Interlinked Sustainability Aspects of Low-Rise Residential Family House Development in Slovakia

Abstract

1. Introduction

2. Materials and Methods

2.1. Low-Rise Residential Family Houses

2.2. Methodology

3. Results and Discussion

3.1. Site Selection and Project Planning

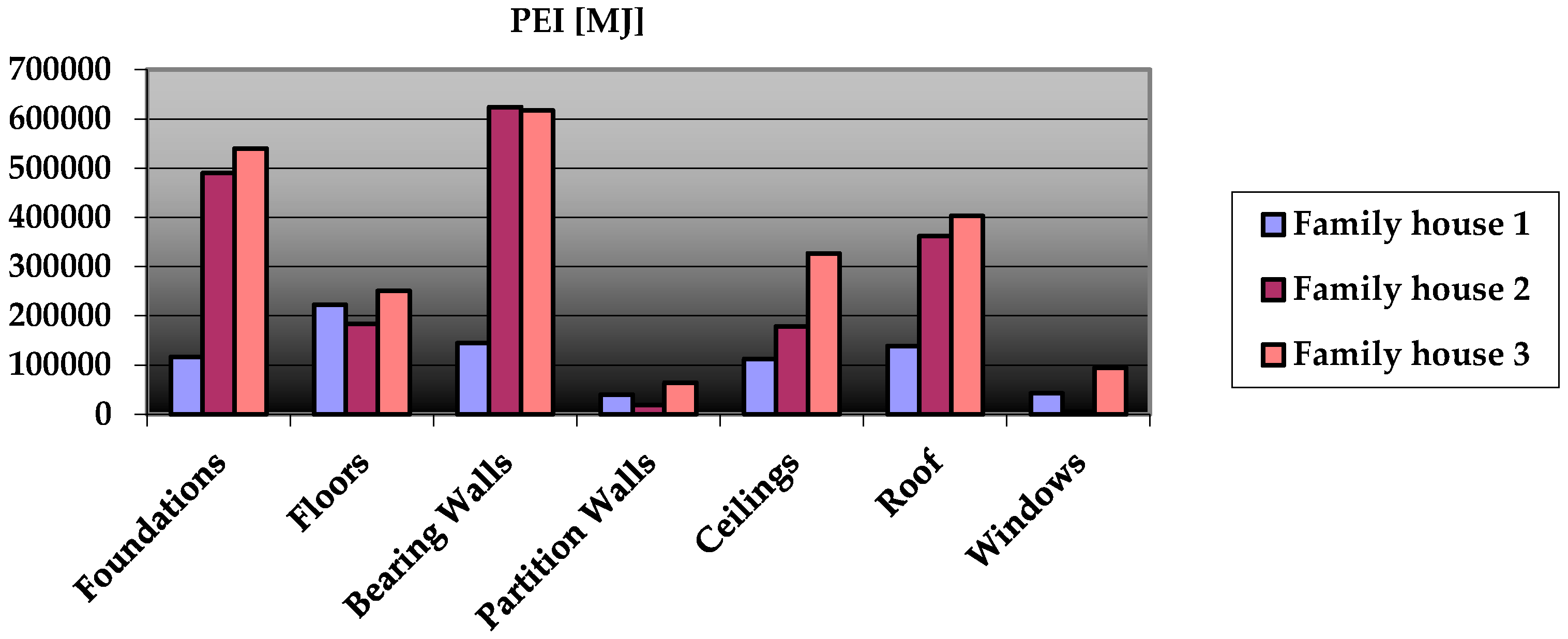

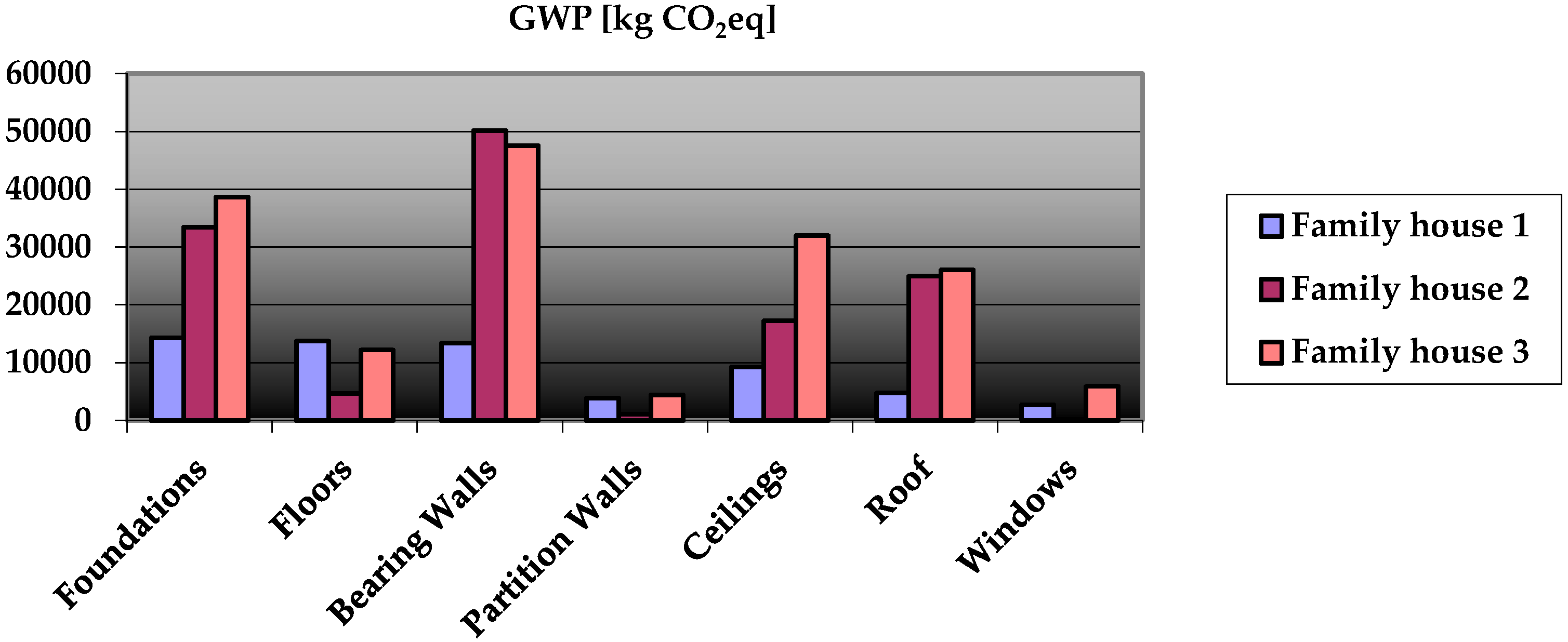

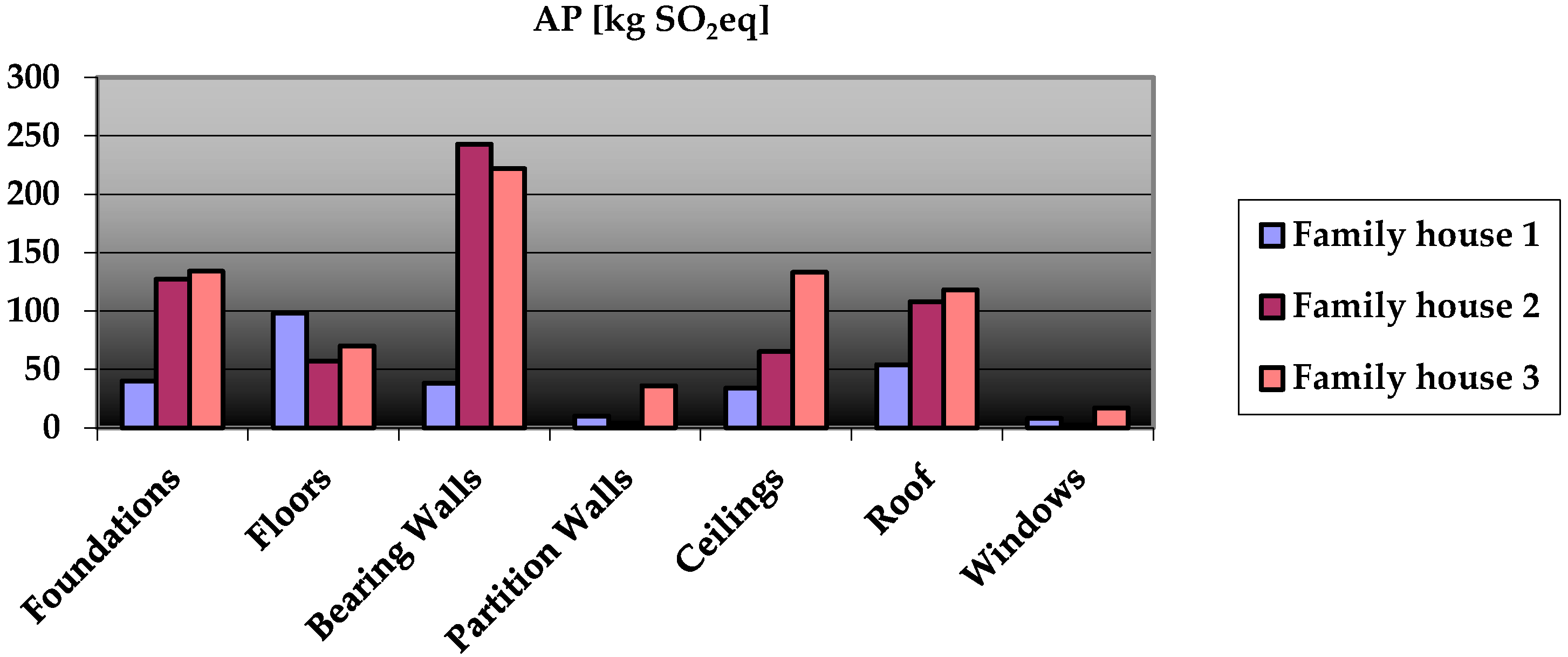

3.2. Building Construction

3.3. Indoor Environment

3.4. Energy Performance

3.5. Water Management

3.6. Waste Management

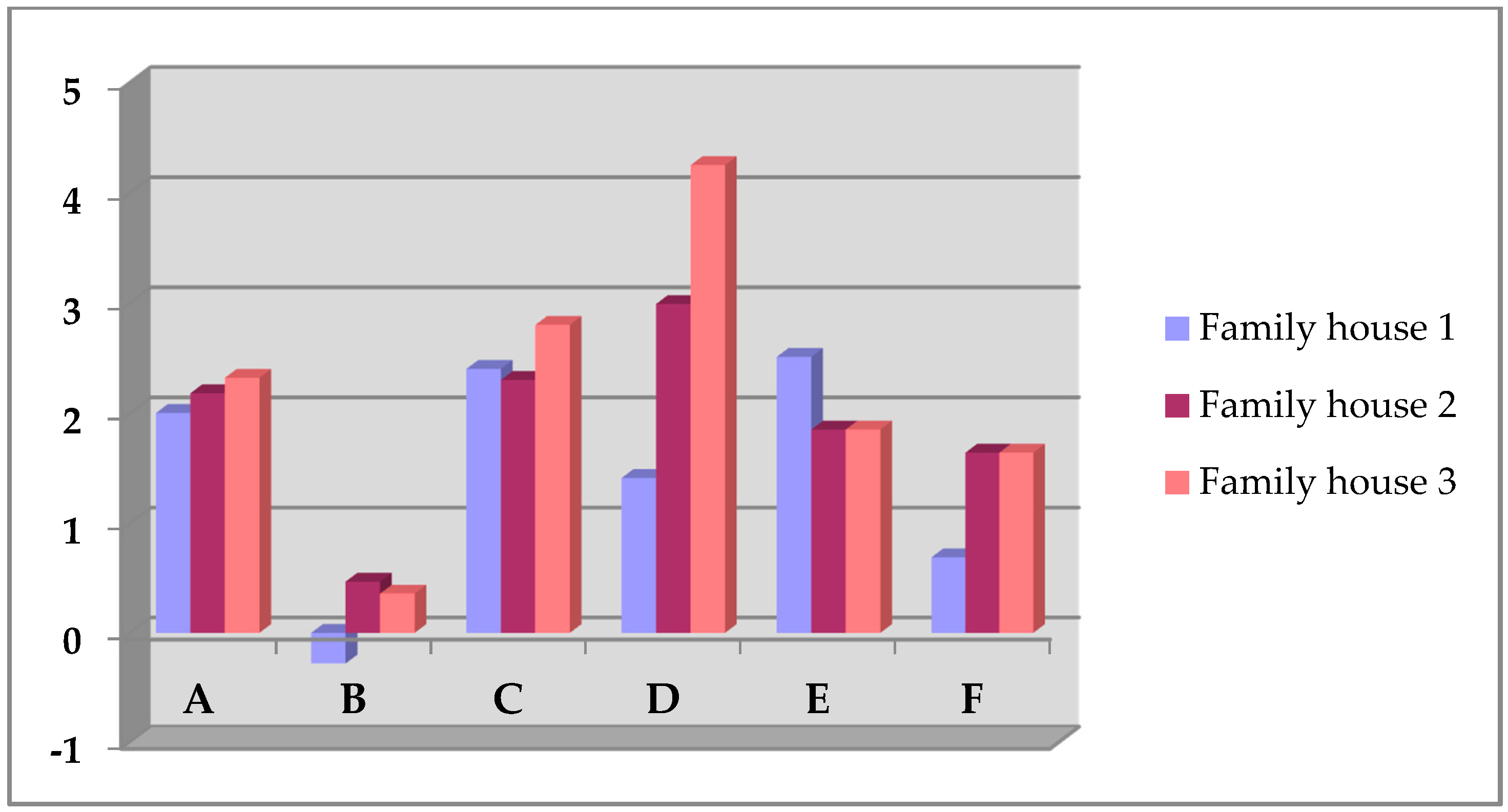

3.7. Results of Overall Evaluation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| ATHENA | Sustainable Materials Institute |

| BEAS | Building Environmental Assessment System |

| BREEAM | Building Research Establishment Environmental Assessment Method |

| CASBEE | Comprehensive Assessment System for Built Environment Efficiency |

| CHTC | Convective Heat Transfer Coefficient |

| CWM | Construction Waste Management |

| EE | Embodied Energy |

| ECO2 | Global Warming Potential (GWP) |

| ESO2 | Acidification Potential (AP) |

| EF | Ecological Footprint |

