Institutional Pressures, Green Supply Chain Management Practices on Environmental and Economic Performance: A Two Theory View

Abstract

:1. Introduction

2. Theoretical Background and Hypotheses

2.1. Institutional Theory

2.2. Resource Dependence Theory (RDT)

2.3. Green Supply Chain Management (GSCM) Practices

- ▪

- Internal Environmental Management (IEM): IEM is the practice of incorporating GSCM into an organization’s strategy and showing their commitment through top management vision, middle management involvement, and spreading across all organizational members through the establishment of cross-functional teams [23]. Proactive companies focus on the IEM as a foundation for the whole GSCM change process.

- ▪

- Eco-Design (ECO): Eco-design is a proactive approach to handle environmental degradation and ensures compliance with pollution prevention at an early stage in the product lifecycle. It also helps in saving the possible costs to be incurred in the future for controlling the damages [49]. This practice takes the environment into consideration from the idea generation to the design of products that use less energy and fewer materials, and minimize toxic emissions, which can positively impact both environmental and economic performance [39,50,51].

- ▪

- Green Purchasing (GP): Green purchasing focuses on cooperating with suppliers to produce environmentally sustainable products [23]. GP is also defined as strategically planned purchasing with the awareness of environment-friendly requirements such as waste minimization and the possibility of reusing and recycling products [33].

- ▪

- Cooperation with Customers (CC): In today’s environment, businesses need to go beyond traditional thinking and acknowledge customers as strategic partners for collaborations on greening issues. CC is the process of involving them from eco-design to distribution, covering packaging as well as the practice of taking back the products [10,52,53]. A long-term trust-based relationship is required to share real-time information and efficiently perform all processes as mentioned above [54,55,56].

- ▪

- Investment Recovery (IR): Investment recovery is a green practice that involves regaining benefits from existing investments which were previously considered as waste [50]. IR treats the sale of excess inventories, scrap and used materials, and excess capital equipment as a strategic decision to obtain the maximum benefits from its resources [23,52].

