Product Diversification in Sustainability Transition: The Forest-Based Bioeconomy in Finland

Abstract

1. Introduction

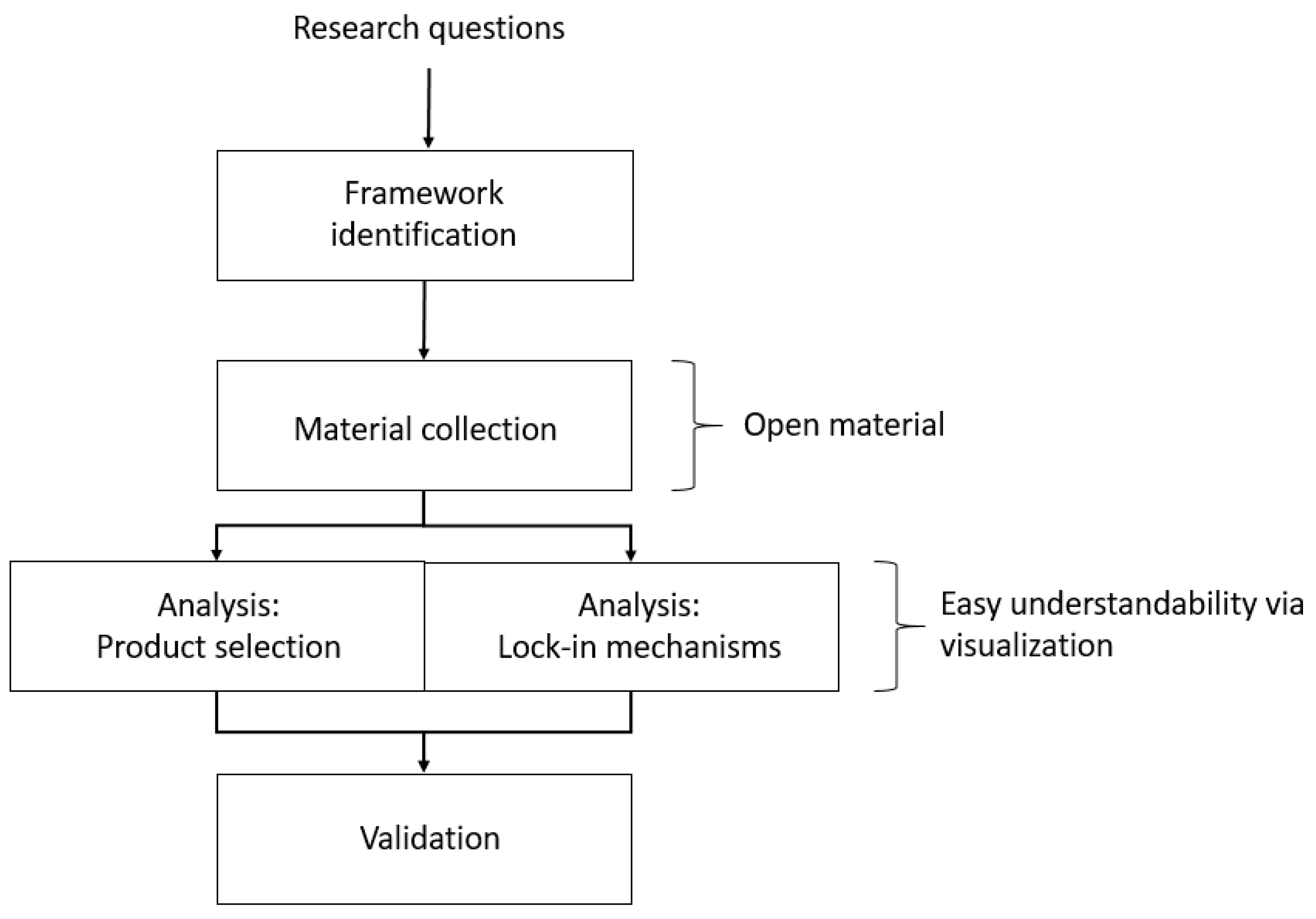

2. Theoretical Framework

3. Materials and Methods

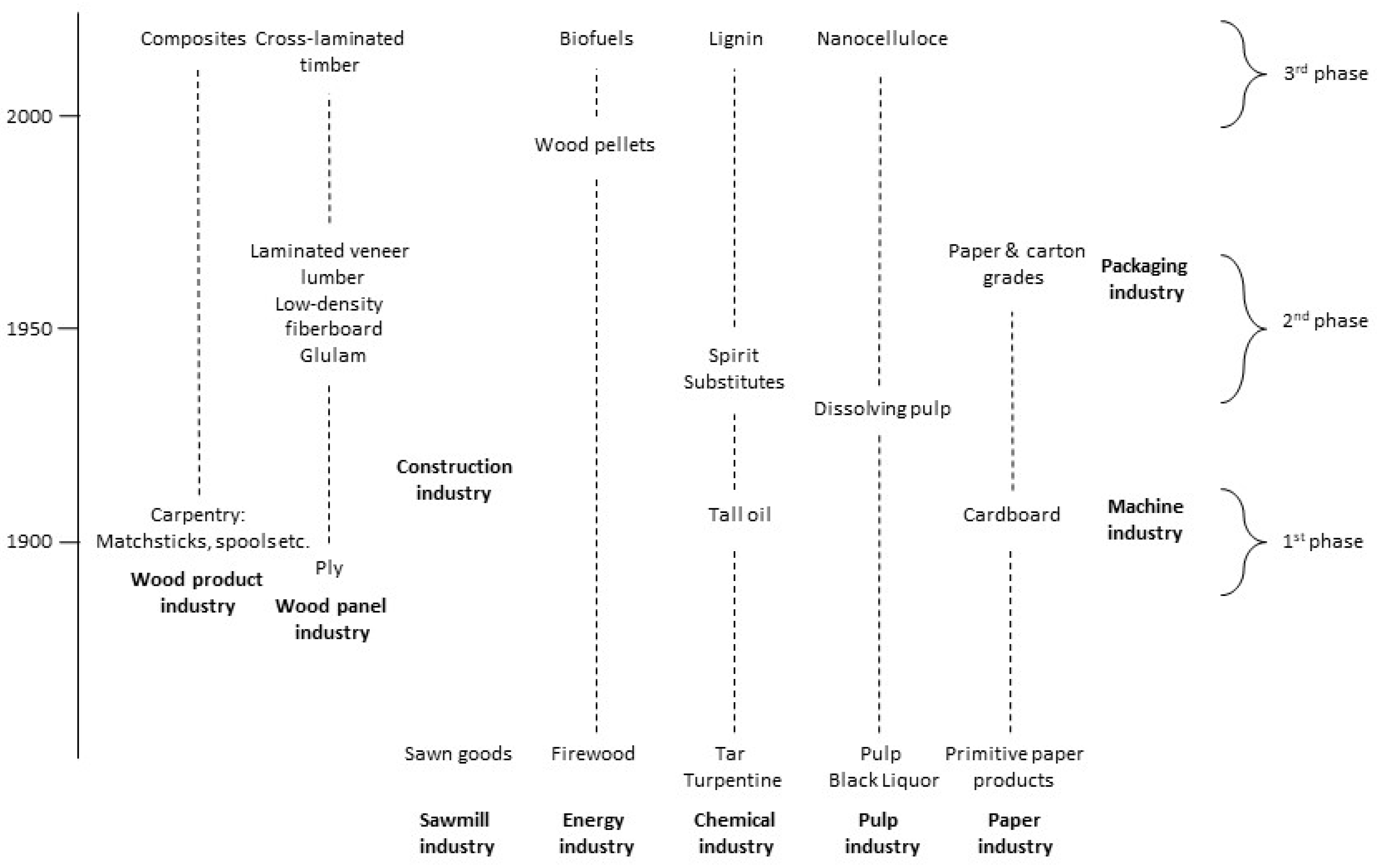

4. Results

4.1. Learning Effects

4.2. Network Effects

4.3. Economies of Scale

4.4. Summary of the Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Title | Translation | Author | Type of Document |

|---|---|---|---|

| Suomen metsäsektori uudistuu ja monipuolistuu | Forest sector in Finland reforms and diversifies | [7] | Magazine article |

| Tilastotietokanta | Statistics database | [10] | Web page |

| Metsäsektorin suhdannekatsaus 2018-2019 | Forest sector’s economic outlook | [12] | Report |

| Puupohjaisen biotalouden taloudelliset vaikutukset ja näkymät | Economic impacts and outlooks of the forest-based bioeconomy | [13] | Working paper |

| Mastering the dynamics of innovation: How companies can seize opportunities in the face of technological change | [44] | Book | |

| Suomen sahateollisuuden historia | History of the Finnish sawmill industry | [53] | Book |

| Saha | Sawmill | [54] | Book |

| Paperin painajainen: Metsäliitto, metsät ja miljardit Suomen kohtaloissa 1984-2014 | Nightmare of paper: Metsäliitto, forests and billions in Finland’s destinies between 1984-2014 | [55] | Book |

| Tervanpoltosta innovaatiotalouteen | From tar-burning to innovation economy | [56] | Book |

