Innovative Processes and Technologies for Nutrient Recovery from Wastes: A Comprehensive Review

Abstract

:1. Introduction

2. Nutrients Recovery Processes (NRPs)

Aerobic Degradation

Aerobic Degradation  Volatilization Anaerobic condition Humus Formation

Volatilization Anaerobic condition Humus Formation  Compost Stable organic matter

Compost Stable organic matter

3. Nutrient Recovery Technologies (NRTs)

4. Pyrolysis

5. Forward Osmosis

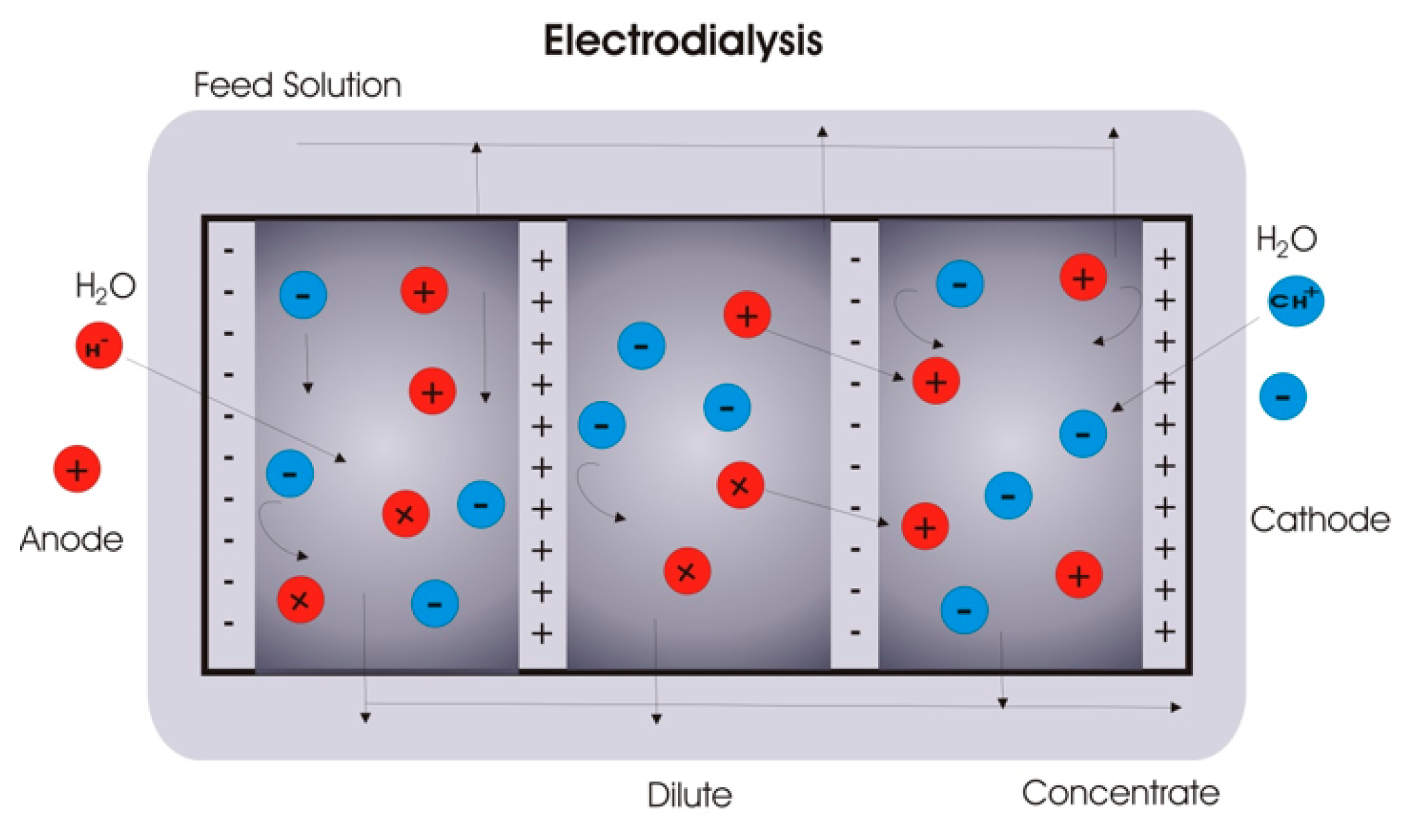

6. Electro-Dialysis

7. Quantification of Environmental Impact Using LCA

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Troschinetz, A.M.; Mihelcic, J.R. Sustainable recycling of municipal solid waste in developing countries. Waste Manag. 2009, 29, 915–923. [Google Scholar] [CrossRef] [PubMed]