2.4. Institutional Pressures and Internal GSCM Practices

2.5. Institutional Pressures and External GSCM Practices

2.6. Relationship of Internal and External GSCM Practices

2.7. Green Supply Chain Management (GSCM) Performance

2.8. Impact of Internal and External GSCM Practices on Environmental and Economic Performance

3. Research Method

3.1. Measures

3.2. Sample Design and Data Collection

3.3. Non-Response Bias

4. Analysis and Results

4.1. Sample Profile

4.2. Measurement Model Assessment

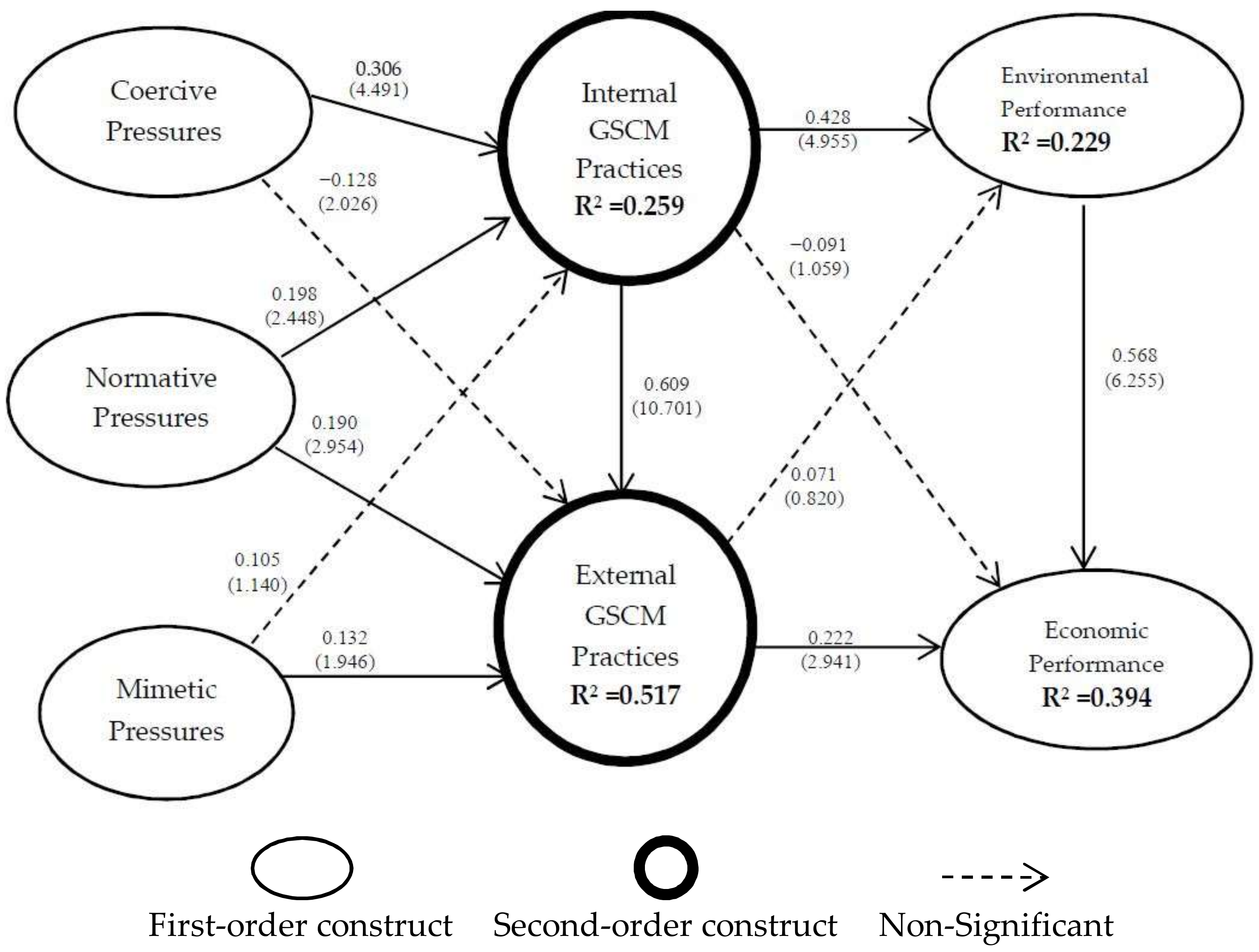

4.3. Structural Model Assessment

5. Discussion

6. Conclusions and Implications

Limitations and Future Research

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Papadopoulos, T.; Hazen, B.; Giannakis, M.; Roubaud, D. Examining the effect of external pressures and organizational culture on shaping performance measurement systems (PMS) for sustainability benchmarking: Some empirical findings. Int. J. Prod. Econ. 2017, 193, 63–76. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Sarkis, J. Manufacturing’s role in corporate environmental sustainability. Int. J. Oper. Manag. 2001, 2, 666–686. [Google Scholar] [CrossRef]

- Varma, A.; Peng, A.C. Moving goods sustainably in surface transportation. Inst. Transp. Eng. J. 2010, 80, 20–24. [Google Scholar]

- Centobelli, P.; Cerchione, R.; Esposito, E. Environmental sustainability in the service industry of transportation and logistics service providers: Systematic literature review and research directions. Transp. Res. Part D Transp. Environ. 2017, 53, 454–470. [Google Scholar] [CrossRef]

- Li, Z.; Xu, Y.; Deng, F.; Liang, X. Impacts of power structure on sustainable supply chain management. Sustainability 2017, 10, 55. [Google Scholar]

- Chandra Shukla, A.; Deshmukh, S.; Kanda, A. Environmentally responsive supply chains: Learnings from the Indian auto sector. J. Adv. Manag. Res. 2009, 6, 154–171. [Google Scholar] [CrossRef]

- De Giovanni, P. Do internal and external environmental management contribute to the triple bottom line? Int. J. Oper. Prod. Manag. 2012, 32, 265–290. [Google Scholar] [CrossRef]

- Geng, R.; Mansouri, S.A.; Aktas, E. The relationship between green supply chain management and performance: A meta-analysis of empirical evidences in Asian emerging economies. Int. J. Prod. Econ. 2017, 183, 245–258. [Google Scholar] [CrossRef]

- Vachon, S.; Klassen, R.D. Extending green practices across the supply chain: The impact of upstream and downstream integration. Int. J. Oper. Prod. Manag. 2006, 26, 795–821. [Google Scholar] [CrossRef]

- De Sousa Jabbour, A.B.L. Understanding the genesis of green supply chain management: Lessons from leading brazilian companies. J. Clean. Prod. 2015, 87, 385–390. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Esposito, E. Environmental sustainability and energy-efficient supply chain management: A review of research trends and proposed guidelines. Energies 2018, 11, 275. [Google Scholar] [CrossRef]

- De Sousa Jabbour, A.B.L.; Vazquez-Brust, D.; Jabbour, C.J.C.; Latan, H. Green supply chain practices and environmental performance in brazil: Survey, case studies, and implications for b2b. Ind. Mark. Manag. 2017, 66, 13–28. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K. Institutional-based antecedents and performance outcomes of internal and external green supply chain management practices. J. Purch. Supply Manag. 2013, 19, 106–117. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. J. Oper. Manag. 2004, 22, 265–289. [Google Scholar] [CrossRef]

- Kim, M.G.; Woo, C.; Rho, J.J.; Chung, Y. Environmental capabilities of suppliers for green supply chain management in construction projects: A case study in Korea. Sustainability 2016, 8, 82. [Google Scholar] [CrossRef]

- Gopal, P.; Thakkar, J. Sustainable supply chain practices: An empirical investigation on Indian automobile industry. Prod. Plan. Control 2016, 27, 49–64. [Google Scholar] [CrossRef]

- Teixeira, A.A.; Jabbour, C.J.C.; de Sousa Jabbour, A.B.L.; Latan, H.; de Oliveira, J.H.C. Green training and green supply chain management: Evidence from brazilian firms. J. Clean. Prod. 2016, 116, 170–176. [Google Scholar] [CrossRef]

- Yang, C.-S. An analysis of institutional pressures, green supply chain management, and green performance in the container shipping context. Transp. Res. Part D Transp. Environ. 2017, in press. [Google Scholar] [CrossRef]

- Vanalle, R.M.; Ganga, G.M.D.; Godinho Filho, M.; Lucato, W.C. Green supply chain management: An investigation of pressures, practices, and performance within the brazilian automotive supply chain. J. Clean. Prod. 2017, 151, 250–259. [Google Scholar] [CrossRef]

- Becker, J.-M.; Klein, K.; Wetzels, M. Hierarchical latent variable models in pls-sem: Guidelines for using reflective-formative type models. Long Range Plan. 2012, 45, 359–394. [Google Scholar] [CrossRef]

- Edwards, J.R. Multidimensional constructs in organizational behavior research: An integrative analytical framework. Organ. Res. Methods 2001, 4, 144–192. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K. Confirmation of a measurement model for green supply chain management practices implementation. Int. J. Prod. Econ. 2008, 111, 261–273. [Google Scholar] [CrossRef]

