Multi-Criteria Group Decision Making for Green Supply Chain Management under Uncertainty

Abstract

:1. Introduction

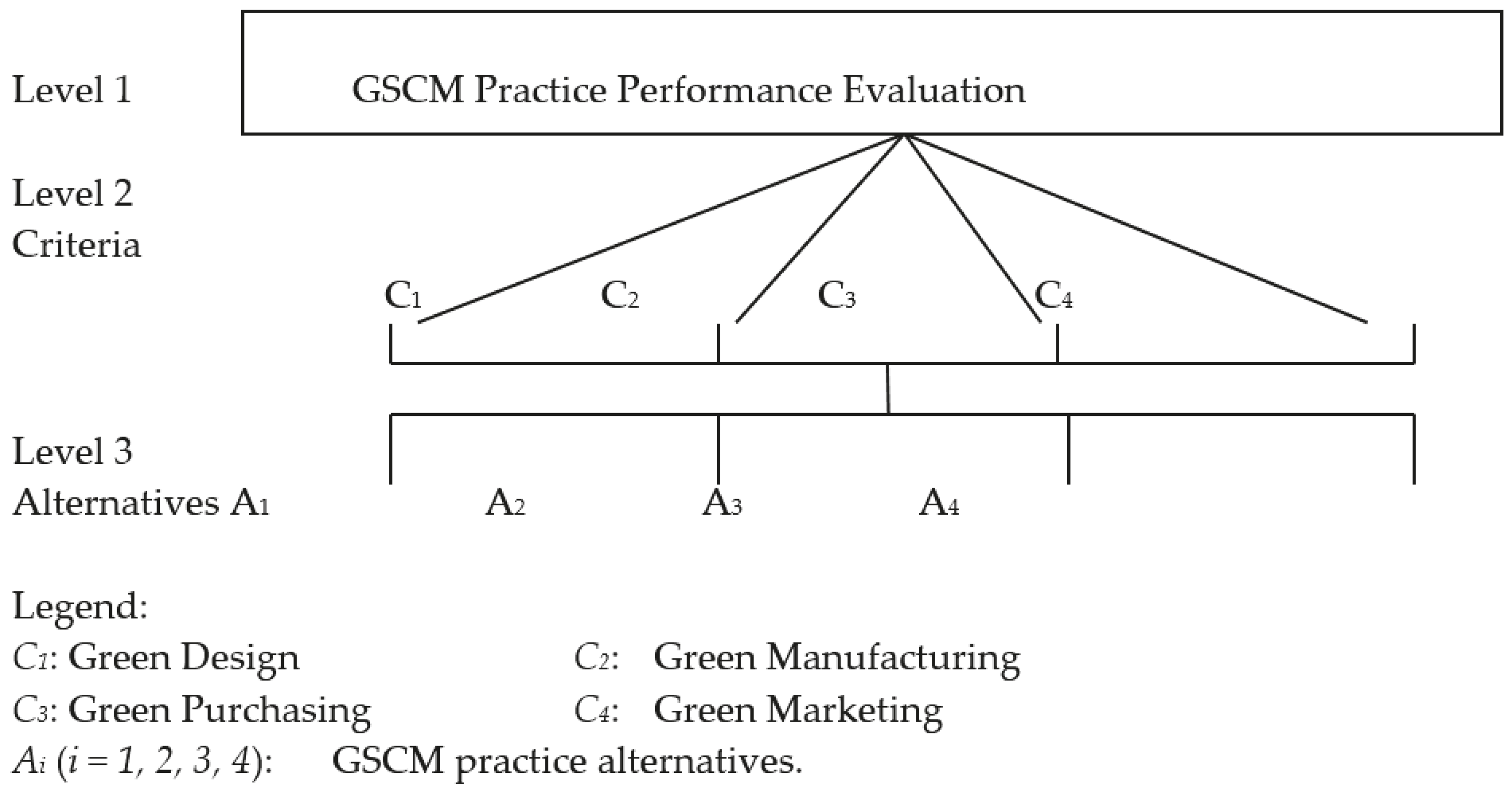

2. Evaluating the Performance of GSCM Practices

3. A Fuzzy Multi-Criteria Group Decision Making Model

- Step 1

- Obtain the decision matrix from each decision maker as expressed in Equation (1).

