1. Introduction

The operations in supply chain and logistics are vital tools for businesses to remain competitive in today’s important economic activities. Transportation activities are significant sources of air pollution and greenhouse gas emissions, with the former known to have harmful effects on human health and the latter being responsible for global warming. These issues have raised concerns on reducing the amount of emissions worldwide [

1].

As today, the success measures for the companies are considered to be lower costs, lower emissions, shorter production time, shorter lead time, less stock, larger product range, more reliable delivery time, better customer services, higher quality, and providing the efficient coordination between demand, supply, and production; however, the trade-off between cost investment and service levels may change over time. Some leading companies are now proactively implementing “green” initiatives. They are also trying to enhance their supply chain management capability to tackle environmental concerns by focusing more on selecting appropriate facility locations and technologies. We are motivated to study a green supply chain network design problem where an initial investment on environmental protection equipment or techniques should be determined in the design phase. This investment can influence the environmental indicators in the operations phase. Therefore, a trade-off exists between the initial investment and its long-term benefit to environment. With such a concern, decisions regarding facility location and capacity allocation have to be integrated with the decisions regarding environmental investment.

In recent years, there have been many studies solving the optimization problems of supply chain and logistics that are related to design and operation. This research proposes an integrated supply model of first-mile/last-mile delivery [

2]. The author describes a real-time scheduling optimization model focusing on the energy efficiency of the operation, and introduces a mathematical model of last-mile delivery problems including scheduling and assignment problems [

3]. Varamath proposed modeling and optimization a three-echelon supply chain network using the particle swarm optimization to address the demand uncertainty and constraints posed by every echelon in the supply chain design operations [

4]. The measurement of supply chain and logistics solutions is performed allowing the quantification of availability, flexibility, efficiency, and plasticity indicators [

5]. Studies show that unmanned aerial vehicles have the potential effectiveness to reduce CO

2 emissions compared to conventional transportation solutions [

6]. Researchers have considered three critical environmental issues, namely the energy used in production processes, greenhouse gas (GHG) emissions from production, and transportation activities, and then presented two models (classical and Vendor Managed Inventory coordination) for a two-level closed-loop supply chain [

7]. Facing the competitive global market, manufacturers are increasingly dependent on the supply chain network. As one of the strategies of the supply chain, just-in-time greatly reduces the inventory in the workflow through frequent production, which enhances the production efficiency of the enterprise [

8]. However, frequent small-scale production requires better responsiveness to transport demands, leading to severe environmental pollution and high transport cost. Based on the just-in-time system [

9], Hashem proposed a multi-criterion decision model to optimize the production, quality, price, cost, equipment, and technology of products, and verified that, with this model, both operation and delivery met consumer demand and export quality standard [

10]. A just-in-time decision system was put forward that improves the sales, design, and production of the products of the company [

11]. To ensure delivery punctuality, Reference [

12] Pedro developed a multi-objective mathematical model based on the three-level distribution network, but the modeling process failed to consider the environmental impact. In recent years, the concept of greenness has been introduced to supply chain management to reflect the environmental impact on the management process [

12]. The logistics directly bear on the sources of environmental pollution such as greenhouse gas emissions. Despite the growing awareness of green logistics, the environmental constraints are seldom adopted for actual logistics operations. The multi-target fuzzy technique is the most desirable tool to build up a green supply chain network. In general, the multi-target fuzzy models have two conflicting goals, namely, minimal cost and minimal environmental impact. TakingtheCO

2 equivalent as the indicator of the environmental impact of logistics operations, an optimized closed-loop supply chain network was present, which integrated the forward and reverse propagations. Since the classic production and distribution models often pursued minimal cost, it is necessary to create a new combinatory optimization model based on the objectives and constraints of green logistics [

13].

In light of the above, this paper aims to minimize the logistics cost and carbon emissions simultaneously. For this purpose, a mathematical model for a three-echelon supply chain network was created considering the relevant constraints such as capacity, production cost, transport cost, carbon emissions, and time window, which are to be solved by the quantum-particle swarm optimization algorithm. The three-echelon supply chain, consisting of suppliers, distribution centers, and retailers, was established based on the number and location of suppliers, the transport method from suppliers to distribution centers, and the quantity of products to be transported from suppliers to distribution centers and then to retailers. Then, the proposed model was applied to a real case of logistics distribution. The results show that the supplier will opt for vehicles with low carbon emissions with the increase in the replenishment time, distances between members of the supply chain, the rate of carbon tax, and the number of retailers.