- Zhang, M.; Tse, Y.K.; Doherty, B.; Li, S.; Akhtar, P. Sustainable supply chain management: Confirmation of a higher-order model. Resour. Conserv. Recycl. 2018, 128, 206–221. [Google Scholar] [CrossRef]

- Hoejmose, S.U.; Adrien-Kirby, A.J. Socially and environmentally responsible procurement: A literature review and future research agenda of a managerial issue in the 21st century. J. Purch. Supply Manag. 2012, 18, 232–242. [Google Scholar] [CrossRef]

- Winter, M.; Knemeyer, A.M. Exploring the integration of sustainability and supply chain management: Current state and opportunities for future inquiry. Int. J. Phys. Distrib. Logist. Manag. 2013, 43, 18–38. [Google Scholar] [CrossRef]

- Ketchen, D.J.; Hult, G.T.M. Bridging organization theory and supply chain management: The case of best value supply chains. J. Oper. Manag. 2007, 25, 573–580. [Google Scholar] [CrossRef]

- Pfeffer, J.; Salancik, G.R. The External Control of Organizations: A Resource Dependence Perspective; Stanford University Press: Palo Alto, CA, USA, 2003. [Google Scholar]

- Wolf, J. The relationship between sustainable supply chain management, stakeholder pressure and corporate sustainability performance. J. Bus. Ethics 2014, 119, 317–328. [Google Scholar] [CrossRef]

- Sarkis, J. A boundaries and flows perspective of green supply chain management. Supply Chain Manag. Int. J. 2012, 17, 202–216. [Google Scholar] [CrossRef]

- Liu, C.-C.; Yu, Y.-H.; Wernick, I.K.; Chang, C.-Y. Using the electronic industry code of conduct to evaluate green supply chain management: An empirical study of Taiwan’s computer industry. Sustainability 2015, 7, 2787–2803. [Google Scholar] [CrossRef]

- Seuring, S.; Gold, S. Sustainability management beyond corporate boundaries: From stakeholders to performance. J. Clean. Prod. 2013, 56, 1–6. [Google Scholar] [CrossRef]

- De Sousa Jabbour, A.B.L.; de Oliveira Frascareli, F.C.; Jabbour, C.J.C. Green supply chain management and firms’ performance: Understanding potential relationships and the role of green sourcing and some other green practices. Resour. Conserv. Recycl. 2015, 104, 366–374. [Google Scholar] [CrossRef]

- Gualandris, J.; Kalchschmidt, M. Customer pressure and innovativeness: Their role in sustainable supply chain management. J. Purch. Supply Manag. 2014, 20, 92–103. [Google Scholar] [CrossRef]

- Scott, W.R. The adolescence of institutional theory. Adm. Sci. Q. 1987, 32, 493–511. [Google Scholar] [CrossRef]

- Williams, Z.; Lueg, J.E.; Taylor, R.D.; Cook, R.L. Why all the changes? An institutional theory approach to exploring the drivers of supply chain security (SCS). Int. J. Phys. Distrib. Logist. Manag. 2009, 39, 595–618. [Google Scholar] [CrossRef]

- Dimaggio, P.; Powell, W. The iron cage revisited: Institutional isomorphism and collective rationality in organizational fields. Am. Sociol. Rev. 1983, 48, 147–160. [Google Scholar] [CrossRef]

- De Grosbois, D. Corporate social responsibility reporting in the cruise tourism industry: A performance evaluation using a new institutional theory based model. J. Sustain. Tour. 2016, 24, 245–269. [Google Scholar] [CrossRef]

- Sarkis, J.; Gonzalez-Torre, P.; Adenso-Diaz, B. Stakeholder pressure and the adoption of environmental practices: The mediating effect of training. J. Oper. Manag. 2010, 28, 163–176. [Google Scholar] [CrossRef]

- Khalifa, M.; Davison, M. Sme adoption of it: The case of electronic trading systems. IEEE Trans. Eng. Manag. 2006, 53, 275–284. [Google Scholar] [CrossRef]

- Chu, S.H.; Yang, H.; Lee, M.; Park, S. The impact of institutional pressures on green supply chain management and firm performance: Top management roles and social capital. Sustainability 2017, 9, 764. [Google Scholar] [CrossRef]

- Walker, H.; Di Sisto, L.; McBain, D. Drivers and barriers to environmental supply chain management practices: Lessons from the public and private sectors. J. Purch. Supply Manag. 2008, 14, 69–85. [Google Scholar] [CrossRef]

- Hollos, D.; Blome, C.; Foerstl, K. Does sustainable supplier co-operation affect performance? Examining implications for the triple bottom line. Int. J. Prod. Res. 2012, 50, 2968–2986. [Google Scholar] [CrossRef]

- Sheu, J.-B. Green supply chain collaboration for fashionable consumer electronics products under third-party power intervention—A resource dependence perspective. Sustainability 2014, 6, 2832–2875. [Google Scholar] [CrossRef]

- Hillman, A.J.; Withers, M.C.; Collins, B.J. Resource dependence theory: A review. J. Manag. 2009, 35, 1404–1427. [Google Scholar] [CrossRef]

- Lai, K.; Wong, C.W.; Lam, J.S.L. Sharing environmental management information with supply chain partners and the performance contingencies on environmental munificence. Int. J. Prod. Econ. 2015, 164, 445–453. [Google Scholar] [CrossRef]

- Sarkis, J.; Zhu, Q.; Lai, K. An organizational theoretic review of green supply chain management literature. Int. J. Prod. Econ. 2011, 130, 1–15. [Google Scholar] [CrossRef]

