Strength Time–Varying and Freeze–Thaw Durability of Sustainable Pervious Concrete Pavement Material Containing Waste Fly Ash

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Design

2.3. Specimen Preparation

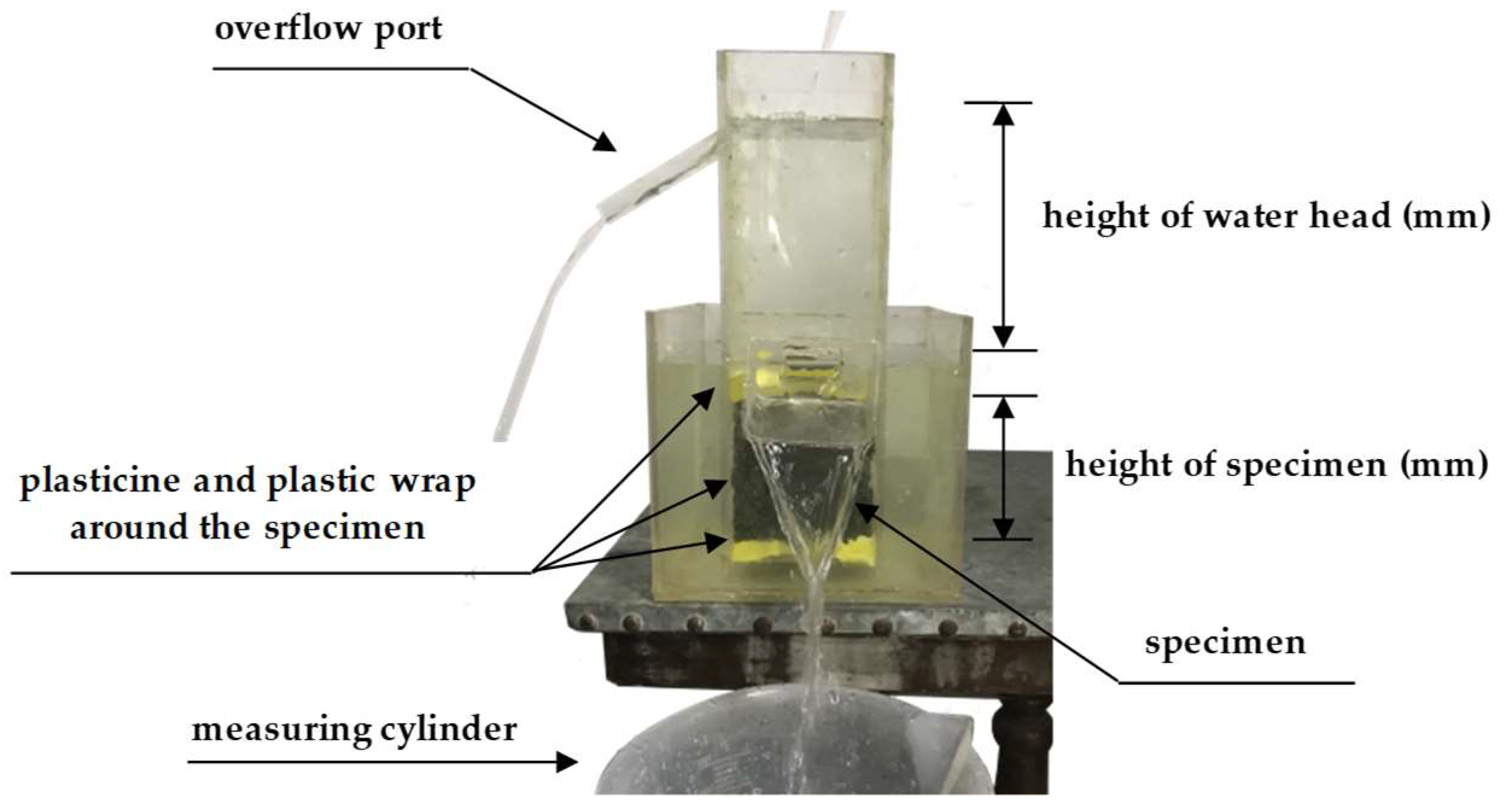

2.4. Testing Methods

3. Results and Discussion

