A Systematic Literature Review of State of Health and State of Charge Estimation Methods for Batteries Used in Electric Vehicle Applications

Abstract

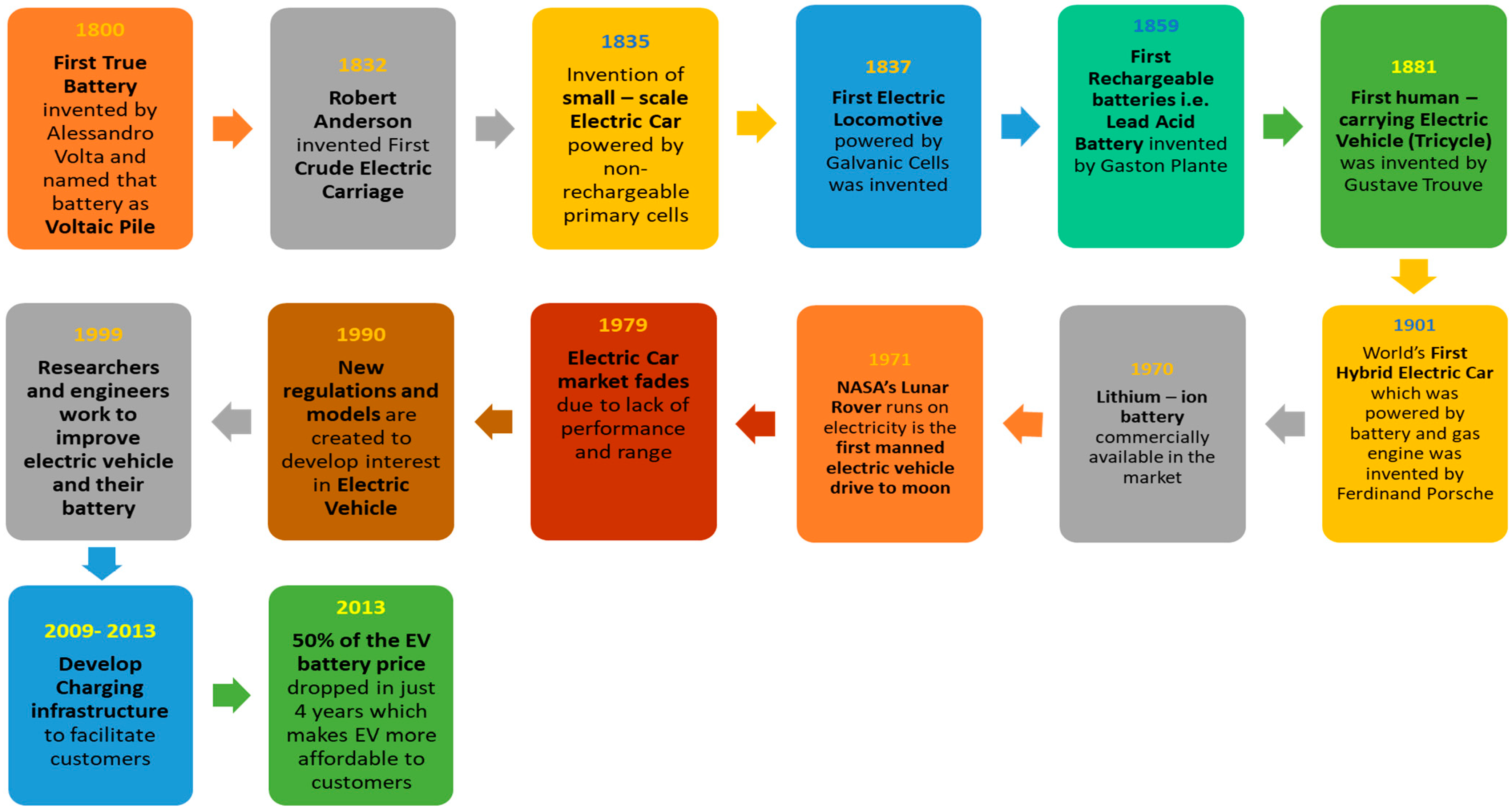

1. Introduction

- Research trends in state estimation, key challenges, and solutions related to BMS are discussed;

- Literature review on SOC and SOH estimation techniques is discussed;

- Publicly available dataset details for Machine Learning/Deep Learning (ML/DL) methods are listed;

- Critical analysis, limitations, and research gaps in existing work are discussed;

- Future direction and unmapped areas are discussed;

- These contributions will help researchers choose the algorithm suited to their research problem.

