Incumbents in the Transition Towards the Bioeconomy: The Role of Dynamic Capabilities and Innovation Strategies

Abstract

1. Introduction

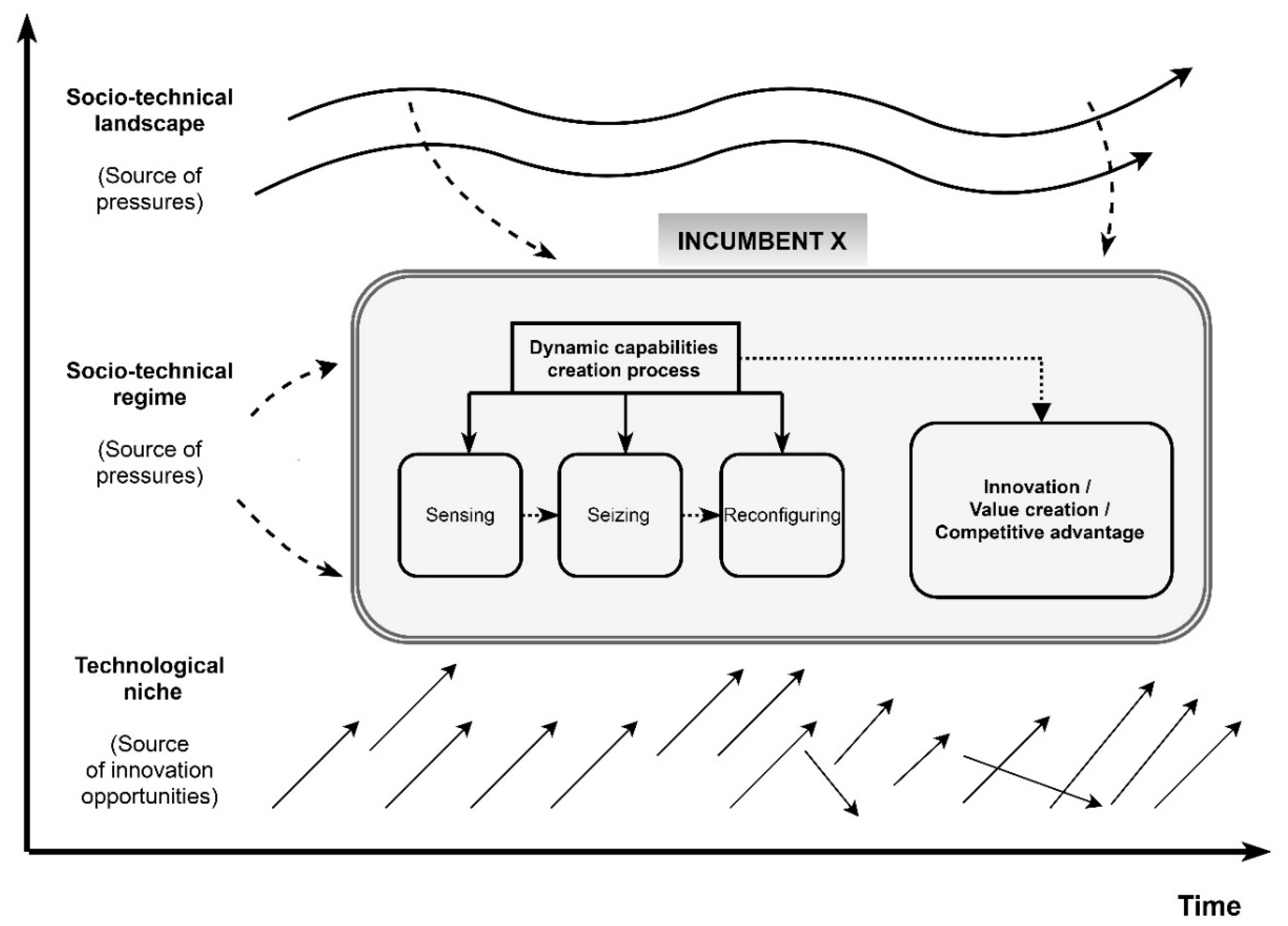

2. Setting the Theoretical Framework

2.1. The Multi-Level Perspective: A Snapshot of Incumbents in Transition

2.2. Dynamic Capabilities for Sustainability

2.3. MLP–DCs Analytical Framework

3. The Norwegian Meat-Processing Sector and the Case Study

4. Data and Methods

5. Exploring the Case through the Lenses of the MLP–DCs Analytical Framework

5.1. Unpacking the MLP Levels

5.1.1. The Socio-Technical Landscape

5.1.2. The Socio-Technical Regime

5.1.3. The Technological Niche

5.2. Untangling the Incumbent’s Dynamic Capabilities Creation Processes

5.2.1. Sensing Process—The Capability of Learning

5.2.2. Seizing Process—The Capability of Financing

5.2.3. Reconfiguring Process—The Capability of Organizational Restructuring

5.3. Discussion

5.3.1. Incumbent’s Innovation Strategies and Dynamic Capabilities

5.3.2. Leveraging Competitive Advantage

6. Conclusions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Date | Organization | Position | Duration | Type of Interview | |

|---|---|---|---|---|---|

| 1 | 12.02.2016 | Incumbent | Business Development Manager | 153 min | Personal interview |

| 2 | 20.04.2016 | Rendering industry | Product and Sales Manager | 84 min | Phone interview |

| 3 | 20.04.2016 | Incumbent | Purchasing Manager | 92 min | Personal interview |

| 4 | 13.05.2016 | Incumbent | Business Development Manager | 57 min | Personal interview |

| 5 | 11.07.2016 | Research institute | Researcher | 85 min | Personal interview |

| 6 | 16.06.2017 | Incumbent | Business Development Manager | 112 min | Personal interview |

| 7 | 15.03.2018 | Industry Confederation | Managing Director | 45 min | Personal interview |

| 8 | 28.06.2018 | Incumbent | Process and Analysis Manager | 67 min | Personal interview |

| 9 | 18.12.2018 | Incumbent | Process and Analysis Manager | 66 min | Personal interview |

| 10 | 09.05.2019 | Incumbent | Business Development Manager | 50 min | Personal interview |

| 11 | 09.05.2019 | Incumbent | R&D senior scientist | 50 min | Personal interview |

References