3.1. Porosity and Permeability

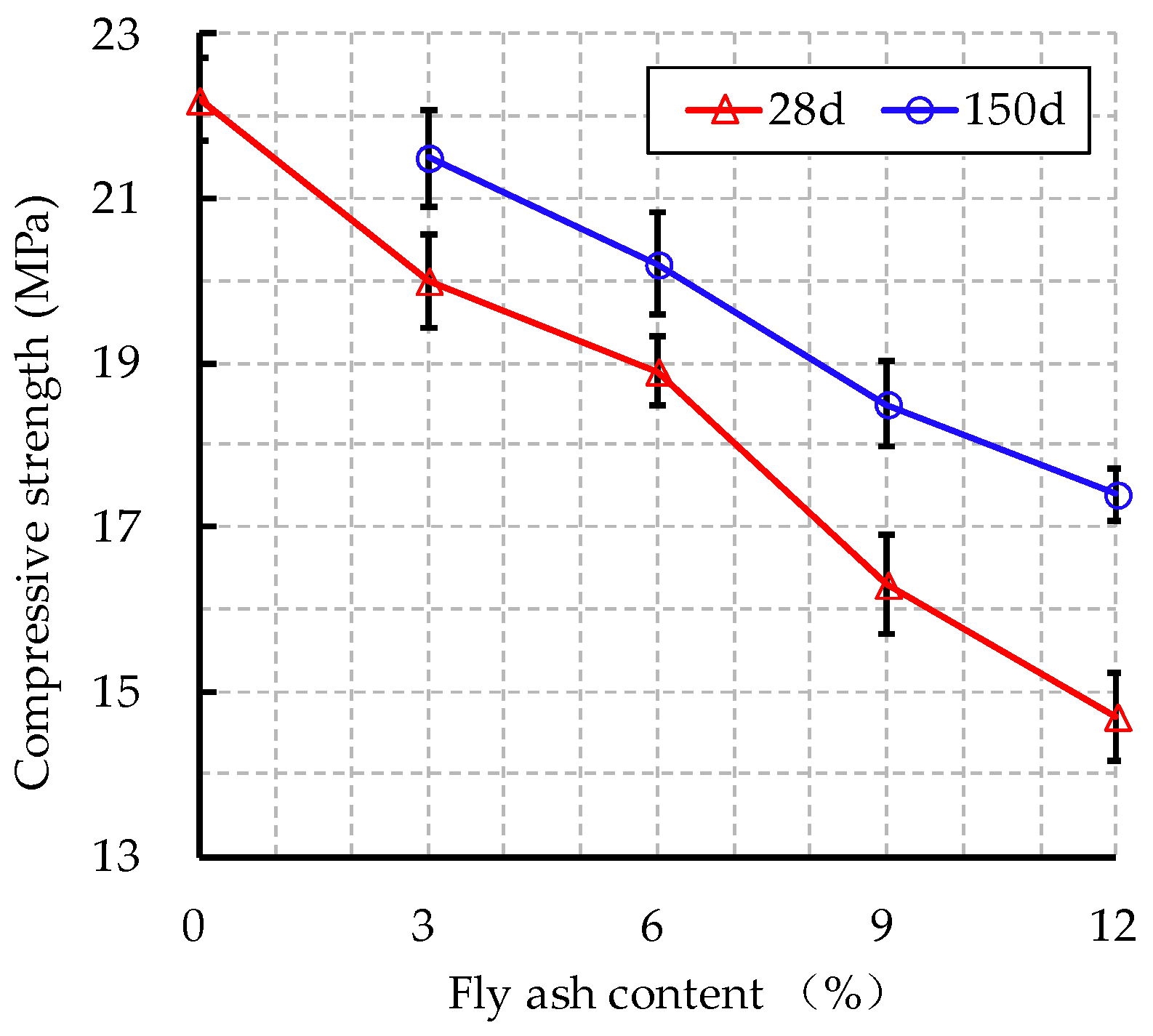

3.2. Compressive Strength

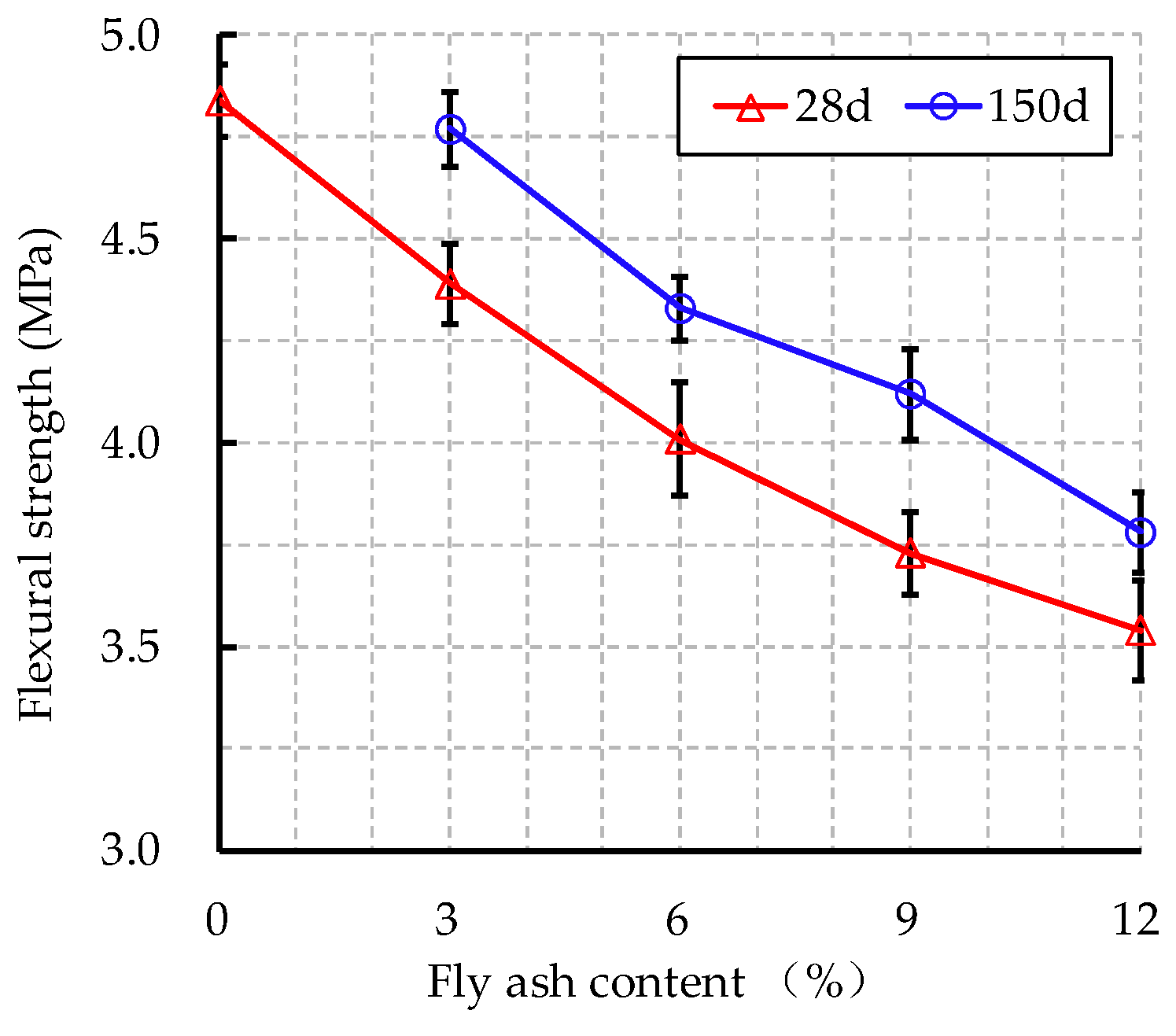

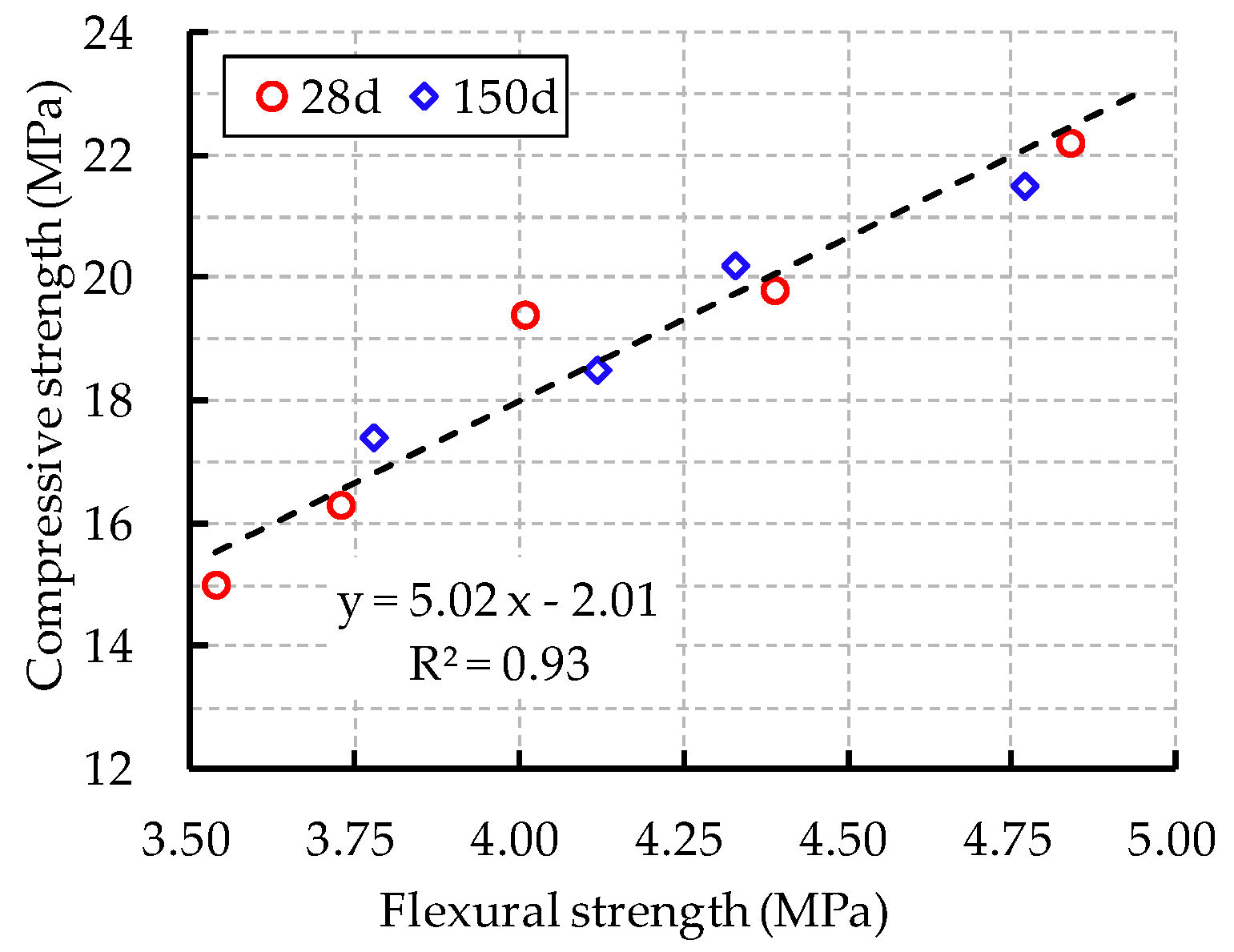

3.3. Flexural Strength

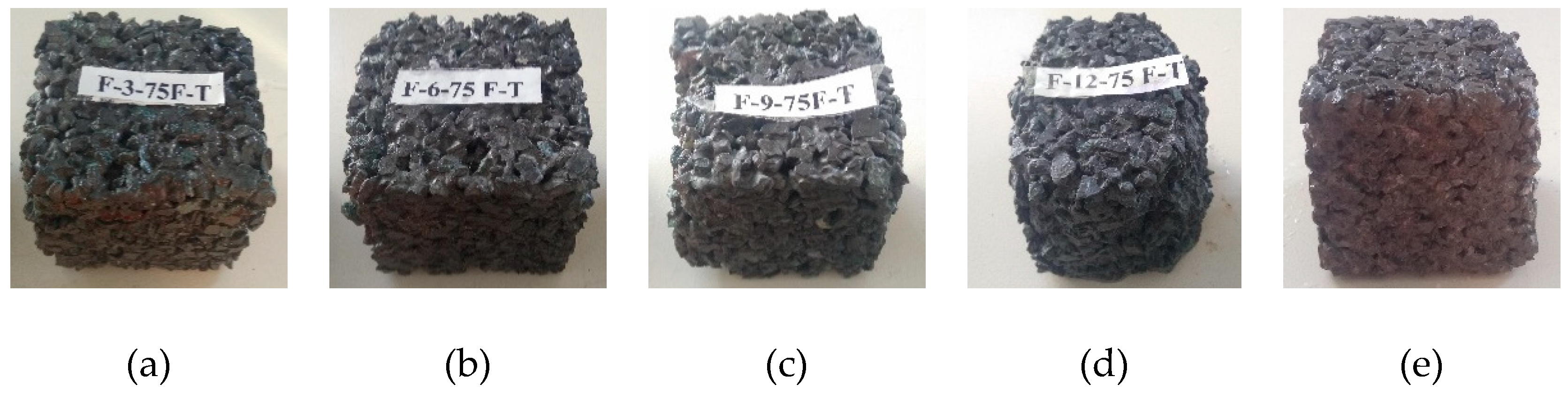

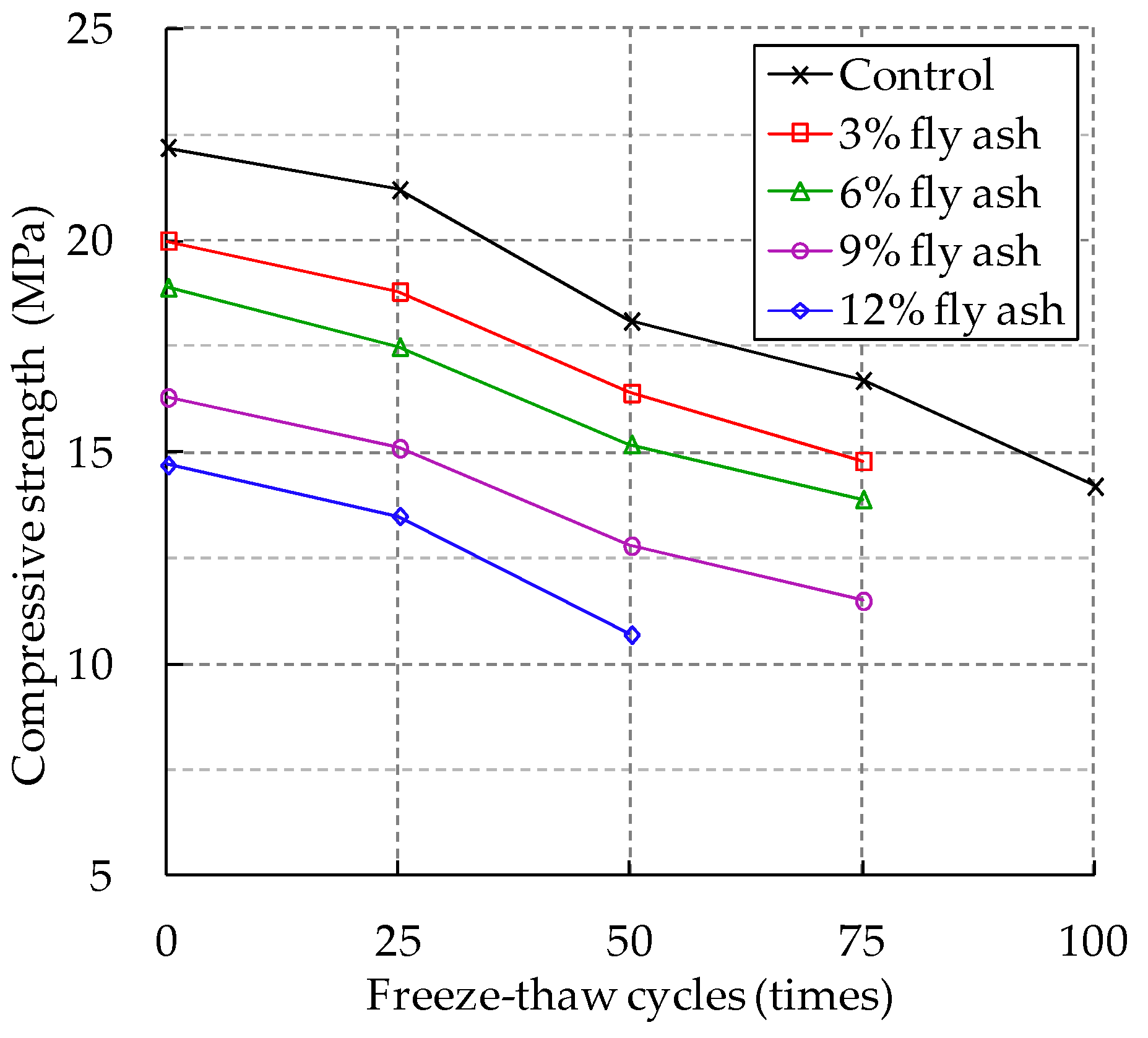