| EMoC | Environmental Model of Construction |

| eQUEST | QUick Energy Simulation Tool |

| FSC | Forest Stewardship Council |

| GHG | Green House Gas |

| HDPE | High-density Polyethylene |

| HVAC | Heating, Ventilation and Air Conditioning |

| IBO | Austrian Institute for Healthy and Ecological Building |

| ITACA Protocol | Italian green buildings assessment tool |

| LCA | Life Cycle Assessment |

| LCIA | Life Cycle Impact Assessment |

| LEED | Leadership in Energy and Environmental Design |

| MFA | Material Flow Analysis |

| NRE | Non-renewable Energy |

| STN | Slovak Technical Normalization |

| TVOC | Total Volatile Organic Compounds |

| Ug | Heat transfer coefficient of glass (W/(m2·K)) |

| θo | Operative temperature (°C) |

References

- Kibert, C.J. Green Building Assessment. In Sustainable Construction, Green Building Design and Delivery, 3rd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013; pp. 119–138. ISBN 978-0-470-90445-9. [Google Scholar]

- Doan, D.T.; Ghaffarianhoseini, A.; Naismith, N.; Zhang, T.; Ghaffarianhoseini, A.; Tookey, J. A critical comparison of green building rating systems. Build. Environ. 2017, 123, 243–260. [Google Scholar] [CrossRef]

