A Survey of Hybrid Braking System Control Methods

Abstract

:1. Introduction

2. Braking Torque Distribution Strategy and Coordination Control of Hybrid Braking Control Methods

3. Primary Research Challenges in Hybrid Braking System Control

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

List of Abbreviations

| ABS | Anti-lock brake system |

| DC | Direct current |

| ECC | Energy constraint control |

| ECE | Economic Commission for Europe |

| EHB | Electrohydraulic braking system |

| EMB | Electromechanical braking system |

| ESC | Electronic stability control |

| EVs | Electric vehicles |

| GA | Genetic algorithm |

| LQR | Linear quadratic regulator |

| MPC | Model predictive control |

| PID | Proportion integration differentiation |

| SMC | Sliding mode control |

| SoC | State of charge |

References

- Li, W. Investigation of Advanced Brake-by-Wire Systems for Electric Vehicles. Doctor Thesis, University of Wollongong, Wollongong, Australia, 2019. [Google Scholar]

- Chougale, R.G.; Lakade, C.R. Regenerative braking system of electric vehicle driven by brushless DC motor using fuzzy logic. In Proceedings of the 2017 IEEE International Conference on Power, Control, Signals and Instrumentation Engineering (ICPCSI), Chennai, India, 21–22 September 2017; pp. 2167–2171. [Google Scholar] [CrossRef]

- Youssef, O.E.; Hussien, M.G.; El-Wahab Hassan, A. A Robust Regenerative-Braking Control of Induction Motors for EVs Applications. Int. Trans. Electr. Energy Syst. 2024, 1, 5526545. [Google Scholar] [CrossRef]

- Zhou, Z.; Mi, C.; Zhang, G. Integrated control of electromechanical braking and regenerative braking in plug-in hybrid electric vehicles. Int. J. Veh. Des. 2012, 58, 223–239. [Google Scholar] [CrossRef]

- Vu, T.V.; Chen, C.K.; Hung, C.W. Study of Hydraulic Regenerative Braking System in Hydraulic Hybrid Vehicles. J. Sci. Eng. Technol. 2011, 7, 9–18. [Google Scholar]

- Chandak, G.A.; Bhole, A.A. A review on regenerative braking in electric vehicle. In Proceedings of the 2017 Innovations in Power and Advanced Computing Technologies (i-PACT), Vellore, India, 21–22 April 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Sathishkumar, A.; Soundararajan, R.; Muthu Vel, T.J.; Arjith, M.B.S.; Sakthivel, G. Review on regenerative braking system. In E-Mobility: A New Era in Automotive Technology; Springer: Berlin/Heidelberg, Germany, 2022; pp. 149–163. [Google Scholar] [CrossRef]

- Chiara, F.; Canova, M. A review of energy consumption, management, and recovery in automotive systems, with considerations of future trends. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2013, 227, 914–936. [Google Scholar] [CrossRef]

- Song, S.X.; Fan, S.Q.; Wang, Q.N. Research on control strategy of In-wheel-motor vehicle electro-mechanical braking system. In Manufacturing Engineering and Intelligent Materials; CRC Press: Boca Raton, FL, USA, 2015; pp. 331–336. [Google Scholar] [CrossRef]

- Gou, Y. Research on electric vehicle regenerative braking system and energy recovery. Int. J. Hybrid Inf. Technol. 2016, 9, 81–90. [Google Scholar] [CrossRef]

- Hu, D. Research Status of Hybrid Brake-by-Wire System, Design and Control of Hybrid Brake-by-Wire System for Autonomous Vehicle; Springer Nature: Singapore, 2022; pp. 11–19. [Google Scholar] [CrossRef]

- Tian, J.; Li, D.; Ye, L. Study on braking characteristics of a novel eddy current-hydraulic hybrid retarder for heavy-duty vehicles. IEEE Trans. Energy Convers. 2020, 35, 1658–1666. [Google Scholar] [CrossRef]

- Castillo, J.J.; Cabrera, J.A.; Guerra, A.J.; Simón, A. A novel electro-hydraulic brake system with tire–road friction estimation and continuous brake pressure control. IEEE Trans. Ind. Electron. 2015, 63, 1863–1875. [Google Scholar] [CrossRef]

- Nian, X.; Peng, F.; Zhang, H. Regenerative braking system of electric vehicle driven by brushless DC motor. IEEE Trans. Ind. Electron. 2014, 61, 5798–5808. [Google Scholar] [CrossRef]

- Patel, P.; Chandra, H.; Sahoo, T. Study on regenerative braking system, considerations of design, safety and associated effects. In Proceedings of the 2015 IEEE International Transportation Electrification Conference (ITEC), Chennai, India, 27–29 August 2015; pp. 1–8. [Google Scholar] [CrossRef]

- Gong, X.; Ge, W.; Yan, J.; Zhang, Y.; Gongye, X. Review on the development, control method and application prospect of brake-by-wire actuator. Actuators 2020, 9, 15. [Google Scholar] [CrossRef]