2. Problem Definition and Modeling

As shown in

Figure 1, the three-echelon supply chain network involves suppliers (S), distribution centers (DC), and retailers (R). Let

S = 1, 2, …,

n be the set of suppliers,

j = 1, 2, …,

n be the set of distribution centers, and

I = 1,2, …,

n be the set of retailers. The suppliers, which differ in capacity, need to distribute products to the retailers through the distribution centers. Both environmental and economic factors should be taken into account before making scientific decisions on the route, order quantity, locations, and number of distribution centers of the delivery process [

14]. The following hypotheses were put forward:

- (1)

The location and capacity of each supplier is fixed. Suitable distribution centers should be selected from multiple potential distribution centers, and the demand for the suitable ones obeys random distribution.

- (2)

The carbon emissions in the supply chain network originate from the routes between the suppliers, distribution centers, and retailers (S–DC–R), the site of distribution centers and the inventory of retailers.

- (3)

The carbon emissions are measured by the amount of CO2 release.

- (4)

The demand for distribution centers and retailers should be met by the same vehicle; only one vehicle is allowed on each distribution route; all of the vehicles share the same maximum load capacity; each vehicle should return to the distribution center after completing the distribution task.

- (5)

Each retailer can be supplied by multiple distribution centers.

- (6)

Each distribution center can be supplied by multiple suppliers.

Parameters are as follows:

| represents a collection of factories |

| represents the collection of distribution lefts |

| represents the set of distributors |

| collection of transport vehicles |

| annual demand of distributor I |

| order quantity of the distribution left j each time |

| distributor I order quantity every time |

| distribution left j unit product inventory holding cost |

| the probability of being out of stock, being the corresponding service level |

| safety inventory coefficient |

| advance order |

| average demand in the distributor’s j cycle |

| the standard deviation in the distributor’s j cycle |

| , the transport distance of factory s to DCj |

| , the transport distance of node e to node I |

| unit transportation cost of factory s to DCj |

| unit distribution cost of DCj distribution unit products to Ri |

| the fixed cost of establishing a potential distribution left |

| supply chain carbon emission quota |

| carbon emission limit penalty factor |

Decision variables:

| represents the number of products shipped from factory s to the potential distribution center |

| represents the number of products delivered to distributor I by the potential distribution center |

| represents the carbon emission limit penalty factor |

(1) Calculate the cost of location–route–inventory [

10,

11].

The fixed construction cost of distribution center location:

where

is the location cost of distribution center with capacity

n.

(2) Calculate the cost of carbon emission.

Facility location carbon emissions:

is the coefficient of carbon emissions,

m is the total energy consumption,

is the process of building a facility for carbon emissions, affected by facility location scale and facilities nature, and

is the energy such as water, electricity, coal, and gas within the facility maintenance.

Transportation carbon emissions:

where

is the unit carbon emission cost,

is the CO

2 emission coefficient,

is the unit distance fuel consumption, and

is the distance from node

i to node

j. When

c0 = 0, the cost of carbon emissions is zero, which means that the cost of carbon emissions is not considered.

Inventory carbon emissions:

where

is the comprehensive emission factor of each energy consumption.

Since

Object 1: Minimize the cost of the location–route–inventory.

Object 2: Minimize the cost of carbon emissions.

s.t.

Equation (9) indicates the DC power constraints, in which Nj is the known parameter, and indicates DCj capacity. Equation (10) is the vehicle capacity constraints, in which VC indicates the biggest capacity vehicle for a given parameter. Equation (11) guarantees that Ri is one and only one car for its service. Equation (12) guarantees every car at most in the service of a DC. Equation (13) shows that the vehicle can’t stay on a node. Equation (14) ensures that the number of products transported to the Retailer is greater than the amount of products shipped from the DC. Equation (15) guarantees the DCi needs are met, and Equations (16)–(18) ensure that the decision variables are non-negative.

