1. Introduction

Conventional global energy resources are depleting at a rapid pace, and there is an added disadvantage of price volatility. Due to high demand and limited reserves, energy resources are doomed to run out [

1]. Fossil fuel prices are in a constant state of turmoil, which is causing severe distress to the economies of fuel-importing countries such as Pakistan. Pakistan has been at the brunt of the incessant energy crisis for more than a decade. Pakistan is situated on 25°N to 34°N latitude, which is a sunny and hot climatic region. In some areas, the weather remains hot for almost 70% of the year. Thus a major share of energy is used to maintain thermal comfort inside the buildings [

2]. Around 45% of the energy consumption in Pakistan is used for domestic purposes, while 27% is used by industrial consumers. Half of the domestic energy is consumed for cooling and heating purposes [

3]. The energy consumption in buildings is increasing with an annual growth rate of 4.7% and 2.5% in the domestic sector and commercial sector, respectively [

4]. This is in stark contrast with the international average, especially in China and in European countries, where 25% of domestic electricity consumption goes to heating and cooling [

2]. A target has been set by the National Energy Conservation Center of Pakistan to bring down the energy consumption in the domestic sector to 30%, which is primarily possible through buildings with low emissions and low energy consumption [

5].

To minimize the energy consumption used for heating and cooling in buildings and to reduce the dependence on conventional Heat, Ventilation, and Air Conditioning (HVAC) systems, many passive techniques have been employed in recent times. The passive techniques consume energy content of natural resources with little or no input from conventional sources of energy. One such technique is the Earth to Air Heat Exchanger (EAHE) system [

6]. EAHE exchange is a system of buried pipes that uses the constant or slightly varying underground temperature as a heat sink/source for the ambient air from the outside atmosphere flowing through these pipes into the building. The underground temperature at certain depths remains constant throughout the year due to the thermal inertial property of soil [

7].

EAHE is a green retrofit for cooling and heating of the buildings [

8]. It is a passive technology that consumes low or no energy with almost no emissions as compared to conventional HVAC technologies, that is why it is termed as a green building technology [

9]. EAHE consumes geothermal energy, which is renewable and hence sustainable source of heating and cooling in buildings [

10]. EAHE reduces greenhouse gases emissions as it does not use any refrigerant as working fluid. The working fluid in EAHE is air [

11].

EAHE systems are divided into subgroups based on their configuration and design into open-loop and closed-loop EAHEs. Open loop EAHEs draw air directly from the atmosphere as shown in

Figure 1a, while closed-loop EAHEs loop the air from a building until the desired temperature is achieved as shown in

Figure 1b [

12]. EAHEs can become a viable alternative to conventional air conditioning systems while giving a simplistic design and mitigating environmental concerns and costs at the same time [

13]. The open loop system is preferred over closed loop as it provides the clean fresh air that circulates through pipes and meets the building cooling/heating requirements as compared to the closed loop where the same air is recirculated through the pipes [

12].

EAHEs have been used for passive air conditioning, but they are impacted by several factors, such as weather, surface temperature, soil temperature and composition, and the geometry of the pipes [

14]. Therefore, site selection for EAHEs is governed by the soil properties, including soil density, thermal diffusivity, conductivity, and the water and rock bed, and the process is complex [

15].

The two performance indicators for EAHE are the temperature drop (temperature difference between the inlet and outlet air) and heat transfer rate. These two factors should be optimized using proper methodology/techniques to improve the performance of EAHE systems [

16]. Several methodologies have been employed to investigate the performance of EAHE systems, summarized as follows.

A model incorporating projections of soil-temperature variations with time and depth was developed based on transient heat flow with certain assumptions. The model predictions had 85% to 90% accuracy as compared to the experimental data [

17]. Another one-dimensional model incorporating convection diffusion with conduction processes was formulated for an air–earth–rock system. The system also considers humidity, it predicted temperature with 90% accuracy, and with a tolerance of 1.4 °C [

18].

The relationship between burial depth, outlet temperature, Reynolds number, and the ratio of the pipe length to the diameter is addressed in [

19]. It is indicated that the outlet temperature is inversely related to the pipe ratio (length to diameter ratio) and directly proportional to the Reynolds number and burial depth [

19].

Convective heat transfer is estimated for large rectangular cross-sectional area EAHE systems. Computational Fluid Dynamics (CFD) simulations were used to train Artificial Neural Network (ANN) models [

20]. Parametric studies were carried out and mathematical relationship between six design parameters and Average Nusselt numbers were established. It was revealed that surface temperature variation, duct outlet section size, and turbulence intensity of air had no effect on average Nusselt numbers. However, it was affected by duct length, inlet cross section area, the temperature difference between surface and inlet air, air velocity, and different operating modes [

20].

