Scube—Concept and Implementation of a Self-balancing, Autonomous Mobility Device for Personal Transport

Abstract

1. Introduction

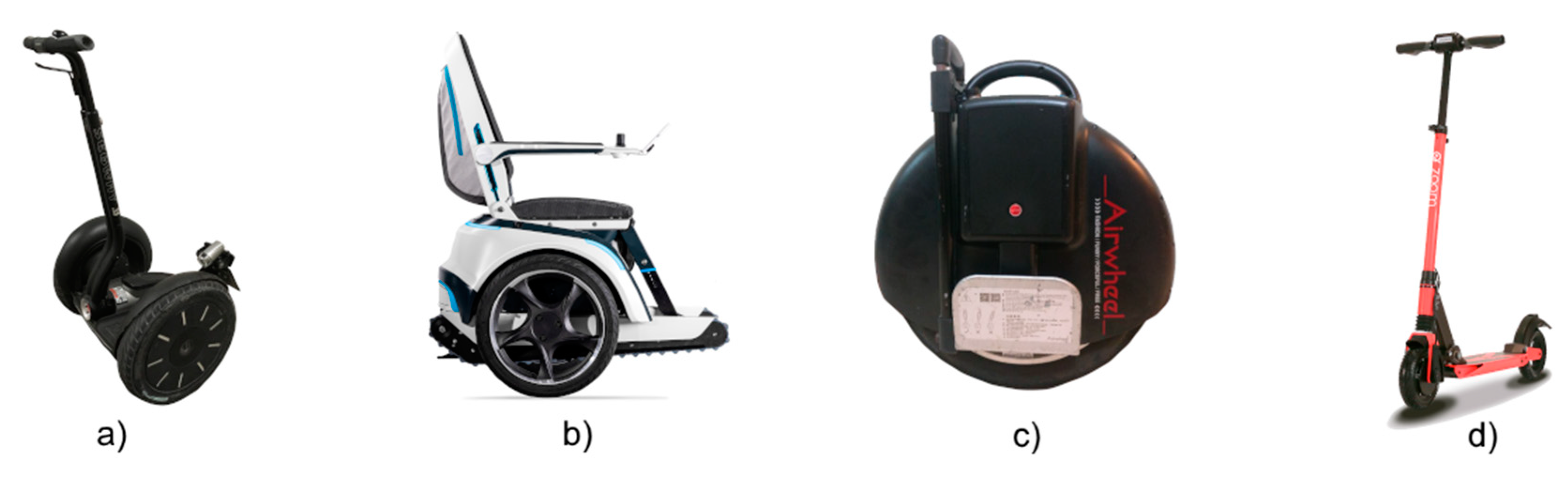

1.1. Motivation and State of Art

1.2. Problem Statement and Concept Description

2. Methodology

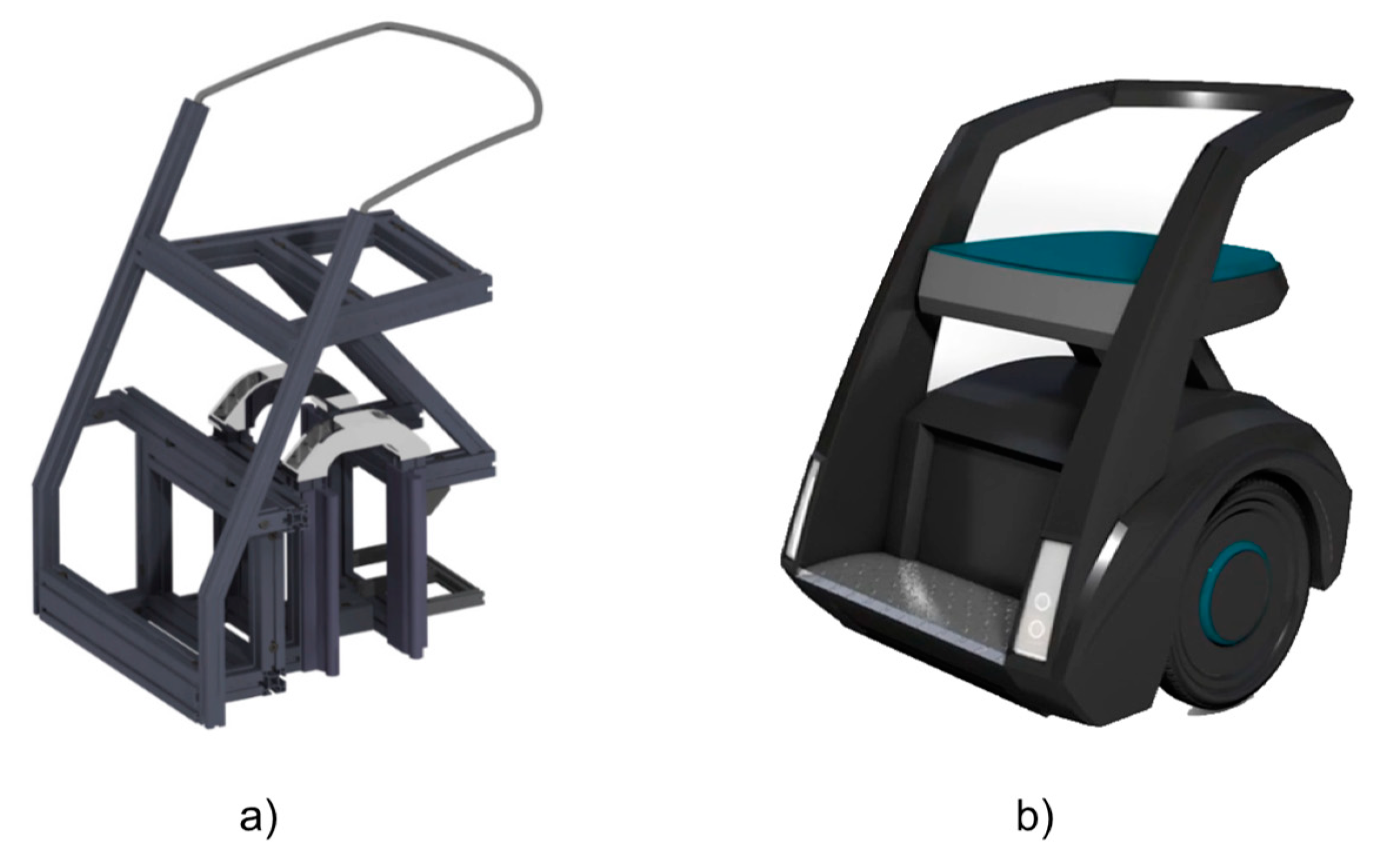

2.1. Ergonomic Design

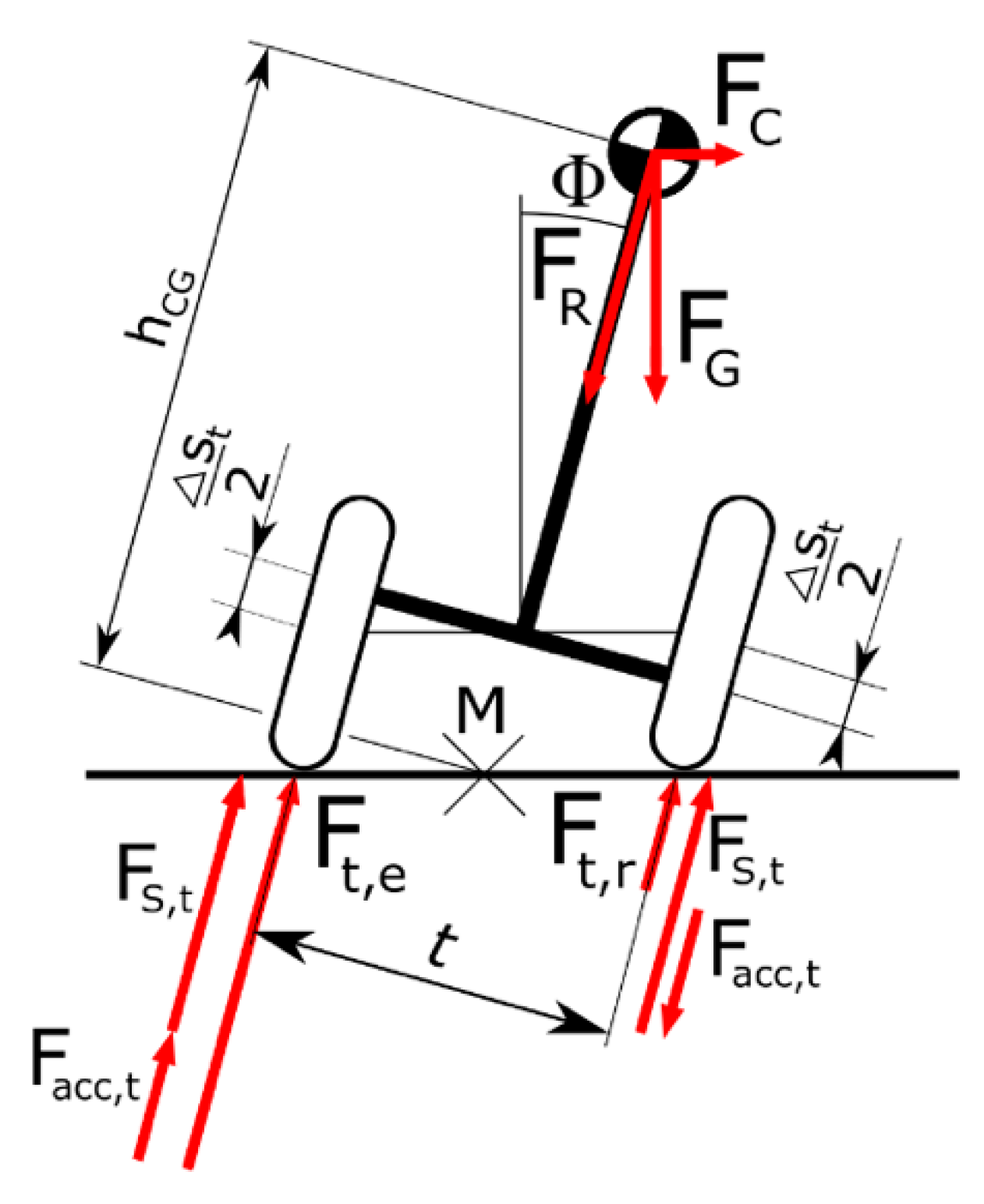

2.1.1. Vehicle Geometry

2.1.2. Suspension/Tilt Mechanism