- Geels, F.W. Reconceptualising the co-evolution of firms-in-industries and their environments: Developing an inter-disciplinary Triple Embeddedness Framework. Res. Policy 2014, 43, 261–277. [Google Scholar] [CrossRef]

- Farla, J.; Markard, J.; Raven, R.; Coenen, L. Sustainability transitions in the making: A closer look at actors, strategies and resources. Technol. Forecast. Soc. Chang. 2012, 79, 991–998. [Google Scholar] [CrossRef]

- Lieberherr, E.; Truffer, B. The impact of privatization on sustainability transitions: A comparative analysis of dynamic capabilities in three water utilities. Environ. Innov. Soc. Transit. 2015, 15, 101–122. [Google Scholar] [CrossRef]

- Hansen, T.; Coenen, L. Unpacking resource mobilisation by incumbents for biorefineries: The role of micro-level factors for technological innovation system weaknesses. Technol. Anal. Strateg. Manag. 2017, 29, 500–513. [Google Scholar] [CrossRef]

- Van Mossel, A.; van Rijnsoever, F.J.; Hekkert, M.P. Navigators through the storm: A review of organization theories and the behavior of incumbent firms during transitions. Environ. Innov. Soc. Transit. 2018, 26, 44–63. [Google Scholar] [CrossRef]

- Markard, J.; Truffer, B. Technological innovation systems and the multi-level perspective: Towards an integrated framework. Res. Policy 2008, 37, 596–615. [Google Scholar] [CrossRef]

- Geels, F.W. The multi-level perspective on sustainability transitions: Responses to seven criticisms. Environ. Innov. Soc. Transit. 2011, 1, 24–40. [Google Scholar] [CrossRef]

- Smith, A.; Hargreaves, T.; Hielscher, S.; Martiskainen, M.; Seyfang, G. Making the most of community energies: Three perspectives on grassroots innovation. Environ. Plan. A 2015, 48, 407–432. [Google Scholar] [CrossRef]

- Markard, J.; Raven, R.; Truffer, B. Sustainability transitions: An emerging field of research and its prospects. Res. Policy 2012, 41, 955–967. [Google Scholar] [CrossRef]

- Safarzyńska, K.; Frenken, K.; van den Bergh, J.C. Evolutionary theorizing and modeling of sustainability transitions. Res. Policy 2012, 41, 1011–1024. [Google Scholar] [CrossRef]

- Vasileiadou, E.; Safarzyńska, K. Transitions: Taking complexity seriously. Futures 2010, 42, 1176–1186. [Google Scholar] [CrossRef]