- Verma, R.L.; Borongan, G.; Memon, M. Municipal Solid Waste Management in Ho Chi Minh City, Viet Nam, Current Practices and Future Recommendation. Procedia Environ. Sci. 2016, 35, 127–139. [Google Scholar] [CrossRef]

- Wang, H.; Nie, Y. Municipal solid waste characteristics and management in China. J. Air Waste Manag. Assoc. 2001, 51, 250–263. [Google Scholar] [CrossRef] [PubMed]

- Zaman, A.U. Identification of waste management development drivers and potential emerging waste treatment technologies. Int. J. Environ. Sci. Technol. 2013, 10, 455–464. [Google Scholar] [CrossRef]

- Godfray, H.C.J.; Beddington, J.R.; Crute, I.R.; Haddad, L.; Lawrence, D.; Muir, J.F.; Pretty, J.; Robinson, S.; Thomas, S.M.; Toulmin, C. Food Security: The Challenge of Feeding 9 Billion People. Science 2010, 327, 812–818. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hellsten, S.; Dalgaard, T.; Rankinen, K.; Tørseth, K.; Bakken, L.; Bechmann, M.; Kulmala, A.; Moldan, F.; Olofsson, S.; Piil, K.; et al. Abating N in Nordic agriculture—Policy, measures and way forward. J. Environ. Manag. 2019, 236, 674–686. [Google Scholar] [CrossRef] [PubMed]

- Sharpley, A.N.; Daniel, T.C.; Edwards, D.R. Phosphorus Movement in the Landscape. J. Prod. Agric. 1993, 6, 492–500. [Google Scholar] [CrossRef]

- Gopalakrishnan, B.G.; Negri, M.C.; Synder, S.W. Redesigning agricultural landscapes for sustainability using bioenergy crops: Quantifying the tradeoffs between agriculture, energy and the environment. Asp. Appl. Biol. 2011, 112, 139–146. [Google Scholar]

- Xu, H.; Wu, M.; Ha, M. Recognizing economic value in multifunctional buffers in the lower Mississippi river basin. Biofuels Bioprod. Biorefining 2019, 13, 55–73. [Google Scholar] [CrossRef]

- Šimunić, I.; Orlović-Leko, P.; Likso, T.; Filipović, V.; Minkina, T. Water quality in hydroameliorated agricultural areas. Agric. Conspec. Sci. 2011, 76, 49–55. [Google Scholar]

- US Environmental Protection Agency. “Trends in Greenhouse Gas Emissions”. Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2012—Trends.EPA.gov; Environmental Protection Agency: Canberra, Australia, 2012. Available online: http://www.epa.gov/climatechange/Downloads/ghgemissions/US-GHG-Inventory-2014-Chapter-2-Trends.pdf (accessed on 23 March 2019).

- Vitousek, P.M.; Naylor, R.; Crews, T.; David, M.B.; Drinkwater, L.E.; Holland, E.; Nziguheba, G. Nutrient imbalances in agricultural development. Science 2009, 324, 1519–1520. [Google Scholar] [CrossRef] [PubMed]

- Obi, F.O.; Ugwuishiwu, B.O.; Nwakaire, J.N. Agricultural waste concept, generation, utilization and management. Niger. J. Technol. 2016, 35, 957–964. [Google Scholar] [CrossRef]

- Adjia, R.; Fezeu, W.M.L.; Tchatchueng, J.B.; Sorho, S.; Echevarria, G.; Ngassoum, M.B. Long term effect of municipal solid waste amendment on soil heavy metal content of sites used for periurban agriculture in Ngaoundere, Cameroon. Afr. J. Environ. Sci. Technol. 2008, 2, 412–421. [Google Scholar]

- Mehta, C.M.; Khunjar, W.O.; Nguyen, V.; Tait, S.; Batstone, D.J. Technologies to recover nutrients from waste streams: A critical review. Crit. Rev. Environ. Sci. Technol. 2015, 45, 385–427. [Google Scholar] [CrossRef]

- Galvez, A.; Sinicco, T.; Cayuela, M.L.; Mingorance, M.D.; Fornasier, F.; Mondini, C. Short term effects of bioenergy by-products on soil C and N dynamics, nutrient availability and biochemical properties. Agric. Ecosyst. Environ. 2012, 160, 3–14. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, X. Changes in physical, chemical, and microbiological properties during the two-stage co-composting of green waste with spent mushroom compost and biochar. Bioresour. Technol. 2014, 171, 274–284. [Google Scholar] [CrossRef] [PubMed]