1.1. Different EV Lithium-Ion Battery Chemistry Comparison

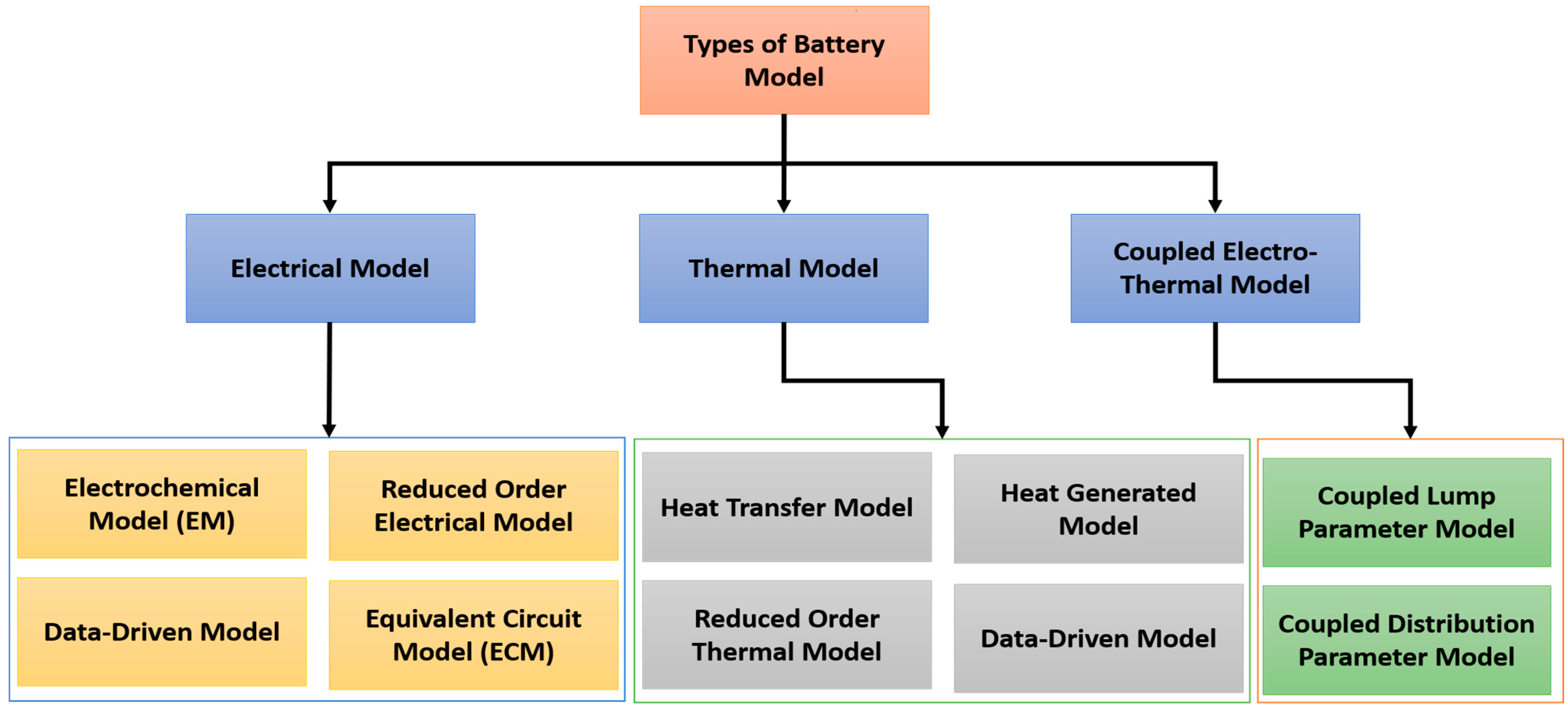

1.2. Battery Modeling

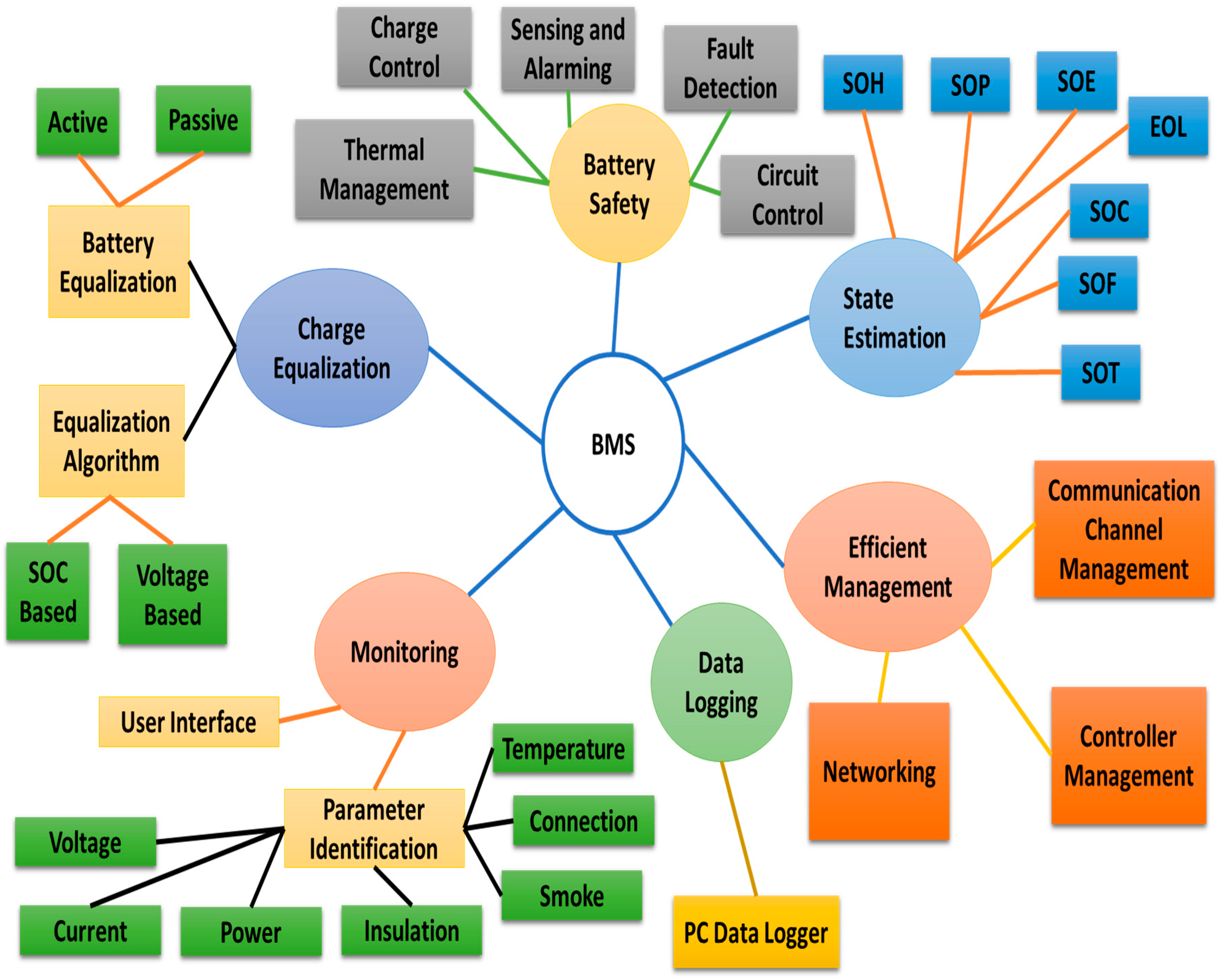

2. Battery Management System Terminologies

2.1. State of Health (SOH)

2.2. State of Charge (SOC)

2.3. State of Temperature (SOT)

2.4. State of Energy (SOE)

2.5. State of Power (SOP)

2.6. State of Function (SOF)

2.7. Remaining Useful Life (RUL)

3. Issues and Challenges in Battery Management System

3.1. Cell Voltage Management

3.2. State Estimation

3.3. Battery Equalization and Normality

3.4. Fault Diagnosis

3.5. Diverse Application of BMS

3.6. Handling of Unknown Hazard

3.7. Lack of Safe Operating Area (SOA) of Battery

3.8. Ensure the Power Converter Operates in a Safe Operating Region

4. Solutions to Tackle Problems in Battery Management Systems

5. Bibliometric Analysis of Research Trend

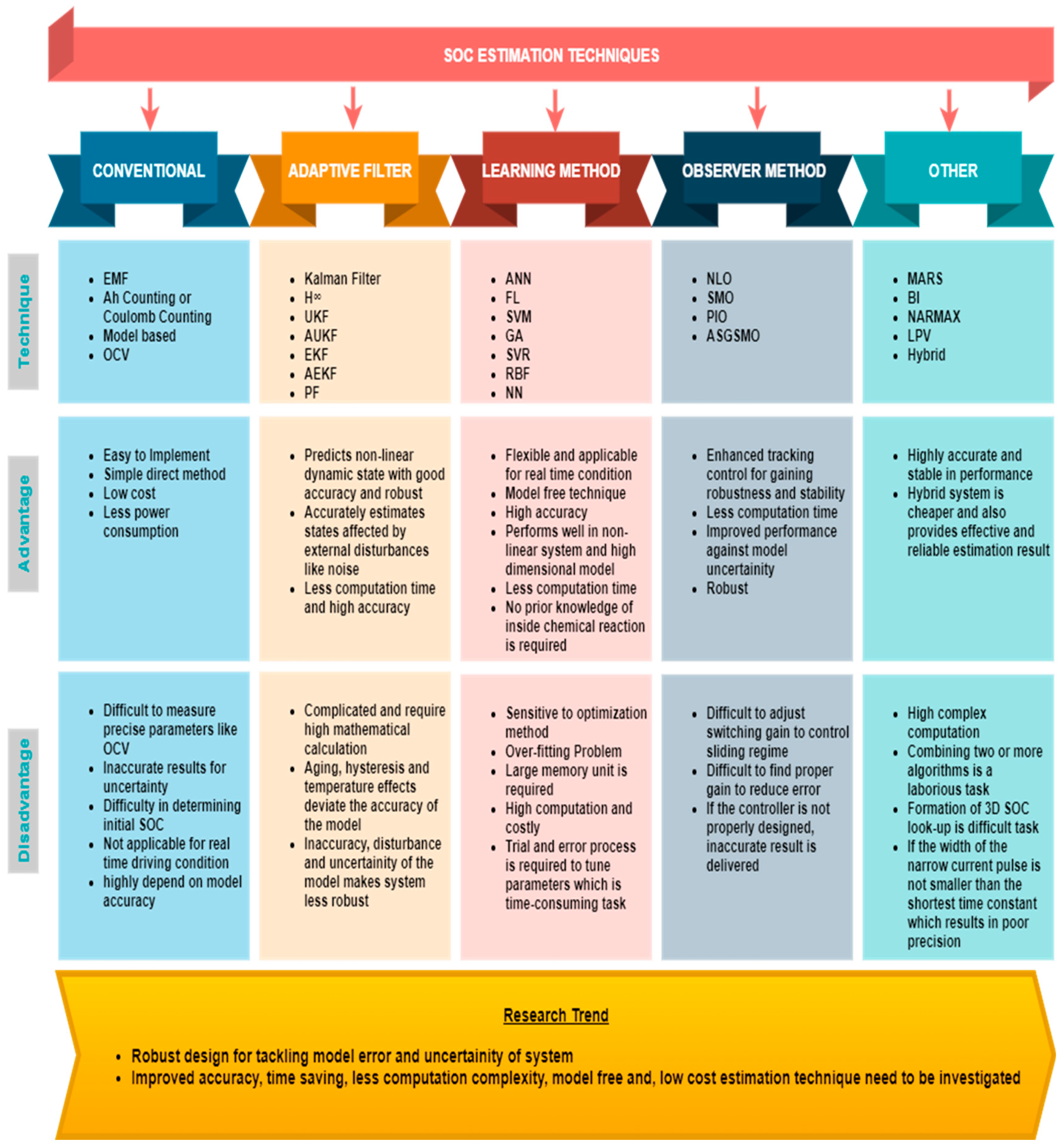

6. Literature Review on SOC Estimation Methods

7. Literature Review on SOH Estimation Methods

8. Critical Analysis of Literature Survey

9. Limitation and Future Perspective

10. Conclusions

- Enable OEMs to visualize their battery performance and bring attention to whether their batteries working up to warranty or not.

- Allow OEMs to upscale sale by demonstrating their battery performance.

- To spread awareness that the replacement of batteries in proper time can and must be undertaken.

- Predictive maintenance of the battery will enhance battery life.

- By tracking SOC and SOH parameters: parking, charging strategy, and driving patterns can be improved.

- Based on the battery capacity, battery retirement, reuse, recycling, and disposal can be planned accordingly.

- Based on the available capacity and aging patterns, pricing of the retired batteries can be determined.

- To spread awareness about the usefulness of disposed batteries and how they can be reused, or that purchasing retired batteries is also helpful.

- Encourage the accumulation of old battery packs, and then identify and cluster the good cells with life and then assemble them to make a new battery.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- World Bank Group. World Bank Document Electric Mobility in India; World Bank Group: Washington, DC, USA, 2021. [Google Scholar]

- Brenna, M.; Foiadelli, F.; Leone, C.; Longo, M. Electric Vehicles Charging Technology Review and Optimal Size Estimation. J. Electr. Eng. Technol. 2020, 15, 2539–2552. [Google Scholar] [CrossRef]

- El-Bayeh, C.Z.; Alzaareer, K.; Aldaoudeyeh, A.-M.I.; Brahmi, B.; Zellagui, M. Charging and Discharging Strategies of Electric Vehicles: A Survey. World Electr. Veh. J. 2021, 12, 11. [Google Scholar] [CrossRef]

- Pillai, R.K.; Suri, R.; Dhuri, S.; Kundu, S. ISGF Study Report EVCharging India July2019; India Smart Grid Forum: New Delhi, India, 2019. [Google Scholar]

- Electric Vehicle. Available online: https://en.wikipedia.org/wiki/Electric_vehicle (accessed on 4 July 2023).

- Projected Impacts of Inflation Reduction Act and Bipartisan Infrastructure Law. Available online: https://www.energy.gov/ (accessed on 4 July 2023).

- Shuang, Q.; Yingqi, L.; Lei, Z. Research on the effect of industrial policy on the development of China’s new energy vehicle power battery recycling industry chain. E3S Web Conf. 2021, 292, 01006. [Google Scholar] [CrossRef]

- Huang, S.-C.; Tseng, K.-H.; Liang, J.-W.; Chang, C.-L.; Pecht, M.G. An Online SOC and SOH Estimation Model for Lithium-Ion Batteries. Energies 2017, 10, 512. [Google Scholar] [CrossRef]

- IEA. Global EV Outlook 2021; IEA: Paris, France, 2021. [Google Scholar]

- Ullah, I.; Liu, K.; Yamamoto, T.; Shafiullah; Jamal, A. Grey wolf optimizer-based machine learning algorithm to predict electric vehicle charging duration time. Transp. Lett. 2022, 1–18. [Google Scholar] [CrossRef]

- Gupta, A.; Manthiram, A. Designing Advanced Lithium-Based Batteries for Low-Temperature Conditions. Adv. Energy Mater. 2020, 10, 2001972. [Google Scholar] [CrossRef]

- Li, S.; Wang, K. The Literature Review on Control Methods of SOH and SOC for Supercapacitors. In Proceedings of the 2019 4th International Conference on Control, Robotics and Cybernetics (CRC), Tokyo, Japan, 27–30 September 2019; pp. 17–21. [Google Scholar] [CrossRef]

- Roman, D.; Saxena, S.; Robu, V.; Pecht, M.; Flynn, D. Machine learning pipeline for battery state-of-health estimation. Nat. Mach. Intell. 2021, 3, 447–456. [Google Scholar] [CrossRef]

- Sarmah, S.B.; Kalita, P.; Garg, A.; Niu, X.-D.; Zhang, X.-W.; Peng, X.; Bhattacharjee, D. A Review of State of Health Estimation of Energy Storage Systems: Challenges and Possible Solutions for Futuristic Applications of Li-Ion Battery Packs in Electric Vehicles. J. Electrochem. Energy Convers. Storage 2019, 16, 040801. [Google Scholar] [CrossRef]

- Zhang, J.; Lee, J. A review on prognostics and health monitoring of Li-ion battery. J. Power Sources 2011, 196, 6007–6014. [Google Scholar] [CrossRef]

- Liu, K.; Li, K.; Peng, Q.; Zhang, C. A brief review on key technologies in the battery management system of electric vehicles. Front. Mech. Eng. 2018, 14, 47–64. [Google Scholar] [CrossRef]

- Vidal, C.; Malysz, P.; Kollmeyer, P.; Emadi, A. Machine Learning Applied to Electrified Vehicle Battery State of Charge and State of Health Estimation: State-of-the-Art. IEEE Access 2020, 8, 52796–52814. [Google Scholar] [CrossRef]

- Berecibar, M.; Gandiaga, I.; Villarreal, I.; Omar, N.; Van Mierlo, J.; van den Bossche, P. Critical review of state of health estimation methods of Li-ion batteries for real applications. Renew. Sustain. Energy Rev. 2016, 56, 572–587. [Google Scholar] [CrossRef]

- Cuma, M.U.; Koroglu, T. A comprehensive review on estimation strategies used in hybrid and battery electric vehicles. Renew. Sustain. Energy Rev. 2015, 42, 517–531. [Google Scholar] [CrossRef]

- Battery Archive Dataset. Available online: www.batteryarchive.org (accessed on 5 November 2022).

