Green Concrete: By-Products Utilization and Advanced Approaches

Abstract

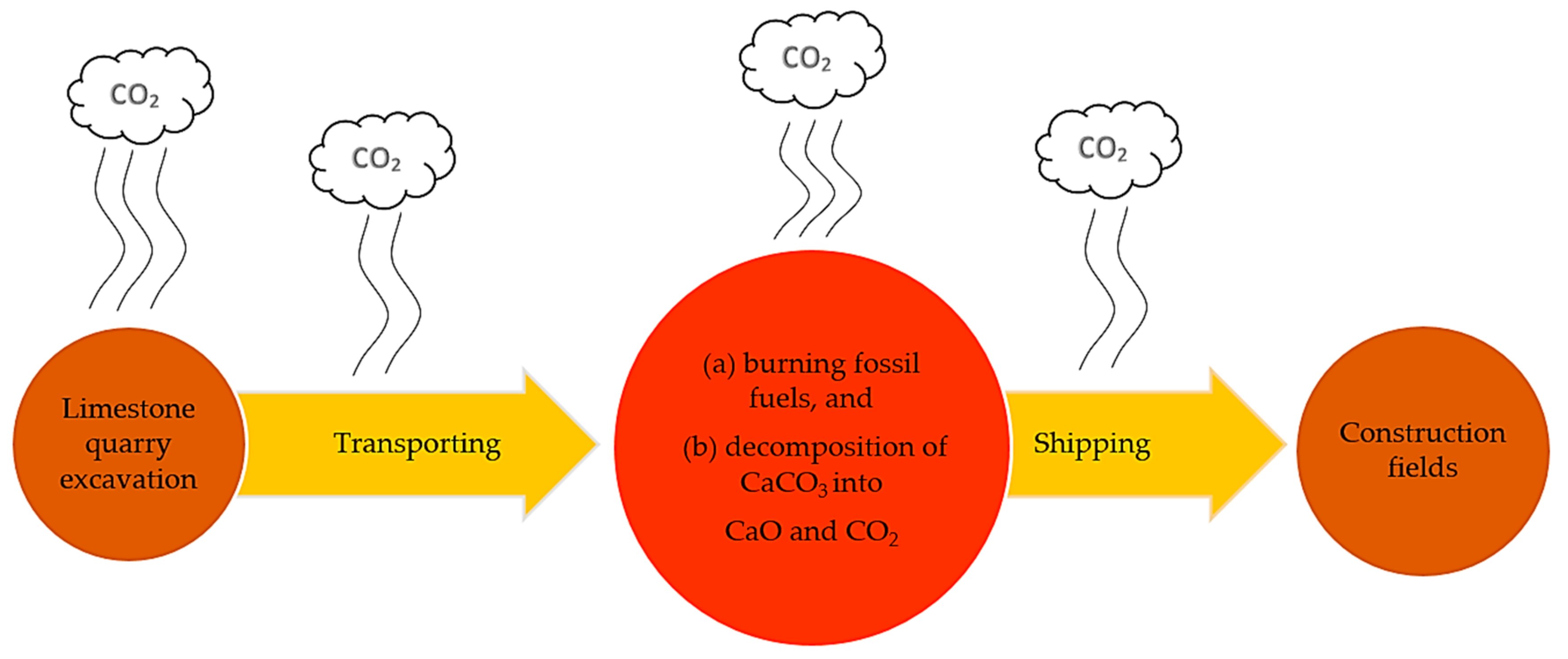

:1. Introduction

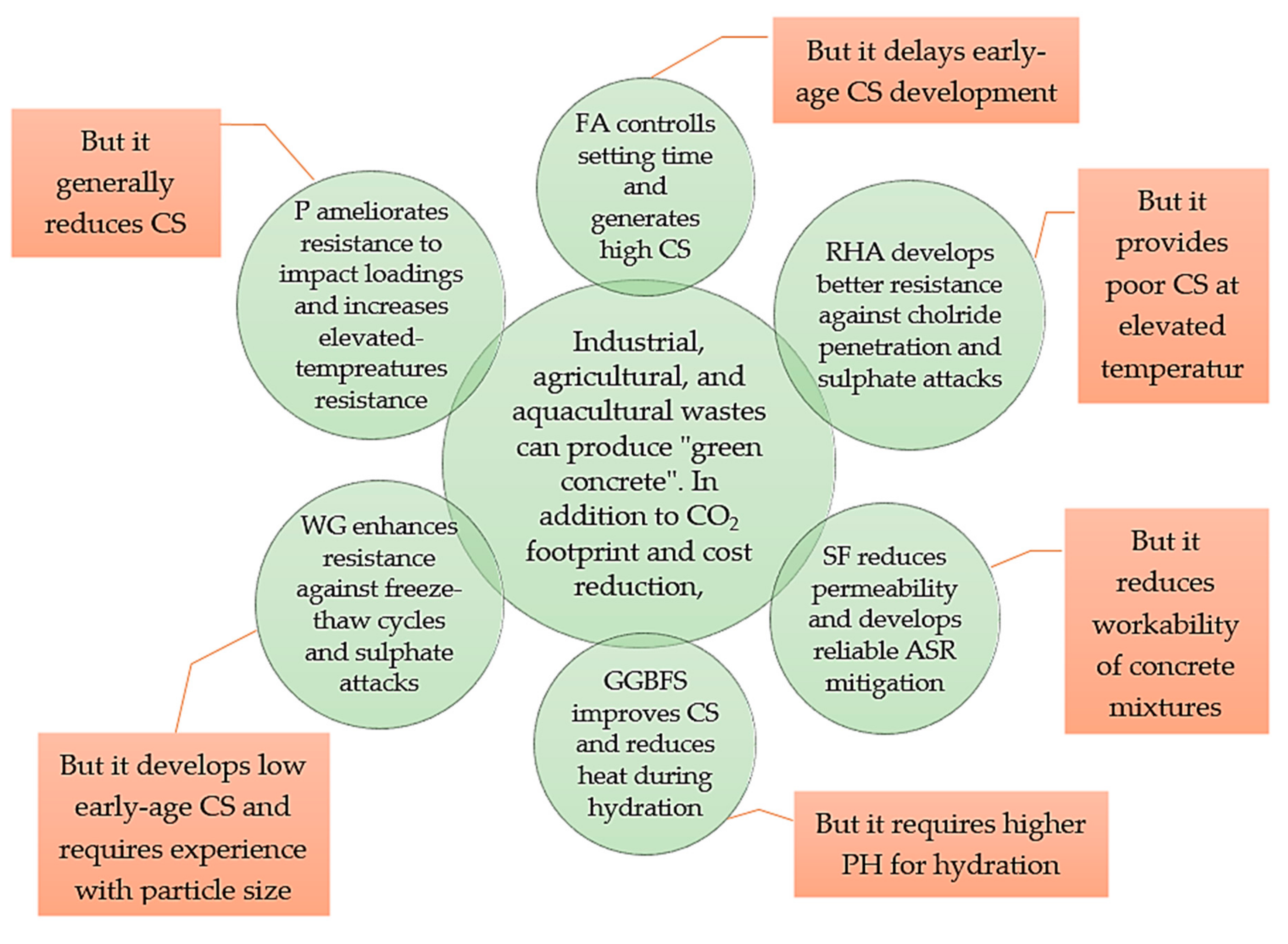

2. Materials Replacing Cement

2.1. Fly Ash (FA)

2.2. Rice Husk Ash (RHA)

2.3. Silica Fume (SF)

2.4. Other Pozzolanic Ashes

3. Materials Replacing Aggregate

4. Materials Replacing Cement and Aggregates

4.1. Ground Granular Blast-Furnace Slag (GGBFS)

4.2. Waste Glass (WG)

4.3. Plastic (P)

4.4. Miscellaneous Substitutes

5. Materials Forming Ternary Systems for Concrete

6. Advanced Approaches for the Sustainability of Concrete

6.1. Understnading and Developing C-S-H

6.2. Investigating on New Materials for Different Sustainable Applications

7. Summary, Prospects, and Challenges

Author Contributions

Funding

Conflicts of Interest

References

- Meyer, C. The greening of the concrete industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Klee, H. The cement sustainability initiative. In Proceeding of Institution of Civil Engineers Engineering Sustainability; Institute of Civil Engineers: London, UK, 2004. [Google Scholar]

- Hendriks, C.A.; Worrell, E.; De Jager, D.; Blok, K.; Riemer, P. Emission reduction of greenhouse gases from the cement industry. In Proceedings of the IEA Greenhouse Gas R&D Programme, Interlaken, Switzerland, August 30–2 September 2000. [Google Scholar]

- Carbon Impact of Concrete. Available online: https://materialspalette.org/concrete/ (accessed on 29 August 2019).

