K.; Zhu, J.; Guo, Y. Comparison of torque characteristics for a novel segmented and a conventional switched reluctance motors. In Proceedings of the 20th International Conference on Electrical Machines and Systems (ICEMS2017), Sydney, NSW, Australia, 11–14 August 2017. [Google Scholar]

- Cheng, H.; Chen, H.; Xu, S.; Yang, S. Adaptive Variable Angle Control in Switched Reluctance Motor Drives for Electric Vehicle Applications. J. Power Electron. 2017, 17, 1512–1522. [Google Scholar]

- Wang, H.; Chen, L.; Sun, X.; Zhou, S. Drive System Design for a Four-Phase BSG Switched Reluctance Motor. In Proceedings of the 2018 IEEE International Conference on Applied Superconductivity and Electromagnetic Devices (ASEMD), Tianjin, China, 15–18 April 2018. [Google Scholar]

- Xu, S.; Chen, H.; Dong, F.; Yang, J. Reliability Analysis on Power Converter of Switched Reluctance Machine System Under Different Control Strategies. IEEE Trans. Ind. Electron. 2019, 66, 6570–6580. [Google Scholar] [CrossRef]

- Sun, Q.; Wu, J.; Gan, C.; Hu, Y.; Jin, N.; Guo, J. A New Phase Current Reconstruction Scheme for Four-Phase SRM Drives Using Improved Converter Topology without Voltage Penalty. IEEE Trans. Ind. Electron. 2018, 65, 133–144. [Google Scholar] [CrossRef]

- Sun, X.; Xiong, Y.; Yang, J.; Tian, X. Torque Ripple Reduction for a 12/8 Switched Reluctance Motor Based on a Novel Sliding Mode Control Strategy. IEEE Trans. Transp. Electrif. 2023, 9, 359–369. [Google Scholar] [CrossRef]

- Sun, X.; Feng, L.; Diao, K.; Yang, Z. An Improved Direct Instantaneous Torque Control Based on Adaptive Terminal Sliding Mode for a Segmented-Rotor SRM. IEEE Trans. Ind. Electron. 2021, 68, 10569–10579. [Google Scholar] [CrossRef]

- Xiao, D.; Ye, J.; Fang, G.; Xia, Z.; Li, H.; Wang, X.; Nahid-Mobarakeh, B.; Emadi, A. Induced Current Reduction in Position-Sensorless SRM Drives Using Pulse Injection. IEEE Trans. Ind. Electron. 2023, 70, 4620–4630. [Google Scholar] [CrossRef]

- de Paula, M.V.; Barros, T.A.D.S. A Sliding Mode DITC Cruise Control for SRM with Steepest Descent Minimum Torque Ripple Point Tracking. IEEE Trans. Ind. Electron. 2022, 69, 151–159. [Google Scholar]

- Sun, X.; Wu, J.; Lei, G.; Guo, Y.; Zhu, J. Torque Ripple Reduction of SRM Drive Using Improved Direct Torque Control with Sliding Mode Controller and Observer. IEEE Trans. Ind. Electron. 2021, 68, 9334–9345. [Google Scholar] [CrossRef]

- Feng, L.; Sun, X.; Guo, D.; Yao, M.; Diao, K. Advanced torque sharing function strategy with sliding mode control for switched reluctance motors. IEEE Trans. Transp. Electrif. 2023, accepted. [Google Scholar] [CrossRef]

- Fang, G.; Scalcon, F.P.; Filho, C.J.V.; Xiao, D.; Nahid-Mobarakeh, B.; Emadi, A. A Unified Wide-Speed Range Sensorless Control Method for Switched Reluctance Machines Based on Unsaturated Reluctance. IEEE Trans. Ind. Electron. 2023, 70, 9903–9913. [Google Scholar] [CrossRef]

- Sun, X.; Tang, X.; Tian, X.; Wu, J.; Zhu, J. Position Sensorless Control of Switched Reluctance Motor Drives Based on a New Sliding Mode Observer Using Fourier Flux Linkage Model. IEEE Trans. Energy Convers. 2022, 37, 978–988. [Google Scholar] [CrossRef]

- Banerjee, R.; Sensarma, P. Low-Cost Realization of Feature Position Estimation Scheme for Switched Reluctance Motor. IEEE Trans. Power Electron. 2023, 38, 2850–2854. [Google Scholar]

- Zhou, D.; Chen, H. Four-Quadrant Position Sensorless Operation of Switched Reluctance Machine for Electric Vehicles over a Wide Speed Range. IEEE Trans. Transp. Electrif. 2021, 7, 2835–2847. [Google Scholar]

- Sun, X.; Tang, X.; Tian, X.; Lei, G.; Guo, Y.; Zhu, J. Sensorless Control with Fault-Tolerant Ability for Switched Reluctance Motors. IEEE Trans. Energy Convers. 2022, 37, 1272–1281. [Google Scholar]

