1. Introduction

Models that apply methods of operational analysis are widely used for inventory management. As a matter of fact, an independent discipline that tackles the various economic and technical issues associated with material management, namely material/inventory theory, arose from operational analysis. Material theory (or more precisely the mathematical theory of inventory and production) deals with streamlining materials, semi-finished products, and product circulation, and the overall effectiveness of their management. The differences between models of material theory lie in which way and through which indicators the estimated consumption is defined, which probability model tests the consumption and the ordering cycle, and in which way the potential risks are estimated [

1,

2].

The deterministic model of inventory management is a basic model in the field of material theory. The parameters for the objective function of the model and its internal structure are mainly focused on the economics of inventory management. Nevertheless, this model takes into consideration only basic factors such as the cost associated with the supply process, the consumption intensity of particular inventory items and the delivery [

3,

4].

The aim of this article is to modify the objective function of the deterministic model of inventory theory and to make specific calculations for individual parameters in such a way that inventories are optimized not only with respect to costs but also in regard to significant factors affecting the supply process [

5]. These factors are the capacity of the means of transport, consumption, the share of inventories in the sales of a company and, last but not the least, the reliability of suppliers.

2. Literature Review

As inventory management is currently a topical issue, it has been addressed in many publications focusing on a variety of problems. It arises, in particular, from the need of enterprises for inventory management results to ensure certain market competitiveness. For instance, this matter is addressed by Atnafu and Balda [

6] in their publication. They focused on small enterprises in Ethiopia and searched for empirical evidence in regard to inventory management that has a significant impact on the competitiveness of micro and small businesses. Inventory management efficiency is often measured through inventory management efficiency indicators. Specifically, it is the stock (inventory) turnover indicator that has been investigated in multiple publications [

7,

8,

9,

10,

11]. The research study [

7] deals with an empirical analysis of the impact of demand uncertainty in the US retail sector on stock turnover performance. The issue of unequal customer demand in the context of inventory is very topical as well. This topic is addressed by authors in the literature [

8], where they search for an answer to the question of whether the high and low inventory turnovers of retailers respond differently to demand shocks?

Other options to influence inventory turnover positively have brought various innovations in the field including the horizontal or vertical integration of supply chain links. These issues have been discussed, for example, in publications [

9,

10]. In publication [

9], the authors generally focus on the role of innovation in terms of the performance of inventory turnover, whereby publication [

10] specifically deals with the impact of vertical integration on inventory turnover and operational performance. Inventory management performance indicators are influenced by both customer demand as well as supplier activity. The literature [

11] proposes a hybrid algorithm that represents a model of inventory management with suppliers aiming to maximize inventory turnover in the manufacturer’s warehouse. One way to increase inventory turnover is to choose the appropriate inventory management model. Many inventory management models have already been designed and operated. A general overview of stochastic models of inventory management is provided in publication [

12], where the authors reviewed literature sources regarding stochastic models. In research study [

13], the authors analyzed the performance of inventory management systems not only through the stochastic model but also from the deterministic model perspective. Deterministic models, or inventory-oriented models with deterministic demand, are addressed in publications [

14,

15,

16,

17] as well.

Different points of views on inventory model designs are examined in studies [

18,

19,

20,

21]. In publications [

18,

19], inventory models are proposed in such a way that various variabilities within inventory management are taken into account, in particular, whether variability is represented by delivery time [

18], or the capacity utilization [

19]. The general objective of inventory management is represented by the requirement for a minimum order size, which is addressed in publication [

20], and also, an important aspect of any industrial area at present, environmental requirement is addressed in the literature [

21]. Other models have been addressed in studies [

22,

23,

24,

25,

26]. Those publications focused on various aspects of inventory management. The lost-sale model is analyzed in [

22], the inventors’ selection model in [

23], an inventory model designed to efficiently redistribute production to individual orders (multi-objective model) is investigated in [

24], a customer service model dealing with the service focus differentiation and response to time guarantees (a base-stock inventory model) in [

25], and, of course, cost models of inventory management (continuous inventory models of diffusion type) are addressed in [

26].

Publication [

27] discusses the topic regarding the production process with supply issues and their cost performance (production–inventory system). Several publications, such as [

28,

29,

30,

31,

32,

33,

34], address performance measurement in various fields in relation to inventory management. The impact of inventory management on overall supply chain performance is described by authors in publications [

28,

29,

30,

31]. While literature [

30] examines the impact of retailers with knowledge of supplier’s inventory on supply chain performance, research study [

31] investigates the effect of control system structure and the performance of an inventory goods flow system with long-variable delay. The interdependence among inventory types and firm performance is elaborated in publication [

32]. The authors of literature reference [

33] discuss financial performance assessment in terms of inventory management practices, and study [

34] is aimed at performance assessment in homogeneous/heterogeneous collaborative enterprise networks with inventory adjustment.

