Enabling Factors and Strategies for the Transition Toward a Circular Economy (CE)

Abstract

1. Introduction

2. Circular Economy Concepts

2.1. Transition toward the Circular Economy Model

- (1)

- How to define value proposition

- (2)

- How to create and deliver value

- (3)

- How to capture value and maintain or regenerate natural, social, and economic capital beyond its organizational boundaries

- (1)

- Sales model

- (2)

- Product design/material composition: this concerns the way products are designed to reuse their components and materials

- (3)

- IT management/data: enabling resource optimization requires a key competence, namely the ability to track products, components, and materials

- (4)

- Maximizing the use of recycled materials/components in order to obtain the value of products, components, and materials’ flow

- (5)

- Operations strategy: building trusted partnerships and long-term relationships with suppliers and customers, including co-creation

- (6)

- HR/incentives: changes require adequate cultural adaptation and capacity-building, training, and rewards programs

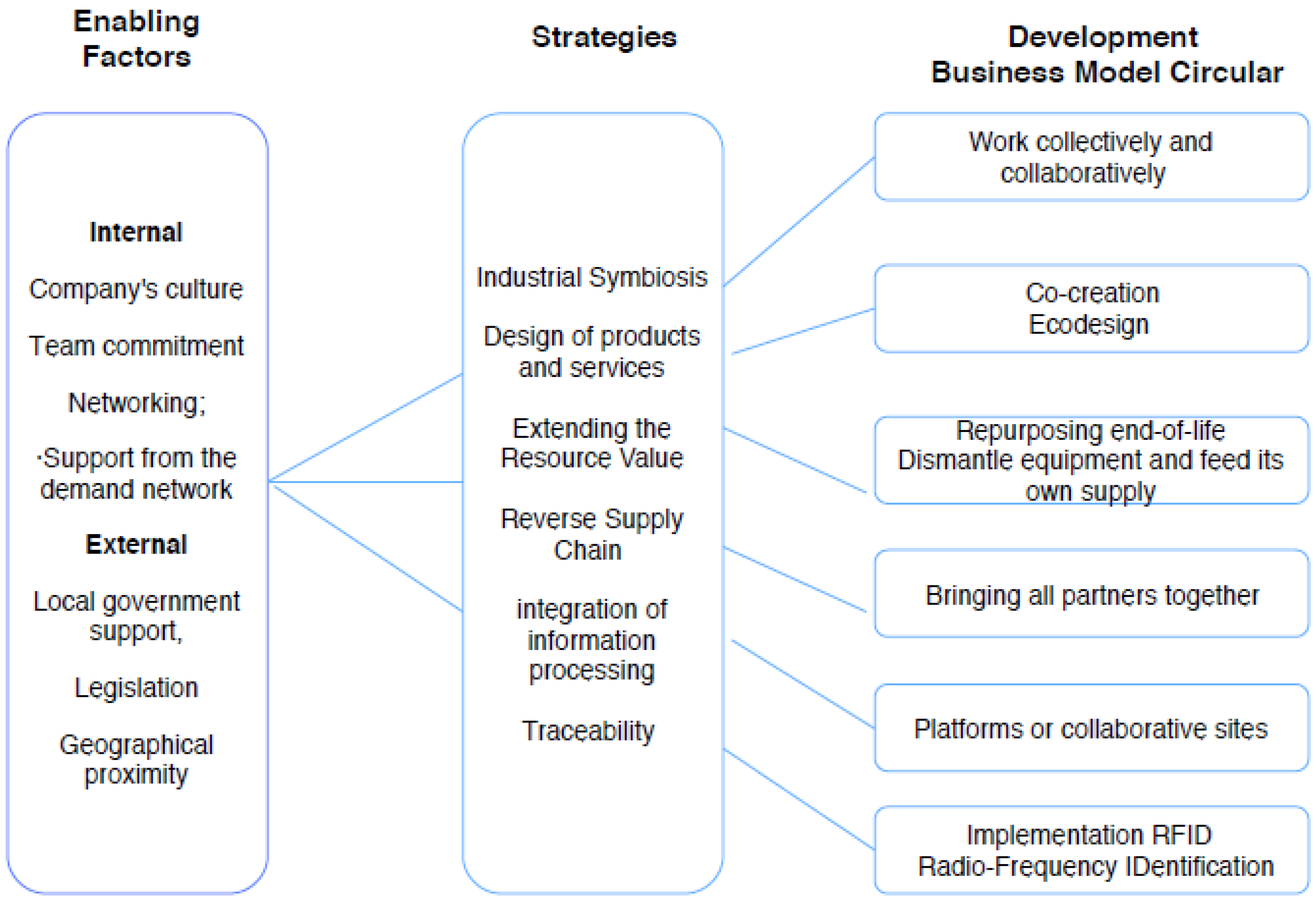

2.2. Enabling Factors and Circular Business Model Strategies

2.2.1. Enabling Factors

- Education

- Legislation by governments, which can create more funding incentives by subscribing to some of the risks associated with innovative business models