- Luzi, M. Automotive Lithium-ion Cell Usage Data Set; IEEE Dataport: Piscataway, NJ, USA, 2018. [Google Scholar] [CrossRef]

- Rahman, A.; Anwar, S.; Izadian, A. Electrochemical model parameter identification of a lithium-ion battery using particle swarm optimization method. J. Power Sources 2016, 307, 86–97. [Google Scholar] [CrossRef]

- Sung, W.; Shin, C.B. Electrochemical model of a lithium-ion battery implemented into an automotive battery management system. Comput. Chem. Eng. 2015, 76, 87–97. [Google Scholar] [CrossRef]

- Jiang, J.; Ruan, H.; Sun, B.; Zhang, W.; Gao, W.; Wang, L.Y.; Zhang, L. A reduced low-temperature electro-thermal coupled model for lithium-ion batteries. Appl. Energy 2016, 177, 804–816. [Google Scholar] [CrossRef]

- Chen, Z.; Sun, M.; Shu, X.; Xiao, R.; Shen, J. Online State of Health Estimation for Lithium-Ion Batteries Based on Support Vector Machine. Appl. Sci. 2018, 8, 925. [Google Scholar] [CrossRef]

- Deng, Z.; Yang, L.; Cai, Y.; Deng, H.; Sun, L. Online available capacity prediction and state of charge estimation based on advanced data-driven algorithms for lithium iron phosphate battery. Energy 2016, 112, 469–480. [Google Scholar] [CrossRef]

- Gong, X.; Xiong, R.; Mi, C.C. A data-driven bias correction method based lithiumion battery modeling approach for electric vehicle applications. IEEE Trans. Ind. Appl. 2015, 52, 1759–1765. [Google Scholar] [CrossRef]

- Li, Y.; Chattopadhyay, P.; Xiong, S.; Ray, A.; Rahn, C.D. Dynamic data-driven and model-based recursive analysis for estimation of battery state-of-charge. Appl. Energy 2016, 184, 266–275. [Google Scholar] [CrossRef]

- Gou, B.; Xu, Y.; Feng, X. An Ensemble Learning-Based Data-Driven Method for Online State-of-Health Estimation of Lithium-Ion Batteries. IEEE Trans. Transp. Electrif. 2020, 7, 422–436. [Google Scholar] [CrossRef]

- Guo, M.; Kim, G.-H.; White, R.E. A three-dimensional multi-physics model for a Li-ion battery. J. Power Sources 2013, 240, 80–94. [Google Scholar] [CrossRef]

- Hu, X.; Asgari, S.; Yavuz, I.; Stanton, S.; Hsu, C.-C.; Shi, Z.; Wang, B.; Chu, H.-K. A Transient Reduced Order Model for Battery Thermal Management Based on Singular Value Decomposition. In Proceedings of the 2014 IEEE Energy Conversion Congress and Exposition (ECCE), Pittsburgh, PA, USA, 14–18 September 2014. [Google Scholar] [CrossRef]

- Muratori, M.; Canova, M.; Guezennec, Y.; Rizzoni, G. A Reduced-Order Model for the Thermal Dynamics of Li-Ion Battery Cells. IFAC Proc. Vol. 2010, 43, 192–197. [Google Scholar] [CrossRef]

- Basu, S.; Hariharan, K.S.; Kolake, S.M.; Song, T.; Sohn, D.K.; Yeo, T. Coupled electrochemical thermal modelling of a novel Li-ion battery pack thermal management system. Appl. Energy 2016, 181, 1–13. [Google Scholar] [CrossRef]

- Goutam, S.; Nikolian, A.; Jaguemont, J.; Smekens, J.; Omar, N.; Bossche, P.V.D.; Van Mierlo, J. Three-dimensional electro-thermal model of li-ion pouch cell: Analysis and comparison of cell design factors and model assumptions. Appl. Therm. Eng. 2017, 126, 796–808. [Google Scholar] [CrossRef]

- Noura, N.; Boulon, L.; Jemeï, S. A Review of Battery State of Health Estimation Methods: Hybrid Electric Vehicle Challenges. World Electr. Veh. J. 2020, 11, 66. [Google Scholar] [CrossRef]

- Zhu, X.; Lin, Q.; You, S.; Chen, S.; Hong, Y. A Review of Battery State of Health Estimation. In Proceedings of the 2019 4th International Conference on Intelligent Green Building and Smart Grid (IGBSG), Yichang, China, 6–9 September 2019. [Google Scholar] [CrossRef]

- Hannan, M.A.; Lipu, M.S.H.; Hussain, A.; Mohamed, A. A review of lithium-ion battery state of charge estimation and management system in electric vehicle applications: Challenges and recommendations. Renew. Sustain. Energy Rev. 2017, 78, 834–854. [Google Scholar] [CrossRef]

- Thakur, A.K.; Prabakaran, R.; Elkadeem, M.; Sharshir, S.W.; Arıcı, M.; Wang, C.; Zhao, W.; Hwang, J.-Y.; Saidur, R. A state of art review and future viewpoint on advance cooling techniques for Lithium–ion battery system of electric vehicles. J. Energy Storage 2020, 32, 101771. [Google Scholar] [CrossRef]

- Komsiyska, L.; Buchberger, T.; Diehl, S.; Ehrensberger, M.; Hanzl, C.; Hartmann, C.; Hölzle, M.; Kleiner, J.; Lewerenz, M.; Liebhart, B.; et al. Critical Review of Intelligent Battery Systems: Challenges, Implementation, and Potential for Electric Vehicles. Energies 2021, 14, 5989. [Google Scholar] [CrossRef]

- Hu, X.; Che, Y.; Lin, X.; Onori, S. Battery Health Prediction Using Fusion-Based Feature Selection and Machine Learning. IEEE Trans. Transp. Electrif. 2021, 7, 382–398. [Google Scholar] [CrossRef]

- Hu, X.; Xu, L.; Lin, X.; Pecht, M. Battery Lifetime Prognostics. Joule 2020, 4, 310–346. [Google Scholar] [CrossRef]

- Eddahech, A.; Briat, O.; Vinassa, J.-M. Real-Time SOC and SOH Estimation for EV Lithium-ion Cell Using Online Parameters Identification. In Proceedings of the 2012 IEEE Energy Conversion Congress and Exposition (ECCE), Raleigh, NC, USA, 15–20 September 2012. [Google Scholar] [CrossRef]

- Feng, F.; Teng, S.; Liu, K.; Xie, J.; Xie, Y.; Liu, B.; Li, K. Co-estimation of lithium-ion battery state of charge and state of temperature based on a hybrid electrochemical-thermal-neural-network model. J. Power Sources 2020, 455, 227935. [Google Scholar] [CrossRef]

- Lai, X.; Huang, Y.; Han, X.; Gu, H.; Zheng, Y. A novel method for state of energy estimation of lithium-ion batteries using particle filter and extended Kalman filter. J. Energy Storage 2021, 43, 103269. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, X. Joint estimation method for maximum available energy and state-of-energy of lithium-ion battery under various temperatures. J. Power Sources 2021, 506, 230132. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; He, H.W.; Xiong, R. A Data-Driven Based State of Energy Estimator of Lithium-ion Batteries Used to Supply Electric Vehicles. Energy Procedia 2015, 75, 1944–1949. [Google Scholar] [CrossRef][Green Version]

- Zheng, L.; Zhu, J.; Wang, G.; He, T.; Wei, Y. Novel methods for estimating lithium-ion battery state of energy and maximum available energy. Appl. Energy 2016, 178, 1–8. [Google Scholar] [CrossRef]

- Hu, X.; Feng, F.; Liu, K.; Zhang, L.; Xie, J.; Liu, B. State estimation for advanced battery management: Key challenges and future trends. Renew. Sustain. Energy Rev. 2019, 114, 109334. [Google Scholar] [CrossRef]

- Hickey, R.; Jahns, T.M. Direct Comparison of State-of-Charge and State-of-Energy Metrics for Lithium-ion Battery Energy Storage. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019. [Google Scholar] [CrossRef]

- Liu, C.; Hu, M.; Jin, G.; Xu, Y.; Zhai, J. State of power estimation of lithium-ion battery based on fractional-order equivalent circuit model. J. Energy Storage 2021, 41, 102954. [Google Scholar] [CrossRef]

- Tan, Y.; Luo, M.; She, L.; Cui, X. Joint Estimation of Ternary Lithium-ion Battery State of Charge and State of Power Based on Dual Polarization Model. Int. J. Electrochem. Sci. 2020, 15, 1128–1147. [Google Scholar] [CrossRef]

- Xie, W.; Ma, L.; Zhang, S.; Jiao, D.; Ma, J. Predicting the State of Power of an Iron-Based Li-Ion Battery Pack Including the Constraint of Maximum Operating Temperature. Electronics 2020, 9, 1737. [Google Scholar] [CrossRef]

- Tang, X.; Liu, K.; Liu, Q.; Peng, Q.; Gao, F. Comprehensive study and improvement of experimental methods for obtaining referenced battery state-of-power. J. Power Sources 2021, 512, 230462. [Google Scholar] [CrossRef]

- Dong, G.; Wei, J.; Chen, Z. Kalman filter for onboard state of charge estimation and peak power capability analysis of lithium-ion batteries. J. Power Sources 2016, 328, 615–626. [Google Scholar] [CrossRef]

- Balagopal, B.; Chow, M.-Y. The State of the Art Approaches to Estimate the State of Health (SOH) and State of Function (SOF) of Lithium Ion Batteries. In Proceedings of the 2015 IEEE 13th International Conference on Industrial Informatics (INDIN), Cambridge, UK, 22–24 July 2015; pp. 1302–1307. [Google Scholar] [CrossRef]

- Park, S.; Ahn, J.; Kang, T.; Park, S.; Kim, Y.; Cho, I.; Kim, J. Review of state-of-the-art battery state estimation technologies for battery management systems of stationary energy storage systems. J. Power Electron. 2020, 20, 1526–1540. [Google Scholar] [CrossRef]

- Shen, P.; Ouyang, M.; Lu, L.; Li, J.; Feng, X. The Co-estimation of State of Charge, State of Health, and State of Function for Lithium-Ion Batteries in Electric Vehicles. IEEE Trans. Veh. Technol. 2018, 67, 92–103. [Google Scholar] [CrossRef]

- Zhang, Z.; Shen, D.; Peng, Z.; Guan, Y.; Yuan, H.; Wu, L. Lithium-ion batteries Remaining Useful Life Prediction Method Considering Recovery Phenomenon. Int. J. Electrochem. Sci. 2019, 14, 7149–7165. [Google Scholar] [CrossRef]

- El Mejdoubi, A.; Chaoui, H.; Sabor, J.; Gualous, H. Remaining Useful Life Prognosis of Supercapacitors Under Temperature and Voltage Aging Conditions. IEEE Trans. Ind. Electron. 2018, 65, 4357–4367. [Google Scholar] [CrossRef]

- Ren, L.; Zhao, L.; Hong, S.; Zhao, S.; Wang, H.; Zhang, L. Remaining Useful Life Prediction for Lithium-Ion Battery: A Deep Learning Approach. IEEE Access 2018, 6, 50587–50598. [Google Scholar] [CrossRef]

- Mei, X.; Fang, H. A Novel Fusion Prognostic Approach for the Prediction of the Remaining Useful Life of a Lithiumion Battery. In Proceedings of the 2018 37th Chinese Control Conference (CCC), Wuhan, China, 25–27 July 2018. [Google Scholar] [CrossRef]

- Lu, L.; Han, X.; Li, J.; Hua, J.; Ouyang, M. A review on the key issues for lithium-ion battery management in electric vehicles. J. Power Sources 2013, 226, 272–288. [Google Scholar] [CrossRef]

- Omariba, Z.B.; Zhang, L.; Sun, D. Review on Health Management System for Lithium-Ion Batteries of Electric Vehicles. Electronics 2018, 7, 72. [Google Scholar] [CrossRef]

- Dost, P.; Kipke, V.; Sourkounis, C. Direct active cell balancing with integrated cell monitoring. IET Electr. Syst. Transp. 2019, 9, 244–250. [Google Scholar] [CrossRef]

- Raber, M.; Hink, D.; Heinzelmann, A.; Abdeslam, D.O. A Novel Non-Isolated Active Charge Balancing Architecture for Lithium-Ion Batteries. In Proceedings of the 2018 IEEE 27th International Symposium on Industrial Electronics (ISIE), Cairns, QLD, Australia, 13–15 June 2018. [Google Scholar] [CrossRef]

