Abstract

This paper shows how system design determines sustainability outcomes of cassava bioethanol production in Colombia. The recovery of the energy contained in by-products is recommended as compared to single product production. In particular, this study assesses the energy, greenhouse gases, water, and land use performance of alternative cassava cascades working at different scales, highlighting the implications of including anaerobic digestion technology in the chain. The centralized systems showed a poorer energy and greenhouse gases performance as compared to decentralized ones in part due to the artificial drying of cassava chips in the centralized facility. Under solar drying of cassava chips, systems with anaerobic digestion produced three to five times more energy than demanded and produced greenhouse gas savings of 0.3 kgCO2eq L EtOH−1. The water balance output depends upon the water reuse within the ethanol industry, which demands 21–23 L EtOH−1. In the anaerobic digestion scenarios, assuming liquid flows are treated separately, complete water recovery is feasible. Land use for cassava cultivation was calculated to be 0.27–0.35 ha tEtOH−1. The energy and water content of the material to digest, the options for digestate reuse, and the recovery of the methane produced are major considerations substantially influencing the role of anaerobic digestion within cassava cascade configurations.

Keywords:

cassava; bioethanol; energy crops; sustainability analysis; biofuels; bioenergy production 1. Introduction

Cassava is a tropical root crop mainly grown in Africa, Asia, and Latin America. It is the fifth staple food in the world after rice, wheat, maize, and potatoes, being a basic component of the diet of a billion people [1]. As it takes at least 8 months of warm weather to produce a harvestable root, cassava is mostly grown in tropical regions. In Latin America, about 12% of the world’s cassava production takes place in about 11.5% of the world’s cassava cultivated area [1].

Traditionally, cassava is cultivated by small-scale farmers who use it as a food crop. However, cassava is also used as animal fodder, for the industrial production of starch, gums, adhesives, and it is also considered an attractive crop for the production of ethanol. In Colombia, cassava’s main use has been domestic consumption (70.5%), followed by fresh animal feed (18.4%), dry cassava for concentrated feed (4.1%), bitter starch (2.2%), and sweet starch (1.8%) [2].

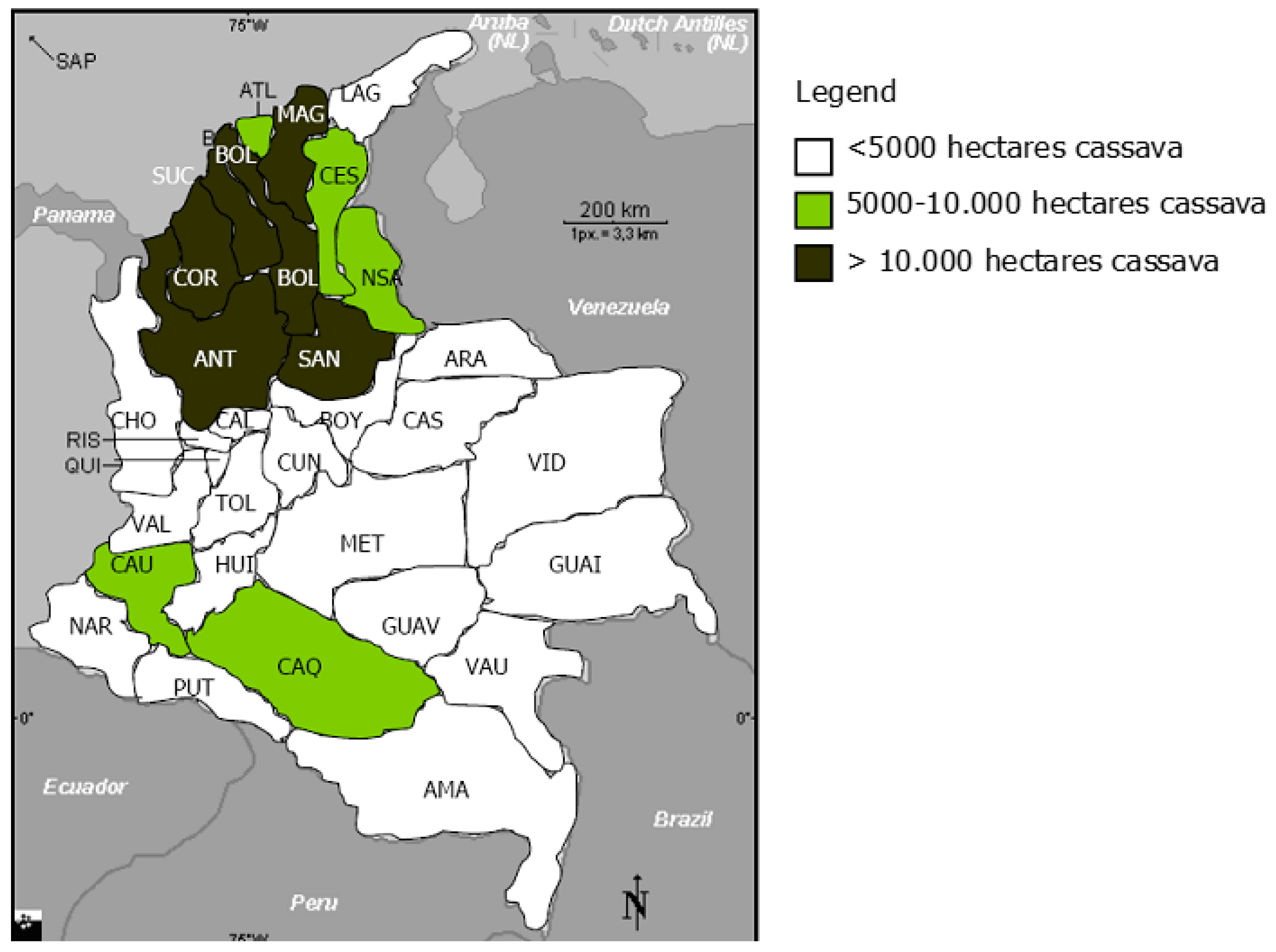

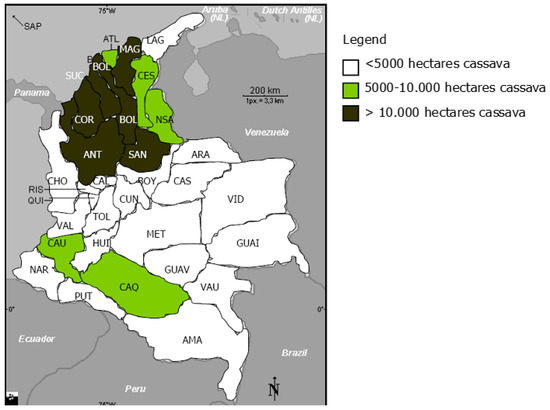

The production of cassava in Colombia amounted to 2.3 million tons in 2012, equivalent to almost 7% of the total agricultural production of the country and 11% of Colombia’s total agricultural land. An average yield of 10.7 ton ha−1 was reported for 2012 [1]. Cassava is cultivated under various climates and soils, but the majority (about 70%) is cultivated in the northern coastal provinces (Figure 1).

Figure 1.

Cassava production in Colombia (adapted from [3]).

Due to the fact that Colombia’s most fertile and flat areas are used for the production of sugarcane and other crops destined for industrial use or export, food crops like cassava are generally grown on the Andean hillsides [4]. Cassava traditionally has been planted by small farmers, having less than 5 ha of cassava per farm, and mostly intercropped with maize and yams. More recently, larger plantation-style plantings of more than 10 ha of cassava per farm have been started in response to a sharp increase in demand from cassava processors [5].

Since 2001, the Colombian government has been promoting biofuels through different laws and reforms. It established a 10% volume blend of bioethanol with gasoline in the main urban centers of the country along with the necessary technical requisites, tax exemptions, and price regulations. The implementation of the law has been fast and, as a result, estimations by the Colombian Ministry of Agriculture and Rural Development indicate that by 2020 about 3.8 million liters of ethanol will be produced per day as compared to the 900,000 liters produced in 2006 [6]. The previous means that about 400,000 ha of land will be dedicated to ethanol production in 2020 vs. 40,000 in 2006.

Cassava in Colombia has the second largest theoretical ethanol production potential per ha if compared to other potential crops. In addition, other advantages of the crop have boosted its popularity as an ethanol feedstock, including its ability to grow well under marginal conditions where few other crops can survive, its tolerance to extreme soil pH, and its resistance to most diseases and pests. Furthermore, cassava is a relatively labor intensive crop which makes it attractive for employment generation, an objective of the Colombian government. Due to the previous, cassava based bio-ethanol is expected to become an important provider of ethanol for the Colombian fuel mixing program. Targets for bioethanol production from cassava mean about 280,000 ha dedicated to ethanol in 2020 vs. 3000 in 2006. The bioethanol target for 2020 also means that the area needed for cassava production is expected to be 2.5 times that of 2005. As a result, by 2020 cassava will be the major provider of bioethanol in the country after sugarcane [7].

As bioethanol is a renewable energy alternative to (partially) replace fossil fuels, many consider it to be a sustainable fuel. However, whether bio-ethanol is truly sustainable, is highly debated [8,9,10,11,12] and depends upon several environmental, economic, and societal considerations. Main issues of concern are the net energy balance of the whole production chain; the overall Greenhouse gases (GHG) (Abbreviations are presented in Table S1) mitigation potential; the competition for resources like land and water, which in turn potentially threaten food security and biodiversity; the large quantities of by-products generated which can lead to substantial pollution; the air pollutant emissions of ethanol enriched gasoline; the GHG emissions associated with land conversion, and numerous social and economic considerations including human rights, property rights, income distribution, governance, and social structures, among others.

So far, no detailed analysis of the environmental implications of bioethanol production from cassava in Colombia has been conducted. Furthermore, whereas other studies on bioethanol production from cassava in Thailand and China [13,14,15] have included the anaerobic digestion step within the assumptions, no detailed description of the technological choices and analysis of its implications have been presented. The present study attempts to cover these knowledge gaps by analyzing the sustainability implications of bioethanol production from cassava in Colombia with two system configurations, i.e., centralized and decentralized, emphasizing the role of anaerobic digestion (AD) to improve sustainability of currently planned bioethanol production.

The indicators covered by this study belong to the environmental sustainability compartment, including energy balance, GHG balance, water, and land use. These indicators have been highlighted as most relevant in the analysis of environmental sustainability of bioenergy systems and/or biomass cascades [10,16,17,18,19,20,21]. In addition, they are most likely to be impacted by the addition of the anaerobic digestion step [13,22,23,24].