| Puusta pitkään: puutuotteiden suunnittelu ja valmistus | Design and production of wood products | [57] | Book |

| Sahatavaratuotanto | Sawmill production | [58] | Book |

| Tuote- ja teknologiainnovaatiot muuttivat rajusti suomalaista paperiteollisuutta 1900-luvun jälkipuoliskolla | Product and technology innovations changed Finnish paper industry in the late 20th century | [60] | Report |

| The fall and the fragmentation of national clusters: Cluster evolution in the paper and pulp industry | [62] | Journal Article | |

| Forest-Based and Related Industries of the European Union—Industrial Districts, Clusters and Agglomerations | [63] | Book | |

| Metsäteollisuusyritysten strategiset kehityspolut: kilpailu, keskittyminen ja kasvu pitkällä aikavälillä | Strategic pathways of the forest industry companies: competition, focus, and growth in middle range timescale | [64] | Book |

| Metsäteollisuus itsenäisessä Suomessa 1918-1968: Suomen Puunjalostusteollisuuden Keskusliitto 1918-1968 | Forest industry in independent Finland between 1918-1968: The Central Association of Finnish Woodworking Industries between 1918-1968 | [65] | Book |

| Institutional Path Dependence in Competitive Dynamics: The Case of | [66] | Journal Article | |

| Finland’s Forest Industry becomes a global player | [67] | Journal Article | |

| Globalisation and the Finnish forest sector: on the internationalisation of forest-industrial operations | [68] | Journal Article | |

| Suomen metsäklusteri tienhaarassa | Finnish forest cluster in crossroads | [69] | Book section |