- Sun, X.; Xiong, Y.; Yao, M.; Wu, J. High Fault-Tolerance Evaluation on Position Signal for Switched Reluctance Motor Drives. IEEE Trans. Energy Convers. 2022, 37, 1844–1853. [Google Scholar]

- Sun, X.; Xue, Z.; Han, S.; Chen, L.; Xu, X.; Yang, Z. Comparative study of fault-tolerant performance of a segmented rotor SRM and a conventional SRM. Bull. Pol. Acad. Sci. Tech. Sci. 2017, 65, 375–381. [Google Scholar] [CrossRef]

- Rana, A.K.; Teja, A.V.R. A Fault-Tolerant Power Converter with Multi-Switch Fault Diagnosis and Repair Capability for 4-Phase 8/6 SRM Drives. IEEE Trans. Transp. Electrif. 2022, 8, 3896–3906. [Google Scholar] [CrossRef]

- Shao, J.; Deng, Z.; Gu, Y. Fault-Tolerant Control of Position Signals for Switched Reluctance Motor Drives. IEEE Trans. Ind. Appl. 2017, 53, 2959–2966. [Google Scholar] [CrossRef]

- Silva, W.; Reis, L.D. Phase fault attenuation in SRM based on generalized predictive control and filter design. Electr. Eng. 2018, 100, 1481–1489. [Google Scholar]

- Sun, X.; Zhu, Y.; Cai, Y.; Xiong, Y.; Yao, M.; Yuan, C. Current fault tolerance control strategy for 3-phase switched reluctance motor combined with position signal reconstruction. IEEE Trans. Energy Convers. 2023. accepted. [Google Scholar] [CrossRef]

- Diao, K.; Sun, X.; Lei, G.; Bramerdorfer, G.; Guo, Y.; Zhu, J. Robust Design Optimization of Switched Reluctance Motor Drive Systems Based on System-Level Sequential Taguchi Method. IEEE Trans. Energy Convers. 2021, 36, 3199–3207. [Google Scholar] [CrossRef]

- Wu, J.; Sun, X.; Zhu, J. Accurate torque modeling with PSO-based recursive robust LSSVR for a segmented-rotor switched reluctance motor. CES Trans. Electr. Mach. Syst. 2020, 4, 96–104. [Google Scholar] [CrossRef]

- Diao, K.; Sun, X.; Lei, G.; Bramerdorfer, G.; Guo, Y.; Zhu, J. System-Level Robust Design Optimization of a Switched Reluctance Motor Drive System Considering Multiple Driving Cycles. IEEE Trans. Energy Convers. 2021, 36, 348–357. [Google Scholar] [CrossRef]

- de Paula, M.V.; Barros, T.A.D.S.; Moreira, H.S.; Catata, E.O.H.; Villalva, M.G.; Filho, E.R. A Dahlin Cruise Control Design Method for Switched Reluctance Motors with Minimum Torque Ripple Point Tracking Applied in Electric Vehicles. IEEE Trans. Transp. Electrif. 2021, 7, 730–740. [Google Scholar] [CrossRef]

- Vujičić, V.P. Minimization of Torque Ripple and Copper Losses in Switched Reluctance Drive. IEEE Trans. Power Electron. 2012, 27, 388–399. [Google Scholar] [CrossRef]

- Song, S.; Huang, S.; Zhao, Y.; Zhao, X.; Duan, X.; Ma, R.; Liu, W. Torque Ripple Reduction of Switched Reluctance Machine with Torque Distribution and Online Correction. IEEE Trans. Ind. Electron. 2023, 70, 8842–8852. [Google Scholar] [CrossRef]

- Sial, M.; Sahoo, N. Torque ripple minimization in SRM drive using second-order-generalized-integrator-based FLL equivalent PR current controller. Electr. Eng. 2023, 105, 2421–2441. [Google Scholar] [CrossRef]

- Li, T.; Sun, X.; Lei, G.; Yang, Z.; Guo, Y.; Zhu, J. Finite-control-set model predictive control of permanent magnet synchronous motor drive systems—An overview. IEEE/CAA J. Autom. Sin. 2022, 9, 2087–2105. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, Y.; Cai, Y.; Tian, X. Compensated deadbeat predictive current control considering disturbance and VSI nonlinearity for in-wheel PMSMs. IEEE/ASME Trans. Mechatron. 2022, 27, 3536–3547. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, Y.; Lei, G.; Guo, Y.; Zhu, J. An improved deadbeat predictive stator flux control with reduced-order disturbance observer for in-wheel PMSMs. IEEE/ASME Trans. Mechatron. 2022, 27, 690–700. [Google Scholar] [CrossRef]

- Mousavi, M.S.; Davari, S.A.; Nekoukar, V.; Garcia, C.; He, L.; Wang, F.; Rodriguez, J. Predictive Torque Control of Induction Motor Based on a Robust Integral Sliding Mode Observer. IEEE Trans. Ind. Electron. 2023, 70, 2339–2350. [Google Scholar] [CrossRef]