- Step 2

- Assess the consensus among the decision makers by Equation (2).

- Step 3

- Determine the relative importance of the criteria as expressed in Equations (3) and (4).

- Step 4

- Calculate the performance of each alternative from all decision makers as in Equation (5).

- Step 5

- Compute the performance index value for each alternative across criteria by Equation (6).

- Step 6

- Rank the alternatives in descending order of their performance index values.

4. An Example

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Deng, H. Multicriteria analysis for benchmarking sustainability development. Benchmark. Int. J. 2015, 22, 791–807. [Google Scholar] [CrossRef]

- Gallego, I. The use of economic, social and environmental indicators as a measure of sustainable development in Spain. Corp. Soc. Responsib. Environ. Manag. 2006, 13, 78–97. [Google Scholar] [CrossRef]

- Magee, L.; Scerri, A.; James, P.; Thom, J.A.; Padgham, L.; Hickmott, S.; Cahill, F. Reframing social sustainability reporting: Towards an engaged approach. Environ. Dev. Sustain. 2013, 15, 225–243. [Google Scholar] [CrossRef]

- Lin, R.J. Using fuzzy DEMATEL to evaluate the green supply chain management practices. J. Clean. Prod. 2013, 40, 32–39. [Google Scholar] [CrossRef]

- Tseng, M.L. Green supply chain management with linguistic preferences and incomplete information. Appl. Soft Comput. 2011, 11, 4894–4903. [Google Scholar] [CrossRef]

- Tseng, M.L.; Chiu, A.S.F. Grey-entropy analytical network process for green innovation practices. Proced. Soc. Behav. Sci. 2012, 57, 10–21. [Google Scholar] [CrossRef]

- Sarkis, J. A boundaries and flows perspective of green supply chain management. Supply Chain Manag. Int. J. 2012, 17, 202–216. [Google Scholar] [CrossRef] [Green Version]

- Govindan, K.; Rajendran, S.; Sarkis, J.; Murugesan, P. Multi criteria decision making approach for green supplier evaluation and selection: A literature review. J. Clean. Prod. 2015, 98, 66–83. [Google Scholar] [CrossRef]

- Sharma, V.K.; Chandna, P.; Bhardwaj, A. Green supply chain management related performance indicators in agro industry: A review. J. Clean. Prod. 2017, 141, 1194–1208. [Google Scholar] [CrossRef]

- Diabat, A.; Govindan, K. An analysis of the drivers affecting the implementation of green supply chain management. Resour. Conserv. Recycl. 2011, 55, 659–667. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C. A comparative literature analysis of definitions for green and sustainable supply chain management. J. Clean. Prod. 2013, 52, 329–341. [Google Scholar] [CrossRef]

- Vachon, S.; Klassen, D. Extending green practices across the supply chain: The impact of upstream and downstream integration. Int. J. Oper. Prod. Manag. 2006, 26, 795–821. [Google Scholar] [CrossRef]

- Dwivedy, M.; Mittal, R.K. Willingness of residents to participate in e-waste recycling in India. Environ. Dev. 2013, 6, 48–68. [Google Scholar] [CrossRef]

- Azevedo, S.G.; Carvalho, H.; Machado, V.C. The influence of green practices on supply chain performance: A case study approach. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 850–871. [Google Scholar] [CrossRef]

- Kannan, G.; Pokharel, S.; Kumar, P.S. A hybrid approach using ISM and fuzzy TOPSIS for the selection of reverse logistics provider. Resour. Conserv. Recycl. 2009, 54, 28–36. [Google Scholar] [CrossRef]