- Gartner, E. Industrially interesting approaches to “low-CO2” cements. Cem. Concr. Res. 2004, 34, 1489–1498. [Google Scholar] [CrossRef]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Hela, R.; Tazky, M.; Bodnarova, L. Possibilities of determination of optimal dosage of power plant fly ash for concrete. J. Teknol. 2016, 78, 59–64. [Google Scholar] [CrossRef]

- Li, G. Properties of high-volume fly ash concrete incorporating nano-SiO2. Cem. Concr. Res. 2004, 34, 1043–1049. [Google Scholar] [CrossRef]

- Ravina, D.; Mehta, P.K. Properties of fresh concrete containing large amounts of fly ash. Cem. Concr. Res. 1986, 16, 227–238. [Google Scholar] [CrossRef]

- Ahmaruzzaman, M. A review on the utilization of fly ash. Prog. Energy Combust. Sci. 2010, 36, 327–363. [Google Scholar] [CrossRef]

- Gamage, N.; Liyanage, K.; Fragomeni, S.; Setunge, S. Overview of different types of fly ash and their use as a building and construction material. In Proceedings of the International Conference of Structural Engineering, Construction and Management, Kandy, Sri Lanka, 15–17 December 2011. [Google Scholar]

- Mahmud, H.B.; Malik, M.F.A.; Kahar, R.A.; Zain, M.F.M.; Raman, S.N. Mechanical Properties and Durability of Normal and Water Reduced High Strength Grade 60 Concrete Containing Rice Husk Ash. J. Adv. Concr. Technol. 2009, 7, 21–30. [Google Scholar] [CrossRef] [Green Version]

- Zareei, S.A.; Ameri, F.; Dorostkar, F.; Ahmadi, M. Rice husk ash as a partial replacement of cement in high strength concrete containing micro silica: Evaluating durability and mechanical properties. Case Stud. Constr. Mater. 2017, 7, 73–81. [Google Scholar] [CrossRef]

- Singh, B. Rice husk ash. In Waste and Supplementary Cementitious Materials in Concrete; Siddique, R., Cachim, P., Eds.; Woodhead Publishing: Cambridge, UK, 2018; pp. 417–460. [Google Scholar]

- Reddy, D.V.; Diana, A.; Marcelina Alvarez, B.S. Rice Husk Ash as a Sustainable Concrete Material for the Marine Environment. In Proceedings of the Sixth LACCEI International Latin American and Caribbean Conference for Engineering and Technology, Tegucigalpa, Honduras, 4–6 June 2008; Partnering to Success: Engineering, Education, Research and Development. LACCEI: Boca Raton, FL, USA, 2008. [Google Scholar]

- Nehdi, M.; Duquette, J.; El Damatty, A. Performance of rice husk ash produced using a new technology as a mineral admixture in concrete. Cem. Concr. Res. 2003, 33, 1203–1210. [Google Scholar] [CrossRef]

- Vigneshwari, M.; Arunachalam, K.; Angayarkanni, A. Replacement of silica fume with thermally treated rice husk ash in Reactive Powder Concrete. J. Clean. Prod. 2018, 188, 264–277. [Google Scholar] [CrossRef]

- Deb, P.S.; Nath, P.; Sarker, P.K. The effects of ground granulated blast-furnace slag blending with fly ash and activator content on the workability and strength properties of geopolymer concrete cured at ambient temperature. Mater. Des. 2014, 62, 32–39. [Google Scholar] [CrossRef] [Green Version]

- Crossin, E. The greenhouse gas implications of using ground granulated blast furnace slag as a cement substitute. J. Clean. Prod. 2015, 95, 101–108. [Google Scholar] [CrossRef]

- Lam, C.H.K.; Lp, A.W.M.; John Patrick, B.; Gordon, M. Use of Incineration MSW Ash: A Review. Sustainability 2010, 2, 1943–1968. [Google Scholar] [CrossRef] [Green Version]

- Topcu, I.B.; Unverdi, A. Properties of High Content Ground Granulated Blast Furnace Slag Concrete. In Proceedings of the 3rd International Sustainable Buildings Symposium, Dubai, UAE, 15–17 March 2017; Firat, S., Kinuthia, J., AbuTair, A., Eds.; Springer International Publishing Ag: Cham, Switzerland, 2018; Volume 6, pp. 114–126. [Google Scholar]

- Aliabdo, A.A.; Elmoaty, A.E.M.A.; Aboshama, A.Y. Utilization of waste glass powder in the production of cement and concrete. Constr. Build. Mater. 2016, 124, 866–877. [Google Scholar] [CrossRef]

- Islam, G.M.S.; Rahman, M.H.; Kazi, N. Waste glass powder as partial replacement of cement for sustainable concrete practice. Int. J. Sustain. Built Environ. 2017, 6, 37–44. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.; Hanif, A.; Usman, M.; Sim, J.; Oh, H. Performance evaluation of concrete incorporating glass powder and glass sludge wastes as supplementary cementing material. J. Clean. Prod. 2018, 170, 683–693. [Google Scholar] [CrossRef]

- Soroushian, P. Strength and durability of recycled aggregate concrete containing milled glass as partial replacement for cement. Constr. Build. Mater. 2012, 29, 368–377. [Google Scholar]

- Yao, Z.T.; Ji, X.S.; Sarker, P.K.; Tang, J.H.; Ge, L.Q.; Xia, M.S.; Xi, Y.Q. A comprehensive review on the applications of coal fly ash. Earth-Sci. Rev. 2015, 141, 105–121. [Google Scholar] [CrossRef] [Green Version]

- Siddique, R.; Khatib, J.; Kaur, I. Use of recycled plastic in concrete: A review. Waste Manag. 2008, 28, 1835–1852. [Google Scholar] [CrossRef]

- Lamond, J.F. Removal and Reuse of Hardened Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2001; p. 26. [Google Scholar]

- FHWA. Transportation Applications of Recycled Concrete Aggregate; in Pavement Design; Federal Highway Administration: Washington, DC, USA, 2004; p. 47.

- Tsang, H.-H. Uses of scrap rubber tires. In Rubber: Types, Properties and Uses; Nova Science Publisher: New York, NY, USA, 2013; pp. 477–491. [Google Scholar]

- Lau, D.; Jian, W.; Yu, Z.; Hui, D. Nano-engineering of construction materials using molecular dynamics simulations: Prospects and challenges. Compos. Part B Eng. 2018, 143, 282–291. [Google Scholar] [CrossRef]

- Sobolev, K. Nanotechnology Nanoengineering of Construction Materials. In Nanotechnology in Construction; Springer International Publishing: Cham, Switzerland, 2015. [Google Scholar]

- Sobolev, K.; Sanchez, F.; Vivian, I.F. The Use of Nanoparticle Admixtures to Improve the Performance of Concrete. In Proceedings of the 4th International Fib Congress, Mumbai, Maharashtra, 10–14 February 2012. [Google Scholar]

- Alder, B.J.; Wainwright, T.E. Studies in Molecular Dynamics. I. General Method. J. Chem. Phys. 1959, 31, 459. [Google Scholar]

- Wu, W.; Al-Ostaz, A.; Cheng, A.H.-D.; Song, C.R. Computation of Elastic Properties of Portland Cement Using Molecular Dynamics. J. Nanomech. Micromech. 2011, 1, 84–90. [Google Scholar] [CrossRef]

- Yu, Z.; Lau, D. Evaluation on mechanical enhancement and fire resistance of carbon nanotube (CNT) reinforced concrete. Coupled Syst. Mech. 2017, 6, 335–349. [Google Scholar]

- Yu, M.F.; Lourie, O.; Mark, J.D.; Moloni, K.; Thomas, K.F.; Rodney, R.S. Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.-H. Computational Geomechanics and Hydraulic Structures; Springer: Singapore, 2019; p. 7. [Google Scholar]

- Song, S.J.; Jennings, H.M. Pore solution chemistry of alkali-activated ground granulated blast-furnace slag. Cem. Concr. Res. 1999, 29, 159–170. [Google Scholar] [CrossRef]

- Yu, J.; Lu, C.; Leung, C.K.Y.; Li, G. Mechanical properties of green structural concrete with ultrahigh-volume fly ash. Constr. Build. Mater. 2017, 147, 510–518. [Google Scholar] [CrossRef]

- Liu, J.; Yu, Q.; Zuo, Z.; Yang, F.; Han, Z.; Qin, Q. Reactivity and performance of dry granulation blast furnace slag cement. Cem. Concr. Compos. 2019, 95, 19–24. [Google Scholar] [CrossRef]

- He, Z.-h.; Li, L.-y.; Du, S.-g. Creep analysis of concrete containing rice husk ash. Cem. Concr. Compos. 2017, 80, 190–199. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, D.; Chen, H. The role of fly ash microsphere in the microstructure and macroscopic properties of high-strength concrete. Cem. Concr. Compos. 2017, 83, 125–137. [Google Scholar] [CrossRef]

- Halstead, W.J. Use of Fly Ash in Concrete; Transportation Research Board: Washington, DC, USA, 1986.