Fuzzy logic controller is applied to optimize the power consumption in an EAHE system [

21]. It was revealed that by using the fuzzy logic controller instead of an on–off controller less energy is consumed by the EAHE system [

21]. Using Genetic algorithm, the EAHE system is evaluated and optimized for four parameters, i.e., air humidity, ambient air temperature, sub-soil temperature, and ground surface temperature [

22].

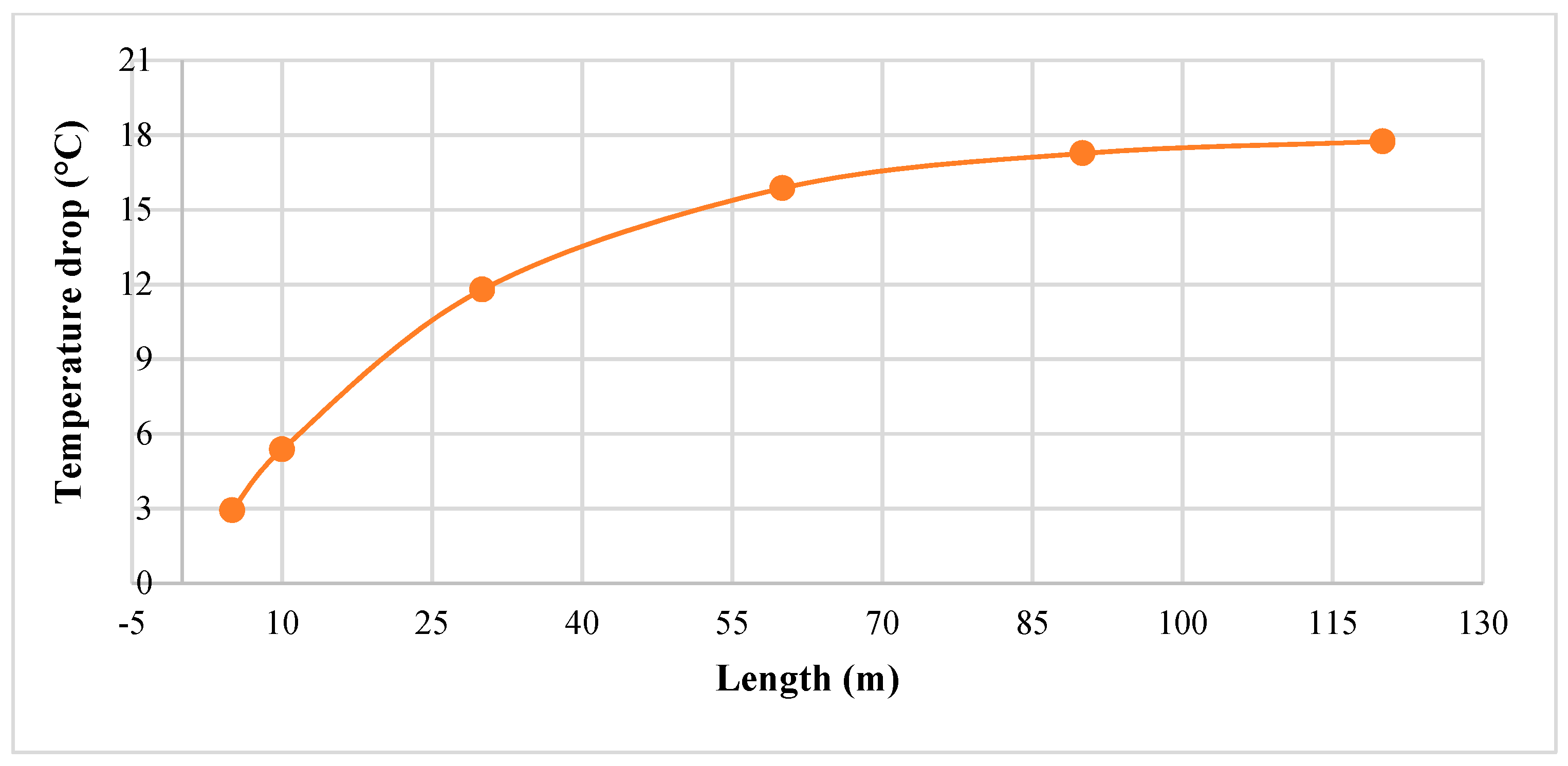

With an increase in the length of the pipe, temperature drops between inlet air and outlet air increases but the rate of change of temperature decreases [

23]. Similarly, after a certain length, the heat transfer remains the same with an increase in the length of the pipe, this phenomenon is termed as saturation length. With an increase in airflow, the saturation length also increases [

24]. Pipe length is the most influential variable that affects the thermal performance of the EAHE system [

25].