- Raut, M.P.; William, S.P.; Bhattacharyya, J.K.; Chakrabarti, T.; Devotta, S. Microbial dynamics and enzyme activities during rapid composting of municipal solid waste—A compost maturity analysis perspective. Bioresour. Technol. 2008, 99, 6512–6519. [Google Scholar] [CrossRef]

- Horrocks, A.; Curtin, D.; Tregurtha, C.; Meenken, E. Municipal Compost as a Nutrient Source for Organic Crop Production in New Zealand. Agronomy 2016, 6, 35. [Google Scholar] [CrossRef]

- Mia, S.; Uddin, M.E.; Kader, M.A.; Ahsan, A.; Mannan, M.A.; Hossain, M.M.; Solaiman, Z.M. Pyrolysis and co-composting of municipal organic waste in Bangladesh: A quantitative estimate of recyclable nutrients, greenhouse gas emissions, and economic benefits. Waste Manag. 2018, 75, 503–513. [Google Scholar] [CrossRef]

- Manyuchi, M.; Phiri, A. Vermicomposting in solid waste management: A review. Int. J. Sci. Eng. Technol. 2013, 2, 1234–1242. [Google Scholar]

- Gupta, R.; Garg, V. Stabilization of primary sewage sludge during vermicomposting. J. Hazard. Mater. 2008, 153, 1023–1030. [Google Scholar] [CrossRef]

- Sen, B.; Chandra, T. Chemolytic and solid-state spectroscopic evaluation of organic matter transformation during vermicomposting of sugar industry wastes. Bioresour. Technol. 2007, 98, 1680–1683. [Google Scholar] [CrossRef] [PubMed]

- Garg, V.; Kaushik, P.; Dilbaghi, N. Vermiconversion of wastewater sludge from textile mill mixed with anaerobically digested biogas plant slurry employing Eisenia foetida. Ecotoxicol. Environ. Saf. 2006, 65, 412–419. [Google Scholar] [CrossRef] [PubMed]

- Garg, V.; Gupta, R. Optimization of cow dung spiked pre-consumer processing vegetable waste for vermicomposting using Eisenia fetida. Ecotoxicol. Environ. Saf. 2011, 74, 19–24. [Google Scholar] [CrossRef] [PubMed]

- Vig, A.P.; Singh, J.; Wani, S.H.; Dhaliwal, S.S. Vermicomposting of tannery sludge mixed with cattle dung into valuable manure using earthworm Eisenia fetida (Savigny). Bioresour. Technol. 2011, 102, 7941–7945. [Google Scholar] [CrossRef] [PubMed]

- Yadav, A.; Garg, V. Feasibility of nutrient recovery from industrial sludge by vermicomposting technology. J. Hazard. Mater. 2009, 168, 262–268. [Google Scholar] [CrossRef]

- Hanc, A.; Pliva, P. Vermicomposting technology as a tool for nutrient recovery from kitchen bio-waste. J. Mater. Cycles Waste Manag. 2013, 15, 431–439. [Google Scholar] [CrossRef]

- Singh, R.; Embrandiri, A.; Ibrahim, M.; Esa, N. Management of biomass residues generated from palm oil mill: Vermicomposting a sustainable option. Resour. Conserv. Recycl. 2011, 55, 423–434. [Google Scholar] [CrossRef]

- Lim, S.L.; Lee, L.H.; Wu, T.Y. Sustainability of using composting and vermicomposting technologies for organic solid waste biotransformation: Recent overview, greenhouse gases emissions and economic analysis. J. Clean. Prod. 2016, 111, 262–278. [Google Scholar] [CrossRef]

- Lim, S.L.; Wu, T.Y.; Lim, P.N.; Shak, K.P.Y. The use of vermicompost in organic farming: Overview, effects on soil and economics. J. Sci. Food Agric. 2015, 95, 1143–1156. [Google Scholar] [CrossRef]

- Edwards, C.A.; Arancon, N.Q.; Sherman, R.L. Vermiculture Technology: Earthworms, Organic Wastes, and Environmental Management; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Garg, V.; Chand, S.; Chhillar, A.; Yadav, A. Growth and reproduction of Eisenia foetida in various animal wastes during vermicomposting. Appl. Ecol. Environ. Res. 2005, 3, 51–59. [Google Scholar] [CrossRef]