2. Methodology

2.1. Goal and Scope Definition

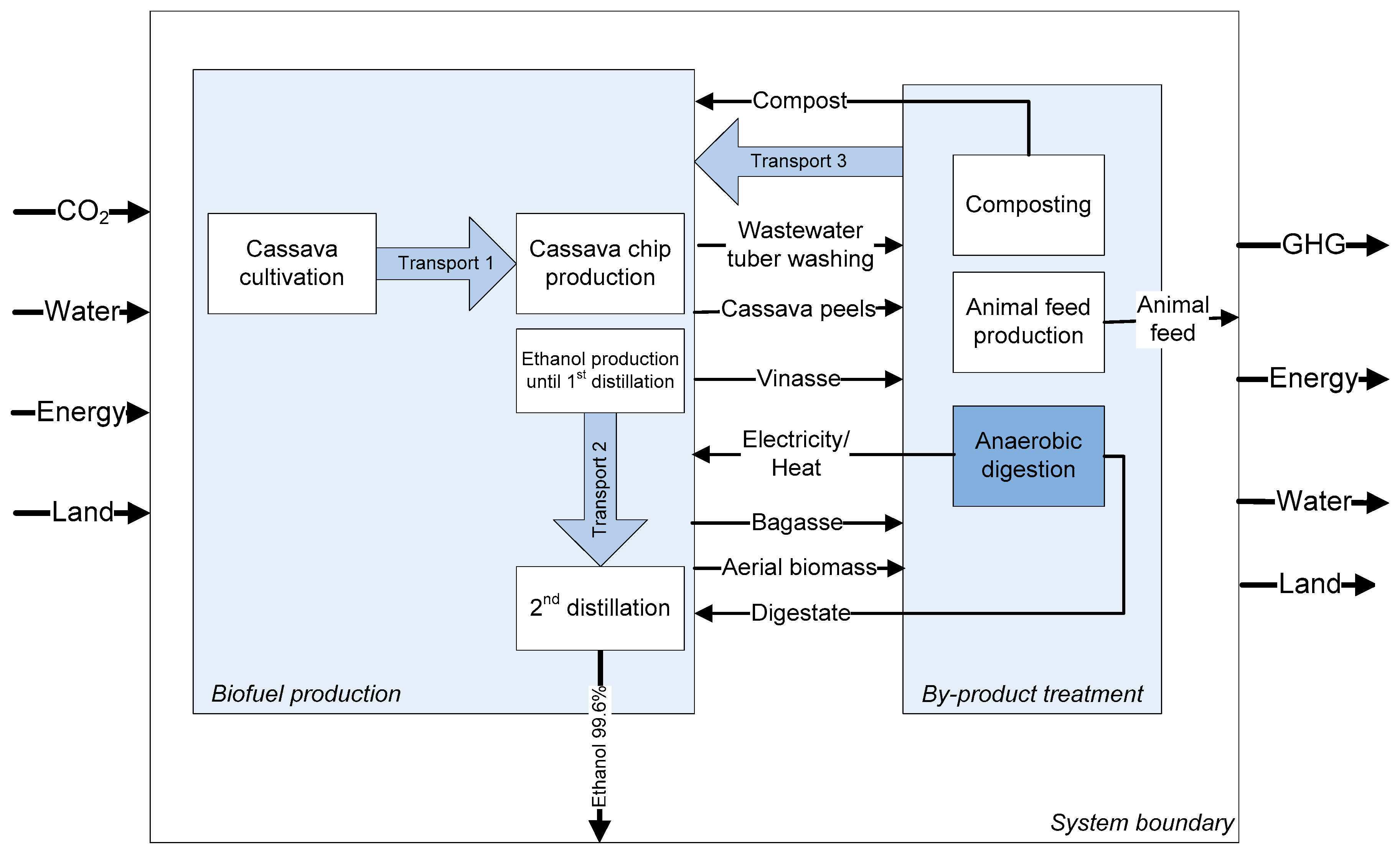

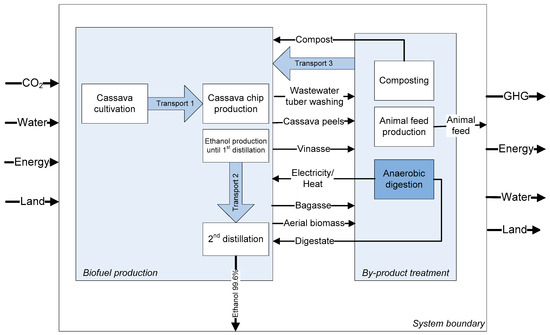

The goal of this study is to assess the energy performance, GHG emissions, water, and land use of alternative cassava cascades for bioethanol production working at different scales, highlighting the implications of including an anaerobic digestion step in the cascade. Complete balances were performed including cassava biomass, carbon, energy, nutrients, and water following the flows and transformation processes in each system. The study comprises the raw materials production, their conversion into bioethanol, and the end-use of by-products. Emphasis is placed on flows related to the cultivation and processing of the cassava, including relevant transportation. Carbon flows associated with the uptake and release of atmospheric carbon during photosynthesis and oxidation of the (intermediate) products as well as those related to change in land use are included in the calculations. N2O emissions from fertilization are also covered. Flows related to the construction of the facilities and transport of the fuels for final use are not included because of the difficulty in their quantification plus their claimed minor contribution to ethanol energy balances [12]. The systems boundary, main process units, and flows are presented in Figure 2. For comparability of results, the functional unit is the production of 100,000 liters fuel ethanol per day, which is about 6% of the expected ethanol production from cassava in Colombia for the year 2020.

Figure 2.

Overview of main elements in the systems studied. The division in ethanol distillation only takes places in decentralized systems.

2.2. Data Collection and Validation

At the time this study was performed there were no cassava based bio-ethanol factories in operation in Colombia, therefore the definition and quantification of the systems are based on field visits, expert interviews, literature study, and experimental results. Information on the amount and composition of by-products was obtained by running the ethanol production process at lab scale at the International Centre for Tropical Agriculture (CIAT) in Palmira, Colombia. The information was cross-validated with literature information on amounts and quality of by-products from cassava [18,25,26,27]. Information on the energy consumption of the ethanol production was obtained from expert interviews according to current design of the facilities, and such information was cross validated with literature values [13,14,28]. Use of different fossil fuels was foreseen as part of the different systems. Direct energy consumption was calculated based on the Low Heating Value (LHV) as proposed by the International Panel for Climate Change (IPCC) [29]. The values are specific for Colombia as reported by local scientific authorities [30]. Indirect energy was calculated as a percentage of the direct energy used, using values reported by Patzek and de Carvalho Macedo [31,32]. Data on GHG emissions from fossil fuels was obtained from the conversion of relevant activity rates to their emission equivalents using emission factors specific for Colombia calculated by local authorities following IPCC guidelines [30,33,34]. Energy content and emissions related to electricity coming from the grid are specific for Colombia where 75–80% of the electricity consumed is generated from hydropower. Energy and GHG emissions associated with agricultural inputs were obtained from different sources [35,36,37,38].

2.3. Systems Definition

Four different cassava bioenergy cascades are evaluated in this study. These systems are chosen to reflect current practices of cassava cultivation and current trends in cassava bioethanol production in Colombia in which two main types of systems are being implemented (these systems differ mainly in the centralization or not of production and processing, also showing differences in the variety of cassava being cultivated). In order to simplify the notation and guide the reader, systems are called centralized (CS) and decentralized (DS). For each type of system, a scenario with and without the anaerobic technology was defined. In the scenarios where AD is not implemented, an alternative use of the by-products was defined for comparison purposes. As a result, the systems analyzed were centralized bioethanol production without biogas production (CS); centralized bioethanol production with biogas production (CS + AD); decentralized bioethanol production without biogas production (DS); and a decentralized bioethanol production with biogas production (DS + AD) (see Table 1).

Table 1.

Main systems characteristics.

The centralized systems are defined as fully mechanized ethanol production systems where both ethanol production and crop production are concentrated in one place. On the contrary, decentralized systems are defined as a number of small ethanol production and crop production sites, where operations are traditionally performed using a significant amount of hand labor, as is the case in Colombia. In such systems, the distilling and dehydration steps do not take place in the same location. That is, at the microplant the ethanol is fermented and distilled until it reaches a 50% concentration and subsequently the resulting EtOH-water mixture is transported to a central factory where the output of 50 microplants is distilled and dehydrated to 99.6% EtOH. This central step reduces investment costs and aids in standardizing the quality of the final product. Two out of four systems make use of anaerobic digestion technology (biogas production) to treat the by-products generated during the bio-ethanol production process including wastewater from root washing, peels, bagasse, vinasse, and leaves/stalks. The other two systems make use of other technologies to add value to the by-products, i.e., composting and animal feed production for the centralized and decentralized system, respectively.

The centralized systems are projected in the eastern plains region (Llanos Orientales) of Colombia. Currently, the cassava cultivation area in the region accounts for 11.5% of the total in the country and the production is concentrated in medium size farmers (6–8 ha) [38]. The average temperature in Meta is 30 °C, and the average amount of rainfall is 2652 mm per year [39]. Eastern plains are considered to have a good potential for centralized cassava cultivation because land is relatively flat, and cassava is one of the few crops that can resist the prevalent extremely acid soil conditions. The nutrient content of the soil is very low, especially in P, K, Ca, and Mg [40]. Since connection to the grid is not in place in this system, the required electricity is coming from burning diesel providing the energy needed for distillation. The decentralized systems are projected in Bolivar, along the Atlantic Coast. This region is selected for its tradition of small-scale farming and cassava cultivation. In addition, the Colombian government has selected this region to establish several cassava based bio-ethanol plants. Bolivar is a hilly region with a hot climate, with an average temperature of 27 °C and an average rainfall of 1057 mm per year [39]. Soils are sandy or clay loam and rich in P and K [40]. It is estimated that the average area used for the cultivation of cassava per farmer in Bolivar is 2 ha [41]. Electricity is available from the grid and coal is used for the distillation as verified on site.

As reflected by the different regional climatic characteristics, two different cassava varieties are used in the centralized and decentralized systems. Roja (CM 4574-7) is used in the centralized systems and MTAI8 (Rayong 60) in the decentralized ones, having an average yield of 25.7 and 28.5 ton fresh roots ha−1 yr−1, respectively. Both varieties have relatively high ethanol yields per ton fresh roots and are already used for industrial production in the selected regions. Varieties are different as they are the best adapted to the two regions identified, Roja is cultivated for the production of ethanol in Llanos Orientales, and MTAI8 has been identified as the best cassava variety for industrial applications in the Atlantic Coast [42].

3. Process Units and Quantification of Systems Flows

The analysis of the systems was performed considering as systems units: cassava cultivation, cassava chip production, ethanol production and by-products treatment, i.e., composting, animal feed or anaerobic digestion.