- Shen, L.; Olfat, L.; Govindan, K.; Khodaverdi, R.; Diabat, A. A fuzzy multi criteria approach for evaluating green supplier’s performance in green supply chain with linguistic preferences. Resour. Conserv. Recycl. 2013, 74, 170–179. [Google Scholar] [CrossRef]

- Thanki, S.; Govindan, K.; Thakkar, J. An investigation on lean-green implementation practices in Indian SMEs using analytical hierarchy process (AHP) approach. J. Clean. Prod. 2016, 135, 284–298. [Google Scholar] [CrossRef]

- Wibowo, S.; Deng, H. Intelligent decision support for effectively evaluating and selecting ships under uncertainty in marine transportation. Expert Syst. Appl. 2012, 39, 6911–6920. [Google Scholar] [CrossRef]

- Deng, H. Multicriteria analysis with fuzzy pairwise comparison. Int. J. Approx. Reason. 1999, 21, 215–231. [Google Scholar] [CrossRef]

- Yeh, C.H.; Deng, H.; Chang, Y.H. Fuzzy multicriteria analysis for performance evaluation of bus companies. Eur. J. Oper. Res. 2000, 126, 1–15. [Google Scholar] [CrossRef]

- Roghanian, E.; Sadjadi, S.J.; Aryanezhad, M.B. A probabilistic bi-level linear multiobjective programming problem to supply chain planning. Appl. Math. Comput. 2007, 188, 786–800. [Google Scholar]

- Torabi, S.A.; Hassini, E. An interactive possibilistic programming approach for multiple objective supply chain master planning. Fuzzy Sets Syst. 2008, 159, 193–214. [Google Scholar] [CrossRef]

- Pinto-Varela, T.; Barbosa-Povoa, A.P.; Novais, A.Q. Bi-objective optimization approach to the design and planning of supply chains: Economic versus environmental performances. Comput. Chem. Eng. 2011, 35, 1454–1468. [Google Scholar] [CrossRef]

- Liu, S.; Papageorgiou, L.G. Multiobjective optimisation of production, distribution and capacity planning of global supply chains in the process industry. Omega 2013, 41, 369–382. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K. Confirmation of a measurement model for green supply chain management practices implementation. Int. J. Prod. Econ. 2008, 111, 261–273. [Google Scholar] [CrossRef]

- Barari, S.; Agarwal, G.; Zhang, W.J.; Mahanty, B.; Tiwari, M.K. A decision framework for the analysis of green supply chain contracts: An evolutionary game approach. Expert Syst. Appl. 2012, 39, 2965–2976. [Google Scholar] [CrossRef]

- Bowen, F.E.; Cousins, P.D.; Lamming, R.C.; Faruk, A.C. The role of supply management capabilities in green supply. Prod. Oper. Manag. 2001, 10, 174–189. [Google Scholar] [CrossRef]

- Mumtaz, U.; Ali, Y.; Petrillo, A. A linear regression approach to evaluate the green supply chain management impact on industrial organizational performance. Sci. Total Environ. 2018, 624, 162–169. [Google Scholar] [CrossRef] [PubMed]

- Wu, G.C. The influence of green supply chain integration and environmental uncertainty on green innovation in Taiwan’s IT industry. Supply Chain Manag. Int. J. 2013, 18, 539–552. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. J. Oper. Manag. 2004, 22, 265–289. [Google Scholar] [CrossRef]

- Sheu, J. Buyer behavior in quality-dominated multi-sourcing recyclable material procurement of green supply chains. Prod. Oper. Manag. 2016, 25, 477–497. [Google Scholar] [CrossRef]

- Arena, U.; Mastellone, M.L.; Perugini, F. The environmental performance of alternative solid waste management options: A lifecycle assessment study. Chem. Eng. J. 2003, 96, 207–222. [Google Scholar] [CrossRef]