- Anwar, S. An anti-lock braking control system for a hybrid electromagnetic/electrohydraulic brake-by-wire system. In Proceedings of the 2004 American control conference, Boston, MA, USA, 30 June–2 July 2004; pp. 2699–2704. [Google Scholar] [CrossRef]

- Dehghani, D. Optimal Anti Lock Braking System with Regenerative Braking in Hybrid Electric Vehicle. Ph.D. Thesis, Universiti Teknologi Malaysia, Johor Bahru, Malaysia, 2014. [Google Scholar]

- Yu, H.; Taheri, S.; Duan, J.; Qi, Z. An integrated cooperative antilock braking control of regenerative and mechanical system for a hybrid electric vehicle based on intelligent tire. Asian J. Control 2016, 18, 55–68. [Google Scholar] [CrossRef]

- Song, J. Performance evaluation of a hybrid electric brake system with a sliding mode controller. Mechatronics 2005, 15, 339–358. [Google Scholar] [CrossRef]

- Anwar, S. Generalized predictive control of yaw dynamics of a hybrid brake-by-wire equipped vehicle. Mechatronics 2005, 15, 1089–1108. [Google Scholar] [CrossRef]

- Satzger, C.W. Predictive Braking Control with Hybrid Actuators. Doctor Thesis, FAU University, Boca Raton, FL, USA, 2017. [Google Scholar]

- Tao, Y.; Xie, X.; Zhao, H.; Xu, W.; Chen, H. A regenerative braking system for electric vehicle with four in-wheel motors based on fuzzy control. In Proceedings of the 2017 36th Chinese Control Conference (CCC), Dalian, China, 26–28 July 2017; pp. 4288–4293. [Google Scholar] [CrossRef]

- Peng, D.; Yin, C.; Zhang, J. Advanced braking control system for hybrid electric vehicle using fuzzy control logic. SAE Tech. Pap. 2006. [Google Scholar] [CrossRef]

- Lupberger, S.; Degel, W.; Odenthal, D.; Bajcinca, N. Nonlinear control design for regenerative and hybrid antilock braking in electric vehicles. IEEE Trans. Control Syst. Technol. 2021, 30, 1375–1389. [Google Scholar] [CrossRef]

- Wei, Z.; Xu, J.; Halim, D. Braking force control strategy for electric vehicles with load variation and wheel slip considerations. IET Electr. Syst. Transp. 2017, 7, 41–47. [Google Scholar] [CrossRef]

- Topalov, A.V.; Oniz, Y.; Kayacan, E.; Kaynak, O. Neuro-fuzzy control of antilock braking system using sliding mode incremental learning algorithm. Neurocomputing 2011, 74, 1883–1893. [Google Scholar] [CrossRef]

- Lee, T.T.; Hsu, C.F.; Lee, S. Robust hybrid control for antilock braking systems. In Proceedings of the SMC’03 Conference Proceedings, 2003 IEEE International Conference on Systems, Man and Cybernetics. Conference Theme-System Security and Assurance (Cat. No. 03CH37483), Washington, DC, USA, 8 October 2003; Volume 1, pp. 84–89. [Google Scholar] [CrossRef]

- Wang, B.; Huang, X.; Wang, J.; Guo, X.; Zhu, X. A robust wheel slip ratio control design combining hydraulic and regenerative braking systems for in-wheel-motors-driven electric vehicles. J. Frankl. Inst. 2015, 352, 577–602. [Google Scholar] [CrossRef]

- El-bakkouri, J.; Ouadi, H.; Saad, A. Adaptive Neuro Fuzzy Inference System Based controller for Electric Vehicle’s hybrid ABS braking. IFAC-PapersOnLine 2022, 55, 371–376. [Google Scholar] [CrossRef]

- Han, J.; Park, Y.; Park, Y. Adaptive regenerative braking control in severe cornering for guaranteeing the vehicle stability of fuel cell hybrid electric vehicle. In Proceedings of the 2011 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 6–9 September 2011; pp. 1–5. [Google Scholar] [CrossRef]

- Tang, J.H.; Wang, K.Y.; Bei, S.Y.; Sousa, M.M. Research on braking force distribution strategy of composite braking system of hybrid electric vehicle. J. Mech. Eng. Res. Dev. 2016, 39, 373–386. [Google Scholar] [CrossRef]

- Ma, Z.; Sun, D. Energy recovery strategy based on ideal braking force distribution for regenerative braking system of a four-wheel drive electric vehicle. IEEE Access 2020, 8, 136234–136242. [Google Scholar] [CrossRef]

- Hu, D. Braking Force Distribution Control of Hybrid Brake-by-Wire System, Design and Control of Hybrid Brake-by-Wire System for Autonomous Vehicle; Springer Nature: Singapore, 2022; pp. 79–103. [Google Scholar] [CrossRef]

- Crolla, D.A.; Cao, D. The impact of hybrid and electric powertrains on vehicle dynamics, control systems and energy regeneration. Veh. Syst. Dyn. 2012, 50 (Suppl. S1), 95–109. [Google Scholar] [CrossRef]

