Permanent Magnet Assisted Synchronous Reluctance Motor for Subway Trains

Abstract

1. Introduction

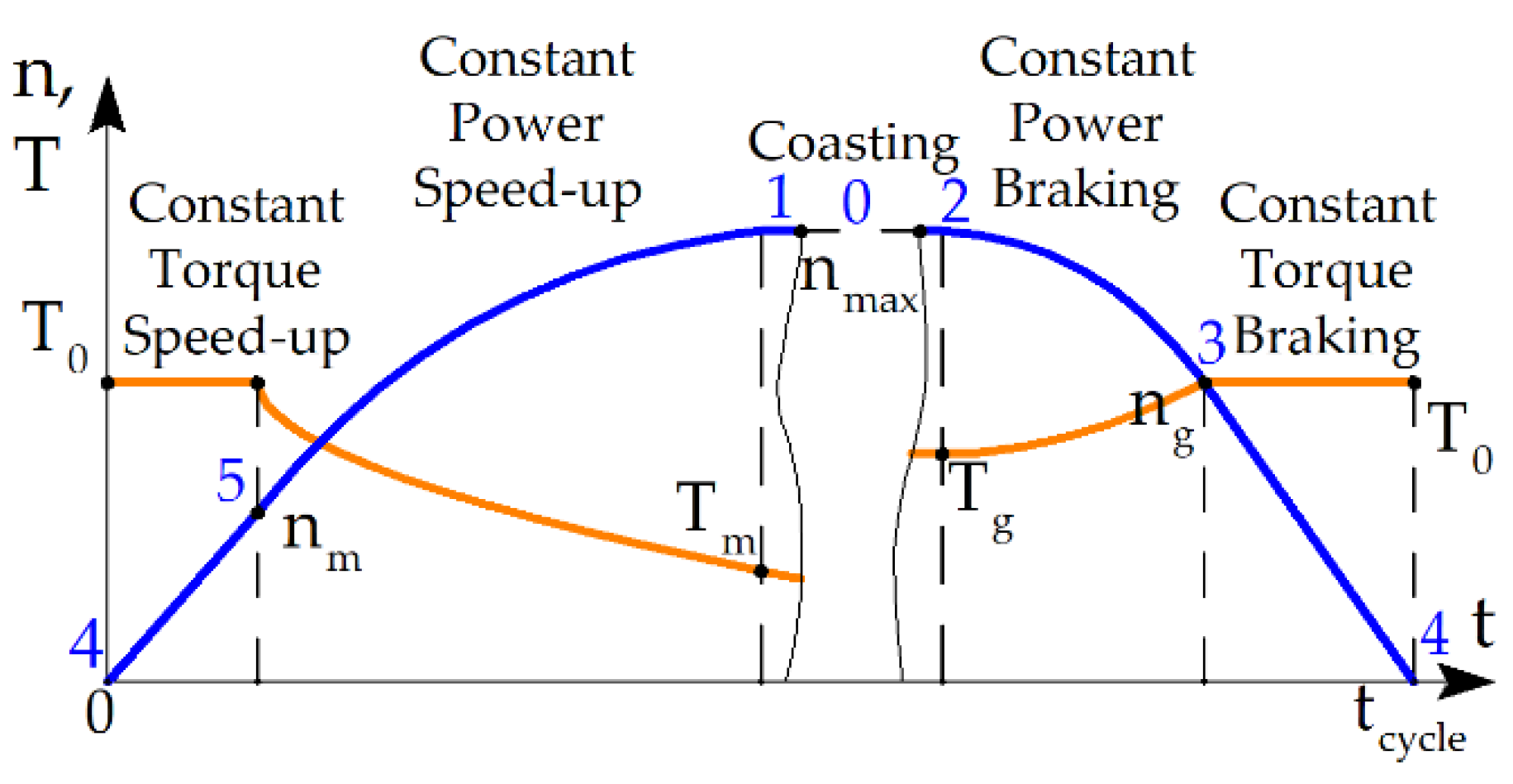

2. Considering the Train Movement Cycle in the Motor Optimization

- (1)

- Acceleration while maintaining a constant torque T0 = 1240 N∙m to a speed nm = 1427 rpm (plot sections 4–5);

- (2)

- Acceleration with constant power up to speed nmax = 4280 rpm (sections 5–1);

- (3)

- Movement by inertia at approximately constant speed (sections 1–2); the model does not take into account friction, and the speed at this stage is assumed to be exactly constant.

- (4)

- Braking from speed nmax to speed ng = 2854 rpm with a constant power (sections 2–3);

- (5)

- Braking with torque T0 = 1240 N∙m to the stop (sections 3–4).