- Yadav, A.; Garg, V. Industrial wastes and sludges management by vermicomposting. Rev. Environ. Sci. Bio/Technol. 2011, 10, 243–276. [Google Scholar] [CrossRef]

- Bhat, S.A.; Singh, S.; Singh, J.; Kumar, S.; Vig, A.P. Bioremediation and Detoxification of Industrial Wastes by Earthworms: Vermicompost as Powerful Crop Nutrient in Sustainable Agriculture. Bioresour. Technol. 2018, 252, 172–179. [Google Scholar] [CrossRef] [PubMed]

- Suthar, S. Evidence of plant hormone like substances in vermiwash: An ecologically safe option of synthetic chemicals for sustainable farming. Ecol. Eng. 2010, 36, 1089–1092. [Google Scholar] [CrossRef]

- Neklyudov, A.; Fedotov, G.; Ivankin, A. Intensification of composting processes by aerobic microorganisms: A review. Appl. Biochem. Microbiol. 2008, 44, 6–18. [Google Scholar] [CrossRef]

- Suthar, S. Production of vermifertilizer from guar gum industrial wastes by using composting earthworm Perionyx sansibaricus (Perrier). Environmentalist 2007, 27, 329–335. [Google Scholar] [CrossRef]

- Suthar, S. Bioremediation of aerobically treated distillery sludge mixed with cow dung by using an epigeic earthworm Eisenia fetida. Environmentalist 2008, 28, 76–84. [Google Scholar] [CrossRef]

- Elvira, C.; Sampedro, L.; Dominguez, J.; Mato, S. Vermicomposting of wastewater sludge from paper-pulp industry with nitrogen rich materials. Soil Biol. Biochem. 1997, 29, 759–762. [Google Scholar] [CrossRef]

- Contreras-Ramos, S.M.; Alvarez-Bernal, D.; Dendooven, L. Characteristics of earthworms (Eisenia fetida) in PAHs contaminated soil amended with sewage sludge or vermicompost. Appl. Soil Ecol. 2009, 41, 269–276. [Google Scholar] [CrossRef]

- Hanc, A.; Chadimova, Z. Nutrient recovery from apple pomace waste by vermicomposting technology. Bioresour. Technol. 2014, 168, 240–244. [Google Scholar] [CrossRef]

- Arumugam, K.; Renganathan, S.; Babalola, O.O.; Muthunarayanan, V. Investigation on paper cup waste degradation by bacterial consortium and Eudrillus eugeinea through vermicomposting. Waste Manag. 2017, 74, 185–193. [Google Scholar] [CrossRef] [PubMed]

- Sharma, K.; Garg, V. Comparative analysis of vermicompost quality produced from rice straw and paper waste employing earthworm Eisenia fetida (Sav.). Bioresour. Technol. 2018, 250, 708–715. [Google Scholar] [CrossRef] [PubMed]

- Cestonaro, T.; de Mendonça Costa, M.S.S.; de Mendonça Costa, L.A.; Pereira, D.C.; Rozatti, M.A.; Martins, M.F.L. Addition of cattle manure to sheep bedding allows vermicomposting process and improves vermicompost quality. Waste Manag. 2017, 61, 165–170. [Google Scholar] [CrossRef] [PubMed]

- Mahaly, M.; Senthilkumar, A.K.; Arumugam, S.; Kaliyaperumal, C.; Karupannan, N. Vermicomposting of distillery sludge waste with tea leaf residues. Sustain. Environ. Res. 2018, 28, 223–227. [Google Scholar] [CrossRef]

- Jadia, C.D.; Fulekar, M. Vermicomposting of vegetable waste: A biophysicochemical process based on hydro-operating bioreactor. Afr. J. Biotechnol. 2008, 7, 3723–3730. [Google Scholar]

- Domínguez, J.; Sanchez-Hernandez, J.C.; Lores, M. Vermicomposting of Winemaking By-Products In Handbook of Grape Processing By-Products; Galanakis, C., Ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 55–78. [Google Scholar]

- Garg, V.K.; Suthar, S.; Yadav, A. Management of food industry waste employing vermicomposting technology. Bioresour. Technol. 2012, 126, 437–443. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Hu, Z.; Xu, X.; Jiang, X.; Zheng, B.; Liu, X.; Kardol, P. Emissions of ammonia and greenhouse gases during combined pre-composting and vermicomposting of duck manure. Waste Manag. 2014, 34, 1546–1552. [Google Scholar] [CrossRef]