- Zhou, S.; Walker, P.; Zhang, N. Parametric design and regenerative braking control of a parallel hydraulic hybrid vehicle. Mech. Mach. Theory 2020, 146, 103714. [Google Scholar] [CrossRef]

- Geng, C.; Ning, D.; Guo, L.; Xue, Q.; Mei, S. Simulation research on regenerative braking control strategy of hybrid electric vehicle. Energies 2021, 14, 2202. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, J.; Sun, D.; Lv, C. Research on control strategy of electric-hydraulic hybrid anti-lock braking system of an electric passenger car. In Proceedings of the 2015 IEEE Intelligent Vehicles Symposium (IV), Seoul, Republic of Korea, 28 June–1 July 2015; pp. 419–424. [Google Scholar] [CrossRef]

- Xu, W.; Zhao, H.; Ren, B.; Chen, H. A regenerative braking control strategy for electric vehicle with four in-wheel motors. In Proceedings of the 2016 35th Chinese Control Conference (CCC), Chengdu, China, 27–29 July 2016; pp. 8671–8676. [Google Scholar] [CrossRef]

- Xu, Q.; Wang, F.; Zhang, X.; Cui, S. Research on the efficiency optimization control of the regenerative braking system of hybrid electrical vehicle based on electrical variable transmission. IEEE Access 2019, 7, 116823–116834. [Google Scholar] [CrossRef]

- Nadeau, J.; Micheau, P.; Boisvert, M. Ideal regenerative braking torque in collaboration with hydraulic brake system. In Proceedings of the 2017 Twelfth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte Carlo, Monaco, 1–13 April 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Han, J.; Park, Y.; Park, Y. Cooperative regenerative braking control for front-wheel-drive hybrid electric vehicle based on adaptive regenerative brake torque optimization using under-steer index. Int. J. Automot. Technol. 2014, 15, 989–1000. [Google Scholar] [CrossRef]

- Xu, W.; Chen, H.; Zhao, H.; Ren, B. Torque optimization control for electric vehicles with four in-wheel motors equipped with regenerative braking system. Mechatronics 2019, 57, 95–108. [Google Scholar] [CrossRef]

- Mohamed, E.; Abouel-Seoud, S.; Elsayed, M. Performance analysis of the ABS control on parallel hybrid electric vehicle equipped with regenerative braking system. SAE Int. J. Passeng. Cars-Electron. Electr. Syst. 2015, 8, 477–491. [Google Scholar] [CrossRef]

- Chu, L.; Sun, W.; Yao, L.; Zhang, Y.; Qu, Y.; Wei, W.; Liu, M.; Li, J. Integrative control strategy of regenerative and hydraulic braking for hybrid electric car. In Proceedings of the 2009 IEEE Vehicle Power and Propulsion Conference, Dearborn, MI, USA, 7–11 September 2009; pp. 1091–1098. [Google Scholar] [CrossRef]

- Kim, D.; Hwang, S.; Kim, H. Vehicle stability enhancement of four-wheel-drive hybrid electric vehicle using rear motor control. IEEE Trans. Veh. Technol. 2008, 57, 727–735. [Google Scholar] [CrossRef]

- Xie, Y.; Wang, S. Research on regenerative braking control strategy and Simulink simulation for 4WD electric vehicle. IOP Conf. Ser. Mater. Sci. Eng. IOP Publ. 2018, 398, 012013. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, Y.; Zhu, R.; Geng, R.; Zhang, J.; Fan, D.; Wang, H. Study on the control strategy of regenerative braking for the hybrid electric vehicle under typical braking condition. IOP Conf. Ser. Mater. Sci. Eng. IOP Publ. 2018, 452, 032092. [Google Scholar] [CrossRef]

- Shu, J.; Zhang, Y.; Yin, C. Longitudinal control of hybrid electric buses using traction motor and pneumatic braking system. WSEAS Trans. Circuits Syst. 2009, 8, 873–882. [Google Scholar]

- Wu, W.; Liu, H.; Zhou, J.; Hu, J.; Yuan, S. Energy efficiency of hydraulic regenerative braking for an automobile hydraulic hybrid propulsion method. Int. J. Green Energy 2019, 16, 1046–1053. [Google Scholar] [CrossRef]

- Lv, C.; Zhang, J.; Li, Y.; Yuan, Y. Novel control algorithm of braking energy regeneration system for an electric vehicle during safety–critical driving maneuvers. Energy Convers. Manag. 2015, 106, 520–529. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, J. Integrated power management and after treatment system control for hybrid electric vehicles with road grade preview. IEEE Trans. Veh. Technol. 2017, 66, 10935–10945. [Google Scholar] [CrossRef]

- Itani, K.; De Bernardinis, A.; Khatir, Z.; Jammal, A. Comparison between two braking control methods integrating energy recovery for a two-wheel front driven electric vehicle. Energy Convers. Manag. 2016, 122, 330–343. [Google Scholar] [CrossRef]

- Liu, Z.-Q.; Mao, J.-T.; Chen, L. Electromagnetic and Friction Integrated Braking Method Based on Hybrid Theory. China J. Highw. Transp. 2019, 32, 183. [Google Scholar]