- Gulbudak, O.; Gokdag, M.; Komurcugil, H. Model Predictive Control Strategy for Induction Motor Drive Using Lyapunov Stability Objective. IEEE Trans. Ind. Electron. 2022, 69, 12119–12128. [Google Scholar] [CrossRef]

- Ayala, M.; Doval-Gandoy, J.; Rodas, J.; Gonzalez, O.; Gregor, R.; Rivera, M. A Novel Modulated Model Predictive Control Applied to Six-Phase Induction Motor Drives. IEEE Trans. Ind. Electron. 2021, 68, 3672–3682. [Google Scholar] [CrossRef]

- Li, T.; Sun, X.; Yao, M.; Guo, D.; Sun, Y. Improved finite control set model predictive current control for permanent magnet synchronous motor with sliding mode observer. IEEE Trans. Transp. Electrif. 2023. [Google Scholar] [CrossRef]

- Cao, B.; Grainger, B.M.; Wang, X.; Zou, Y.; Reed, G.F.; Mao, Z.-H. Direct Torque Model Predictive Control of a Five-Phase Permanent Magnet Synchronous Motor. IEEE Trans. Power Electron. 2021, 36, 2346–2360. [Google Scholar] [CrossRef]

- Zhu, H.; Xiao, X.; Li, Y. Torque Ripple Reduction of the Torque Predictive Control Scheme for Permanent-Magnet Synchronous Motors. IEEE Trans. Ind. Electron. 2012, 59, 871–877. [Google Scholar] [CrossRef]

- Chen, W.; Zeng, S.; Zhang, G.; Shi, T.; Xia, C. A Modified Double Vectors Model Predictive Torque Control of Permanent Magnet Synchronous Motor. IEEE Trans. Power Electron. 2019, 34, 11419–11428. [Google Scholar] [CrossRef]

- Sun, X.; Cao, J.; Lei, G.; Guo, Y.; Zhu, J. A robust deadbeat predictive controller with delay compensation based on composite sliding mode observer for PMSMs. IEEE Trans. Power Electron. 2021, 36, 10742–10752. [Google Scholar] [CrossRef]

- Kim, I.; Chan, R.; Kwak, S. Model predictive control method for CHB multi-level inverter with reduced calculation complexity and fast dynamics. IET Electr. Power Appl. 2017, 11, 784–792. [Google Scholar] [CrossRef]

- Chen, L.; Xu, H.; Sun, X. A novel strategy of control performance improvement for six-phase permanent magnet synchronous hub motor drives of EVs under new European driving cycle. IEEE Trans. Veh. Technol. 2021, 70, 5628–5637. [Google Scholar] [CrossRef]

- Vazquez, S.; Leon, J.I.; Franquelo, L.G.; Rodriguez, J.; Young, H.A.; Marquez, A.; Zanchetta, P. Model predictive control: A review of its applications in power electronics. IEEE Ind. Electron. Mag. 2014, 8, 16–31. [Google Scholar] [CrossRef]

- Rakovic, S.V.; Levine, W.S. Handbook of Model Predictive Control; Springer: Berlin, Germany, 2018. [Google Scholar]

- Karamanakos, P.; Liegmann, E.; Geyer, T.; Kennel, R. Model predictive control of power electronic systems: Methods, results, and challenges. IEEE Open J. Ind. Appl. 2020, 1, 95–114. [Google Scholar] [CrossRef]

- Yan, N.; Cao, X.; Deng, Z. Direct torque control for switched reluctance motor to obtain high torque-ampere ratio. IEEE Trans. Ind. Electron. 2019, 66, 5144–5152. [Google Scholar] [CrossRef]

- Mwasilu, F.; Nguyen, H.T.; Choi, H.H.; Jung, J. Finite set model predictive control of interior PM synchronous motor drives with an external disturbance rejection technique. IEEE/ASME Trans. Mechatron. 2017, 22, 762–773. [Google Scholar] [CrossRef]

- Li, X.; Shamsi, P. Model predictive current control of switched reluctance motors with inductance auto-calibration. IEEE Trans. Ind. Electron. 2016, 63, 3934–3941. [Google Scholar] [CrossRef]

- Camacho, E.F.; Alba, C.B. Model Predictive Control, 2nd ed.; Ser. Advanced Textbooks in Control and Signal Processing; Springer: London, UK, 2007. [Google Scholar]

- Kennel, R.; Linder, A.; Linke, M. Generalized Predictive Control (GPC)-Ready for Use in Drive Applications. In Proceedings of the 2001 IEEE 32nd Annual Power Electronics Specialists Conference, Vancouver, BC, Canada, 17–21 June 2001; pp. 1839–1844. [Google Scholar]

- Linder, A.; Kanchan, R.; Kennel, R.; Stolze, P. Model-Based Predictive Control of Electric Drives; Cuvillier: Göttingen, Germany, 2010. [Google Scholar]