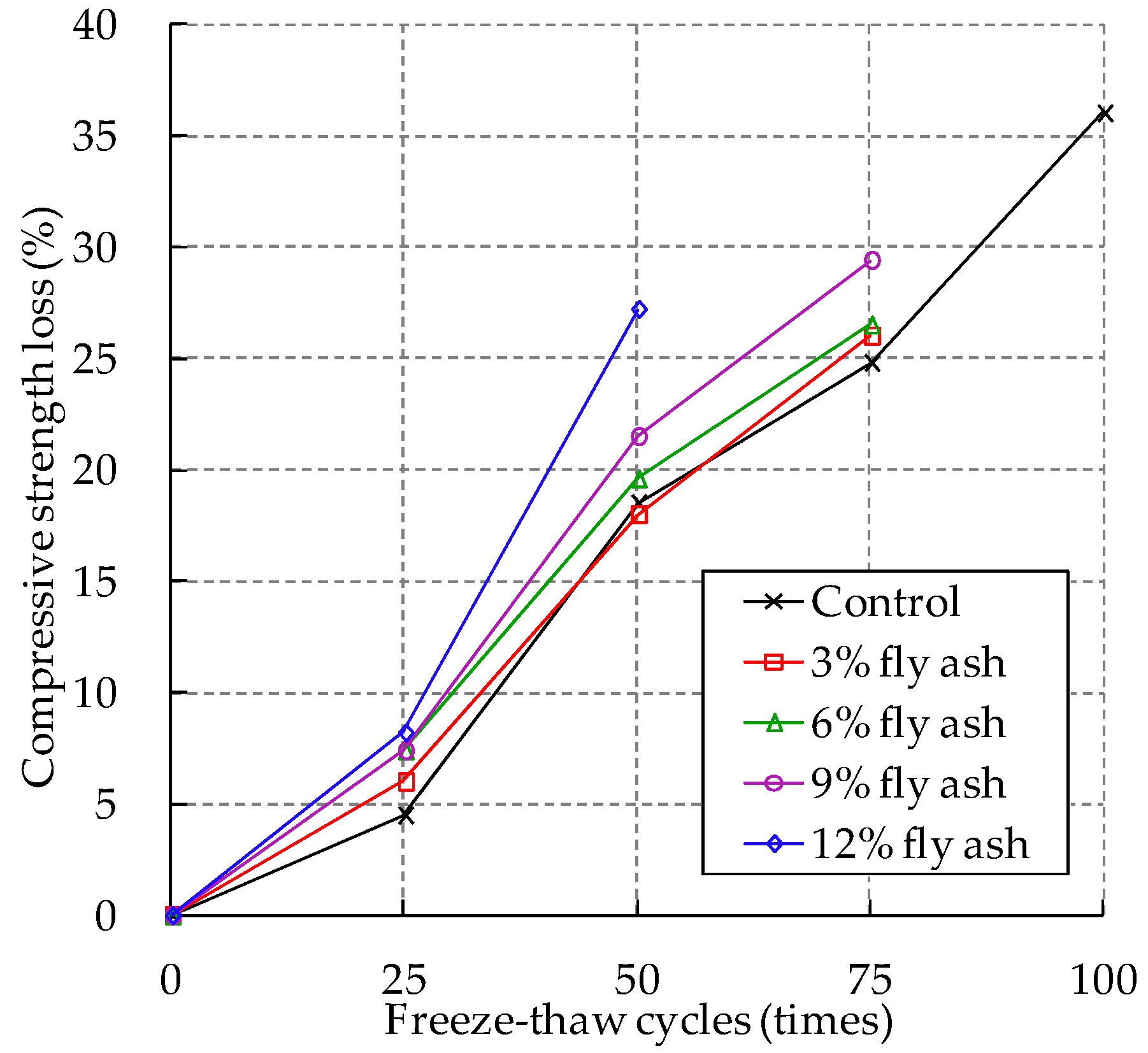

3.4. Freeze–Thaw Resistance

4. Conclusions

- The fly ash modified pervious concrete designed with equivalent volume replacement of cement did not affect the effective porosity, thus the permeability of pervious concrete hardly changed with the content of fly ash compared to the unmodified control pervious concrete.

- The early-age compressive strength and flexural strength of fly ash modified pervious concrete was decreased by the addition of fly ash. The higher content of fly ash, the lower compressive strength and flexural strength. Compared to the early-age compressive strength and flexural strength, the long-term compressive strength and flexural strength increased at all fly ash incorporation levels, which indicated that the age had an important effect on the strengths of fly ash modified pervious concrete.