- Corporate social responsibility motivation [26]

2.2.2. Business Model Circular Strategies

- (1)

- Integrated design with reverse logistics

- (2)

- In relation to value delivery, companies need to design distribution channels depending on the target segment

- (3)

- Co-creation

- (4)

- Feasibility of repurposing end-of-life

2.3. Research Framework Proposal

3. Methodology

3.1. Research Script

- Section A:

- Establishing the company’s general information

- Section B:

- Description of services and products

- Section C:

- Description methods and innovations that managers from this company use to improve the implementation of circular systems

- Section D:

- Structure of the business model

- Section E:

- Enabling factors and strategies adopted to develop the concept of circular business

3.2. Choice of Enterprises

3.3. Respondents’ Profiles

3.4. Case Study

3.4.1. Company A

Methods and Innovations

“The operations go far beyond the recycling of materials but rather the aggregation of value of the components and materials aiming at the extension of the life cycle. An example is the reuse of components for manufacturing new products, reindustrialization of components and parts of products as new products in other industries. We call it reuse, reindustrialization, and remanufacturing. We also generate information about field data and waste from our customers after the end of product life.”

Strategies Adopted to Develop the Concept of Circular Business

3.4.2. Company B

Methods and Innovations

Enabling Factors and Strategies Adopted to Develop the Concept of Circular Business

- -

- Research and development (R&D)

- -

- Training and qualification

- -

- Institute of technology

- -

- Recycling center

- -

- Standardization and conformity

- -

- Destination and reinsertion of materials

- -

- Universities

- -

- Research centers

- -

- Excellence center in radio-frequency identification (RFID) (managed by the company’s main client)

- -

- Collection network

- -

- Supplier network

- -

- Consolidation and selection

- -

- Disassembly

- -

- Technology and innovation, which includes partnerships with research centers, universities, excellence centers in RFID, with their own structure, focused on training and education, Research and Development (R&D) and technology (institute of technology).

- -

- Execution, which includes partnerships with networks, supplier networks, companies responsible for disassembly, consolidation, and sorting, with their own recycling structure.

4. Results

Results Discussion

- Developing business units linked to large multinational companies, yet having an independent organizational structure, being financially sustainable for both cases A and B

- Dismantling equipment and feeding their own supply

- Creating new organizational routines independent of the companies that they are linked to

- Developing ecosystems based on reverse logistics, recycling facilities, research and development, and reverse supply chains

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ness, D. Sustainable urban infrastructure in China: Towards a Factor 10 improvement in resource productivity through integrated infrastructure system. Int. J. Sustain. Dev. World Ecol. 2008, 15, 288–301. [Google Scholar]

- Singh, J.; Ordoñez, I. Resource recovery from post-consumer waste: Important lessons for the upcoming circular economy. J. Clean. Prod. 2016, 134, 342–353. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition. Available online: http://mvonederland.nl/system/files/media/towards-the-circular-economy.pdf (accessed on 15 January 2017).

- Feng, Z.; Yan, N. Putting a circular economy into practice in China. Sustain. Sci. 2007, 2, 95–101. [Google Scholar]

- Naustdalslid, J. Circular economy in China—The environmental dimension of the harmonious society. Int. J. Sustain. Dev. World Ecol. 2014, 21, 303–313. [Google Scholar] [CrossRef]

- Mathews, J.A. Naturalizing capitalism: The next Great Transformation. Futures 2001, 43, 868–879. [Google Scholar] [CrossRef]

- Scheepens, A.E.; Vogtländer, J.G.; Brezet, J.C. Two life cycle assessment (LCA) based methods to analyse and design complex (regional) circular economy systems. Case: Making water tourism more sustainable. J. Clean. Prod. 2016, 114, 257–268. [Google Scholar] [CrossRef]

- Zink, T.; Geyer, R. Circular Economy Rebound. J. Ind. Ecol. 2017, 21, 593–602. [Google Scholar] [CrossRef]

- Gregson, N.; Crang, M.; Fuller, S.; Holmes, H. Interrogating the circular economy: The moral economy of resource recovery in the EU. Econ. Soc. 2014, 42, 218–243. [Google Scholar] [CrossRef]