- Zhang, Z.W. Study on Hybrid Vehicle Regenerative Braking Control Parameters Affecting to Vehicle Performance Analysis and Simulation. Key Eng. Mater. 2014, 579, 745–748. [Google Scholar] [CrossRef]

- Liu, T.; Zheng, J.; Su, Y.; Zhao, J. A study on control strategy of regenerative braking in the hydraulic hybrid vehicle based on ECE regulations. Math. Probl. Eng. 2013, 2013, 1–9. [Google Scholar] [CrossRef]

- Lin, C.M.; Li, H.Y. Intelligent hybrid control system design for antilock braking systems using self-organizing function-link fuzzy cerebellar model articulation controller. IEEE Trans. Fuzzy Syst. 2013, 21, 1044–1055. [Google Scholar] [CrossRef]

- Zhang, J.; Kong, D.; Chen, L.; Chen, X. Optimization of control strategy for regenerative braking of an electrified bus equipped with an anti-lock braking system. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2012, 226, 494–506. [Google Scholar] [CrossRef]

- Zhang, Y. The Application of Regenerative Braking System to the Commercial Hybrid Vehicles with All-Wheel Drive System. Master’s Thesis, University of Windsor, Windsor, ON, Canada, 2017. [Google Scholar]

- Xu, L.; He, X.; Shen, X. Improving energy recovery rate of the regenerative braking system by optimization of influencing factors. Appl. Sci. 2019, 9, 3807. [Google Scholar] [CrossRef]

- Shyrokau, B.; Wang, D.; Savitski, D.; Ivanov, V. Vehicle dynamics control with energy recuperation based on control allocation for independent wheel motors and brake system. Int. J. Powertrains 2013, 2, 153–181. [Google Scholar] [CrossRef]

- Li, W.; Du, H.; Li, W. Four-wheel electric braking system configuration with new braking torque distribution strategy for improving energy recovery efficiency. IEEE Trans. Intell. Transp. Syst. 2019, 21, 87–103. [Google Scholar] [CrossRef]

- Huynh, Q.V.; Dat, L.V.; Le, K.T. An intelligent regenerative braking strategy for power-split hybrid electric vehicle. Int. J. Mech. Eng. Appl. 2020, 8, 27. [Google Scholar] [CrossRef]

- Pan, S.; Song, Z.; Wang, X. Electro-mechanical braking force distribution strategy for electric vehicle. In Proceedings of the 2015 IEEE International Conference on Communication Problem-Solving (ICCP), Guilin, China, 16–18 October 2015; pp. 387–390. [Google Scholar] [CrossRef]

- Basrah, M.S.; Siampis, E.; Velenis, E.; Cao, D.; Long, S. Wheel slip control with torque blending using linear and nonlinear model predictive control. Veh. Syst. Dyn. 2017, 55, 1665–1685. [Google Scholar] [CrossRef]

- Wu, J.; Wang, X.; Li, L.; Qin, C.; Du, Y. Hierarchical control strategy with battery aging consideration for hybrid electric vehicle regenerative braking control. Energy 2018, 145, 301–312. [Google Scholar] [CrossRef]

- Kiddee, K.; Keyoonwong, W.; Khan-Ngern, W. An HSC/battery energy storage system-based regenerative braking system control mechanism for battery electric vehicles. IEEJ Trans. Electr. Electron. Eng. 2019, 14, 457–466. [Google Scholar] [CrossRef]

- Chu, L.; Shang, M.; Fang, Y.; Guo, J.; Zhou, F. Braking force distribution strategy for HEV based on braking strength. In Proceedings of the 2010 International Conference on Measuring Technology and Mechatronics Automation, Changsha, China, 13–14 March 2010; Volume 1, pp. 759–764. [Google Scholar] [CrossRef]

- Naik, B.; Shim, T. Effective Brake Torque Allocation in Regenerative Braking System Considering Shaft Vibration Using Model Predictive Control. Dyn. Syst. Control Conf. Am. Soc. Mech. Eng. 2015, 57243, V001T10A006. [Google Scholar] [CrossRef]

- Zhu, Y.; Wu, H.; Zhen, C. Regenerative braking control under sliding braking condition of electric vehicles with switched reluctance motor drive system. Energy 2021, 230, 120901. [Google Scholar] [CrossRef]

- Li, W.; Du, H.; Li, W. A new torque distribution strategy for blended anti-lock braking systems of electric vehicles based on road conditions and driver’s intentions. SAE Int. J. Passeng. Cars-Mech. Syst. 2016, 9, 107–115. [Google Scholar] [CrossRef]

- Liu, B.; Li, L.; Wang, X.; Cheng, S. Hybrid electric vehicle downshifting strategy based on stochastic dynamic programming during regenerative braking process. IEEE Trans. Veh. Technol. 2018, 67, 4716–4727. [Google Scholar] [CrossRef]

- Li, W.; Du, H.; Li, W. Driver intention based coordinate control of regenerative and plugging braking for electric vehicles with in-wheel PMSMs. IET Intell. Transp. Syst. 2018, 12, 1300–1311. [Google Scholar] [CrossRef]