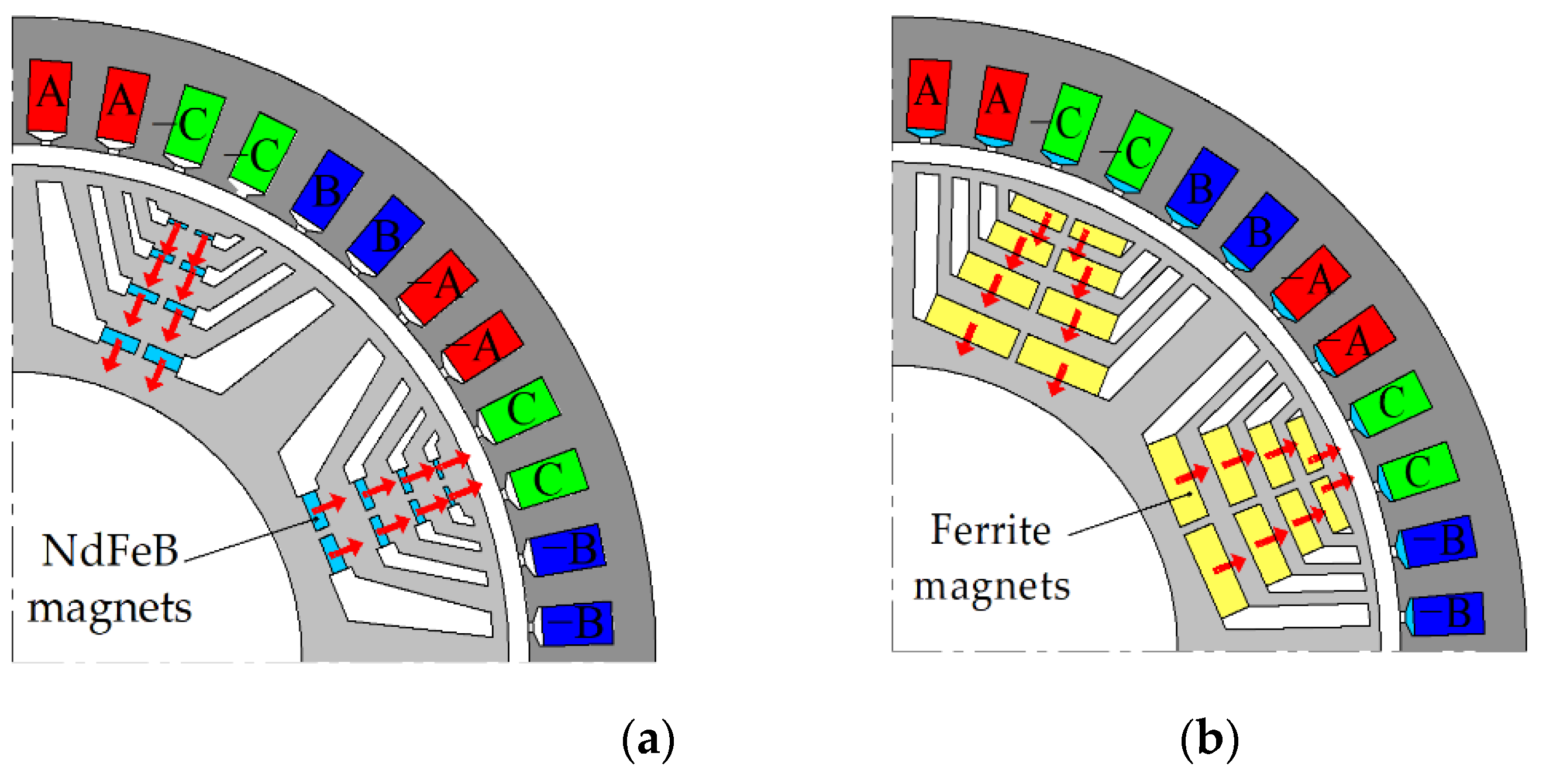

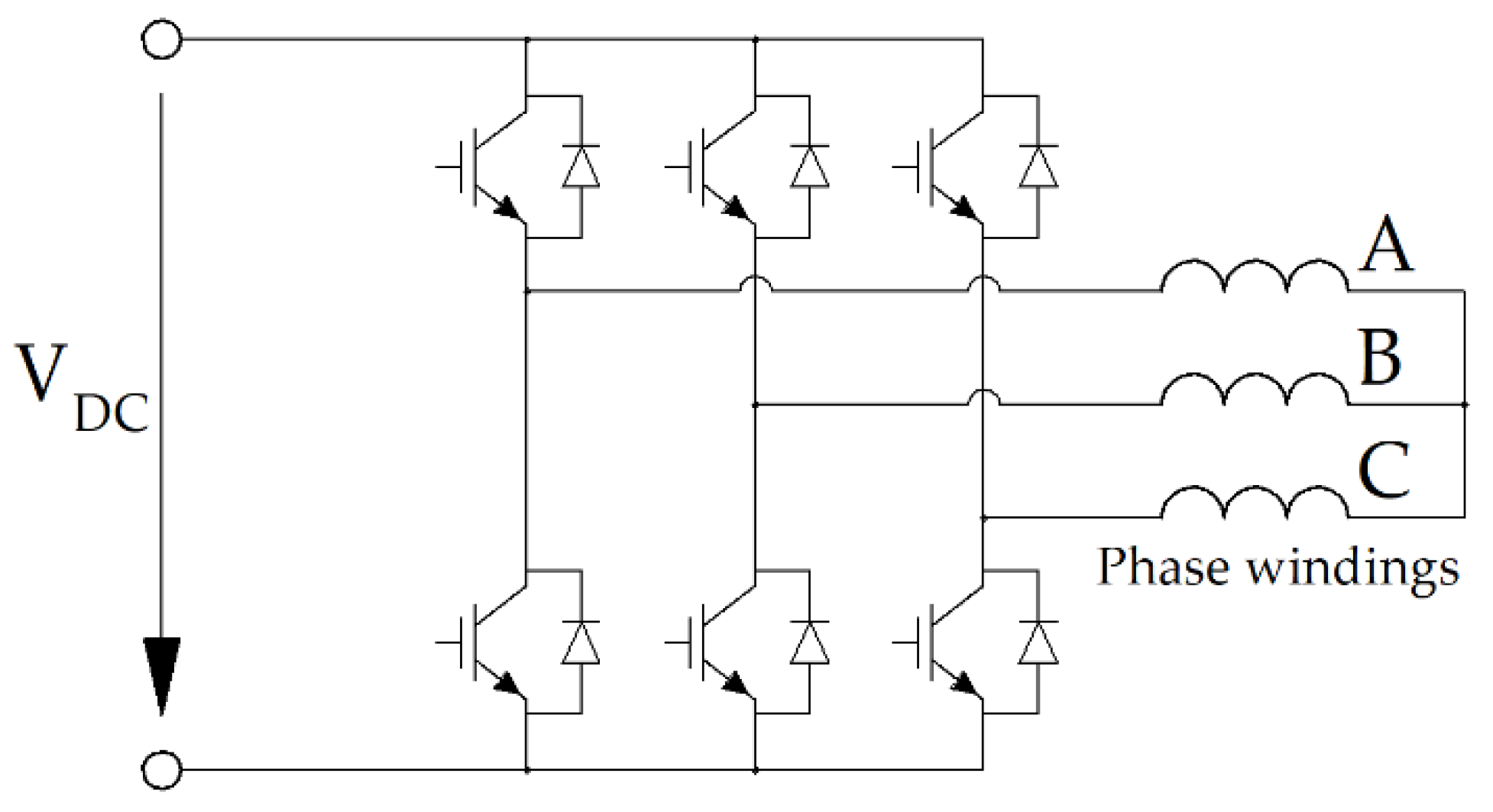

3. Main Design Features of the Motor and Traction Inverter

4. Objective Function and Optimization Procedure

- (1)

- Firstly, there is a focus on minimizing the overall energy loss during operation, represented by the average loss factor <Ploss>. This value is derived from an assessment of losses across various operating points, with weights assigned according to their relative importance;

- (2)

- Secondly, the algorithm is aimed at reducing the peak current Iarm consumed by the motor armature winding at operating points 1–5, since minimizing this value allows for reducing the cost of power switches of the traction inverter at a given voltage limit. The power factor was not considered as an objective because it may take high values at high current values when the available voltage is not used enough;

- (3)