- Scott, J.T. The Sustainable Business a Practitioner’s Guide to Achieving Long-Term Profitability and Competitiveness, 2nd ed.; Greenleaf Publishing: Sheffield, UK, 2015. [Google Scholar]

- Witjes, S.; Lozano, R. Towards a more Circular Economy: Proposing a framework linking sustainable public procurement and sustainable business models. Resour. Conserv. Recycl. 2016, 112, 37–44. [Google Scholar] [CrossRef]

- Van Buren, N.; Demmers, M.; van der Heijden, R.; Witlox, F. Towards a Circular Economy: The Role of Dutch Logistics Industries and Governments. Sustainability 2016, 8, 647. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Schaltegger, S.; Hansen, E.G.; Lüdeke-Freund, F. Business models for sustainability: Origins, present research, and future avenues. Organ. Environ. 2016. [Google Scholar] [CrossRef]

- Van Renswoude, K.; Wolde, A.T.; Joustra, D.J. Circular Business Models. Part 1: An introduction to IMSA’s Circular Business Model Scan. Available online: https://groenomstilling.erhvervsstyrelsen.dk/sites/default/files/media/imsa_circular_business_models_-_april_2015_-_part_1.pdf (accessed on 25 July 2017).

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Lewandowski, M. Designing the Business Models for Circular Economy—Towards the Conceptual Framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef]

- Pateli, A.G.; Giaglis, G.M. A research framework for analysing eBusiness models. Eur. J. Inf. Syst. 2004, 13, 302–314. [Google Scholar] [CrossRef]

- Wirtz, B.W. Business Model Management: Design—Instruments—Success Factors, 1st ed.; Springer: Dordrecht, The Netherlands, 2011. [Google Scholar]

- Bocken, N.M.; Short, S.W.; Rana, P.; Evans, S. A literature and practice review to develop sustainable business model archetypes. J. Clean. Prod. 2014, 65, 42–56. [Google Scholar] [CrossRef]

- Linder, M.; Williander, M. Circular Business Model Innovation: Inherent Uncertainties. Bus. Strateg. Environ. 2015, 26, 182–196. [Google Scholar] [CrossRef]

- Bocken, N.M.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Laubscher, M.; Marinelli, T. Integration of Circular Economy in Business. In Proceedings of the Conference: Going Green—CARE INNOVATION 2014, Vienna, Austria, 17–20 November 2014. [Google Scholar]

- Wynstra, F.; Axelsson, B.; Van Weele, A. Driving and enabling factors for purchasing involvement in product development. Eur. J. Purch. Supply Manag. 2000, 6, 129–141. [Google Scholar] [CrossRef]

- Ma, L.; Song, W.; Zhou, Y. Modeling enablers of environmentally conscious manufacturing strategy: An integrated method. Sustainability 2018, 10, 2284. [Google Scholar] [CrossRef]

- Rizos, V.; Behrens, A.; Van Der Gaast, W.; Hofman, E.; Ioannou, A.; Kafyeke, T.; Topi, C. Implementation of circular economy business models by small and medium-sized enterprises (SMEs): Barriers and enablers. Sustainability 2016, 8, 1212. [Google Scholar] [CrossRef]

- Luken, R.; Rompaey, F.V. Drivers for and barriers to environmentally sound technology adoption by manufacturing plants in nine developing countries. J. Clean. Prod. 2008, 16, 67–77. [Google Scholar] [CrossRef]

- Oghazi, P.; Mostaghel, R. Circular Business Model Challenges and Lessons Learned—An Industrial Perspective. Sustainability 2018, 10, 739. [Google Scholar] [CrossRef]

- Chertow, M.R. Industrial symbiosis: Literature and taxonomy. Annu. Rev. Energy Environ. 2000, 25, 313–337. [Google Scholar] [CrossRef]

- De Abreu, M.C.S.; Ceglia, D. On the implementation of a circular economy: The role of institutional capacity-building through industrial symbiosis. Resour. Conserv. Recycl. 2018, 138, 99–109. [Google Scholar] [CrossRef]

- Ayres, R.; Simonis, U. (Eds.) Industrial Metabolism: Restructuring for Sustainable Development; United Nations University Press: Tokyo, Japan, 1994. [Google Scholar]

- Short, S.; Bocken, N.; Barlow, C.; Chertow, M. From refining sugar to growing tomatoes. Industrial ecology and business model evolution. J. Ind. Ecol. 2014, 18, 603–618. [Google Scholar] [CrossRef]