- Kamaruzzaman, S.N.; Lou, E.C.W.; Zainon, N.; Zaid, S.M.; Wong, P.F. Environmental assessment schemes for non-domestic building refurbishment in the Malaysian context. Ecol. Indic. 2016, 69, 548–558. [Google Scholar] [CrossRef]

- Abdel Aleem, S.H.E.; Zobaa, A.F.; Abdel Mageed, H.M. Assessment of energy credits for the enhancement of the Egyptian Green Pyramid Rating System. Energy Policy 2015, 87, 407–416. [Google Scholar] [CrossRef]

- Asdrubali, F.; Baldinelli, G.; Bianchi, F.; Sambuco, S. A comparison between environmental sustainability rating systems LEED and ITACA for residential buildings. Build. Environ. 2015, 86, 98–108. [Google Scholar] [CrossRef]

- Seinre, E.; Kurnitski, J.; Voll, H. Building sustainability objective assessment in Estonian context and a comparative evaluation with LEED and BREEAM. Build. Environ. 2014, 82, 110–120. [Google Scholar] [CrossRef]

- Rastogi, A.; Choi, J.K.; Hong, T.; Lee, M. Impact of different LEED versions for green building certification and energy efficiency rating system: A Multifamily Midrise case study. Appl. Energy 2017, 205, 732–740. [Google Scholar] [CrossRef]