3.1. Cassava Cultivation

Cultivation of cassava involves ploughing, planting, fertilizer application, pesticide application, irrigation, harvesting, and packing activities within the farm. In the centralized systems, all processes are mechanized as much as possible. Planting of cassava is done semi-mechanically, as tractors are used to prepare the soil. A mixture of chemical and biological herbicides and pesticides are used for weeding and disease control. As assessed in the field, on average 5.5 kg ha−1 of herbicides (Alacror, Diuron and Glyphosate) are applied in the centralized system, whereas 2.8 kg ha−1 (Alacror and Diuron) are applied in the decentralized one. Despite these very high amounts applied, additional manual weeding is required. Pesticides are applied in the centralized and decentralized systems at 4.3 and 0.7 kg ha−1, respectively [43]. Cassava harvesting is done using mechanical diggers to pull out the roots. Based on Ospina et al., the fuel consumption per hectare was calculated from the power specifications of the machinery a two-row model cassava planter PC-20 of 65 HP and a cassava harvester P900 of 90 HP, and considering an average fuel consumption of 2.75 HP-h per liter diesel fuel [44]. The tractors operate at an efficiency of 6.2 and 6.5 ha d−1.

Cassava production in the decentralized systems is performed in a traditional way as is the case in Bolivar department in Colombia. Planting, weeding, and harvesting are all done manually by the farm owners and their relatives (field interviews). Herbicides are applied but pesticides are not. Irrigation is disregarded considering that the minimal amount of water required for cassava cultivation, i.e., 555 mm per year [45], is exceeded by the rainfall in both regions. Fertilizer requirements are taken from the recommendations of Howeler and Cadavid considering differences per region [40]. The amount applied was compared to the nutrient extraction as calculated following the study by Howeler [26] and compensated in the case of potassium, as in the long-term its application is important to avoid depletion. The growing period is assumed to be 365 days, one crop rotation takes place once every three years and 10% of the fresh root harvest is lost due to diseases (field interviews). The labor requirements per hectare of cassava are based on Cock, Perez Crespo and Ospina [46,47,48].

3.2. Cassava Chips Production

Fresh cassava needs to be processed into cassava chips to prevent deterioration. Once cassava is harvested it is transported to the drying facility, where it is weighed, washed, peeled, chopped, and dried. Per liter EtOH, 8 liters of water are used for root washing [27]. Drying can be done naturally, taking advantage of solar energy, or artificially, which allows for the operation to be independent of seasonality. In the decentralized systems cassava is dried using solar energy. A sun drying plant covering an area of 2000 m2 and working 20 weeks per year, can process 1440 ton of fresh cassava in the same period. It requires a chopping machine working with a diesel motor of 6 kW and 1 man-day working force per ton fresh cassava [49]. In the centralized systems cassava is dried artificially, by a system operating on diesel, consuming 121 L ton−1 fresh cassava. In addition, electricity is used for other operations at 78 kWh ton−1 fresh cassava [43].

3.3. Ethanol Production

The ethanol production starts by mixing the cassava chips with water and blending them into a homogenous pulp. Each ton of cassava chips is mixed with 8 litres of water before entering the fermentation tanks. After the mixing and blending, the pulp passes through the hydrolysis and fermentation tanks where enzymes are dosed at 2 mL L−1 of starch [50]. The fermented cassava pulp is filtered, and the remaining liquid is then purified to 99.6% in distillation and dehydration units. In the centralized system, ethanol is produced in a modern facility using diesel for electricity generation. For the distillation, steam is produced using diesel fuel. In the decentralized system, the ethanol production process follows the design performed by researchers in CIAT, which aims to minimize investment costs, give opportunities to small holders, and adapt to the available local resources. Electricity used is coming from the grid and distillation is performed using coal as fuel source. Energy inputs in ethanol conversion were assessed on site. Emissions associated to the material inputs into ethanol production other than fossil fuels were considered to be negligible [32].

3.4. Transport

Three segments of transport are considered, which include the transport of crop material, including roots and aerial biomass, from the fields to the ethanol factories, the transport of crude ethanol from the microplants to the distillery in the case of the decentralized systems, and from the distillery to the fields when compost or digestate is transported back. The average distance from the fields to the ethanol factory in the centralized system was calculated to be 50 km by assuming a circular distribution of the area needed to produce the 100,000 L EtOH d−1. The cassava is transported in trucks with 10 ton capacity. In the decentralized system, 113 farmers having an average farm size of 2 ha are needed to supply each microplant with the demanded cassava. They transport their product also in trucks with 10 ton capacity, with the average distance to the microplant being 6 km. Partially distilled ethanol is transported 40 km from the microplant to the central dehydration facility by means of trucks having 6000 liter capacity. In all cases, diesel is used for transportation at an average efficiency of 2.5 km L−1 [35].

3.5. By-Products Characterization and Treatment Options

Five main by-products are generated in the systems, which are cassava aerial biomass, including leaves, petioles and part of stalks, wastewater from root washing (WWt), peels, bagasse, and vinasse. It is considered that 87.5% of the stalks produced are available, the rest being used as planting material for the next season [50,51]. Quantification and characterization of the flows is presented in Table 2. Amount and composition of peels, bagasse, and vinasse were calculated according to laboratory experiments and cross-validated with pilot and full-scale facilities found in the literature [13,17,27,52]. Cassava peels and bagasse are produced in similar amounts, showing also similar solids and organic content. Vinasse is produced in great quantities 12–15 liter per liter EtOH [17,27] and is a crucial residue to treat due to its undesirable characteristics for direct reuse or disposal including offensive high organic load and odor. The wastewater from root washing is also a substantial amount with a low Chemical Oxygen Demand (COD) and nutrient content [27], which can be treated either for reuse at the ethanol facility or for final disposal in the environment.

Table 2.

Cassava bioethanol production by-product amounts and characteristics.