- Vazquez, S.; Montero, C.; Bordons, C.; Franquelo, L.G. Model predictive control of a VSI with long prediction horizon. In Proceedings of the 2011 IEEE International Symposium on Industrial Electronics, Gdansk, Poland, 27–30 June 2011; pp. 1805–1810. [Google Scholar]

- Sonawane, A.; Gawande, S.P.; Kadwane, S.G.; Ramteke, M.R. Nearly constant switching frequency hysteresis-based predictive control for distributed static compensator applications. IET Power Electron. 2016, 9, 2174–2185. [Google Scholar] [CrossRef]

- Preindl, M.; Bolognani, S. Comparison of direct and PWM model predictive control for power electronic and drive systems. In Proceedings of the 2013 Twenty-Eighth Annual IEEE Applied Power Electronics Conference and Exposition, Long Beach, CA, USA, 17–21 March 2013; p. 25262533. [Google Scholar]

- Taylor, J.; Valencia, D.F.; Bilgin, B.; Narimani, M.; Emadi, A. Comparison of Current Control Strategies for Low- and High-Power Switched Reluctance Motor Drives. In Proceedings of the 2020 IEEE Transportation Electrification Conference & Expo (ITEC), Chicago, IL, USA, 23–26 June 2020. [Google Scholar]

- Anuchin, A.; Bogdanov, A.; Demidova, G.; Savkin, D.; Fedorova, K.; Gulyaeva, M. Model Predictive Control of a Direct Current Motor Utilizing Lookup Tables. In Proceedings of the 11th International Conference on Electrical Power Drive Systems (ICEPDS), St. Petersburg, Russia, 4–7 October 2020. [Google Scholar]

- Anuchin, A.; Demidova, G.; Hao, C.; Zharkov, A.; Bogdanov, A.; Smidl, V. Continuous Control Set Model Predictive Control of a Switch Reluctance Drive Using Lookup Tables. Energies 2020, 13, 3317. [Google Scholar] [CrossRef]

- Li, X.; Shamsi, P. Inductance Surface Learning for Model Predictive Current Control of Switched Reluctance Motors. IEEE Trans. Transp. Electrif. 2015, 1, 287–297. [Google Scholar] [CrossRef]

- Li, X.; Shamsi, P. Adaptive Model Predictive Current Control for DSSRM Drives. In Proceedings of the 2014 IEEE Transportation Electrification Conference and Expo (ITEC), Dearborn, MI, USA, 15–18 June 2014. [Google Scholar]

- Anuchin, A.; Bogdanov, A.; Demidova, G.; Stolyarov, E.; Surnin, D.; Vagapov, Y. Online Magnetization Surface Identification for a Switched Reluctance Motor. In Proceedings of the 2020 55th International Universities Power Engineering Conference (UPEC), Turin, Italy, 1–4 September 2020. [Google Scholar]

- Li, B.; Ling, X.; Huang, Y.; Gong, L.; Liu, C. Predictive current control of a switched reluctance machine in the direct-drive manipulator of cloud robotics. Clust. Comput. J. Netw. Softw. Tools Appl. 2017, 20, 3037–3049. [Google Scholar] [CrossRef]

- Mehta, S.; Kabir, M.; Husain, I. Extended Speed Current Profiling Algorithm for Low Torque Ripple SRM using Model Predictive Control. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition (ECCE), Portland, OR, USA, 23–27 September 2018; pp. 4558–4563. [Google Scholar]

- Pereira, M.; Araújo, R.E. Model-Free Finite-Set Predictive Current Control with Optimal Cycle Time for a Switched Reluctance Motor. IEEE Trans. Ind. Electron. 2023, 70, 8355–8364. [Google Scholar] [CrossRef]

- Li, C.; Du, Q.; Liu, X. Indirect predictive torque control for switched reluctance motor in EV application. Energy Rep. 2022, 8, 857–865. [Google Scholar] [CrossRef]

- Ahmad, S.S.; Narayanan, G. Predictive Control Based Constant Current Injection Scheme for Characterization of Switched Reluctance Machine. IEEE Trans. Ind. Appl. 2018, 54, 3383–3392. [Google Scholar] [CrossRef]

- Shen, S.; Wang, H.; Feng, Y.; Li, M.; Zhong, Y. Predictive Current Control for Switched Reluctance Motor Based on Local Linear Phase Voltage Model. Appl. Sci. 2022, 12, 1688. [Google Scholar] [CrossRef]

- Pereira, M.; Melo, P.; Araújo, R.E. A Back-EMF Estimation Method for a Switched Reluctance Motor using Model Predictive Control. In Proceedings of the 2020 IEEE Vehicle Power and Propulsion Conference (VPPC), Gijon, Spain, 18 November–16 December 2020. [Google Scholar]

- Mikail, R.; Husain, I.; Sozer, Y.; Islam, M.S.; Sebastian, T. A Fixed Switching Frequency Predictive Current Control Method for Switched Reluctance Machines. IEEE Trans. Ind. Appl. 2014, 50, 3717–3726. [Google Scholar] [CrossRef]