- Ganesan, K.; Rajagopal, K.; Thangavel, K. Rice husk ash blended cement: Assessment of optimal level of replacement for strength and permeability properties of concrete. Constr. Build. Mater. 2008, 22, 1675–1683. [Google Scholar] [CrossRef]

- Habeeb, G.A.; Mahmud, H.B. Study on properties of rice husk ash and its use as cement replacement material. Mater. Res. 2010, 13, 185–190. [Google Scholar] [CrossRef]

- Ahsan, M.B.; Hossain, Z. Supplemental use of rice husk ash (RHA) as a cementitious material in concrete industry. Constr. Build. Mater. 2018, 178, 1–9. [Google Scholar] [CrossRef]

- Holland, T.C.; Detwiler, R. Guide for the Use of Silica Fume in Concrete; ACI Committee Report: Farmington Hills, MI, USA, 2006; p. 63. [Google Scholar]

- Holland, T.C. Silica Fume User’s Manual; U.S. Department of Transportation: Washington, DC, USA, 2005.

- Aly, M.; Hashmi, M.S.J.; Olabi, A.G.; Messeiry, M.; Abadir, E.F.; Hussain, A.I. Effect of colloidal nano-silica on the mechanical and physical behaviour of waste-glass cement mortar. Mater. Des. 2012, 33, 127–135. [Google Scholar] [CrossRef]

- Taha, B.; Nounu, G. Utilizing Waste Recycled Glass as Sand/Cement Replacement in Concrete. J. Mater. Civ. Eng. 2009, 21, 709–721. [Google Scholar] [CrossRef]

- Bignozzi, M.C.; Saccani, A.; Barbieri, L.; Lancellotti, I. Glass waste as supplementary cementing materials: The effects of glass chemical composition. Cem. Concr. Compos. 2015, 55, 45–52. [Google Scholar] [CrossRef]

- Flynn, R.T.; Grisinger, T.J. Slag Cement in Concrete and Mortar; American Concrete Institute: Farmington Hills, MI, USA, 2003. [Google Scholar]

- American Society for Testing of Materials. Standard Test Methods for Chemical Analysis of Hydraulic Cement; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Sarker, P.; McKenzie, L. Strength and hydration heat of concrete using fly ash as a partial replacement of cement. In Proceedings of the 24th Biennial Conference of the Concrete Institute Australia, Sydney, Australia, 17–19 September 2009; Kaewunruen, S., Remennikov, A.M., Eds.; Concrete Institute of Australia: Sydney, Australia, 2009. [Google Scholar]

- Antiohos, S.K.; Papadakis, V.G.; Tsimas, S. Rice husk ash (RHA) effectiveness in cement and concrete as a function of reactive silica and fineness. Cem. Concr. Res. 2014, 61–62, 20–27. [Google Scholar] [CrossRef]

- Zhang, M.H.; Lastra, R.; Malhotra, V.M. Rice-husk ash paste and concrete: Some aspects of hydration and the microstructure of the interfacial zone between the aggregate and paste. Cem. Concr. Res. 1996, 26, 963–977. [Google Scholar] [CrossRef]

- Barnett, S.J.; Soutsos, M.N.; Millard, S.G.; Bungey, J.H. Strength development of mortars containing ground granulated blast-furnace slag: Effect of curing temperature and determination of apparent activation energies. Cem. Concr. Res. 2006, 36, 434–440. [Google Scholar] [CrossRef]

- Bilim, C.; Atiş, C.D.; Tanyildizi, H.; Karahan, O. Predicting the compressive strength of ground granulated blast furnace slag concrete using artificial neural network. Adv. Eng. Softw. 2009, 40, 334–340. [Google Scholar] [CrossRef]

- Golewski, G.L. Green concrete composite incorporating fly ash with high strength and fracture toughness. J. Clean. Prod. 2018, 172, 218–226. [Google Scholar] [CrossRef]

- Lam, L.; Wong, Y.L.; Poon, C.S. Degree of hydration and gel/space ratio of high-volume fly ash/cement systems. Cem. Concr. Res. 2000, 30, 747–756. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Supit, S.W.M. Compressive strength and durability properties of high volume fly ash (HVFA) concretes containing ultrafine fly ash (UFFA). Constr. Build. Mater. 2015, 82, 192–205. [Google Scholar] [CrossRef]

- American Society for Testing of Materials. Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Bui, D.D.; Hu, J.; Stroeven, P. Particle size effect on the strength of rice husk ash blended gap-graded Portland cement concrete. Cem. Concr. Compos. 2005, 27, 357–366. [Google Scholar] [CrossRef]

- Chao-Lung, H.; Anh-Tuan, B.L.; Chun-Tsun, C. Effect of rice husk ash on the strength and durability characteristics of concrete. Constr. Build. Mater. 2011, 25, 3768–3772. [Google Scholar] [CrossRef]

- Ismail, M.S.; Waliuddin, A.M. Effect of rice husk ash on high strength concrete. Constr. Build. Mater. 1996, 10, 521–526. [Google Scholar] [CrossRef]

- Marthong, C. Effect of rice husk ash (RHA) as partial replacement of cement on concrete properties. Int. J. Eng. Res. Technol. 2012, 1, 6. [Google Scholar]

- Molaei Raisi, E.; Amiri, J.V.; Davoodi, M.R. Influence of rice husk ash on the fracture characteristics and brittleness of self-compacting concrete. Eng. Fract. Mech. 2018, 199, 595–608. [Google Scholar] [CrossRef]

- Rodríguez de Sensale, G. Strength development of concrete with rice-husk ash. Cem. Concr. Compos. 2006, 28, 158–160. [Google Scholar] [CrossRef]

- Zhang, M.H.; Malhotra, V.M. High-performance concrete incorporating rice husk ash as a supplementary cementing material. ACI Mater. J. 1996, 93, 629–636. [Google Scholar]

- Radlinski, M.; Olek, J. Investigation into the synergistic effects in ternary cementitious systems containing portland cement, fly ash and silica fume. Cem. Concr. Compos. 2012, 34, 451–459. [Google Scholar] [CrossRef]

- Ghasemzadeh, F.; Shekarchi, M.; Sajedi, S.; Moradllo, M.K.; Sadati, S. Effect of Silica Fume and Ground Granulated Blast-Furnace Slag on Shrinkage in High Performance Concrete. In Proceedings of the 6th International Conference on Concrete under Severe Conditions, Environment and Loading, Yucatan, Mexico, 7–9 June 2010. [Google Scholar]

- Rafat Siddique, M.I.K. Supplementary Cementing Materials; Springer: Heidelberg/Berlin, Germany, 2011. [Google Scholar]

- Aliabdo, A.A.; Elmoaty, A.E.M.A.; Emam, M.A. Factors affecting the mechanical properties of alkali activated ground granulated blast furnace slag concrete. Constr. Build. Mater. 2019, 197, 339–355. [Google Scholar] [CrossRef]

- Patra, R.K.; Mukharjee, B.B. Influence of incorporation of granulated blast furnace slag as replacement of fine aggregate on properties of concrete. J. Clean. Prod. 2017, 165, 468–476. [Google Scholar] [CrossRef]