- Teece, D.J. Explicating dynamic capabilities: The nature and microfoundations of (sustainable) enterprise performance. Strateg. Manag. J. 2007, 28, 1319–1350. [Google Scholar] [CrossRef]

- Teece, D.J.; Pisano, G.; Shuen, A. Dynamic capabilities and strategic management. Strateg. Manag. J. 1997, 18, 509–533. [Google Scholar] [CrossRef]

- Pisano, G.P. Toward a prescriptive theory of dynamic capabilities: Connecting strategic choice, learning, and competition. Ind. Corp. Chang. 2017, 26, 747–762. [Google Scholar] [CrossRef]

- Ambrosini, V.; Bowman, C. What are dynamic capabilities and are they a useful construct in strategic management? Int. J. Manag. Rev. 2009, 11, 29–49. [Google Scholar] [CrossRef]

- Wang, C.L.; Ahmed, P.K. Dynamic capabilities: A review and research agenda. Int. J. Manag. Rev. 2007, 9, 31–51. [Google Scholar] [CrossRef]

- Cainelli, G.; De Marchi, V.; Grandinetti, R. Does the development of environmental innovation require different resources? Evidence from Spanish manufacturing firms. J. Clean. Prod. 2015, 94, 211–220. [Google Scholar] [CrossRef]

- Iles, A.; Martin, A.N. Expanding bioplastics production: Sustainable business innovation in the chemical industry. J. Clean. Prod. 2013, 45, 38–49. [Google Scholar] [CrossRef]

- Dangelico, R.M.; Pujari, D.; Pontrandolfo, P. Green Product Innovation in Manufacturing Firms: A Sustainability-Oriented Dynamic Capability Perspective. Bus. Strategy Environ. 2017, 26, 490–506. [Google Scholar] [CrossRef]

- De Marchi, V. Environmental innovation and R & D cooperation: Empirical evidence from Spanish manufacturing firms. Res. Policy 2012, 41, 614–623. [Google Scholar] [CrossRef]

- Ketata, I.; Sofka, W.; Grimpe, C. The role of internal capabilities and firms’ environment for sustainable innovation: Evidence for Germany. RD Manag. 2015, 45, 60–75. [Google Scholar] [CrossRef]

- Nidumolu, R.; Prahalad, C.K.; Rangaswami, M.R. Why sustainability is now the key driver of innovation. IEEE Eng. Manag. Rev. 2015, 43, 85–91. [Google Scholar] [CrossRef]

- Mousavi, S.; Bossink, B.A.G. Firms’ capabilities for sustainable innovation: The case of biofuel for aviation. J. Clean. Prod. 2017, 167, 1263–1275. [Google Scholar] [CrossRef]

- Júnior, N.B.; Faccin, K.; Volkmer Martins, B.; Balestrin, A. Knowledge-based dynamic capabilities for sustainable innovation: The case of the green plastic project. Sustainability 2019, 11, 2392. [Google Scholar] [CrossRef]

- Mousavi, S.; Bossink, B.; van Vliet, M. Microfoundations of companies’ dynamic capabilities for environmentally sustainable innovation: Case study insights from high-tech innovation in science-based companies. Bus. Strategy Environ. 2019, 28, 366–387. [Google Scholar] [CrossRef]

- Fuenfschilling, L.; Truffer, B. The structuration of socio-technical regimes—Conceptual foundations from institutional theory. Res. Policy 2014, 43, 772–791. [Google Scholar] [CrossRef]

- Geels, F.W. Ontologies, socio-technical transitions (to sustainability), and the multi-level perspective. Res. Policy 2010, 39, 495–510. [Google Scholar] [CrossRef]

- Smink, M.M.; Hekkert, M.P.; Negro, S.O. Keeping sustainable innovation on a leash?Exploring incumbents’ institutional strategies. Bus. Strategy Environ. 2013, 24, 86–101. [Google Scholar] [CrossRef]

- Geels, F.W. Processes and patterns in transitions and system innovations: Refining the co-evolutionary multi-level perspective. Technol. Forecast. Soc. Chang. 2005, 72, 681–696. [Google Scholar] [CrossRef]

- Lynch, S.A.; Mullen, A.M.; O’Neill, E.E.; García, C.Á. Harnessing the Potential of Blood Proteins as Functional Ingredients: A Review of the State of the Art in Blood Processing. Compr. Rev. Food Sci. Food Saf. 2017, 16, 330–344. [Google Scholar] [CrossRef]

