Evaluating the Link between Low Carbon Reductions Strategies and Its Performance in the Context of Climate Change: A Carbon Footprint of a Wood-Frame Residential Building in Quebec, Canada

Abstract

:1. Introduction

2. Conceptual Framework and Methods

2.1. Carbon Footprint Approach

- Scope 1—occur from sources that are owned or controlled by the company, also referred to as direct GHGs;

- Scope 2—emissions from the generation of purchased electricity consumed by a company, also referred to as energy indirect GHGs;

- Scope 3—emissions that are a consequence of the activities of the company but occur from sources not owned or controlled by the company, cradle to end of life approach, also referred to as other indirect GHGs.

2.2. Carbon Footprint of Base Scenario

2.2.1. Case Study Building

Prefabrication

2.2.2. Functional Unit and System Boundary

2.2.3. Life Cycle Inventory

Materials Acquisition and Material Production

Assembly

2.2.4. Life Cycle Impact Assessment (LCIA)

2.2.5. Characterization Factor of Biogenic Carbon in LCA

2.3. Description of Carbon Reduction Strategies

3. Results and Discussions

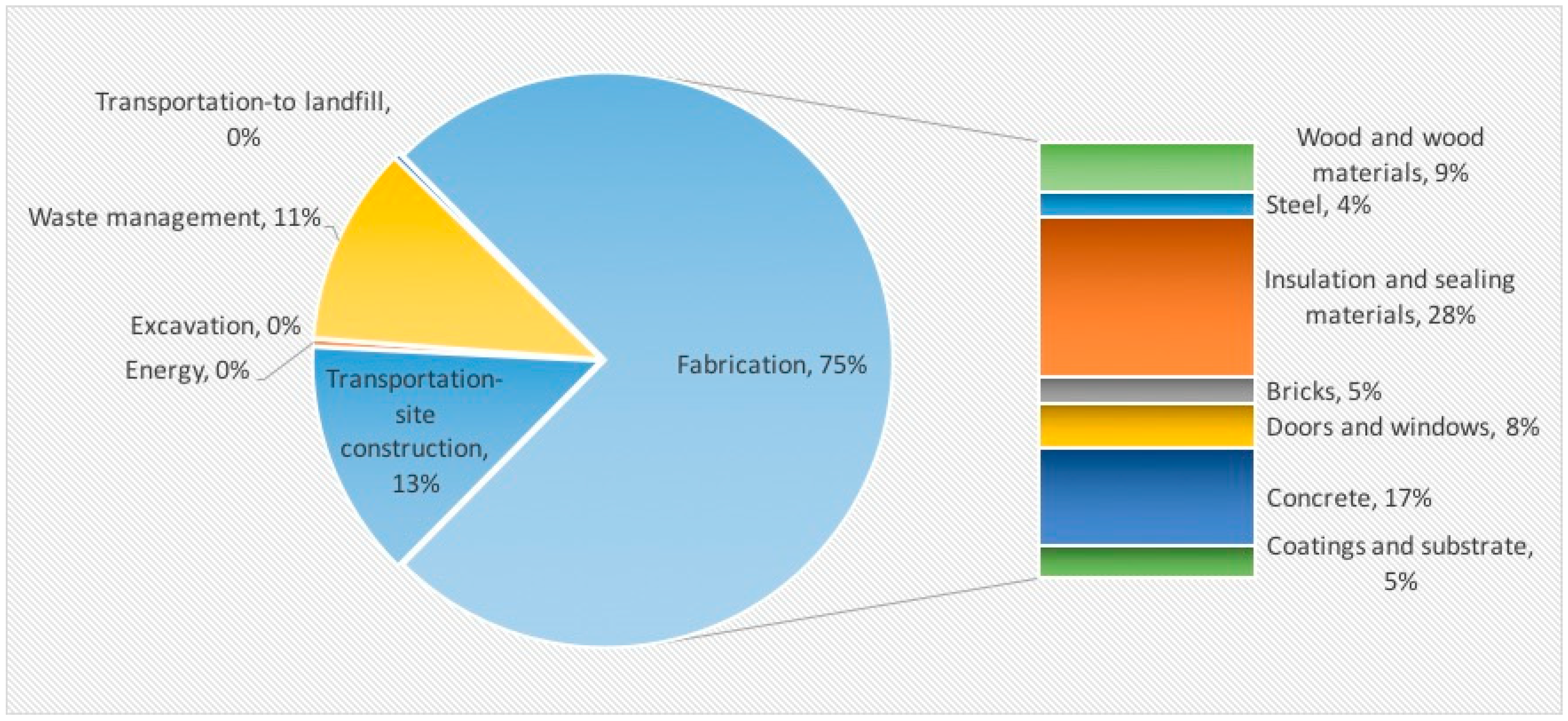

3.1. CFP of the Baseline Scenario

3.2. Carbon Footprint of Buildings Materials

3.3. Implementation of Carbon Reduction Strategies

3.3.1. Material Recycle and Reuse Benefits

3.3.2. Local Sourcing of Materials and Components and Adoption of Biofuels

Local Materials

Adoption of Biofuels

3.3.3. Low Carbon Materials

Cellulose

Unfired Clay Bricks

Low Carbon Concrete

3.4. Comparison and Ranking of Carbon Reductions Strategies vs. Base Scenario

3.5. Carbon Reduction Strategies and Climate Change

4. Conclusions

- The results of this study support the positive use of prefabricated approach in buildings as an alternative construction method based on wood-frame-materials in Quebec.

- The above results imply that from the perspective of overall performance, low-carbon strategies are beneficial to climate change mitigation technology that can balance operational performance and environmental performance to achieve the zero emissions buildings’.

