1. Introduction

Global warming is one of the most serious problems facing the whole world, with the main cause being a large amount of greenhouse gas (GHG) emissions that are generated by human economic activities [

1]. Many countries and organizations have issued and implemented corresponding regulations to control the carbon emissions, such as carbon cap, carbon cap and offset, carbon cap and trade, or carbon tax regulation in order to reduce GHG emissions and mitigate the environmental problems. Taking China as an example, the carbon cap and trade regulation is widely accepted and it has launched its pilot emission trading system (ETS) in seven regions in 2013 [

2]. Subsequently, in 2017, the National Development and Reform Commission announced the official launch of the national carbon market, and would gradually expand the market coverage [

3]. Along with the frequently introduced carbon emission policies and gradually expanded carbon market, the limitation of carbon emissions has become a problem that enterprises must face, especially for high-energy consuming enterprises, such as cold chain logistics [

4].

Cold chain logistics is a low-temperature supply chain system that combines refrigeration industry and logistics. In recent years, with the improvement of people’s living standards, it has developed rapidly. According to relevant data, in 2015, the transaction volume of China’s cold chain logistics market was 158.3 billion yuan, which reached 220 billion yuan in 2016 with an increase of 22.3% over 2015 [

5]. In 2020, the compound growth rate of China’s cold chain market is expected to reach 17.1% [

6]. However, although its development promotes economic development to some certain extent, it also imposes a serious burden on the environment. When compared with normal logistics, the cold chain logistics need to use refrigeration equipment (e.g., refrigerated vehicle) to maintain the freshness of the products, which normal operation will consume enormous energy and produce significant carbon emissions simultaneously [

7]. Adekomaya et al. [

8] reported that the fossil fuels that are used in transport refrigeration accounted for 15% of world’s energy use and 40% of the global greenhouse effect comes from emissions that are generated from food transportation. Therefore, in the context of stringent governmental carbon regulations and consumers’ increasing expectation for environmental friendliness, it becomes a necessity that the incorporation of carbon emission reduction into the operational decision on logistics management. Afterwards, how to make operational decisions to reduce carbon emissions of cold chain activities and promote sustainable development of enterprises becomes a rough problem that needs to be solved imperatively.

For past few years, there is some research on low-carbon cold chain logistics. Most research focuses on the optimization of operational decision on cold chain network, which significantly contributes to green logistics [

9], such as distribution optimization [

10,

11] and inventory strategy optimization [

12] in cold chain logistics. However, although they demonstrated that operation optimization is conducive to reducing carbon emissions, they almost focused on single-stage optimization, few researches studied the holistic optimization of integrated inventory and transportation activities. In fact, firms ought to prefer a holistic optimization whether from an economic or sustainable perspective. According to the relevant report, the total cost of transportation and inventory account for 96% of the logistics costs [

13]. As for carbon emissions that are generated from inventory and transportation activities, it negatively contributes to the environment. It is noted that 14% of global greenhouse gas emissions in 2010 came from the transportation sector according to report [

14]. With reference to inventory stage, the accompanying warehousing operations that employ special cold warehouse or freezer produce significant carbon emissions [

12]. Furthermore, the inventory scheme will also influence the distribution planning decision. Therefore, more attention should be focused on the holistic optimization of integrated inventory and transportation problem in cold chain logistics to accomplish the purpose of both economy and environment.

In addition, considering carbon regulation constraints in optimization models is a good way to reduce the carbon emission from existing research regarding low-carbon cold chain [

10,

11,

15], which can also reflect the effectiveness of the carbon regulation and provide some insights into how to make better decision on carbon regulation formulation [

16]. However, most articles doing research only consider one kind of regulation. In fact, in China, or even the world, there are still no specific carbon regulations implemented in cold chain logistics industry. Subsequently, we need to think about some questions: do these carbon policies have the same effect on the carbon emission reduction and economic performance of cold chain logistics? If there js some difference, then what is it? From these points of view, this paper focused on an integrated inventory and transportation problem, namely the inventory routing problem (IRP), of a two-echelon supply chain that includes a supplier and a series of retailers, while simultaneously considering four existing carbon regulations.