- Henchion, M.; McCarthy, M.; O’Callaghan, J. Transforming Beef By-products into Valuable Ingredients: Which Spell/Recipe to Use? Front. Nutr. 2016, 3, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Toldrá, F.; Mora, L.; Reig, M. New insights into meat by-product utilization. Meat Sci. 2016, 120, 54–59. [Google Scholar] [CrossRef] [PubMed]

- Mirabella, N.; Castellani, V.; Sala, S. Current options for the valorization of food manufacturing waste: A review. J. Clean. Prod. 2014, 65, 28–41. [Google Scholar] [CrossRef]

- Garnett, T. Food sustainability: Problems, perspectives and solutions. Proc. Nutr. Soc. 2013, 72, 29–39. [Google Scholar] [CrossRef] [PubMed]

- Garnett, T. Three perspectives on sustainable food security: Efficiency, demand restraint, food system transformation. What role for life cycle assessment? J. Clean. Prod. 2014, 73, 10–18. [Google Scholar] [CrossRef]

- Our World in Data. Greenhouse Gas Emissions per Gram of Protein, by Food Product. Available online: https://ourworldindata.org/grapher/greenhouse-gas-emissions-per-gram-of-protein-by-food-type (accessed on 11 April 2019).

- Clark, M.; Tilman, D. Comparative analysis of environmental impacts of agricultural production systems, agricultural input efficiency, and food choice. Environ. Res. Lett. 2017, 12, 1–11. [Google Scholar] [CrossRef]

- Stopa, A. New Technologies, Automation, and Robotics Come to Meat Processing. Available online: http://www.myprocessexpo.com/blog/industry-perspectives/new-technologies-automation-and-robotics-come-to-meat-processing/ (accessed on 22 August 2017).

- Egelyng, H.; Romsdal, A.; Hansen, H.; Slizyte, R.; Carvajal, A.; Jouvenot, L.; Hebrok, M.; Honkapää, K.; Wold, J.; Seljåsen, R. Cascading Norwegian Co-streams for Bioeconomic Transition. J. Clean. Prod. 2017, 172, 3864–3873. [Google Scholar] [CrossRef]

- Coenen, L.; Hansen, T.; Rekers, J.V. Innovation policy for grand challenges. an economic geography perspective. Geogr. Compass 2015, 9, 483–496. [Google Scholar] [CrossRef]

- European Commission. Towards a Circular Economy: A Zero Waste Programme for Europe. Available online: http://eur-lex.europa.eu/resource.html?uri=cellar:50edd1fd-01ec-11e4-831f-01aa75ed71a1.0001.01/DOC_1&format=PDF (accessed on 14 February 2017).

- Bugge, M.M.; Hansen, T.; Klitkou, A. What is the bioeconomy? A review of the literature. Sustainability 2016, 8, 691. [Google Scholar] [CrossRef]

- Birch, K.; Levidow, L.; Papaioannou, T. Sustainable Capital? The Neoliberalization of Nature and Knowledge in the European “Knowledge-based Bio-economy”. Sustainability 2010, 2, 2898–2918. [Google Scholar] [CrossRef]

- Aguilar, A.; Wohlgemuth, R.; Twardowski, T. Perspectives on bioeconomy. New Biotechnol. 2018, 40, 181–184. [Google Scholar] [CrossRef] [PubMed]

- De Besi, M.; McCormick, K. Towards a bioeconomy in Europe: National, regional and industrial strategies. Sustainability 2015, 7, 10461–10478. [Google Scholar] [CrossRef]

- McCormick, K.; Kautto, N. The bioeconomy in Europe: An overview. Sustainability 2013, 5, 2589–2608. [Google Scholar] [CrossRef]

- Pfau, S.; Hagens, J.; Dankbaar, B.; Smits, A. Visions of Sustainability in Bioeconomy Research. Sustainability 2014, 6, 1222–1249. [Google Scholar] [CrossRef]

- Sillanpää, M.; Ncibi, C. A Sustainable Bioeconomy: The Green Industrial Revolution; Springer: Berlin, Germany, 2017. [Google Scholar]

- Vainio, A.; Ovaska, U.; Varho, V. Not so sustainable? Images of bioeconomy by future environmental professionals and citizens. J. Clean. Prod. 2019, 210, 1396–1405. [Google Scholar] [CrossRef]