- Kopicki, R.; Berg, M.J.; Legg, L.; Dasppa, V.; Maggioni, C. Reuse and Recycling-Reverse Logistics Opportunities; Council of Logistics Management: Oak Brook, IL, USA, 1993. [Google Scholar]

- Rao, P.; Holt, D. Do green supply chains lead to competitiveness and economic performance? Int. J. Oper. Prod. Manag. 2005, 25, 898–916. [Google Scholar] [CrossRef]

- Awasthi, A.; Chauhan, S.S.; Goyal, S.K. A fuzzy multicriteria approach for evaluating environmental performance of suppliers. Int. J. Prod. Econ. 2010, 126, 370–378. [Google Scholar] [CrossRef]

- Hu, H.; Hsu, C.W. Critical factors for implementing green supply chain management practice: An empirical study of electrical and electronics industries in Taiwan. Manag. Res. Rev. 2010, 33, 586–608. [Google Scholar] [CrossRef]

- Sarkis, J. Greening Supply Chain Management; GMI 35 Autumn; Greenleaf Publishing: Melbourne, Australia, 2001. [Google Scholar]

- Mangla, S.; Govindan, K.; Luthra, S. Critical success factors for reverse logistics in Indian industries: A structural model. J. Clean. Prod. 2016, 129, 608–621. [Google Scholar] [CrossRef]

- Lee, V.H.; Ooi, K.B.; Chong, A.Y.; Seow, C. Creating technological innovation via supply chain management: An empirical analysis. Expert Syst. Appl. 2014, 41, 6983–6994. [Google Scholar] [CrossRef]

- Luthra, S.; Garg, D.; Haleem, A. Green supply chain management: Implementation and performance—A literature review and some issues. J. Adv. Manag. Res. 2014, 11, 20–46. [Google Scholar] [CrossRef]

- Chen, C.C.; Shih, H.S.; Shyur, H.J.; Wu, K.S. A business strategy selection of green supply chain management via an analytic network process. Comput. Math. Appl. 2012, 64, 2544–2557. [Google Scholar] [CrossRef]

- Ginsberg, J.M.; Bloom, P.N. Choosing the right green marketing strategy. MIT Sloan Manag. Rev. 2004, 46, 79–84. [Google Scholar]

- Carter, C.R.; Ellram, L.M. Reverse logistics: A review of the literature and framework for future investigation. J. Bus. Logist. 1998, 19, 85–102. [Google Scholar]

- Lin, L.; Yuan, X.H.; Xia, Z.Q. Multicriteria fuzzy decision-making methods based on intuitionistic fuzzy sets. J. Comput. Syst. Sci. 2007, 73, 84–88. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K. Institutional-based antecedents and performance outcomes of internal and external green supply chain management practices. J. Purchas. Supply Manag. 2013, 19, 106–117. [Google Scholar] [CrossRef]

- Fang, C.; Zhang, J. Performance of green supply chain management: A systematic review and meta analysis. J. Clean. Prod. 2018, 183, 1064–1081. [Google Scholar] [CrossRef]

- Linton, J.D.; Klassen, R.; Jayaraman, V. Sustainable supply chains: An introduction. J. Oper. Manag. 2007, 25, 1075–1082. [Google Scholar] [CrossRef]

- Park, J.H.; Cho, H.J.; Kwun, Y.C. Extension of the VIKOR method to dynamic intuitionistic fuzzy multiple attribute decision making. Comput. Math. Appl. 2013, 65, 731–744. [Google Scholar] [CrossRef]

- Qin, J.; Liu, X.; Pedrycz, W. An extended TODIM multi-criteria group decision making method for green supplier selection in interval type-2 fuzzy environment. Eur. J. Oper. Res. 2017, 258, 626–638. [Google Scholar] [CrossRef]