- Nath, G.; Singh, K. Vermiwash: A potent liquid biofertilizer. Res. J. Sci. Technol. 2016, 8, 21. [Google Scholar] [CrossRef]

- Hosseinzadeh, S.R.; Amiri, H.; Ismaili, A. Effect of vermicompost levels on morphologic traits and nutrient concentration of chickpea (Cicer arietinum L. cv. Pirouz) under water stress. J. Environ. Stress. Crop Sci. 2017, 10, 531–545. [Google Scholar]

- Hosseinzadeh, S.R.; Amiri, H.; Ismaili, A. Evaluation of photosynthesis, physiological, and biochemical responses of chickpea (Cicer arietinum L. cv. Pirouz) under water deficit stress and use of vermicompost fertilizer. J. Integr. Agric. 2018, 17, 2426–2437. [Google Scholar] [CrossRef]

- Das, T.; Debnath, P.; Satpute, S.; Bandyopadhyay, S. Effect of phosphorus enriched vermicompost on growth and yield of groundnut (Arachis hypogaea L.) as Influenced by soil phosphorus use efficiency. Indian J. Sci. Technol. 2015, 8, 1–11. [Google Scholar] [CrossRef]

- Khan, F.A.; Narayan, S.; Bhat, S.A.; Maqbool, R. Vermipriming-a noble technology for seed invigouration in rice (Oryza sativa L.). Skuast J. Res. 2016, 18, 124–129. [Google Scholar]

- Jaybhaye, M.M.; Bhalerao, S.A. Influence of Vermiwash on Germination and Growth Parameters of Seedlings of Green gram (Vigna radiata L.) and Black gram (Vigna mungo L.). Int. J. Curr. Microbiol. App. Sci. 2015, 4, 634–643. [Google Scholar]

- Mahmoudi, S.V.R.; Nasri, M.; Azizi, P. The effect of different type of vermicompost organic fertilizer litter on quantitive, qualitative and biochemical characteristics of green mung bean (Vigna radiata L.) in drought stress conditions in Varamin. Int. J. Adv. Biotechnol. Res. 2016, 7, 205–215. [Google Scholar]

- Ahmadvand, G.; Sanjani, A.S. The Effect of Chemical, Biological and Organic Nutritional Treatments on Sunflowers Yield and Yield Components under the Influence of Water Deficit Stress. Būm/Shināsī-I Kishāvarzī 2016, 8, 107–119. [Google Scholar]

- Choudhary, R.; Yadav, L.; Parihar, S. Effect of Vermicompost and Fertility Levels on Growth and Yield of Pearl millet (Pennisetum glaucum L.). Ann. Arid Zone 2015, 54, 59–61. [Google Scholar]

- Tognetti, C.; Laos, F.; Mazzarino, M.J.; Hernández, M.T. Composting vs. Vermicomposting: A Comparison of End Product Quality. Compos. Sci. Util. 2005, 13, 6–13. [Google Scholar] [CrossRef]

- Bridle, T.R.; Pritchard, D. Energy and nutrient recovery from sewage sludge via pyrolysis. Water Sci. Technol. 2004, 50, 169–175. [Google Scholar] [CrossRef]

- Carpenter, S.R.; Caraco, N.F.; Correll, D.L.; Howarth, R.W.; Sharpley, A.N.; Smith, V.H. Nonpoint pollution of surface waters with phosphorus and nitrogen. Ecol. Appl. 1998, 8, 559–568. [Google Scholar] [CrossRef]

- Cantrell, K.; Ro, K.; Mahajan, D.; Anjom, M.; Hunt, P.G. Role of thermochemical conversion in livestock waste-to-energy treatments: obstacles and opportunities. Ind. Eng. Chem. Res. 2007, 46, 8918–8927. [Google Scholar] [CrossRef]

- Jenkins, A.; Jenkinson, C. Primefact 963—Biochar Basics; Department of Primary Industries: Orange, NSW, Australia, 2007. [Google Scholar]

- Kammann, C.I.; Schmidt, H.P.; Messerschmidt, N.; Linsel, S.; Steffens, D.; Müller, C.; Joseph, S. Plant growth improvement mediated by nitrate capture in co-composted biochar. Sci. Rep. 2015, 5, 11080. [Google Scholar] [CrossRef] [PubMed]