- D’Amato, D.; Droste, N.; Allen, B.; Kettunen, M.; Lähtinen, K.; Korhonen, J.; Leskinen, P.; Matthies, B.; Toppinen, A. Green, circular, bio economy: A comparative analysis of sustainability avenues. J. Clean. Prod. 2017, 168, 716–734. [Google Scholar] [CrossRef]

- European Commission. A Sustainable Bioeconomy for Europe: Strengthening the Connection between Economy, Society and the Environment-Updated Bioeconomy Strategy; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Geels, F.W. Technological transitions as evolutionary reconfiguration processes: A multi-level perspective and a case-study. Res. Policy 2002, 31, 1257–1274. [Google Scholar] [CrossRef]

- Alkemade, F.; Hekkert, M.P.; Negro, S.O. Transition policy and innovation policy: Friends or foes? Environ. Innov. Soc. Transit. 2011, 1, 125–129. [Google Scholar] [CrossRef]

- Geels, F.W. The dynamics of transitions in socio-technical systems: A multi-level analysis of the transition pathway from horse-drawn carriages to automobiles (1860–1930). Technol. Anal. Strateg. Manag. 2005, 17, 445–476. [Google Scholar] [CrossRef]

- Kemp, R.; Schot, J.; Hoogma, R. Regime shifts to sustainability through processes of niche formation: The approach of strategic niche management. Technol. Anal. Strateg. Manag. 1998, 10, 175–198. [Google Scholar] [CrossRef]

- Geels, F.W.; Schot, J. Typology of sociotechnical transition pathways. Res. Policy 2007, 36, 399–417. [Google Scholar] [CrossRef]

- Karltorp, K.; Sandén, B.A. Explaining regime destabilisation in the pulp and paper industry. Environ. Innov. Soc. Transit. 2012, 2, 66–81. [Google Scholar] [CrossRef]

- Steen, M.; Weaver, T. Incumbents’ diversification and cross-sectorial energy industry dynamics. Res. Policy 2017, 46, 1071–1086. [Google Scholar] [CrossRef]

- Genus, A.; Coles, A.-M. Rethinking the multi-level perspective of technological transitions. Res. Policy 2008, 37, 1436–1445. [Google Scholar] [CrossRef]

- Berkhout, F.; Smith, A.; Stirling, A. Socio-technological regimes and transition contexts. In System Innovation and the Transition to Sustainability: Theory, Evidence and Policy; Elzen, B., Geels, F.W., Green, K., Eds.; Edward Elgar: Cheltenham, UK, 2004; pp. 48–75. [Google Scholar]

- Berlo, K.; Wagner, O.; Heenen, M. The Incumbents’ Conservation Strategies in the German Energy Regime as an Impediment to Re-Municipalization—An Analysis Guided by the Multi-Level Perspective. Sustainability 2017, 9, 53. [Google Scholar] [CrossRef]

- Hess, D.J. Sustainability transitions: A political coalition perspective. Res. Policy 2014, 43, 278–283. [Google Scholar] [CrossRef]

- Wesseling, J.; Farla, J.; Hekkert, M. Exploring car manufacturers’ responses to technology-forcing regulation: The case of California’s ZEV mandate. Environ. Innov. Soc. Transit. 2015, 16, 87–105. [Google Scholar] [CrossRef]

- Wesseling, J.; Farla, J.; Sperling, D.; Hekkert, M. Car manufacturers’ changing political strategies on the ZEV mandate. Transp. Res. Part D Transp. Environ. 2014, 33, 196–209. [Google Scholar] [CrossRef]

- Vandermeulen, V.; van der Steen, M.; Stevens, C.V.; Van Huylenbroeck, G. Industry expectations regarding the transition toward a biobased economy. Biofuels Bioprod. Biorefin. 2012, 6, 453–464. [Google Scholar] [CrossRef]

- Kishna, M.; Negro, S.; Alkemade, F.; Hekkert, M. Innovation at the end of the life cycle: Discontinuous innovation strategies by incumbents. Ind. Innov. 2017, 24, 263–279. [Google Scholar] [CrossRef]

- Budde, B.; Alkemade, F.; Weber, K.M. Expectations as a key to understanding actor strategies in the field of fuel cell and hydrogen vehicles. Technol. Forecast. Soc. Chang. 2012, 79, 1072–1083. [Google Scholar] [CrossRef] [PubMed]

- Penrose, E.T. The Theory of the Growth of the Firm; Oxford University Press: Oxford, UK, 1995. [Google Scholar]