The carbon emission regulations that are considered in this paper are carbon cap, carbon tax, carbon cap-and-trade, and carbon cap offset, which have been approved and implemented by some countries or organizations. The carbon cap regulation is one of the policies considered to reduce the carbon emission in the United States (US) by the Congress of the United States, Congressional Budget Office [

17]. European countries, like Denmark, Finland, Sweden, Netherlands, and Norway, firstly implemented the carbon tax regulation [

18]. As for carbon cap and trade regulation, the carbon emissions are tradable through a trading system, such as the European Union Emissions Trading System (EU-ETS) [

19]. The carbon cap offset regulations is often employed by originations who voluntarily decrease their carbon emissions by investing a carbon offset project or activity [

20]. From these, we can see that these regulations are very influential and their coverage will expand in the future, so it is valuable to further study these policies in the field of the cold chain logistics. The main purpose of this paper is to reduce the carbon emissions of cold chain by optimizing the operational decision on the inventory control and transportation planning, simultaneously. Our other purpose is to provide some reference for government decision-making on carbon regulation development in cold chain logistics by analyzing the difference of the effect of these carbon policies on the cold chain.

This paper is based on the four existing carbon policies, which are carbon cap, carbon tax, carbon cap-and-trade, and carbon cap offset, investigate the optimization of inventory routing problem in cold chain logistics while considering carbon regulations. Firstly, based on four existing carbon emissions regulations, four optimized green cold chain inventory routing problem models were constructed. Subsequently, the genetic simulated annealing algorithm (GASA) is developed in order to efficiently solve the proposed models. The main advantages of the proposed models are as follows: (1) These models explicitly account for carbon dioxides that are generated not only by transportation sector, but also the inventory stage. (2) This paper systematically analyzes the cost items concerned with cold chain logistics, which includes inventory cost, damage cost, fixed vehicle cost, fuel consumption cost and carbon emission related cost (except the model under carbon cap regulation). (3) According to the rule of each carbon regulation, the corresponding carbon constraints or carbon emission related cost are included in the models. (4) The proposed GASA algorithm combines the genetic algorithm and simulated annealing algorithm, which efficiently enhanced the local search capabilities of the algorithm.

The rest of this paper is structured, as follows: the relevant literature to the problem addressed this paper is reviewed in

Section 2. The model formulations are proposed in

Section 3. A solution method is described in

Section 4. The algorithm experiment and results analysis are shown in

Section 5. Finally, conclusions are presented in

Section 6.