- Wu, C.Y.; Huang, Y.Y.; Ku, C.H. Development of an Active and Passive Balancing Strategy for a LiFePO4 Battery Pack. In Proceedings of the 2018 IEEE International Conference on Applied System Invention (ICASI), Chiba, Japan, 13–17 April 2018. [Google Scholar] [CrossRef]

- Dalvi, S.; Thale, S. Design of DSP Controlled Passive Cell Balancing Network Based Battery Management System for EV Application. In Proceedings of the 2020 IEEE India Council International Subsections Conference (INDISCON), Visakhapatnam, India, 3–4 October 2020. [Google Scholar] [CrossRef]

- Kıvrak, S.; Özer, T.; Oğuz, Y.; Kelek, M.M. Novel active and passive balancing method-based battery management system design and implementation. J. Power Electron. 2021, 21, 1855–1865. [Google Scholar] [CrossRef]

- Zhang, F.; Rehman, M.M.U.; Zane, R.; Maksimovic, D. Hybrid Balancing in a Modular Battery Management System for Electric-Drive Vehicles. In Proceedings of the 2017 IEEE Energy Conversion Congress and Exposition (ECCE), Cincinnati, OH, USA, 1–5 October 2017. [Google Scholar] [CrossRef]

- Gao, Z.; Chin, C.S.; Chiew, J.H.K.; Jia, J.; Zhang, C. Design and Implementation of a Smart Lithium-Ion Battery System with Real-Time Fault Diagnosis Capability for Electric Vehicles. Energies 2017, 10, 1503. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, S.; Hu, X. A Fault Diagnosis Method for Lithium-Ion Battery Packs Using Improved RBF Neural Network. Front. Energy Res. 2021, 9, 702139. [Google Scholar] [CrossRef]

- Xiong, R.; Sun, W.; Yu, Q.; Sun, F. Research progress, challenges and prospects of fault diagnosis on battery system of electric vehicles. Appl. Energy 2020, 279, 115855. [Google Scholar] [CrossRef]

- Ham, H.; Han, K.; Lee, H. Battery System Modeling for a Military Electric Propulsion Vehicle with a Fault Simulation. Energies 2013, 6, 5168–5181. [Google Scholar] [CrossRef]

- Samanta, A.; Williamson, S.S. A Survey of Wireless Battery Management System: Topology, Emerging Trends, and Challenges. Electronics 2021, 10, 2193. [Google Scholar] [CrossRef]

- Lee, Y.-J.; Kim, S.-Y. A Study on Configuration of Small Wind Turbines for Maximum Capacity of Wind Power Systems Interconnected With a Building. Trans. Korean Inst. Electr. Eng. 2017, 66, 605–612. [Google Scholar] [CrossRef]

- Rehman, M.M.U.; Zhang, F.; Zane, R.; Maksimovic, D. Design and Control of an Integrated BMS/DC-DC System for Electric Vehicles. In Proceedings of the 2016 IEEE 17th Workshop on Control and Modeling for Power Electronics (COMPEL), Trondheim, Norway, 27–30 June 2016. [Google Scholar] [CrossRef]

- Wang, C.-W.; Lu, L.-J.; Chi, Z.-X.; You, J.-L. A Novel Structural Design of Wireless Lithium-Ion Battery Management System (BMS) by Using Pulse Width Modulation Method for Charging and Discharging. In Proceedings of the 2016 International Conference on Advanced Materials for Science and Engineering (ICAMSE), Tainan, Taiwan, 12–13 November 2016. [Google Scholar] [CrossRef]

- Berrueta, A.; Martin, I.S.; Pascual, J.; Sanchis, P.; Ursua, A. On the Requirements of the Power Converter for Second-Life Lithium-Ion Batteries. In Proceedings of the 2019 21st European Conference on Power Electronics and Applications (EPE 19 ECCE Europe), Genova, Italy, 3–5 September 2019. [Google Scholar] [CrossRef]

- Vatanparvar, K.; Faezi, S.; Burago, I.; Levorato, M.; Al Faruque, M.A. Extended Range Electric Vehicle With Driving Behavior Estimation in Energy Management. IEEE Trans. Smart Grid 2019, 10, 2959–2968. [Google Scholar] [CrossRef]

- Sui, X.; He, S.; Vilsen, S.B.; Meng, J.; Teodorescu, R.; Stroe, D.-I. A review of non-probabilistic machine learning-based state of health estimation techniques for Lithium-ion battery. Appl. Energy 2021, 300, 117346. [Google Scholar] [CrossRef]

- Waag, W.; Fleischer, C.; Sauer, D.U. Critical review of the methods for monitoring of lithium-ion batteries in electric and hybrid vehicles. J. Power Sources 2014, 258, 321–339. [Google Scholar] [CrossRef]

- Xiong, R.; Cao, J.; Yu, Q.; He, H.; Sun, F. Critical Review on the Battery State of Charge Estimation Methods for Electric Vehicles. IEEE Access 2017, 6, 1832–1843. [Google Scholar] [CrossRef]

- Li, Y.; Liu, K.; Foley, A.M.; Zülke, A.; Berecibar, M.; Nanini-Maury, E.; Van Mierlo, J.; Hoster, H.E. Data-driven health estimation and lifetime prediction of lithium-ion batteries: A review. Renew. Sustain. Energy Rev. 2019, 113, 109254. [Google Scholar] [CrossRef]

- Abdullah, H.M.; Gastli, A.; Ben-Brahim, L. Reinforcement Learning Based EV Charging Management Systems–A Review. IEEE Access 2021, 9, 41506–41531. [Google Scholar] [CrossRef]

- Rezvanizaniani, S.M.; Liu, Z.; Chen, Y.; Lee, J. Review and recent advances in battery health monitoring and prognostics technologies for electric vehicle (EV) safety and mobility. J. Power Sources 2014, 256, 110–124. [Google Scholar] [CrossRef]

- Omariba, Z.B.; Zhang, L.; Sun, D. Review of Battery Cell Balancing Methodologies for Optimizing Battery Pack Performance in Electric Vehicles. IEEE Access 2019, 7, 129335–129352. [Google Scholar] [CrossRef]

- Lin, Q.; Wang, J.; Xiong, R.; Shen, W.; He, H. Towards a smarter battery management system: A critical review on optimal charging methods of lithium ion batteries. Energy 2019, 183, 220–234. [Google Scholar] [CrossRef]

- Deng, J.; Bae, C.; Denlinger, A.; Miller, T. Electric Vehicles Batteries: Requirements and Challenges. Joule 2020, 4, 511–515. [Google Scholar] [CrossRef]

- Zhang, R.; Xia, B.; Li, B.; Cao, L.; Lai, Y.; Zheng, W.; Wang, H.; Wang, W. State of the Art of Lithium-Ion Battery SOC Estimation for Electrical Vehicles. Energies 2018, 11, 1820. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, Y.; Wu, J.; Cheng, W.; Zhu, Q. SOC estimation for lithium-ion battery using the LSTM-RNN with extended input and constrained output. Energy 2023, 262, 125375. [Google Scholar] [CrossRef]

- Shen, W.X.; Chan, C.C.; Lo, E.W.C.; Chau, K.T. Adaptive neuro-fuzzy modeling of battery residual capacity for electric vehicles. IEEE Trans. Ind. Electron. 2002, 49, 677–684. [Google Scholar] [CrossRef]

- Saha, B.; Goebel, K.; Poll, S.; Christophersen, J. An integrated approach to battery health monitoring using bayesian regression and state estimation. In Proceedings of the 2007 IEEE Autotestcon, Baltimore, MD, USA, 17–20 September 2007; pp. 646–653. [Google Scholar]

- Shen, W. State of available capacity estimation for lead-acid batteries in electric vehicles using neural network. Energy Convers. Manag. 2007, 48, 433–442. [Google Scholar] [CrossRef]

- Antón, J.C.; Nieto, P.J.G.; Viejo, C.B.; Vilán, J.A.V. Support Vector Machines Used to Estimate the Battery State of Charge. IEEE Trans. Power Electron. 2013, 28, 5919–5926. [Google Scholar] [CrossRef]

- Zheng, Y.; Cui, Y.; Han, X.; Ouyang, M. A capacity prediction framework for lithium-ion batteries using fusion prediction of empirical model and data-driven method. Energy 2021, 237, 121556. [Google Scholar] [CrossRef]

- Eddahech, A.; Briat, O.; Vinassa, J. Adaptive Voltage Estimation for EV Lithium-ion Cell Based on Artificial Neural Networks State-of-Charge Meter. In Proceedings of the 2012 IEEE International Symposium on Industrial Electronics, Hangzhou, China, 28–31 May 2012. [Google Scholar] [CrossRef]

- Barbarisi, O.; Canaletti, R.; Glielmo, L.; Gosso, M.; Vasca, F. State of Charge Estimator for NiMH Batteries. In Proceedings of the 41st IEEE Conference on Decision and Control, Las Vegas, NV, USA, 10–13 December 2002. [Google Scholar] [CrossRef]

- Guo, G.; Zhuo, S.; Xu, P.; Cao, J.; Bai, Z.; Cao, B. Estimation the Residual Capacity of Ni-MH Battery Pack Using NARMAX Method for Electric Vehicles. In Proceedings of the 2008 3rd IEEE Conference on Industrial Electronics and Applications, Singapore, 3–5 June 2008. [Google Scholar] [CrossRef]

- Shen, W.X.; Chau, K.T.; Chan, C.C.; Lo, E.W.C. Neural Network-Based Residual Capacity Indicator for Nickel-Metal Hydride Batteries in Electric Vehicles. IEEE Trans. Veh. Technol. 2005, 54, 1705–1712. [Google Scholar] [CrossRef]

- Windarko, N.A.; Choi, J.-H. SOC Estimation Based on OCV for NiMH Batteries Using an Improved Takacs Model. J. Power Electron. 2010, 10, 181–186. [Google Scholar] [CrossRef]

- Yongqin, Z.; Yanming, Z.; Pengshu, Z.; Chunli, H. Study of battery state-of-charge estimation for hybrid electric vehicles. In Proceedings of the 2011 6th International Forum on Strategic Technology, Harbin, China, 22–24 August 2011. [Google Scholar] [CrossRef]

- Singh, P.; Fennie, C.; Reisner, D. Fuzzy logic modelling of state-of-charge and available capacity of nickel/metal hydride batteries. J. Power Sources 2004, 136, 322–333. [Google Scholar] [CrossRef]

- Piao, C.-H.; Fu, W.-L.; Wang, J.; Huang, Z.-Y.; Cho, C. Estimation of the State of Charge of Ni-MH Battery Pack Based on Artificial Neural Network. In Proceedings of the INTELEC 2009–31st International Telecommunications Energy Conference, Incheon, Republic of Korea, 18–22 October 2009. [Google Scholar] [CrossRef]

- Sun, B.; Wang, L. The SOC Estimation of NIMH Battery Pack for HEV Based on BP Neural Network. In Proceedings of the 2009 International Workshop on Intelligent Systems and Applications, Wuhan, China, 23–24 May 2009. [Google Scholar] [CrossRef]

- Wu, G.; Lu, R.; Zhu, C.; Chan, C. An Improved Ampere-Hour Method for Battery State of Charge Estimation Based on Temperature, Coulomb Efficiency Model and Capacity Loss Model. In Proceedings of the 2010 IEEE Vehicle Power and Propulsion Conference, Lille, France, 1–3 September 2010. [Google Scholar] [CrossRef]

- Li, H.; Liao, C.; Wang, L. Research on State-of-Charge Estimation of Battery Pack Used on Hybrid Electric Vehicle. In Proceedings of the 2009 Asia-Pacific Power and Energy Engineering Conference, Wuhan, China, 27–31 March 2009. [Google Scholar] [CrossRef]