| Innovaatiojohtaminen ja sen vaikutuksia metsäteollisuudessa | Innovation management and its impacts in the forest industry | [70] | Journal Article |

| Forest biorefineries—A business opportunity for the Finnish forest cluster | [71] | Journal Article | |

| Tervasta Thermowoodiin- puun vuosisadat | From tar to thermowood—woods centuries | [75] | Web page |

| Tervanpoltto | Tar-burning | [76] | Newspaper article |

| Competitive Behaviour and Business Innovation in the Forest Industry: Family Firms, Listed Companies and Cooperatives Compared | [77] | Journal Article | |

| Uusi luonnonvaratalous: onko biomassa avain kestävään kasvuun? | New natural resource economy: is biomass a key to sustainable growth? | [78] | Book |

| Suomen teollisuustuotannon kasvun vuodet | Growth years of the industrial production in Finland | [79] | Web page |

| Suomen metsäklusteri tienhaarassa | Finnish forest cluster in crossroads | [69] | Book |

| Suomen metsäteollisuuden historia 1600-luvulta nykypäivään ainutlaatuisena kirjasarjana | History of the Finnish forest industry since 17th century until nowadays available as book series | [80] | Web page |

| UPM-Kymmene: metsän jättiläisen synty | Birth of the forest product industry leader | [81] | Book |

| Paperin tuotanto ja kulutus mailman markkinoilla | Paper production and consumption in the world market | [82] | Web page |

| Aasian merkitys kasvaa metsäteollisuuden ulkomaankaupassa | Significance of Asia increases in the forest industry sales | [83] | Web page |

| Suomen metsiä myydään halpana selluna kiinalaisille: "Suomalainen metsäteollisuus saa syyttää tästä itseään | Finnish forest are sold as cheap pulp to Chinese: Finnish forest industry can blame itself | [84] | Newspaper Article |

| Katsaus Suomen sellutehdasinvestointeihin | Overview of the pulp factory investments in Finland | [85] | Web page |

Appendix B

| Sector | Title | Translation | Content | Author | Type of Document |

|---|---|---|---|---|---|

| Wood product | Metsän jättiläisen synty | Birth of the forest product industry leader | Around the 1900s, there were carpenter, matchstick and spool factories, and product diversification, e.g., ply factories produced also spoons, forks, ice hockey sticks and boats | [82] | Book |

| Kaikkea muuta puusta | Everything else from wood | Wood-plastic composites are used e.g., in furniture, guitar and speaker production | [91] | Book | |

| Wood panel | Kiina jätti kaikki muut jälkeensä - ennen vuotta 1970 Suomi tuotti neljä kertaa enemmän vaneria kuin Kiina | China left behind all the others; before 1970, Finland produced four times more ply than China | First plywood mill was built in 1893 | [92] | Newspaper Article |

| Liimapuukäsikirja | Glulam handbook | Glulam production started in 1945 due to war reparations | [93] | Book | |

| Vanhoja ja vähän uudempiakin rakennusmateriaaleja | Old and new construction materials | LDF production started in the 1950s | [94] | Web page | |

| LVL | LVL | Laminated veneer lumber production started in the 1970s | [95] | Presentation | |

| CLT- tehdas avattiin Kuhmossa | CLT factory launched in Kuhmo | Cross-laminated timber production started in 2014 | [96] | Newspaper Article | |

| Construction | Puurakennusten suunnittelu | Design of wooden building | Prefab production in the construction industry started in the 1920s | [97] | Book |

| Energy | Pelletti palaa, mutta vaatimattomasti | Wood pellets burns modestly | Wood pellet production started in the 1990s | [98] | Web page |

| Lajissaan mailman ensimmäinen- UPM:n Lappeenrannan 175 miljoonan euron biojalostamo aloitti kaupallisen tuotannon | First in the field in the world: UPM biorefinery that cost 175 million euros started commercial production in Lappeenranta | Forest-based biofuel production started in 2014 | [99] | Newspaper Article | |

| Chemical | Tervantuotannosta innovaatiobiotalouteen | Tar production to innovation bioeconomy | Industrial tar production didn’t become significant part of chemical industry | [56] | Book |

| Mäntyöljy on biopohjaisten tuotteiden aarreaitta | Tall oil is a treasury of bioproducts | Tall oil refinement started in the 1910s | [100] | Web page | |

| Metsän jättiläisen synty | The birth of the forest product industry leader | Spirit factory launched during the WW2 | [81] | Book | |

| Oulun mäntyöljy- ja tärpättijalosteet | Oulu’s tall oil and turpentine products | In 1943, substitute production from turpentine started. In 1950 tall oil and turpentine distillery launched in Nuottasaari. | [101] | Report | |

| Suomessa muhii jättipotti—tehdas eristi puusta aineen, josta voi valmistaa ympäristöystävällisiä maaleja ja liimoja | Jackpot brews in Finland: The factory separated substance that can be utilized in environmentally friendly paint and glue products | Lignin production started in 2015 | [102] | Newspaper Article | |

| Pulp | Liukosellun lupaus | Promise of dissolving pulp | Rayon production started in the end of the 1930s. | [103] | Book section |

| Nanosellu on tuleivaisuuden supermateriaali—niin lujaa, että sitä on testattu luotiliivien materiaaliksi | Nanocellulose is a super material of the future: it’s so strong that it has tested in bulletproof vest | Nanocellulose production has been in small-scale | [104] | Newspaper Article | |