- By using the CO2-e emissions as global indicator, the CC reduction per m2 floor area in baseline scenario can reach up to 25% fewer emissions than traditional buildings built with steel or concrete.

- During the life-cycle of baseline scenario, total embodied carbon emissions of 275 kg CO2-e was calculated. The fabrication of building material phase contributed the most (75%) to the carbon emissions, while transportation (13%), construction (1%) and waste management (11%) contribute to 25%.

- The four actions implemented have an environmental benefit in reducing CO2-e emissions. The analysis of low carbon strategies showed an overall carbon reduction approximately 104 kg CO2-e (38%) in comparison to baseline scenario.

- The CO2-e emissions reduction in the building sector as climate change mitigation is perfectly feasible by following different working lines. The four actions implemented have an environmental benefit in reducing GHG emissions. The particleboard production scenario has a greater environmental benefit when considering temporary carbon storage. The ranking of actions can be stablished as follows:

- Use of particle board production using wood wastes (14.6%)

- Use of local source for materials and components (11.7%)

- Substitution of concrete composition (3.8%)

- Use of light clay bricks (3.6%)

- Use of hardwood flooring system (3.1%)

- Reduction of rate wastes (wood, concrete and steel) (1%)

- Use of cellulose insulation (0.8%)

- Use of B20 blend as fuel for on-site machines. (0.1%)

Author Contributions

Acknowledgments

Conflicts of Interest

References

- IPCC. Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge: New York, NY, USA, 2013. [Google Scholar]

- UNEP. The Emissions Gap Report 2016. The Emissions Gap Report 2016. United Nations Environment Programme (UNEP); United Nations Environment Programme: Nairobi, Kenya, 2016. [Google Scholar]

- Dechezleprêtre, A.; Glachant, M.; Haščič, I.; Johnstone, N.; Ménière, Y. Invention and transfer of climate change-mitigation technologies: A global analysis. Rev. Environ. Econ. Policy 2011, 5, 109–130. [Google Scholar] [CrossRef] [Green Version]