2.1.3. System Processing Units

2.1.4. Powertrain

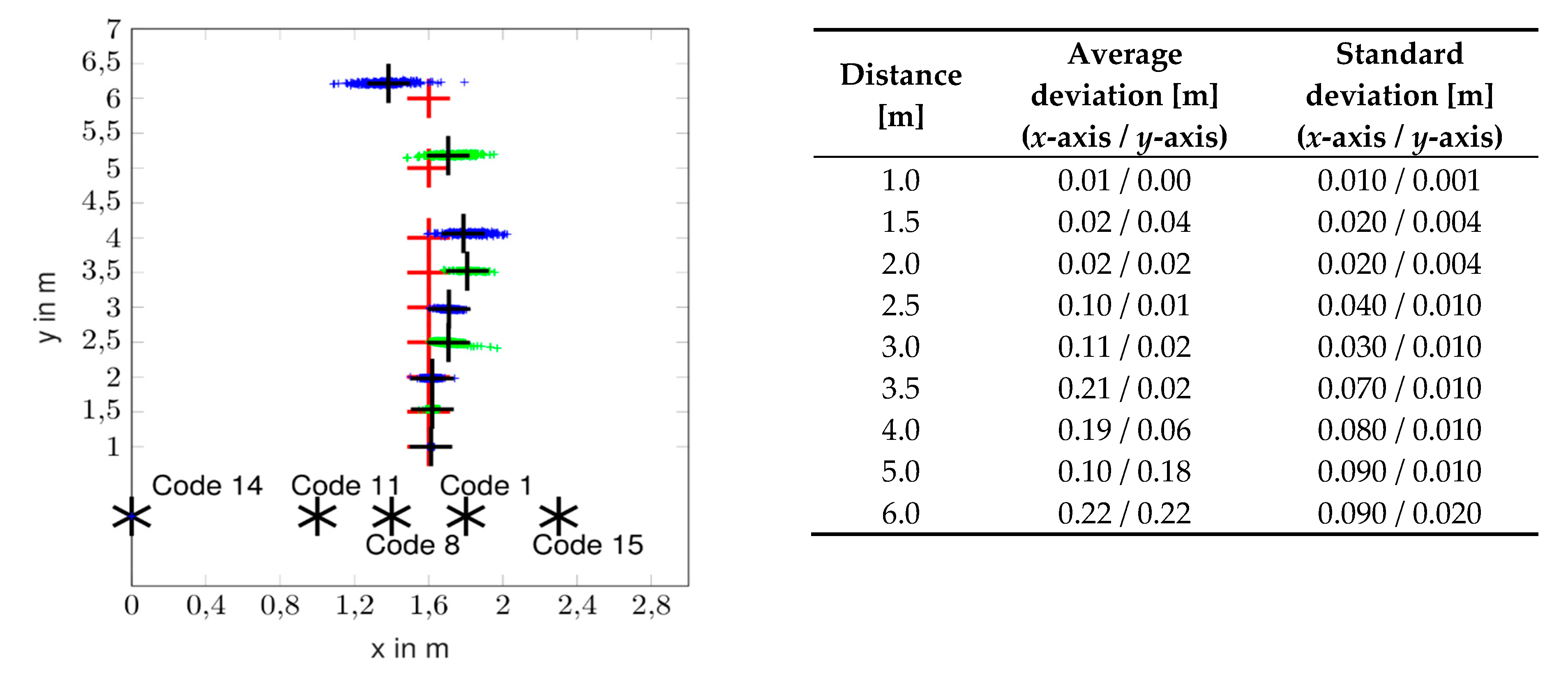

2.2. Localisation

3. Results

3.1. Structure/Body

3.2. Simulation of the Tilt Mechanism

3.3. Vehicle Performance

3.4. Localisation Results

4. Conclusions and Outlook

Author Contributions

Funding

Conflicts of Interest

References

- United Nations. World Urbanization Prospects. The 2014 Revision: Highlights; UN: New York, NY, USA, 2014; ISBN 978-92-1-151517-6. [Google Scholar]

- Polzin, S. Setting Expectations for Mobility as a Service. Available online: https://www.planetizen.com/node/90839 (accessed on 20 March 2018).

- Brooks, R.A. Seat for Self-Propelled Narrow-Track Vehicle. U.S. Patent No 5,857,535, 12 January 1999. [Google Scholar]

- Saeger, M.; Simon, M.; Valluri, A. Method for Operating a Tilting Running Gear and an Active Tilting Running Gear for a Non-Rail-Bourne Vehicle. U.S. Patent No 9,821,620, 21 November 2017. [Google Scholar]

- Ishii, S.; Yamano, I. Travel Device. U.S. Patent Application No 11/984,154, 19 June 2008. [Google Scholar]

- Yuji Hosoda, S.; Egawa, J.; Tamamoto; Nakmura, R.; Horiuchi, T. Mobile Robot. U.S. Patent 7,649,331 B2, 19 January 2010. [Google Scholar]

- Segway Inc. Our Story. Available online: http://www.segway.com/about/our-story (accessed on 23 October 2017).