- Vanegas, P.; Peeters, J.R.; Cattrysse, D.; Tecchio, P.; Ardente, F.; Mathieux, F.; Dewulf, W.; Duflou, J.R. Ease of disassembly of products to support circular economy strategies. Resour. Conserv. Recycl. 2018, 135, 323–334. [Google Scholar] [CrossRef]

- Masi, D.; Day, S.; Godsell, J. Supply Chain Configurations in the Circular Economy: A Systematic Literature Review. Sustainability 2017, 9, 1602. [Google Scholar] [CrossRef]

- Nasir, M.H.A.; Genovese, A.; Acquaye, A.A.; Koh, S.C.L.; Yamoah, F. Comparing linear and circular supply chains: A case study from the construction industry. Int. J. Prod. Econ. 2017, 183, 443–457. [Google Scholar] [CrossRef]

- Genefke, J. Collaboration costs. In Collaboration Strategies and Multi-Organizational Partnerships; Tallieux, T., Ed.; Garant: Leuven-Apeldoorn, Belgium, 2001. [Google Scholar]

- Franco, M.A. Circular economy at the micro level: A dynamic view of incumbents’ struggles and challenges in the textile industry. J. Clean. Prod. 2017, 168, 833–845. [Google Scholar] [CrossRef]

- Genovese, A.; Acquaye, A.A.; Figueroa, A.; Koh, S.L. Sustainable supply chain management and the transition towards a circular economy: Evidence and some applications. Omega 2017, 66, 344–357. [Google Scholar] [CrossRef]

- Govindan, K.; Soleimani, H.; Kannan, D. Reverse logistics and closed-loop supply chain: A comprehensive review to explore the future. Eur. J. Oper. Res. 2014, 2014, 603–626. [Google Scholar] [CrossRef]

- Zhou, C.; Zhang, P. Research on Reverse Logistics System Base on Circular Economy. In Proceedings of the 2007 International Conference on Wireless Communications, Networking and Mobile Computing, Shanghai, China, 21–25 September 2007; pp. 3744–3746. [Google Scholar]

- Rashid, A.; Asif, F.M.; Krajnik, P.; Nicolescu, C.M. Resource Conservative Manufacturing: An essential change in business and technology paradigm for sustainable manufacturing. J. Clean. Prod. 2013, 57, 166–177. [Google Scholar] [CrossRef]

- Goyal, S.; Sergi, B.S.; Jaiswal, M. How to design and implement social business models for base-of-the-pyramid (BoP) markets? Eur. J. Dev. Res. 2015, 27, 850–867. [Google Scholar] [CrossRef]

- Moreno, M.; De los Rios, C.; Rowe, Z.; Charnley, F. A Conceptual Framework for Circular Design. Sustainability 2016, 8, 937. [Google Scholar] [CrossRef]

- Coughlan, D.; Fitzpatrick, C.; McMahon, M. Repurposing end of life notebook computers from consumer WEEE as thin client computers—A hybrid end of life strategy for the Circular Economy in electronics. J. Clean. Prod. 2018, 192, 809–820. [Google Scholar] [CrossRef]

- Gassmann, O.; Frankenberger, K.; Csik, M.; Weiblen, T. The 4I-framework of business model innovation: A structured view on process phases and challenges. Int. J. Prod. Dev. 2013, 18, 249–273. [Google Scholar]

- Adams, K.; Osmani, M.; Thorpe, T.; Thornback, J. Circular economy in construction: current awareness, challenges and enablers. Available online: https://dspace.lboro.ac.uk/dspace-jspui/bitstream/2134/24136/3/jwarm.16.00011.pdf (accessed on 25 July 2018).

- Velte, C.J.; Steinhilper, R. Complexity in a Circular Economy: A Need for Rethinking Complexity Management Strategies. In Proceedings of the World Congress on Engineering, London, UK, 29 June–1 July 2016. [Google Scholar]

- Jabbour, C.J.C.; de Sousa Jabbour, A.B.L.; Sarkis, J.; Godinho Filho, M. Unlocking the circular economy through new business models based on large-scale data: An integrative framework and research agenda. Technol. Forecast. Soc. Chang. 2017. [Google Scholar] [CrossRef]

- Teece, D.J. Business models, business strategy and innovation. Long Range Plan. 2010, 43, 172–194. [Google Scholar] [CrossRef]

- Zott, C.; Amit, R. Business model design: An activity system perspective. Long Range Plan. 2010, 43, 216–226. [Google Scholar] [CrossRef]

- Yin, R.K.; Estudo de Caso: Planejamento e Métodos. Bookman Editora. Available online: https://saudeglobaldotorg1.files.wordpress.com/2014/02/yin-metodologia_da_pesquisa_estudo_de_caso_yin.pdf (accessed on 25 July 2018).