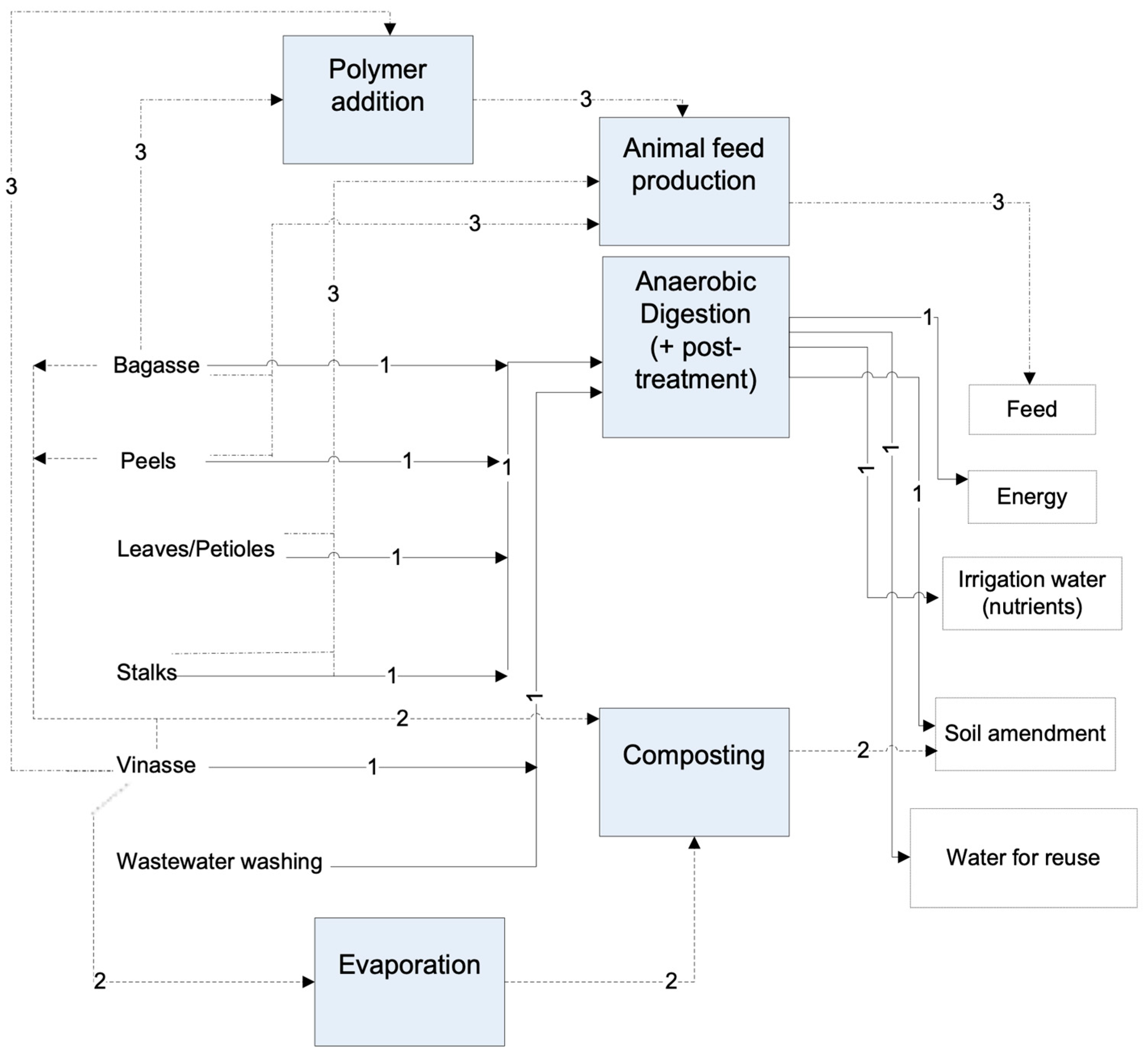

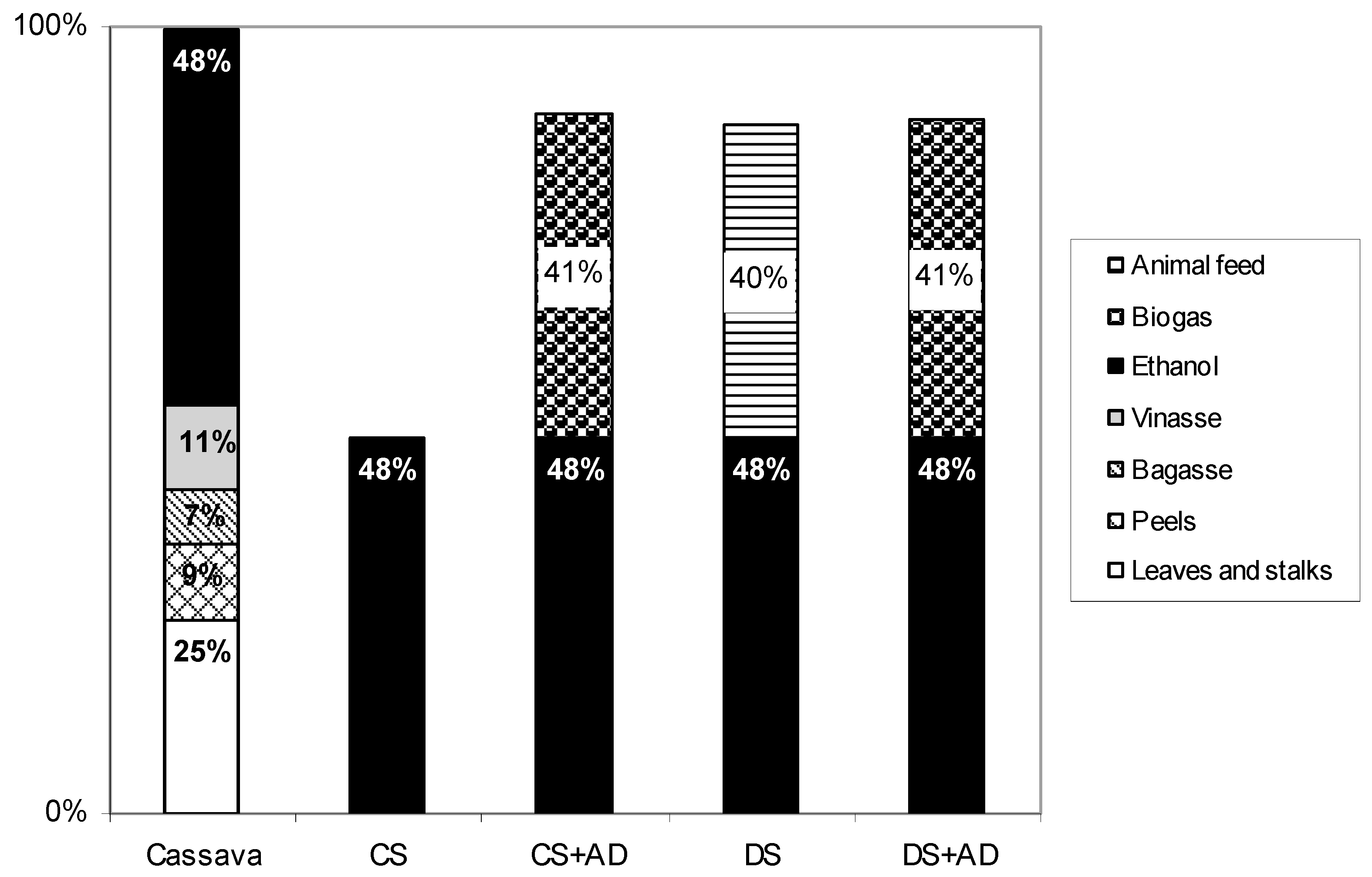

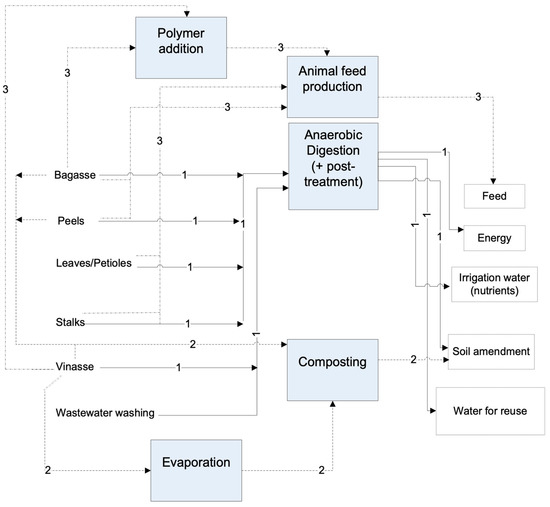

Different conversion alternatives could be used to add value to cassava by-products. In this study alternatives chosen for the systems without AD correspond with the current situation in Colombia (Figure 3). In the CS, composting of the main by-products of the ethanol industry is considered, whereas aerial biomass is left on the land. In the DS, conversion of main by-products for animal feed production is implemented. In CS + AD, all residues including aerial biomass are added value whereas in the DS + AD, aerial biomass is left on the land as it is produced in a different location from where ethanol conversion is taking place. In all cases, wastewater flows not treated by AD are assumed to be treated by aerobic treatment to meet discharge standards using intermediate rate trickling filters, allowing concomitant nitrification with a loading of 0.24–0.48 kg BOD m−3 d−1 at 5 kW 10−3 m−3 [52].

Figure 3.

Overview of by-product treatment routes for residues from cassava ethanol production relevant to Colombia. The number refers to alternative conversion routes: 1. Anaerobic digestion, 2. Composting, 3. Animal feed.

3.5.1. Composting

In the CS, peels, bagasse, and vinasse are composted. Composting was chosen as the alternative for this system as it is current practice in sugarcane based bioethanol producing facilities in Colombia. Vinasse is evaporated to 35% Total Solids (TS) content in order to be incorporated into the composting process. The efficiency of the composting process in converting COD is assumed to be 50%, with 4 tons of water being removed per ton COD converted. In addition, it is considered that 35% of the N in the input is lost in the process, with 5% of total N emitted consisting nitrous oxide emissions (N2O as CO2eq) [24]. Energy consumption in the process is calculated assuming 0.4 kg steam needed per liter of water evaporated [53] and 32.5 kWh used per ton of compost produced [25]. GHG emissions were calculated as the sum of carbon dioxide (CO2) and methane (CH4) as CO2eq, which together account for the total amount of COD removed by the composting process. Methane emissions were calculated as 0.35% of the emissions of CO2. The remaining COD corresponds to the long-term emissions of CO2, which were calculated stoichiometrically as 44/32 grams of carbon dioxide produced per gram of COD removed [26].

3.5.2. Animal Feed Production

In the DS, residues from ethanol production are used for producing animal feed. Conventional animal feed production is an energy intensive process requiring about the same amount of energy as required for the ethanol process [54]. Decision makers in Colombia are considering an approach in which the vinasse is pre-treated by adding polymers to concentrate it to 10%TS, followed by centrifugation to reach 25%TS. Nutritional blocks and nutritional salt bags for ruminant animals are produced requiring 45% and 30% weight basis of concentrated vinasse and weighing 25 and 40 kg, respectively. In both cases, additional root flour, leaf and stalk flour, urea, and mineral salts are required. A basket centrifuge using 105 kWh t TS−1 direct electricity and working at 90% solids efficiency is assumed to be used and polymers to be dosed at 3 g per kg TS−1. The energy demand for the preparation of the feed is 1.3 and 1.1 kWh per block/bag, respectively [43].

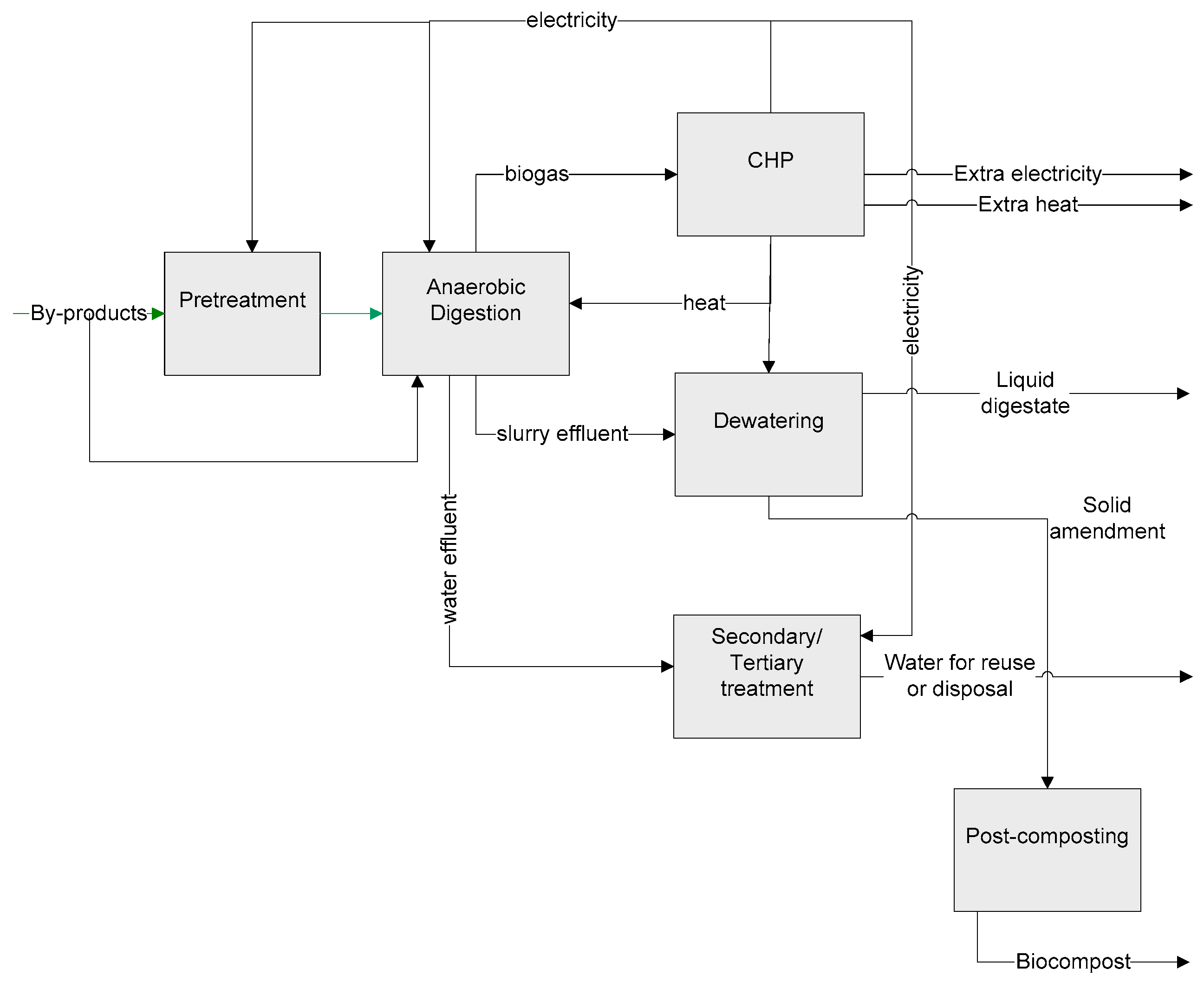

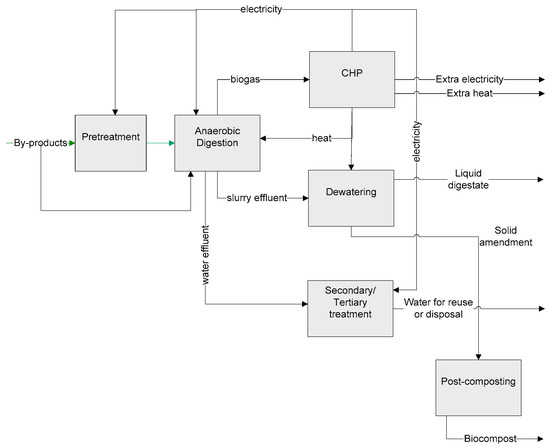

3.5.3. Anaerobic Digestion

The methane output for all digesters was calculated based on the COD content and the volume of the input flows considering a theoretical methane yield of 0.35 m3 CH4 kg−1 COD. The biogas is turned into electricity and heat using a Combined Heat and Power (CHP )unit expected to operate at 90% efficiency, i.e., 35% electricity and 55% heat [55]. Calculations of the net energy output were made considering electricity and heat produced are partially used in the anaerobic digestion facility for pretreatment, digester operation, and digestate dewatering.