| Paper | Jokapäiväinen paperimme | Our daily paper | Wood-based papermaking for a newspaper, wallpaper and wrapping paper started around the 1850s | [105] | Web page |

| Aaltopahvin valmistus ja jalostus | Corrugated cardboard production and processing | Corrugated cardboard production started in the 1910s | [106] | Book | |

| Nestepakkauskartonki | Liquid packaging board | Liquid packaging board production started in the early 1950s | [107] | Report | |

| Paino- ja kirjoituspaperien kehitys 1970-90-luvuilla | Development of graphic and writing paper between the 1970s and the 1990s | Transformation of graphic and writing paper production towards high-grade products started in the 1960s | [59] | Report | |

| Juantehdas: olutpahvista graafisen kartongin laatujohtajaksi | Juantehdas: from beer board to leader in graphic carton | Carton machine renovated thoroughly in the 1960s | [108] | Report | |

| Packaging | Pakkausten historiaa | History of packaging products | Trend in disposable packaging in the 1960s | [109] | Web page |

| Machine | Tervantuotannosta innovaatiotalouteen | From tar production to innovation economy | First paper machines produced in Vyborg in between 1904-1910. | [56] | Book |

References

- European Comission. Bioeconomy. Available online: http://ec.europa.eu/programmes/horizon2020/en/h2020-sectin/bioeconomy (accessed on 10 January 2019).

- Bio-Based Industries Joint Undertaking. About BBI JU. Available online: https://www.bbi-europe.eu/about/about-bbi (accessed on 10 January 2019).

- European Comission Economy. Available online: https://ec.europa.eu/knowledge4policy/bioeconomy/topic/economy_en (accessed on 20 February 2019).

- Bioeconomy. Finnish Bioeconomy Strategy. Available online: https://www.biotalous.fi/wp-content/uploads/2015/01/Suomen_biotalousstrategia_2014.pdf (accessed on 20 February 2019).

- Bioeconomy. Wood and Forest. Available online: https://www.biotalous.fi/puu-ja-metsa/ (accessed on 10 January 2019).

- Ministry of Agriculture and Forestry of Finland. Metsäteollisuus Suomessa. Available online: https://mmm.fi/metsat/puun-kaytto/metsateollisuus-suomessa (accessed on 10 January 2019).

- Hänninen, R. Suomen metsäsektori monipuolistuu ja uudistuu. Available online: http://www.metla.fi/ohjelma/mtu/pdf/Suomen_metsasektori_monipuolistuu_ja_uudistuu_Hanninen_R.pdf (accessed on 10 January 2019).

- Lehtonen, P. Metsäteollisuuden Globaali Kilpailykyky. Available online: http://www.ptt.fi/ennusteet/metsaala/metsasektori-2017-kevat.html (accessed on 10 January 2019).

- Kivistö, J. Suomen rakennemuutos alueiden näkökulmasta. Available online: https://helda.helsinki.fi/bof/bitstream/handle/123456789/14416/eurotalous_analyysi_29.pdf?sequence=1 (accessed on 10 January 2019).

- Luke. Tilastotietokanta. Available online: http://statdb.luke.fi/PXWeb/pxweb/fi/LUKE/LUKE__04 Metsa/?rxid=37351054-dec1-4d3a-9964-7e4fad7f285c (accessed on 25 January 2019).

- PTT. Uudet investoinnit ja sahateollisuuden kohentuneet markkinanäkymät suuntaavat metsäsektorin kehitystä. Available online: http://www.ptt.fi/ennusteet/metsaala/metsasektori-2017-kevat.html (accessed on 10 January 2019).

- Viitanen, J.; Mutanen, A. (Eds.) Metsäsektorin suhdannekatsaus 2018–2019; Luonnonvara- ja biotalouden tutkimus 46/2018; Luonnonvarakeskus: Helsinki, Finland, 2018; 73s; Available online: http://jukuri.luke.fi/bitstream/handle/10024/542785/luke-luobio_46_2018.pdf?sequence=5&isAllowed=y (accessed on 10 January 2019).

- Hietala, J.; Huovari, J. Puupohjaisen biotalouden taloudelliset vaikutukset ja näkymät. Available online: http://www.ptt.fi/media/img/nostot/tp-184.pdf (accessed on 23 January 2019).

- Prime Minister’s Office Finland. Kohti biotaloutta: Kapeikot ja ohjauskeinojen suuntaus. Available online: http://julkaisut.valtioneuvosto.fi/handle/10024/160323 (accessed on 24 January 2019).

- Korhonen, J.; Giurca, A.; Brockhaus, M.; Toppinen, A. Actors and Politics in Finland’s Forest-Based Bioeconomy Network. Sustainability 2018, 10, 3785. [Google Scholar] [CrossRef]

- Perkins, R. Technological “Lock-In”; International Society for Ecological Economics: Boston, MA, USA, 2003. [Google Scholar]

- Unruh, G.C. Understanding carbon lock-in. Energy Policy 2000, 28, 817–830. [Google Scholar] [CrossRef]

- Ministry of Economic Affairs and Employment of Finland. Wood-Based Bioeconomy Solving Global Challenges. Available online: http://julkaisut.valtioneuvosto.fi/bitstream/handle/10024/79985/TEM_oppaat_2_2017_Wood_based_Bioeconomy_Solving_Global_challange_29052017web.pdf?sequence=1&isAllowed=y (accessed on 26 January 2019).