- Mia, S.; Dijkstra, F.A.; Singh, B. Long-term aging of biochar: A molecular understanding with agricultural and environmental implications. In Advances in Agronomy; Academic Press: Cambridge, MA, USA, 2017; Volume 141, pp. 1–51. [Google Scholar]

- Kizito, S.; Luo, H.; Lu, J.; Bah, H.; Dong, R.; Wu, S. Role of Nutrient-Enriched Biochar as a Soil Amendment during Maize Growth: Exploring Practical Alternatives to Recycle Agricultural Residuals and to Reduce Chemical Fertilizer Demand. Sustainability 2019, 11, 3211. [Google Scholar] [CrossRef]

- Zhang, J.; She, Q.; Chang, V.W.C.; Tang, C.Y.; Webster, R.D. Mining Nutrients (N, K, P) from Urban Source-Separated Urine by Forward Osmosis Dewatering. Environ. Sci. Technol. 2015, 48, 3386–3394. [Google Scholar] [CrossRef] [PubMed]

- Saleem, A.; Fareed, I.; Irshad, M.; Mahmood, Q.; Eneji, A.E.; Shahzad, M. Transformations of Phosphorus and Other Plant Nutrients in Poultry Litter Composted with Sugarcane and Cabbage Wastes. Compos. Sci. Util. 2018, 26, 114–127. [Google Scholar] [CrossRef]

- Biederman, L.A.; Harpole, W.S. Biochar and its effects on plant productivity and nutrient cycling: A meta-analysis. Gcb Bioenergy 2013, 5, 202–214. [Google Scholar] [CrossRef]

- Pognani, M.; Barrena, R.; Font, X.; Sánchez, A. A complete mass balance of a complex combined anaerobic/aerobic municipal source-separated waste treatment plant. Waste Manag. 2012, 32, 799–805. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nurhidayati, N.; Machfudz, M.; Murwani, I. Direct and residual effect of various vermicompost on soil nutrient and nutrient uptake dynamics and productivity of four mustard Pak-Coi (Brassica rapa L.) sequences in organic farming system. Int. J. Recycl. Org. Waste Agric. 2018, 7, 173–181. [Google Scholar] [CrossRef] [Green Version]

- Si, L.; Xie, Y.; Ma, Q.; Wu, L. The Short-Term Effects of Rice Straw Biochar, Nitrogen and Phosphorus Fertilizer on Rice Yield and Soil Properties in a Cold Waterlogged Paddy Field. Sustainability 2018, 10, 537. [Google Scholar] [CrossRef]

- Xie, M.; Shon, H.K.; Gray, S.R.; Elimelech, M. Membrane-based processes for wastewater nutrient recovery: Technology, challenges, and future direction. Water Res. 2016, 89, 210–221. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Wang, Y.; Zhang, X.; Feng, H.; Li, C.; Xu, T. Phosphate Recovery from Excess Sludge by Conventional Electrodialysis (CED) and Electrodialysis with Bipolar 821 Membranes (EDBM). Ind. Eng. Chem. Res. 2013, 52, 15896–15904. [Google Scholar] [CrossRef]

- Roy, P.; Nei, D.; Orikasa, T.; Xu, Q.; Okadome, H.; Nakamura, N.; Shiina, T. A review of life cycle assessment (LCA) on some food products. J. Food Eng. 2009, 90, 1–10. [Google Scholar] [CrossRef]

- Dutta, B.; Raghavan, V. A life cycle assessment of environmental and economic balance of biochar systems in Quebec. Int. J. Energy Environ. Eng. 2014, 5, 106. [Google Scholar] [CrossRef]

- Saer, A.; Lansing, S.; Davitt, N.H.; Graves, R.E. Life cycle assessment of a food waste composting system: Environmental impact hotspots. J. Clean. Prod. 2013, 52, 234–244. [Google Scholar] [CrossRef]

- Thanh, N.P.; Matsui, Y. Assessment of potential impacts of municipal solid waste treatment alternatives by using life cycle approach: A case study in Vietnam. Environ. Monit. Assess. 2013, 185, 7993–8004. [Google Scholar] [CrossRef] [PubMed]