- The addition of fly ash significantly decreased the freeze–thaw resistance of pervious concrete. The compressive strength loss of fly ash modified pervious concrete under freeze–thaw cycles was higher than the unmodified control pervious concrete. The freeze–thaw resistance of fly ash modified pervious concrete decreased with the increasing fly ash content.

- Although fly ash was not positive to the properties of pervious concrete, it was still feasible to apply fly ash as a substitute for cement in pervious concrete.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hu, M.C.; Zhang, X.Q.; Siu, Y.L.; Li, Y.; Tanaka, K.; Yang, H. Flood mitigation by permeable pavements in Chinese sponge city construction. Water 2018, 10, 172. [Google Scholar] [CrossRef]

- Liu, H.; Jia, Y.W.; Niu, C.W. ‘‘Sponge city’’ concept helps solve China’s urban water problems. Environ. Earth. Sci. 2017, 76, 473. [Google Scholar] [CrossRef]

- Ho, H.L.; Huang, R.; Hwang, H.C.; Lin, W.T.; Hsu, H.W. Waste-based pervious concrete for climate-resilient pavements. Materials 2018, 11, 900. [Google Scholar] [CrossRef] [PubMed]

- Chandrappa, A.K.; Biligiri, K.P. Pervious concrete as a sustainable pavement material–Research findings and future prospects: A state-of-the-art review. Constr. Build. Mater. 2016, 111, 262–274. [Google Scholar] [CrossRef]

- Li, J.S.; Zhang, Y.; Liu, G.L.; Peng, X.H. Preparation and performance evaluation of an innovative pervious concrete pavement. Constr. Build. Mater. 2017, 138, 479–485. [Google Scholar] [CrossRef]

- Richards, D.R.; Edwards, P.J. Using water management infrastructure to address both flood risk and the urban heat island. Int. J. Water. Resour. Dev. 2017, 34, 490–498. [Google Scholar] [CrossRef]

- Zhu, Z.H.; Chen, X.H. Evaluating the effects of low impact development practices on urban flooding under different rainfall intensities. Water 2017, 9, 548. [Google Scholar] [CrossRef]

- Du, S.Q.; Shi, P.J.; Rompaey, A.V.; Wen, J.H. Quantifying the impact of impervious surface location on flood peak discharge in urban areas. Nat. Hazards 2015, 76, 1457–1471. [Google Scholar] [CrossRef]

- Wei, T.; Wijesiri, B.; Jia, Z.L.; Li, Y.X.; Goonetilleke, A. Re-thinking classical mechanistic model for pollutant build-up on urban impervious surfaces. Sci. Total Environ. 2019, 651, 114–121. [Google Scholar] [CrossRef]

- Neithalath, N.; Sumanasooriya, M.S.; Deo, O. Characterizing pore volume, sizes, and connectivity in pervious concretes for permeability prediction. Mater. Charact. 2010, 61, 802–813. [Google Scholar] [CrossRef]

- Putman, B.J.; Neptune, A.I. Comparison of test specimen preparation techniques for pervious concrete pavements. Constr. Build. Mater. 2011, 25, 3480–3485. [Google Scholar] [CrossRef]

- Liu, R.T.; Liu, H.J.; Sha, F.; Yang, H.L.; Zhang, Q.S.; Shi, S.S.; Zheng, Z. Investigation of the porosity distribution, permeability, and mechanical performance of pervious concretes. Processes 2018, 6, 78. [Google Scholar] [CrossRef]

- Ngohpok, C.; Sata, V.; Satiennam, T.; Klungboonkrong, P.; Chindaprasirt, P. Mechanical properties, thermal conductivity, and sound absorption of pervious concrete containing recycled concrete and bottom ash aggregates. KSCE J. Civ. Eng. 2018, 22, 1369–1376. [Google Scholar] [CrossRef]

- Nguyen, D.H.; Sebaibi, N.; Boutouil, M.; Leleyter, L.; Baraud, F. A modified method for the design of pervious concrete mix. Constr. Build. Mater. 2014, 73, 271–282. [Google Scholar] [CrossRef]

- Korat, K.L.; Ducman, V.; Netinger, I. Influence of aggregate type and size on properties of pervious concrete. Constr. Build. Mater. 2015, 78, 69–76. [Google Scholar]

- Wang, L.; Yang, H.Q.; Dong, Y.; Chen, E.; Tang, S.W. Environmental evaluation, hydration, pore structure, volume deformation and abrasion resistance of low heat Portland (LHP) cement-based materials. J. Clean. Prod. 2018, 203, 540–558. [Google Scholar] [CrossRef]

- Xu, X.N.; Yang, Y.L.; Xiao, C.; Zhang, X.M. Energy balance and global warming potential of corn straw-based bioethanol in China from a life cycle perspective. Int. J. Green Energy 2018, 15, 296–304. [Google Scholar] [CrossRef]

- Pellecchia, M.; Negri, I. Particulate matter collection by honey bees (Apis mellifera, L.) near to a cement factory in Italy. PeerJ 2018, 6, e5322. [Google Scholar] [CrossRef]

- Wang, C.Y.; Olsson, G.; Liu, Y. Coal-fired power industry water-energy-emission nexus: A multi-objective optimization. J. Clean. Prod. 2018, 203, 367–375. [Google Scholar] [CrossRef]

- Temuujin, J.; Surenjav, E.; Ruescher, C.H.; Vahlbruch, J. Processing and uses of fly ash addressing radioactivity (critical review). Chemosphere 2019, 216, 866–882. [Google Scholar] [CrossRef]