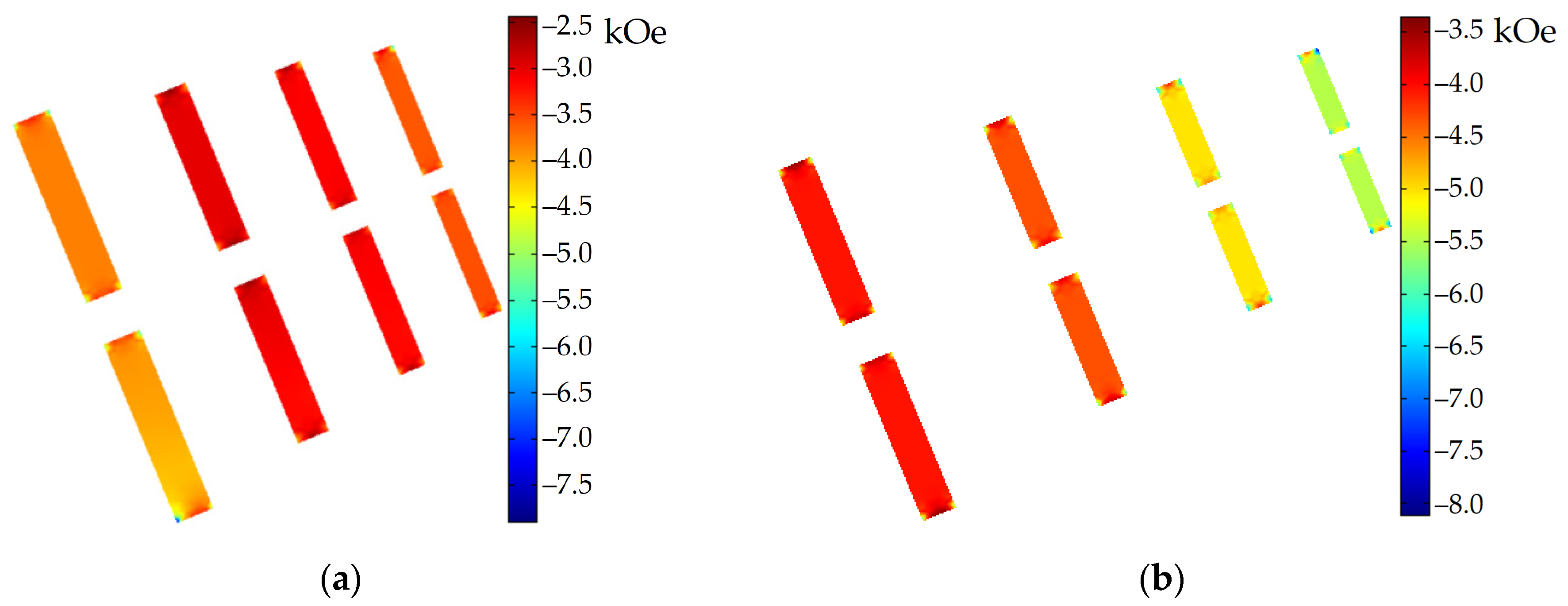

- It is also important to reduce the motor torque ripple TRi at operating points 1–5 to ensure a longer lifetime of the powertrain;

- (4)

- Minimizing the mass of the rotor Mrot (its magnetic core plus magnets). The rotor mass is added to the optimization function, since it affects the service life of the bearings, and an excessively large rotor mass will lead to unreasonably rapid failure of the bearings;

- (5)

- Minimizing the mass of the permanent magnets Mmag. The mass of permanent magnets is added to the optimization function, since permanent magnets are the most expensive material in the magnetic core, and their excessive use will lead to an unjustified increase in the cost of the machine.

5. REaSynRM Optimization Results

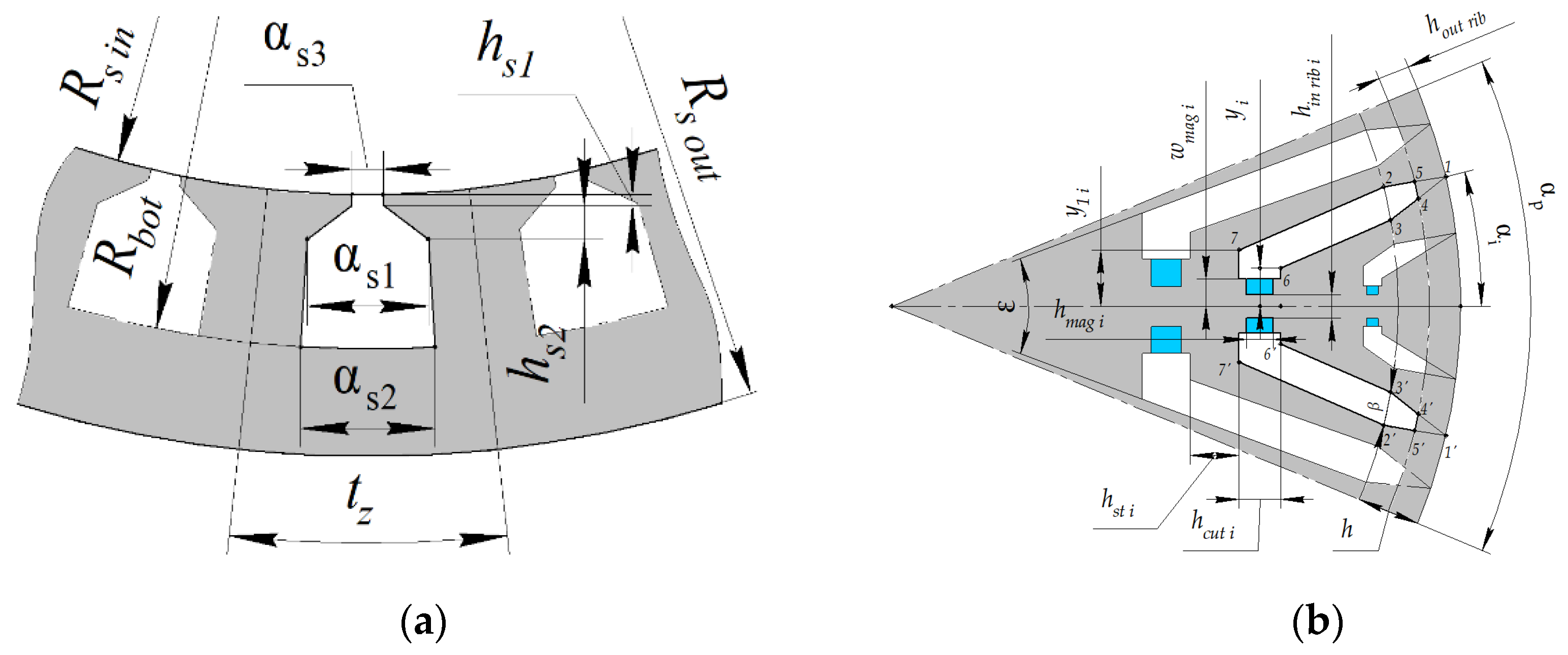

5.1. REaSynRM Optimization Parameters

y1i = yi ∙ c, i = 1, 2, 3;

yi + 1 = y1i ∙ g, i = 1, 2, 3, 4;

hcut i = acut + bcut (i − 1), i = 1, 2, 3, 4;

hst i = ast + bst (i − 1), i = 1, 2, 3.