- Dahlstrøm, O.; Sørnes, K.; Eriksen, S.T.; Hertwich, E.G. Life cycle assessment of a single-family residence built to either conventional-or passive house standard. Energy Build. 2012, 54, 470–479. [Google Scholar] [CrossRef]

- Citherlet, S.; Defaux, T. Energy and environmental comparison of three variants of a family house during its whole life span. Build. Environ. 2007, 42, 591–598. [Google Scholar] [CrossRef]

- Zabalza Bribian, I.; Aranda Usón, A.; Scarpellini, S. Life cycle assessment in buildings: State-of-the-art and simplified LCA methodology as a complement for building certification. Build. Environ. 2009, 44, 2510–2520. [Google Scholar] [CrossRef]

- Alshamrani, O.S.; Galal, K.; Alkass, S. Integrated LCAeLEED sustainability assessment model for structure and envelope systems of school buildings. Build. Environ. 2014, 80, 61–70. [Google Scholar] [CrossRef]

- Ingrao, C.; Scrucca, F.; Tricase, C.; Asdrubali, F. A comparative Life Cycle Assessment of external wall-compositions for cleaner construction solutions in buildings. J. Clean. Prod. 2016, 124, 283–298. [Google Scholar] [CrossRef]

- Berardi, U. Sustainability Assessment in the Construction Sector: Rating Systems and Rated Buildings. Sustain. Dev. 2012, 20, 411–424. [Google Scholar] [CrossRef]

- Vilcekova, S.; Culakova, M.; Kridlova Burdova, E.; Katunska, J. Energy and Environmental Evaluation of Non-transparent Constructions of Building Envelope for Wooden Houses. Energies 2015, 8, 11047–11075. [Google Scholar] [CrossRef]

- Uğur, L.O.; Leblebici, N. An examination of the LEED green building certification system in terms of construction costs. Renew. Sustain. Energy Rev. 2017. [Google Scholar] [CrossRef]

- Vilcekova, S.; Kridlova Burdova, E. Environmental Assessment of Building, 1st ed.; Civil Engineering Faculty, Institute of Environmental Engineering: Kosice, Slovakia, 2010; ISBN 978-80-553-0361-1. [Google Scholar]

- Urban Zoning Plan City of Kosice. Available online: http://www.kosice.sk/static/up_2013_V-3.htm (accessed on 25 October 2017).

- Environmental Regionalization of Slovakia. Report on the State of the Environment of the Slovak Republic in 2015. Available online: http://enviroportal.sk/spravy/detail/224 (accessed on 25 October 2017).

- Tebbouche, H.; Bouchair, A.; Grimes, S. Towards an environmental approach for the sustainability of buildings in Algeria. Energy Procedia 2017, 119, 98–110. [Google Scholar] [CrossRef]

- Alba-Rodríguez, M.D.; Martinez-Rocamora, A.; González-Vallejo, P.; Ferreira-Sanchéz, A.; Marrero, M. Building rehabilitation versus demolition and new construction: Economic and environmental assessment. Environ. Impact Assess. Rev. 2017, 66, 115–126. [Google Scholar] [CrossRef]

- Waltjen, T. Passivhaus-Bauteilkatalog, Ökologisch bewertete Konstruktionen; Springer: Wien, Austria, 2009; p. 347. [Google Scholar]

- De Klijn-Chevalerias, M.; Javed, S. The Dutch approach for assessing and reducing environmental impacts of building materials. Build. Environ. 2017, 111, 147–159. [Google Scholar] [CrossRef]

- Dong, Y.H.; Ng, S.T. A life cycle assessment model for evaluating the environmental impacts of building construction in Hong Kong. Build. Environ. 2015, 89, 183–191. [Google Scholar] [CrossRef]

- Rincón, L.; Castell, A.; Pérez, G.; Solé, C.; Boer, D.; Cabeza, L.F. Evaluation of the environmental impact of experimental buildings with different constructive systems using Material Flow Analysis and Life Cycle Assessment. Appl. Energy 2013, 109, 544–552. [Google Scholar] [CrossRef]

- MacNaughton, P.; Spengler, J.; Vallarino, J.; Santanam, S.; Satish, U.; Allen, J. Environmental perceptions and health before and after relocation to a green building. Build. Environ. 2016, 104, 138–144. [Google Scholar] [CrossRef] [PubMed]

- Gobakis, K.; Kolokotsa, D. Coupling building energy simulation software with microclimatic simulation for the evaluation of the impact of urban outdoor conditions on the energy consumption and indoor environmental quality. Energy Build. 2017, 157, 101–115. [Google Scholar] [CrossRef]

- Saez de Guinoa, A.; Zambrana-Vasquez, D.; Alcalde, A.; Corradini, M.; Zabalza-Bribian, I. Environmental assessment of a nano-technological aerogel-based panel for building insulation. J. Clean. Prod. 2017, 161, 1404–1415. [Google Scholar] [CrossRef]

- Brambilla, A.; Salvalai, G.; Imperadori, M.; Sesana, M.M. Nearly zero energy building renovation: From energy efficiency to environmental efficiency, a pilot case study. Energy Build. 2018, 166, 271–283. [Google Scholar] [CrossRef]

- Krarti, M.; Dubey, K.; Howarth, N. Evaluation of building energy efficiency investment options for the Kingdom of Saudi Arabia. Energy 2017, 134, 595–610. [Google Scholar] [CrossRef]

- Las-Heras-Casas, J.; López-Ochoa, L.M.; Paredes-Sánchez, J.P.; López-González, L.M. Implementation of biomass boilers for heating and domestic hot water in multi-family buildings in Spain: Energy, environmental, and economic assessment. J. Clean. Prod. 2018, 176, 590–603. [Google Scholar] [CrossRef]