- Blissett, R.S.; Rowson, N.A. A review of the multi-component utilization of coal fly ash. Fuel 2012, 97, 1–23. [Google Scholar] [CrossRef]

- Yao, Z.T.; Ji, X.S.; Sarker, P.K.; Tang, J.H.; Ge, L.Q.; Xia, M.S.; Xi, Y.Q. A comprehensive review on the applications of coal fly ash. Earth Sci. Rev. 2015, 141, 105–121. [Google Scholar] [CrossRef]

- Karthik, A.; Sudalaimani, K.; Vijayakumar, C.T.; Saravanakumar, S.S. Effect of bio-additives on physico-chemical properties of fly ash-ground granulated blast furnace slag based self cured geopolymer mortars. J. Hazard. Mater. 2019, 361, 56–63. [Google Scholar] [CrossRef] [PubMed]

- Kurda, R.; Silvestre, J.D.; Brito, J. Life cycle assessment of concrete made with high volume of recycled concrete aggregates and fly ash. Resour. Conserv. Recyc 2018, 139, 407–417. [Google Scholar] [CrossRef]

- Wu, W.J.; Wang, R.; Zhu, C.Q.; Meng, Q.S. The effect of fly ash and silica fume on mechanical properties and durability of coral aggregate concrete. Constr. Build. Mater. 2018, 185, 69–78. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, Z.C.; Yang, Y.G.; Yao, Y. Measurement and correlation of ductility and compressive strength for engineered cementitious composites (ECC) produced by binary and ternary systems of binder materials: Fly ash, slag, silica fume and cement. Constr. Build. Mater. 2014, 68, 192–198. [Google Scholar] [CrossRef]

- Uthaman, S.; Vishwakarma, V.; George, R.P.; Ramachandran, D.; Kumari, K.; Preetha, R.; Premila, M.; Rajaraman, R.; Kamachi Mudali, U.; Amarendra, G. Enhancement of strength and durability of fly ash concrete in seawater environments: Synergistic effect of nanoparticles. Constr. Build. Mater. 2018, 187, 448–459. [Google Scholar] [CrossRef]

- Ma, H.X.; Yu, H.F.; Li, C.; Tan, Y.S.; Cao, W.T.; Da, B. Freeze–thaw damage to high–performance concrete with synthetic fibre and fly ash due to ethylene glycol deicer. Constr. Build. Mater. 2018, 187, 197–204. [Google Scholar] [CrossRef]

- Muthaiyan, U.M.; Thirumalai, S. Studies on the properties of pervious fly ash–cement concrete as a pavement material. Cogent Eng. 2017, 4, 1318802. [Google Scholar] [CrossRef]

- Aoki, Y.; Sri Ravindrarajah, R.; Khabbaz, H. Properties of pervious concrete containing fly ash. Road Mater. Pavement Des. 2012, 13, 1–11. [Google Scholar] [CrossRef]

- Zaetang, Y.; Wongsa, A.; Sata, V.; Chindaprasirt, P. Use of coal ash as geopolymer binder and coarse aggregate in pervious concrete. Constr. Build. Mater. 2015, 96, 289–295. [Google Scholar] [CrossRef]

- Peng, H.; Yin, J.; Song, W.M. Mechanical and hydraulic behaviors of Eco-friendly pervious concrete incorporating fly ash and blast furnace slag. Appl. Sci. 2018, 8, 895. [Google Scholar] [CrossRef]

- Perez, L.S.; Hwang, S. Mix design and pollution control potential of pervious concrete with non-compliant waste fly ash. J. Environ. Manag. 2016, 176, 112–118. [Google Scholar] [CrossRef] [PubMed]

- Carrasquillo, V.L.; Hwang, S. Comparative assessment of pervious concrete mixtures containing fly ash and nanomaterials for compressive strength, physical durability, permeability, water quality performance and production cost. Constr. Build. Mater. 2017, 139, 148–158. [Google Scholar] [CrossRef]

- Liu, H.B.; Luo, G.B.; Wei, H.B.; Yu, H. Strength, permeability, and freeze-thaw durability of pervious concrete with different aggregate sizes, porosities, and water-binder ratios. Appl. Sci. 2018, 8, 1217. [Google Scholar] [CrossRef]

- Liu, H.B.; Luo, G.B.; Gong, Y.F.; Wei, H.B. Mechanical properties, permeability, and freeze–thaw resistance of pervious concrete modified by waste crumb rubbers. Appl. Sci. 2018, 8, 1843. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Technical Specification for Pervious Cement Concrete Pavement; Ministry of Housing and Urban-Ural Construction of the People’s Republic of China: Beijing, China, 2009. (In Chinese)

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Standard for Test. Method of Mechanical Properties on Ordinary Concrete; Ministry of Housing and Urban-Ural Construction of the People’s Republic of China: Beijing, China, 2002. (In Chinese)

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Standard for Test. Methods of Long-Term Performance and Durability of Ordinary Concrete; Ministry of Housing and Urban-Ural Construction of the People’s Republic of China: Beijing, China, 2009. (In Chinese)