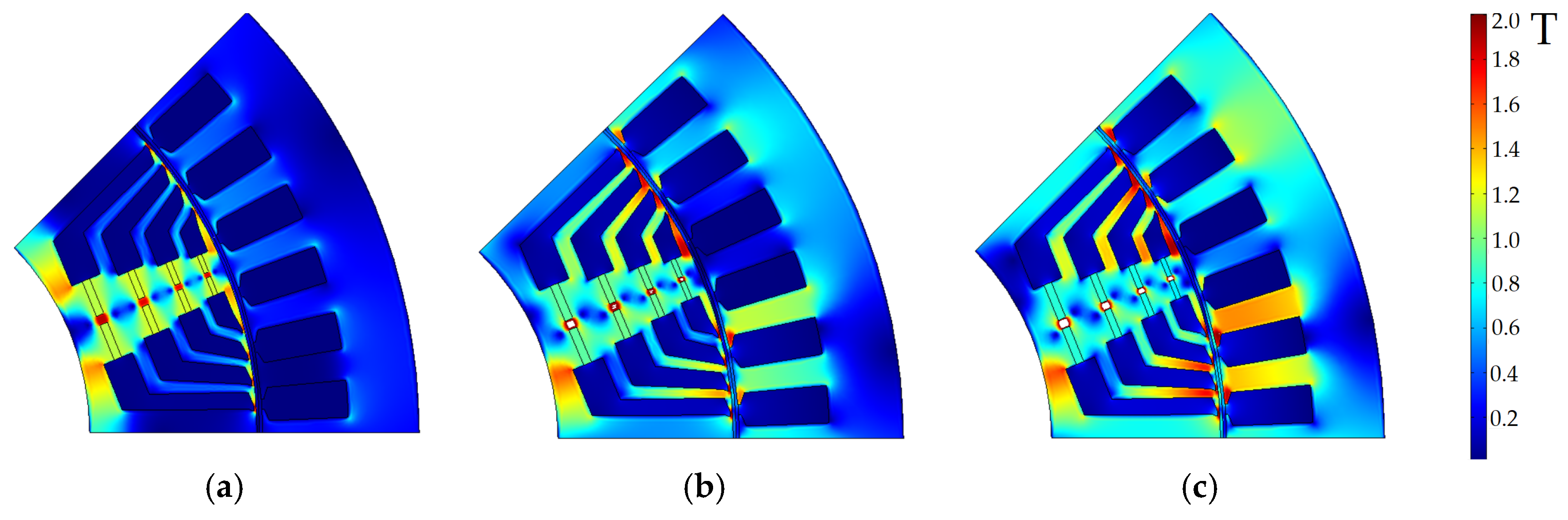

5.2. REaSynRM Optimization Results

- (1)

- The average losses after optimization were reduced by 100% × (11.11 − 7.63)/11.11 = 31.3%;

- (2)

- The core loss during the train coasting decreases by 1.67/0.8 = 2.1 times;

- (3)

- The maximum current consumption by the motor from the traction inverter decreased by 100% × (1395 − 896)/1395 = 35.7%;

- (4)

- The maximum torque ripple decreased by 33.2 − 15.3 = 17.9%;

- (5)