- Qin, Z.; Zhuang, Q.; Cai, X.; He, Y.; Huang, Y.; Jiang, D.; Lin, E.; Liu, Y.; Tang, Y.; Wang, M.Q. Biomass and biofuels in China: Toward bioenergy resource potentials and their impacts on the environment. Renew. Sustain. Energy Rev. 2017. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, J.; Lin, Y.; Si, Y.; Huang, C.; Yang, J.; Huang, B.; Li, W. Present situation and future prospect of renewable energy in China. Renew. Sustain. Energy Rev. 2017, 76, 865–871. [Google Scholar] [CrossRef]

- Graham, P.; Henry Abanda, F.; Korytarova, K.; Ürge-Vorsatz, D.; Zain Ahmed, A.; Akbari, H.; Bertoldi, P.; Cabeza, L.F.; Eyre, N.; Gadgil, A.; et al. Buildings. In Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Volker Krey: Cambridge, UK; New York, NY, USA, 2014. [Google Scholar]

- Roh, S.; Tae, S.; Suk, S.J.; Ford, G. Evaluating the embodied environmental impacts of major building tasks and materials of apartment buildings in Korea. Renew. Sustain. Energy Rev. 2017, 73, 135–144. [Google Scholar] [CrossRef]

- Shadram, F.; Johansson, T.D.; Lu, W.; Schade, J.; Olofsson, T. An integrated BIM-based framework for minimizing embodied energy during building design. Energy Build. 2016, 128, 592–604. [Google Scholar] [CrossRef]

- Yeo, D.; Gabbai, R.D. Sustainable design of reinforced concrete structures through embodied energy optimization. Energy Build. 2011, 43, 2028–2033. [Google Scholar] [CrossRef]

- Thomark, C. Environmental Analysis of a Building with Reused Building Materials. Available online: http://muep.mau.se/handle/2043/9844 (accessed on 31 July 2018).

- Akbarnezhad, A.; Xiao, J. Estimation and Minimization of Embodied Carbon of Buildings: A Review. Buildings 2017, 7, 5. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S. Life cycle design and prefabrication in buildings: A review and case studies in Hong Kong. Autom. Constr. 2014, 39, 195–202. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Fung, I.W.H.; Sing, M.C.P.; Ogunlana, S.O. Best practice of prefabrication implementation in the Hong Kong public and private sectors. J. Clean. Prod. 2015, 109, 216–231. [Google Scholar] [CrossRef]

- Cao, X.; Li, X.; Zhu, Y.; Zhang, Z. A comparative study of environmental performance between prefabricated and traditional residential buildings in China. J. Clean. Prod. 2015, 109, 131–143. [Google Scholar] [CrossRef]

- Sambito, M.; Freni, G. LCA methodology for the quantification of the carbon footprint of the integrated urban water system. Water 2017, 9. [Google Scholar] [CrossRef]

- Wiedmann, T.; Minx, J. Ecological Economics; Pertsova, C., Ed.; Nova Science Publishers, Inc.: New York, NY, USA, 2007; ISBN 6312317269. [Google Scholar]

- Laurent, A.; Olsen, S.I.; Hauschild, M.Z. Carbon footprint as environmental performance indicator for the manufacturing industry. CIRP Ann.-Manuf. Technol. 2010, 59, 37–40. [Google Scholar] [CrossRef]

- Parravicini, V.; Svardal, K.; Krampe, J. Greenhouse Gas Emissions from Wastewater Treatment Plants. Energy Procedia 2016, 97, 246–253. [Google Scholar] [CrossRef]

- ISO. ISO 14067:2013 Greenhouse gases—Carbon footprint of products—Requirements and guidelines for quantification and communication. Int. Organ. Stand. 2013, 64. [Google Scholar] [CrossRef]

- International Organization for Standardisation ISO. 1440 Environmental management-life cycle assessment-principles and framework. Lond. Br. Stand. Inst. 2006. [Google Scholar] [CrossRef]

- La Société d’habitation du Québec Prject de Démonstration. Available online: http://www.webcitation.org/71E6BHrRd (accessed on 10 October 2017).