- Nelson, R.R.; Winter, S. An Evolutionary Theory of Economic Change; Harvard University Press: Cambridge, MA, USA, 1982. [Google Scholar]

- Liebowitz, S.J.; Margolis, S.E. Path dependence, lock-in, and history. J. Law Econ. Organ. 1995, 11, 205–226. [Google Scholar] [CrossRef]

- Liu, L.; Yu, B.; Wu, W. The Formation and Effects of Exploitative Dynamic Capabilities and Explorative Dynamic Capabilities: An Empirical Study. Sustainability 2019, 11, 2581. [Google Scholar] [CrossRef]

- Zhou, S.S.; Zhou, A.J.; Feng, J.; Jiang, S. Dynamic capabilities and organizational performance: The mediating role of innovation. J. Manag. Organ. 2017, 1–17. [Google Scholar] [CrossRef]

- Levitt, B.; March, J.G. Organizational learning. Annu. Rev. Sociol. 1988, 14, 319–338. [Google Scholar] [CrossRef]

- Woiceshyn, J.; Daellenbach, U. Integrative capability and technology adoption: Evidence from oil firms. Ind. Corp. Chang. 2005, 14, 307–342. [Google Scholar] [CrossRef]

- Verona, G.; Ravasi, D. Unbundling dynamic capabilities: An exploratory study of continuous product innovation. Ind. Corp. Chang. 2003, 12, 577–606. [Google Scholar] [CrossRef]

- Salvato, C. The Role of Micro-Strategies in the Engineering of Firm Evolution. J. Manag. Stud. 2003, 40, 83–108. [Google Scholar] [CrossRef]

- Lazonick, W.; Prencipe, A. Dynamic capabilities and sustained innovation: Strategic control and financial commitment at Rolls-Royce plc. Ind. Corp. Chang. 2005, 14, 501–542. [Google Scholar] [CrossRef]

- Smith, A.; Voß, J.-P.; Grin, J. Innovation studies and sustainability transitions: The allure of the multi-level perspective and its challenges. Res. Policy 2010, 39, 435–448. [Google Scholar] [CrossRef]

- Stenzel, T.; Frenzel, A. Regulating technological change—The strategic reactions of utility companies towards subsidy policies in the German, Spanish and UK electricity markets. Energy Policy 2008, 36, 2645–2657. [Google Scholar] [CrossRef]

- Geels, F.W. Disruption and low-carbon system transformation: Progress and new challenges in socio-technical transitions research and the Multi-Level Perspective. Energy Res. Soc. Sci. 2018, 37, 224–231. [Google Scholar] [CrossRef]

- Fichter, K.; Clausen, J. Diffusion dynamics of sustainable innovation-insights on diffusion patterns based on the analysis of 100 sustainable product and service innovations. J. Innov. Manag. 2016, 4, 30–67. [Google Scholar] [CrossRef]

- Weber, K.M.; Rohracher, H. Legitimizing research, technology and innovation policies for transformative change: Combining insights from innovation systems and multi-level perspective in a comprehensive ‘failures’ framework. Res. Policy 2012, 41, 1037–1047. [Google Scholar] [CrossRef]

- Unruh, G.C. Understanding carbon lock-in. Energy Policy 2000, 28, 817–830. [Google Scholar] [CrossRef]

- Rumelt, R. Towards a strategic theory of the firm. In Competitive Strategic Management; Lamb, R., Ed.; Prentice-Hall: Upper Saddle River, NJ, USA, 1984; pp. 556–570. [Google Scholar]

- A Meaty Planet. The Economist, 4 May 2019.

- Jayathilakan, K.; Sultana, K.; Radhakrishna, K.; Bawa, A. Utilization of byproducts and waste materials from meat, poultry and fish processing industries: A review. J. Food Sci. Technol. 2012, 49, 278–293. [Google Scholar] [CrossRef]

- Mullen, A.M.; Alvarez, C.; Zeugolis, D.I.; Henchion, M.; O’Neill, E.; Drummond, L. Alternative uses for co-products: Harnessing the potential of valuable compounds from meat processing chains. Meat Sci. 2017, 132, 90–98. [Google Scholar] [CrossRef] [PubMed]

- Tanner, A.N.; Strøm-Andersen, N. Meat processing and animal by-products: Industrial dynamics and institutional settings. In From Waste to Value: Valorisation Pathways for Organic Waste Streams in Circular Bioeconomies; Klitkou, A., Fevolden, A.M., Capasso, M., Eds.; Routledge: Abingdon, UK, 2019; pp. 127–144. [Google Scholar]

- Prestegard, S.S.; Pettersen, I.; Nebell, I.; Svennerud, M.; Brattenborg, N. Mat og Industri 2017: Status og Utvikling i Norsk Matindustri. Available online: http://matogindustri.no/matogindustri/dokument/Mat_og_industri_2017_plansjer_for_nedlasting.pdf (accessed on 18 March 2018).