- Pfingsten, J.; Rickert, J.; Lipus, K. Estimation of the content of ground granulated blast furnace slag and different pozzolanas in hardened concrete. Constr. Build. Mater. 2018, 165, 931–938. [Google Scholar] [CrossRef]

- Iucolano, F.; Liguori, B.; Caputo, D.; Colangelo, F.; Cioffi, R. Recycled plastic aggregate in mortars composition: Effect on physical and mechanical properties. Mater. Des. (1980–2015) 2013, 52, 916–922. [Google Scholar] [CrossRef]

- Duxson, P.; Provis, J.L.; Lukey, G.C.; Van Deventer, J.S.J. The role of inorganic polymer technology in the development of ‘green concrete’. Cem. Concr. Res. 2007, 37, 1590–1597. [Google Scholar] [CrossRef]

- Kim, J.H.; Kwon, W.T. Semi-Dry Carbonation Process Using Fly Ash from Solid Refused Fuel Power Plant. Sustainability 2019, 11, 908. [Google Scholar] [CrossRef]

- Sasmal, S.; Anoop, M.B. 7-Nanoindentation for evaluation of properties of cement hydration products. In Nanotechnology in Eco-Efficient Construction, 2nd ed.; Pacheco-Torgal, F., Diamanti, M.V., Nazari, A., Granqvist, C.G., Pruna, A., Amirkhanian, S., Eds.; Woodhead Publishing: Sawston, UK, 2019; pp. 141–161. [Google Scholar]

- Solak, A.M.; Tenza-Abril, A.J.; Saval, J.M.; García-Vera, V.E. Effects of Multiple Supplementary Cementitious Materials on Workability and Segregation Resistance of Lightweight Aggregate Concrete. Sustainability 2018, 10, 4304. [Google Scholar] [CrossRef]

- Colangelo, F.; Farina, I.; Penna, R.; Feo, L.; Fraternali, F.; Cioffi, R. Use of MSWI fly ash for the production of lightweight artificial aggregate by means of innovative cold bonding pelletization technique. Chemical and morphological characterization. Chem. Eng. Trans. 2017, 60, 121–126. [Google Scholar]

- Kukier, U.; Sumner, M.E., VI. 9-Agricultural utilization of coal combustion residues. In Waste Management Series; Twardowska, I., Ed.; Elsevier: Amsterdam, The Netherlands, 2004; Volume 4, pp. 1003–1017. [Google Scholar]

- Alaka, H.A.; Oyedele, L.O. High volume fly ash concrete: The practical impact of using superabundant dose of high range water reducer. J. Build. Eng. 2016, 8, 81–90. [Google Scholar] [CrossRef]

- Mehta, P.K. Properties of blended cements made from rice husk ash. J. Proc. 1977, 74, 440–442. [Google Scholar]

- Zain, M.F.M.; Islam, M.N.; Mahmud, F.; Jamil, M. Production of rice husk ash for use in concrete as a supplementary cementitious material. Constr. Build. Mater. 2011, 25, 798–805. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Mahdikhani, M.; Ahmadibeni, G. The effect of rice husk ash on mechanical properties and durability of sustainable concretes. Int. J. Civ. Eng. 2009, 7, 83–91. [Google Scholar]

- Hwang, C.L.; Chandra, S. 4-The use of rice husk ash in concrete. In Waste Materials Used in Concrete Manufacturing; Chandra, S., Ed.; William Andrew Publishing: Westwood, NJ, USA, 1996; pp. 184–234. [Google Scholar]

- Nguyen, V. Rice Husk Ash as a Mineral Admixture for Ultra High Performance Concrete. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 20 September 2011. [Google Scholar]

- Olutoge, F.A.; Adesina, P.A. Effects of rice husk ash prepared from charcoal-powered incinerator on the strength and durability properties of concrete. Constr. Build. Mater. 2019, 196, 386–394. [Google Scholar] [CrossRef]

- Paris, J.M.; Roessler, J.G.; Ferraro, C.C.; DeFord, H.D.; Townsend, T.G. A review of waste products utilized as supplements to Portland cement in concrete. J. Clean. Prod. 2016, 121, 1–18. [Google Scholar] [CrossRef]

- American Society for Testing Materials. Standard Specification for Silica Fume Used in Cementitious Mixtures; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Kurdowski, W.; Nocuń-Wczelik, W. The tricalcium silicate hydration in the presence of active silica. Cem. Concr. Res. 1983, 13, 341–348. [Google Scholar] [CrossRef]

- Khatri, R.P.; Sirivivatnanon, V.; Gross, W. Effect of different supplementary cementitious materials on mechanical properties of high performance concrete. Cem. Concr. Res. 1995, 25, 209–220. [Google Scholar] [CrossRef]

- American Association of State and Highway Transportation Officials. Standard Specification for Silica Fume Used in Cementitious Mixtures; AASHTO: Washington, DC, USA, 2013.

- Zhang, Z.; Zhang, B.; Yan, P. Comparative study of effect of raw and densified silica fume in the paste, mortar and concrete. Constr. Build. Mater. 2016, 105, 82–93. [Google Scholar] [CrossRef]

- İnan Sezer, G. Compressive strength and sulfate resistance of limestone and/or silica fume mortars. Constr. Build. Mater. 2012, 26, 613–618. [Google Scholar] [CrossRef]

- Ganjian, E.; Pouya, H.S. The effect of Persian Gulf tidal zone exposure on durability of mixes containing silica fume and blast furnace slag. Constr. Build. Mater. 2009, 23, 644–652. [Google Scholar] [CrossRef]

- Jalal, M.; Pouladkhan, A.; Harandi, O.F.; Jafari, D. Comparative study on effects of Class F fly ash, nano silica and silica fume on properties of high performance self compacting concrete. Constr. Build. Mater. 2015, 94, 90–104. [Google Scholar] [CrossRef]

- Tamimi, A.; Hassan, N.M.; Fattah, K.; Talachi, A. Performance of cementitious materials produced by incorporating surface treated multiwall carbon nanotubes and silica fume. Constr. Build. Mater. 2016, 114, 934–945. [Google Scholar] [CrossRef]

- Sobhani, J.; Najimi, M. Electrochemical impedance behavior and transport properties of silica fume contained concrete. Constr. Build. Mater. 2013, 47, 910–918. [Google Scholar] [CrossRef]

- Bhanja, S.; Sengupta, B. Influence of silica fume on the tensile strength of concrete. Cem. Concr. Res. 2005, 35, 743–747. [Google Scholar] [CrossRef]

- Song, H.-W.; Pack, S.-W.; Nam, S.-H.; Jang, J.-C.; Saraswathy, V. Estimation of the permeability of silica fume cement concrete. Constr. Build. Mater. 2010, 24, 315–321. [Google Scholar]

- Choi, P.; Yeon, J.H.; Yun, K.-K. Air-void structure, strength, and permeability of wet-mix shotcrete before and after shotcreting operation: The influences of silica fume and air-entraining agent. Cem. Concr. Compos. 2016, 70, 69–77. [Google Scholar] [CrossRef]

- Papa, E.; Medri, V.; Kpogbemabou, D.; Morinière, V.; Laumonier, J.; Vaccari, A.; Rossignol, S. Porosity and insulating properties of silica-fume based foams. Energy Build. 2016, 131, 223–232. [Google Scholar] [CrossRef]

- Boddy, A.M.; Hooton, R.D.; Thomas, M.D.A. The effect of the silica content of silica fume on its ability to control alkali–silica reaction. Cem. Concr. Res. 2003, 33, 1263–1268. [Google Scholar] [CrossRef]

- Li, Z.; Venkata, H.K.; Rangaraju, P.R. Influence of silica flour–silica fume combination on the properties of high performance cementitious mixtures at ambient temperature curing. Constr. Build. Mater. 2015, 100, 225–233. [Google Scholar] [CrossRef]

- Stasta, P.; Boran, J.; Bebar, L.; Stehlik, P.; Oral, J. Thermal processing of sewage sludge. Appl. Therm. Eng. 2006, 26, 1420–1426. [Google Scholar] [CrossRef]

- Liu, G.; Yang, Z.; Chen, B.; Zhang, J.; Liu, X.; Zhang, Y.; Su, M.; Ulgiati, S. Scenarios for sewage sludge reduction and reuse in clinker production towards regional eco-industrial development: A comparative emergy-based assessment. J. Clean. Prod. 2015, 103, 371–383. [Google Scholar] [CrossRef]