- Bhangu, B.S.; Bentley, P.; Stone, D.A.; Bingham, C.M. Observer Techniques for Estimating the State-of-Charge and State-of-Health of VRLABs for Hybrid Electric Vehicles. In Proceedings of the 2005 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 7 September 2005. [Google Scholar] [CrossRef]

- Qiang, J.; Ao, G.; He, J.; Chen, Z.; Yang, L. An Adaptive Algorithm of NiMH Battery State of Charge Estimation for Hybrid Electric Vehicle. In Proceedings of the 2008 IEEE International Symposium on Industrial Electronics, Cambridge, UK, 30 June–2 July 2008. [Google Scholar] [CrossRef]

- Zhou, Y.; Sun, J.; Wang, X. Power Battery Charging State-of-Charge Prediction Based on Genetic Neural Network. In Proceedings of the 2010 2nd International Conference on Information Engineering and Computer Science, Wuhan, China, 25–26 December 2010. [Google Scholar] [CrossRef]

- Junping, W.; Jingang, G.; Lei, D. An adaptive Kalman filtering based State of Charge combined estimator for electric vehicle battery pack. Energy Convers. Manag. 2009, 50, 3182–3186. [Google Scholar] [CrossRef]

- Wang, J.; Cao, B.; Chen, Q.; Wang, F. Combined state of charge estimator for electric vehicle battery pack. Control. Eng. Pract. 2007, 15, 1569–1576. [Google Scholar] [CrossRef]

- Vasebi, A.; Bathaee, S.; Partovibakhsh, M. Predicting state of charge of lead-acid batteries for hybrid electric vehicles by extended Kalman filter. Energy Convers. Manag. 2008, 49, 75–82. [Google Scholar] [CrossRef]

- Yamazaki, T.; Sakurai, K.; Muramoto, K. Estimation of the Residual Capacity of Sealed Lead-Acid Batteries by Neural Network. In Proceedings of the INTELEC–Twentieth International Telecommunications Energy Conference (Cat. No.98CH36263), San Francisco, CA, USA, 4–8 October 1998. [Google Scholar] [CrossRef]

- Bhangu, B.S.; Bentley, P.; Stone, D.A.; Bingham, C.M. Nonlinear Observers for Predicting State-of-Charge and State-of-Health of Lead-Acid Batteries for Hybrid-Electric Vehicles. IEEE Trans. Veh. Technol. 2005, 54, 783–794. [Google Scholar] [CrossRef]

- Wang, T.-W.; Yang, M.-J.; Shyu, K.-K.; Lai, C.-M. Design Fuzzy SOC Estimation for Sealed Lead-Acid Batteries of Electric Vehicles in Reflex TM. In Proceedings of the 2007 IEEE International Symposium on Industrial Electronics, Vigo, Spain, 4–7 June 2007. [Google Scholar] [CrossRef]

- Li, X.; Xiao, M.; Malinowski, K.; Choe, S.-Y. State-of-Charge (SOC) Estimation Based on Reduced Order of Electrochemical Model for a Pouch Type High Power Li-Polymer Battery. In Proceedings of the 2011 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 6–9 September 2011. [Google Scholar] [CrossRef]

- Rahimi-Eichi, H.; Baronti, F.; Chow, M.-Y. Online Adaptive Parameter Identification and State-of-Charge Coestimation for Lithium-Polymer Battery Cells. IEEE Trans. Ind. Electron. 2014, 61, 2053–2061. [Google Scholar] [CrossRef]

- Kim, I.-S. Nonlinear State of Charge Estimator for Hybrid Electric Vehicle Battery. IEEE Trans. Power Electron. 2008, 23, 2027–2034. [Google Scholar] [CrossRef]

- Plett, G.L. Sigma-point Kalman filtering for battery management systems of LiPB-based HEV battery packs: Part 1: Introduction and state estimation. J. Power Sources 2006, 161, 1356–1368. [Google Scholar] [CrossRef]

- Plett, G.L. Sigma-point Kalman filtering for battery management systems of LiPB-based HEV battery packs: Part 2: Simultaneous state and parameter estimation. J. Power Sources 2006, 161, 1369–1384. [Google Scholar] [CrossRef]

- Xiong, R.; Sun, F.; He, H.; Nguyen, T.D. A data-driven adaptive state of charge and power capability joint estimator of lithium-ion polymer battery used in electric vehicles. Energy 2013, 63, 295–308. [Google Scholar] [CrossRef]

- Xiong, R.; Sun, F.; Gong, X.; Gao, C. A data-driven based adaptive state of charge estimator of lithium-ion polymer battery used in electric vehicles. Appl. Energy 2014, 113, 1421–1433. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, C.; Zhang, X. State-of-charge estimation of the lithium-ion battery system with time-varying parameter for hybrid electric vehicles. IET Control Theory Appl. 2014, 8, 160–167. [Google Scholar] [CrossRef]

- Liu, X.; Chen, Z.; Zhang, C.; Wu, J. A novel temperature-compensated model for power Li-ion batteries with dual-particle-filter state of charge estimation. Appl. Energy 2014, 123, 263–272. [Google Scholar] [CrossRef]

- Xiong, R.; He, H.; Sun, F.; Liu, X.; Liu, Z. Model-based state of charge and peak power capability joint estimation of lithium-ion battery in plug-in hybrid electric vehicles. J. Power Sources 2013, 229, 159–169. [Google Scholar] [CrossRef]

- Waag, W.; Sauer, D.U. Adaptive estimation of the electromotive force of the lithium-ion battery after current interruption for an accurate state-of-charge and capacity determination. Appl. Energy 2013, 111, 416–427. [Google Scholar] [CrossRef]

- Xu, J.; Mi, C.C.; Cao, B.; Deng, J.; Chen, Z.; Li, S. The State of Charge Estimation of Lithium-Ion Batteries Based on a Proportional-Integral Observer. IEEE Trans. Veh. Technol. 2013, 63, 1614–1621. [Google Scholar] [CrossRef]

- Bao, H.; Yu, Y. State of Charge Estimation for Electric Vehicle Batteries Based on LS-SVM. In Proceedings of the 2013 5th International Conference on Intelligent Human-Machine Systems and Cybernetics, Hangzhou, China, 26–27 August 2013; Volume 1, pp. 442–445. [Google Scholar] [CrossRef]

- Antón, J.C.; Nieto, P.J.G.; Juez, F.J.d.C.; Lasheras, F.S.; Viejo, C.B.; Gutiérrez, N.R. Battery State-of-Charge Estimator Using the MARS Technique. IEEE Trans. Power Electron. 2013, 28, 3798–3805. [Google Scholar] [CrossRef]

- Zhou, F.; Wang, L.; Lin, H.; Lv, Z. High Accuracy State-of-Charge Online Estimation of EV/HEV Lithium Batteries Based on Adaptive Wavelet Neural Network. In Proceedings of the 2013 IEEE ECCE Asia Downunder, Melbourne, VIC, Australia, 3–6 June 2013. [Google Scholar] [CrossRef]

- Jiang, C.; Taylor, A.; Duan, C.; Bai, K. Extended Kalman Filter Based Battery State of Charge(SOC) Estimation for Electric Vehicles. In Proceedings of the 2013 IEEE Transportation Electrification Conference and Expo (ITEC), Detroit, MI, USA, 16–19 June 2013. [Google Scholar] [CrossRef]

- Hu, C.; Youn, B.D.; Chung, J. A multiscale framework with extended Kalman filter for lithium-ion battery SOC and capacity estimation. Appl. Energy 2012, 92, 694–704. [Google Scholar] [CrossRef]

- Zhang, Y.; Song, W.; Lin, S.; Feng, Z. A novel model of the initial state of charge estimation for LiFePO4 batteries. J. Power Sources 2014, 248, 1028–1033. [Google Scholar] [CrossRef]

- Guo, S.; Ma, L. A comparative study of different deep learning algorithms for lithium-ion batteries on state-of-charge estimation. Energy 2023, 263, 125872. [Google Scholar] [CrossRef]

- Salkind, A.J.; Fennie, C.; Singh, P.; Atwater, T.; Reisner, D.E. Determination of state-of-charge and state-of-health of batteries by fuzzy logic methodology. J. Power Sources 1999, 80, 293–300. [Google Scholar] [CrossRef]

- Wu, X.; Mi, L.; Tan, W.; Qin, J.L.; Na Zhao, M. State of Charge (SOC) Estimation of Ni-MH Battery Based on Least Square Support Vector Machines. Adv. Mater. Res. 2011, 211–212, 1204–1209. [Google Scholar] [CrossRef]

- Gou, B.; Xu, Y.; Feng, X. State-of-Health Estimation and Remaining-Useful-Life Prediction for Lithium-Ion Battery Using a Hybrid Data-Driven Method. IEEE Trans. Veh. Technol. 2020, 69, 10854–10867. [Google Scholar] [CrossRef]

- He, H.; Xiong, R.; Guo, H.; Li, S. Comparison study on the battery models used for the energy management of batteries in electric vehicles. Energy Convers. Manag. 2012, 64, 113–121. [Google Scholar] [CrossRef]

- Venugopal, P.; Vigneswaran, T. State-of-Health Estimation of Li-ion Batteries in Electric Vehicle Using IndRNN under Variable Load Condition. Energies 2019, 12, 4338. [Google Scholar] [CrossRef]

- Vanem, E.; Salucci, C.B.; Bakdi, A.; Alnes, Ø.Å.S. Data-driven state of health modelling—A review of state of the art and reflections on applications for maritime battery systems. J. Energy Storage 2021, 43, 103158. [Google Scholar] [CrossRef]

- Epding, B.; Rumberg, B.; Jahnke, H.; Stradtmann, I.; Kwade, A. Investigation of significant capacity recovery effects due to long rest periods during high current cyclic aging tests in automotive lithium ion cells and their influence on lifetime. J. Energy Storage 2019, 22, 249–256. [Google Scholar] [CrossRef]

- Eddahech, A.; Briat, O.; Vinassa, J.-M. Lithium-ion battery performance improvement based on capacity recovery exploitation. Electrochim. Acta 2013, 114, 750–757. [Google Scholar] [CrossRef]

- Liu, D.; Pang, J.; Zhou, J.; Peng, Y.; Pecht, M. Prognostics for state of health estimation of lithium-ion batteries based on combination Gaussian process functional regression. Microelectron. Reliab. 2013, 53, 832–839. [Google Scholar] [CrossRef]

- Saha, B.; Goebel, K.; Poll, S.; Christophersen, J. Prognostics Methods for Battery Health Monitoring Using a Bayesian Framework. IEEE Trans. Instrum. Meas. 2009, 58, 291–296. [Google Scholar] [CrossRef]

- Han, X.; Ouyang, M.; Lu, L.; Li, J. A comparative study of commercial lithium ion battery cycle life in electric vehicle: Capacity loss estimation. J. Power Sources 2014, 268, 658–669. [Google Scholar] [CrossRef]

- Chen, Z.; Mi, C.C.; Fu, Y.; Xu, J.; Gong, X. Online battery state of health estimation based on Genetic Algorithm for electric and hybrid vehicle applications. J. Power Sources 2013, 240, 184–192. [Google Scholar] [CrossRef]

- Zenati, A.; Desprez, P.; Razik, H.; Rael, S. A Methodology to Assess the State of Health of Lithium-Ion Batteries Based on the Batterys Parameters and a Fuzzy Logic System. In Proceedings of the 2012 IEEE International Electric Vehicle Conference, Greenville, SC, USA, 4–8 March 2012. [Google Scholar] [CrossRef]