- Marinoski, A.K.; Forgiarini Rupp, R.; Ghisi, E. Environmental benefit analysis of strategies for potable water savings in residential buildings. J. Environ. Manag. 2018, 206, 28–39. [Google Scholar] [CrossRef] [PubMed]

- Hossain, M.U.; Wu, Z.; Poon, C.S. Comparative environmental evaluation of construction waste management through different waste sorting systems in Hong Kong. Waste Manag. 2017, 69, 325–335. [Google Scholar] [CrossRef] [PubMed]

| Figure of Family Houses—Photo/Floor Plan of the First Floor | ||

|---|---|---|

|  |  |

|  |  |

| Family House 1 | Family House 2 | Family House 3 |

| Built-up area, Useful floor area, Built-up volume, Number of storey’s | ||

| 111.0 m2; 211.5 m2; 613.4 m3; two-story building without basement | 296.0 m2; 278.2 m2; 1185.6 m3; single-story building with basement | 248.5 m2; 445.1 m2; 1693.7 m3; two-story building with basement |

| Foundations | ||

| reinforced concrete foundation strip | reinforced concrete foundation strip | reinforced concrete foundation strip |

| External walls, surface finishes | ||

| aerated concrete blocks (Ytong Lambda) with a thickness of 375 mm; external plaster | ceramic blocks (Porotherm), combined with reinforced concrete walls with a thickness of 250–300 mm; silicate exterior plaster, combined with stone cladding | sheeting concrete blocks, combined with Porotherm blocks with a thickness of 300 mm; silicate exterior plaster, combined with aluminum composite wall panels |

| Ceiling structures | ||

| reinforced concrete slabs with a thickness of 200 mm | reinforced concrete slabs with a thickness of 200 mm | reinforced concrete slabs with a thickness of 200 mm |

| Roof construction, roof covering | ||

| saddle roof, wood structure, lightweight asphalt-board | flat roof, reinforced concrete slabs, extensive and intensive vegetation roof | flat roof, reinforced concrete slabs, two-layer waterproofing modified belts |

| Interior walls, surface finishes of walls | ||

| gypsum plasterboard with a thickness of 150 mm, lime plasters and ceramic tiles | sandwich constructions from plasterboard and thermal insulation from mineral wool with a thickness of 150 mm, gypsum plasters and ceramic tiles | Porotherm blocks with a thickness of 150 mm, gypsum plasters and ceramic tiles |

| Floor and ceiling surface finishes | ||

| floors—wooden floor, ceramic tiles, linoleum, ceilings—gypsum plasters, plasterboard | floors—wooden floor, ceramic tiles, linoleum, concrete paving, ceilings—plasterboard, architectural concrete | floors—wooden floor, ceramic tiles, PVC, concrete floor, ceilings—gypsum plasters, plasterboard |

| Insulations of ground floor, external walls and roof | ||

| ground floor—waterproofing PVC, polystyrene with a thickness of 100 mm, external walls—without insulation, roof—mineral wool with a thickness of 300 mm | ground floor—2× geotextile, waterproofing PVC, expanded polystyrene with a thickness of 350 mm, external walls—mineral wool thickness 200 mm, roof—expanded polystyrene with a thickness of 200 mm, waterproofing PVC, protective fabrics of artificial fibers, drainage foil, filtration textile | ground floor—3× geotextile, waterproofing PVC, extruded polystyrene with a thickness of 120 mm, external walls—mineral wool with a thickness of 250 mm, roof—2× geotextile, extruded polystyrene with a thickness of 200 mm |

| Windows | ||

| Plastic windows (Fenestra) with triple glazing (Ug = 0.6 W/m2K) and horizontal plastic interior blinds | aluminum windows (SCHUCO) with triple glazing (Ug = 0.6 W/m2K) and horizontal aluminum exterior blinds | aluminum windows (Aliplast) with triple glazing (Thermoglass) (Ug = 0.7 W/m2K) and horizontal aluminum exterior blinds |

| Heating or cooling, ventilation | ||

| electric heating by low temperature radiant ceiling panels (Ecosun), hot water fireplace (ABX-Stockholm), natural ventilation | floor and ceiling heating by heat pump type earth-water (IVT PremiumLine), fireplace, ceiling cooling—dry system (REHAU), natural ventilation | floor heating and radiator by gas boiler with additional solar systems, fireplace (Bruner), heat and ventilation recovery units (Atrea Duplex) |

| Connection to engineering networks | ||

| electrical and water connection, cesspool | electrical, sewage and water connection | electrical, gas, sewage and water connection |

| Fields | Subfields and Indicators |

|---|---|

| A | A1—Selection of location for the construction; A2—Selection of location vulnerable to flooding; A3—Selection of location nearby recipient; A4—Selection of Brownfield areas; A5—Distance of construction site to road-traffic infrastructure; A6—Distance to commercial and cultural facilities; A7—Distance to sport and active recreation; A8—Distance to public or natural green space; A9—Possibility of connection to engineering networks; A10—Possibilities exploitation of renewable energy sources; A11—Possibility to maximize passive solar gains by the orientation of the building; A12—Compatibility of the urban design with local cultural values; A13—The occurrence of transport infrastructure in the construction site; A14—The share of green spaces in the construction site |

| B | B1 Materials: B1.1—Product environmental labeling; B1.2—Use of local materials; B1.3—Use of recycled materials; B1.4—Use of substitutes in concrete; B1.5—Radioactivity of building materials; B2—Life cycle of materials: B2.1—Primary energy embodied in building materials; B2.2—Global warming potential; B2.3—Acidification potential |

| C | C1—Thermal comfort during the heating season; C2—Thermal comfort during the cooling season; C3—Natural ventilation and mechanical ventilation; C4—Noise attenuation through the exterior envelope; C5—Noise isolation between primary occupancy areas; C6—Daylighting; C7—Shading and blinds; C8—Artificial lighting; C9—The materials used in the building; C10—Transfer of pollutants from the garage space into the user space of the house |