- Schneider, P.; Anh, L.; Wagner, J.; Reichenbach, J.; Hebner, A. Solid Waste Management in Ho Chi Minh City, Vietnam: Moving towards a Circular Economy? Sustainability 2017, 9, 286. [Google Scholar] [CrossRef]

| S. No. | Factors Effecting Vermicomposting | Characteristics of Vermicomposting |

|---|---|---|

| (1) | Degradation rate | Rapid |

| (2) | Temperature | 25–40 °C |

| (3) | PH | Neutral |

| (4) | Humidity | High |

| (5) | Carbon to Nitrogen Ratio (C:N) | <20 °C |

| (6) | Mode of Action | It involves microbes and earthworms. |

| (7) | End product | Stable homogenous fine peat like material and vermiwash which is a liquid portion contains humic acid. |

| (8) | Nutritional status | High due to N, P, K, S and traces of other elements but this mainly depends on what one is feeding to its catalytic agents i.e., worms. |

| (9) | Usage | Not adopted at fullest on industrial level yet. |

| (10) | Capital | High |

| (11) | Shortcomings | It is difficult to maintain its parameter’s ranges, such as T, pH, and humidity level. |

| S No. | Crops | Treatments | Parameters Affected by the Addition of Vermiwash and Vermicompost | Literature Cited |

|---|---|---|---|---|

| 01 | Triticum aestivum | Goat dung and vegetable wastes as additives with the qty. of 10 g m−2. | Plants show vigorous growth when vermiwash which is rich in humic acid is applied through foliar spray. Zinc and copper also become available to the plant by the activity of worms and microbes supplied by vermicomposting. | [51] |

| 02 | Zea mays | Three levels of vermicomposting, i.e., 0%, 50%, and 100% respectively with same 03 levels of NPK as former. | Crop is more responsive to at 100% of NPK and vermicomposting. This treatment shows maximum height, i.e., 158.22 cm, more leaves per plant, i.e., 11, cob length 17–18 cm, the highest yield of 42.70 qha−1, and maximum net return. | [52] |

| 03 | Cicer arietinum | Use of vermicompost as fertilizer. | Increased photosynthetic activity reported in gram when subjected to drought. As vermicompost is rich in hormone alike substance humic acid which is known for mitigating the effect of water stress, alleviates the effect of drought on the crop. | [52,53] |

| 04 | Brassica compestris | 03 levels of vermicompost, i.e., control, 2.5 and 05 t ha−1 have been used along with 05 levels of different nutrients, i.e., Fe, Zn, and S. | Increasing level of vermicompost tends to enhance plant height, no. of siliqua per plant and no. of seeds per siliqua, grain weight, biological and grain yield of this crop. Whereas, the application of mentioned nutrients increases the available nitrogen, phosphorus, potassium, sulfur, zinc, iron, manganese, and copper. It is also influential on the oil content, availability of organic carbon, EC and pH of soil. Combination of both treatments proves to be more beneficial as compared to separate application. | [53] |

| 05 | Arachis hypogea | Application of phosphorus enriched vermicompost. | A crop treated with vermicompost that is enriched in P at the rate of 150% with sufficient water conditions resulted in more yield as compared to the treatment utilizing P at 100% with inorganic fertilizer. | [54] |

| 06 | Oryza sativa | Priming of seeds with vermicomposting. | Better seed emergence rate and development of early and healthy seedlings. | [55] |

| 07 | Vigna radiata | Cow dung with Eisenia foetida. | When vermiwash applied at the concentration of 10%, 20%, and 30% it increases the plant growth. It also stimulates the length of hypocotyl and radical. It is responsible for early seedling establishment as well. | [56] |

| 08 | Vigna mungo | Vermicompost made up with cattle litter, equine litter, and poultry litter. | Addition of vermicomposting to the soil during the life cycle of this crop resulted in enhanced growth, better combating with water stress, more pods, increase accumulation of protein content, and more biological and grain yield. | [57] |

| 09 | Helianthus annuus | Application of vermicompost with inorganic fertilizer. | In water deficit conditions, vermicompost tends to increase the water holding capacity and availability of nutrients lead to improvement of plant growth, more source-to-sink accumulation of assimilates in sunflower. | [58] |

| 10 | Pennisetum glaucum | Four levels of vermicompost with RDF, i.e., 60 kg N and 30 kg of P (recommended dose of fertilizer) levels. | Addition of vermicompost with 100% RDF shows a better result than control and 50% RDF. Crop shows more height, number of effective tillers, and grain weight. | [59] |

| Composting | Vermicomposting | |

|---|---|---|

| Depth | Can be any depth | Worms usually prefer to live in the top 6–12” of the bedding (cannot be deep) |

| Convenience | Outdoors only with specialized buildings and equipment | outdoors or indoors |