- Coenen, L.; Moodysson, J.; Martin, H. Path Renewal in Old Industrial Regions: Possibilities and Limitations for Regional Innovation Policy. Reg. Stud. 2015, 49, 850–865. [Google Scholar] [CrossRef]

- Novotny, M.; Laestadius, S. Beyond papermaking: Technology and market shifts for wood-based biomass industries—Management implications for large-scale industries. Technol. Anal. Strateg. Manag. 2014, 26, 875–891. [Google Scholar] [CrossRef]

- Smith, A.; Stirling, A.; Berkhout, F. The governance of sustainable sociotechnical transitions. Res. Policy 2005, 34, 1491–1510. [Google Scholar] [CrossRef]

- Markard, J.; Raven, R.; Truffer, B. Sustainability transitions: An emerging field of research and its prospects. Res. Policy 2012, 41, 955–967. [Google Scholar] [CrossRef]

- Rotmans, J.; Loorbach, D. Complexity and Transition Management. J. Ind. Ecol. 2009, 13, 184–196. [Google Scholar] [CrossRef]

- Kemp, R.; Rip, A.; Schot, J. Constructing transition paths through the management of niches BT—Path Dependence and Creation. In Path Dependence and Creation; Lawrence Erlbaum Associates, Inc.: Mahwah, NJ, USA, 2001; pp. 269–299. [Google Scholar]

- Arthur, W.B. Competing Technologies, Increasing Returns, and Lock-In by Historical Events. Econ. J. 1989, 99, 116–131. [Google Scholar] [CrossRef]

- Arthur, W.B. Increasing returns and the new world of business. Harv. Bus. Rev. 1996, 74, 100–109. [Google Scholar]

- Klitkou, A.; Bolwig, S.; Hansen, T.; Wessberg, N. The role of lock-in mechanisms in transition processes: The case of energy for road transport. Environ. Innov. Soc. Transit. 2015, 16, 22–37. [Google Scholar] [CrossRef]

- Kuokkanen, A.; Mikkilä, M.; Kuisma, M.; Kahiluoto, H.; Linnanen, L. The need for policy to address the food system lock-in: A case study of the Finnish context. J. Clean. Prod. 2017, 140, 933–944. [Google Scholar] [CrossRef]

- Bjørnåvold, A.; Van Passel, S. The lock-in effect and the greening of automotive cooling systems in the European Union. J. Environ. Manag. 2017, 203, 1199–1207. [Google Scholar] [CrossRef] [PubMed]

- Meynard, J.-M.; Charrier, F.; Fares, M.; Le Bail, M.; Magrini, M.-B.; Charlier, A.; Messéan, A. Sociotechnical lock-in hinders crop diversification in France. Agron. Sustain. Dev. 2018, 38, 54. [Google Scholar] [CrossRef]

- Stirling, A. A general framework for analysing diversity in science, technology and society. J. R. Soc. Interface 2007, 4, 707–719. [Google Scholar] [CrossRef]

- Von Bertalanffy, L. General system theory. N. Y. 1968, 41973, 40. [Google Scholar]

- Boulding, K.E. General Systems Theory—The Skeleton of Science. Manag. Sci. 1956, 2, 197–208. [Google Scholar] [CrossRef]

- Thurner, S.; Hanel, R.; Klimek, P. Introduction to the Theory of Complex Systems; Oxford University Press: Oxford, UK, 2018. [Google Scholar]

- Geels, F.W. Co-evolutionary and multi-level dynamics in transitions: The transformation of aviation systems and the shift from propeller to turbojet (1930–1970). Technovation 2006, 26, 999–1016. [Google Scholar] [CrossRef]

- Geels, F.W. Technological transitions as evolutionary reconfiguration processes: A multi-level perspective and a case-study. Res. Policy 2002, 31, 1257–1274. [Google Scholar] [CrossRef]

- Geels, F.W. From sectoral systems of innovation to sociotechnical systems: Insights about dynamics and change from sociology and institutional theory. Res. Policy 2004, 33, 897–920. [Google Scholar] [CrossRef]

- Dosi, G. Technological paradigms and technological trajectories: A suggested interpretation of the determinants and directions of technical change. Res. Policy 1982, 11, 147–162. [Google Scholar] [CrossRef]

- Nelson, R.R.; Winter, S.G. In search of useful theory of innovation. Res. Policy 1977, 6, 36–76. [Google Scholar] [CrossRef]

- Geels, F.W. A sociotechnical analysis of low-carbon transitions: Introducing the multi-level perspective into transport studies. J. Transp. Geogr. 2012, 24, 471–482. [Google Scholar] [CrossRef]

- David, P. Clio and the Economics of QWERTY. Am. Econ. Rev. 1985, 75, 332–337. [Google Scholar]

- Cairns, R.C. Climate geoengineering: Issues of path dependence and sociotechnical lock-in. Wiley Interdiscip. Rev. Clim. Chang. 2014, 5, 649–661. [Google Scholar] [CrossRef]

- Unruh, G.C. Escaping carbon lock-in. Energy Policy 2002, 30, 317–325. [Google Scholar] [CrossRef]

- Utterback, J. Mastering the Dynamics of Innovation: How Companies Can Seize Opportunities in the Face of Technological Change; University of Illinois at Urbana-Champaign’s Academy for Entrepreneurial Leadership Historical Research Reference in Entrepreneurship; SSRN: Rochester, NY, USA, 1994. [Google Scholar]