| D | D1—Operation energy: D1.1—Energy for heating; D1.2—Energy for domestic hot water; D1.3—Energy for mechanical ventilation and cooling; D1.4—Energy for lighting; D1.5—Energy for appliances; D2—Active systems using renewable energy sources: D2.1—Solar system/heat pump; D2.2—Photovoltaic technology; D2.3—Heat recuperation; D3—Energy management: D3.1—System of energy management |

| E | E1—Reduction and regulation of water flow in water systems; E2—The water management of surface runoff; E3—Drinking water supply; E4—System of grey water |

| F | F1—Plan of waste disposal originating in the construction process; F2—Measures to minimize waste resulting from building operation; F3—Measures to minimize emissions resulting from air pollution sources |

| Key for Assessment | Certification Scale | |

|---|---|---|

| −1 | unacceptable building | Unacceptable building |

| 0 | acceptable building | BEAS CERTIFIED |

| 0–1.5 | acceptable building | BEAS BRONZE |

| 1.5–3 | good building | BEAS SILVER |

| 3–4 | better building | BEAS GOLD |

| 4–5 | best building | BEAS PLATINUM |

| Indicator | Criteria |

|---|---|

| A1 | Class of environmental level: from heavily deteriorated to a high level of environment |

| A2 | Place of construction outside the flood territory: minimum peak elevation of construction site over 100 years of water is between 1 m and 25 m |

| A3 | Distance from the construction site to the recipient: <15 m to >75 m |

| A4 | Brownfield Revitalization: construction on a Greenfield/Brownfield |

| A5 | Distance from the building to the road-traffic infrastructure: >500 m to <100 m |

| A6 | Distance from the building to the commercial and cultural facilities: >1000 m to <500 m |

| A7 | Distance from the building to sport and active recreation: >1000 m to <500 m |

| A8 | Distance to the public or natural green space: >1000 m to <500 m |

| A9 | Possibility of connection to public construction sites: there is no possibility of connection to engineering networks; there is a possibility of connection to engineering networks, such as water and sewage connections, as well as electricity and gas connections |

| A10 | Potential of the construction site exploitation of renewable energy sources: there are no possibilities for exploitation; there is a possibility to use up to three systems using renewable energy sources |

| A11 | Percentage area of the building oriented east—west: 40–100% |

| A12 | Assessment of the building status with local cultural values relating to design and architecture, including functional and aesthetic aspects: the architectural design does not respect the existing cultural values in relation to urban design and architecture—a prime example of compatibility with cultural values relating to urban design and architecture |

| A13 | Assessment of the construction site in view of the occurrence of the transport network in the given settlement structure: occurrence of significant transport infrastructure (highway, road of 1st, 2nd or 3rd class and local or tertiary roads) |

| A14 | To ensure the minimum percentage of green areas for the construction of family houses: minimum percentage of green spaces of the total land area <60% to >75% |

| Family House 1 | Family House 2 | Family House 3 | |

|---|---|---|---|

| Score | |||

| A1 | −1 | −1 | −1 |

| territory with strongly disturbed environment | territory with strongly disturbed environment | territory with strongly disturbed environment | |

| A2 | 5 | 5 | 5 |

| no flood territory | no flood territory | no flood territory | |

| A3 | 3 | 5 | 5 |

| 48 m | 120 m | >75 m | |

| A4 | 3 | 3 | 3 |

| outside the brownfield area | outside the brownfield area | outside the brownfield area | |

| A5 | −1 | −1 | 0 |

| 616 m | 750 m | 500 m | |

| A6 | −1 | −1 | −1 |

| >1000 m | >1000 m | >1000 m | |

| A7 | −1 | −1 | 0 |

| >1000 m | >1000 m | <1000 m | |

| A8 | 5 | 5 | 5 |

| <500 m | <500 m | <500 m | |

| A9 | 0 | 5 | 5 |

| possibility of connection to water connection, as well as electricity connection | possibility of connection to water and sewage connections, as well as electricity and gas connections | possibility of connection to water and sewage connections, as well as electricity and gas connections | |

| A10 | 3 | 5 | 5 |

| possibility to use two systems using renewable energy sources (photovoltaic panels, heat pumps) | possibility to use three systems using renewable energy sources (solar panels, photovoltaic panels, heat pumps) | possibility to use three renewable energy sources (solar panels, photovoltaic panels, heat pumps) | |

| A11 | −1 | 0 | 0 |

| 41.8% | 60.1% | 51.5% | |

| A12 | 3 | 3 | 3 |

| fully respects | fully respects | fully respects | |

| A13 | 5 | 5 | 5 |

| local and tertiary roads | local and tertiary roads | local and tertiary roads | |

| A14 | 5 | −1 | −1 |

| 79.52% | 37.04% | 52.51% | |

| Indicator | Criteria |

|---|---|

| B1–B1.1 | The environmental use of appropriate construction products: percentage share of the built-in product <0% until >50% |

| B1.2 | Distance of manufacturing materials from the construction site: >500 km to <100 km |

| B1.3 | Minimum required recyclable share in the built-in building material: recyclable share in the built-in materials <20% to >50% |

| B1.4 | Recommendation to replace cement with concrete: percentage weight of the replaced cement compared with concrete <20% to >50% |

| B1.5 | Limitation of the use of materials containing natural radionuclides: mass 226Ra activity in the construction products >120 Bq/kg to <100 Bq/kg |

| B2–B2.1 | Primary energy consumption: primary energy embodied in the building materials >1500 MJ/m2 to <600 MJ/m2 |