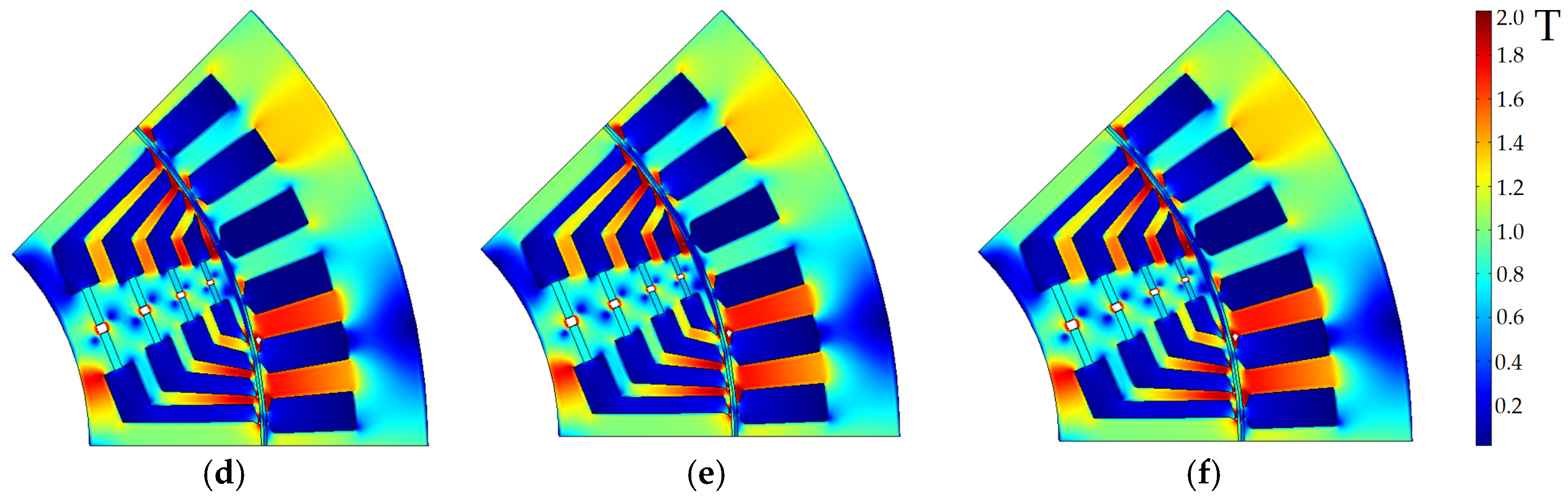

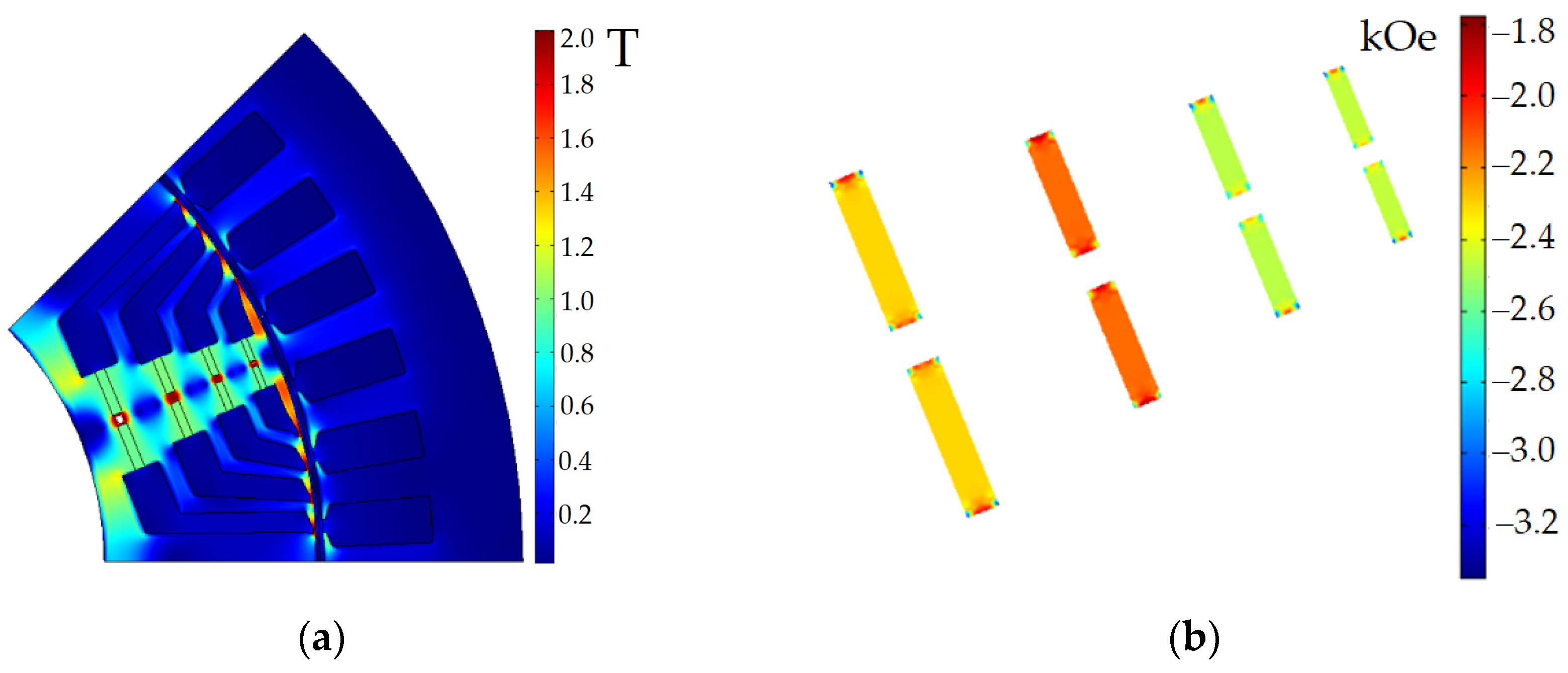

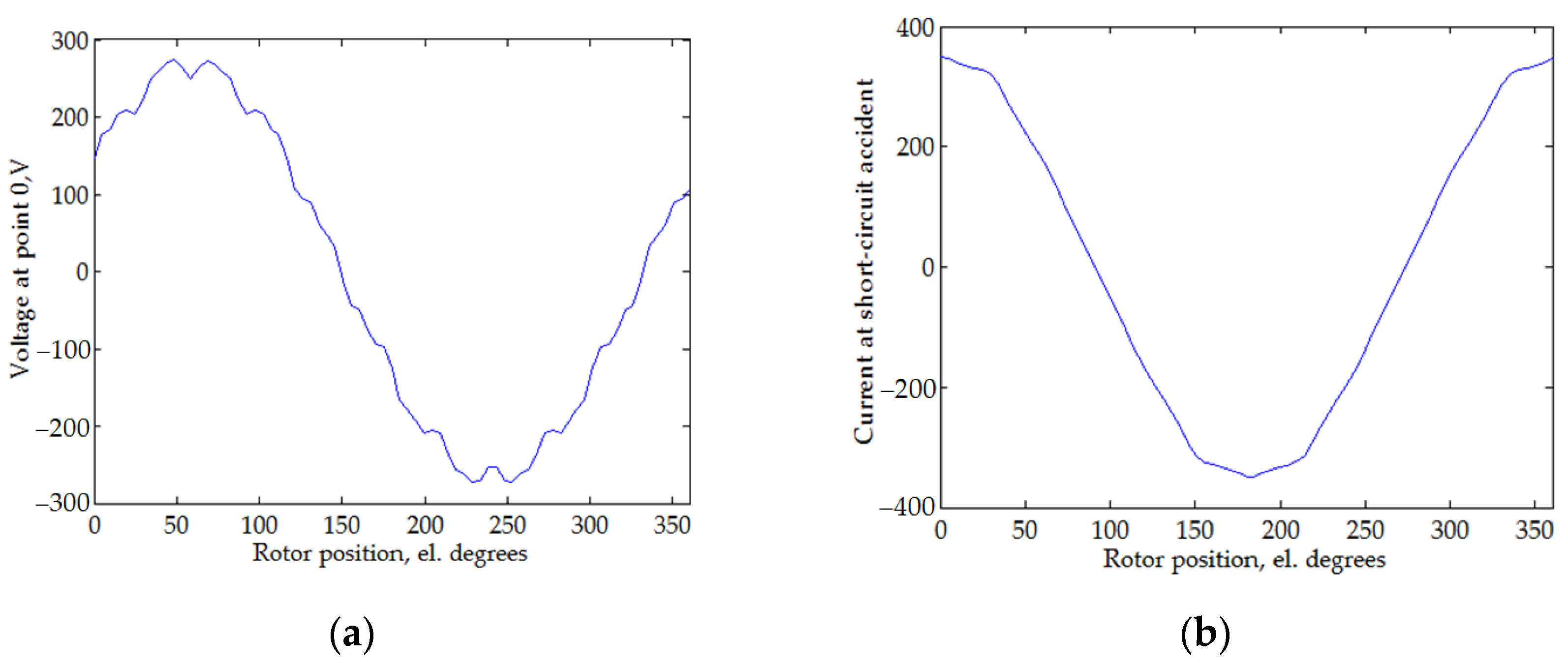

- In the emergency short-circuit mode, the loss in the winding is (1.29 − 1.09)/1.29 = 15.5% less than in operating point 1 (high-speed motor mode), in which the loss is significantly less than in the full torque operating point, and the demagnetizing force is 8.1/3.3 = 2.5 times less.

6. Performance Comparison of the REaSynRM and FaSynRM

- (1)

- The selected length of the REaSynRM, excluding the winding end parts, is shorter than that of the FaSynRM by (24 − 20)/24 = 17%, while the torque density and efficiency are close to those of the FaSynRM [16];

- (2)

- In this application, the average loss of the REaSynRM is 100% × (7.63 − 7.40)/7.63 = 3.0% greater than that of the FaSynRM;

- (3)

- The maximum armature current for the REaSynRM is 100% × (896 − 839)/896 = 6.4% greater than for the FaSynRM;

- (4)

- The mass of the REaSynRM rotor is 100% × (98.4 − 64.4)/98.4 = 34.5% less than that of the FaSynRM. This will ensure a longer service life of the bearings in the case of the REaSynRM;

- (5)

- Due to the full use of the higher potential of rare earth magnets, the mass of the magnets in the REaSynRM is reduced by 6.4 times compared to the FaSynRM. As a result, the cost of rare-earth magnets is only (393.7 − 369.2)/393.7 = 6.2% higher than the cost of ferrites in the FaSynRM, while a ratio of their prices per kg of 126.6/18.46 = 6.9 times;

- (6)

- The total mass of the REaSynRM active materials is 100% × (241 − 206.9)/241= 14.1% less than that of the FaSynRM;

- (7)

- In comparison to the FaSynRM, the REasSynRM incurs a 100% × (847.7 − 818.2)/847.7 = 3.5% increase in total material costs. This suggests that there is no significant increase in the cost of the REaSynRM, which is achieved by reducing the mass of the magnets compared to the FaSynRM with the reasonable use of this small amount of rare-earth magnets.

7. Conclusions

- High coercivity helps reduce magnet thickness without the risk of irreversible demagnetization.

- Due to their high remanent flux density, rare earth magnets produce sufficient magnetic flux even when placed into a short section of magnetic barriers.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Railway Pro. Alstom Tests a New Train Traction System in China. Press Release. 29 May 2023. Available online: https://www.railwaypro.com/wp/alstom-tests-a-new-train-traction-system-in-china/ (accessed on 5 September 2024).