- Haque, M.E.; Chowdhury, A.; Das, S.; Sozer, Y.; Venegas, F.; Colavincenzo, D. Phase Collaborative Interleaving Method to Reduce DC-Link Current Ripple in Switched Reluctance Machine Drive. In Proceedings of the 2021 IEEE Energy Conversion Congress and Exposition (ECCE), Vancouver, BC, Canada, 10–14 October 2021. [Google Scholar]

- Li, Y.; Wang, G.; Li, C. A performance assessment of model predictive direct power control and model predictive direct current control for switched reluctance motor drive systems. IEEJ Trans. Electr. Electron. Eng. 2018, 13, 632–641. [Google Scholar] [CrossRef]

- Valencia, D.F.; Filho, S.R.; Callegaro, A.D.; Preindl, M.; Emadi, A. Virtual-Flux Finite Control Set Model Predictive Control of Switched Reluctance Motor Drives. In Proceedings of the IECON 2019—45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019. [Google Scholar]

- Pupadubsin, R.; Somsiri, P.; Chayopitak, N.; Tungpimolrut, K.; Jitkreeyan, P.; Kachapornkul, S. Simple Predictive Delta-Modulation Current Regulator for Switched Reluctance Motor Drive. In Proceedings of the ICEMS 2008: 11th International Conference on Electrical Machines and Systems, Wuhan, China, 17–20 October 2008; Volume 1–8, pp. 3333–3337. [Google Scholar]

- Abdel-Fadil, R.; Számel, L. Enhancement of the Switched Reluctance Motor Performance for Electric Vehicles Applications Using Predictive Current Control. In Proceedings of the 2018 International IEEE Conference and Workshop in Óbuda on Electrical and Power Engineering (CANDO-EPE), Budapest, Hungary, 20–21 November 2018. [Google Scholar]

- Cai, H.; Li, M.; Wang, H.; Shen, S.; Wang, W. Torque Ripple Minimization for Switched Reluctance Motor with Predictive Current Control Method. In Proceedings of the 2017 20th International Conference on Electrical Machines and Systems (ICEMS), Sydney, NSW, Australia, 11–14 August 2017. [Google Scholar]

- Anuchin, A.; Podzorova, V.; Hirz, M.; Datlinger, C.; Aarniovuori, L.; Popova, V.; Demidova, G.; Hao, C. Model Predictive Control with Reduced Integration Step Size of a Switched Reluctance Drive. In Proceedings of the 2020 XI International Conference on Electrical Power Drive Systems (ICEPDS), St. Petersburg, Russia, 4–7 October 2020. [Google Scholar]

- Anuchin, A.; Shpak, D.; Kotelnikova, A.; Dmitriev, A.; Bogdanov, A.; Demidova, G. Encoderless Rotor Position Estimation of a Switched Reluctance Drive Operated under Model Predictive Control. In Proceedings of the 2020 IEEE 61th International Scientific Conference on Power and Electrical Engineering of Riga Technical University (RTUCON), Riga, Latvia, 5–7 November 2020. [Google Scholar]

- Mehta, S.; Pramod, P.; Husain, I. Analysis of Dynamic Current Control Techniques for Switched Reluctance Motor Drives for High Performance Applications. In Proceedings of the 2019 IEEE Transportation Electrification Conference and Expo (ITEC), Detroit, MI, USA, 19–21 June 2019. [Google Scholar]

- Torrico, B.; Almeida, R.; Reis, L.D.; Silva, W.; Pontes, R. Robust Control Based on Generalized Predictive Control Applied to Switched Reluctance Motor Current Loop. J. Dyn. Syst. Meas. Control. Trans. Asme 2014, 136, 031021. [Google Scholar] [CrossRef]

- Ge, L.; Yuan, R.; Cheng, Q.; Zhong, J.; Bao, C.; Song, S. Model Predictive Torque and Force Control of a Switched Reluctance Machine. In Proceedings of the 2021 IEEE International Conference on Predictive Control of Electrical Drives and Power Electronics (PRECEDE), Jinan, China, 20–22 November 2021. [Google Scholar]

- Peyrl, H.; Papafotiou, G.; Morari, M. Model predictive torque control of a Switched Reluctance Motor. In Proceedings of the 2009 IEEE International Conference on Industrial Technology, Churchill, VIC, Australia, 10–13 February 2009. [Google Scholar]

- Li, C.; Zhao, B.; Liu, J.; Liu, X. A Novel Predictive Torque Controller for Switched Reluctance Motor Drives. IEEJ Trans. Electr. Electron. Eng. 2023, 18, 72–80. [Google Scholar] [CrossRef]

- Tarvirdilu-Asl, R.; Nalakath, S.; Bilgin, B.; Emadi, A. A Finite Control Set Model Predictive Torque Control for Switched Reluctance Motor Drives with Adaptive Turn-off Angle. In Proceedings of the 45th Annual Conference of The Ieee Industrial Electronics Society (IECON 2019), Lisbon, Portugal, 14–17 October 2019; pp. 840–845. [Google Scholar]