For the purpose of calculating electricity use and emissions different operations were included as part of the AD facility (Figure 4). For materials with more than 10%TS, pretreatment is needed for substrate homogenization, requiring 33 MJ per ton by-product input [56]. The use of electricity for the operation of the biogas plant is assumed to be 66 MJ per ton raw material [56]. In all cases single stage continuous mesophilic digesters managing more than 10 tons raw material per year are used. Due to constant high temperature conditions in the studied areas and the high temperature of vinasse, i.e., 72–80 °C [57], it is not required to use the produced heat from the CHP for the operation of the digester at mesophilic temperature. Reuse of the digestate is a crucial consideration when evaluating the incorporation of anaerobic digestion in the bioenergy chain [58]. Digestate offers many advantages as part of an agricultural production system, including the high content of mineralized nutrients. The content of organic matter in the digestate can help improve soil structure and has reported weed suppression capacity [59,60]. Nonetheless energy needs associated with its transportation and spreading, and the emissions taking place during storage and spreading, also need to be considered.

Figure 4.

Operations included as part of anaerobic digestion (AD) facility sub-units are included in the analysis according to the type of facility evaluated.

The amount of digestate produced was calculated by assuming a 25% TS removal during the AD process [60] whereas its COD content was calculated by subtracting the COD used for methane generation from the total influent. All nutrients coming from the input materials are preserved in the digestate. Based on previous research on digestate properties of manure-maize codigestion it was assumed that 50%, 50%, 70%, and 30% of COD, N, P, and K, respectively, remain in the liquid digestate [60]. Energy needs for dewatering were assumed to be 10 MJ kg−1, while requirements for loading and spreading were calculated to be 0.63 and 0.52 liters diesel per ton liquid and solid digestate, respectively [56]. The energy needed for transport of the digestate was calculated following the same assumptions previously outlined (see Section 3.4). When relevant, the (empty) transport provided by the trucks delivering cassava to the ethanol facilities was subtracted from the energy demand for digestate transport differentiating liquid and solid flows. Following the previous considerations, AD scenarios were designed departing from the amount and characteristics of the different flows, i.e., TS, nutrient content and energy potential, and the possibilities for reuse of the digestate (See Table 3). The alternative digestion of leaves and stalks was considered as well as the separate treatment of wastewater from washing tubers. In all alternatives, digestate is dewatered, the resulting solids are composted for further stabilization, and the liquid digestate is left for reuse in cassava fields.

In the CS + AD, four alternatives were evaluated. In alternatives 1 and 2 the digestion of all by-products is considered, including leaves and stalks, meaning that extra transport and handling is required. Whereas in alternative 1 all flows are codigested, in alternative 2 solid and liquid flows are digested apart. In alternative 3 the digestion of all by-products except wastewater from washing tubers is assumed. In this case such wastewater is aerobically treated to meet reuse standards within the ethanol plant. Alternative 4 considers the digestion of all by-products except aerial biomass. In the DS + AD, three alternatives are considered. In alternative 1 wastewater from washing tubers, peel, bagasse, and vinasse are mixed and digested together. Alternatives 2 and 3 consider the separate digestion of solid and liquid by-products in the microplant. In the first case, only industrial by-products are treated whereas alternative 3 also considers the digestion of leaves and stalks. In all alternatives, the extra vinasse produced in the central distillation-dehydration facility is treated in an Upflow Anaerobic Sludge Blanket UASB reactor and further polished by means of trickling filters.

Among the different sub-units considered in the alternatives evaluated, the electricity for running the biogas plant is the most energy consuming activity, followed by the energy needed for aerobic polishing of the wastewater when necessary. From comparing CS1 and CS4, it is concluded that it is energy profitable to use the aerial biomass for biogas production and subsequently disposing it in land as the double amount of energy can be produced. Further, when comparing CS2 and CS3, it is noticed that it is profitable to separately digest the solid and liquid flows and to avoid the anaerobic treatment of the water from tuber washing due to its low energy content. Hence, alternative CS2 is selected as it is the one producing more energy, the most energy efficient and the one providing more possibilities for water reuse in the ethanol facility. In the case of the decentralized systems, alternative 3, considering the digestion of aerial biomass, is also the most energy profitable, its energy efficiency being comparable to that of digesting only the industrial by-products.

4. Systems Performance

4.1. Energy Performance

The energy performance was evaluated by means of different indicators, which include Energy Balance (Ebalance), Net Energy Ratio (NER), the Net Renewable Energy Ratio (NRER), and Biomass Energy Efficiency (BEff). The Ebalance indicates the net energy produced by the systems after subtraction of all energy inputs. The NER reports the net energy recovered as a fraction of the total energy input of the system. In turn, the NRER reports a ratio of the energy recovered but compared to the non-renewable energy input only, this is an estimation of the fossil replacement value of the system. The BEff represents the percentage of energy from the cassava plant (root, leaves, and stacks) that is recovered in ‘usable’ energy (ethanol, electricity, heat), being a measurement of resource use efficiency (see Equations (1)–(4)).

As can be seen in Table 4, the CS demands 1809 TJ yr−1 extra energy, which results in a negative NER of −0.70, meaning that 70% more energy than produced is needed for such a system. The conversion of by-products by AD improves the energy balance leading to 10% more energy produced than demanded in the CS + AD. In both centralized systems, ethanol conversion is the most energy consuming step. In the CS ethanol conversion demands 70% of the total energy input, whereas only 6% of the energy is demanded by cassava cultivation, and an extra 23% of the energy demand goes to the composting process in the system without AD. Among ethanol conversion activities, artificial drying of the cassava represents most of the direct energy input, accounting for 74% in the CS. Given this large contribution, alternatives are explored in the sensitivity analysis. In the CS + AD, the energy output from AD is able to cover most ethanol conversion energy inputs. In addition, savings are produced due to the avoidance of composting, giving a total difference in the energy balance of 1899 TJ yr−1.

Table 4.

Energy performance of alternative bioethanol production systems from cassava in Colombia.

Decentralized systems are substantially less energy intensive as compared to centralized systems due to the use of solar drying or the artificial process. The system with AD has a positive Ebalance producing 637 TJ yr−1. The system producing animal feed appears approximately energy neutral (−82 TJ yr−1). Nevertheless, in this system the energy needed for the additives to the animal feed has not been considered, therefore indirect energy inputs are expected to be higher.

The NRER in all systems is equal or very similar to the NER, meaning that energy inputs other than fossil fuels make an insignificant contribution to the system.

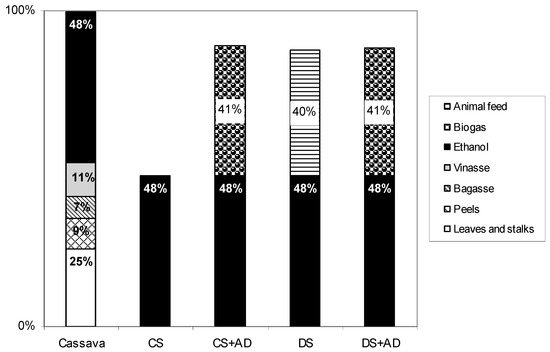

In the biomass energy efficiency analysis, approximately 75% of the energy fixated by the cassava plant is found in the cassava tubers, while the remainder is present in the aerial biomass (Figure 5). In the CS, only 48% of the energy in cassava is recovered as useful energy output in the form of ethanol. In the CS + AD, a total energy efficiency of 89% is produced, where 41% of the energy being recovered is in the form of electricity and heat from the biogas. In the DS also 48% of the energy is recovered as usable ethanol energy. The energy contained in the leaves, stalks, peels, vinasse, and bagasse is recovered as animal feed for an extra 40% of the total energy input. Similarly, in the DS + AD, a total 89% of the energy in cassava is recovered as usable energy.

Figure 5.

Biomass energy efficiency of alternative bioethanol production systems from cassava.

4.2. GHG Balance

GHG emissions were calculated and grouped in four categories. In category 1, flows related to the uptake of atmospheric carbon by photosynthesis and release by oxidation in the different industrial processes and final use of the products was included, as well as flows related to the application of nitrogen in fertilizers and amendments in cassava cultivation. In category 2, all flows related to the use of fossil fuels in the different processes were accounted for, whereas category 3 corresponds to an estimation of emissions related to change in land use. Category 4 corresponds to the avoided emissions due to the positive energy outcomes of the systems studied, i.e., ethanol, electricity, and heat. The total GHG balance is calculated following Equation (5)

As can be seen in Table 5, the GHG emissions from category 2, i.e., ethanol production, are the most important in all systems except in the DS + AD where the emissions from category 1 are most prominent. In all cases, net emissions from category 1 exceed the carbon capture by the cassava plant. GHG emissions ranged from 33,345 to 63,372 tCO2eq yr−1 for the different systems, which is equivalent to 18%, 31%, 40%, and 78% of total emissions in the CS, CS + AD, DS, and DS + AD, respectively. The higher category 1 emissions in the decentralized systems is the result of lower amounts of fixated CO2 due to lower yields of the cassava variety compared to the centralized ones.

Table 5.

Direct and indirect GHG emissions of alternative bioethanol production systems from cassava.

The impact of land use change in the GHG balance of the systems is accounted for in category 3 by assuming a conservative conversion in land use of 25% from natural grassland. Those emissions are calculated and amortized over 30 years using emission data reported by Searchinger et al. [21]. The contribution of such emissions represents only 4–10% of total emissions in the studied systems. Overall, the CS delivers net GHG emissions of 5.3 kgCO2eq L EtOH−1 while the DS emits 1.4 kgCO2eq L EtOH−1. Both systems with AD produced an almost even GHG balance, where CS + AD emits 0.4 kgCO2eq L EtOH−1 and DS + AD produce GHG savings of 0.3 kgCO2eq L EtOH−1. Systems taking advantage of the energy in the biogas produce only 20% and 36% of the emissions of the systems without AD during the ethanol production process. These differences are the result of the use of coal and diesel instead of biogas.

4.3. Water Balance

According to our estimation, 27–31 L of water per liter of ethanol are used in the cassava production systems without accounting for the water needed for steam production. Of these, 21–23 L are provided for the ethanol production in water for washing tubers and pulping, while the rest is incorporated in the cassava biomass. Hence the net water use without accounting for rainwater incorporated in biomass is 776,340–836,839 ton yr−1.

Water used in cleaning the cassava tubers constitutes about 30% of the water output, and in all systems is treated and reused within the ethanol process providing important water savings. If considering total water input and reuse, all systems except the CS would show substantial water savings. In the CS, 46% of the water incorporated in the system is evaporated during the compost production process. Similarly, 44% of the water output leaving the DS is coming from the animal feed production. This flow could be reused within the ethanol process. In the AD systems, the digestion of by-products generates a substantial amount of water savings (70% of the total water output). In addition, 12% to 14% of the water input is left in the digestate which needs to be adequately disposed of in the fields to take advantage of the nutrients they contain.