3. Materials and Methods

Inspired by quantum mechanics [

15] and the trajectory analysis of particle swarm optimization [

16,

17], in order to enhance the global searching ability, we combine the quantum-inspired evolutionary algorithm (QEA) and particle swarm optimization (PSO), and propose a new quantum-behaved particle swarm optimization (QPSO). In QPSO, to enhance the global searching ability, the mean individual best-known position of the population, denoted as

mbest, is introduced, such that particle

xi can be updated according to the following equations:

where

pbesti and

gbest are the individual and global best-known positions for particle

xi, respectively, while the attractor is the local attractor of particle

xi based on the

pbesti and

gbest.

d = 1, 2, …,

D.

D is the dimension of the search space.

N is the population size.

ϕ is a random number within [0, 1];

α is the contraction-expansion coefficient. The value of

α is either a positive constant or a linearly decreasing positive number. The latter is beneficial to the robustness of the algorithm. When the QPSO is applied to real-world problems, detailed description of the contraction–expansion coefficient and its impact on particles’ behavior from theoretical and experimental perspectives are provided [

18]. It is shown that the upper bound of the contraction–expansion coefficient is 1.781 approximately.

The useful information contained in the individual and global best-known positions of particles is often overlooked. For a local attractor obtained by traditional means, the fitness is greater than its individual and global best-known positions. By contrast, some elements of the attractor become worse than those in the two positions. Thus, some elements may move in the wrong directions, leading to deterioration in the next generation. Below is a simple example for the unwanted phenomena.

Let

be a three-dimensional (3D) sphere function, whose minimum solution is [0, 0, 0]. For particle

xi, the current individual best-known position is

pbesti = [0, 4, 8], and its global best-known position is

gbest = [8, 0, 2]. Traditionally, the local attractor of this particle is obtained by Equation (21). For simplicity, the parameter

ϕ was set to 0.5, turning the equation into:

Now, it is necessary to find an efficient way to combine the good information in pbesti and gbest. By the method of exhaustion, two-dimensional (2D) tests must be conducted to find the best combination, which is very difficult and unrealistic in high dimensions. This calls for a strategy to identify the suitable combination with fewer tests. Fortunately, the orthogonal test meets the above requirements. Hence, this paper designs an orthogonal operator that combines the good information in pbesti and gbest.

Another problem relates to how to increase the population diversity of the evolutionary algorithm and prevent premature convergence. The premature convergence means that the algorithm has converged at a position other than the global optimum. In this case, the current particle position of a particle will be the same as the

pbesti and

gbest. Furthermore, a collaborative learning strategy was adopted, in order to prevent QPSO falling into the local optimum trap. In this strategy, the mean value of Gaussian distribution is

pbesti. The standard deviation of Gaussian distribution is the distance between current

pbesti and mean personal best position

mbest. The mutation of

pbesti is shown in Equation (23):