- Körner, O.; Schmidt, D.; Wetzel, W. Energy efficient propulsion technology based on permanent magnet synchronous motors. Eng. Veh. Technol. 2023, 121, 296–304. Available online: https://assets.new.siemens.com/siemens/assets/api/uuid:d699a038-d754-46d1-9c17-7241daa549ca/siemens-mobility-Energy-efficient-propulsion-technology-eb-technical-article-en-original..pdf (accessed on 5 September 2024).

- Toshiba Global. Permanent Magnet Synchronous Motor (PMSM). Supply Record. Available online: https://www.global.toshiba/ww/products-solutions/railway/rolling-stock/pmsm.html (accessed on 5 September 2024).

- Tokyo Metro Tested Synchronous Reluctance Traction Motors. Railvolution: The Professional On-Line Magazine of Rail Transport Worldwide. Available online: https://www.railvolution.net/news/tokyo-metro-tested-synchronous-reluctance-traction-motors (accessed on 5 September 2024).

- Wang, Y.; Bianchi, N.; Qu, R. Comparative Study of Non-Rare-Earth and Rare-Earth PM Motors for EV Applications. Energies 2022, 15, 2711. [Google Scholar] [CrossRef]

- Burress, T.; Campbell, S. Benchmarking EV and HEV power electronics and electric machines. In Proceedings of the 2013 IEEE Transportation Electrification Conference and Expo (ITEC), Detroit, MI, USA, 16–19 June 2013; pp. 1–6. [Google Scholar]

- Calvo, E.S.; Potoradi, D. Synchronous reluctance motors with and without permanent magnets for high performance low cost electrical drives. In Proceedings of the 2015 5th International Electric Drives Production Conference (EDPC), Nuremberg, Germany, 15–16 September 2015. [Google Scholar]

- Liu, Z.; Hu, Y.; Wu, J.; Zhang, B.; Feng, G. A Novel Modular Permanent Magnet-Assisted Synchronous Reluctance Motor. IEEE Access 2022, 9, 19947–19959. [Google Scholar] [CrossRef]

- Barcaro, M.; Pradella, T.; Furlan, I. Low-torque ripple design of a ferrite-assisted synchronous reluctance motor. IET Electr. Power Appl. 2016, 10, 319–329. [Google Scholar] [CrossRef]

- Pellegrino, G.; Jahns, T.M.; Bianchi, N.; Soong, W.L.; Cupertino, F. The Rediscovery of Synchronous Reluctance and Ferrite Permanent Magnet Motors: Tutorial Course Notes; Springer: New York, NY, USA, 2016; p. 136. [Google Scholar]

- McKinsey & Company. The Net-Zero Materials Transition: Implications for Global Supply Chains, Report. July 2023. Available online: https://www.mckinsey.com/industries/metals-and-mining/our-insights/the-net-zero-materials-transition-implications-for-global-supply-chains (accessed on 14 August 2024).

- Dong, S.; Li, W.; Chen, H.; Han, R. The status of Chinese permanent magnet industry and R&D activities. AIP Adv. 2017, 7, 1–17. [Google Scholar]

- Ibrahim, M.N.; Silwal, B.; Sergeant, P. Permanent Magnet-Assisted Synchronous Reluctance Motor Employing a Hybrid Star-Delta Winding for High Speed Applications. In Proceedings of the 2018 XIII International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018. [Google Scholar]

- Li, Y.; Yang, H.; Lin, H.; Fang, S.; Wang, W. A Novel Magnet-Axis-Shifted Hybrid Permanent Magnet Machine for Electric Vehicle Applications. Energies 2019, 12, 641. [Google Scholar] [CrossRef]

- Liu, X.; Li, Y.; Liu, Z.; Ling, T.; Luo, Z. Analysis and design of a high power density permanent magnet-assisted synchronous reluctance machine with low-cost ferrite magnets for EVs/HEVs. COMPEL Int. J. Comput. Math. Electr. Electron. Eng. 2016, 35, 1949–1964. [Google Scholar] [CrossRef]

- Dmitrievskii, V.; Kazakbaev, V.; Prakht, V. Performance Comparison of Traction Synchronous Motors with Ferrite Magnets for a Subway Train: Reluctance versus Homopolar Variants. Appl. Sci. 2023, 13, 9988. [Google Scholar] [CrossRef]

- Wang, J.; Yuan, X.; Atallah, K. Design Optimization of a Surface-Mounted Permanent-Magnet Motor with Concentrated Windings for Electric Vehicle Applications. IEEE Trans. Veh. Technol. 2013, 62, 1053–1064. [Google Scholar] [CrossRef]

- Lacock, S.; du Plessis, A.A.; Booysen, M.J. Electric Vehicle Drivetrain Efficiency and the Multi-Speed Transmission Question. World Electr. Veh. J. 2023, 14, 342. [Google Scholar] [CrossRef]

- Guo, S.; Zhao, H.; Wang, Y.; Yin, X.; Qi, H.; Li, P.; Lin, Z. A Design Technique of Traction Motor for Efficiency Improvement Based on Multiobjective Optimization. World Electr. Veh. J. 2021, 12, 260. [Google Scholar] [CrossRef]

- Ramakrishnan, K.; Stipetic, S.; Gobbi, M.; Mastinu, G. Optimal Sizing of Traction Motors Using Scalable Electric Machine Model. IEEE Trans. Transp. Electrif. 2018, 4, 314–321. [Google Scholar] [CrossRef]

- Dmitrievskii, V.; Prakht, V.; Kazakbaev, V.; Anuchin, A. Design Optimization of the Magnet-Free Synchronous Homopolar Motor of a Subway Train. Appl. Sci. 2022, 12, 12647. [Google Scholar] [CrossRef]

- Dmitrievskii, V.; Prakht, V.; Kazakbaev, V. Design Optimization of a Synchronous Homopolar Motor with Ferrite Magnets for Subway Train. Mathematics 2023, 11, 589. [Google Scholar] [CrossRef]

- Moghaddam, R.R. Synchronous Reluctance Machine (SynRM) Design. Thesis for the Degree of Master of Science in Engineering, Royal Institute of Technology, Department of Electrical Engineering, Electrical Machines and Power Electronics, Stockholm. 2007. Available online: https://www.diva-portal.org/smash/get/diva2:753114/FULLTEXT01.pdf (accessed on 14 August 2024).

- Wogi, L.; Thelkar, A.; Tahiro, T.; Ayana, T.; Urooj, S.; Larguech, S. Particle Swarm Optimization Based Optimal Design of Six-Phase Induction Motor for Electric Propulsion of Submarines. Energies 2022, 15, 2994. [Google Scholar] [CrossRef]

- Kang, Y.-R.; Son, J.-C.; Lim, D.-K. Optimal Design of IPMSM for Fuel Cell Electric Vehicles Using Autotuning Elliptical Niching Genetic Algorithm. IEEE Access 2020, 8, 117405–117412. [Google Scholar] [CrossRef]

- Prakht, V.; Dmitrievskii, V.; Kazakbaev, V.; Anuchin, A. Comparative Study of Electrically Excited Conventional and Homopolar Synchronous Motors for the Traction Drive of a Mining Dump Truck Operating in a Wide Speed Range in Field-Weakening Region. Mathematics 2022, 10, 3364. [Google Scholar] [CrossRef]

- Lagarias, J.C.; Reeds, J.A.; Wright, M.H.; Wright, P.E. Convergence properties of the Nelder–Mead simplex method in low dimensions. SIAM J. Optim. 1998, 9, 112–147. [Google Scholar] [CrossRef]

- The MathWorks, Inc. Find Minimum of Unconstrained Multivariable Function Using Derivative-Free Method. MATLAB Documentation. 1994–2023. Available online: https://www.mathworks.com/help/matlab/ref/fminsearch.html (accessed on 14 August 2024).