- Segway Inc. Reference Manual. Segway Personal Transporter (PT) i2, x2. Available online: http://www.segway.com/media/1688/referencemanual.pdf (accessed on 23 October 2017).

- Scewo. Scewo Bro Brochure. Available online: https://scewo.ch/wp-content/uploads/2018/10/Scewo-Bro_A5_EN.pdf (accessed on 20 November 2018).

- Airwheel Unicycles. Airwheel X8. Available online: http://airwheelunicycle.com/Airwheel-X8 (accessed on 23 May 2018).

- Zoom Urban Transport. Zoom Stryder Electric Scooter. Available online: https://www.ridezoom.co/ (accessed on 23 September 2018).

- Scewo. Scewo Press Kit. Available online: https://scewo.ch/ (accessed on 20 November 2018).

- Andersen, H.; Eng, Y.H.; Leong, W.K.; Zhang, C.; Kong, H.X.; Pendleton, S.; Ang, M.H.; Rus, D. Autonomous personal mobility scooter for multi-class mobility-on-demand service. In Proceedings of the 2016 IEEE 19th International Conference on Intelligent Transportation Systems (ITSC), Rio de Janeiro, Brazil, 1–4 November 2016; pp. 1753–1760. [Google Scholar]

- Kleine ergonomische Datensammlung; Lange, W., Windel, A., Kirchner, J.-H., Bundesanstalt für Arbeitsschutz und Arbeitsmedizin, Eds.; Praxiswissen Arbeitssicherheit; 13., aktualisierte Aufl.; TÜV-Media: Köln, Germany, 2009; ISBN 978-3-8249-1244-5. [Google Scholar]

- Chuan, T.K.; Hartono, M.; Kumar, N. Anthropometry of the Singaporean and Indonesian populations. Int. J. Ind. Ergonom. 2010, 40, 757–766. [Google Scholar] [CrossRef]

- Hatam, B.; Herrmann, T.; Medovy, V.; Merkle, L.; Lim, J.S.D.; Sim, L.L.; Lu, Y.; Ten, W.X.R. Team “Micromobility” Final Report globalDrive 16/17. 2017; Unpublished Results. [Google Scholar]

- DIN 18040-1:2010-10: Barrierefreies Bauen—Planungsgrundlagen—Teil 1: Öffentlich zugängliche Gebäude. 2010. Available online: https://nullbarriere.de/din18040-1.htm (accessed on 24 October 2017).

- Building and Construction Authority Singapore. Code on Accessibility in the Built Environment 2013. Available online: https://www.bca.gov.sg/BarrierFree/others/ACCESSIBILITY_CODE_2013.pdf (accessed on 24 October 2017).

- Thomson Industries. Pro-Series/Electromechanical Linear Actuator—Installation and Operation Manual. Available online: https://www.thomsonlinear.com/downloads/actuators/Electrak_Pro_Series_mnen.pdf (accessed on 24 October 2017).

- AAEON Technology (Europe), B.V. Up Board—Specification. Available online: http://www.up-board.org/wp-content/uploads/2016/05/UPDatasheetV8.5.pdf (accessed on 6 October 2017).

- Libmraa—Low Level Skeleton Library for Communication on GNU/Linux platforms. Available online: https://github.com/intel-iot-devkit/mraa (accessed on 2 June 2018).

- Intel Corporation. Intel RealSense Camera R200: Embedded Infrared Assisted Stereovision 3D Imaging System with Color Camera: Product Datasheet. Available online: https://www.mouser.com/pdfdocs/intel_realsense_camera_r200.pdf (accessed on 15 January 2018).

- Arduino, s.r.l. Arduino Due—Tech Specs. Available online: https://store.arduino.cc/usa/arduino-due (accessed on 15 January 2018).