| B2.2 | The amount of CO2 emissions from non-renewable sources: global warming potential >100 kg/m2 to <10 kg/m2 |

| B2.3 | The amount of SO2 emissions from non-renewable sources: acidification potential >0.45 kg/m2 to <0.25 kg/m2 |

| Family House 1 | Family House 2 | Family House 3 | |

|---|---|---|---|

| Score | |||

| B1.1 | −1 | 0 | −1 |

| no built-in product with an environmental label | built-in product with an environmental label (Eco friendly)—over 10% | built-in product with an environmental label (FSC certification)—to 10% | |

| B1.2 | 0 | 0 | 0 |

| 250–500 km | 250–500 km | 250–500 km | |

| B1.3 | −1 | 5 | 5 |

| no use of recycled materials | >50% | >50% | |

| B1.4 | −1 | −1 | −1 |

| <20% | <20% | <20% | |

| B1.5 | 5 | 5 | 5 |

| <100 Bq/kg | <100 Bq/kg | <100 Bq/kg | |

| B2.1 | −1 | −1 | −1 |

| 3787.9 MJ/m2 | 6695.4 MJ/m2 | 5157.8 MJ/m2 | |

| B2.2 | −1 | −1 | −1 |

| 286.9 kg/m2 | 473.4 kg/m2 | 374.6 kg/m2 | |

| B2.3 | −1 | −1 | −1 |

| 1.30 kg/m2 | 2.18 kg/m2 | 1.64 kg/m2 | |

| Indicator | Criteria |

|---|---|

| C1 | Design value of operative temperature according to EN 15251: 2007: operative temperature in 95% of buildings during the heating season (θo < 18 °C to θo ≥ 21 °C) |

| C2 | Design value of operative temperature according to EN 15251: 2007: operative temperature during the cooling season does not meet the requirements—meets the requirements |

| C3 | Natural ventilation: The total area of the openings in the exterior envelope is at least 5% of the total floor area, and at least 50% of the space has ventilation from the top down—the total area of the openings in the exterior envelope is at least 10% of the total floor area, and more than 90% of the space has ventilation from the top down. Mechanical ventilation: design requirements of the STN EN 15251: 2007: does not meet the minimum requirements—exceeds the minimum requirements. |

| C4 | Noise attenuation through the exterior envelope in residential areas of cities according to Slovak standard STN 73 0532. (Quality class of sound insulation <2 to ≥4) |

| C5 | Noise attenuation between the rooms of the building: airborne sound insulation does not meet the minimum requirements—exceeds the minimum requirements according to STN 73 0532 |

| C6 | Daylight factor according to STN 73 0580: does not reach the minimum values for the scheduled tasks—reaches minimum values for the scheduled tasks |

| C7 | Design shielding measures to prevent glare in interior spaces: no designed shielding elements—the most appropriate shielding elements are designed |

| C8 | The level and quality of lux illuminance for the scheduled tasks: inappropriate level and quality of lux illuminance for the scheduled tasks—high level quality of lux illuminance for the scheduled tasks |

| C9 | The choice of materials with low or no release of TVOC emission intensity: no selected materials with a low release of TVOC emission intensity—materials with no release of TVOC emission intensity |

| C10 | Isolated space or rooms in which pollutants can be produced: The built-in garage is not ventilated nor functionally connected with the indoor spaces—garage outside the building, built-in garage is ventilated and functionally connected with indoor spaces with a CO2 sensor |

| Family House 1 | Family House 2 | Family House 3 | |

|---|---|---|---|

| Scales of Evaluating | |||

| C1 | 0 | 0 | 0 |

| 18 ≤ θo < 20 °C | 18 ≤ θo < 20 °C | 18 ≤ θo < 20 °C | |

| C2 | −1 | 0 | 0 |

| does not use cooling system | fulfilled the minimum requirements | fulfilled the minimum requirements | |

| C3 | 5 | 5 | 5 |

| Natural ventilation: at least 10% of the total floor area and more than 90% of the ventilation space from the top down | Natural ventilation: at least 10% of the total floor area and more than 90% of the ventilation space from the top down | Mechanical ventilation in 100% of the space exceeds the minimum requirements | |

| C4 | 5 | 5 | 5 |

| 4 | 4 | 4 | |

| C5 | 0 | 3 | 3 |

| fulfilled the minimum requirements of the standard | exceeded the minimum requirements of the standard | exceeded the minimum requirements of the standard | |

| C6 | 5 | 5 | 5 |

| fulfilled minimum values | fulfilled minimum values | fulfilled minimum values | |

| C7 | 5 | 5 | 5 |

| the most appropriate shielding elements designed | the most appropriate shielding elements designed | the most appropriate shielding elements designed | |

| C8 | 5 | 5 | 5 |

| high level quality of lux illuminance | high level quality of lux illuminance | high level quality of lux illuminance | |

| C9 | 0 | 0 | 0 |

| materials with a low-level release of TVOC emission intensity selected | materials with a low-level release of TVOC emission intensity selected | materials with a low-level release of TVOC emission intensity selected | |

| C10 | 5 | 0 | 0 |

| garage outside the building | built-in garage is ventilated and functionally connected with indoor spaces, with the required door panel | built-in garage is ventilated and functionally connected with indoor spaces, with the required door panel | |

| Indicator | Criteria |

|---|---|

| D1.1 | Class of energy for heating according to the Law No. 555/2005 of the energy performance of buildings: from an energy class lower than C to energy class A |

| D1.2 | Class of energy for domestic hot water according to the Law No. 555/2005 of the energy performance of buildings: from an energy class lower than C to energy class A |

| D1.3 | Building uses a mechanical ventilation system or cooling system: there is no ventilation or cooling—ventilation ensured by air conditioning |

| D1.4 | Energy demand for lighting in family houses is not rated according to Slovak standards. |