- Wibowo, S.; Deng, H. Consensus-based decision support for multicriteria group decision making. Comput. Ind. Eng. 2013, 66, 625–633. [Google Scholar] [CrossRef]

- Yeh, C.H.; Deng, H.; Wibowo, S.; Xu, Y. Fuzzy multicriteria decision support for information systems project selection. Int. J. Fuzzy Syst. 2010, 12, 170–179. [Google Scholar]

- Chen, Z.; Yang, W. A new multiple attribute group decision making method in intuitionistic fuzzy setting. Appl. Math. Model. 2011, 35, 4424–4437. [Google Scholar] [CrossRef]

- Tan, C.; Deng, H. A multi-criteria group decision making procedure using interval-valued intuitionistic fuzzy sets. J. Comput. Inf. Syst. 2010, 6, 855–863. [Google Scholar]

- Wang, W.; Liu, X. The multi-attribute decision making method based on interval-valued intuitionistic fuzzy Einstein hybrid weighted geometric operator. Comput. Math. Appl. 2013, 66, 1845–1856. [Google Scholar] [CrossRef]

- Zhao, H.; Xu, Z.S.; Ni, M.F.; Liu, S.S. Generalized aggregation operators for intuitionistic fuzzy sets. Int. J. Intell. Syst. 2010, 25, 1–30. [Google Scholar] [CrossRef]

- Herrera-Viedma, E.; Alonso, S.; Chiclana, F.; Herrera, F. A consensus model for group decision making with incomplete fuzzy preference relations. IEEE Trans. Fuzzy Syst. 2007, 15, 863–877. [Google Scholar] [CrossRef]

- Chen, S.M.; Tan, J.M. Handling multicriteria fuzzy decision making problems based on vague set theory. Fuzzy Sets Syst. 1994, 67, 163–172. [Google Scholar] [CrossRef]

- Yang, M.G.; Hong, P.; Modi, S.B. Impact of lean manufacturing and environmental management on business performance: An empirical study of manufacturing firms. Int. J. Prod. Econ. 2011, 129, 251–261. [Google Scholar] [CrossRef]

- Gualandris, J.; Kalchschmidt, M. Customer pressure and innovativeness: Their role in sustainable supply chain management. J. Purchas. Supply Manag. 2014, 20, 92–103. [Google Scholar] [CrossRef]

- Glover, J.L.; Champion, D.; Daniels, K.J.; Dainty, A.J.D. An institutional theory perspective on sustainable practices across the dairy supply chain. Int. J. Prod. Econ. 2014, 152, 102–111. [Google Scholar] [CrossRef] [Green Version]

- Hung, W.L.; Yang, M.S. Similarity measures of intuitionistic fuzzy sets based on Hausdorff distance. Pattern Recogn. Lett. 2004, 25, 1603–1611. [Google Scholar] [CrossRef]

- Ren, J.; Liang, H. Multi-criteria group decision-making based sustainability measurement of wastewater treatment processes. Environ. Impact Assess. Rev. 2017, 65, 91–99. [Google Scholar] [CrossRef]

- Wibowo, S.; Deng, H. Multi-criteria group decision making for evaluating the performance of e-waste recycling programs under uncertainty. Waste Manag. 2015, 40, 127–135. [Google Scholar] [CrossRef] [PubMed]

- Xia, M.; Xu, Z. Hesitant fuzzy information aggregation in decision making. Int. J. Approx. Reason. 2011, 52, 395–407. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.M.; Chang, C.H. Fuzzy multiattribute decision making based on transformation techniques of intuitionistic fuzzy values and intuitionistic fuzzy geometric averaging operators. Inf. Sci. 2016, 352–353, 133–149. [Google Scholar] [CrossRef]