- Pierson, P. Increasing Returns, Path Dependence, and the Study of Politics. Am. Political Sci. Rev. 2000, 94, 251–267. [Google Scholar] [CrossRef]

- Arthur, W.B. Increasing Returns and Path Dependence in the Economy; University of Michigan Press: Ann Arbor, MI, USA, 1994. [Google Scholar]

- Hughes, T.P. The evolution of large technological systems. In The Social Construction of Technological Systems: New Directions in the Sociology and History of Technology; MIT Press: Cambridge, MA, USA, 1987; pp. 51–82. [Google Scholar]

- Arrow, K.J. The Economic Implications of Learning by Doing. Rev. Econ. Stud. 1962, 29, 155–173. [Google Scholar] [CrossRef]

- Cowan, R. Nuclear power reactors: A study in technological lock-in. J. Econ. Hist. 1990, 50, 541–567. [Google Scholar] [CrossRef]

- Safarzyńska, K.; van den Bergh, J.C.J.M. Demand-supply coevolution with multiple increasing returns: Policy analysis for unlocking and system transitions. Technol. Forecast. Soc. Chang. 2010, 77, 297–317. [Google Scholar] [CrossRef]

- Kallis, G.; Norgaard, R.B. Coevolutionary Ecological Economics; Elsevier: Amsterdam, The Netherlands, 2010; Volume 69. [Google Scholar]

- Rip, A.; Kemp, R. Technological change. Hum. Choice Clim. Chang. 1998, 2, 327–399. [Google Scholar]

- Ahvenainen, J. Suomen sahateollisuuden historia; WSOY: Porvoo, Finland, 1984. [Google Scholar]

- Kuisma, M. Saha; Kustannusosakeyhtiö Siltala: Helsinki, Finland, 2011. [Google Scholar]

- Kuisma, M.; Siltala, S.; Keskisarja, T. Paperin painajainen: Metsäliitto, metsät ja miljardit Suomen kohtaloissa 1984–2014; Kustannusosakeyhtiö Siltala: Helsinki, Finland, 2014. [Google Scholar]

- Leppälä, K. Tervanpoltosta innovaatiotalouteen; Avain: Helsinki, Finland, 2012. [Google Scholar]

- Loukola, S.; Immonen, P. Puusta pitkään: Puutuotteiden suunnittelu ja valmistus; WSOY: Porvoo, Finland, 2001. [Google Scholar]

- Sipi, M. Sahatavaratuotanto, 2nd ed.; Opetushallitus: Helsinki, Finland, 2002. [Google Scholar]

- Huuskonen, J.; Pakarinen, H. Paino- ja kirjoituspaperien kehitys 1970- ja 90-luvulla. Available online: https://www.puunjalostusinsinoorit.fi/biometsateollisuus/innovaatiot/4-paperin-ja-kartongin-valmistus/4.1-paino-ja-kirjoituspaperien-kehitys-1970-90-luvuilla/ (accessed on 11 February 2019).

- Huuskonen, J.; Palsanen, J.; Sierilä, P.; Levlin, J.-E.; Niemi, T.; Sundquist, J.; Wartiovaara, I. Tuote- ja teknologiainnovaatiot muuttivat rajusti suomalaista paperiteollisuutta 1900-luvun jälkipuoliskolla. Available online: https://www.puunjalostusinsinoorit.fi/site/assets/files/1356/innovaatioiden_yhteenveto_2014_painoversio.pdf (accessed on 11 February 2019).

- Pakarinen, S.; Mattila, T.; Melanen, M.; Nissinen, A.; Sokka, L. Sustainability and industrial symbiosis—The evolution of a Finnish forest industry complex. Resour. Conserv. Recycl. 2010, 54, 1393–1404. [Google Scholar] [CrossRef]

- Järvinen, J.; Lamberg, J.-A.; Pietinalho, L. The fall and the fragmentation of national clusters: Cluster evolution in the paper and pulp industry. J. For. Econ. 2012, 18, 218–241. [Google Scholar] [CrossRef]

- Hazley, C. Forest-Based and Related Industries of the European Union—Industrial Districts, Clusters and Agglomerations. Available online: https://www.etla.fi/julkaisut/b160-fi/ (accessed on 15 February 2019).

- Näsi, J.; Lamberg, J.-A.; Ojala, J.; Sajasalo, P. Metsäteollisuusyritysten strategiset kehityspolut: Kilpailu, keskittyminen ja kasvu pitkällä aikavälillä; Tekes: Helsinki, Finland, 2001. [Google Scholar]

- Laurila, J.; Mäkinen, E.; Vuorimaa, H. Metsäteollisuus itsenäisessä Suomessa 1918–1968: Suomen Puunjalostusteollisuuden Keskusliitto 1918–1968; Suomen Paperi- ja Puutavaralehti: Helsinki, Finland, 1968. [Google Scholar]

- Lamberg, J.; Laurila, J.; Nokelainen, T. Institutional Path Dependence in Competitive Dynamics: The Case of Paper Industries in Finland and the USA. Manag. Decis. Econ. 2017, 38, 971–991. [Google Scholar] [CrossRef]

- Kaar, E.-J. Finland’s Forest Industry becomes a global player. Unitas 2000, 72, 14. [Google Scholar]

- Aukusti, A. Globalisation and the Finnish forest sector: On the internationalisation of forest-industrial operations. Int. J. Geogr. 2002, 180, 237–250. [Google Scholar]

- Lammi, M. Suomen metsäklusteri tienhaarassa; Seppälä, R., Ed.; Tekes: Helsinki, Finland, 2000; Available online: https://docplayer.fi/11124219-Suomen-metsaklusteri-tienhaarassa.html (accessed on 26 January 2019).