The literature review conducted suggests that there are a number of research studies aimed at designing different inventory management models as well as evaluating inventory management performance. The objective of our manuscript is, based on a performed research study, to demonstrate the positive impact of a purposeful change in the objective function parameters on inventory management performance indicators.

4. Comparison of Applying the Deterministic Model and the Designed Model

A research study dealing with the optimization of the supply process was used to compare the application of the deterministic model and that of the model with modified objective function. Three representatives in relation to inventories were chosen in a specific company according to their stochastic character in the consumption of the particular inventory item. The input data is presented in

Table 1.

Following the data on specific inventory items of the given company, the calculations needed to optimize the supply process using the deterministic model (

Section 4.1) and the proposed model (

Section 4.2) will be performed in following sections.

4.1. Determination of the Optimal Order Size

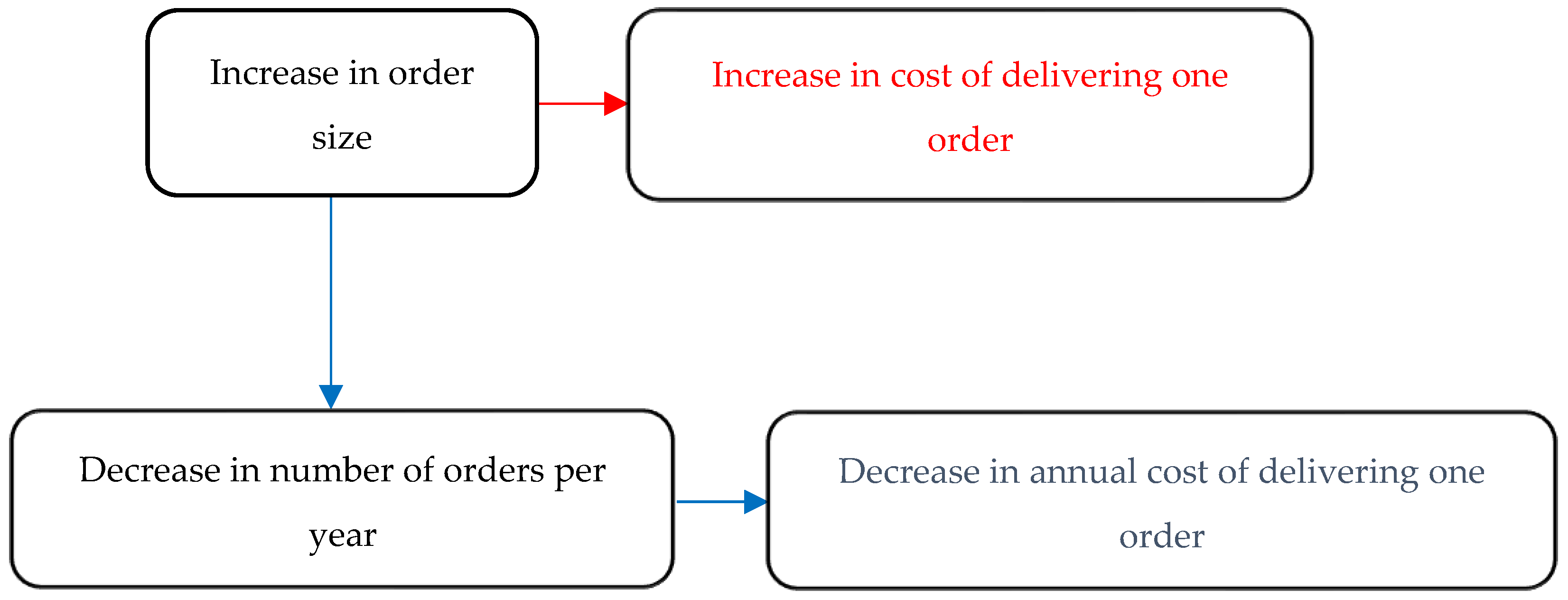

The extent and parameters for the calculation of the optimal order size Qopt differ for the model with modified objective function and the deterministic model. In contrast to the deterministic model, the modified model of inventory management takes into consideration the daily consumption of inventories I [m.u./day] in contrast to the annual consumption of inventories I [m.u./year] and the annual delivery cost NdodR in contrast to one-off delivery cost Ndod.

The reason for calculating annual delivery cost is that this value also takes into consideration the number of orders carried out per year R, which depends on order size Q; on the one hand, the smaller the order, the lower the one-off delivery cost is Ndod, while, on the other hand, it means a larger number of orders carried out per year R, which also means an increase in delivery cost per year NdodR.