- Mathivathanan, D.; Kannan, D.; Haq, A.N. Sustainable supply chain management practices in Indian automotive industry: A multi-stakeholder view. Resour. Conserv. Recycl. 2018, 128, 284–305. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in malaysia: A survey. Int. J. Prod. Econ. 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Green, K.W., Jr.; Zelbst, P.J.; Meacham, J.; Bhadauria, V.S. Green supply chain management practices: Impact on performance. Supply Chain Manag. Int. J. 2012, 17, 290–305. [Google Scholar] [CrossRef]

- Zsidisin, G.A.; Siferd, S.P. Environmental purchasing: A framework for theory development. Eur. J. Purch. Supply Manag. 2001, 7, 61–73. [Google Scholar] [CrossRef]

- Chan, R.Y.; He, H.; Chan, H.K.; Wang, W.Y. Environmental orientation and corporate performance: The mediation mechanism of green supply chain management and moderating effect of competitive intensity. Ind. Mark. Manag. 2012, 41, 621–630. [Google Scholar] [CrossRef]

- Bouzon, M.; Govindan, K.; Rodriguez, C.M.T. Evaluating barriers for reverse logistics implementation under a multiple stakeholders’ perspective analysis using grey decision making approach. Resour. Conserv. Recycl. 2018, 128, 315–335. [Google Scholar] [CrossRef]

- Saeed, A. Role of TEAM (Trust, Ethics, Alignment, & Motivation) for Successful Implementation of Supply Chain Management of Retail Store Chains in Pakistan: A Conceptual Model. In Proceedings of the 1st International Conference on Business Management (ICoBM), Lahore, Pakistan, 5–6 January 2011; Available online: https://cscr.umt.edu.pk/Research-and-Publications/Research-Papers.aspx (accessed on 9 May 2018).

- Marshall, D.; McCarthy, L.; Heavey, C.; McGrath, P. Environmental and social supply chain management sustainability practices: Construct development and measurement. Prod. Plan. Control 2015, 26, 673–690. [Google Scholar] [CrossRef]

- Eltayeb, T.K.; Zailani, S.; Ramayah, T. Green supply chain initiatives among certified companies in Malaysia and environmental sustainability: Investigating the outcomes. Resour. Conserv. Recycl. 2011, 55, 495–506. [Google Scholar] [CrossRef]

- González-Benito, J.; González-Benito, Ó. Environmental proactivity and business performance: An empirical analysis. Omega 2005, 33, 1–15. [Google Scholar] [CrossRef]

- Hanim Mohamad Zailani, S.; Eltayeb, T.K.; Hsu, C.-C.; Choon Tan, K. The impact of external institutional drivers and internal strategy on environmental performance. Int. J. Oper. Prod. Manag. 2012, 32, 721–745. [Google Scholar] [CrossRef]

- Yu, W.; Ramanathan, R. An empirical examination of stakeholder pressures, green operations practices and environmental performance. Int. J. Prod. Res. 2015, 53, 6390–6407. [Google Scholar] [CrossRef]

- Yu, J.; Welford, R.; Hills, P. Industry responses to eu weee and rohs directives: Perspectives from China. Corp. Soc. Responsib. Environ. Manag. 2006, 13, 286–299. [Google Scholar] [CrossRef]

- Esfahbodi, A.; Zhang, Y.; Watson, G.; Zhang, T. Governance pressures and performance outcomes of sustainable supply chain management–an empirical analysis of uk manufacturing industry. J. Clean. Prod. 2017, 155, 66–78. [Google Scholar] [CrossRef]

- Seles, R.P.; Michel, B.; Jabbour, A.B.L.S.; Dangelico, R.M.; Jabbour, C.J.C. Green Supply Chain Practices as a Consequence of the Green Bullwhip Effect: Understanding the Relationship. Available online: https://strathprints.strath.ac.uk/57056/ (accessed on 8 May 2018).

- Saeed, A.; Yun, J.; Priyankara, H.P.R. Globalization and Green Supply Chain Management: Role of Multinational Companies in Pakistan—An Institutional Theory Perspective. In Proceedings of the International Conference on Innovation and Management (ICIM2016), Kualalumpur, Malaysia, 28–30 November 2016. [Google Scholar]

- Zhu, Q.; Geng, Y.; Fujita, T.; Hashimoto, S. Green supply chain management in leading manufacturers: Case studies in japanese large companies. Manag. Res. Rev. 2010, 33, 380–392. [Google Scholar] [CrossRef]

- Sancha, C.; Longoni, A.; Giménez, C. Sustainable supplier development practices: Drivers and enablers in a global context. J. Purch. Supply Manag. 2015, 21, 95–102. [Google Scholar] [CrossRef]

- Beske, P.; Koplin, J.; Seuring, S. The use of environmental and social standards by german first-tier suppliers of the volkswagen ag. Corp. Soc. Responsib. Environ. Manag. 2008, 15, 63–75. [Google Scholar] [CrossRef]

- Hoejmose, S.U.; Grosvold, J.; Millington, A. The effect of institutional pressure on cooperative and coercive ‘green’supply chain practices. J. Purch. Supply Manag. 2014, 20, 215–224. [Google Scholar] [CrossRef]

- Vachon, S.; Klassen, R.D. Environmental management and manufacturing performance: The role of collaboration in the supply chain. Int. J. Prod. Econ. 2008, 111, 299–315. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K. Green supply chain management innovation diffusion and its relationship to organizational improvement: An ecological modernization perspective. J. Eng. Technol. Manag. 2012, 29, 168–185. [Google Scholar] [CrossRef]

- Beamon, B.M. Measuring supply chain performance. Int. J. Oper. Prod. Manag. 1999, 19, 275–292. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Patel, C.; McGaughey, R.E. A framework for supply chain performance measurement. Int. J. Prod. Econ. 2004, 87, 333–347. [Google Scholar] [CrossRef]

- Morais, D.; Barbieri, J.C. Social Performance Measurement for Sustainable Supply Chain Management. Available online: https://www.researchgate.net/publication/303365409_Social_performance_measurement_for_sustainable_supply_chain_management (accessed on 8 May 2018).