- Gibbs, G. Qualitative Data Analysis: Explorations with NVivo (Understanding Social Research); Open University Press: Buckingham, UK, 2002. [Google Scholar]

- Voss, C.; Tsikriktsis, N.; Frohlich, M. Case Research in Operations Management. Int. J. Oper. Prod. Manag. 2002, 22, 195–219. [Google Scholar] [CrossRef]

| Enabling factors (internal and external) | Authors |

Internal

| [27,29] |

External

| [30,32] |

| Strategies | Authors |

| Industrial symbiosis | [32] |

| Design of products and services | [43] |

| Extending the resource value | [33] |

| Reverse supply chain | [35,36] |

| Integration of information processing and traceability | [46,48,49] |

| Company | Sector of Activity | Services and Products | Features |

|---|---|---|---|

| A | Commercial refrigeration | Works with commercial refrigeration equipment at the end of life, turning it into new products, reverse logistics, and recycling. | Offers solutions and infrastructure to meet the market’s needs of reverse operation for white-goods appliances and commercial refrigeration. (Business Unit—Startup) |

| B | Electronic equipment | Uses sustainable solutions for the use of recycled raw materials and reverse logistics system. | Integrates eco-sustainable solutions geared for the consumer electronics market. (Business Unit—Startup) |

| Company | Sector of Activity | Professional Role | Location of Investigation |

|---|---|---|---|

| A | Commercial refrigeration |

|

|

| B | Electronic equipment |

|

|

| Strategies | Case A | Case B | Literature |

|---|---|---|---|

| Reverse logistics | Management of operations is responsible for two logistics plants: the correct opening and separation of compressors and home appliances | Developed an infrastructure for reverse logistics; knowledge of manufacturing to dismantle equipment | Aligned to [35,36,40,41] |

| Intersectoral collaboration/partnerships/supplier Engagement | Highlights partnerships, but not characterized as an ecosystem linked to sustainability as case B | Participates in a partners network, establishing an ecosystem of innovation and technology | Ecosystem strategy emerged from the case B study research |

| Technology-laboratory structure and interaction with universities | Evidences the development of technology and innovation of laboratory structure and researchers, interaction with universities | Showed the development of a sustainable innovation center (laboratory) and interaction with universities and the development of joint products | Strategy related to interaction with universities emerged from the case study research |

| Traceability and integration of information | The company did not show the use of sensing (RFID) in reverse logistics | Intense use of information technology (highlighting RFID) and partnership with the RFID Excellence Center | Aligned to [48,49] |

| Strategies for circular product design | Design for “technological cycle” | Projects developed with universities and research centers; design processes and expansion of service models and performance | Aligned to [45] |

| Enabling Factors | Case A | Case B | Literature |

|---|---|---|---|

| Legislation: PNRS | Drives the development of the business unit to comply with legislation | Encourages its partners to adopt processes to comply with the legislation | Factor emerged from the literature [27,28] |

| Organizational culture | Ease of adopting the principles of the circular economy by an independent business unit | Ease of adopting principles of the circular economy by an independent business unit | Factor emerged from the literature [27] |

| New organizational routines and processes | Automation of dismantling processes that allow a reduction in conversion costs, allowing a reduction of costs and leveraging the growth strategy Operation | New processes were created, people empowered, and machinery acquired | Factor emerged from the case study research |

| Independent business unit of a large company | Evidenced by case A | Evidenced by case B | Factor emerged from the case study research |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Mattos, C.A.; De Albuquerque, T.L.M. Enabling Factors and Strategies for the Transition Toward a Circular Economy (CE). Sustainability 2018, 10, 4628. https://doi.org/10.3390/su10124628

De Mattos CA, De Albuquerque TLM. Enabling Factors and Strategies for the Transition Toward a Circular Economy (CE). Sustainability. 2018; 10(12):4628. https://doi.org/10.3390/su10124628

Chicago/Turabian StyleDe Mattos, Claudia Aparecida, and Thiago Lourenço Meira De Albuquerque. 2018. "Enabling Factors and Strategies for the Transition Toward a Circular Economy (CE)" Sustainability 10, no. 12: 4628. https://doi.org/10.3390/su10124628

APA StyleDe Mattos, C. A., & De Albuquerque, T. L. M. (2018). Enabling Factors and Strategies for the Transition Toward a Circular Economy (CE). Sustainability, 10(12), 4628. https://doi.org/10.3390/su10124628