A low-velocity airflow provides more contact between the pipe and air hence increasing the heat transfer. An air velocity from 0.5 to 2.5 was considered for cooling performance of an EAHE system; where it was found that at the lowest flowing air velocity the temperature drop was maximum [

26]. In an experimental study [

27], three different velocities were considered for the pipe with a diameter of 0.1 m and length 19.2 m. It was observed that the maximum temperature drop of 12.9 °C occurs at 2 m/s and the minimum temperature drop occurs at 11.3 °C at 5 ms

−1 [

27].

The number of passes and geometrical configuration of pipes also impacts the EAHE performance. A numerical investigation of different geometrical configurations of pipes of an EAHE system shows that the thermal performance was enhanced by up to 115% and 73% for heating and cooling, respectively, by increasing the number of buried pipes covering the same area and accommodating the fixed mass flow rate [

28]. The performance of an EAHE can be improved by using multiple-pipe configurations. A multiple-pipe configuration with a separation of 1.5 m and a depth of 3 m has better thermal performance than a single-pipe configuration [

29].

In a simulation study of an EAHE system [

30], three different parameters were simulated. The three parameters were inlet air temperature, ground temperature, and airflow rate in laboratory conditions. The highest heat transfer rate was observed at airflow of 0.07 kg s

−1 and ground temperature of 23 °C. In addition, the highest temperature drop of 9.62 °C occurred at 0.07 kg s

−1 and ground temperature of 23 °C [

30].

The thermal performance of an EAHE system was simulated in the Energy Plus program (simulation software to model energy consumption in buildings) in [

31]. It was concluded that the thermal performance depends up on the pipe depth and length. Results indicated that an EAHE module can reduce the cooling load by almost 50% [

31]. The model in [

32] studied in the hot, arid climatic conditions of Kuwait, analyzing the climatic impact. It was found that the EAHE system could not perform alone in these conditions but could be used and performed best in conjunction with a conventional air conditioning system [

32]. A numerical simulating model [

18] based on fluid dynamics and heat transfer conditions is modelled to predict the thermal behavior of EAHE. The model predicts that the temperature remains constant at 3 m depth. In addition, the model does the same computation, 45% faster, compared to other model [

18]. The EAHE system causes a decrease of 8 °C in summer and an increase of 2 °C in winter. A Quasi mathematical model was developed in MATLAB using an energy balance equation in [

33]. Air and soil temperatures were estimated using CFD. The parametric study for pipe length and pipe diameter for three different materials i.e., polyvinyl chloride (PVC), steel, and copper was reported to be the same [

33].

1.1. Response Surface Method (RSM)

The Response Surface Method (RSM) was introduced by Box and Wilson for optimization of engineering problems [

34]. It employs various approximate optimization techniques based on mathematical and statistical models. Through these techniques, a response that depends on various parameters is optimized [

35]. RSM consists of two essential components i.e., Design of Experiment (DoE) and Regression Analysis. DoE is a systematic method that gives the design sample between input variables and the output response variable. Regression analysis estimates the response variable under the influence of independent variables [

36]. The process of RSM is similar to that of experimental process [

37]. First of all, the influencing factors are identified, and their response are measured at various levels. Secondly, through ANOVA (Analysis of Variance) the significant factors, individual effect, and interaction effect is determined. Lastly, using the regression equation the response is predicted for any unknown values of significant factors [

37].

The Response Surface Method is based on the following steps [

38]:

Design experiment and measure responses at various levels of variables

Develop and apply first and second response surfaces

Determine parameters influencing the process for maximum and minimum responses

Identify correlations between the variables through plots

Develop a regression equation for significant parameters

The response surface is given as a function of independent and continuous variables by the following equation:

where

n is the number of variables influencing the response function

Y. It is rather important to establish a valid functional correlation between the response surface and variables.

Limited research outcomes have been reported in which a statistical optimization technique is used to identify the significant contribution of these parameters, optimize these significant parameters, and to predict the performance of EAHE systems on the basis of the contribution of these significant parameters.

In this paper statistical optimization methodology is used, in contrast to the previously prevalent simulation-based models and mathematical models used for parametric study of the influencing variables. A mathematical model is developed both for predicting sub-soil temperature using soil model and performance, i.e., temperature drop in flowing air and heat transfer of EAHE systems using the EAHE model. Parametric analysis is carried out using an EAHE mathematical model to determine the levels for the selected three parameters (length, diameter, and air velocity) for further optimization through the optimization technique Response Surface Method. This paper is structured in different sections.