- Laosirihongthong, T.; Adebanjo, D.; Choon Tan, K. Green supply chain management practices and performance. Ind. Manag. Data Syst. 2013, 113, 1088–1109. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K. Examining the effects of green supply chain management practices and their mediations on performance improvements. Int. J. Prod. Res. 2012, 50, 1377–1394. [Google Scholar] [CrossRef]

- Zailani, S.; Govindan, K.; Iranmanesh, M.; Shaharudin, M.R.; Chong, Y.S. Green innovation adoption in automotive supply chain: The malaysian case. J. Clean. Prod. 2015, 108, 1115–1122. [Google Scholar] [CrossRef]

- Rao, P.; Holt, D. Do green supply chains lead to competitiveness and economic performance? Int. J. Oper. Prod. Manag. 2005, 25, 898–916. [Google Scholar] [CrossRef]

- Huang, X. Green Supply Chain Management in Manufacturing Small and Medium-Sized Enterprises: Perspective from Chang Chiang Delta. Ph.D. Thesis, University of Liverpool, Liverpool, UK, 2013. [Google Scholar]

- Zhu, Q.; Sarkis, J.; Lai, K. Green supply chain management implications for “closing the loop”. Transp. Res. Part E Logist. Transp. Rev. 2008, 44, 1–18. [Google Scholar] [CrossRef]

- Mitra, S.; Datta, P.P. Adoption of green supply chain management practices and their impact on performance: An exploratory study of Indian manufacturing firms. Int. J. Prod. Res. 2014, 52, 2085–2107. [Google Scholar] [CrossRef]

- Esfahbodi, A.; Zhang, Y.; Watson, G. Sustainable supply chain management in emerging economies: Trade-offs between environmental and cost performance. Int. J. Prod. Econ. 2016, 181, 350–366. [Google Scholar] [CrossRef]

- Lee, S.M.; Tae Kim, S.; Choi, D. Green supply chain management and organizational performance. Ind. Manag. Data Syst. 2012, 112, 1148–1180. [Google Scholar] [CrossRef]

- Saeed, A.; Priyankara, H.P.R.; Naotunna, N.P.G.S.I. Role of normative pressures to adopt green supply chain management practices and their impact on environmental and economic performance. In Proceedings of the International Conference on Innovation and Management, Swansi, UK, 28–29 September 2017. [Google Scholar]

- Bowen, F.E.; Cousins, P.D.; Lamming, R.C.; Farukt, A.C. The role of supply management capabilities in green supply. Prod. Oper. Manag. 2001, 10, 174–189. [Google Scholar] [CrossRef]

- Eduardo, O.; Moneva, J.M.; Álvarez, I. Sustainable supply chain and company performance: A global examination. Supply Chain Manag. Int. J. 2014, 19, 332–350. [Google Scholar]

- Yang, C.-S.; Lu, C.-S.; Haider, J.J.; Marlow, P.B. The effect of green supply chain management on green performance and firm competitiveness in the context of container shipping in taiwan. Transp. Res. Part E Logist. Transp. Rev. 2013, 55, 55–73. [Google Scholar] [CrossRef]

- Beske-Janssen, P.; Johnson, M.P.; Schaltegger, S. 20 years of performance measurement in sustainable supply chain management–what has been achieved? Supply Chain Manag. Int. J. 2015, 20, 664–680. [Google Scholar] [CrossRef]

- Huo, B.; Han, Z.; Zhao, X.; Zhou, H.; Wood, C.H.; Zhai, X. The impact of institutional pressures on supplier integration and financial performance: Evidence from China. Int. J. Prod. Econ. 2013, 146, 82–94. [Google Scholar] [CrossRef]

- Oke, A.; Prajogo, D.I.; Jayaram, J. Strengthening the innovation chain: The role of internal innovation climate and strategic relationships with supply chain partners. J. Supply Chain Manag. 2013, 49, 43–58. [Google Scholar] [CrossRef]

- Okumus, B.; Ali, F.; Bilgihan, A.; Ozturk, A.B. Psychological factors influencing customers’ acceptance of smartphone diet apps when ordering food at restaurants. Int. J. Hosp. Manag. 2018, 72, 67–77. [Google Scholar] [CrossRef]

- Younis, H.; Sundarakani, B.; Vel, P. The Impact of the Dimensions of Green Supply Chain Management Practices on Corporate Performance; Emerald Group Publishing Limited: Bingley, UK, 2016. [Google Scholar]

- Fornell, C.; Larcker, D.F. Evaluating structural equation models with unobservable variables and measurement error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Burnett, R.D.; Hansen, D.R.; Quintana, O. Eco-efficiency: Achieving productivity improvements through environmental cost management. Account. Public Interest 2007, 7, 66–92. [Google Scholar] [CrossRef]

- Ringle, C.M.; Wende, S.; Becker, J.-M. Smartpls 3.2.7; SmartPLS GmbH: Boenningstedt, Germany, 2015. [Google Scholar]

- Field, A. Discovering Statistics Using SPSS; Sage Publications: Thousand Oaks, CA, USA, 2009. [Google Scholar]

- Sarstedt, M.; Ringle, C.M.; Hair, J.F. Partial least squares structural equation modeling. In Handbook of Market Research; Springer: New York, NY, USA, 2017; pp. 1–40. [Google Scholar]