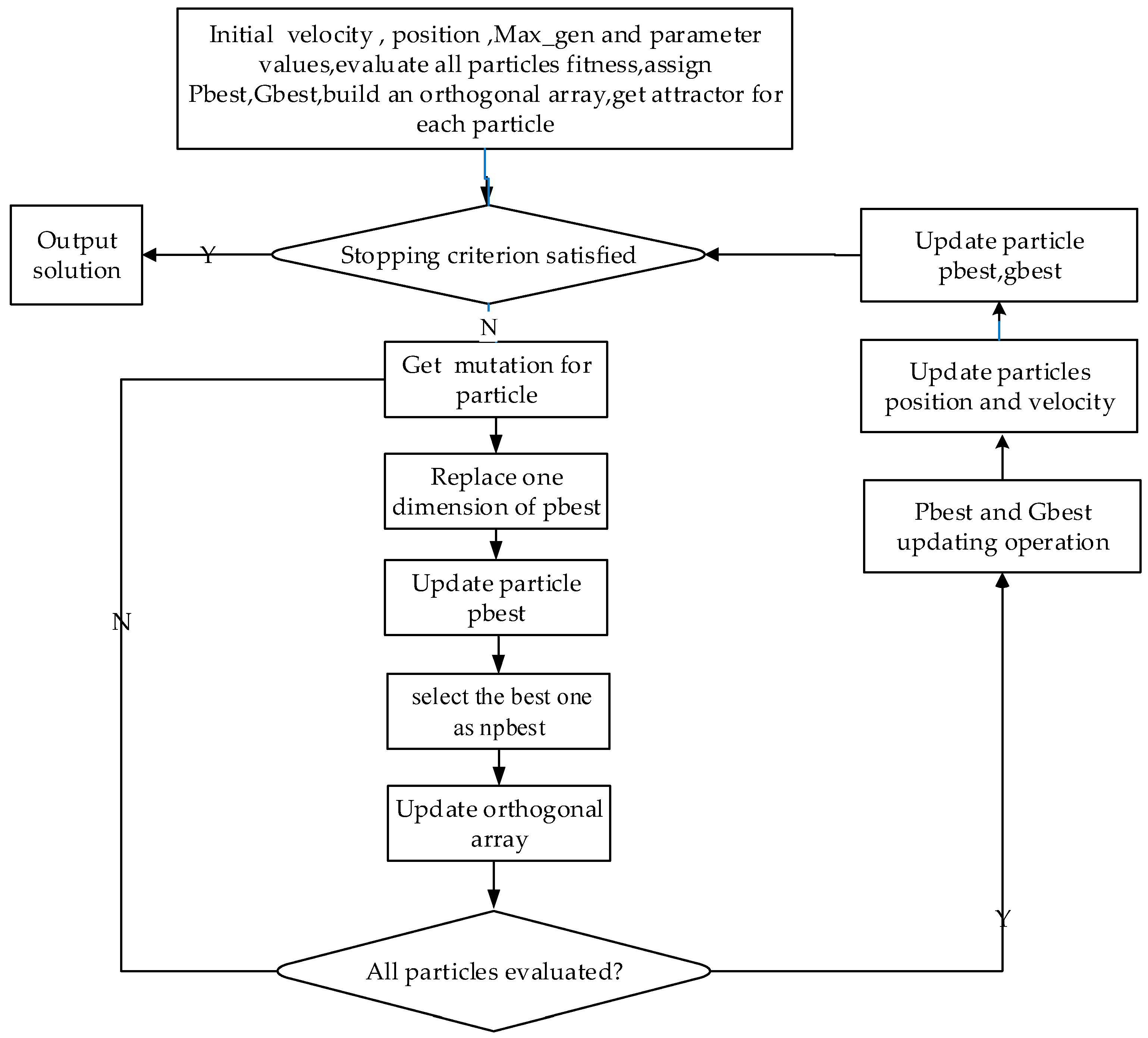

The detailed procedure of QPSO is shown in Algorithm 1. The framework of the proposed QPSO lies in the strategy to construct local attractors for particles. In QPSO, a particle uses the collaborative learning strategy to acquire a local attractor only if its local best position

pbesti has been held. The procedure of QPSO is shown in Algorithm 1. The flowchart of QPSO is shown in

Figure 2.

| Algorithm 1. Procedure of QPSO |

- 1:

Initialize

- (a)

P(t) = (p1, p2, …, pn); % Pt is particle population, each particle in Pt is randomly initialized within the range of the searching space - (b)

Fit(Pt) = FitnessCalculation(Pt); % Calculate the fitness values of Pt - (c)

pbest(t) = P(t); % The personal best population is initialized as Pt - (d)

gbest(t) = FindBest(Pbest(t)); % gbest is the best individual in pbesti - (e)

For each particle pi, let stayi = 0; % stayi represents the number of generations for which particle pi has stays

- 2:

Get attractori for each individual pi - (a)

If stayi ≤ G, then get attractori according to Equation (22); - (b)

stayi > G then %collaborative learning strategy

- ①:

For pbesti, get k mutation individuals by Equation (23). - ②:

For each dimension j of pbesti, do - (i)

Replace the jth dimension of pbestj with that of the k individuals obtained in Step 1, respectively. Then, k new individuals (npbest1, npbest2, …, npbest(k)) are obtained. - (ii)

Get the fitness values of (npbest1, npbest2, …, npbest(t)) and select the best one as npbest. - (iii)

Take the jth dimension of best(t), pbest(t, as that of the attractori.

- 3:

Update - (a)

Update P(t+1) according to (20) and (21); - (b)

Fit(t + 1) = Fitness Calculation(Pt + 1); % Calculate the fitness values of Pt+1; - (c)

If Fit(P(t)) is better than Fit(Pbest(t)), then Pbest(t+1) = P(t + 1) and stayi = 0. Otherwise, pbest(t + 1) = pbest(t)and stayi = stayi + 1; - (d)

gbest(t + 1) = FindBest(pbest(t + 1); % gbest(t + 1) is the best individual in Pbest(t + 1)

- 4:

If the stop condition is satisfied, then output gbest. Otherwise, go to Step 2.

|

QE [

19] and PSO [

20,

21,

22,

23] are two state-of-the-art algorithms. We choose two benchmarking functions to compare the results obtained by QE, PSO and QPSO; the results are representative and helpful to make the comparisons more comprehensive and convincing.