6. Conclusions

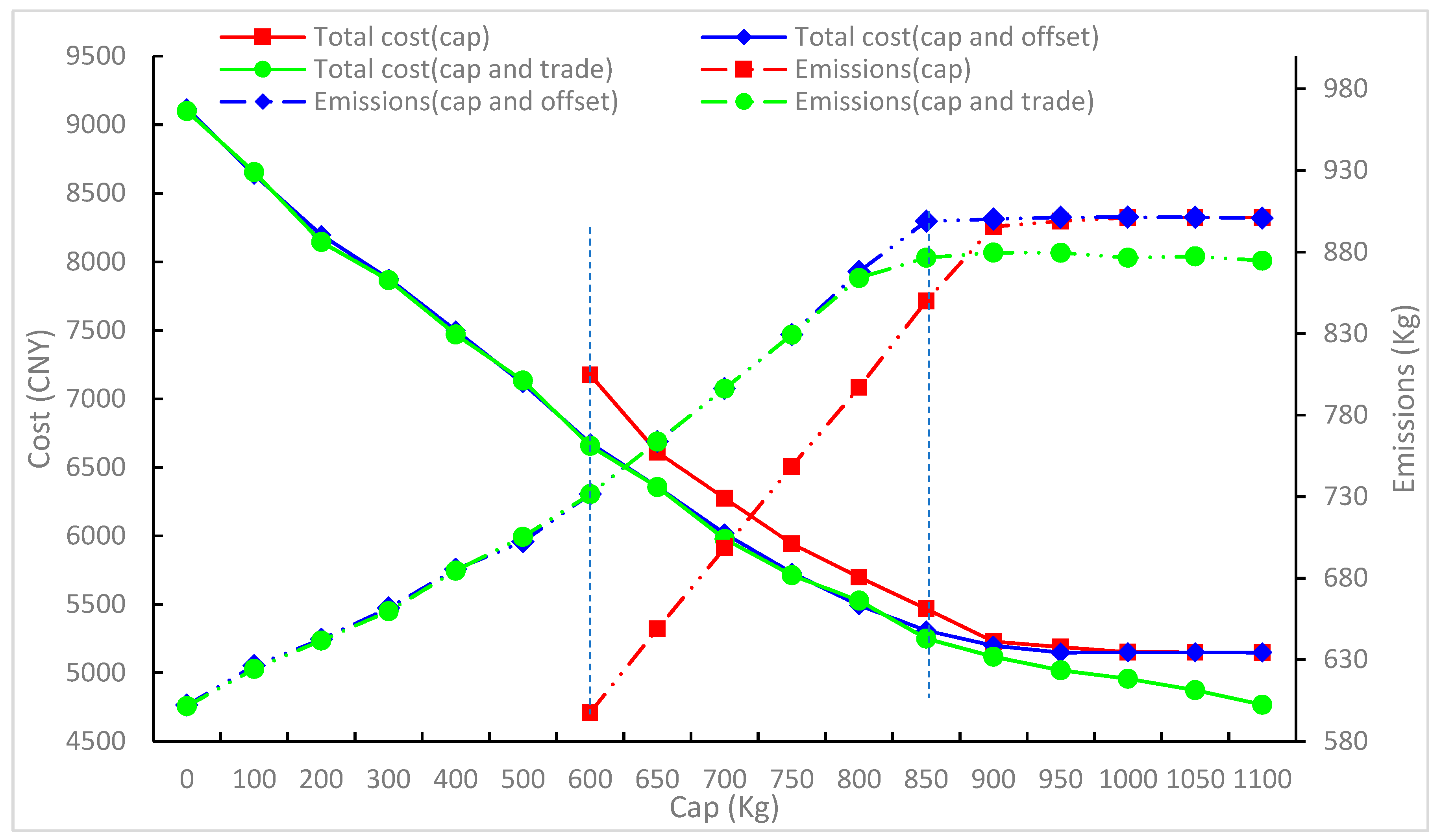

As people become increasingly concerned about environmental issues, many countries have enacted some policies to reduce carbon emissions. As a high emission industry, the cold chain logistics will eventually be affected by carbon emission regulations. However, in China, or even the world, the carbon emission regulation for the cold chain logistics industry is still in the discussion stage. Therefore, this paper focuses on the cold chain inventory routing optimization problem under carbon regulations and systematically analyzes the impacts of carbon emission regulations on cold chain logistics, to provide suggestions for the development of the cold chain enterprises and some valuable reference for government decision-making on carbon emission regulation development. Based on the four existing carbon emission regulations: carbon cap, carbon cap offset, carbon cap-and-trade, and carbon tax policy, four models for cold chain IRP, which jointly minimizes the operational cost, as well as the cost of carbon emissions are constructed. Different from traditional IRP, the cold chain IRP models in this paper comprehensively accounts for the carbon emissions not only produced by transportation sector but also inventory stage, which is not explicitly calculated in previous paper. The cold chain IRP also concerns the cargo damage and refrigeration factors, which makes the cold chain IRP models more complicated but important. Subsequently, a genetic simulated annealing algorithm (GASA) is developed to solve the problem. Through comparison experiments, the effectiveness and efficiency of the GASA was verified. Next, the models and the algorithm are used in an actual instance to carry out a series of sensitivity experiments to analyze the impacts of different carbon policies on the carbon emissions and the total cost. Some interesting phenomena are observed from the parameter sensitivity analyses under different policies. These insights can not only offer advice for companies to balance costs and environmental effects, but also suggest ideas for governments to employ suitable policies and establish reasonable carbon caps and prices.

The limitations of this paper and future work are as follows: this paper focuses on the inventory routing problem for cold chain logistics, without considering the customer satisfaction factor, which may influence the optimal scheme. Therefore, the further in-depth study on the inventory routing problem while considering customer satisfaction is needed.