Overall, significant differences in net water use are found in the different systems. The CS is a high water demanding one (505,502 ton yr−1), in contrast with water saving system in the CS + AD (19,193 ton yr−1). In both DS systems, similar water consumption results equivalent to 10% of that in the CS, i.e., 53,756–55,784 ton yr−1.

4.4. Land Use and Soil Quality

Approximately 13,092–16,844 ha yr−1 of arable land are needed in the centralized and decentralized systems, including rotation and losses. A total of 60% of this amount corresponds to the area cultivated with cassava [65]. This means that 0.27–0.35 ha need to be cultivated with cassava to produce 1 ton of ethanol. Solar drying of the cassava chips as performed in the decentralized systems also demand land, about 1.4 m2 ton−1 fresh cassava [49]. However, when calculating the total amount of land required for the decentralized systems, such amount is insignificant as compared to the cultivated land, i.e., 31 ha yr−1.

With regards to soil quality, three of the different scenarios analyzed consider the return of by-products to land in the form of compost or solid/liquid digestate which incorporates valuable material for building up soil structure and fertility. When such by-products are applied on the land cultivated with cassava, an application rate of 6, 14, and 16 ton ha−1 yr−1 compost/solid digestate results from the CS, CS + AD and DS + AD respectively. In the case of liquid digestate 6 and 5 ton ha−1 yr−1 are to be applied in the CS + AD and DS + AD, respectively.

Total nutrient recirculation achieved in the different systems is 37%, 42%, −181%, and 73% for the CS, CS + AD, DS, and DS + AD, respectively. In the CS + AD, AD allows for higher recirculation of nutrients as composting is limited by the nitrogen losses during the process. The animal feed scenario implies the export of the nutrients outside the system boundaries including those present in the leaves for which fertilization is originally not provided. Thus, a negative nutrient balance is a result.

4.5. Overall Performance of the Studied Systems

Through an analysis of the overall performance of the four systems, centralized systems show a poorer energy and GHG performance as compared to decentralized ones (Table 6). In addition, systems with AD show a better energy balance and GHG performance as compared to their counterpart. The CS + AD produce water savings, whereas the two decentralized systems consume limited amounts of water. All systems behave similarly in terms of land use, with the variability related to the yield differences of the two cassava varieties studied. Nutrient recirculation as performed in the AD systems in the form of concentrated effluents made possible savings of 42–73% in imported fertilizers.

Table 6.

Overall comparison of alternative bioethanol production systems from cassava in Colombia.

5. Discussion and Concluding Remarks

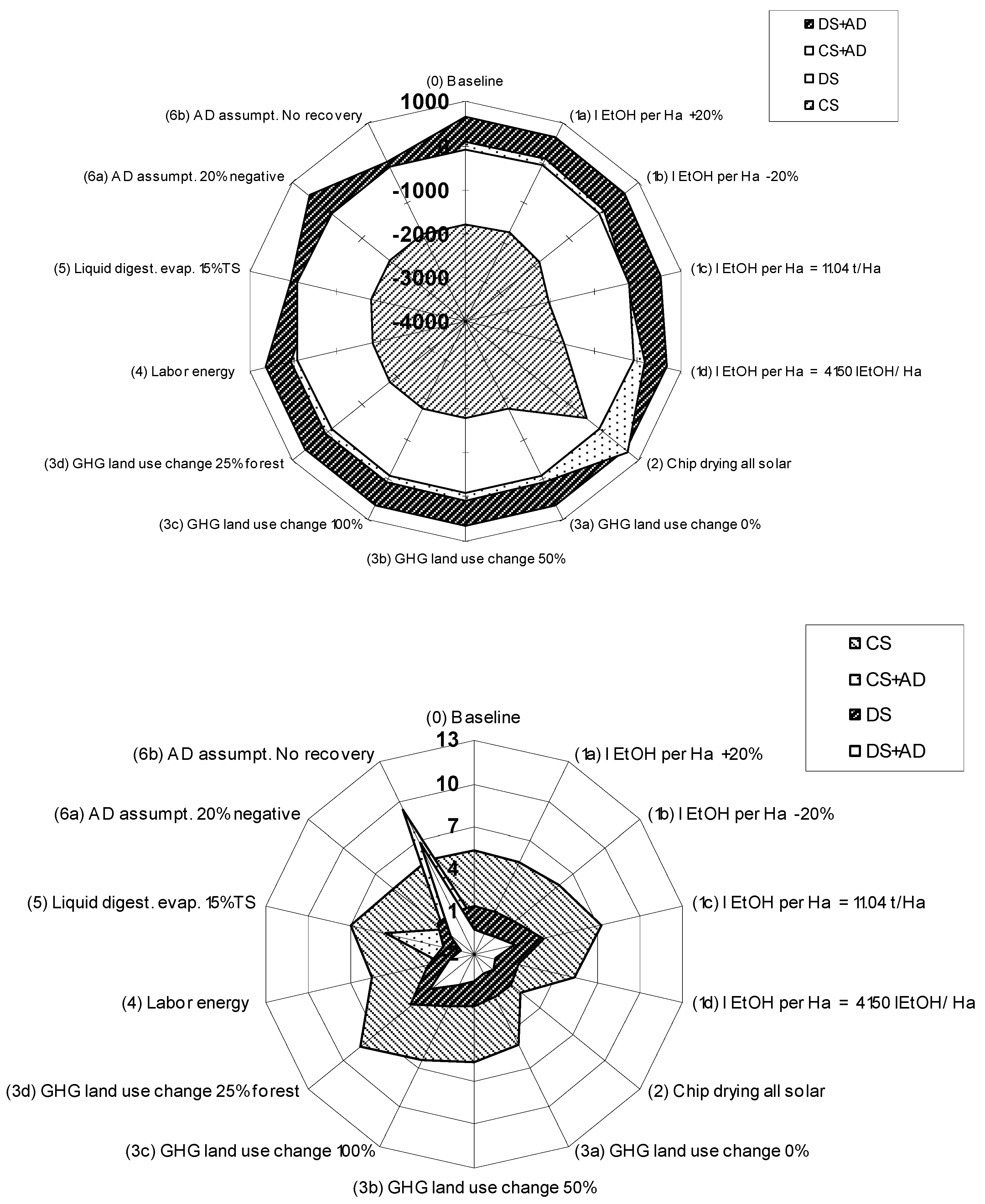

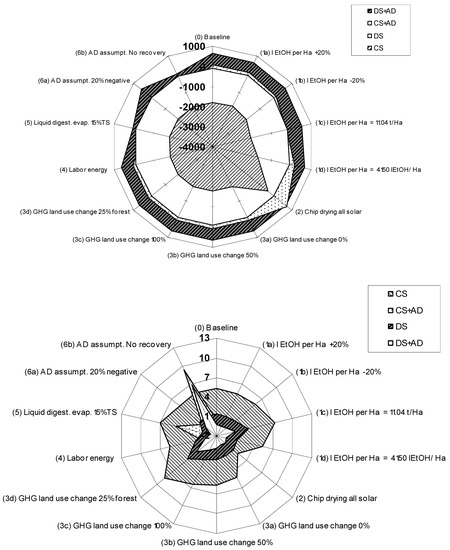

5.1. Sensitivity Analysis

From the results of this study it is clear that some of the main assumptions have a considerable impact in the performance of the systems. Therefore, a sensitivity analysis was developed. This helps to clarify the effect of systems design and the assumed activity rates, and energy and emission factors in the overall performance (Figure 6). The following are the revised assumptions and their impact in the output of the different systems.

Figure 6.

Sensitivity analysis of alternative scenarios of cassava bioethanol production. Above Ebalance in TJ yr−1 and below GHG balance in kg CO2eq per L EtOH−1.

(1) Assumed EtOH yield per ha. Ethanol yields considered in this study were 3648 and 4694 L EtOH ha−1 cassava, for the centralized and decentralized systems, respectively. As can be observed in Figure 6, when assuming the average Colombian cassava yield, the CS and DS systems diminish their net energy output by 267–296 and 120–133 TJ yr−1, respectively. As a result, the CS + AD will deliver a negative energy balance. Assuming the same ethanol yield per ha in all systems, i.e., 4150 l EtOH ha−1 calculated from an average yield of 27.1 ton cassava root ha−1 and an average ethanol yield of 192 L EtOH ton−1 peeled root, does not affect the classification of the systems in terms of their energy outcome as the decentralized systems are still favored over the centralized ones. The GHG balance is less sensitive to changes in yield assumptions; however, decreasing the yield to average Colombian yield will cause the systems with AD to become net emitters of GHG, i.e., 2.4 and 1 kg CO2eq L EtOH−1 for the CS + AD and DS + AD, respectively. Land use is affected mainly by the cassava yield, where a low yield of 11 tons of cassava tuber ha−1 means more than 100% increment in land use in all systems.

(2) Use of solar energy for drying cassava chips in the CS systems. It was clear from the energy balance results that the artificial drying process has considerable negative consequences in the energy performance of the CS. Studies from other countries have assumed the use of solar drying [66,67], if the centralized system would make use of solar drying, the CS + AD will deliver the best energy outcome, i.e., Ebalance of 732 TJ yr−1, whereas the net energy losses in the CS will become only 27% of the ones originally assessed. The systems with AD will still be the only ones delivering a positive energy outcome producing 3.4 and 4.8 times more energy than demanded in the centralized and decentralized system, respectively. Such positive outcome will also influence the GHG emissions, as the CS would produce only 2.2 vs. 6.8 kg CO2eq L EtOH−1 as previously determined, and the CS + AD will generate a net GHG emissions savings of −1.7 kg CO2eq L EtOH−1.

(3) GHG emissions from land use change. The total area of cassava cultivated in Colombia in 2005 was 180,600 ha [65] and only 3000 ha were dedicated to ethanol production in 2006 [7]. Current targets for land dedicated to ethanol production from cassava in 2010 are 110,000 ha and if considering losses and rotation the total amount of land needed would be approximately 183,700 ha. In this study, it has been assumed that 25% of the land used is converted natural grassland; however, this could very well be an underestimation. If land used for cassava cultivation would come entirely from natural pastureland, an extra GHG emission of −0.87 and −0.67 kg CO2eq L EtOH−1 would be produced in the centralized and decentralized systems, respectively. However, if only 25% of the total area would replace tropical forest instead of natural pastureland, emissions will increase in 2.88 and 2.24 kg CO2eq L EtOH−1 in the centralized and decentralized systems, respectively. These figures show the importance of properly assessing the land use changes and their origin.