- Canada, G. Of Weahter Information in Canada. Available online: http://www.webcitation.org/71IvZFNwk (accessed on 10 October 2017).

- Zhu, H.; Hong, J.; Shen, G.Q.; Mao, C.; Zhang, H.; Li, Z. The exploration of the life-cycle energy saving potential for using prefabrication in residential buildings in China. Energy Build. 2018, 166, 561–570. [Google Scholar] [CrossRef]

- Pujadas-Gispert, E.; Sanjuan-Delmás, D.; Josa, A. Environmental analysis of building shallow foundations: The influence of prefabrication, typology, and structural design codes. J. Clean. Prod. 2018, 186, 407–417. [Google Scholar] [CrossRef]

- Mao, C.; Shen, Q.; Shen, L.; Tang, L. Comparative Study of Greenhouse Gas Emissions between Off-Site Prefabrication and Conventional Construction Methods: Two Case Studies of Residential Projects. Available online: http://ira.lib.polyu.edu.hk/handle/10397/25904 (accessed on 31 July 2018).

- Anand, C.K.; Amor, B. Recent developments, future challenges and new research directions in LCA of buildings: A critical review. Renew. Sustain. Energy Rev. 2017, 67, 408–416. [Google Scholar] [CrossRef] [Green Version]

- Abd Rashid, A.F.; Yusoff, S. A review of life cycle assessment method for building industry. Renew. Sustain. Energy Rev. 2015, 45, 244–248. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Société d’habitation du Québec (SHQ). Life Cycle Assessment of Residencial Buildings; SHQ: Quebec, QC, Canada, 2016. [Google Scholar]

- International Organization for Standardization (ISO). ISO 14040:2006—Environmental Management—Life Cycle Assessment—Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- 2006 IPCC Guidelines for National Greenhouse Gas Inventories. Available online: https://www.ipcc-nggip.iges.or.jp/public/2006gl/ (accessed on 31 July 2018).

- Cherubini, F.; Peters, G.P.; Berntsen, T.; Strømman, A.H.; Hertwich, E. CO2 emissions from biomass combustion for bioenergy: Atmospheric decay and contribution to global warming. GCB Bioenergy 2011, 3, 413–426. [Google Scholar] [CrossRef]

- Bright, R.M.; Cherubini, F.; Strømman, A.H. Climate impacts of bioenergy: Inclusion of carbon cycle and albedo dynamics in life cycle impact assessment. Environ. Impact Assess. Rev. 2012, 37, 2–11. [Google Scholar] [CrossRef]

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Mahalle, L.; Lavoie, P.; Meek, P.; McDonald, J. A Comparative Life Cycle Assessment of Canadian Hardwood Flooring with Alternative Flooring Types. Available online: http://docplayer.net/9017155-A-comparative-life-cycle-assessment-of-canadian-hardwood-flooring-with-alternative-flooring-types-acknowledgements.html (accessed on 31 July 2018).

- Oti, J.E.; Kinuthia, J.M. Stabilised unfired clay bricks for environmental and sustainable use. Appl. Clay Sci. 2012, 58, 52–59. [Google Scholar] [CrossRef]

- Lawania, K.; Sarker, P.; Global, W. Warming Implications of the Use of By-Products and Recycled Materials in Western Australia’s Housing Sector. Materials 2015, 8, 6909–6925. [Google Scholar] [CrossRef]

- Blengini, G.A. Life cycle of buildings, demolition and recycling potential: A case study in Turin, Italy. Build. Environ. 2009, 44, 319–330. [Google Scholar] [CrossRef]

- Kim, M.H.; Song, H.B. Analysis of the global warming potential for wood waste recycling systems. J. Clean. Prod. 2014, 69, 199–207. [Google Scholar] [CrossRef]