- Guo, Z.; Qiu, X.; Hou, G.; Liaw, B.Y.; Zhang, C. State of health estimation for lithium ion batteries based on charging curves. J. Power Sources 2014, 249, 457–462. [Google Scholar] [CrossRef]

- Klass, V.; Behm, M.; Lindbergh, G. A support vector machine-based state-of-health estimation method for lithium-ion batteries under electric vehicle operation. J. Power Sources 2014, 270, 262–272. [Google Scholar] [CrossRef]

- Remmlinger, J.; Buchholz, M.; Soczka-Guth, T.; Dietmayer, K. On-board state-of-health monitoring of lithium-ion batteries using linear parameter-varying models. J. Power Sources 2013, 239, 689–695. [Google Scholar] [CrossRef]

- Remmlinger, J.; Buchholz, M.; Meiler, M.; Bernreuter, P.; Dietmayer, K. State-of-health monitoring of lithium-ion batteries in electric vehicles by on-board internal resistance estimation. J. Power Sources 2011, 196, 5357–5363. [Google Scholar] [CrossRef]

- Hung, M.-H.; Lin, C.-H.; Lee, L.-C.; Wang, C.-M. State-of-charge and state-of-health estimation for lithium-ion batteries based on dynamic impedance technique. J. Power Sources 2014, 268, 861–873. [Google Scholar] [CrossRef]

- He, Z.; Gao, M.; Ma, G.; Liu, Y.; Chen, S. Online state-of-health estimation of lithium-ion batteries using Dynamic Bayesian Networks. J. Power Sources 2014, 267, 576–583. [Google Scholar] [CrossRef]

- Yang, J.; Xia, B.; Huang, W.; Fu, Y.; Mi, C. Online state-of-health estimation for lithium-ion batteries using constant-voltage charging current analysis. Appl. Energy 2018, 212, 1589–1600. [Google Scholar] [CrossRef]

- Zou, Y.; Hu, X.; Ma, H.; Li, S.E. Combined State of Charge and State of Health estimation over lithium-ion battery cell cycle lifespan for electric vehicles. J. Power Sources 2015, 273, 793–803. [Google Scholar] [CrossRef]

- You, G.-W.; Park, S.; Oh, D. Real-time state-of-health estimation for electric vehicle batteries: A data-driven approach. Appl. Energy 2016, 176, 92–103. [Google Scholar] [CrossRef]

- Ng, K.S.; Moo, C.-S.; Chen, Y.-P.; Hsieh, Y.-C. Enhanced coulomb counting method for estimating state-of-charge and state-of-health of lithium-ion batteries. Appl. Energy 2009, 86, 1506–1511. [Google Scholar]

- Chiang, Y.-H.; Sean, W.-Y.; Ke, J.-C. Online estimation of internal resistance and open-circuit voltage of lithium-ion batteries in electric vehicles. J. Power Sources 2011, 196, 3921–3932. [Google Scholar] [CrossRef]

- Yang, D.; Wang, Y.; Pan, R.; Chen, R.; Chen, Z. A Neural Network Based State-of-Health Estimation of Lithium-Ion Battery in Electric Vehicles. Energy Procedia 2017, 105, 2059–2064. [Google Scholar] [CrossRef]

- Xiong, R.; Sun, F.; Chen, Z.; He, H. A data-driven multi-scale extended Kalman filtering based parameter and state estimation approach of lithium-ion polymer battery in electric vehicles. Appl. Energy 2014, 113, 463–476. [Google Scholar] [CrossRef]

- Hu, X.; Li, S.E.; Jia, Z.; Egardt, B. Enhanced sample entropy-based health management of Li-ion battery for electrified vehicles. Energy 2014, 64, 953–960. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Y.; Liu, C.; Chen, Z. A novel approach of battery pack state of health estimation using artificial intelligence optimization algorithm. J. Power Sources 2018, 376, 191–199. [Google Scholar] [CrossRef]

- Keil, P.; Jossen, A. Impact of Dynamic Driving Loads and Regenerative Braking on the Aging of Lithium-Ion Batteries in Electric Vehicles. J. Electrochem. Soc. 2017, 164, A3081–A3092. [Google Scholar] [CrossRef]

- Xu, J.; Zhen, A.; Cai, Z.; Wang, P.; Gao, K.; Jiang, D. State of Health Diagnosis and Remaining Useful Life Prediction of Lithium-Ion Batteries Based on Multi-Feature Data and Mechanism Fusion. IEEE Access 2021, 9, 85431–85441. [Google Scholar] [CrossRef]

- Wu, J.; Cui, X.; Zhang, H.; Lin, M. Health Prognosis with Optimized Feature Selection for Lithium-Ion Battery in Electric Vehicle Applications. IEEE Trans. Power Electron. 2021, 36, 12646–12655. [Google Scholar] [CrossRef]

- Xiao, B.; Xiao, B.; Liu, L. State of Health Estimation for Lithium-Ion Batteries Based on the Constant Current–Constant Voltage Charging Curve. Electronics 2020, 9, 1279. [Google Scholar] [CrossRef]

- Alves, J.; Baptista, P.C.; Gonçalves, G.A.; Duarte, G.O. Indirect methodologies to estimate energy use in vehicles: Application to battery electric vehicles. Energy Convers. Manag. 2016, 124, 116–129. [Google Scholar] [CrossRef]

- Hamar, J.C.; Erhard, S.V.; Canesso, A.; Kohlschmidt, J.; Olivain, N.; Jossen, A. State-of-health estimation using a neural network trained on vehicle data. J. Power Sources 2021, 512, 230493. [Google Scholar] [CrossRef]

- Sulzer, V.; Mohtat, P.; Aitio, A.; Lee, S.; Yeh, Y.T.; Steinbacher, F.; Khan, M.U.; Lee, J.W.; Siegel, J.B.; Stefanopoulou, A.G.; et al. The challenge and opportunity of battery lifetime prediction from field data. Joule 2021, 5, 1934–1955. [Google Scholar] [CrossRef]

- Sun, H.; Sun, J.; Zhao, K.; Wang, L.; Wang, K. Data-Driven ICA-Bi-LSTM-Combined Lithium Battery SOH Estimation. Math. Probl. Eng. 2022, 2022, 9645892. [Google Scholar] [CrossRef]

- Iurilli, P.; Brivio, C.; Carrillo, R.E.; Wood, V. Physics-Based SoH Estimation for Li-Ion Cells. Batteries 2022, 8, 204. [Google Scholar] [CrossRef]

| Battery Chemistry Names | Nominal Voltage (V) | Energy Density | Life Cycle | Safety | Cost | Battery Manufacturing Capacity in the World |

|---|---|---|---|---|---|---|

| LFP | 3.2 | low | Long life | Safest to use | expensive | 17% |

| NMC | 3.6 | high | Average life | Safe to use | expensive | 55% |

| LCO | 3.6 | high | Average life | Requires safety measures | cheaper | 18% (LCO and including other chemistries) |

| LMO | 3.7 | low | Short life | Safe to use | expensive | 2% |

| NCA | 3.6 | high | Average life | Require safety | expensive | 7% |

| Dataset Category | Description | Cell Chemistry/No. of Cells | Variables |

|---|---|---|---|

| NASA data set [16,17] | NASA provides six experimental datasets at various DODs, discharge current rates, and temperatures. | 18650 NCA (2 Ah)/34 cells | V, I, T, IR, Q |

| CALCE data set [16,17] | CALCE provides a dataset of the aging cycle at different CC-CV charges and CC discharges. | Prismatic LCO (1.35 Ah)/12 cells | V, I, T, IR, Q, E |

| A123 System data set [16] | This dataset is used for comparative study. | LFP | Q, V, I, T, IR |

| CALCE, NASA, Oxford [18] | The dataset is divided into groups based on charging protocol. | Oxford -Pouch cell (740 mAh)/8 cells | V, I, T |

| Lithium-ion Panasonic NCR 18650 PF [19] | Six drive dataset is used for training purposes and another three drive cycle dataset is used for testing. | NMC (2.9 Ah) | V, I, T |

| Battery Archive dataset [20] | This dataset is taken from various institutions and converted into a standard format. | LFP, NMC, NCA, LCO, NMC-LCO | Q, Form Factor, T, SOC, C-rate during charge/ discharge |

| Automotive Lithium-ion Cell Usage dataset [21] | This dataset is generated from a programmable battery cycler simulation using a cell in an electric car using a Federal drive cycle. | lithium polymer cell (15 Ah) | T, V, I, SOC, Cycle |

| S.No. | Keyword/(s) | NoD in SCOPUS | NoD in WoS | Duplicate Documents |

|---|---|---|---|---|

| 1. | Machine Learning | 257,589 | 580,832 | |

| 2. | State of Health | 1765 | 5798 | |

| 3. | State of Charge | 8731 | 23,492 | |

| 4. | Machine Learning AND State of Health | 64 | 246 | 46 |

| 5. | Machine Learning AND Charge State of Charge | 104 | 476 | 59 |

| 6. | State of Health AND State of Charge | 659 | 2291 | 588 |

| S.No. | Reference | Topic of Review Documentation | Discussion on Paper |

|---|---|---|---|

| 1. | [16] | BMS | Battery types, modeling categories, state estimation techniques, and charging approaches are discussed. |

| 2. | [19] | BEV and HEV components estimation techniques | Different estimation strategies for battery management, vehicle energy management, and vehicle control are discussed. |

| 3. | [35] | HEV battery SOH estimation methods | Experimental-based, model-based, and Machine Learning based SOH estimation methods are discussed, along with the advantages and disadvantages. |

| 4. | [36] | Battery SOH estimation | Different SOH estimation methods are discussed |

| 5. | [37] | SOC estimation methods | Conventional, adaptive filters, learning algorithms and non-linear observer methods are discussed for SOC estimation. Challenges and issues in battery management are also discussed. |

| 6. | [14] | SOH estimation methods | Different SOH estimation methods discussed in different papers comparison along with advantages and disadvantages |

| 7. | [15] | SOC estimation methods, RUL prediction methods | Different SOC estimation methods, voltage and capacity estimation, and RUL prediction methods are discussed. |

| 8. | [77] | BMS issues | Detail discussion on BMS operation, function, and key issues faced in BMS |

| 9. | [38] | Battery thermal issues and management techniques | Detail discussion on battery thermal behavior, problems, ways to manage thermal issues by cooling techniques in battery, challenges, and future scope |

| 10. | [80] | ML-based SOH estimation methods | Different non-probabilistic ML-based SOH estimation methods are compared in terms of publication trend, advantages, disadvantages, challenges, and also according to different metrics. Non-probabilistic ML algorithms are Linear Regression, Ensemble Learning, Nearest Neighbor regression, Support Vector Machines, Artificial Neural Networks, and their variants. |

| 11. | [39] | BMS | BMS functions, reconfiguration topology, and challenges like fault diagnosis are discussed |

| 12. | [81] | Battery monitoring methods | SOC, impedance, capacity, power, SOH, and RUL estimation techniques are discussed in general |

| 13. | [82] | SOC estimation methods | General discussion on types of battery models for SOC estimation and battery pack SOC estimation methods |

| 14. | [83] | SOH estimation techniques | Differential analysis-based, ML-based SOH estimation methods are discussed, along with advantages and disadvantages. RUL prediction methods are also discussed. |

| 15. | [84] | EV charging management | EV charging control strategies, charging management techniques and their pros-cons are discussed. |

| 16. | [85] | Battery health prognostic | Challenges in battery health and different techniques for health issues are discussed |