- Pavlík, Z.; Fořt, J.; Záleská, M.; Pavlíková, M.; Trník, A.; Medved, I.; Keppert, M.; Koutsoukos, P.G.; Černý, R. Energy-efficient thermal treatment of sewage sludge for its application in blended cements. J. Clean. Prod. 2016, 112, 409–419. [Google Scholar] [CrossRef]

- Lynn, C.J.; Dhir, R.K.; Ghataora, G.S.; West, R.P. Sewage sludge ash characteristics and potential for use in concrete. Constr. Build. Mater. 2015, 98, 767–779. [Google Scholar] [CrossRef] [Green Version]

- Baeza-Brotons, F.; Garcés, P.; Payá, J.; Saval, J.M. Portland cement systems with addition of sewage sludge ash. Application in concretes for the manufacture of blocks. J. Clean. Prod. 2014, 82, 112–124. [Google Scholar] [Green Version]

- Valls, S.; Yagüe, A.; Vázquez, E.; Mariscal, C. Physical and mechanical properties of concrete with added dry sludge from a sewage treatment plant. Cem. Concr. Res. 2004, 34, 2203–2208. [Google Scholar] [CrossRef]

- Monzó, J.; Payá, J.; Borrachero, M.V.; Girbés, I. Reuse of sewage sludge ashes (SSA) in cement mixtures: The effect of SSA on the workability of cement mortars. Waste Manag. 2003, 23, 373–381. [Google Scholar] [CrossRef]

- Abdullahi, M. Characteristics of wood ash/OPC concrete. Leonardo Electron. J. Pract. Technol. 2006, 8, 9–16. [Google Scholar]

- Raheem, A.A.; Olasunkanmi, B.S.; Folorunso, C.S. Saw Dust Ash as Partial Replacement for Cement in Concrete. Organ. Technol. Manag. Constr. Int. J. 2012, 4, 474–480. [Google Scholar] [CrossRef]

- Cheah, C.B.; Ramli, M. The implementation of wood waste ash as a partial cement replacement material in the production of structural grade concrete and mortar: An overview. Resour. Conserv. Recycl. 2011, 55, 669–685. [Google Scholar] [CrossRef]

- Chusilp, N.; Jaturapitakkul, C.; Kiattikomol, K. Utilization of bagasse ash as a pozzolanic material in concrete. Constr. Build. Mater. 2009, 23, 3352–3358. [Google Scholar] [CrossRef]

- Rukzon, S.; Chindaprasirt, P. Utilization of bagasse ash in high-strength concrete. Mater. Des. 2012, 34, 45–50. [Google Scholar] [CrossRef]

- Rajasekar, A.; Arunachalam, K.; Kottaisamy, M.; Saraswathy, V. Durability characteristics of Ultra High Strength Concrete with treated sugarcane bagasse ash. Constr. Build. Mater. 2018, 171, 350–356. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Patnaikuni, I.; Wu, Y.-F. Pozzolanic reaction of sugarcane bagasse ash and its role in controlling alkali silica reaction. Constr. Build. Mater. 2017, 148, 231–240. [Google Scholar] [CrossRef]

- N Dwivedi, V.; Singh, N.P.; Das, S.S.; Singh, N. A new pozzolanic material for cement industry: Bamboo leaf ash. Int. J. Phys. Sci. 2006, 1, 106–111. [Google Scholar]

- Singh, N.; Das, S.S.; Dwivedi, V.N. Hydration of Bamboo Leaf Ash Blended Portland Cement. Indian J. Eng. Mater. Sci. 2007, 14, 69–76. [Google Scholar]

- Villar-Cociña, E.; Morales, E.V.; Santos, S.F.; Savastano, H.; Frías, M. Pozzolanic behavior of bamboo leaf ash: Characterization and determination of the kinetic parameters. Cem. Concr. Compos. 2011, 33, 68–73. [Google Scholar] [CrossRef]

- Frías, M.; Savastano, H.; Villar, E.; de Rojas, M.I.S.; Santos, S. Characterization and properties of blended cement matrices containing activated bamboo leaf wastes. Cem. Concr. Compos. 2012, 34, 1019–1023. [Google Scholar] [CrossRef]

- Umoh, A.; Odesola, I. Characteristics of Bamboo Leaf Ash Blended Cement Paste and Mortar. Civ. Eng. Dimens. 2015, 17, 22–28. [Google Scholar]

- Xie, X.; Zhou, Z.; Jiang, M.; Xu, X.; Wang, Z.; Hui, D. Cellulosic fibers from rice straw and bamboo used as reinforcement of cement-based composites for remarkably improving mechanical properties. Compos. Part B Eng. 2015, 78, 153–161. [Google Scholar] [CrossRef]

- Correia, V.d.C.; Santos, S.F.; Mármol, G.; Curvelo, A.A.d.S.; Savastano, H. Potential of bamboo organosolv pulp as a reinforcing element in fiber–cement materials. Constr. Build. Mater. 2014, 72, 65–71. [Google Scholar] [CrossRef]

- Sooraj, V.M. Effect of Palm Oil Fuel Ash (POFA) on Strength Properties of Concrete. Int. J. Sci. Res. Publ. 2013, 3, 1–7. [Google Scholar]

- Sata, V.; Jaturapitakkul, C.; Kiattikomol, K. Utilization of Palm Oil Fuel Ash in High-Strength Concrete. J. Mater. Civ. Eng. 2004, 16, 623–628. [Google Scholar] [CrossRef]

- Khankhaje, E.; Hussin, M.W.; Mirza, J.; Rafieizonooz, M.; Salim, M.R.; Siong, H.C.; Warid, M.N.M. On blended cement and geopolymer concretes containing palm oil fuel ash. Mater. Des. 2016, 89, 385–398. [Google Scholar] [CrossRef]

- Islam, M.M.U.; Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z. Mechanical and fresh properties of sustainable oil palm shell lightweight concrete incorporating palm oil fuel ash. J. Clean. Prod. 2016, 115, 307–314. [Google Scholar] [CrossRef]

- Dumne, S. Effect of superplasticizer on fresh and hardened properties of self-compacting concrete containing fly ash. Am. J. Eng. Res. 2014, 3, 205–211. [Google Scholar]

- Awal, A.S.M.A.; Nguong, S.K. A short-term investigation on high volume palm oil fuel ash (pofa) concrete. In Proceedings of the 35th Conference on Our World in Concrete and Structures, Singapore, 26–27 August 2010. [Google Scholar]

- Nagaratnam, B.H.; Rahman, M.E.; Mirasa, A.K.; Mannan, M.A.; Lame, S.O. Workability and heat of hydration of self-compacting concrete incorporating agro-industrial waste. J. Clean. Prod. 2016, 112, 882–894. [Google Scholar] [CrossRef]

- Ranjbar, N.; Mehrali, M.; Alengaram, U.J.; Metselaar, H.S.C.; Jumaat, M.Z. Compressive strength and microstructural analysis of fly ash/palm oil fuel ash based geopolymer mortar under elevated temperatures. Constr. Build. Mater. 2014, 65, 114–121. [Google Scholar] [CrossRef]

- ACI Committee E701. Aggregates for Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2016. [Google Scholar]

- Forster, S.W. Recycled concrete as aggregate. Concr. Int. 1986, 8, 34–40. [Google Scholar]

- Tavakoli, M.; Soroushian, P. Strengths of recycled aggregate concrete made using field-demolished concrete as aggregate. ACI Mater. J. 1996, 93, 182–190. [Google Scholar]

- Chen, H.H.; Su, R.K.L.; Kwan, A.K.H. Fracture Toughness of Plain Concrete Made of Crushed Granite Aggregate. HKIE Trans. 2011, 18, 6–12. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vazquez, E.; Mari, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Katz, A. Properties of concrete made with recycled aggregate from partially hydrated old concrete. Cem. Concr. Res. 2003, 33, 703–711. [Google Scholar] [CrossRef]

- Jain, N.; Garg, M.; Minocha, A.K. Green Concrete from Sustainable Recycled Coarse Aggregates: Mechanical and Durability Properties. J. Waste Manag. 2015. [Google Scholar] [CrossRef]

- Rahal, K. Mechanical properties of concrete with recycled coarse aggregate. Build. Environ. 2007, 42, 407–415. [Google Scholar] [CrossRef]