- SSB. Kjøtproduksjon. Available online: https://www.ssb.no/jord-skog-jakt-og-fiskeri/statistikker/slakt (accessed on 17 August 2019).

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development. Available online: http://www.un.org/ga/search/view_doc.asp?symbol=A/RES/70/1&Lang=E (accessed on 19 August 2017).

- Yin, R.K. Case Study Research: Design and Methods, 5th ed.; SAGE: Thousand Oaks, CA, USA, 2014. [Google Scholar]

- Van Driel, H.; Schot, J. Radical innovation as a multilevel process: Introducing floating grain elevators in the port of Rotterdam. Technol. Cult. 2005, 46, 51–76. [Google Scholar] [CrossRef]

- European Commission. Russian Import Ban on EU Products. Available online: https://ec.europa.eu/food/safety/international_affairs/eu_russia/russian_import_ban_eu_products_en (accessed on 4 August 2019).

- Norwegian Food Safety Authority. Veileder Animalske Biprodukter. Available online: https://www.mattilsynet.no/sletting/veileder_animalske_biprodukter_10692009_og_1422011.17525/binary/Veileder%20animalske%20biprodukter%20(1069-2009%20og%20142-2011) (accessed on 19 August 2017).

- Galanakis, C.M. Recovery of high added-value components from food wastes: Conventional, emerging technologies and commercialized applications. Trends Food Sci. Technol. 2012, 26, 68–87. [Google Scholar] [CrossRef]

- Galanakis, C.M. Food Waste Recovery: Processing Technologies and Industrial Techniques; Academic Press: Cambridge, MA, USA, 2015. [Google Scholar]

- Wheelwright, S.C.; Clark, K.B. Dynamic Manufacturing: Creating the Learning Organization; The Free Press: New York, NY, USA, 1988. [Google Scholar]

- Hansen, T.; Winther, L. Competitive low-tech manufacturing and challenges for regional policy in the European context--lessons from the Danish experience. Camb. J. Reg. Econ. Soc. 2014, 7, 449–470. [Google Scholar] [CrossRef]

- Cohen, W.M.; Levinthal, D.A. Absorptive capacity: A new perspective on learning and innovation. Adm. Sci. Q. 1990, 35, 128–152. [Google Scholar] [CrossRef]

- Misangyi, V.F.; Weaver, G.R.; Elms, H. Ending corruption: The interplay among institutional logics, resources, and institutional entrepreneurs. Acad. Manag. Rev. 2008, 33, 750–770. [Google Scholar] [CrossRef]

- Amit, R.; Schoemaker, P.J. Strategic assets and organizational rent. Strateg. Manag. J. 1993, 14, 33–46. [Google Scholar] [CrossRef]

- Karim, S. Modularity in organizational structure: The reconfiguration of internally developed and acquired business units. Strateg. Manag. J. 2006, 27, 799–823. [Google Scholar] [CrossRef]

- Bergek, A.; Berggren, C.; Magnusson, T.; Hobday, M. Technological discontinuities and the challenge for incumbent firms: Destruction, disruption or creative accumulation? Res. Policy 2013, 42, 1210–1224. [Google Scholar] [CrossRef]

- Tushman, M.L.; Anderson, P. Technological discontinuities and organizational environments. Adm. Sci. Q. 1986, 31, 439–465. [Google Scholar] [CrossRef]

- Christensen, C.M.; Rosenbloom, R.S. Explaining the attacker’s advantage: Technological paradigms, organizational dynamics, and the value network. Res. Policy 1995, 24, 233–257. [Google Scholar] [CrossRef]

- Augenstein, K.; Palzkill, A. The dilemma of incumbents in sustainability transitions: A narrative approach. Adm. Sci. 2015, 6, 1–23. [Google Scholar] [CrossRef]

- Ansari, S.S.; Krop, P. Incumbent performance in the face of a radical innovation: Towards a framework for incumbent challenger dynamics. Res. Policy 2012, 41, 1357–1374. [Google Scholar] [CrossRef]