- Prakht, V.; Dmitrievskii, V.; Kazakbaev, V. Mathematical modeling ultra premium efficiency (IE5 class) PM assisted synchronous reluctance motor with ferrite magnets. In Proceedings of the 2018 25th International Workshop on Electric Drives: Optimization in Control of Electric Drives (IWED), Moscow, Russia, 31 January–2 February 2018; pp. 1–6. [Google Scholar] [CrossRef]

- ChenYang NdFeB Magnets. Price List of Standard Block Magnets. Available online: http://www.ndfebmagnets.de/CY-PriceList-NdFeB-Block.pdf (accessed on 14 August 2024).

- IBSMagnet. Hard Ferrite Magnets, Product Information. 2020. Available online: https://ibsmagnet.com/products/dauermagnete/hartferrit.php (accessed on 14 August 2024).

| Stage | Stage Name | Duration, s |

|---|---|---|

| 4–5 | Acceleration with a constant torque | 6.9 |

| 5–1 | Acceleration with a constant power | 27.8 |

| 0 | Coasting at a steady speed | 57.3 |

| 2–3 | Deceleration with a constant power | 8.7 |

| 3–4 | Deceleration with a constant torque | 13.9 |

| Operating Point, i | Operating Point Name | Speed, rpm | Torque, N∙m | wi | ki | wexi * |

|---|---|---|---|---|---|---|

| 0 | Coasting mode; maximum speed | 4280 | 0 | - | - | 0.5 |

| 1 | Driving mode; maximum speed | 4280 | 413.4 | 0.363 | 0.97 | 0.181 |

| 2 | Braking mode; maximum speed | 4280 | 826.9 | 0.091 | 0.99 | 0.046 |

| 3 | Braking mode; changing from constant power to constant torque | 2854 | 1240 | 0.182 | 1.1 | 0.091 |

| 4 | Zero speed | 0 | 1240 | 0.182 | 0.97 | 0.091 |

| 5 | Driving mode; changing from maximum torque to constant power | 1427 | 1240 | 0.182 | 0.97 | 0.091 |

| Parameter | REaSynRM | FaSynRM [16] |

|---|---|---|

| Phase number | 3 | |

| Pole number | 8 | |

| Magnet grade | N40H | Y30H-2 |

| Steel grade | M270-35A | |

| Steel thickness, mm | 0.35 | |

| Stator slot number | 48 | |

| Number of the armature winding layers | 1 | |

| Number of the stator slots per pole and phase q | 2 | |

| Rotor flux barrier number per pole | 4 | |

| Parameter | Value |

|---|---|

| Stator parameters | |

| Machine length excluding winding end parts L, mm | 200 |

| Stator outer radius Rs out, mm | 250 |

| Stator parameter hs1, mm | 1 |

| Stator parameter hs2, mm | 3 |

| Stator slot thickness ratio αs1/αs2 | 1.05 |

| Rotor parameters | |

| Outer rotor ribs thickness hout rib, mm | 1 |

| Inner rotor ribs thickness hin rib i, mm | 1.5; 2.5; 3.5; 4 |

| Rotor parameter h, mm | 3 |

| Rotor parameter ε | 0.8∙αp |

| Rotor parameter a | 0.4777∙αp |

| Remanent flux density of the PMs, T | 1.2 |

| Relative magnetic conductivity of permanent magnets | 1.05 |

| Parameter | Initial Design | Optimized Design |

|---|---|---|

| Stator parameters | ||

| Inner stator radius Rs in, m | 0.2 | 0.1834 |

| Stator slot bottom radius Rbot, m | 0.23 | 0.2199 |

| Stator slot thickness αs1 | 0.4 ∙ tz | 0.572 ∙ tz |

| Rotor parameters | ||

| ast, mm | 4 | 4.46 |

| bst, mm | 1 | 1.22 |

| acut, mm | 4 | 7.90 |

| bcut, mm | 1 | 1.74 |

| B | 0.0777 ∙ αp | 0.0762 ∙ αp |

| C | 1.07 | 1.125 |

| G | 1.07 | 1.113 |

| β, rad | 0.01 | 0.0201 |

| Magnet’s thickness ratio, hmag,i/hcut,i | 0.5 | 0.257 |

| Magnet’s width ratio, wmag,i/yi | 0.5 | 0.485 |

| Other parameters | ||

| Air gap width δ, mm | 1 | 2.33 |

| Current angle, electrical degrees | 50; 50; 50; 50 | 64.3; 66.8; 59.7; 55.6 |

| Parameter | Before Optimization | ||||

| Operating point, i | 1 | 2 | 3 | 4 | 5 |

| Rotational speed n, rpm | 4280 | 4280 | 2854 | 0 | 1427 |

| Amplitude of the armature phase current Iarm, A | 483 | 876 | 1377 | 1388 | 1395 |

| Efficiency, % | 92.3 | 93.3 | 93.7 | 0 | 92.4 |

| Output mechanical power P2, kW | 185.3 | −370.6 | −370.6 | 0 | 185.3 |

| Torque, N∙m | 413 | 827 | 1240 | 0 | 1240 |

| Input electrical power, kW | 200.7 | 345.7 | 347.3 | 11.3 | 200.5 |

| Mechanical loss, kW * | 3.55 | 3.55 | 1.06 | 0 | 0.14 |

| Armature copper loss, kW | 1.29 | 4.67 | 11.31 | 11.31 | 11.31 |

| Stator lamination loss, kW | 9.68 | 15.09 | 9.95 | 0 | 3.46 |

| Rotor lamination loss, kW | 0.91 | 1.61 | 1.02 | 0 | 0.26 |

| Total loss, kW | 15.42 | 24.92 | 23.35 | 11.31 | 15.16 |

| Rotational speed n, rpm | 4280 | 4280 | 2854 | 0 | 1427 |

| Average losses <Ploss>, kW | 11.11 | ||||

| Number of turns in armature winding | 1.75 | ||||

| Power factor | 0.83 | 0.75 | 0.65 | 0 | 0.64 |

| Line-to-line voltage amplitude Varm, V | 621.3 | 757.5 | 600.1 | 9.4 | 307.6 |

| Torque ripple, % | 31.6 | 32.6 | 33.2 | 33.2 | 33.2 |

| Parameter | After Optimization | ||||

| Rotational speed n, rpm | 4280 | 4280 | 2854 | 0 | 1427 |

| Amplitude of the armature phase current Iarm, A | 445 | 709 | 896 | 888 | 894 |