- Rahal, K.N.; Alrefaei, Y.T. Shear strength of recycled aggregate concrete beams containing stirrups. Constr. Build. Mater. 2018, 191, 866–876. [Google Scholar] [CrossRef]

- Sagoe-Crentsil, K.K.; Brown, T.; Taylor, A.H. Performance of concrete made with commercially produced coarse recycled concrete aggregate. Cem. Concr. Res. 2001, 31, 707–712. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.A.; de Brito, J.; Fiol, F. Micro- and macro-porosity of dry- and saturated-state recycled aggregate concrete. J. Clean. Prod. 2019, 211, 932–940. [Google Scholar] [CrossRef]

- Thomas, J.; Thaickavil, N.N.; Wilson, P.M. Strength and durability of concrete containing recycled concrete aggregates. J. Build. Eng. 2018, 19, 349–365. [Google Scholar] [CrossRef]

- Xiao, J.Z.; Li, J.B.; Zhang, C. Mechanical properties of recycled aggregate concrete under uniaxial loading. Cem. Concr. Res. 2005, 35, 1187–1194. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Abreu, V.; Evangelista, L.; de Brito, J. The effect of multi-recycling on the mechanical performance of coarse recycled aggregates concrete. Constr. Build. Mater. 2018, 188, 480–489. [Google Scholar] [CrossRef]

- McNeil, K.; Kang, T.H.-K. Recycled Concrete Aggregates: A Review. Int. J. Concr. Struct. Mater. 2013, 7, 61–69. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.W.; Jeong, C.Y.; Lee, J.S.; Kim, K.H. Applicability of Ground Granulated Blast-Furnace Slag for Precast Concrete Beams Subjected to Bending Moment. J. Asian Archit. Build. Eng. 2014, 13, 633–639. [Google Scholar] [CrossRef] [Green Version]

- Gholampour, A.; Ozbakkaloglu, T. Performance of sustainable concretes containing very high volume Class-F fly ash and ground granulated blast furnace slag. J. Clean. Prod. 2017, 162, 1407–1417. [Google Scholar] [CrossRef]

- Qu, Z.Y.; Yu, Q.L. Synthesizing super-hydrophobic ground granulated blast furnace slag to enhance the transport property of lightweight aggregate concrete. Constr. Build. Mater. 2018, 191, 176–186. [Google Scholar] [CrossRef]

- Sanjuán, M.Á.; Estévez, E.; Argiz, C.; Barrio, D.d. Effect of curing time on granulated blast-furnace slag cement mortars carbonation. Cem. Concr. Compos. 2018, 90, 257–265. [Google Scholar] [CrossRef]

- Majhi, R.K.; Nayak, A.N.; Mukharjee, B.B. Development of sustainable concrete using recycled coarse aggregate and ground granulated blast furnace slag. Constr. Build. Mater. 2018, 159, 417–430. [Google Scholar] [CrossRef]

- Glass: Material-Specific Data. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/glass-material-specific-data (accessed on 21 February 2019).

- EU Glass Packaging Closed Loop Recycling Steady at 74 Percent. Available online: https://feve.org/about-glass/statistics/ (accessed on 23 February 2019).

- Ling, T.-C.; Poon, C.-S.; Wong, H.-W. Management and recycling of waste glass in concrete products: Current situations in Hong Kong. Resour. Conserv. Recycl. 2013, 70, 25–31. [Google Scholar] [CrossRef]

- Jani, Y.; Hogland, W. Waste glass in the production of cement and concrete—A review. J. Environ. Chem. Eng. 2014, 2, 1767–1775. [Google Scholar] [CrossRef]

- Tamanna, N.; Sutan, N.M.; Lee, D.T.C.; Yakub, I. Utilization of Waste Glass in Concrete. In Proceedings of the 6th International Engineering Conference, Energy and Environment (ENCON 2013), Kuching, Sarawak, Malaysia, 2–4 July 2013. [Google Scholar]

- Kim, I.S.; Choi, S.Y.; Yang, E.I. Evaluation of durability of concrete substituted heavyweight waste glass as fine aggregate. Constr. Build. Mater. 2018, 184, 269–277. [Google Scholar] [CrossRef]

- Gu, L.; Ozbakkaloglu, T. Use of recycled plastics in concrete: A critical review. Waste Manag. 2016, 51, 19–42. [Google Scholar] [CrossRef]

- Europe, P. Plastics—The Facts 2017; European Association of Plastics Recycling & Recovery Organisations: Brussels, Belgium, 2018. [Google Scholar]

- Kao, E. More than 17 Million Pieces of Plastic Waste Flushed into Sea via Hong Kong’s Shing Mun River Each Year; South China Morning Post: Hong Kong, China, 2018. [Google Scholar]

- Schaefer, C.E.; Kupwade-Patil, K.; Ortega, M.; Soriano, C.; Büyüköztürk, O.; White, A.E.; Short, M.P. Irradiated recycled plastic as a concrete additive for improved chemo-mechanical properties and lower carbon footprint. Waste Manag. 2018, 71, 426–439. [Google Scholar] [CrossRef] [PubMed]

- Ismail, Z.Z.; Al-Hashmi, E.A. Use of waste plastic in concrete mixture as aggregate replacement. Waste Manag. 2008, 28, 2041–2047. [Google Scholar] [CrossRef] [PubMed]

- Rebeiz, K.S.; Craft, A.P. Plastic waste management in construction: Technological and institutional issues. Resour. Conserv. Recycl. 1995, 15, 245–257. [Google Scholar] [CrossRef]

- Saxena, R.; Siddique, S.; Gupta, T.; Sharma, R.K.; Chaudhary, S. Impact resistance and energy absorption capacity of concrete containing plastic waste. Constr. Build. Mater. 2018, 176, 415–421. [Google Scholar] [CrossRef]

- Jibrael, M.A.; Peter, F. Strength and Behavior of Concrete Contains Waste Plastic. J. Ecosyst. Ecogr. 2016, 6, 2–5. [Google Scholar] [CrossRef]

- Saikia, N.; de Brito, J. Use of plastic waste as aggregate in cement mortar and concrete preparation: A review. Constr. Build. Mater. 2012, 34, 385–401. [Google Scholar] [CrossRef]

- Colangelo, F.; Cioffi, R.; Liguori, B.; Iucolano, F. Recycled polyolefins waste as aggregates for lightweight concrete. Compos. Part B Eng. 2016, 106, 234–241. [Google Scholar] [CrossRef]

- Fraternali, F.; Ciancia, V.; Chechile, R.; Rizzano, G.; Feo, L.; Incarnato, L. Experimental study of the thermo-mechanical properties of recycled PET fiber-reinforced concrete. Compos. Struct. 2011, 93, 2368–2374. [Google Scholar] [CrossRef]

- Fraternali, F.; Farina, I.; Polzone, C.; Pagliuca, E.; Feo, L. On the use of R-PET strips for the reinforcement of cement mortars. Compos. Part B Eng. 2013, 46, 207–210. [Google Scholar] [CrossRef]

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of art review and future applications. Compos. Part B Eng. 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Al-Manaseer, A.A.; Dalal, T.R. Concrete Containing Plastic Aggregates. Concr. Int. 1997, 19, 47–52. [Google Scholar]

- Choi, Y.-W.; Moon, D.-J.; Chung, J.-S.; Cho, S.-K. Effects of waste PET bottles aggregate on the properties of concrete. Cem. Concr. Res. 2005, 35, 776–781. [Google Scholar] [CrossRef]

- Xuan, D.X.; Shui, Z.H.; Wu, S.P. Influence of silica fume on the interfacial bond between aggregate and matrix in near-surface layer of concrete. Constr. Build. Mater. 2009, 23, 2631–2635. [Google Scholar] [CrossRef]

- Jiang, L. The interfacial zone and bond strength between aggregates and cement pastes incorporating high volumes of fly ash. Cem. Concr. Compos. 1999, 21, 313–316. [Google Scholar] [CrossRef]

- Thorneycroft, J.; Orr, J.; Savoikar, P.; Ball, R.J. Performance of structural concrete with recycled plastic waste as a partial replacement for sand. Constr. Build. Mater. 2018, 161, 63–69. [Google Scholar] [CrossRef]

- Ferreira, L.; de Brito, J.; Saikia, N. Influence of curing conditions on the mechanical performance of concrete containing recycled plastic aggregate. Constr. Build. Mater. 2012, 36, 196–204. [Google Scholar] [CrossRef]