- Dong, Y.H.; Ng, S.T. A life cycle assessment model for evaluating the environmental impacts of building construction in Hong Kong. Build. Environ. 2015, 89, 183–191. [Google Scholar] [CrossRef]

- Canadian Wood Council (CWC). Sustainability and Life Cycle Analysis for Residential Buildings; Canadian Wood Council: Quebec, QC, Canada, 2010. [Google Scholar]

- Lessard, Y. Modélisation de L’influence de la Sélection des Matériaux sur le Profil Environnemental du Cycle de vie D’un Bâtiment à Bureaux: Évaluation Critique de Leed V4; Universite de Sherbrooke: Sherbrooke, QC, Canada, 2017. [Google Scholar]

- Zabalza Bribián, I.; Capilla, A.V.; Usón, A.A. Life cycle assessment of building materials: Comparative analysis of energy and environmental impacts and evaluation of the eco-efficiency improvement potential. Build. Environ. 2011, 46, 1133–1140. [Google Scholar] [CrossRef]

- Güereca, L.P.; Torres, N.; Juárez-López, C.R. The co-processing of municipal waste in a cement kiln in Mexico. A life-cycle assessment approach. J. Clean. Prod. 2015, 107, 741–748. [Google Scholar] [CrossRef]

- Dodoo, A.; Gustavsson, L.; Sathre, R. Lifecycle primary energy analysis of low-energy timber building systems for multi-storey residential buildings. Energy Build. 2014, 81, 84–97. [Google Scholar] [CrossRef]

- Pons, O.; Wadel, G. Environmental impacts of prefabricated school buildings in Catalonia. Habitat Int. 2011, 35, 553–563. [Google Scholar] [CrossRef]

- Kulshrestha, S. Resins for Construction. Available online: https://www.buildotechindia.com/resins-for-construction/ (accessed on 3 May 2017).

- Kumbhar, S.; Kulkarni, N.; Rao, A.B.; Rao, B. Environmental Life Cycle Assessment of Traditional Bricks in Western Maharashtra, India. Energy Procedia 2014, 54, 260–269. [Google Scholar] [CrossRef]

- Renzulli, P.; Notarnicola, B.; Tassielli, G.; Arcese, G.; Di Capua, R. Life Cycle Assessment of Steel Produced in an Italian Integrated Steel Mill. Sustainability 2016, 8, 719. [Google Scholar] [CrossRef]

- Aye, L.; Ngo, T.; Crawford, R.H.H.; Gammampila, R.; Mendis, P. Life cycle greenhouse gas emissions and energy analysis of prefabricated reusable building modules. Energy Build. 2012, 47, 159–168. [Google Scholar] [CrossRef]

- O’Brien, K.R.; Ménaché, J.; O’Moore, L.M. Impact of fly ash content and fly ash transportation distance on embodied greenhouse gas emissions and water consumption in concrete. Int. J. Life Cycle Assess. 2009, 14, 621–629. [Google Scholar] [CrossRef] [Green Version]

- Foti, D. Preliminary analysis of concrete reinforced with waste bottles PET fibers. Constr. Build. Mater. 2011, 25, 1906–1915. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, D.; Tsutsumi, A.; You, S. Sustainable energy technologies for energy saving and carbon emission reduction. Appl. Energy 2017, 194, 223–224. [Google Scholar] [CrossRef] [Green Version]

- Azevedo, I.; Leal, V.M.S. Methodologies for the evaluation of local climate change mitigation actions: A review. Renew. Sustain. Energy Rev. 2017, 79, 681–690. [Google Scholar] [CrossRef]