- Sun, H.; Yang, L.; Jing, J.; Luo, Y. Control strategy of hydraulic/electric synergy system in heavy hybrid vehicles. Energy Convers. Manag. 2011, 52, 668–674. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, W.; Liu, Z.; Zeng, M. Comfort braking control for brake-by-wire vehicles. Mech. Syst. Signal Process. 2019, 133, 106255. [Google Scholar] [CrossRef]

- Khajvand, F.; Zareinejad, M.; Rezaei, S.M.; Baghestan, K. Design and implementation of a series hydraulic hybrid propulsion system to increase regenerative braking energy saving range. Energy Convers. Manag. 2023, 279, 116754. [Google Scholar] [CrossRef]

- Pan, C.; Wang, J.; Huang, A.; Chen, L.; Jiang, H.; Wang, L.; Xu, X. The analysis of series hybrid energy storage system for regenerative braking based on energy constraint control aimed at deceleration. CSEE J. Power Energy Syst. 2022, 1–14. [Google Scholar]

- Naseri, F.; Farjah, E.; Ghanbari, T. An efficient regenerative braking system based on battery/supercapacitor for electric, hybrid, and plug-in hybrid electric vehicles with BLDC motor. IEEE Trans. Veh. Technol. 2016, 66, 3724–3738. [Google Scholar] [CrossRef]

- Ye, K.; Li, P.; Li, H. Optimization of hybrid energy storage system control strategy for pure electric vehicle based on typical driving cycle. Math. Probl. Eng. 2020, 2020, 1–12. [Google Scholar] [CrossRef]

- Yu, Z.; Shi, B.; Xiong, L.; Han, W. Coordinated control under transitional conditions in hybrid braking of electric vehicle. In Proceedings of the Brake Colloquium & Exhibition-36th Annual, Palm Desert, CA, USA, 14–17 October 2018. [Google Scholar] [CrossRef]

- Yang, Y.; He, Y.; Yang, Z.; Fu, C.; Cong, Z. Torque coordination control of an electro-hydraulic composite brake system during mode switching based on braking intention. Energies 2020, 13, 2031. [Google Scholar] [CrossRef]

- Shang, M.; Chu, L.; Guo, J.; Fang, Y.; Zhou, F. Braking force dynamic coordinated control for hybrid electric vehicles. In Proceedings of the 2010 2nd International Conference on Advanced Computer Control, Shenyang, China, 27–29 March 2010; Volume 4, pp. 411–416. [Google Scholar] [CrossRef]

- Yang, Z.; Xu, S.; Lu, X.; Gang, L. Control of Integrated Electro-Hydraulic Braking System Based on Flutter Compensation. J. Tongji Univ. 2015, 43, 1063–1068. [Google Scholar]

- Jo, C.; Ko, J.; Yeo, H.; Yeo, T. Cooperative regenerative braking control algorithm for an automatic-transmission-based hybrid electric vehicle during a downshift. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2012, 226, 457–467. [Google Scholar] [CrossRef]

- Tang, Q.; Yang, Y.; Luo, C.; Yang, Z.; Fu, C. A novel electro-hydraulic compound braking system coordinated control strategy for a four-wheel-drive pure electric vehicle driven by dual motors. Energy 2022, 241, 122750. [Google Scholar] [CrossRef]

- Junzhi, Z.; Xin, L.; Shanglou, C.; Pengjun, Z. Coordinated control for regenerative braking system. In Proceedings of the 2008 IEEE Vehicle Power and Propulsion Conference, Harbin, China, 3–5 September 2008; pp. 1–6. [Google Scholar] [CrossRef]

- Zhang, L.; Yu, L.; Pan, N.; Zhang, Y. Cooperative control of regenerative braking and friction braking in the transient process of anti-lock braking activation in electric vehicles. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2016, 230, 1459–1476. [Google Scholar] [CrossRef]

- Li, L.; Li, X.; Wang, X.; Liu, Y. Transient switching control strategy from regenerative braking to anti-lock braking with a semi-brake-by-wire system. Veh. Syst. Dyn. 2016, 54, 231–257. [Google Scholar] [CrossRef]

- Kwon, M.H.; Park, J.H.; Gwak, G.S.; Huh, J.W.; Choi, H.K.; Hwang, S.H. Cooperative control for friction and regenerative braking systems considering dynamic characteristic and temperature condition. Int. J. Automot. Technol. 2016, 17, 437–446. [Google Scholar] [CrossRef]

- Zhao, D.; Chu, L.; Xu, N.; Sun, C.; Xu, Y. Development of a cooperative braking system for front-wheel drive electric vehicles. Energies 2018, 11, 378. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, C.; Zhang, Q.; He, X. Torque coordination control during braking mode switch for a plug-in hybrid electric vehicle. Energies 2017, 10, 1684. [Google Scholar] [CrossRef]

- Li, W.; Li, H.; Huang, Z.; Liu, J.; Dang, S.; Du, H. A new braking torque distribution strategy based on braking actuator characteristics and a command signal for a blended braking system. IET Intell. Transp. Syst. 2022, 16, 825–841. [Google Scholar] [CrossRef]