- Saikia, N.; Brito, J.d. Waste polyethylene terephthalate as an aggregate in concrete. Mater. Res. 2013, 16, 341–350. [Google Scholar] [CrossRef] [Green Version]

- Kan, A.; Demirboğa, R. A new technique of processing for waste-expanded polystyrene foams as aggregates. J. Mater. Process. Technol. 2009, 209, 2994–3000. [Google Scholar] [CrossRef]

- Hamdani-Devarennes, S.; el Hage, R.; Dumazert, L.; Sonnier, R.; Ferry, L.; Lopez-Cuesta, J.M.; Bert, C. Water-based flame retardant coating using nano-boehmite for expanded polystyrene (EPS) foam. Prog. Org. Coat. 2016, 99, 32–46. [Google Scholar] [CrossRef]

- Ganiron, T.U., Jr. Sustainable Management of Waste Coconut Shells as Aggregates in Concrete Mixture. J. Eng. Sci. Technol. Rev. 2013, 6, 7–14. [Google Scholar] [CrossRef]

- Yerramala, A.; Ramachandrudu, C. Properties of Concrete with Coconut Shells as Aggregate Replacement. Int. J. Eng. Invent. 2012, 1, 21–31. [Google Scholar]

- Olanipekun, E.A.; Olusola, K.O.; Ata, O. A comparative study of concrete properties using coconut shell and palm kernel shell as coarse aggregates. Build. Environ. 2006, 41, 297–301. [Google Scholar] [CrossRef]

- Gunasekaran, K.; Ramasubramani, R.; Annadurai, R.; Chandar, S.P. Study on reinforced lightweight coconut shell concrete beam behavior under torsion. Mater. Des. 2014, 57, 374–382. [Google Scholar] [CrossRef]

- Danso, H. Properties of Coconut, Oil Palm and Bagasse Fibres: As Potential Building Materials. Procedia Eng. 2017, 200, 1–9. [Google Scholar] [CrossRef]

- Ali, M.; Li, X.; Chouw, N. Experimental investigations on bond strength between coconut fibre and concrete. Mater. Des. 2013, 44, 596–605. [Google Scholar] [CrossRef]

- Binici, H.; Yucegok, F.; Aksogan, O.; Kaplan, H. Effect of corncob, wheat straw, and plane leaf ashes as mineral admixtures on concrete durability. J. Mater. Civ. Eng. 2008, 20, 478–483. [Google Scholar] [CrossRef]

- Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z.; Yap, S.P.; Lee, S.C. Green concrete partially comprised of farming waste residues: A review. J. Clean. Prod. 2016, 117, 122–138. [Google Scholar] [CrossRef]

- Qudoos, A.; Kim, H.G.; Atta ur, R.; Ryou, J.-S. Effect of mechanical processing on the pozzolanic efficiency and the microstructure development of wheat straw ash blended cement composites. Constr. Build. Mater. 2018, 193, 481–490. [Google Scholar] [CrossRef]

- Ataie, F.F.; Riding, K.A. Thermochemical Pretreatments for Agricultural Residue Ash Production for Concrete. J. Mater. Civ. Eng. 2013, 25, 1703–1711. [Google Scholar] [CrossRef]

- Aksoğan, O.; Binici, H.; Ortlek, E. Durability of concrete made by partial replacement of fine aggregate by colemanite and barite and cement by ashes of corn stalk, wheat straw and sunflower stalk ashes. Constr. Build. Mater. 2016, 106, 253–263. [Google Scholar] [CrossRef]

- Biricik, H.; Aköz, F.; Türker, F.; Berktay, I. Resistance to magnesium sulfate and sodium sulfate attack of mortars containing wheat straw ash. Cem. Concr. Res. 2000, 30, 1189–1197. [Google Scholar] [CrossRef]

- Al-Akhras, N.M.; Abu-Alfoul, B.A. Effect of wheat straw ash on mechanical properties of autoclaved mortar. Cem. Concr. Res. 2002, 32, 859–863. [Google Scholar] [CrossRef]

- Al-Akhras, N.M.; Al-Akhras, K.M.; Attom, M.F. Thermal cycling of wheat straw ash concrete. Proc. Inst. Civ. Eng. Constr. Mater. 2008, 161, 9–15. [Google Scholar] [CrossRef]

- National Bureau of Statistics of China. China Statistical Yearbook 2013; China Statistics Press: Beijing, China, 2013.

- Lertwattanaruk, P.; Makul, N.; Siripattarapravat, C. Utilization of ground waste seashells in cement mortars for masonry and plastering. J. Environ. Manag. 2012, 111, 133–141. [Google Scholar] [CrossRef] [PubMed]

- Yang, E.-I.; Yi, S.-T.; Leem, Y.-M. Effect of oyster shell substituted for fine aggregate on concrete characteristics: Part I: Fundamental properties. Cem. Concr. Res. 2005, 35, 2175–2182. [Google Scholar] [CrossRef]

- Kuo, W.-T.; Wang, H.-Y.; Shu, C.-Y.; Su, D.-S. Engineering properties of controlled low-strength materials containing waste oyster shells. Constr. Build. Mater. 2013, 46, 128–133. [Google Scholar] [CrossRef] [Green Version]

- Eo, S.-H.; Yi, S.-T. Effect of oyster shell as an aggregate replacement on the characteristics of concrete. Mag. Concr. Res. 2015, 67, 833–842. [Google Scholar] [CrossRef]

- Yoon, H.; Park, S.; Lee, K.; Park, J. Oyster shell as substitute for aggregate in mortar. Waste Manag. Res. 2004, 22, 158–170. [Google Scholar] [CrossRef] [PubMed]

- Martínez-García, C.; González-Fonteboa, B.; Martínez-Abella, F.; López-Carro, D. Performance of mussel shell as aggregate in plain concrete. Constr. Build. Mater. 2017, 139, 570–583. [Google Scholar] [CrossRef]

- Chin-Peow, W.; Poi-Ngian, S.; Tahir, M.M.; Kueh, A.; Hong, B. Compressive strength of ground waste seashells in cement mortars for masonry and plastering. Appl. Mech. Mater. 2015, 727–728, 167–170. [Google Scholar]

- Li, G.Y.; Zhao, X.H. Properties of concrete incorporating fly ash and ground granulated blast-furnace slag. Cem. Concr. Compos. 2003, 25, 293–299. [Google Scholar] [CrossRef]

- Pu, L.; Unluer, C. Durability of carbonated MgO concrete containing fly ash and ground granulated blast-furnace slag. Constr. Build. Mater. 2018, 192, 403–415. [Google Scholar] [CrossRef]

- ACI Committee 318. Building Code Requirements for Structural Concrete and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2011; p. 503. [Google Scholar]

- Inti, S.; Sharma, M.; Tandon, V. Ground Granulated Blast Furnace Slag (GGBS) and Rice Husk Ash (RHA) Uses in the Production of Geopolymer Concrete. In Proceedings of the Geo-Chicago 2016, Chicago, IL, USA, 14–18 August 2016; pp. 621–632. [Google Scholar]

- Ramani, P.V.; Chinnaraj, P.K. Geopolymer concrete with ground granulated blast furnace slag and black rice husk ash. Građevinar 2015, 67, 741–747. [Google Scholar]

- Mehta, A.; Siddique, R. Sustainable geopolymer concrete using ground granulated blast furnace slag and rice husk ash: Strength and permeability properties. J. Clean. Prod. 2018, 205, 49–57. [Google Scholar] [CrossRef]

- Jayalakshmi Sasidharan Nair, B.J. Study of Properties of Concrete using GGBS and Recycled Concrete Aggregates. Int. J. Eng. Res. Technol. (IJERT) 2016. [Google Scholar] [CrossRef]

- Radonjanin, V.; Malešev, M.; Marinković, S.; Al Malty, A.E.S. Green recycled aggregate concrete. Constr. Build. Mater. 2013, 47, 1503–1511. [Google Scholar] [CrossRef]

- Kim, K.; Shin, M.; Cha, S. Combined effects of recycled aggregate and fly ash towards concrete sustainability. Constr. Build. Mater. 2013, 48, 499–507. [Google Scholar] [CrossRef]