- Arduino, s.r.l. Arduino Leonardo—Tech Specs. Available online: https://store.arduino.cc/usa/arduino-leonardo-with-headers (accessed on 15 January 2018).

- ROS ROS History. Available online: http://www.ros.org/history/ (accessed on 25 October 2017).

- dmg-movement. Motoren Übersicht. Available online: http://www.dmg-movement.de/Motoren.htm (accessed on 15 January 2018).

- Roboteq. Brushless DC Motor Controllers: FBL2360. Available online: https://www.roboteq.com/index.php/roboteq-products-and-services/brushless-dc-motor-controllers/324/fbl2360-detail (accessed on 15 January 2018).

- Linergy Engineering GmbH. Fahrradakku LiFePO4 6V/2,5Ah-25Ah aus A123 ANR26650 Zellen—A Version. Available online: https://www.linergy-shop.de/de/Fahrradakku-LiFePO4-36V-2-3Ah-aus-A123-ANR26650-Zellen---A-Version---315-425-1065.html (accessed on 15 January 2018).

- Arduino, s.r.l. Arduino 101—Tech Specs. Available online: https://store.arduino.cc/usa/arduino-101 (accessed on 15 January 2018).

- Ultrasonic Ranging Module HC—SR04. Available online: https://cdn.sparkfun.com/datasheets/Sensors/Proximity/HCSR04.pdf (accessed on 15 January 2018).

- Borenstein, J.; Everett, H.R.; Feng, L. Where am I? Sensors and Methods for Mobile Robot Positioning; University of Michigan: Ann Arbor, MI, USA, 2016. [Google Scholar]

- Computer Vision; Ikeuchi, K., Ed.; Springer US: Boston, MA, USA, 2014; ISBN 978-0-387-30771-8. [Google Scholar]

- MayTec Aluminium Systemtechnik GmbH the MayTec Connection System. Available online: http://www.maytec.de (accessed on 15 January 2018).

| Size of QR-Code | Maximum Distance for Recognition |

|---|---|

| DIN A1 | 7–8 m |

| DIN A2 | 5–7 m |

| DIN A3 | 3–4 m |

| DIN A4 | 2 m |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Klöppel, M.; Römer, F.; Wittmann, M.; Hatam, B.; Herrmann, T.; Sim, L.L.; Lim, J.S.D.; Lu, Y.; Medovy, V.; Merkle, L.; et al. Scube—Concept and Implementation of a Self-balancing, Autonomous Mobility Device for Personal Transport. World Electr. Veh. J. 2018, 9, 48. https://doi.org/10.3390/wevj9040048

Klöppel M, Römer F, Wittmann M, Hatam B, Herrmann T, Sim LL, Lim JSD, Lu Y, Medovy V, Merkle L, et al. Scube—Concept and Implementation of a Self-balancing, Autonomous Mobility Device for Personal Transport. World Electric Vehicle Journal. 2018; 9(4):48. https://doi.org/10.3390/wevj9040048

Chicago/Turabian StyleKlöppel, Manfred, Felix Römer, Michael Wittmann, Bijan Hatam, Thomas Herrmann, Lee Leng Sim, Jun Siang Douglas Lim, Yunfan Lu, Vladimir Medovy, Lukas Merkle, and et al. 2018. "Scube—Concept and Implementation of a Self-balancing, Autonomous Mobility Device for Personal Transport" World Electric Vehicle Journal 9, no. 4: 48. https://doi.org/10.3390/wevj9040048

APA StyleKlöppel, M., Römer, F., Wittmann, M., Hatam, B., Herrmann, T., Sim, L. L., Lim, J. S. D., Lu, Y., Medovy, V., Merkle, L., Ten, W. X. R., Ongel, A., Hong, Y. J. J., Ng, H. W., & Lienkamp, M. (2018). Scube—Concept and Implementation of a Self-balancing, Autonomous Mobility Device for Personal Transport. World Electric Vehicle Journal, 9(4), 48. https://doi.org/10.3390/wevj9040048