- Pesonen, P. Innovaatiojohtaminen ja sen vaikutuksia metsäteollisuudessa; VTT Publ. 622; VTT Technical Research Centre of Finland: Espoo, Finland, 2006. [Google Scholar]

- Hämäläinen, S.; Näyhä, A.; Pesonen, H.-L. Forest biorefineries—A business opportunity for the Finnish forest cluster. J. Clean. Prod. 2011, 19, 1884–1891. [Google Scholar] [CrossRef]

- Mason, J. Qualitative Researching; Sage Publications: Thousand Oaks, CA, USA, 2002. [Google Scholar]

- Koskinen, I.; Alasuutari, P.; Peltonen, T. Laadulliset menetelmät kauppatieteissä; Gummerus Kirjapaino; Vastapaino: Tampere, Finland, 2005. [Google Scholar]

- Riessman, C.K. Narrative Analysis; University of Huddersfield: Huddersfield, UK, 2005. [Google Scholar]

- Finnish Forest Industries. Available online: https://www.metsateollisuus.fi/tiedotteet/tervasta-thermowoodin-puun-vuosisadat/ (accessed on 26 January 2019).

- Kaleva. Available online: https://www.kaleva.fi/terva/tervan-tuotanto/tervanpoltto/549986/ (accessed on 26 February 2019).

- Ojala, J.; Melander, A.; Lamberg, J.-A. Competitive Behaviour and Business Innovation in the Forest Industry: Family Firms, Listed Companies and Cooperatives Compared. In Proceedings of the XIV International Economic History Congress, Helsinki, Finland, 21–25 August 2006. [Google Scholar]

- Hildén, M.; Hallanaro, E.-L.; Karjalainen, L.; Järvelä, M. Uusi Luonnonvaratalous: Onko biomassa avain kestävaän kasvuun? Gaudeamus: Helsinki, Finland, 2013. [Google Scholar]

- Statistics Finland. Available online: https://www.stat.fi/tup/suomi90/toukokuu.html (accessed on 14 February 2019).

- Finnish Forest Industries. Available online: https://www.metsateollisuus.fi/tiedotteet/suomen-metsateollisuuden-historia-1600-luvulta-nykypaivaan-ainutlaatuisena-kirjasarjana/ (accessed on 10 February 2019).

- Tuuri, A. UPM-Kymmene: Metsän jättiläisen synty; Otava: Helsinki, Finland, 1999. [Google Scholar]

- Finnish Forest Industries. Available online: https://www.metsateollisuus.fi/edunvalvonta/tuotteet/paperin-tuotanto-kulutus-maailman-markkinoilla/ (accessed on 31 January 2019).

- Luke. Available online: https://www.luke.fi/uutiset/aasian-merkitys-kasvaa-metsateollisuuden-ulkomaankaupassa/ (accessed on 28 February 2019).

- Yle. Available online: https://yle.fi/uutiset/3-10173727 (accessed on 18 February 2019).

- Forest Cluster. Available online: http://forestcluster.fi/katsaus-suomen-sellutehdasinvestointeihin/ (accessed on 10 January 2019).

- Peltoniemi, M. Mechanisms of capability evolution in the Finnish forest industry cluster. J. For. Econ. 2013, 19, 190–205. [Google Scholar] [CrossRef]

- Páez-Avilés, C.; Van Rijnsoever, F.J.; Juanola-Feliu, E.; Samitier, J. Multi-disciplinarity breeds diversity: The influence of innovation project characteristics on diversity creation in nanotechnology. J. Technol. Transf. 2018, 43, 458–481. [Google Scholar] [CrossRef]

- D’Costa, A.P. Export Growth and Path Dependence: The Locking-in of Innovations in the Software Industry. Sci. Technol. Soc. 2002, 7, 51–89. [Google Scholar] [CrossRef]

- Finnish Forest Association. Available online: https://smy.fi/artikkeli/metsan-arvo-on-noussut-huimasti-metsateollisuuden-tuotannon-ei-ratkaisu-on-uusi-tuotanto-ei-sellusovinismi/ (accessed on 1 February 2019).

- Kaicell Fibers. Available online: http://kaicellfibers.com/biojalostamohanke/kysymyksiae-ja-vastauksia-faq/ (accessed on 10 January 2019).

- Commitee for the Future. Available online: https://www.eduskunta.fi/FI/tietoaeduskunnasta/julkaisut/Documents/tuvj_3+2013.pdf (accessed on 10 January 2019).

- Kouvolan Sanomat. Available online: https://kouvolansanomat.fi/uutiset/talous/2ce8f2f9-c2b6-418f-8022-fac4447c0803 (accessed on 10 January 2019).

- Suomen Liimapuuyhdistys ry & Puuinfo Oy. Liimapuukäsikirja: Osa 1; Suomen Liimapuuyhdistys ry & Puuinfo Oy: Alajärvi, Finland, 2014. [Google Scholar]

- Rakennustarkkailija. Available online: https://rakennustarkkailija.com/2017/09/22/vanhoja-ja-vahan-uudempiakin-rakennusmateriaaleja/ (accessed on 10 January 2019).