- Henseler, J.; Ringle, C.M.; Sarstedt, M. A new criterion for assessing discriminant validity in variance-based structural equation modeling. J. Acad. Mark. Sci. 2015, 43, 115–135. [Google Scholar] [CrossRef]

- Peng, D.X.; Lai, F. Using partial least squares in operations management research: A practical guideline and summary of past research. J. Oper. Manag. 2012, 30, 467–480. [Google Scholar] [CrossRef]

- Ringle, C.M.; Sarstedt, M.; Mitchell, R.; Gudergan, S.P. Partial least squares structural equation modeling in HRM research. Int. J. Hum. Resour. Manag. 2018, 1–27. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Ali, S.S. Exploring the relationship between leadership, operational practices, institutional pressures and environmental performance: A framework for green supply chain. Int. J. Prod. Econ. 2015, 160, 120–132. [Google Scholar] [CrossRef]

- Kauppi, K.; Hannibal, C. Institutional pressures and sustainability assessment in supply chains. Supply Chain Manag. Int. J. 2017, 22, 458–472. [Google Scholar] [CrossRef]

- Ramanathan, U.; Gunasekaran, A. Supply chain collaboration: Impact of success in long-term partnerships. Int. J. Prod. Econ. 2014, 147, 252–259. [Google Scholar] [CrossRef]

- Eltayeb, T.K.; Zailani, S. Going green through green supply chain initiatives towards environmental sustainability. Oper. Supply Chain Manag. 2009, 2, 93–110. [Google Scholar]

- Bhakoo, V.; Choi, T. The iron cage exposed: Institutional pressures and heterogeneity across the healthcare supply chain. J. Oper. Manag. 2013, 31, 432–449. [Google Scholar] [CrossRef]

- Gholami, R.; Sulaiman, A.B.; Ramayah, T.; Molla, A. Senior managers’ perception on green information systems (is) adoption and environmental performance: Results from a field survey. Inf. Manag. 2013, 50, 431–438. [Google Scholar] [CrossRef]

- Saeed, A.; Yun, J. The impact of internal environmental management on environmental performance: Assessing the mediating role of open innovation and moderating role of absorptive capacity. Eur. J. Bus. Manag. 2017, 9, 47–53. [Google Scholar]

- Zhu, Q.; Sarkis, J. The moderating effects of institutional pressures on emergent green supply chain practices and performance. Int. J. Prod. Res. 2007, 45, 4333–4355. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Geng, Y. Green supply chain management in China: Pressures, practices and performance. Int. J. Oper. Prod. Manag. 2005, 25, 449–468. [Google Scholar] [CrossRef]

- De Giovanni, P.; Vinzi, V.E. Covariance versus component-based estimations of performance in green supply chain management. Int. J. Prod. Econ. 2012, 135, 907–916. [Google Scholar] [CrossRef]

- Dubey, R.; Bag, S.; Ali, S.S. Green supply chain practices and its impact on organisational performance: An insight from Indian rubber industry. Int. J. Logist. Syst. Manag. 2014, 19, 20–42. [Google Scholar] [CrossRef]

- Zhu, Q.; Geng, Y.; Sarkis, J. Shifting chinese organizational responses to evolving greening pressures. Ecol. Econ. 2016, 121, 65–74. [Google Scholar] [CrossRef]

| Cities | Lahore | Faisalabad | Sialkot | |||

| 78 (37.68%) | 58 (28.02%) | 71 (34.30%) | ||||

| Industry | Textile | Chemicals | Leather | Pharmaceuticals | Sports Goods | Others |

| 57 (27.54%) | 28 (13.53%) | 51 (24.64%) | 26 (12.56%) | 27 (13.04%) | 18 (8.70%) | |

| Number of Employees | <200 | 200–500 | 501–750 | 751–1000 | 1001–2000 | >2000 |

| 49 (23.67%) | 33 (15.94%) | 19 (9.18%) | 26 (12.56%) | 38 (18.36%) | 42 (20.29%) | |

| Designation | CEO | Manager Supply Chain | Operations Manager | Quality Manager | Manager R&D | Finance Manager |

| 15 (7.25) | 53 (25.60) | 44 (21.26%) | 38 (18.36%) | 29 (14.01%) | 28 (13.53%) | |

| Construct | Items | Loading | Mean | Standard Deviation | Skew-ness | Kurtosis | T Value |

|---|---|---|---|---|---|---|---|

| Coercive Pressures (CP): Alpha = 0.812; CR = 0.874; AVE = 0.634 | CP1 | 0.791 | 4.282 | 0.879 | −1.454 | 2.055 | 13.89 |

| CP2 | 0.75 | 4.057 | 0.84 | −0.688 | 0.128 | 14.872 | |

| CP3 | 0.793 | 4.139 | 0.944 | −1.119 | 1.143 | 13.439 | |

| CP4 | 0.847 | 3.788 | 0.939 | −0.532 | 0.059 | 28.048 | |

| Normative Pressures (NP): Alpha = 0.682; CR = 0.805; AVE = 0.509 | NP2 | 0.736 | 3.665 | 1.103 | −0.699 | −0.004 | 14.199 |

| NP3 | 0.743 | 3.525 | 1.154 | −0.453 | −0.622 | 11.742 | |

| NP4 | 0.744 | 4.041 | 0.962 | −0.961 | 0.613 | 15.198 | |

| Mimetic Pressures (MP): Alpha = 0.799; CR = 0.883; AVE = 0.715 | MP1 | 0.865 | 3.687 | 1.079 | −0.641 | −0.142 | 22.354 |