- Leonard-Barton, D. Core capabilities and core rigidities: A paradox in managing new product development. Strateg. Manag. J. 1992, 13, 111–125. [Google Scholar] [CrossRef]

- Leonard-Barton, D. Wellsprings of Knowledge: Building and Sustaining the Sources of Innovation; Harvard Business School Press: Boston, MA, USA, 1995. [Google Scholar]

| Project | Time Frame | Type of Residues | Current Market | Window(s) of Opportunity | Innovative Path(s) | Targeted Market(s) |

|---|---|---|---|---|---|---|

| A | 2012–2015 | By-products derived from animal and marine industries | Low value products markets | Increase the knowledge base on enzymatic hydrolysis of animal and marine by-products | Developing rapid screening techniques for process monitoring of industrial enzymatic protein hydrolysis | New markets for utilization of animal and marine hydrolysates |

| B | 2012–2018 | Norwegian biomass derived from different industrial streams | NA | Establishing a national “enzyme development pipeline” | Developing competitive enzyme technologies able to utilize a wide range of Norwegian biomass | NA |

| C | 2013–2017 | Low value side-streams of Norwegian food industry | NA | Producing films based on products like polysaccharides (starch) from potato, gelatin, and protein from mammals and fish as well as chicken feathers | Developing biodegradable mulch films for weed control in row-crop production | Environmentally friendly substitute for herbicides, as well as for petroleum-based polymer mulch films |

| D | 2013–2017 | Chicken by-products (e.g., chicken bone cake) | NA | Addressing the potential obesity-reducing effects of bioactive compounds from meat on chicken bones and wings | Enzymatic breakdown of proteins Producing liquid or dried peptide hydrolysate with high quality and high value applications | Pet-feed markets Functional proteins/peptides for human products |

| E | 2014–2017 | Eggshell | NA | Converting eggshell membrane into raw material for biomedical applications | Biomedical process technology | Biomedical applications (e.g., new skin regeneration, wound healing) |

| F | 2015–2019 | By-products of food processing industry | NA | Developing new concepts and methods for flexible and sustainable food processing in Norway, capable of coping with the small volumes and high biological variation of existing raw materials | iProcess innovations e.g., 3D CAD anatomical models based on X-ray CT imaging and image processing; visual guidance of robot for adaptive processing, dedicated multifunctional and dexterous grippers challenging processing operation | NA |

| G | 2015–2023 | By-products, residues not suitable for direct human consumption | NA | Developing sustainable feed ingredients from natural bioresources unsuited for direct human consumption | Innovative feed processing technology, conversion of national bioresources into feed for farm animals and fish | Novel feed ingredients |

| H | 2016–2019 | Plus products | NA | A new slaughter and cutting concept—improvement with the proposed processing method, based on pre-cutting of pig with warm cutting, form outside and in, and part-atomization | NA | |

| I | 2017–2019 | 12,000 tons of residues (plus products) from mechanical deboning of chicken | Cheap feed ingredients | Converting low-value plus products into high-value ingredients and foods for higher-paying markets | Enzymatic protein hydrolysis (EPH) | Sport/fitness market, and the elderly market |

| J | 2017–2020 | Poultry (chicken carcasses before and after mechanical de-boning) and dairy processing by-products | NA | Screening protein hydrolysate from poultry and dairy processing by-products for potential antidiabetic peptides | Antidiabetic peptides in protein hydrolysates | Medical applications |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Strøm-Andersen, N. Incumbents in the Transition Towards the Bioeconomy: The Role of Dynamic Capabilities and Innovation Strategies. Sustainability 2019, 11, 5044. https://doi.org/10.3390/su11185044

Strøm-Andersen N. Incumbents in the Transition Towards the Bioeconomy: The Role of Dynamic Capabilities and Innovation Strategies. Sustainability. 2019; 11(18):5044. https://doi.org/10.3390/su11185044

Chicago/Turabian StyleStrøm-Andersen, Nhat. 2019. "Incumbents in the Transition Towards the Bioeconomy: The Role of Dynamic Capabilities and Innovation Strategies" Sustainability 11, no. 18: 5044. https://doi.org/10.3390/su11185044

APA StyleStrøm-Andersen, N. (2019). Incumbents in the Transition Towards the Bioeconomy: The Role of Dynamic Capabilities and Innovation Strategies. Sustainability, 11(18), 5044. https://doi.org/10.3390/su11185044