- Wang, C. Research on the Control Strategy of EHB-Motor Compound Braking System for the Electric Vehicle; Jilin University: Jilin, China, 2017. [Google Scholar] [CrossRef]

- Li, W.; Li, H.; Huang, C.; Xu, K.; Sun, T.; Du, H. Observer-based coordinated control for blended braking system with actuator delay. Actuators 2021, 10, 193. [Google Scholar] [CrossRef]

- Du, Y.C.; Qin, C.A.; You, S.X.; Xia, H.C. Efficient coordinated control of regenerative braking with pneumatic anti-lock braking for hybrid electric vehicle. Sci. China Technol. Sci. 2017, 60, 399–411. [Google Scholar] [CrossRef]

- Zhang, J.; Lv, C.; Gou, J.; Kong, D. Cooperative control of regenerative braking and hydraulic braking of an electrified passenger car. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2012, 226, 1289–1302. [Google Scholar] [CrossRef]

- Xu, Q.; Zhou, C.; Huang, H.; Zhang, X. Research on the coordinated control of regenerative braking system and ABS in hybrid electric vehicle based on composite structure motor. Electronics 2021, 10, 223. [Google Scholar] [CrossRef]

- Yin, G.; Jin, X.J. Cooperative control of regenerative braking and antilock braking for a hybrid electric vehicle. Math. Probl. Eng. 2013, 2013, 1–9. [Google Scholar] [CrossRef]

- Kumar, C.S.N.; Subramanian, S.C. Cooperative control of regenerative braking and friction braking for a hybrid electric vehicle. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2016, 230, 103–116. [Google Scholar] [CrossRef]

- Ji, F.Z.; Zhou, X.X.; Zhu, W.B. Coordinate control of electro-hydraulic hybrid brake of electric vehicles based on Carsim. Appl. Mech. Mater. 2014, 490, 1120–1125. [Google Scholar] [CrossRef]

| Refs. | Control Algorithm |

|---|---|

| [20] | Sliding mode control |

| [21,22] | Predictive control |

| [23,24] | Fuzzy control |

| [25] | Nonlinear control |

| [26] | PID |

| [27] | Neuro-fuzzy control |

| [28,29] | Robust control |

| [30] | Adaptive Neuro Fuzzy |

| [31] | Adaptive control |

| Classification | Influence Factor | Control Algorithm | Advantages of Control Algorithms | Refs. |

|---|---|---|---|---|

| A specific proportional | Anti-lock braking system (ABS) | Nonlinear-sliding-mode-type control | Fast response speed | [17] |

| Adaptive neuro fuzzy | Adaptability | [30] | ||

| PID control | Model-free | [44] | ||

| Fuzzy | Interpretability | [45] | ||

| ESC | Fuzzy-rule-based control | Adaptability | [46] | |

| - | - | [47,48] | ||

| All conditions | Adaptive fuzzy control | Adaptability | [49] | |

| - | - | [50] | ||

| Safety-critical driving maneuvers | Sliding mode control | Fast response speed | [51] | |

| Road grade preview | - | - | [52] | |

| Two-wheel front driven | Sliding mode control | Fast response speed | [53] | |

| Load variation and wheel slip considerations | PID | Model-free | [26] | |

| - | Hybrid theory | Adaptability | [54] | |

| Different road surfaces | Fuzzy logic | Interpretability | [55] | |

| ECE regulations | - | - | [56] | |

| - | Predictive braking control | Optimization | [22] | |

| Optimized proportion | ABS | Nonlinear Control | Accuracy | [25] |

| Robust control | Robustness | [29] | ||

| Self-organizing function-link Fuzzy cerebellar model Articulation controller | Adaptability | [57] | ||

| Optimal control | Optimization | [58] | ||

| ESC | LQR | Optimization | [31] | |

| Optimal control | Optimization | [59] | ||

| All conditions | Model predictive control | Optimization | [56] | |

| Optimal control | Optimization | [56,60,61] | ||

| Neural-network sliding mode control | Accuracy | [62] | ||

| Fuzzy Logic Control | Interpretability | [63,64] | ||

| Linear and nonlinear model predictive control | Optimization | [65] | ||

| Battery | MPC | Optimization | [66,67] | |

| Braking strength | - | - | [68] | |

| Shaft vibration | Model predictive control | Optimization | [69] | |

| Sliding braking condition | Multi-objective optimization strategy | Optimization | [70] | |

| Road conditions and driver’s intentions | Model predictive control | Optimization | [71] | |

| Downshifting strategy | Stochastic dynamic programming | Optimization | [72] | |

| Driver’s braking intention | Model predictive control | Optimization | [73] | |

| Other factors | Battery state | - | - | [74] |

| Braking safety and ride comfort | - | - | [75] | |

| ECE R13H | Robust sliding mode controller | Robustness | [53] | |

| All conditions | Artificial neural network | Accuracy | [76] | |

| Energy constraint control (ECC) | Robustness | [77] | ||

| Battery/supercapacitor | - | - | [78] | |

| DC/DC | Genetic algorithm (GA)-fuzzy control | Optimization | [79] |

| Classification | Subclass | Control Algorithm | Advantages of Control Algorithms | Refs. |