Furthermore, the calculation of annual delivery cost NdodR must take into consideration changes in delivery cost as a result of exceeding the capacity of the means of transport kPJ and the consumption of the particular inventory, which in turn significantly influences the number of orders carried out per year R, and which is closely associated with annual delivery cost NdodR.

Another change regarding the parameters consists in the calculation of the optimal order size Qopt according to the modified model and its dependence on the newly created parameter W, which substitutes individual storage cost nskl in the deterministic model. Parameter W, apart from storage cost nskl, also takes into consideration their dependence on inventory funds VFP, which enhances the economic effectiveness of inventory management. The inventory level H means the key variable for the calculation of parameter W depends on consumption intensity I, delivery period d, purchase price CN and the reliability of the supplier DS. This not only increases economic effectiveness, but also minimizes the risks associated with the lack of inventories.

Figure 2 illustrates how the optimal order size is determined through distribution curves that indicate changes in the

NdodR and

W parameters in relation to order size

QN for the model with modified objective function.

The blue curve represents the change in NdodR depending on QN at the limited vehicle capacity. The red curve depicts the dependence of the capital tied up in inventory W on QN at a certain intensity and the nature of the given inventory consumption, while also taking into account the delivery period and reliability of the supplier in terms of the delivery process.

Table 2 compares calculations for the optimal order size

Qopt according to the deterministic model of inventory management and the model with modified objective function. It also includes specific calculations for the optimal order size

Qopt for the individual representatives of the inventories (α, β, γ) identified and defined in

Table 1.

4.2. Determination of the Order Cycle Duration

The order cycle duration t depends on the optimal order size Qopt and the consumption intensity I. The deterministic model and the model with modified objective function differ in the way they determine the order cycle t, whereby, under the former, the calculation is based on annual consumption I [m.u./year] and, under the latter, on daily consumption I [m.u./day].

The order cycle duration t for the modified model is calculated only for inventories consumed continuously. Orders for other inventory items are classified according to ‘inventory level’

H (according to Equation (14)). The calculations for the order cycle duration on the basis of both models are presented in

Table 3.

The lower the optimal order size Qopt derived from the modified model of inventory management, the shorter the order cycle t; this fact has a favorable impact on the indicator for the speed of inventory turnover v. The higher the speed of inventory turnover v, the more economically effective the inventory management.

4.3. Determination of the Inventory Level

The methods for calculating the inventory level H significantly differ between the two models. Under the deterministic model, the determination of inventory level H is based on consumption intensity I, the delivery period d and the order cycle duration t.

The modified model of inventory management determines the inventory level H in such a way that minimizes the likelihood of the risk of a lack of inventories to almost zero. The method for the calculation of the losses that would be suffered as a result of the lack of inventories Sned (10), allows other factors relevant to the supply process to be taken into consideration. These factors include the reliability of the supplier of the particular inventory DS, the extent to which the specific inventory participates in the sales of the final product F and the purchase price of the specific inventory CN.

Figure 3 illustrates how the optimal inventory level is determined through distribution curves that indicate changes in the

W and

Sned parameters in relation to inventory level

HN for the model with modified objective function.

The blue curve represents the dependence of the capital tied up in inventory W on HN at a certain intensity and the nature of given inventory consumption, while also taking into account the delivery period and reliability of the supplier in terms of the delivery process. The red curve shows the likelihood of the risk of a lack of inventories and the resulting cost Sned depending on the inventory level in the warehouse HN.

The calculations for the emergency supply inventory α and the determination of the signal inventory level

H for inventory β and γ according to the deterministic and modified model of inventory management are presented in

Table 4.

The modified model of inventory management determines:

the size of the emergency supply for inventories consumed continuously through the year;

the size of the signal inventory for inventories with a consumption that is affected by seasonal fluctuations or surges.

5. Results and Discussion

In general, most of the published studies dealing with inventory management issues are aimed at applying existing inventory management models (see literature review chapter) as well as publications [

38,

39,

40,

41,

42,

43,

44]. Unlike those literature sources, this manuscript is focused on an in-depth analysis of the existing model internal structure, i.e., the deterministic model of inventory management, and investigates options to improve its objective function through the appropriate design of its parameters. The research purpose of this article is, thus, to propose the inventory management model that, when applied in practice, will allow a company to optimize the inventory level as well as the entire supply process, while taking into account the whole scale of criteria that have not been incorporated into existing models yet. These criteria do not only consist of a cost criterion, as is the case with existing models [

12,

45], but also consider other significant factors affecting supply process continuity.