- Poveda, C.A.; Young, R. Potential benefits of developing and implementing environmental and sustainability rating systems: Making the case for the need of diversification. Int. J. Sustain. Built. Environ. 2015, 4, 1–11. [Google Scholar] [CrossRef]

| Life Cycle Stage | Material/Process | Quantity (per 1 m2 of Building | CFP Emissions (kg CO2-e) | Source of Data |

|---|---|---|---|---|

| Material acquisition and material production | Cross Laminated Timber (CLT) | 0.27 m3 | 21.00 | Ecoinvent v3.1 modified (Quebec context) |

| Glue laminated | 0.0019 m3 | 0.92 | Ecoinvent v3.1 | |

| Steel | 3.98 kg | 10.68 | Ecoinvent v3.1 | |

| Gypsum fiberboard | 4.92 m2 | 7.97 | Ecoinvent v3.1 | |

| Concrete | 0.15 m3 | 44.08 | Ecoinvent v3.1 | |

| Vinyl boards | 3.15 kg | 72.35 | Ecoinvent v3.1 | |

| Granite | 3.88 kg | 0.54 | Ecoinvent v3.1 | |

| Ceramic tiles | 1.83 kg | 1.47 | Ecoinvent v3.1 | |

| Primer | 0.499 kg | 0.93 | Ecoinvent v3.1 | |

| Paint | 1.35 kg | 3.91 | Ecoinvent v3.1 | |

| Bricks | 50.23 kg | 12.02 | Ecoinvent v3.1 | |

| Windows | 0.03 m2 | 0.61 | Ecoinvent v3.1 | |

| Metal doors | 0.06 m2 | 3.36 | Ecoinvent v3.1 | |

| Wooden doors | 0.30 m2 | 16.06 | Ecoinvent v3.1 adapted from US LCI | |

| Fiberglas | 1.72 kg | 4.58 | Ecoinvent v3.1 | |

| Insulation EPS | 1.15 kg | 1.05 | Ecoinvent v3.1 | |

| Rigid polyisocyanurate insulation | 0.0560 kg | 0.29 | Ecoinvent v3.1 | |

| Spray polyurethane | 0.06 kg | 0.29 | Ecoinvent v3.1 | |

| Elastomeric membrane | 0.28 kg | 1.27 | Ecoinvent v3.1 | |

| Coverage bitumen membrane | 0.08 kg | 0.09 | Ecoinvent v3.1 | |

| Copper | 1.01 kg | 1.94 | Ecoinvent v3.1 | |

| Transportation to site assembly (Distance range: 250 for local materials (wood, concrete) and 500 km for other materials) | 188.81 t-km | 36.70 | Ecoinvent v3.1 | |

| Assembly | Electricity | 85.65 kwh | 0.73 | Created (SHQ, 2016) |

| Excavation | 0.0264 m3 | 0.013 | Ecoinvent v3.1 | |

| Diesel | 0.9919 kwh | 0.33 | Ecoinvent v3.1 | |

| Transportation from site construction to landfill (25 km) | 0.60 t-km | 0.479 | Ecoinvent v3.1 | |

| Waste Management (25 km is considered from site assembly to landfill) (WM) (wood) | 9.91 kg | 14.52 | Ecoinvent v3.1 | |

| WM (gypsum) | 5.26 kg | 0.076 | Ecoinvent v3.1 | |

| WM (Iron metals) | 6.11 kg | 0.37 | Ecoinvent v3.1 | |

| WM (Non-iron metals) | 1.97 kg | 0.014 | Ecoinvent v3.1 | |

| WM (plastic) | 0.1656 kg | 0.015 | Ecoinvent v3.1 | |

| WM (carton/paper) | 3.83 kg | 5.13 | Ecoinvent v3.1 | |

| WM (insulation wool) | 0.4228 kg | .003 | Ecoinvent v3.1 | |

| WM (Polythene) | 3.46 kg | 10.39 | Ecoinvent v3.1 | |

| WM Transportation (25 km) | 0.6298 t-km | 0.82 | Ecoinvent v3.1 |

| Carbon Reduction Strategies | Actions | Modifications | Reference |

|---|---|---|---|

| Low carbon materials | Substitution of thermal materials | Cellulose insulation (recycled newsprint) | [34] |