- Levonen, J. Available online: http://www.win-hanke.fi/images/LVL_esitys_Jussi_Levonen_DigiPuu-seminaari_Savonia-amk_28.4.2016.pdf (accessed on 20 February 2019).

- Kainuun Sanomat. Available online: https://www.woodpolis.fi/images/2014/Kainuun_Sanomat_2_12_2014.pdf (accessed on 20 February 2019).

- Siikanen, U. Puurakennusten Suunnittelu; Rakennustieto: Helsinki, Finland, 1998. [Google Scholar]

- Energiauutiset. Available online: https://www.energiauutiset.fi/tilastouutiset/pelletti-palaa-mutta-vaatimattomasti.html (accessed on 21 January 2019).

- Tekniikka & Talous. Available online: https://www.tekniikkatalous.fi/tekniikka/metsa/2015-01-12/Lajissaan-maailman-ensimmäinen---UPMn-Lappeenrannan-175-miljoonan-euron-biojalostamo-aloitti-kaupallisen-tuotannon-3258200.html (accessed on 20 February 2019).

- Bioeconomy. Available online: http://www.biotalous.fi/mantyoljy-on-biopohjaisten-tuotteiden-aarreaitta/ (accessed on 10 February 2019).

- Niemi, T. Available online: https://www.puunjalostusinsinoorit.fi/biometsateollisuus/innovaatiot/9-sivutuotteet-ja-selluloosan-jatkojalosteet/9.9-oulun-mantyoljy-ja-tarpattijalosteet/ (accessed on 10 February 2019).

- Yle. Available online: https://yle.fi/uutiset/3-10098485 (accessed on 22 February 2019).

- Viitala, E.-J. Liukosellun Lupaus. Available online: http://www.metla.fi/aikakauskirja/full/ff16/ff163181.pdf (accessed on 22 February 2019).

- Yle. Available online: https://yle.fi/uutiset/3-10198035 (accessed on 12 February 2019).

- Niinikoski, E. Available online: http://www.craftmuseum.fi/kiertonayttelyt/jokapaivainen_paperimme/jokapaivainen_paperimme_kasiohjelma.pdf (accessed on 1 February 2019).

- Laakso, O.; Rintamäki, T. Aaltopahvin valmistus ja jalostus; Opetushallitus: Helsinki, Finland, 2000. [Google Scholar]

- Salste, M. Available online: https://www.puunjalostusinsinoorit.fi/biometsateollisuus/innovaatiot/4-paperin-ja-kartongin-valmistus/4.12-nestepakkauskartonki/ (accessed on 1 February 2019).

- Sierilä, P. Available online: https://www.puunjalostusinsinoorit.fi/biometsateollisuus/innovaatiot/4-paperin-ja-kartongin-valmistus/4.14-juantehdas-olutpahvista-graafisen-kartongin-laatujohtajaksi/ (accessed on 1 February 2019).

- Finnish National Agency for Education. Available online: http://www04.edu.fi/elintarvikkeidenpakkaaminen/historia.shtml (accessed on 26 February 2019).

| 1850–1917 | 1917–1945 | 1945–1970 | 1970–2000 | 2000–2019 | |

|---|---|---|---|---|---|

| Change in product range | High | Low | High | Low | High |

| Network effects | International purchases of technology and hiring foreign professionals Symbiosis between the wood product, wood panel and machine industries | Associations and cartels Large-scale Western timber networks Creation of a wooden house industry | Symbiosis with the packaging industry Dispersed networks | International ownership of companies Large scale Western paper networks Robust domestic cluster | Increased Asian networks |

| Dispersed networks | |||||

| Economies of scale | Vertical integration Centralization Forest purchases | Horizontal and vertical integration | Horizontal and vertical integration Renovation and upgrading of production lines | Horizontal and vertical integration | Foreign investment |

| Learning effects | Strategic focus on forest resources and raw material management Technological focus on incremental improvements in the sawmill industry Increased quality in technical research and education Sawmill and PPI journals | Strategic focus on finished products Increased research and consulting | Technological focus on incremental improvements in the sawmill and PPI | Changes in R&D: focus on chemicals and pulp and paper products |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luhas, J.; Mikkilä, M.; Uusitalo, V.; Linnanen, L. Product Diversification in Sustainability Transition: The Forest-Based Bioeconomy in Finland. Sustainability 2019, 11, 3293. https://doi.org/10.3390/su11123293

Luhas J, Mikkilä M, Uusitalo V, Linnanen L. Product Diversification in Sustainability Transition: The Forest-Based Bioeconomy in Finland. Sustainability. 2019; 11(12):3293. https://doi.org/10.3390/su11123293

Chicago/Turabian StyleLuhas, Jukka, Mirja Mikkilä, Ville Uusitalo, and Lassi Linnanen. 2019. "Product Diversification in Sustainability Transition: The Forest-Based Bioeconomy in Finland" Sustainability 11, no. 12: 3293. https://doi.org/10.3390/su11123293

APA StyleLuhas, J., Mikkilä, M., Uusitalo, V., & Linnanen, L. (2019). Product Diversification in Sustainability Transition: The Forest-Based Bioeconomy in Finland. Sustainability, 11(12), 3293. https://doi.org/10.3390/su11123293