|---|---|---|---|---|

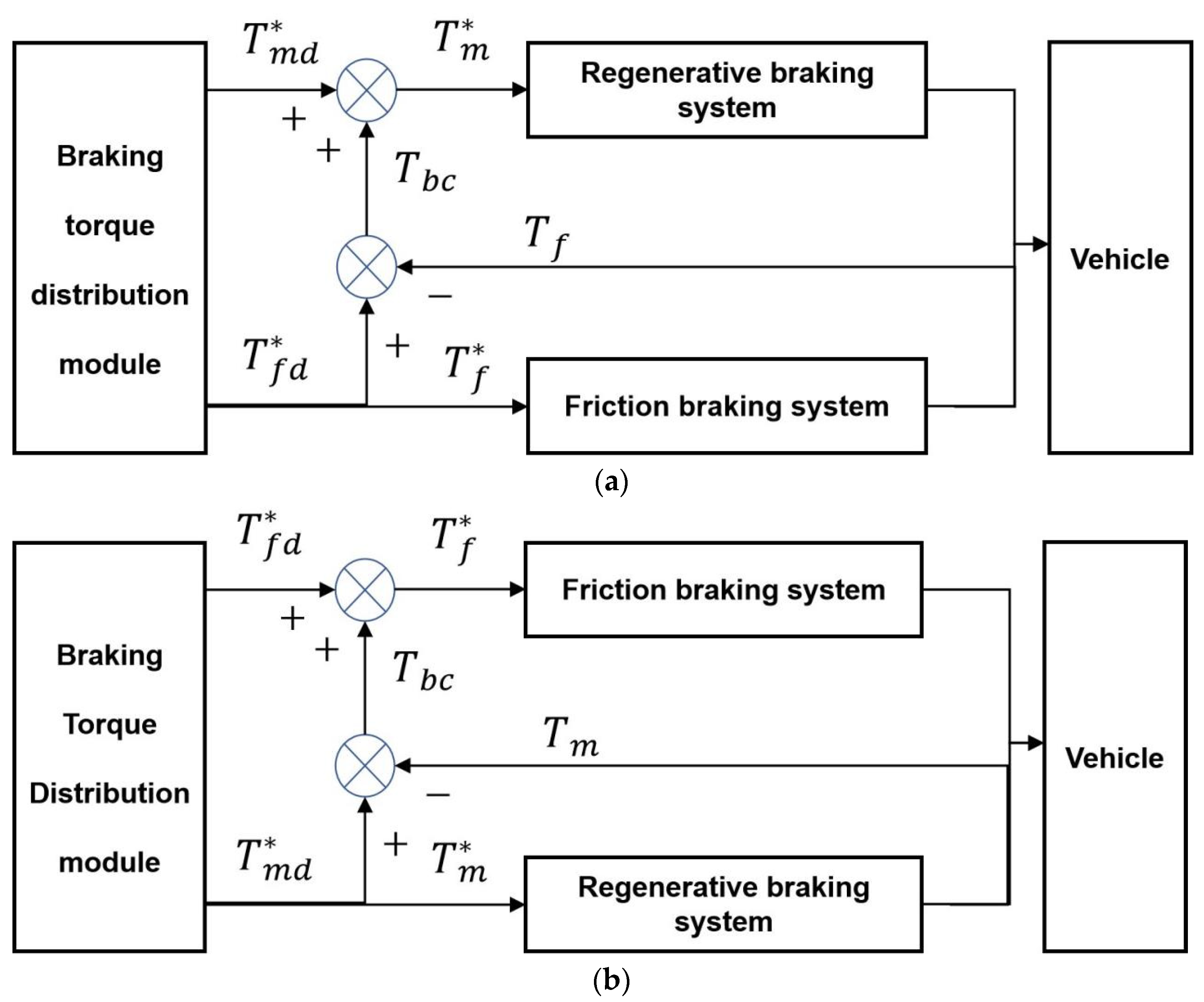

| Braking torque coordination without compensation module | Closed-loop control mainly based on regenerative braking | - | - | [80] |