| Speed | Hot composting takes 6–9 months to produce fertilizer | Much faster |

| Heat Levels | Hot as the aerobic breakdown of organic matter releases carbon dioxide and heat, resulting in piles than can top 70 °C | Cooler process with temperatures ranging between 10–32 °C |

| Microbial Populations | Dominated by thermophilic (or “heat-loving”) microbes | Dominated by mesophilic microbes |

| Aeration | Turning is required | Turning is not required |

| Cost | Cheap | Needs care for worms protections |

| Financial Value | Cheap | Much greater financial value |

| Municipal Compost (MC) | Municipal Vermicompost (MV) | Backyard Vermicompost (BV) | |

|---|---|---|---|

| Microbial biomass C (μg C g−1) | 1147.00a | 703.00b | 335.00c |

| Urease (μmol NH4+ g−1h−1) | 3.54b | 3.90b | 6.11a |

| BAA-Protease (μmol NH4+ g−1h−1) | 0.31c | 0.96b | 1.83a |

| Phosphatse (μmol PNP g−1h−1) | 237.00c | 398.00b | 676.00a |

| Dehyrogenase (μg INTF g−1) | 193.00a | 123.00b | 77.00c |

| Treatment | Nitrogen (N) | Phosphorus (P) | Potassium (K) | References |

|---|---|---|---|---|

| Composting of poultry litter with sugarcane and cabbage waste (20–100 days) | N decreased from 26 to 22 g kg−1 with increase in composting days | Extractable P decreased with composting time which was higher at early stages | K Increased from 725–775 mg kg−1 with increase in composting days | [69] |

| Biochar | No effect | Increased (above ground productivity) | Increased | [70] |

| Only composting | 50% of initial N was found in final compost | 86.4% P was retained at final stage of composting | - | [71] |

| Vermicomposting (plant and animal wastes) | Highest N uptake (168–188 kg ha−1) was recorded with 10-20 t ha−1 compost application | P uptake was not influenced by direct application. However, rate of 10 tha−1 gave highest nutrient uptake (29–37 kg ha−1) | Uptake of K was increased | [72] |

| Vermi composting (vegetable waste, mixture of spent mushroom waste, cow dung and leaf litter) | Uptake increased (160 kg ha−1) | Increase up to 33 kg ha−1 | K uptake (102 kg ha−1) decreased as compared to N but was higher than P. | [72] |

| Vermicomposting (mixture of coconut, vegetable waste, leaf litter and cow dung) | Increased up to 168 kg ha−1 | Relatively decreased (increased up to 32 kg ha−1) as compared to N uptake. | Increased (109 kg ha−1) | [72] |

| Vermicomposting (cow dung, leaf litter, vegetable waste and sugarcane) | 142 kg ha−1 uptake was recorded | Decreased uptake of P (31 kg ha−1) | Decreased (91 kg ha−1) | [72] |

| Biochar (rice straw) with nitrogen and phosphorus fertilizers | Increased total uptake by plants up to (166.6 kg ha−1) | Increase up to 40 kg ha−1 | - | [73] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, M.; Ahmad, S.; Fayyaz-ul-Hassan; Qadir, G.; Hayat, R.; Shaheen, F.A.; Raza, M.A. Innovative Processes and Technologies for Nutrient Recovery from Wastes: A Comprehensive Review. Sustainability 2019, 11, 4938. https://doi.org/10.3390/su11184938

Ahmed M, Ahmad S, Fayyaz-ul-Hassan, Qadir G, Hayat R, Shaheen FA, Raza MA. Innovative Processes and Technologies for Nutrient Recovery from Wastes: A Comprehensive Review. Sustainability. 2019; 11(18):4938. https://doi.org/10.3390/su11184938

Chicago/Turabian StyleAhmed, Mukhtar, Shakeel Ahmad, Fayyaz-ul-Hassan, Ghulam Qadir, Rifat Hayat, Farid Asif Shaheen, and Muhammad Ali Raza. 2019. "Innovative Processes and Technologies for Nutrient Recovery from Wastes: A Comprehensive Review" Sustainability 11, no. 18: 4938. https://doi.org/10.3390/su11184938

APA StyleAhmed, M., Ahmad, S., Fayyaz-ul-Hassan, Qadir, G., Hayat, R., Shaheen, F. A., & Raza, M. A. (2019). Innovative Processes and Technologies for Nutrient Recovery from Wastes: A Comprehensive Review. Sustainability, 11(18), 4938. https://doi.org/10.3390/su11184938