(4) Labor accountability within energy balance. Previous studies [11,13,15] have considered the energy embodied in human labor as part of the energy inputs into the ethanol systems. Although the addition of this flow is contestable because of its different nature in relation to other energy flows, it is a fact that energy embedded in labor is also indirectly coming from fossil energy. An energy consumption of 2.3 MJ h−1 is frequently used for this type of calculation, although higher energy consumption (12.1 MJ h−1) has also been calculated [18]. In this study total energy coming from labor is substantially different in centralized and decentralized systems; hence an estimation of the extra energy invested in labor is included considering 2.3 MJ h−1 energy consumption. The inclusion of labor within the energy calculations means extra 13 and 17 TJ yr−1 energy use in the centralized and decentralized systems, respectively, that is 1% and 20% differences in the Ebalance.

(5) Liquid digestate reuse and irrigation water demand. It is important to recognize that the positive performance of the AD systems is closely related to choice for separate treatment of liquid and solids flows. Apart from allowing substantial water reuse within the ethanol industry, such choice implies considerable energy savings and avoidance of GHG emissions related to liquid digestate handling. An alternative to the separate digestion could be the mixed digestion of liquid and solid flows. However as there is a limited possibility for irrigation due to the limited water demand of cassava and the rainfall availability in the studied regions, the (partial) evaporation of this digestate to concentrate the nutrients for agricultural reuse could be required. To exemplify the implications of such a choice, calculations were performed for a system digesting all cassava by-products assuming centrifugation followed by liquid digestate evaporation from 5 to 15%TS with an energy use of 0.93 GJ ton−1 water evaporated [53]. Following the previous assumptions extra 605 TJ yr−1 will be demanded which is equivalent to the total energy use of the CS + AD.

(6) Change in assumptions anaerobic digestion. Energy recovery from AD can fluctuate depending on system design and operation. In addition, due to the high global warming potential of CH4, assumptions on its losses are critical. A negative AD scenario of 20% more emissions, 20% more energy use, and 70% energy recovery was evaluated. The change in assumptions substantially impact the outcome of the systems. The NER substantially diminishes from 0.10 to −0.07 and from 4.85 to 2.17, in the CS + AD and DS + AD, respectively. The GHG balance is less affected by emissions in the AD systems increasing by 0.3–0.4 kgCO2eq L EtOH−1. The overall outcome will remain the same with the AD systems being more energy and GHG profitable than their counterparts. Further, the extreme case of no methane recovery is considered. In such a case, the Ebalance will diminish by 884 and 609 TJ yr−1 in the CS + AD and DS + AD, respectively, whereas GHG emissions will increment in 8.9 and 7.1 kg CO2eq L EtOH−1. The benefits of AD will remain in terms of energy as the technology is significantly less energy consuming than the compost scenario and slightly better than the animal feed production processes. However, GHG emissions will significantly outweigh the other scenarios, making the AD option no longer appealing.

5.2. Conclusions

Bioethanol production from cassava in Colombia was shown to deliver substantially different environmental outcomes depending on the system design. The energy balance, GHG balance, and water balances fluctuated in a wide range, i.e., −1809 to 637 TJ yr−1, −0.3–5.3 kg CO2eq L EtOH−1, −19,193–505,502 ton yr−1, respectively. Further, it was made evident that without the energy recovery provided by AD, the production of bioethanol from cassava in Colombia is not sustainable from an energy and GHG perspective. In the centralized systems, it is not desirable to implement artificial drying of cassava since it is an enormously energy consuming activity. The decentralized systems demonstrate that both animal feed production and anaerobic digestion can be feasible from an energy and GHG balance perspective although benefits from AD will be remarkably higher.

The energy outcome of the AD process was shown to always be greater than its energy input for the different configurations evaluated, i.e., above 67%. The energy and water content of the material to digest, the use of aerial biomass, the options for digestate reuse, and the recovery of the methane produced are major considerations that substantially influence the role of AD within cascade configurations.

The role of AD in this study was clarified by defining different design options and further contesting assumptions within the sensitivity analysis. The energy outcome of the AD process has always been shown to be positive, i.e., above 67% for the different configurations. The importance of the type of influent to be digested is evident. On one hand, the energy benefits of digesting aerial biomass outweighed the energy costs of its loading and spreading by more than double in the centralized system. On the other hand, the digestion of the diluted wastewater from root washing decreased the net energy output of the system. The type of influent to digest needs to be carefully examined not only in view of its energy content but also taking into account the reuse of the digestate output.

Cassava bioethanol production in Colombia and other countries has to be approached with major caution; general analyses are not desirable as they hide the substantial differences in outcome coming from the system design and context conditions. The analysis and design of bioethanol production has to be approached from a systems perspective in which by-products are added value in an energy rational way if the systems are to be called ‘renewable’ and beneficial from an ‘environmental’ perspective.

Supplementary Materials

The following are available online at https://www.mdpi.com/2071-1050/11/14/3968/s1, Table S1: List of Abbreviations.

Author Contributions

Conceptualization, C.P.-P., M.S., J.v.L., R.R.; methodology, C.P.-P., M.S., J.v.L., R.R.; software, C.P.-P.; formal analysis, C.P.-P., M.S., J.v.L.; investigation, C.P.-P., S.H.; resources, M.S., R.R.; data curation, C.P.-P.; writing—original draft preparation, C.P.-P.; writing—review and editing, C.P.-P., M.S., J.v.L.,; visualization, C.P.-P.; supervision, M.S., J.v.L., R.R.; project administration, M.S.; funding acquisition, M.S.

Funding

This research received no external funding.

Acknowledgments

The authors acknowledge the valuable contribution of CIAT for the completion of this work, particularly Elizabeth Alvarez for facilitating the laboratory equipment and materials needed for the bioethanol experiments conducted for this research. They also thank Marcelo Villena for his contribution in editing the final version of this scientific paper.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- FAOSTAT. FAO ProdStat 2012. Available online: http://faostat.fao.org/site/567/DesktopDefault.aspx?PageID=567#ancor (accessed on 11 October 2013).

- Balcazar, A.; Mansilla, H. Cassava Crop Development in Colombia; FAO: Bogotá, Colombia, 2004. [Google Scholar]

- Bajes Mora, F. La Yuca: Un Ingrediente Estratégico en la Fabricación de Alimentos Balanceados para Animales; Ministerio de Agricultura y Desarrollo Rural: Bogotá, Colombia, 1998.

- Sonder, K.; Muller-Samann, K.; Hilger, T.; Leihner, D. Erosion Control and Prediction in Cassava Based Cropping Systems in the Southern Andean Region of Colombia; Universidad Bonn: Bonn, Germany, 2001. [Google Scholar]

- Gottret, M.V.; Escobar, Z.; Perez, S. El sector yuquero en Colombia: Desarrollo y Competitividad. In La Yuca en el Tercer Milenio. Sistemas Modernos de Producción, Procesamiento, Utilización y Comercialización Cali; Ospina, B., Ceballos, H., Eds.; CIAT, CLAYUCA: Cali, Colombia, 2002. [Google Scholar]

- MADR. Apuesta Exportadora Agropecuaria 2006–2020; Ministerio de Agricultura y Desarrollo Rural: Bogotá, Colombia, 2006; 19p.

- Henao Estrada, J. Potencial de Biocombustibles en Antioquia; BIRD Antioquia: Itagui, Colombia, 2008; 94p. [Google Scholar]

- Enguidanos, M.; Soria, A.; Kavalov, B.; Jensen, P. Techno-Economic Analysis of Bio-Alcohol Production in the EU: A Short Summary for Decision-Makers; European Commission. Institute for Prospective Technological Studies: Seville, Spain, 2002; 34p. [Google Scholar]

- Niven, R. Ethanol in gasoline: Environmental impacts and sustainability review article. Renew. Sustain. Energy Rev. 2005, 9, 535–555. [Google Scholar] [CrossRef]

- Pimentel, D.P.T.; Cecil, G. Ethanol Production: Energy, Economic, and Environmental Losses. J. Environ. Contam. Toxicol. 2007, 189, 25–41. [Google Scholar]

- Pimentel, D. Ethanol Fuels: Energy Balance, Economics and Environmental Impacts are Negative. Nat. Resour. Res. 2003, 12, 127–134. [Google Scholar] [CrossRef]

- Shapouri, H.; Duffield, J.A.; Wang, M. The Energy Balance of Corn Ethanol Revisited. Trans. Am. Soc. Agric. Eng. 2003, 46, 959–968. [Google Scholar]

- Dai, D.; Hu, Z.; Pu, G.; Li, H.; Wang, C. Energy efficiency and potentials of cassava fuel ethanol in Guangxi region of China. Energy Convers. Manag. 2006, 4, 1686–1699. [Google Scholar] [CrossRef]

- Leng, R.; Wang, Y.S.; Zhang, C.; Dai, D.; Pu, G. Life cycle inventory and energy analysis of cassava-based fuel ethanol in China. J. Clean. Prod. 2008, 16, 374–384. [Google Scholar] [CrossRef]

- Nguyen, T.L.T.; Gheewala, S.H.; Garivait, S. Full chain energy analysis of fuel ethanol from cassava in Thailand. Environ. Sci. Technol. 2007, 41, 4135–4142. [Google Scholar] [CrossRef]

- Van Haandel, A.C. Integrated energy production and reduction of the environmental impact at alcohol distillery plants. Water Sci. Technol. 2005, 52, 49–57. [Google Scholar] [CrossRef]

- Wilkie, A.C.; Riedesel, K.J.; Owens, J.M. Stillage characterization and anaerobic treatment of ethanol stillage from conventional and cellulosic feedstocks. Biomass Bioenergy 2000, 19, 63–102. [Google Scholar] [CrossRef]

- Zvinavashe, E.; Elbersen, H.W.; Slingerland, M.; Kolijn, S.; Sanders, J.P. Cassava for food and energy: Exploring potential benefits of processing of cassava into cassava flour and bioenergy at farmstead and community levels in rural Mozambique. Biofuels Bioprod. Biorefining 2011, 5, 151–164. [Google Scholar] [CrossRef]

- Cramer, J.; Wissema, E.; van Bruijne, M.; Lammers, E.; Dijk, D.; Jager, H.; van Bennekom, S.; Breunese, E.; Horster, R.; van Leenders, C.; et al. Testing Frameworks for Sustainable Biomass; Project Group Sustainable Production of Biomass: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Dornburg, V. Multi-Functional Biomass Systems; Utrecht University: Utrecht, The Netherlands, 2004; 216p. [Google Scholar]

- Searchinger, T. Use of US croplands for biofuels increases greenhouse gases through emissions from land-use change. Science 2008, 319, 1238–1240. [Google Scholar] [CrossRef] [PubMed]

- Baldassano, J.M.; Soriano, C. Emission of greenhouse gases from anaerobic digestion processes: comparison with other municipal solid waste treatments. Water Sci. Technol. 2000, 41, 275–282. [Google Scholar] [CrossRef]

- Borjesson, P.; Berglund, M. Environmental systems analysis of biogas systems—Part I: Fuel-cycle emissions. Biomass Bioenergy 2006, 30, 469–485. [Google Scholar] [CrossRef]