| Fuzzy control | Interpretability | [81] | ||

| Closed-loop control mainly based on friction braking | - | - | [82,83] | |

| Model predictive control | Optimization | [84] | ||

| Optimal control | Optimization | [85] | ||

| - | - | [86] | ||

| Fuzzy logic | Interpretability | [87] | ||

| Sliding mode control | Fast response speed | [88] | ||

| - | - | [89,90,91] | ||

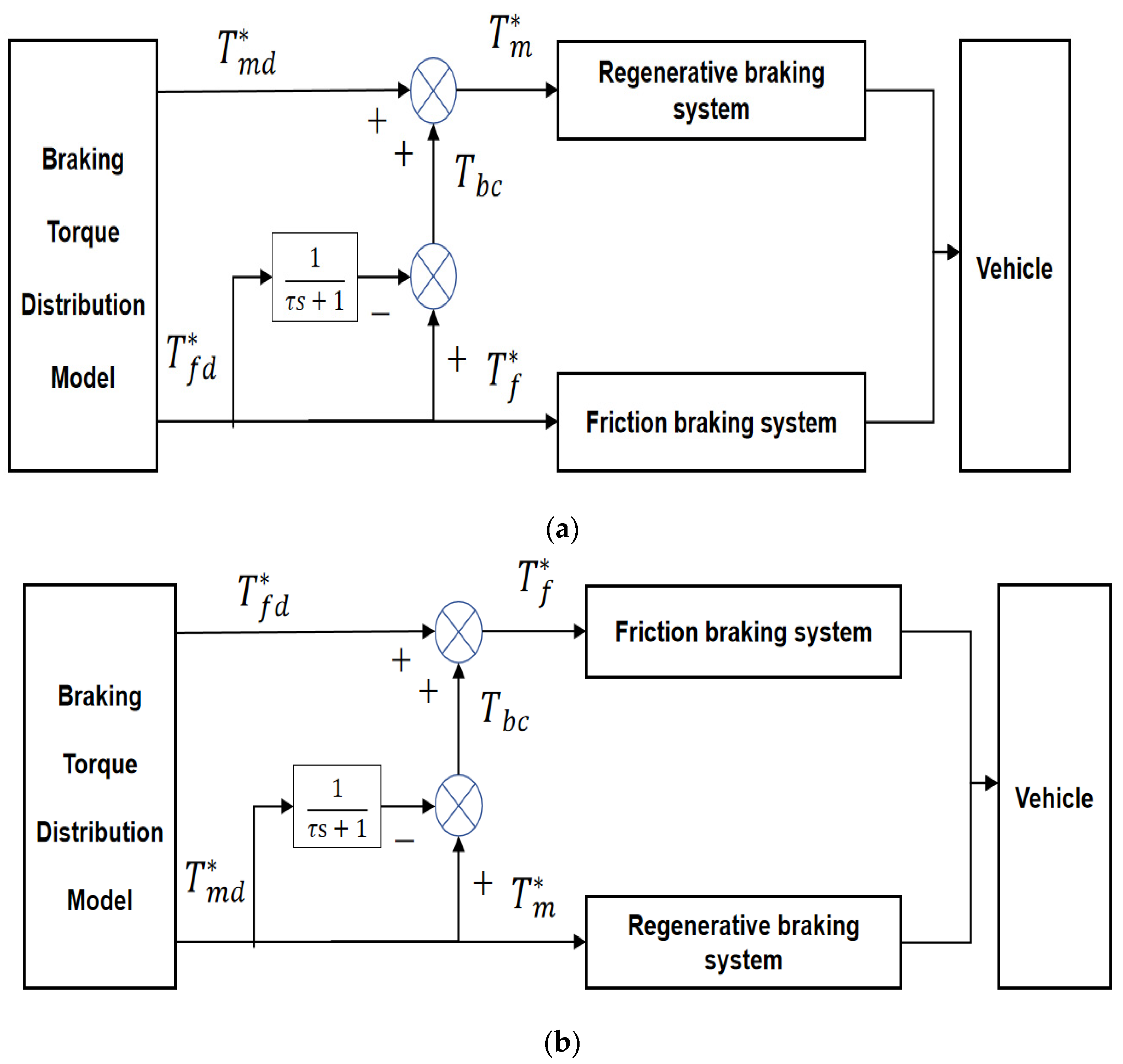

| Braking torque coordination with compensation module | Closed-loop control mainly based on regenerative braking | Input-constrained-based sliding mode control | Robustness and fast response speed | [92] |

| Active disturbance rejection controller | Robustness | [93] | ||

| Closed-loop control mainly based on friction braking | Sliding mode control | Fast response speed | [94] | |

| MPC | Optimization | [95] | ||

| - | - | [96] | ||

| Other factors | Parallel mode | Model predictive control | Optimization | [97,98] |

| Fixed ratio | Sliding mode control and fuzzy logic control | Fast response speed and accuracy | [99] | |

| - | - | [100] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Wang, M.; Huang, C.; Li, B. A Survey of Hybrid Braking System Control Methods. World Electr. Veh. J. 2024, 15, 372. https://doi.org/10.3390/wevj15080372

Li W, Wang M, Huang C, Li B. A Survey of Hybrid Braking System Control Methods. World Electric Vehicle Journal. 2024; 15(8):372. https://doi.org/10.3390/wevj15080372

Chicago/Turabian StyleLi, Wenfei, Ming Wang, Chao Huang, and Boyuan Li. 2024. "A Survey of Hybrid Braking System Control Methods" World Electric Vehicle Journal 15, no. 8: 372. https://doi.org/10.3390/wevj15080372

APA StyleLi, W., Wang, M., Huang, C., & Li, B. (2024). A Survey of Hybrid Braking System Control Methods. World Electric Vehicle Journal, 15(8), 372. https://doi.org/10.3390/wevj15080372