In contrast to the parameters for the deterministic model of inventory management, the model with modified objective function not only optimizes inventories in relation to delivery cost Ndod, storage nskl and the purchase price of inventory CN, but also takes into consideration the potential losses that would be suffered if inventories were not available on time Sned. Moreover, the modified model works with an annual delivery cost NdodR instead of one-off delivery cost Ndod, which results in the long-term sustainable economic effectiveness of the supply process.

The incorporation of parameter NdodR in the objective function of the modified model may cause a considerable increase in the average inventory level , which would consequently reduce the speed of inventory turnover v. The reduction in the speed of inventory turnover v along with the increase in the inventory level H in the company represents emergency supplies, i.e., signal supply may be caused by incorporating parameter W in the objective function of the modified model. Apart from parameter W, the incorporation of parameter Sned may also play an important role in increasing the maintained inventory level H in the company.

The average inventory level

, together with the speed of inventory turnover

v, is a leading indicator of the effectiveness of inventory management [

39]. The average inventory level

amounts to ½ the optimal order size

Qopt (see Equation (15)).

Table 5 compares the figures for the average inventory levels for the individual items

regarding the optimal order size

Qopt according to both models of inventory management.

Under the modified model of inventory management, the average inventory level for β and γ is significantly lower because, unlike the deterministic model, it takes fluctuations and surges in inventory consumption into consideration.

This important fact is further confirmed by the indicator for the speed of inventory turnover

v, which shows how many times per year, i.e., reporting periods, the original inventories are changed for new ones (see Equation (16)). The key goal is to achieve the highest possible speed of inventory turnover

v [

40].

In

Table 6, the figures for the optimal speed of inventory turnover

v according to both models of inventory management are compared.

Table 7 compares the results of the application of the modified model (light gray areas) to that of the deterministic model (dark gray areas) of inventory management.

Based on the obtained results summarized in the table above (see

Table 7), predesignated research prerequisites (see

Section 3.2.4) may be confirmed or disproved. For better clarity, the research prerequisites, as well as their confirmation or disproving, are listed in the

Table 8 as follows.

Following the results of the case study conducted within this manuscript, it can be stated that the optimal order size is lower for all the inventory item types that have been the subject of the research, which results in a shorter order cycle as well. This is due to the fact that the proposed model, in addition to storage cost, also takes into account the level of capital tied up in inventory items, which are dependent on the inventory level in the warehouse. For the same reason, the optimal inventory level kept in the warehouse after the proposed model application is lower compared to the results of the deterministic model application and, thereby, the average inventory level in the warehouse is lower as well. These facts have a positive effect on the storage cost value as well as the overall level of capital tied up in inventory. Due to the lower optimal order size, the order cycle is also shorter, thus increasing the inventory turnover rate, which is a significant indicator of the supply process being managed efficiently.

6. Conclusions

The objective of this article was to modify the parameters and thus the objective function of the inventory theory deterministic model in order that other important aspects which influence inventory management could be taken into consideration. In doing so, account was not only taken of the cost associated with inventories, consumption intensity and delivery period, but also the capacity of the means of transport, consumption, the share of inventories in sales and, last but not the least, the reliability of suppliers.

The effectiveness of optimizing inventories by implementing the modified model was verified through its application and the subsequent comparison of the results with the existing deterministic model. Order size, order cycle duration and sustained inventory levels were compared, as were the speed of inventory turnover and the average inventory level as key indicators of the effectiveness of inventory management.

The results of the research study have revealed that the optimal order size is smaller for all the inventories that were included in the research study, which indicates a shorter order cycle. It results from the fact that inventories optimized through the model with modified objective function not only take into consideration storage cost, but also their dependence on inventory funds, which is dependent on the inventory level in storage.

For this reason, the optimal sustained inventory level in storage was lower after the application of the modified model in comparison to the results obtained through the deterministic model; the average inventory level in storage was therefore also lower. These observations have a favorable impact on the amount of storage cost and overall dependence on inventory funds. Furthermore, the smaller optimal order size indicates a shorter order cycle, which in turn means a higher speed of inventory turnover, which is a key indicator of an effectively controlled supply process.

As for future research recommendations, due to the wide range of criteria within the model proposed leading to large-scale calculations, it would be, therefore, reasonable to develop a software application based on the designed inventory model in order to automate the overall or partial inventory optimization processes. Another alternative may be to implement the proposed model in MS Excel using the specific mathematical, statistical and graphical functions. After entering the input parameters, the developed software application should allow calculating and creating optimization graphs to determine the optimal order size and the optimal inventory level, as well as the optimal order cycle, in an enterprise. Developing the specific SW application for the designed model would help towards automating optimization processes that would greatly contribute to both time and cost savings.