- Yang, W.; Gou, B.; Lei, Y.; Song, X.; Wang, J. SRM torque ripple suppression method based on model predictive control. Adv. Technol. Electr. Eng. Energy 2020, 39, 18–28. [Google Scholar]

- Yuan, R.; Cheng, Q.; Song, S.; Ge, L.; Zhao, X.; Ma, R.; Liu, W. A Method of Torque Ripple Suppression of SRM based on Model Predictive Control. In Proceedings of the 2021 IEEE International Conference on Predictive Control of Electrical Drives and Power Electronics (PRECEDE), Jinan, China, 20–22 November 2021. [Google Scholar]

- Feng, L.; Sun, X.; Yang, Z.; Diao, K. Optimal torque sharing function control for switched reluctance motors based on active disturbance rejection controller. IEEE/ASME Trans. Mechatron. 2023; accepted. [Google Scholar]

- Sun, X.; Xiong, Y.; Yao, M.; Tang, X.; Tian, X. A unified control method combined with improved TSF and LADRC for SRMs using modified grey wolf optimization algorithm. ISA Trans. 2022, 131, 662–671. [Google Scholar] [CrossRef]

- Li, Y.; Wang, R.; Wang, G.; Li, C.; Fan, Y.; Liu, J. Predictive Direct Torque Control for Switched Reluctance Motor Drive System. In Proceedings of the 2018 37th Chinese Control Conference (CCC), Wuhan, China, 25–27 July 2018; pp. 3871–3876. [Google Scholar]

- Sheng, L.; Wang, G.; Fan, Y.; Liu, J.; Liu, D.; Mu, D. An Improved Direct Predictive Torque Control for Torque Ripple and Copper Loss Reduction in SRM Drive. Appl. Sci. 2023, 13, 5319. [Google Scholar] [CrossRef]

- Li, M.; Gao, T.; Zhu, H.; Shen, S.; Xu, Y. Predictive Torque Control of Switched Reluctance Motor Based on Torque Sharing Function. Proc. CSU-EPSA 2021, 33, 123–129. [Google Scholar]

- Ge, L.; Fan, Z.; Du, N.; Huang, J.; Xiao, D.; Song, S. Model Predictive Torque and Force Control for Switched Reluctance Machines based on Online Optimal Sharing Function. IEEE Trans. Power Electron. 2023, 37, 1–10. [Google Scholar] [CrossRef]

- Brauer, H.J.; Hennen, M.D.; De Doncker, R.W. Control for Polyphase Switched Reluctance Machines to Minimize Torque Ripple and Decrease Ohmic Machine Losses. IEEE Trans. Power Electron. 2012, 27, 370–378. [Google Scholar] [CrossRef]

- Hu, H.; Cao, X.; Yan, N.; Deng, Z. A New Predictive Torque Control Based Torque Sharing Function for Switched Reluctance Motors. In Proceedings of the 2019 22nd International Conference on Electrical Machines and Systems (ICEMS 2019), Harbin, China, 11–14 August 2019; pp. 4184–4188. [Google Scholar]

- Li, W.; Cui, Z.; Ding, S.; Chen, F.; Guo, Y. Model Predictive Direct Torque Control of Switched Reluctance Motors for Low-Speed Operation. IEEE Trans. Energy Convers. 2022, 37, 1406–1415. [Google Scholar] [CrossRef]

- Ren, P.; Zhu, J.; Jing, Z.; Guo, Z.; Xu, A. Minimization of torque ripple in switched reluctance motor based on MPC and TSF. IEEJ Trans. Electr. Electron. Eng. 2021, 16, 1535–1543. [Google Scholar] [CrossRef]

- Song, S.; Hei, R.; Ma, R.; Liu, W. Model Predictive Control of Switched Reluctance Starter/Generator with Torque Sharing and Compensation. IEEE Trans. Transp. Electrif. 2020, 6, 1519–1527. [Google Scholar] [CrossRef]

- Feng, L.; Sun, X.; Tian, X.; Diao, K. Direct Torque Control with Variable Flux for an SRM Based on Hybrid Optimization Algorithm. IEEE Trans. Power Electron. 2022, 37, 6688–6697. [Google Scholar] [CrossRef]

- Diao, K.; Sun, X.; Lei, G.; Guo, Y.; Zhu, J. Multiobjective System Level Optimization Method for Switched Reluctance Motor Drive Systems Using Finite-Element Model. IEEE Trans. Ind. Electron. 2020, 67, 10055–10064. [Google Scholar] [CrossRef]

- Sun, X.; Diao, K.; Lei, G.; Guo, Y.; Zhu, J. Real-Time HIL Emulation for a Segmented-Rotor Switched Reluctance Motor Using a New Magnetic Equivalent Circuit. IEEE Trans. Power Electron. 2020, 35, 3841–3849. [Google Scholar] [CrossRef]