The spatial characteristics of the test function are shown in

Figure 3.

As can be seen from the test data in

Table 1, the optimal solution was found in all 30 independent runs of QPSO. The power is 100%. Compared with QEA and PSO, it has the ability to search for more accurate optimal value and find the optimal value. The number of iterations is much smaller than QEA and PSO.

Figure 4 shows the average evaluation times and running time of three algorithms from 30 runs to the optimal solution. It can be seen that the number of times that QPSO finds the optimal solution is about 200 times, which is about four times less than QEA and PSO. However, the total running time decreased a lot. It can be seen that the time complexity of QPSO is significantly lower than that of QEA and PSO. Since the collaborative learning strategy prevents QPSO from falling into the local optimum trap, this adopted operator can control and achieve the balance between exploitation and exploration.

4. Case Study

The case study targets a large cold chain logistics enterprise in China. The enterprise runs many breading and processing facilities in southeastern China; it manages 13 large cold warehouses, with a total storage of 85,000 tons, and owns over 140 freezer cars. The distribution network of the enterprise covers most of the provinces and regions in China. As a comprehensive food processor, this enterprise engages in pig breeding, slaughtering, and processing, cold meat processing, and the manufacturing of meat products (e.g., canned food). The enterprise has set up a logistics subsidiary to integrate pig breeding, slaughtering, and processing, cold meat processing, and the manufacturing of meat products, aiming to improve the service levels, shorten the delivery times, and ensure product quality. Both economic and environmental factors were considered in the creation of a secondary supply chain network between the plants, distribution centers, and retailers.

Table 2 and

Table 3 present the maximum capacity per cycle (15 days) of the three food processing plants of the enterprises, assuming that the demand of each local retailer obeys normal distribution.

Table 4 presents the data of the distribution centers.

Table 5 records the distribution of the demand per cycle of the 10 retailers.

Table 6 lists the data related to the regional distribution centers. For simplicity, the construction cost of each distribution center was calculated by the 24 cycles of each year.

Table 3 and

Table 4 respectively display the plant-distribution center distance, and the transport cost per unit of product. During the transport, the carbon emissions varied significantly with the congestion degree, road flatness, land slope, and fuel consumption. Therefore, the carbon emissions correlation coefficient which Hao employed for further analysis [

24].

Table 7 show the distribution center–retailer distance, and the transport distance per unit of product.

Table 8,

Table 9 and

Table 10 respectively present the relationship between carbon emissions and the energy consumption per unit of product and the unit of distance for the plant–distribution center and distribution center–retailer.

Table 11 gives the fixed carbon emissions of the distribution centers and the variable carbon emissions of the plants and retailers.

In this case, each retailer can be supplied by multiple distribution centers, and each center can be supplied by multiple plants. Then, the proposed model was applied to simulate this case on Matlab 7.1. The simulation parameters are as follows: the carbon emissions limit = 10,000 kg, the carbon penalty coefficient = 10, the service level = 95%, the inventory safety coefficient = 1.65, and the pre-order period = 6d. The simulated results (e.g., the optimal total cost, the economic cost, the carbon emissions, and the carbon emissions penalty) are presented in

Table 12 and

Table 13 below.

The calculation shows in

Table 12 reveals that the distribution of the whole supply chain relies on the regional distribution centers of Fuzhou, Nanjing and Huzhou. As shown in

Table 13, the total cost, the economic cost, the carbon emissions, and the excess carbon emissions were respectively 1,417,264.5 yuan, 1,407,330.2 yuan, 29,885.4 kg, and 19,885.4 kg. Hence, the carbon emissions penalty accounts for 12.3% of the total cost.

Table 14 shows the quantity of products delivered from each distribution center to each retailer. It can be seen that the Fuzhou distribution center delivers products to Nanping, Zhangzhou, and Taizhou, with the inventory safety coefficient of 195.7 tons; the Nanjing distribution center delivers products to Taizhou, Suzhou, Hangzhou, Fuyang, and Yichang, with the inventory safety coefficient of 243.9 tons, the Zhuzhou distribution center delivers products to Nanchang and Pingxiang, with the inventory safety coefficient of 195.7 tons.