| MP2 | 0.885 | 3.481 | 1.098 | −0.492 | −0.341 | 26.37 | |

| MP3 | 0.785 | 3.744 | 1.004 | −0.827 | 0.441 | 14.092 | |

| Eco-Design (ECO): Alpha = 0.618; CR = 0.839; AVE = 0.723 | ECO1 | 0.837 | 3.873 | 0.976 | −0.996 | 0.791 | 19.769 |

| ECO3 | 0.864 | 3.88 | 0.973 | −0.915 | 0.775 | 24.765 | |

| Internal Environmental Management (IEM): Alpha = 0.894; CR = 0.916; AVE = 0.611 | IEM1 | 0.729 | 3.984 | 0.963 | −0.93 | 0.563 | 15.181 |

| IEM2 | 0.77 | 3.883 | 0.942 | −0.516 | −0.314 | 16.729 | |

| IEM3 | 0.793 | 3.772 | 1.037 | −0.577 | −0.275 | 23.653 | |

| IEM4 | 0.798 | 3.706 | 1.11 | −0.569 | −0.449 | 28.524 | |

| IEM8 | 0.823 | 3.652 | 0.977 | −0.81 | 0.615 | 17.943 | |

| IEM9 | 0.819 | 3.665 | 1.083 | −0.82 | 0.258 | 20.886 | |

| Green Purchase (GP): Alpha = 0.90; CR = 0.921; AVE = 0.626 | GP2 | 0.727 | 3.668 | 1.047 | −0.783 | 0.189 | 17.318 |

| GP3 | 0.788 | 3.301 | 1.148 | −0.293 | −0.607 | 15.325 | |

| GP5 | 0.824 | 3.063 | 1.159 | −0.148 | −0.761 | 22.987 | |

| GP6 | 0.749 | 3.402 | 1.175 | −0.587 | −0.5 | 16.969 | |

| GP7 | 0.852 | 3.196 | 1.144 | −0.314 | −0.753 | 28.084 | |

| GP8 | 0.760 | 3.32 | 1.134 | −0.495 | −0.426 | 15.594 | |

| GP9 | 0.831 | 3.225 | 1.203 | −0.528 | −0.568 | 27.225 | |

| Investment Recovery (IR): Alpha = 0.777; CR = 0.899; AVE = 0.817 | IR4 | 0.891 | 3.456 | 1.137 | −0.416 | −0.646 | 20.036 |

| IR5 | 0.917 | 3.348 | 1.125 | −0.556 | −0.406 | 20.474 | |

| Cooperation with Customers (CC): Alpha = 0.86; CR = 0.905; AVE = 0.705 | CC1 | 0.871 | 3.342 | 1.118 | −0.472 | −0.382 | 24.215 |

| CC2 | 0.883 | 3.557 | 1.099 | −0.591 | −0.149 | 15.977 | |

| CC3 | 0.8 | 3.481 | 1.083 | −0.581 | 0.022 | 14.505 | |

| CC4 | 0.801 | 3.38 | 1.126 | −0.4 | −0.447 | 15.038 | |

| Environmental Performance: Alpha = 0.913; CR = 0.933; AVE = 0.698 | EnvtP1 | 0.828 | 3.623 | 1.111 | −0.953 | 0.398 | 32.423 |

| EnvtP2 | 0.843 | 3.737 | 1.027 | −0.954 | 0.668 | 30.452 | |

| EnvtP3 | 0.866 | 3.655 | 1.101 | −0.726 | −0.151 | 39.767 | |

| EnvtP4 | 0.822 | 3.82 | 1.017 | −0.957 | 0.751 | 31.11 | |

| EnvtP5 | 0.834 | 3.782 | 1.016 | −0.917 | 0.801 | 34.956 | |

| EnvtP6 | 0.819 | 3.873 | 0.953 | −1.001 | 1.161 | 21.038 | |

| Economic Performance: Alpha = 0.831; CR = 0.881; AVE = 0.599 | EconP1 | 0.755 | 3.636 | 1.078 | −0.576 | −0.291 | 27.617 |

| EconP2 | 0.803 | 3.886 | 0.924 | −0.811 | 0.696 | 28.011 | |

| EconP3 | 0.829 | 3.585 | 0.929 | −0.37 | −0.016 | 28.951 | |

| EconP4 | 0.815 | 3.443 | 1.031 | −0.325 | −0.274 | 23.943 | |

| EconP5 | 0.655 | 3.658 | 0.96 | −0.478 | 0.101 | 11.948 |

| CC | CP | ECO | Econ | Envt | GP | IEM | IR | MP | NP | |

|---|---|---|---|---|---|---|---|---|---|---|

| CC | 0.744 | 0.262 | 0.433 | 0.293 | 0.292 | 0.806 | 0.650 | 0.470 | 0.445 | 0.416 |

| CP | 0.246 | 0.801 | 0.446 | 0.267 | 0.306 | 0.358 | 0.460 | 0.185 | 0.637 | 0.686 |

| ECO | 0.360 | 0.369 | 0.756 | 0.382 | 0.506 | 0.416 | 0.501 | 0.364 | 0.326 | 0.283 |

| Econ | 0.255 | 0.223 | 0.307 | 0.787 | 0.681 | 0.368 | 0.297 | 0.446 | 0.201 | 0.252 |

| Envt | 0.264 | 0.271 | 0.427 | 0.603 | 0.853 | 0.303 | 0.402 | 0.437 | 0.248 | 0.214 |