- Fang, G.; Ye, J.; Xiao, D.; Xia, Z.; Emadi, A. Computational-Efficient Model Predictive Torque Control for Switched Reluctance Machines with Linear-Model-Based Equivalent Transformations. IEEE Trans. Ind. Electron. 2022, 69, 5465–5477. [Google Scholar] [CrossRef]

- Fang, G.; Ye, J.; Xiao, D.; Xia, Z.; Emadi, A. Low-Ripple Continuous Control Set Model Predictive Torque Control for Switched Reluctance Machines Based on Equivalent Linear SRM Model. IEEE Trans. Ind. Electron. 2022, 69, 12480–12495. [Google Scholar] [CrossRef]

- Ge, L.; Zhong, J.; Huang, J.; Song, S. Model Predictive Torque Control of Switched Reluctance Machine based on Torque-balanced Measurement and Flux-based Torque Estimation. In Proceedings of the 2021 24th International Conference on Electrical Machines and Systems (ICEMS 2021), Gyeongju, Republic of Korea, 31 October–3 November 2021; pp. 867–872. [Google Scholar]

- Ge, L.; Zhong, J.; Huang, J.; Jiao, N.; Song, S.; De Doncker, R.W. A Novel Model Predictive Torque Control of SRMs with Low Measurement Effort. IEEE Trans. Ind. Electron. 2023, 70, 3561–3570. [Google Scholar] [CrossRef]

- Li, C.; Wang, G.; Li, Y.; Xu, A. An improved finite-state predictive torque control for switched reluctance motor drive. IET Electr. Power Appl. 2018, 12, 144–151. [Google Scholar] [CrossRef]

- Goto, H.; Ichinokura, O. Model prediction based instantaneous torque control of switched reluctance motor. In Proceedings of the 2014 International Conference on Electrical Machines (ICEM), Berlin, Germany, 2–5 September 2014. [Google Scholar]

- Ding, W.; Li, J.; Yuan, J. An Improved Model Predictive Torque Control for Switched Reluctance Motors with Candidate Voltage Vectors Optimization. IEEE Trans. Ind. Electron. 2023, 70, 4595–4607. [Google Scholar] [CrossRef]

- Li, J.; Ding, W.; Yuan, J.; Liu, Z.; Hu, R. An Improved Model Predictive Control Method of Switched Reluctance Motor Based on Direct Torque Control. In Proceedings of the 2021 24th International Conference on Electrical Machines and Systems (ICEMS), Gyeongju, Republic of Korea, 31 October–3 November 2021. [Google Scholar]

- Villegas, J.; Vazquez, S.; Carrasco, J.M.; Gil, I. Model Predictive Control of a switched reluctance machine using discrete Space Vector Modulation. In Proceedings of the 2010 IEEE International Symposium on Industrial Electronics, Bari, Italy, 4–7 July 2010. [Google Scholar]

- Zhang, X.; Cao, Y.; Ye, Z.; Wang, F. SRM Torque Predictive Control Based on Discrete Space Vector Modulation. Power Electron. 2020, 54, 56–59. [Google Scholar]

- Tarvirdilu-Asl, R.; Nalakath, S.; Valencia, D.; Bilgin, B.; Emadi, A. Finite Control Set Model Predictive Control for Switched Reluctance Motor Drives with Reduced Torque Tracking Error. In Proceedings of the IECON 2021—47th Annual Conference of The IEEE Industrial Electronics Society, Toronto, ON, Canada, 13–16 October 2021. [Google Scholar]

- Valencia, D.; Tarvirdilu-Asl, R.; Garcia, C.; Rodriguez, J.; Emadi, A. A Look-up Table-based Model Predictive Torque Control of Switched Reluctance Motor Drives with Improved Prediction. In Proceedings of the 2021 IEEE Transportation Electrification Conference & Expo (ITEC), Chicago, IL, USA, 21–25 June 2021; pp. 315–320. [Google Scholar]

- Xu, A.; Shang, C.; Chen, J.; Zhu, J.; Han, L. A New Control Method Based on DTC and MPC to Reduce Torque Ripple in SRM. IEEE Access 2019, 7, 68584–68593. [Google Scholar] [CrossRef]

- Ge, L.; Zhong, J.; Cheng, Q.; Fan, Z.; Song, S.; De Doncker, R.W. Model Predictive Control of Switched Reluctance Machines for Suppressing Torque and Source Current Ripples Under Bus Voltage Fluctuation. IEEE Trans. Ind. Electron. 2023, 70, 11013–11021. [Google Scholar] [CrossRef]

- Qi, F.; Raley, I.; Stippich, A.; De Doncker, R. Model Predictive Overload Control of an Automotive Switched Reluctance Motor for Frequent Rapid Accelerations. In Proceedings of the 2016 19th International Conference on Electrical Machines and Systems (ICEMS 2016), Chiba, Japan, 13–16 November 2016. [Google Scholar]