| 17. | [86] | Cell Balancing | Different cell balancing techniques and importance of cell balancing are discussed |

| 18. | [56] | State Indicators | Familiarizing with the terms SOC, SOH, SOF, SOT and research trends on state indicators |

| 19. | [63] | BMS | BMS performing stages, monitoring, protection, management strategy, key issues in BMS and opportunities-challenges in battery are discussed |

| 20. | [48] | BMS | Defining battery state terminologies, methods for state estimation and related key issues and future direction are discussed |

| 21. | [12] | SOC and SOH control methods | Aging and SOC control methods for super-capacitors are discussed in general. |

| 22. | [87] | Charging methods | Different charging methods are discussed in general |

| Ref. | Year of Publication | Battery Type | Parameter Condition | Model/Method | Description | Average Error | Future Scope |

|---|---|---|---|---|---|---|---|

| [96] | 2012 | Li-NMC, 4.2 V and, 100 Ah | Charge/discharge pulses at different current levels | Recursive least squared algorithm (RLS) | Ah counting method along with ECE 15 European drive cycle | Max. error @ 0.8% and the mean relative error @ 0.07% | |

| [97] | 2002 | NiMH | Charging/discharging cycle | Model-based | State-space model-based estimation | unspecified | Comparison of estimator by considering uncertainty in battery parameter |

| [98] | 2008 | NiMH 80 Ah, 96 V | Current, voltage | NARMAX | Estimate residual capacity by using FUDS drive cycle | Max. avg. error @ 0.02% | Investigation of robustness of the model to overcome external disturbance |

| [99] | 2005 | NiMH 45 Ah, 24 V, 25 °C | 3 Discharging current profile, terminal voltage | 3-layer NN | 32 testing dataset, discharging and regenerative current distribution and, temperature. Low-cost microcontroller is used | Avg. Relative error @ 2.67% | Performing on different battery modules and influence of aging effect, perform on dynamic models of NiMH battery and on HEV for determining fully charged state |

| [91] | 2002 | NiMH | Constant current discharge, random discharge and standard discharge | ANFIS | Low-cost microcontroller is used. | Avg. Relative error @ 2% | Can be performed on other battery types. |

| [100] | 2010 | NiMH 100 Ah, 1.2 V | Charging discharging | OCV | Takacs model is used which is based on hysteresis phenomenon of OCV | 10% | |

| [101] | 2011 | 6 series NiMH, 8 Ah, 1.2 V | Charging discharging at constant current | radial basis function network (RBF) | MATLAB and ADVISOR software are used, data collected between 15–85% SOC | MSE@ 1.618% | |

| [102] | 2004 | 3 cells series NiMH, 2.7 Ah | EIS over 100 cycles | Fuzzy Logic | Charged @ C/3 rate at 4 h, discharged C/2 rate for 28 cycles | ±5% | |

| [103] | 2009 | NiMH | Current, voltage and past SOC | ANN | 4 networks | 5% | |

| [104] | 2009 | NiMH | Current, voltage and past SOC | BPNN | Short term (ST), long term (LT). BPNN has good self adaptability | 1.94%@ ST, 0.93% @ LT | To improve local minimum, training speed and accuracy GA should be added to BPNN |

| [105] | 2010 | NiMH 27 Ah | Different temperature, charge and discharge current rate | Ah method | 0 °C, −18 °C, −12 °C, 25 °C @ temperature, 1/3 C, 1 C, 3 C @charge rate, 1/3 C @ discharge rate | 3.6% | Coulomb efficiency and SOC analysis in high temperature can be performed with this model in future |

| [106] | 2009 | NiMH, HEV on dynamic model | Hysteresis effect, polarization effect, internal resistance | EKF | Capacity balance test and capacity consume test | Mean error @ 3%, maximum error @ 7% | |

| [107] | 2005 | Lead–acid, HEV on dynamic model | Real-time drive cycle | Hybrid (KF + EKF) | 2% | This work can be extended for different models and cell chemistries | |

| [108] | 2008 | HEV, NiMH | Voltage, current, SOC | Hybrid or Adaptive (EKF + Coulomb accumulation + OCV) |

|

| |

| [109] | 2010 | 10NiMH batteries in series @1.2 V, 8 Ah, HEV | Different charging rates @ 4 C, 3 C, 2 C, 1 C, 0.5 C | Hybrid (GA + BPNN) | Fast convergence speed and strong learning ability | MSE BP @ 0.9408%, 8 steps MSE GA-BP @ 0.7577%, 3 steps | |

| [110] | 2009 | NiMH | C/3 rate discharge test, current and voltage record during FUDS drive cycle | Hybrid (AEKFAh) | Max. Discharge current @ 129.2 A, max. Charge current @ 63.8 A, temperature ranges @ 25.91–27.52 °C | AEKFAh error @ 2.4%, Ah error @ 11.4% | |

| [111] | 2007 | NiMH battery | C/3 rate discharge test, current and voltage record during FUDS drive cycle | Hybrid (KalmanAh) | Max. Discharge current @ 129.2 A, max. Charge current @ 63.8 A, temperature ranges @ 25.91–27.52 °C | KalmanAh error @ 2.5%, Ah error @ 11.4% | |

| [93] | 2007 | 12 V lead–acid battery, EV | Discharge and regenerative capacity distribution, which represents different discharge current profiles @ theoretical and practical data, different temperature | NN | 7 Input neurons @ different discharge current, regenerative current, temperature. 1 Output neuron @ State Of Available Capacity (SOAC). 11 hidden neurons | Avg. Relative percentage error (ARPE) of NN@ 2% | This work can be extended for other types of EV battery |

| [112] | 2008 | 6 Ah, 2 V lead–acid battery, HEV, | Discharging current, OCV test for initial parameters | Dynamic ECM model with EKF | Comparison of static (Rint-based SOC estimation) and dynamic (EKF-based SOC estimation) | 3% | |

| [113] | 1998 | Sealed-type lead–acid battery | Temperature, terminal voltage, discharge current, internal impedance | NN | 4 Input neurons @ discharge current, temperature, terminal voltage, internal impedance. 10 Output neurons @ 0–100% in 10% step size SOC. 50 hidden neurons | Max. Error @ 10%, avg. Error @ 3% | Finding new ways for improvement is the next research plan |

| [114] | 2005 | Lead–acid battery, HEV | Dynamic ECM model | KF | Charging discharging of cells through observer technique | 1% | |

| [115] | 2007 | 24 V lead–acid battery | Charging, internal resistance | Fuzzy Logic | Proposed method avoids over-charging and under-charging | 5% | |

| [116] | 2011 | Li-polymer battery | Full discharge test (4.15–2.5 V) @ 1 C, 2 C, 5 C | Reduced-order EM | Different ECM, reduce order EM, full order EM, experimental model is analyzed | 1% | Perform analysis with high discharge current rate up to 10 C along with different ambient temperature |

| [117] | 2014 | Li-polymer battery, Voc- SOC relationship, charging–discharging | RC ECM | Adaptive method | EKF and state-observer is used for over-potential dynamic of battery | Max. Error: SOC co-estimation @ 0.063, EKF @ 0.077, Sliding Observer @0.12 | |

| [118] | 2008 | Li-polymer battery, HEV | Charge–discharge test at different temp. | Sliding mode observer | RC model is developed by OCV test and then SMO is applied for SOC estimation | 3% | |

| [119] | 2006 | 3.8 V, 7.5 Ah, Li-polymer battery, HEV | 16USSD cycles, separated by 40 A discharge pulse and 5 min. rest time, 90–10% SOC range | Sigma Point KF(SPKF) | Enhanced Self Correction Model (ESCM) which is a discrete-time state-space model. ESCM is used for cell modeling because it includes effect due to OCV, internal resistance, voltage time constant and hysteresis. Comparing error in SPKF with EKF for SOC estimation |

| This work can be extended for accurately estimating SOC if cell parameters are taken real time in order to overcome manufacturing difference between cells and also tracking aging effect in cell parameters |

| [120] | 2006 | GEN3 (old cell) 20 C capable, 7.5 Ah and GEN4 (new cell) 30 C capable, 5 Ah, both Li-polymer battery, HEV | 18USSD cycles, separated by 15 A discharge pulse and 5 min. rest time, 90–10% SOC range | Square Root-Sigma Point KF(SR-SPKF) | One cell data is used to fine-tune cell model parameter and another cell data is used to test in dynamic condition for filter analysis |

| |

| [121] | 2013 | 3.7 V, 32 Ah Li-polymer battery, EV | Voltage, current, DST test | Adaptive Extended KF (AEKF), lumped battery model | Multi-state joint estimator is used along with 3 different degraded cells capacity. SOC estimator is verified via DST test | 1% | |

| [122] | 2014 | 3.7 V, 32 Ah Li-polymer battery, EV | Voltage, current | lumped battery model, AEKF | RLS-based online parameter updating, SOC estimator is verified at 5 different loading profiles (DST and FUDS) and different degradation capacity | Max. Error @1.5% | In future, data-driven approach based on joint SOC and peak power estimation |

| [123] | 2014 | 50 Ah, 51.2 V Lithium-ion battery, HEV | Charging–discharging @ 285A max. rate, current and voltage measured @ 1s. interval, temperature (20 °C) | RC model, H∞ filter | 0.3 C discharging from 100% SOC to 90% SOC. Then, OCV, HPPC test @ Id = 1 C, Ic = 0.75 C, performance of filter is verified via 6 USSD cycle test. | Without time-varying parameter @ 4% (Max. error), 1.4813% (Mean error). Time-varying parameter @ 2.49% (Max. error), 0.8436% (Mean error) | |

| [94] | 2013 | 60 Ah Lithium-ion battery, LFP chemistry | 3 times discharge test at particular C-rate in controlled environment, Dynamic Stress Test, current, voltage, temperature | SVM- SVR, RBF kernel | Charging @ 0.3 C up to 3.6 V (18 A), discharging @ 0.33 C (20 A), CCCV charging method, cut-off voltage @ 2.8 V | Max. error @ 6%, RMSE @ 0.71% | This model can be further applied and tested for different similar battery chemistry |

| [124] | 2014 | Lithium-ion battery, LFP chemistry, EV | Temperature, current @ input variable and terminal voltage @ output variable | Dual particle filter (DPF) based battery model | Temperature and current taken as input to model parameters to find the relationship between voltage, internal resistance and temperature of battery | MAE: DPF @ 0.67%, UKF @ 1.37%, EKF @ 2.05% | Study of energy loss in internal resistance and efficiency of charging–discharging will improve the energy range of the battery |

| [125] | 2013 | 60 V, max. charge–discharge current @300 A, Lithium-ion battery, LMO chemistry, PHEV | Current, voltage, temperature | AEKF, Dynamic electrochemical polarization battery model, joint estimation approach | Available capacity test, HPPC test, OCV test, UDDS driving test, dynamic cycle test | Max. error @ 0.02 or 2% | In future, dynamic battery model has to focus on online parameter identification method and systematic validation test for available peak power capacity estimation |

| [126] | 2013 | NMC, 40 Ah Lithium-ion battery, EV | Voltage, current | EMF | By using EMF-OCV, SOC is estimated | 2% | |

| [127] | 2014 | Lithium-ion battery | Voltage, current | PIO | RC battery model, USSD drive cycle | 2% | |

| [128] | 2013 | LFP, 3.2 V, 12 Ah Lithium-ion battery | Battery terminal voltage, current, temperature @ input, SOC @ output | LS-SVM | Select sample data, prepare and process it, build training and prediction sample dataset, select k-function and parameter, set objective function, find Lagrange Multiplier a and b, build prediction model and predict future SOC | LS-SVM @ 2%, BPNN @ 3% | |