- Borjesson, P.; Berglund, M. Environmental systems analysis of biogas systems—Part II: The environmental impact of replacing various reference systems. Biomass Bioenergy 2007, 31, 326–344. [Google Scholar] [CrossRef]

- Cereda, M.P.; Takahashi, M. Cassava wastes: Their characterization, and uses and treatment in Brazil. In Cassava Flour and Starch: Progress in Research and Development; CIAT: Palmira, Colombia, 1996. [Google Scholar]

- Howeler, R.H. Nutrient inputs and losses in cassava-based cropping systems: Examples from Vietnam and Thailand. In Proceedings of the Workshop on Nutrient Balances for Sustainable Agriculture Production and Natural Resource Management in Southeast Asia, Bangkok, Thailand, 20–22 February 2001. [Google Scholar]

- Klinsukont, C.; Ploypatarapinyo, S.; Dararatana, K.; Pingchavalitsophee, J.; Chetthadomdecha, J. Wastewater Treatment System for Cassava Ethanol Distillery; Institute of Scientific and Technological Research: Bangkok, Thailand, 1991. [Google Scholar]

- Nguyen, T.L.T.; Gheewala, S.; Garivait, S. Energy balance and GHG-abatement cost of cassava utilization for fuel ethanol in Vietnam. Energy Policy 2007, 35, 4585–4596. [Google Scholar] [CrossRef]

- IPCC. Revised 1996 IPCC Guidelines for National Greenhouse Gas Inventories. 1996. Available online: http://www.ipcc-nggip.iges.or.jp/public/gl/invs6a.html (accessed on 10 March 2008).

- ACCEFYN. Factores de Emisión de los Combustibles Colombianos- Emission Factors for Colombian Fuels; Academia Colombiana de Ciencias Exactas, Físicas y Naturales: Bogotá, Colombia, 2003. Available online: http://www.siame.gov.co/siame/documentos/documentacion/mdl/DOC/18_FECOC.doc (accessed on 12 May 2007).

- Patzek, T. Thermodynamics of the Corn-Ethanol Biofuel Cycle. Crit. Rev. Plant Sci. 2004, 23, 519–567. [Google Scholar] [CrossRef]

- De Carvalho Macedo, I.; Lima Verde Leal, M.; Azevedo Ramos da Silva, J. Assessment of Greenhouse Gas Emissions in the Production and Use of Ethanol in Brazil; Government of the State of Sao Paulo: Sao Paulo, Brazil, 2004; 37p.

- ACCEFYN. Inventario Preliminar de Gases de Efecto Invernadero, Fuentes y Sumideros: Colombia-1990; Academia Colombiana de Ciencias Exactas, Físicas y Naturales: Bogotá, Colombia, 1990; Available online: http://www.accefyn.org.co/Web_GEI(actualizada)/Archivos_gei/I_Cap00_Generalidades.PDF (accessed on 10 February 2009).

- UPME. Metodología Simplificada Para el Cálculo de la Línea base para Proyectos de Pequeña Escala; Unidad de Planeación Minero Energética: Bogotá, Colombia, 2004; 12p.

- Fluck, R.C. Energy in Farm Production; Elsevier: Amsterdam, The Netherlands, 1992. [Google Scholar]

- Kongshaug, G. Energy consumption and greenhouse gas emissions in fertilizer production. In Proceedings of the IFA Technical Conference, Marrakech, Morocco, 28 September–1 October 1998. [Google Scholar]

- Maraseni, T.; Cockfield, G.; Apan, A. A comparison of greenhouse gas emissions from inputs into farm enterprises in Southeast Queensland, Australia. J. Environ. Sci. Health Part A 2007, 42, 11–18. [Google Scholar] [CrossRef]

- Bastianoni, S.; Marchettini, N. Ethanol production from biomass: Analysis of process efficiency and sustainability. Biomass Bioenergy 1996, 11, 411–418. [Google Scholar] [CrossRef]

- IDEAM. Available online: www.ideam.gov.co (accessed on 10 February 2009).

- Howeler, R.H.; Cadavid, L.F. Short-and long-term fertility trials in Colombia to determine the nutrient requirements of cassava. Fertil. Res. 1990, 26, 61–80. [Google Scholar] [CrossRef]

- Hogevorst, S. The Sustainability of Cassava Based Bioethanol Production in Colombia: The Added Value of Anaerobic Digestion; Wageningen University: Wageningen, The Netherlands, 2007. [Google Scholar]

- Ceballos, H. La yuca en Colombia y el Mundo: Nuevas Perspectivas para un Cultivo Milenario. In La Yuca en el Tercer Milenio. Sistemas Modernos de Producción, Procesamiento, Utilización y Comercialización; Ospina, B., Ceballos, H., Eds.; CIAT, CLAYUCA: Cali, Colombia, 2002. [Google Scholar]

- Arriaga Sierra, H. Economic Benefit and Costs of Ethanol Production from Cssava in Colombia. Master’s Thesis, Wageningen University, Wageningen, The Netherlands, 2008; 81p. [Google Scholar]

- Ospina, B.; Cadavid, L.F.; Garcia, M.L.; Alcalde, C. Mechanization of Cassava Production in Colombia; Howeler, R.H., Ed.; CIAT: Bangkok, Thailand, 2002. [Google Scholar]

- Caraballo, L.; Velásquez, E. Respuestas de tres cultivares de yuca a diferentes condiciones hídricas y fechas de cosecha. Agronomía Tropical 2000, 50, 267–284. [Google Scholar]

- Cock, J.H. Cassava: New Potential for a Neglected Crop; Westview Press Inc.: Boulder, CO, USA, 1985. [Google Scholar]

- Perez-Crespo. Integrated Cassava Projects; Report nr Working document No. 78; Catholic Relief Services: Baltimore, MD, USA, 1991. [Google Scholar]

- Ospina, B.; García, M.L.; Alcalde, A. Sistemas mecanizados de siembra y cosecha para el cultivo de la yuca. In La Yuca en el Tercer Milenio. Sistemas Modernos de Producción, Procesamiento, Utilización y Comercialización; Ospina, B., Ceballos, H., Eds.; CIAT-CLAYUCA: Cali, Colombia, 2002. [Google Scholar]

- Ospina, B.; Best, R.; Alonso, L. Tecnologías para el manejo de la yuca en poscosecha. In La Yuca en el Tercer Milenio. Sistemas Modernos de Producción, Procesamiento, Utilización y Comercialización; Ospina, B., Ceballos, H., Eds.; CIAT-CLAYUCA: Cali, Colombia, 2002. [Google Scholar]

- Castaño, H.; Cardona, M.; Mejía, C.; Acosta, A. Ethanol production from cassava flour in simultaneous enzymatic hydrolysis and fermentation system. Dyna 2011, 78, 158–166. [Google Scholar]

- López, J. Semilla vegetativa de yuca. In La Yuca en el Tercer Milenio. Sistemas Modernos de Producción, Procesamiento, Utilización y Comercialización; Ospina, B., Ceballos, H., Eds.; CIAT, CLAYUCA: Cali, Colombia, 2002. [Google Scholar]

- Tchobanoglous, G.; Burton, F.; Stensel, D. Wastewater Engineering Treatment and Reuse; McGraw-Hill: New York, NY, USA, 2004. [Google Scholar]

- Maroulis, Z.; Zaravacos, G. Food Process Design; CRC Press: Boca Raton, FL, USA, 2003; 536p. [Google Scholar]

- Drosg, B.; Wirthensohn, T.; Konrad, G.; Hornbachner, D.; Loderer, C.; Waltenberger, R.; Kyrchmayr, R.; Braun, R. Comparing central and peripheral anaerobic digestion of stillage from a large-scale bioethanol plant to animal feed production. Water Sci. Technol. 2008, 58, 1483–1489. [Google Scholar] [CrossRef] [PubMed]

- De Mes, T.Z.D.; Stams, A.J.M.; Reith, J.H.; Zeeman, G. Methane production by anaerobic digestion of wastewater and solid wastes. In Bio-Methane & Bio-Hydrogen. Status and Perspectives of Biological Methane and Hydrogen Production; Reith, J.H., Wijfels, R.H., Barten, H., Eds.; Dutch Biological Hydrogen Foundation: The Hague, The Netherlands, 2003; pp. 58–102. [Google Scholar]

- Berglund, M.; Borjesson, P. Assessment of energy performance in the life-cycle of biogas production. Biomass Bioenergy 2006, 30, 254–266. [Google Scholar] [CrossRef]

- Nandy, T.; Shastry, S.; Kaul, S.N. Wastewater management in a cane molasses distillery involving bioresource recovery. J. Environ. Manag. 2002, 65, 25–38. [Google Scholar] [CrossRef]

- Berglund, M. Biogas Production from a Systems Analytical Perspective. Ph.D. Thesis, Lund University, Lund, Sweden, 2006; 164p. [Google Scholar]

- Lehtomaki, A.; Bjornsson, L. Two-stage anaerobic digestion of energy crops: Methane production, nitrogen mineralization and heavy metal mobilization. Environ. Technol. 2006, 27, 209–218. [Google Scholar] [CrossRef] [PubMed]

- De Vries, J.W. Closing Material Cycles through Reincorporation of Digested Crop Material into the Farming Environment: Agricultural and Environmental Implications; Wageningen University: Wageningen, The Netherlands, 2007; 107p. [Google Scholar]

- Cuzin, N.; Farinet, J.L.; Segretain, C.; Labat, M. Methanogenic fermentation of cassava peel using a pilot plug flow digester. Bioresour. Technol. 1992, 41, 259–264. [Google Scholar] [CrossRef]

- Mai, H.N.P. Integrated Treatment of Tapioca Processing Industrial Wastewater. Based on Environmental Biotechnology. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 2006; 177p. [Google Scholar]

- Angelidaki, I.; Sanders, W. Assessment of the anaerobic biodegradability of macropollutants. Re/Views Environ. Sci. Bio/Technol. 2004, 3, 1–13. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency—EPA. Solid Waste Management and Greenhouse Gases: A Life-Cycle Assessment of Emissions and Sinks, 3rd ed.; EPA: Washington, DC, USA, 2006; p. 170.

- IICA. Observatorio Agrocadenas de Colombia; Ministerio de Agricultura y Desarrollo Rural: Bogotá, Colombia, 2006. Available online: www.agrocadenas.gov.co (accessed on 10 February 2009).

- Nguyen, T.L.T.; Gheewala, S.H. Life cycle assessment of fuel ethanol from Cassava in Thailand. Int. J. Life Cycle Assess. 2008, 13, 147–154. [Google Scholar] [CrossRef]

- Von Blottnitz, H.; Curran, M.A. A review of assessments conducted on bio-ethanol as a transportation fuel from a net energy, greenhouse gas, and environmental life cycle perspective. J. Clean. Prod. 2007, 15, 607–619. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).