- Neville, A.M. Property of concrete, 4th ed.; China Architecture and Building Press: Beijing, China, 2009; pp. 199–203. ISBN 9787112127436. [Google Scholar]

| Physical Property | Index |

|---|---|

| Type | natural granite coarse aggregate |

| Size (mm) | 4.75–9.5 |

| Apparent density (kg/m3) | 2786 |

| Bulk density (kg/m3) | 1534 |

| Bulk porosity (%) | 44.9 |

| Crushing value (%) | 9.7 |

| Needle-like particle content (%) | 7.1 |

| Water absorption (%) | 1.63 |

| Density (g/cm3) | Specific Surface Area (m2/kg) | Setting Time (min) | Compressive Strength (MPa) | Flexural Strength (MPa) | |||

|---|---|---|---|---|---|---|---|

| Initial Setting | Final Setting | 3 d | 28 d | 3 d | 28 d | ||

| 2.96 | 342 | 182 | 251 | 21.8 | 47.6 | 4.7 | 7.5 |

| Materials | Chemical Composition (%) | |||||

|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | CaO | MgO | Fe2O3 | SO3 | |

| Cement | 22.6 | 5.6 | 62.7 | 1.7 | 4.3 | 2.5 |

| Fly ash | 51.3 | 22.8 | 10.7 | 2.8 | 6.9 | 1.9 |

| Mix ID | Coarse Aggregate | Cement | Fly Ash | Water | Superplasticizer |

|---|---|---|---|---|---|

| Control | 1503.3 | 479.9 | 0 | 144.0 | 3.84 |

| FA-3 | 1503.3 | 462.0 | 14.3 | 142.9 | 3.81 |

| FA-6 | 1503.3 | 444.3 | 28.4 | 141.8 | 3.78 |

| FA-9 | 1503.3 | 426.9 | 42.2 | 140.7 | 3.75 |

| FA-12 | 1503.3 | 409.8 | 55.9 | 139.7 | 3.73 |

| Mix ID | Porosity (%) | Permeability Coefficient (mm/s) | 28 d CS 1 (MPa) | 28 d FS 2 (MPa) | 150 d CS (MPa) | 150 d FS (MPa) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean | SD 3 | Mean | SD | Mean | SD | Mean | SD | Mean | SD | Mean | SD | |

| Control | 14.0 | 0.4 | 3.91 | 0.12 | 22.2 | 0.50 | 4.84 | 0.09 | – | – | – | – |

| FA-3 | 14.1 | 0.2 | 3.94 | 0.15 | 20.0 | 0.57 | 4.39 | 0.10 | 21.5 | 0.59 | 4.77 | 0.09 |

| FA-6 | 13.7 | 0.4 | 3.79 | 0.13 | 18.9 | 0.43 | 4.01 | 0.14 | 20.2 | 0.62 | 4.33 | 0.08 |

| FA-9 | 14.5 | 0.3 | 3.97 | 0.11 | 16.3 | 0.61 | 3.73 | 0.10 | 18.5 | 0.51 | 4.12 | 0.11 |

| FA-12 | 13.8 | 0.3 | 3.87 | 0.13 | 14.7 | 0.54 | 3.54 | 0.12 | 17.4 | 0.32 | 3.78 | 0.10 |

| Mix ID | Compressive Strength and Its Loss After Freeze–Thaw Cycles | |||||||

|---|---|---|---|---|---|---|---|---|

| 25 Cycles | 50 Cycles | 75 Cycles | 100 Cycles | |||||

| Compressive Strength (MPa) | Loss (%) | Compressive Strength (MPa) | Loss (%) | Compressive Strength (MPa) | Loss (%) | Compressive Strength (MPa) | Loss (%) | |

| Control | 21.2 | 4.5 | 18.1 | 18.5 | 16.7 | 24.8 | 14.2 | 36.0 |

| FA-3 | 18.8 | 6.0 | 16.4 | 18.0 | 14.8 | 26.0 | – | – |

| FA-6 | 17.5 | 7.4 | 15.2 | 19.6 | 13.9 | 26.5 | – | – |

| FA-9 | 15.1 | 7.4 | 12.8 | 21.5 | 11.5 | 29.4 | – | – |

| FA-12 | 13.5 | 8.2 | 10.7 | 27.2 | – | – | – | – |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Luo, G.; Wang, L.; Gong, Y. Strength Time–Varying and Freeze–Thaw Durability of Sustainable Pervious Concrete Pavement Material Containing Waste Fly Ash. Sustainability 2019, 11, 176. https://doi.org/10.3390/su11010176

Liu H, Luo G, Wang L, Gong Y. Strength Time–Varying and Freeze–Thaw Durability of Sustainable Pervious Concrete Pavement Material Containing Waste Fly Ash. Sustainability. 2019; 11(1):176. https://doi.org/10.3390/su11010176

Chicago/Turabian StyleLiu, Hanbing, Guobao Luo, Longhui Wang, and Yafeng Gong. 2019. "Strength Time–Varying and Freeze–Thaw Durability of Sustainable Pervious Concrete Pavement Material Containing Waste Fly Ash" Sustainability 11, no. 1: 176. https://doi.org/10.3390/su11010176

APA StyleLiu, H., Luo, G., Wang, L., & Gong, Y. (2019). Strength Time–Varying and Freeze–Thaw Durability of Sustainable Pervious Concrete Pavement Material Containing Waste Fly Ash. Sustainability, 11(1), 176. https://doi.org/10.3390/su11010176