- Qi, F.; Stippich, A.; Ralev, I.; Klein-Hessling, A.; De Doncker, R.W. Model Predictive Control of a Switched Reluctance Machine for Guaranteed Overload Torque. IEEE Trans. Ind. Appl. 2019, 55, 1321–1331. [Google Scholar] [CrossRef]

- Saeed, J.; Niakinezhad, M.; Fernando, N.; Wang, L. Model Predictive Control of an Electric Vehicle Motor Drive Integrated Battery Charger. In Proceedings of the 2019 IEEE 13th International Conference on Compatibility, Power Electronics and Power Engineering (CPE-POWERENG), Sonderborg, Denmark, 23–25 April 2019. [Google Scholar]

- Shang, C.; Xu, A.; Huang, L.; Chen, J. Flux linkage optimization for direct torque control of switched reluctance motor based on model predictive control. IEEJ Trans. Electr. Electron. Eng. 2019, 14, 1105–1113. [Google Scholar] [CrossRef]

- Silva, W.; Reis, L.D.; Torrrico, B.; Almeida, R. Speed Control in Switched Reluctance motor Based on Generalized Predictive Control. In Proceedings of the 2013 Brazilian Power Electronics Conference (COBEP), Gramado, Brazil, 27–31 October 2013; pp. 903–908. [Google Scholar]

- Song, S.; Liu, J.; Zhao, Y.; Ge, L.; Ma, R.; Liu, W. High-Dynamic Four-Quadrant Speed Adjustment of Switched Reluctance Machine with Torque Predictive Control. IEEE Trans. Ind. Electron. 2022, 69, 7733–7743. [Google Scholar] [CrossRef]

- Tang, Y.; He, Y.; Wang, F.; Lin, G.; Rodríguez, J.; Kennel, R. A Centralized Control Strategy for Grid-Connected High-Speed Switched Reluctance Motor Drive System with Power Factor Correction. IEEE Trans. Energy Convers. 2021, 36, 2163–2172. [Google Scholar] [CrossRef]

- Tang, Y.; He, Y.; Wang, F.; Kennel, R. Voltage-Sourced Converter Fed High-Speed Switched Reluctance Motor Drive System with Energy Feedback and Near-Unity Power Factor. IEEE Trans. Ind. Electron. 2022, 69, 3460–3470. [Google Scholar]

- Yang, J.; Huo, L. Nonlinear predictive control for SRM based on TSE. In Proceedings of the 2009 Chinese Control and Decision Conference, Guilin, China, 17–19 June 2009. [Google Scholar]

- Besselmann, T.J.; Van de moortel, S.; Almèr, S.; Jörg, P.; Ferreau, H.J. Model predictive control in the multi-megawatt range. IEEE Trans. Ind. Electron. 2016, 63, 4641–4648. [Google Scholar] [CrossRef]

- Bostanci, E.; Moallem, M.; Parsapour, A.; Fahimi, B. Opportunities and challenges of switched reluctance motor drives for electric propulsion: A comparative study. IEEE Trans. Transp. Electrif. 2017, 3, 58–75. [Google Scholar]

- Al-Amyal, F.; Számel, L. Research on Novel Hybrid Torque Sharing Function for Switched Reluctance Motors. IEEE Access 2022, 10, 91306–91315. [Google Scholar] [CrossRef]

| Methods | Fixed Switching Rate | Cost Function Based | Algorithm Complexity | Whether to Include Constraint Processing |

|---|---|---|---|---|

| Deadbeat Predictive Control | Yes | No | normal | No |

| Generalized Predictive Control | Yes | Yes | normal | No |

| Continuous Control Set Model Predictive Control | Yes | Yes | complicated | Yes |

| Finite Control Set Model Predictive Control | No | Yes | complicated | Yes |

| Hysteresis Predictive control | No | No | normal | No |

| Limitations | Advantages | Direction of Development |

|---|---|---|

| Low power, low voltage systems | / | High power machines |

| Traditional SRM topology | / | Other motor topologies such as segmented rotor SRM, dual stator SRM, or mutually coupled SRM |

| / | Ability to function during malfunctions and high-speed conditions, and high DC link utilization | Applications in electrified power systems |

| / | Independent control of each phase | Combination with fault-tolerant control |

| / | Rapid current response and precise current tracking when running near unaligned positions | Utilized during high-speed operation when the inductance is low |

| / | Combinability of control loops | Combination with sensor-less control of the speed loop |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Yao, M.; Sun, X. A Review on Predictive Control Technology for Switched Reluctance Motor System. World Electr. Veh. J. 2023, 14, 221. https://doi.org/10.3390/wevj14080221

Zhu Y, Yao M, Sun X. A Review on Predictive Control Technology for Switched Reluctance Motor System. World Electric Vehicle Journal. 2023; 14(8):221. https://doi.org/10.3390/wevj14080221

Chicago/Turabian StyleZhu, Yiliang, Ming Yao, and Xiaodong Sun. 2023. "A Review on Predictive Control Technology for Switched Reluctance Motor System" World Electric Vehicle Journal 14, no. 8: 221. https://doi.org/10.3390/wevj14080221