Section 1 introduces the concept of EAHE system and RSM and also summarizes previous literature on these topics.

Section 2 outlines the materials and methodology used in this research.

Section 3 explains and discusses the results of the study.

Section 4 concludes the study with findings.

4. Discussion

A new approach for optimization of EAHE was successfully developed using statistical modeling in contrast to the simulation-based models prevalent in the literature. Three influencing variables, length, diameter, and air velocity, were studied and optimized using the statistical optimization technique called RSM. A house in Peshawar city of Pakistan was used as a case study. The results gathered using mathematical models and optimization techniques led to the following findings.

The soil model predicts that temperature varies between 20 and 26 °C at a depth of 3 m. Therefore, the optimal depth to install the EAHE system is 3 m or more to achieve an outlet temperature between 20 and 26 °C for the weather and soil conditions of Peshawar.

The effectiveness of the design parameters was determined. The effective length for the earth-to-air heat exchanger, for which a significant amount of temperature drop occurs, lies between 20 and 70 m. The effective diameter that significantly influences the temperature drop lies between 0.1 and 0.3 m, and for air velocity the range is 3 to 7 m/s.

RSM indicates that all the three design parameters have a significant effect on the heat transfer rate (cooling load) and the model used is significant, as indicated by ANOVA (see

Table 6). Diameter is the most significant contributor to the cooling load with the largest F-value compared to length and air velocity. Similarly, the length and diameter have the largest interaction effect on the cooling load, having the largest F-value compared to other interaction effects i.e., length and air velocity and diameter and air velocity. Regression Equation (19) can be used to predict the heat transfer rate (cooling load) using any value of the significant parameters, which are length, diameter, and air velocity.

In addition, from the contour plot (

Figure 8) between air velocity and diameter for holding the length at 50–70 m, the 3 KW cooling load, which is the cooling load for a single room, can be achieved with between 0.18 and 0.25 m in diameter and air velocity ranging from 5 to 7 m/s.

The RSM optimization technique gives different ranges for the cooling load with different alternatives. It would help the designers in decision making to select the cheapest alternative in terms of pipe material, excavation cost, and installation cost. The soil model predicts the underground temperature knowing the underground temperature profile, and optimal depth where the temperature lies between the ranges of thermal comfort can be selected. Resultantly, it helps in minimizing excavation costs to dig up the land for installation of pipes. Moreover, as shown in the contour plots, the same amount of cooling load wattage can be compensated using a range for each parameter. Regression Equation (19) estimates the cooling load for any value of the influencing parameter as an input. In contrast to using complex simulation tools, using the proposed approach, the designers and manufactures can use any statistical tool to design the EAHE systems efficiently and effectively. The major disadvantage of this approach is that it does not accommodate the condensation factor inside the pipes, which will be incorporated into a future model. In previous studies the influencing variables were discussed but their significant impact on the performance of EAHEs was not proven statistically; it is proven in this study.

Before reaching the current developed method in the manuscript, extensive literature reviews were carried out. Previously, high-end software like CFD and other fluid analysis and building management software were used for analysis and optimization. This software is expensive, requires high-computing-power computers, and expertise in operating the software. Current methodology uses simple heat transfer and energy governing equations to design, analyze, and then using statistical techniques the parameters influencing the performance of system are optimized. This approach can easily be implemented using simple statistical tools. This approach is useful as it does not need high computing power computers and expertise in this field.

The EAHE system is clean and green as it does not contribute to greenhouse gases emissions. The working fluid in this technology is air rather than refrigerants. It has negligible maintenance costs as it uses just a simple blower fan, and the expected system life depends upon the pipe’s life. It can be used stand-alone or can be integrated with conventional HVAC systems to minimize the cost associated with maintaining thermal comfort inside the building. The limitations of EAHE system is its initial capital cost and the availability of land to install this system.

Moreover, the methodology is not case specific. It takes soil data and weather data as an input for any building load. The contour plot (

Figure 8) provided different alternatives. For example, for a cooling load of 3 kW, each point on a border line between light blue and light green gives a different configuration of pipe parameters and air flow. Each of these points are different alternatives. Using this approach, the contour plots gives an idea of different configuration of influencing variables i.e., length, diameter, and air velocity. The regression equation generated as a result of this approach predicts the cooling load for any selected alternative based on a tradeoff between different alternatives. The cost associated with different configurations of pipe parameters and blower power consumption for same cooling load can be estimated based on the information provided by the contour plots. The alternatives can be evaluated and decisions shall be made based on the cost benefit analysis of each of these alternatives.