| Substitution of alternative flooring types | Hardwood flooring system | [35] | |

| Use of low-carbon bricks | Use of Lower Clay-Lime-GGBS (GGBS—Ground Granulated Blast-furnace Slag) unfired brick types | [36] | |

| Replacement of cement concrete (100% OPC) by combination of by-products | New concrete mix 70% OPC + 30% F.A (OPC—Ordinary Portland Cement, FA—Fly ash, NA—Natural Aggregate, RCA—Recycled crush aggregate, NS—Natural sand). 60% N.A. + 40% RCA 100% N.S | [37] | |

| Material minimization | Reduction of low waste ratios | Wood 7% Concrete 7% Steel 7% | [38] |

| Reuse and recycle materials | Use of wood waste materials to produce new materials | Production and carbon storage in particleboard of wood wastes (7%) | [39] |

| Local sourcing and use of biofuels | Use of local materials | Change of transportation distance (50 km) and | [8] |

| Use of biodiesel (B20) for transportation | Implementation of biodiesel as a fuel for on-site machines (blend mix B20) | [40] |

| Strategy | Actions | Original Material Emissions Kg CO2-e (Baseline) | Single Kg CO2-e (New Implementation) | Single Reduction (Kg CO2-e) | Overall Reduction % (Baseline = 275 kg CO2-e) |

|---|---|---|---|---|---|

| Low carbon materials | Cellulose insulation (recycled newsprint) | 2.92 | 0.73 | 2.19 | 0.8% |

| Hardwood flooring system | 3.6 | −4.8 | 8.4 | 3.1% | |

| Light clay brick | 12.02 | 2.054 | 9.96 | 3.6% | |

| Substitution of clinker by mineral additions in cement | 44.089 | 33.50 | 10.58 | 3.8% | |

| Material minimization | Ratio waste of Wood 7% | 14.52 | 12.05 | 2.46 | 0.9% |

| Ratio waste of Concrete 7% | None | None | None | None | |

| Ratio waste of Steel 7% | 0.37 | 0.021 | 0.35 | 0.1% | |

| Reuse and recycle materials | Carbon storage in particleboard of wood wastes (7%) | 12.05 | −28.17 | 40.22 | 14.6% |

| Local sources and biofuels adoption | Local materials distance 50 km | 37.52 | 5.42 | 32.09 | 11.7% |

| Mix B20 | 0.33 | 0.082 | 0.24 | 0.1% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Padilla-Rivera, A.; Amor, B.; Blanchet, P. Evaluating the Link between Low Carbon Reductions Strategies and Its Performance in the Context of Climate Change: A Carbon Footprint of a Wood-Frame Residential Building in Quebec, Canada. Sustainability 2018, 10, 2715. https://doi.org/10.3390/su10082715

Padilla-Rivera A, Amor B, Blanchet P. Evaluating the Link between Low Carbon Reductions Strategies and Its Performance in the Context of Climate Change: A Carbon Footprint of a Wood-Frame Residential Building in Quebec, Canada. Sustainability. 2018; 10(8):2715. https://doi.org/10.3390/su10082715

Chicago/Turabian StylePadilla-Rivera, Alejandro, Ben Amor, and Pierre Blanchet. 2018. "Evaluating the Link between Low Carbon Reductions Strategies and Its Performance in the Context of Climate Change: A Carbon Footprint of a Wood-Frame Residential Building in Quebec, Canada" Sustainability 10, no. 8: 2715. https://doi.org/10.3390/su10082715

APA StylePadilla-Rivera, A., Amor, B., & Blanchet, P. (2018). Evaluating the Link between Low Carbon Reductions Strategies and Its Performance in the Context of Climate Change: A Carbon Footprint of a Wood-Frame Residential Building in Quebec, Canada. Sustainability, 10(8), 2715. https://doi.org/10.3390/su10082715