| [129] | 2013 | LFP, 3.2 V, 100 Ah Lithium-ion battery, 0.3 C rate charging | Battery current, voltage, temperature | MARS | SOC (25–90%), CCCV @ charge method, CC @ discharge method | 1% | Using this model for testing of dynamic data profile |

| [96] | 2012 | Lithium-ion battery, EV | Battery current, voltage, temperature, SOC | RLS | ECE 15 drive cycle, real data and RNN-based SOC predictor used for battery modeling and terminal voltage estimation | Max. error @ 1.032%, mean error @ 0.1744% | |

| [130] | 2013 | Lithium-ion battery | Voltage, temperature | AWNN | AWNN response of SOC estimation is comparable to BPNN and WNN | 2% | |

| [131] | 2013 | Lithium-ion battery | Charge–discharge | EKF | SOC varies from 5–95% | 1% | |

| [132] | 2012 | 7.5 Ah Lithium-ion prismatic battery | Cell terminal voltage, current, SOC | Hybrid (EKF + coulomb counting) | ESC model, 15 UDDS test, 100–4% SOC | Dual EKF @ 6.573%, Multi-scale framework @3.93% | To investigate the effect of time-scale on accuracy and State of Life (SOL) prediction of proposed work with lifetime cell aging test |

| Ref. | Year of Publication | Battery Type | Parameter Condition | Model/Method | Description | Average Error | Future Scope |

|---|---|---|---|---|---|---|---|

| [96] | 2012 | Li-NMC, 4.2 V and, 100 Ah | Charge/discharge pulses at different current levels | Recursive least squared algorithm (RLS) | Ah counting method along with ECE 15 European drive cycle, battery internal resistance is identified | Max. error @ 0.92% and the mean relative error @ 0.14% | |

| [145] | 2014 | 5 different Lithium-ion batteries (NMC/LTO, 20 Ah), (LFP/C, 60 Ah, 11 Ah), (LMO/C, 35 Ah, 10 Ah), pure EV | Different temperature (45 °C, 5 °C) at different seasons | Genetic Algorithm, Semi-empirical capacity loss model for online and offline SOH estimation | Reference Performance Test (RPT) (combination of HPPC test and capacity test), cycle life test | 1% | |

| [146] | 2013 | Pouch cell, 32 Ah, 4.05 V full voltage, Lithium-ion battery, EV, HEV | Diffusion capacitance, current, terminal voltage, different charge/discharge rate | Genetic Algorithm, 2-order RC model | RC model diffusion capacitance is compared with experimental result capacity obtained. Diffusion capacitance is reciprocal of capacity or SOH. | 5.11% | Further improving convergence speed |

| [147] | 2012 | 4 V, 30 Ah Lithium-ion battery | Temperature (−30 °C to 90 °C), current (0 to 400 A) | Fuzzy Logic (FL) | FL-based SOH estimator is developed by varying temperature and current | Unspecified | |

| [148] | 2014 | Lithium-ion battery (LMO chemistry) | Different charging/discharging rate, interval time, voltage, temperature | ECM | 6 different cells are tested under different charging/discharging current rates, voltages, temperatures, end of charge/discharge current–voltage and times. Model parameters are identified via the Least Square method | 2% | |

| [149] | 2014 | Lithium-ion battery, PHEV | Current, temperature, SOC @ input parameters, voltage @ output parameter | SVM | Dynamic conditions, such as temperature-dependent/independent resistance/capacity and different SOC range taken for virtual and experimental analysis | unspecified | |

| [150] | 2013 | Lithium-ion battery, HEV | Temperature, cell aging, current, voltage | Linear Parameter Varying (LPV) Model | Central Difference KF (CDKF) based LPV model | unspecified | |

| [151] | 2011 | 6.5 Ah Lithium-ion battery, HEV | Measured terminal voltage, current, temperature | ECM | Temperature, SOC, current affects internal resistance of battery incorporating ohmic and polarization resistance | unspecified | Further research will be performed on considering inner cell temperature and dynamic load condition |

| [152] | 2014 | 2150 mAh Samsung Lithium-ion battery (NCA chemistry) | Change in voltage and current during charging/discharging process | Dynamic Impedance Technique | Calculating a, b, SOC values through mathematical equation then SOH is calculated and this method is independent of temperature variation, data recorded @ 1 s | SOC estimated and actual SOC error @5% | |

| [153] | 2014 | 3.7 V, 6000 mAh Li-Mn battery | Terminal voltage of battery recorded during constant charge process | Dynamic Bayesian Network (DBN) | Capacity test, lifecycle test, SOC @hidden nodes, terminal voltage @ observed nodes, data recorded @ 10 s, categorizing aging states into 5 @ >95%—brand new, 95–90%—new, 90–85%—ok, 85–80%—old, <80%—very old | 5% | |

| [154] | 2018 | Four 3.2 V, 2.5 Ah Lithium-ion battery (LFP chemistry) | Voltage and current during charging process at CV mode | 1st order RC ECM | Current time constant is correlated to nominal battery capacity @ −0.988 to indicate SOH, sampling freq. 1 Hz. In original BMS sampling freq. is 100 Hz | 2.5% | In future, higher-order RC model tested under different battery chemistry, charging protocol and temp. |

| [155] | 2015 | Lithium-ion battery (NMC chemistry), EV | 1st order RC ECM, 2 EKF | Sampling freq. 10 Hz, HPPC test, RLS algorithm is used for polarization resistance and capacitance extraction, FUDS and DST drive test | unspecified | ||

| [156] | 2016 | Battery, EV | 10 driving profiles, current, voltage, temperature, charging/discharging rate | NN | Combination of different temperature, charging/discharging rate and driving profile 80 dataset is prepared. Classification and regression both take place on offline and online dataset | 2.18% | Charging/discharging experiment data can be taken along with rest period for more realistic condition |

| [157] | 2009 | Lithium-ion battery | Charging–discharging voltage and current of battery | CC method | SOC determination by three modes: charging, discharging, open-circuit mode. Hence, SOC(t) = SOH(t)—DOD(t) | 1.08% | |

| [158] | 2011 | Li-polymer battery | OCV, internal resistance | ECM, Internal resistance method | Lookup table and simulation of adaptive control method for controlling parameters | 1% | |

| [159] | 2017 | 10 Lithium-ion battery (LPF chemistry), 10 Ah, 25 °C | 1st order ECM, 3-layer BPNN | HPCC test is conducted for model parameter identification and verification | |||

| [160] | 2014 | 32 Ah Lithium-ion battery | Change in level time scale of RC parameter | Lumped battery model, Data-driven method multi-scale EKF | Different tests have been performed for characterization and aging. Then, macro and micro-level evaluation other cases are performed for capacity estimation, inaccurate initial SOC and current integral | Peak estimation error @ 2% | |

| [161] | 2014 | 8 Lithium-ion battery, NMC chemistry | Discharge curve voltage sequence, different temperatures | Sample entropy | HPPC test is conducted to obtain voltage sequence. By non-linear LS optimization, capacity at different temperature is estimated. Finally, prediction of other 7 batteries capacity at different temperatures is calibrated. | Avg. relative error @ 2% | |

| [143] | 2013 | Lithium-ion battery, NASA dataset | Charging–discharging cycles | GPFR | Battery 5,6,7 is taken for analysis. Regeneration is taken into account for SOH estimation. | For battery 7, MAPE @ 0.017, RMSE @ 1.73 | Self-recharge phenomenon is taken into account for SOH estimation. |

| [144] | 2009 | 18650 Lithium-ion battery | Electrochemical model parameters | Bayesian Framework (RVM-PF) | RBPF model is used for finding correlation between capacity and EM parameters (RE and RCT) and RUL prediction. | This model-based approach can handle uncertainty like NN and GPR. | |

| [162] | 2018 | 38 Ah, 3.7 V Lithium-ion battery, NMC chemistry | Electrochemical model and ECM | PSO-GA | PF is employed in SOC and OCV for noise reduction occurring in battery terminal voltage and current drift. RSLM is used to update cell capacity | In future, SOH estimation can be evaluated by using different temperature condition | |

| [163] | 2017 | 2.8 Ah Panasonic Lithium-ion battery, NCA chemistry, EV | Different driving load profiles at constant current discharge @ different temperature, cycle depth and SOC | Real-time driving profile | Effect of regenerative braking, calendar aging and cyclic aging @ different temperature. | Calendar aging decreases with low temp., whereas cyclic aging increases. Cycling at high SOC will lead to capacity recovery, due to regenerative braking cycle depth decrease. | |

| [164] | 2021 | Lithium-ion battery | NASA dataset (charge, discharge, impedance) | NPSO-SVR, ORPF model | SVR and NPSO are used for SOH estimation and ORPF is used for RUL prediction. | ||

| [165] | 2021 | 50 Ah Lithium-ion battery | Voltage data from 11,000 charging processes (charged capacity and incremental capacity) | Ridge regression, PSO | IC and charged capacity curves are extracted from raw data. 250 features are extracted from angles are optimized by using the feature wrapper method. Then, ridge regression method is used for SOH estimation. PSO is used for multi-objective optimization of features. | In future, battery pack characteristics will be considered for SOH estimation. | |

| [166] | 2020 | Lithium-ion battery, NASA dataset | CC-CV charging curve | LS-SVR with polynomial kernel function | Grey relational analysis is used for feature selection. In SVR model, K-fold cross-validation is performed for hyper-parameter tuning. | RMSE @ 0.95–1.36% | |

| [167] | 2016 | Lithium-ion battery | Vehicle dynamics (speed, acc., slope), energy usage (data obtained from battery terminals) | Indirect method | Real-time vehicle data is captured for calibrating energy usage. | ||

| [168] | 2021 | Lithium-ion battery, BEV | Km driven, charge through-put, SOC, C-rate, temp., age of vehicle | NN | By using Pearson correlation, it is found that C-rate and SOC are less correlated to SOH. | RMSE @ 3% | In future, different algorithms will be tested for these 704 real-time vehicle datasets. |

| [169] | 2021 | Lithium-ion battery | Different parameters extracted from field and physical modeling-based. | Data-driven, physical model | By conducting RPT tests SOH can be easily determined. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Swarnkar, R.; Ramachandran, H.; Ali, S.H.M.; Jabbar, R. A Systematic Literature Review of State of Health and State of Charge Estimation Methods for Batteries Used in Electric Vehicle Applications. World Electr. Veh. J. 2023, 14, 247. https://doi.org/10.3390/wevj14090247

Swarnkar R, Ramachandran H, Ali SHM, Jabbar R. A Systematic Literature Review of State of Health and State of Charge Estimation Methods for Batteries Used in Electric Vehicle Applications. World Electric Vehicle Journal. 2023; 14(9):247. https://doi.org/10.3390/wevj14090247

Chicago/Turabian StyleSwarnkar, Radhika, Harikrishnan Ramachandran, Sawal Hamid Md Ali, and Rani Jabbar. 2023. "A Systematic Literature Review of State of Health and State of Charge Estimation Methods for Batteries Used in Electric Vehicle Applications" World Electric Vehicle Journal 14, no. 9: 247. https://doi.org/10.3390/wevj14090247

APA StyleSwarnkar, R., Ramachandran, H., Ali, S. H. M., & Jabbar, R. (2023). A Systematic Literature Review of State of Health and State of Charge Estimation Methods for Batteries Used in Electric Vehicle Applications. World Electric Vehicle Journal, 14(9), 247. https://doi.org/10.3390/wevj14090247