| D1.5 | Electrical appliances with low energy consumption expressed as energy class: at least one appliance is in an energy class less than B—all appliances are in energy class A |

| D2.1 | Using solar system/heat pump for heating and hot water: no use of solar system/heat pump—solar system/heat pump covers more than 75% of energy consumption |

| D2.2 | Photovoltaic technology: no photovoltaic technology used—photovoltaic technology covers more than 60% of energy consumption |

| D2.3 | Heat recuperation: no heat recuperation used—heat recuperation uses more than 75% of waste heat |

| D3.1 | Monitoring of operation and maintenance of building services: there is no energy management system—energy management system is established |

| Family House 1 | Family House 2 | Family House 3 | |

|---|---|---|---|

| Score | |||

| D1.1 | 5 | 5 | 5 |

| A | A | A | |

| D1.2 | 3 | 5 | 5 |

| B | A | A | |

| D1.3 | −1 | 0 | 5 |

| no mechanical ventilation system used | no mechanical ventilation system used but cooling system used | mechanical ventilation system with air treatment | |

| D1.4 | 0 | 0 | 0 |

| - | - | - | |

| D1.5 | 5 | 5 | 5 |

| A | A | A | |

| D2.1 | −1 | 5 | 5 |

| no renewable energy sources used | heat pump | solar system | |

| D2.2 | −1 | −1 | −1 |

| no photovoltaic technology used | no photovoltaic technology used | no photovoltaic technology used | |

| D2.3 | −1 | −1 | 5 |

| no heat recuperation used | no heat recuperation used | heat recuperation | |

| D3.1 | −1 | 5 | 5 |

| no system of energy management established | system of energy management into three components | system of energy management into three components | |

| Indicator | Criteria |

|---|---|

| E1 | Consumption of drinking water: there are no devices for reducing and regulating water flow or there are designed devices for reducing and regulating water flow |

| E2 | The quality management system of water from surface runoff: water from surface runoff is not captured or water from surface runoff is captured |

| E3 | The quality of drinking water |

| E4 | Drinking water system and gray water system are separated: no split system is proposed, or a split system of drinking water and gray water is designed |

| Family House 1 | Family House 2 | Family House 3 | |

|---|---|---|---|

| Score | |||

| E1 | 0 | 3 | 3 |

| designed equipment to reduce and control the water flow in the armature | designed equipment to reduce and control the water flow in the armature and flush toilet | designed equipment to reduce and control the water flow in the armature and flush toilet | |

| E2 | 5 | 0 | 0 |

| collected in storage tank and is used for irrigation | sewage system and vegetation roof | sewage system and surface runoff are collected in storage tank and are used for irrigation | |

| E3 | 5 | 5 | 5 |

| sufficient amount of fresh water with a high quality | sufficient amount of fresh water with a high quality | sufficient amount of fresh water with a high quality | |

| E4 | −1 | −1 | −1 |

| no split potable and gray water system used | no split potable and gray water system used | no split potable and gray water system used | |

| Indicator | Criteria |

|---|---|

| F1 | Waste management plan: no waste balance is drawn up—very detailed Waste Management Plan is developed |

| F2 | Collection, sorting and recycling of municipal waste: separate collection of waste components is not ensured—separate collection of up to 5 waste components is ensured |

| F3 | Source of air pollution: there is a source of air pollution—there is no source of air pollution |

| Family House 1 | Family House 2 | Family House 3 | |

|---|---|---|---|

| Scales of Evaluating | |||

| F1 | 0 | 3 | 3 |

| prepared general waste management plan | prepared detailed waste management plan | prepared detailed waste management plan | |

| F2 | 3 | 3 | 3 |

| ensured the separate collection of the four components of municipal waste | ensured the separate collection of the four components of municipal waste | ensured the separate collection of the four components of municipal waste | |

| F3 | −1 | −1 | −1 |

| fireplace with solid fuel | fireplace with solid fuel | fireplace with solid fuel | |

| Field | Percentage Weight | House 1 | House 2 | House 3 | |

|---|---|---|---|---|---|

| A | Site selection and project planning | 14.71% | 2.00 | 2.18 | 2.32 |

| B | Building constructions | 20.59% | −0.28 | 0.47 | 0.36 |

| C | Indoor environment | 23.56% | 2.40 | 2.30 | 2.80 |

| D | Energy performance | 26.47% | 1.41 | 2.99 | 4.25 |

| E | Water management | 8.88% | 2.51 | 1.85 | 1.85 |

| F | Waste management | 5.88% | 0.69 | 1.64 | 1.64 |

| Total assessment | 100% | 1.44 BEAS BRONZE | 2.01 BEAS SILVER | 2.46 BEAS SILVER | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vilčeková, S.; Selecká, I.; Burdová, E.K.; Mečiarová, Ľ. Interlinked Sustainability Aspects of Low-Rise Residential Family House Development in Slovakia. Sustainability 2018, 10, 3966. https://doi.org/10.3390/su10113966

Vilčeková S, Selecká I, Burdová EK, Mečiarová Ľ. Interlinked Sustainability Aspects of Low-Rise Residential Family House Development in Slovakia. Sustainability. 2018; 10(11):3966. https://doi.org/10.3390/su10113966

Chicago/Turabian StyleVilčeková, Silvia, Iveta Selecká, Eva Krídlová Burdová, and Ľudmila Mečiarová. 2018. "Interlinked Sustainability Aspects of Low-Rise Residential Family House Development in Slovakia" Sustainability 10, no. 11: 3966. https://doi.org/10.3390/su10113966

APA StyleVilčeková, S., Selecká, I., Burdová, E. K., & Mečiarová, Ľ. (2018). Interlinked Sustainability Aspects of Low-Rise Residential Family House Development in Slovakia. Sustainability, 10(11), 3966. https://doi.org/10.3390/su10113966