According to the

Table 15, when the carbon emissions limit was 10,000 kg and the carbon emissions penalty coefficient was 10, the optimal distribution plan involves three distribution centers: Fuzhou, Nanjing, and Zhuzhou. When the carbon emissions limit was 10,000 kg and the carbon emissions penalty coefficient was 20, the optimal distribution plan involves two distribution centers: Nanjing and Fuzhou. Comparing the two optimal plans, the two-center plan reduced the total cost by 101,506.3 yuan, increased the economic cost by 13,006.3 yuan and lowered carbon emissions by 5517.7 kg from the level of the three-center plan. In addition, when the carbon emissions limit was 10,000 kg and the carbon emissions penalty coefficient was 30, the optimal distribution plan involves two distribution centers: Nanjing and Nanping. When the carbon emissions limit was 10,000 kg and the carbon emissions penalty coefficient was 40, the optimal distribution plan involves two distribution centers, they are Fuzhou and Hefei. Comparing the two optimal plans, the second plan increased the total cost by 174,239.9 yuan, reduced the economic cost by 30,885.9 yuan, and reduced the carbon emissions by 172 kg from the level of the first plan. Summing up, the whole supply chain will emit less CO

2 by increasing the carbon emissions penalty.

Furthermore, according to the

Table 16, when the carbon emissions limit was 30,000 kg and the carbon emissions penalty coefficient was 10, the optimal distribution plan involves three distribution centers: Fuzhou, Nanjing, and Zhuzhou. In this case, the carbon emissions (29,885.4 kg) was below the carbon emissions limit, indicating that the carbon emissions penalty was zero. When the carbon emissions limit was adjusted to 25,000 kg, the optimal plan involved two distribution centers: Nanjing and Fuzhou. In this case, the carbon emissions (24,367.7 kg) was still below the carbon emissions limit, and thus the carbon emissions penalty remained zero. Meanwhile, the carbon emissions dropped to 5517.7 kg. When the carbon emissions limit was lowered to 20,000 kg, the optimal plan still involved two distribution centers: Nanjing and Fuzhou. However, the carbon emissions (241,135.5 kg) exceeded the limit, leading to a penalty of 41,135 yuan. Therefore, the reduction of carbon emissions limit can pressurize the enterprise to cut down the carbon emissions of the supply chain through low-carbon design.

Overall, the total cost of the supply chain increased with the reduction of the carbon emissions limit and the growth in the carbon emissions penalty coefficient. These laws will help enterprises optimize the design of supply chain network, making it possible to strike a balance between economic benefit and environmental effect.

5. Conclusions

It is common in the logistics and supply chain that the objectives of decreasing logistic costs, carbon emissions, and increasing energy efficiency are targeted at the multi-level of the supply chain’s members. This work has developed a methodology based on heuristic optimization to minimize the logistics costs and carbon emissions based on relevant constraints, which aims to improve enterprise’s interests.

The described model represents an integrated optimization problem including the assignment of open tasks to scheduled routes, the scheduling of open tasks, and there scheduling of existing delivery routes. The optimization problem, which is described by an objective function representing the minimization of the logistic costs and carbon emissions and constraints, including loading capacity limits and time frames, is a hard problem. For the solution of this problem, a quantum-particle swarm optimization-based heuristic was developed. The developed heuristic is an improved version of the quantum-inspired evolutionary algorithm and basic particle swarm optimization; its increased performance is validated with benchmarking functions.

The integrated optimization model of the real-time scheduling of a multi-echelon logistics problem is solved with these heuristics. As the scenarios showed, cooperation makes it possible to increase the energy efficiency through the minimization of carbon emissions under different constraints. In the case of package delivery service providers, the time frame and the loading capacity of the package delivery trucks are important constraints; as the mentioned scenarios show, they are influencing their reliability, availability, flexibility, and economic footprints.

The described model framework and the optimization approach make it possible to support managerial decisions; not only the operation strategy of the running trucks, but also the cooperation strategy of different package delivery service providers are influenced by the results of the above described contribution. Some recommendations for possible future studies are as follows: it would be helpful to develop approaches that are beyond analyzing scheduling and assignment possibilities and also consider other areas of interest, such as human resource strategies, delivery truck sizing, out sourcing possibilities, or the rate of carbon tax.