| Efficiency, % | 94.9 | 95.5 | 95.9 | 0 | 95.0 |

| Output mechanical power P2, kW | 185.3 | −370.6 | −370.6 | 0 | 185.3 |

| Torque, N∙m | 413 | 827 | 1240 | 0 | 1240 |

| Input electrical power, kW | 195.2 | 353.9 | 355.5 | 7.0 | 195.0 |

| Mechanical loss, kW * | 3.55 | 3.55 | 1.06 | 0 | 0.14 |

| Armature copper loss, kW | 1.69 | 4.56 | 7.21 | 6.97 | 6.97 |

| Stator lamination loss, kW | 4.11 | 7.75 | 6.57 | 0 | 2.59 |

| Rotor lamination loss, kW | 0.55 | 0.86 | 0.27 | 0 | 0.06 |

| Total loss, kW | 9.90 | 16.72 | 15.11 | 6.97 | 9.75 |

| Average losses <Ploss>, kW | 7.63 | ||||

| Number of turns in armature winding | 2.77 | ||||

| Power factor | 0.86 | 0.79 | 0.71 | 0 | 0.69 |

| Line-to-line voltage amplitude Varm, V | 626.1 | 757.5 | 708.5 | 9.1 | 365.9 |

| Torque ripple, % | 17.8 | 17.8 | 14.3 | 15.3 | 15.3 |

| Parameter | Operating Point, i | |||||

|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | 5 | |

| Rotational speed n, rpm | 4280 | 4280 | 4280 | 2854 | 0 | 1427 |

| Amplitude of the armature phase current Iarm, A | 0 | 450 | 693 | 833 | 832 | 839 |

| Efficiency η, % * | - | 94.7 | 95.4 | 96.0 | 0 | 95.3 |

| Output mechanical power P2, kW | −4.19 | 185.3 | −370.6 | −370.6 | 0 | 185.3 |

| Torque T, N∙m | 0 | 413.4 | 826.9 | 1240 | 1240 | 1240 |

| Input electrical power P1, kW | 0 | 195.6 | 353.5 | 355.9 | 6.2 | 194.4 |

| Mechanical loss Pmech, kW | 3.55 | 3.55 | 3.55 | 1.06 | 0 | 0.14 |

| Armature copper loss Parm DC, kW | 0 | 1.76 | 4.44 | 6.37 | 6.22 | 6.22 |

| Stator lamination loss Piron st, kW | 0.49 | 4.25 | 7.88 | 6.89 | 0 | 2.70 |

| Rotor lamination loss Piron rt, kW | 0 | 0.77 | 1.21 | 0.33 | 0 | 0.07 |

| Total loss Ploss, kW ** | 4.04 | 10.33 | 17.08 | 14.65 | 6.22 | 9.12 |

| Average losses <Ploss>, kW | 7.40 | |||||

| Power factor | - | 0.910 | 0.791 | 1 | 0.769 | 0.735 |

| Line-to-line voltage amplitude Varm, V | - | 621 | 757 | 665 | 9 | 356 |

| Torque ripple, % | - | 16 | 16 | 11 | 10 | 10 |

| Maximum demagnetizing force, kOe | 2.0 | |||||

| Parameter | Operating Point, i | |||||

|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | 5 | |

| Rotational speed n, rpm | 4280 | 4280 | 4280 | 2854 | 0 | 1427 |

| Amplitude of the armature phase current Iarm, A | 0 | 445 | 709 | 896 | 888 | 894 |

| Efficiency η, % * | - | 94.9 | 95.5 | 95.9 | 0 | 95.0 |

| Output mechanical power P2, kW | −4.35 | 185.3 | −370.6 | −370.6 | 0 | 185.3 |

| Torque T, N∙m | 0 | 413 | 827 | 1240 | 0 | 1240 |

| Input electrical power P1, kW | 0 | 195.2 | 353.9 | 355.5 | 7.0 | 195.0 |

| Mechanical loss Pmech, kW | 3.55 | 3.55 | 3.55 | 1.06 | 0 | 0.14 |

| Armature copper loss Parm DC, kW | 0 | 1.69 | 4.56 | 7.21 | 6.97 | 6.97 |

| Stator lamination loss Piron st, kW | 0.79 | 4.11 | 7.75 | 6.57 | 0 | 2.59 |

| Rotor lamination loss Piron rt, kW | 0.1 | 0.55 | 0.86 | 0.27 | 0 | 0.06 |

| Total loss Ploss, kW ** | 4.35 | 9.90 | 16.72 | 15.11 | 6.97 | 9.75 |

| Average losses <Ploss>, kW | 7.63 | |||||

| Power factor | - | 0.86 | 0.79 | 0.71 | 0 | 0.69 |

| Line-to-line voltage amplitude Varm, V | - | 626.1 | 757.5 | 708.5 | 9.1 | 365.9 |

| Torque ripple, % | - | 17.8 | 17.8 | 14.3 | 15.3 | 15.3 |

| Maximum demagnetizing force, kOe | 8.1 | |||||

| Parameter | FaSynRM | REaSynRM |

|---|---|---|

| Stator lamination mass, kg | 104.6 | 100.8 |

| Rotor lamination mass, kg | 78.4 | 61.3 |

| Armature copper mass, kg | 38 | 41.7 |

| Magnets mass, kg | 20 | 3.11 |

| Total rotor material mass, kg | 98.4 | 64.4 |

| The total mass of the active materials, kg | 241 | 206.9 |

| Stator lamination cost, USD | 104.6 | 100.8 |

| Rotor lamination cost, USD | 78.4 | 61.3 |

| Armature copper cost, USD | 266 | 291.9 |

| Magnets cost, USD | 369.2 | 393.7 |

| The total cost of the active materials, USD * | 818.2 | 847.72 |

| Total length of the stator lamination L, mm | 240 | 200 |

| Stator lamination outer diameter D, mm | 500 | 500 |

| Air gap, mm | 2.23 | 2.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dmitrievskii, V.; Kazakbaev, V.; Prakht, V.; Anuchin, A. Permanent Magnet Assisted Synchronous Reluctance Motor for Subway Trains. World Electr. Veh. J. 2024, 15, 417. https://doi.org/10.3390/wevj15090417

Dmitrievskii V, Kazakbaev V, Prakht V, Anuchin A. Permanent Magnet Assisted Synchronous Reluctance Motor for Subway Trains. World Electric Vehicle Journal. 2024; 15(9):417. https://doi.org/10.3390/wevj15090417

Chicago/Turabian StyleDmitrievskii, Vladimir, Vadim Kazakbaev, Vladimir Prakht, and Alecksey Anuchin. 2024. "Permanent Magnet Assisted Synchronous Reluctance Motor for Subway Trains" World Electric Vehicle Journal 15, no. 9: 417. https://doi.org/10.3390/wevj15090417

APA StyleDmitrievskii, V., Kazakbaev, V., Prakht, V., & Anuchin, A. (2024). Permanent Magnet Assisted Synchronous Reluctance Motor for Subway Trains. World Electric Vehicle Journal, 15(9), 417. https://doi.org/10.3390/wevj15090417