| GP | 0.710 | 0.337 | 0.350 | 0.313 | 0.285 | 0.754 | 0.839 | 0.531 | 0.474 | 0.583 |

| IEM | 0.571 | 0.406 | 0.412 | 0.262 | 0.368 | 0.753 | 0.763 | 0.484 | 0.440 | 0.571 |

| IR | 0.365 | 0.156 | 0.259 | 0.346 | 0.356 | 0.417 | 0.374 | 0.795 | 0.228 | 0.362 |

| MP | 0.365 | 0.507 | 0.250 | 0.132 | 0.204 | 0.409 | 0.363 | 0.176 | 0.819 | 0.774 |

| NP | 0.338 | 0.502 | 0.220 | 0.201 | 0.177 | 0.472 | 0.448 | 0.260 | 0.556 | 0.771 |

| CP | NP | MP | Internal * | External * | Envt | Econ | |

|---|---|---|---|---|---|---|---|

| Alpha | 0.812 | 0.682 | 0.799 | 0.637 | 0.748 | 0.913 | 0.831 |

| CR | 0.874 | 0.805 | 0.833 | 0.844 | 0.794 | 0.933 | 0.881 |

| AVE | 0.634 | 0.509 | 0.715 | 0.643 | 0.670 | 0.698 | 0.599 |

| CP | Econ | Envt | External | Internal | MP | NP | |

|---|---|---|---|---|---|---|---|

| CP | 0.802 | 0.267 | 0.306 | 0.360 | 0.622 | 0.637 | 0.686 |

| Econ | 0.222 | 0.787 | 0.681 | 0.468 | 0.431 | 0.201 | 0.252 |

| Envt | 0.271 | 0.605 | 0.853 | 0.442 | 0.583 | 0.248 | 0.214 |

| External | 0.310 | 0.363 | 0.357 | 0.818 | 0.887 | 0.511 | 0.597 |

| Internal | 0.461 | 0.314 | 0.442 | 0.644 | 0.855 | 0.529 | 0.560 |

| MP | 0.506 | 0.129 | 0.204 | 0.402 | 0.375 | 0.819 | 0.774 |

| NP | 0.501 | 0.203 | 0.182 | 0.451 | 0.402 | 0.557 | 0.769 |

| No. | Hypotheses | Beta | T Value | p-Value | Bias Corrected Confidence Interval | Decision |

|---|---|---|---|---|---|---|

| 1 | H1a: CP → Internal | 0.306 | 4.491 | 0.000 | [0.169, 0.432] | Supported |

| 2 | H1b: NP → Internal | 0.198 | 2.448 | 0.014 | [0005, 0.330] | Supported |

| 3 | H1c: MP → Internal | 0.105 | 1.140 | 0.254 | [−0.053, 0.299] | Not Supported |

| 4 | H2a: CP → External | −0.128 | 2.026 | 0.043 | [−0.253, −0.006] | Not Supported |

| 5 | H2b: NP → External | 0.190 | 2.954 | 0.003 | [0.082, 0.333] | Supported |

| 6 | H2c: MP → External | 0.132 | 1.946 | 0.052 | [0.007, 0.281] | Supported |

| 7 | H3: Internal → External | 0.609 | 10.701 | 0.000 | [0.451, 0.668] | Supported |

| 8 | H4a: Internal → Environment | 0.428 | 4.955 | 0.000 | [0.187, 0.516] | Supported |

| 9 | H4b: Internal → Economic | −0.091 | 1.059 | 0.290 | [−0.221, 0.100] | Not Supported |

| 10 | H5a: External → Environment | 0.071 | 0.820 | 0.412 | [−0.034, 0.278] | Not Supported |

| 11 | H5b: External → Economic | 0.222 | 2.941 | 0.003 | [0.059, 0.345] | Supported |

| 12 | H6: Environment → Economic | 0.568 | 6.255 | 0.000 | [0.363, 0.725] | Supported |

| f2 in Relation to | ||||||

|---|---|---|---|---|---|---|

| R2 | Q2 | Internal | External | Envt | Econ | |

| CP | - | - | 0.086 | 0.021 | - | - |

| NP | - | - | 0.034 | 0.044 | - | - |

| MP | - | - | 0.009 | 0.024 | - | - |

| Internal | 0.259 | 0.164 | - | 0.578 | 0.131 | 0.006 |

| External | 0.517 | 0.289 | - | - | - | - |

| Envt | 0.229 | 0.137 | - | - | - | 0.409 |

| Econ | 0.394 | 0.224 | - | - | - | - |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saeed, A.; Jun, Y.; Nubuor, S.A.; Priyankara, H.P.R.; Jayasuriya, M.P.F. Institutional Pressures, Green Supply Chain Management Practices on Environmental and Economic Performance: A Two Theory View. Sustainability 2018, 10, 1517. https://doi.org/10.3390/su10051517

Saeed A, Jun Y, Nubuor SA, Priyankara HPR, Jayasuriya MPF. Institutional Pressures, Green Supply Chain Management Practices on Environmental and Economic Performance: A Two Theory View. Sustainability. 2018; 10(5):1517. https://doi.org/10.3390/su10051517

Chicago/Turabian StyleSaeed, Amer, Yun Jun, Saviour Ayertey Nubuor, Hewawasam Puwakpitiyage Rasika Priyankara, and Mahabaduge Prasad Fernando Jayasuriya. 2018. "Institutional Pressures, Green Supply Chain Management Practices on Environmental and Economic Performance: A Two Theory View" Sustainability 10, no. 5: 1517. https://doi.org/10.3390/su10051517

APA StyleSaeed, A., Jun, Y., Nubuor, S. A., Priyankara, H. P. R., & Jayasuriya, M. P. F. (2018). Institutional Pressures, Green Supply Chain Management Practices on Environmental and Economic Performance: A Two Theory View. Sustainability, 10(5), 1517. https://doi.org/10.3390/su10051517