- Beske, P.; Land, A.; Seuring, S. Sustainable supply chain management practices and dynamic capabilities in the food industry: A critical analysis of the literature. Int. J. Prod. Econ. 2014, 152, 131–143. [Google Scholar] [CrossRef]

| Criteria | References |

|---|---|

| Green design | [9,10,14,16,25,26,31,34,35,36,37,38,44] |

| Green purchasing | [10,12,16,34,37,39,40] |

| Green manufacturing | [8,9,14,17,25,26,41] |

| Green marketing | [25,26,42,43,45,46,47] |

| Alternative A1 | Alternative A2 | Alternative A3 | Alternative A4 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D1 | D2 | D3 | D1 | D2 | D3 | D1 | D2 | D3 | D1 | D2 | D3 | |

| C1 | (0.91, 0.05) | (0.48, 0.43) | (0.58, 0.27) | (0.57, 0.27) | (0.60, 0.32) | (0.57, 0.34) | (0.43, 0.48) | (0.57, 0.27) | (0.67, 0.16) | (0.70, 0.17) | (0.62, 0.32) | (0.62, 0.32) |

| C2 | (0.70, 0.24) | (0.75, 0.16) | (0.75, 0.18) | (0.95, 0.03) | (0.77, 0.14) | (0.75, 0.18) | (0.62, 0.32) | (0.65, 0.29) | (0.18, 0.74) | (0.57, 0.27) | (0.75, 0.18) | (0.71, 0.19) |

| C3 | (0.55, 0.37) | (0.67, 0.16) | (0.60, 0.32) | (0.62, 0.32) | (0.42, 0.52) | (0.63, 0.34) | (0.48, 0.39) | (0.71, 0.19) | (0.57, 0.27) | (0.48, 0.39) | (0.86, 0.04) | (0.60, 0.32) |

| C4 | (0.49, 0.36) | (0.63, 0.34) | (0.42, 0.52) | (0.84, 0.11) | (0.84, 0.14) | (0.62, 0.32) | (0.15, 0.83) | (0.55, 0.37) | (0.48, 0.39) | (0.75, 0.22) | (0.67, 0.16) | (0.42, 0.52) |

| Alternatives | Decision Makers | Degree of Similarity |

|---|---|---|

| A1 | D1 | 0.32 |

| D2 | 0.57 | |

| D3 | 0.49 | |

| A2 | D1 | 0.48 |

| D2 | 0.51 | |

| D3 | 0.34 | |

| A3 | D1 | 0.53 |

| D2 | 0.31 | |

| D3 | 0.52 | |

| A4 | D1 | 0.39 |

| D2 | 0.42 | |

| D3 | 0.51 |

| Criteria | Weights |

|---|---|

| C1 | (0.67, 0.21) |

| C2 | (0.80, 0.11) |

| C3 | (0.37, 0.48) |

| C4 | (0.60, 0.30) |

| Alternative | Performance Index Value | Ranking |

|---|---|---|

| A1 | 0.608 | 3 |

| A2 | 0.675 | 1 |

| A3 | 0.587 | 4 |

| A4 | 0.642 | 2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, H.; Luo, F.; Wibowo, S. Multi-Criteria Group Decision Making for Green Supply Chain Management under Uncertainty. Sustainability 2018, 10, 3150. https://doi.org/10.3390/su10093150

Deng H, Luo F, Wibowo S. Multi-Criteria Group Decision Making for Green Supply Chain Management under Uncertainty. Sustainability. 2018; 10(9):3150. https://doi.org/10.3390/su10093150

Chicago/Turabian StyleDeng, Hepu, Feng Luo, and Santoso Wibowo. 2018. "Multi-Criteria Group Decision Making for Green Supply Chain Management under Uncertainty" Sustainability 10, no. 9: 3150. https://doi.org/10.3390/su10093150

APA StyleDeng, H., Luo, F., & Wibowo, S. (2018). Multi-Criteria Group Decision Making for Green Supply Chain Management under Uncertainty. Sustainability, 10(9), 3150. https://doi.org/10.3390/su10093150