- Sunayana, S.; Barai, S.V. Recycled aggregate concrete incorporating fly ash: Comparative study on particle packing and conventional method. Constr. Build. Mater. 2017, 156, 376–386. [Google Scholar] [CrossRef]

- Darsanasiri, A.G.N.D.; Matalkah, F.; Ramli, S.; Al-Jalode, K.; Balachandra, A.; Soroushian, P. Ternary alkali aluminosilicate cement based on rice husk ash, slag and coal fly ash. J. Build. Eng. 2018, 19, 36–41. [Google Scholar] [CrossRef]

- Isaia, G.C.; Gastaldini, A.L.G.; Moraes, R. Physical and pozzolanic action of mineral additions on the mechanical strength of high-performance concrete. Cem. Concr. Compos. 2003, 25, 69–76. [Google Scholar] [CrossRef]

- Tuncan, M.; Karasu, B.; Yalçın, M. The Suitability for Using Glass and Fly Ash in Portland Cement Concrete. In Proceedings of the 11th International Society of Offshore and Polar Engineers (ISOPE) Congress, Stavenger, Norway, 17–22 June 2001; Volume 4. [Google Scholar]

- Berry, M.; Stephens, J.; Cross, D. Performance of 100% Fly Ash Concrete with Recycled Glass Aggregate. ACI Mater. J. 2011, 108, 378–384. [Google Scholar]

- Lam, C.S.; Poon, C.S.; Chan, D. Enhancing the performance of pre-cast concrete blocks by incorporating waste glass—ASR consideration. Cem. Concr. Compos. 2007, 29, 616–625. [Google Scholar] [CrossRef]

- Madandoust, R.; Ghavidel, R. Mechanical properties of concrete containing waste glass powder and rice husk ash. Biosyst. Eng. 2013, 116, 113–119. [Google Scholar] [CrossRef]

- Younes, M.M.; Abdel-Rahman, H.A.; Khattab, M.M. Utilization of rice husk ash and waste glass in the production of ternary blended cement mortar composites. J. Build. Eng. 2018, 20, 42–50. [Google Scholar] [CrossRef]

- Popovics, S. Concrete Materials, 2nd ed.; William Andrew: Norwich, NY, USA, 1992. [Google Scholar]

- Yu, Z.; Lau, D. Nano- and mesoscale modeling of cement matrix. Nanoscale Res. Lett. 2015, 10, 173. [Google Scholar] [CrossRef] [PubMed]

- Qin, R.; Hao, H.; Rousakis, T.; Lau, D. Effect of shrinkage reducing admixture on new-to-old concrete interface. Compos. Part B Eng. 2019, 167, 346–355. [Google Scholar] [CrossRef]

- Bruntland, Report of the World Commission on Environment and Development; Our Common Future: Dordrecht, The Netherlands, 1987.

- Li, Z. Advanced Concrete Technology; John Wiley & Sons, Inc: Hoboken, NJ, USA, 2011; Volume 1. [Google Scholar]

- Harbec, D.; Bahri, H.; Tagnit-Hamou, A.; Gitzhofer, F. New Silica Fume from Recycled Waste Glass; Springer: Cham, Switzerland, 2014; pp. 161–190. [Google Scholar]

- Sanchez, F.; Sobolev, K. Nanotechnology in concrete—A review. Constr. Build. Mater. 2010, 24, 2060–2071. [Google Scholar] [CrossRef]

- Thomas, J.J.; Jennings, H.M.; Chen, J.J. Influence of Nucleation Seeding on the Hydration Mechanisms of Tricalcium Silicate and Cement. J. Phys. Chem. C 2009, 113, 4327–4334. [Google Scholar] [CrossRef] [Green Version]

- Land, G.; Stephan, D. Preparation and Application of Nanoscaled C-S-H as an Accelerator for Cement Hydration. In Nanotechnology in Construction; Konstantin, S., Surendra, P.S., Eds.; Springer International Publishing: Prague, Czech Republic, 2015; pp. 117–122. [Google Scholar]

- Yu, Z.; Zhou, A.; Lau, D. Mesoscopic packing of disk-like building blocks in calcium silicate hydrate. Sci. Rep. 2016, 6, 36967. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gaitero, J.J.; Campillo, I.; Guerrero, A. Reduction of the calcium leaching rate of cement paste by addition of silica nanoparticles. Cem. Concr. Res. 2008, 38, 1112–1118. [Google Scholar] [CrossRef] [Green Version]

- Qing, Y.; Zenan, Z.; Deyu, K.; Rongshen, C. Influence of nano-SiO2 addition on properties of hardened cement paste as compared with silica fume. Constr. Build. Mater. 2007, 21, 539–545. [Google Scholar] [CrossRef]

- Flores Vivian, I.; Sobolev, K. The Effect of Nano-SiO2 on Cement Hydration. In Nanotechnology in Construction; Konstantin, S., Surendra, P.S., Eds.; Springer International Publishing: Prague, Czech Republic, 2015; pp. 167–172. [Google Scholar]

- Yehdego, T.; Peethamparan, S. The Role of Nano Silica in Modifying the Early Age Hydration Kinetics of Binders Containing High Volume Fly Ashes. In Nanotechnology in Construction; Springer International Publishing: Berlin, Germany, 2015; pp. 399–405. [Google Scholar]

- Yaphary, Y.L.; Yu, Z.; Lam, R.H.W.; Lau, D. Effect of triethanolamine on cement hydration toward initial setting time. Constr. Build. Mater. 2017, 141, 94–103. [Google Scholar] [CrossRef]

- Foldyna, J.; Foldyna, V.; Zeleňák, M. Dispersion of Carbon Nanotubes for Application in Cement Composites. Procedia Eng. 2016, 149, 94–99. [Google Scholar] [CrossRef] [Green Version]

- Peigney, A.; Laurent, C.; Flahaut, E.; Bacsa, R.R.; Rousset, A. Specific surface area of carbon nanotubes and bundles of carbon nanotubes. Carbon 2001, 39, 507–514. [Google Scholar] [CrossRef] [Green Version]

- Petrunin, S.; Vaganov, V.; Sobolev, K. The Effect of Functionalized Carbon Nanotubes on Phase Composition and Strength of Composites. In Nanotechnology in Construction; Springer International Publishing: Berlin, Germany, 2015; pp. 245–251. [Google Scholar]

- Sindu, B.S.; Sasmal, S. Properties of carbon nanotube reinforced cement composite synthesized using different types of surfactants. Constr. Build. Mater. 2017, 155, 389–399. [Google Scholar] [CrossRef]

- Abu Al-Rub, R.K.; Ashour, A.I.; Tyson, B.M. On the aspect ratio effect of multi-walled carbon nanotube reinforcements on the mechanical properties of cementitious nanocomposites. Constr. Build. Mater. 2012, 35, 647–655. [Google Scholar] [CrossRef]

- Kang, S.-T.; Seo, J.-Y.; Park, S.-H. The characteristics of CNT/cement composites with acid-treated MWCNTs. Adv. Mater. Sci. Eng. 2015, 2015, 308725. [Google Scholar] [CrossRef]

- Kaynakli, O. A review of the economical and optimum thermal insulation thickness for building applications. Renew. Sustain. Energy Rev. 2012, 16, 415–425. [Google Scholar] [CrossRef]

- Zhou, A.; Wong, K.-W.; Lau, D. Thermal insulating concrete wall panel design for sustainable built environment. Sci. World J. 2014, 2014, 279592. [Google Scholar] [CrossRef]

- Zhou, A.; Yu, Z.; Chow, C.L.; Lau, D. Enhanced solar spectral reflectance of thermal coatings through inorganic additives. Energy Build. 2017, 138, 641–647. [Google Scholar] [CrossRef]

- Meng, F.; Elsahati, M.; Liu, J.; Richards, R.F. Thermal resistance between amorphous silica nanoparticles. J. Appl. Phys. 2017, 121, 194302. [Google Scholar] [CrossRef]

- Lau, D.; Qiu, Q.; Zhou, A.; Chow, C.L. Long term performance and fire safety aspect of FRP composites used in building structures. Constr. Build. Mater. 2016, 126, 573–585. [Google Scholar] [CrossRef]

| Size and Compounds | Cement | FA Class F | FA Class C | RHA | SF | WG | GGBFS |

|---|---|---|---|---|---|---|---|

| Particle size (µm) | 5–60 [40] 0.1–110 [41] 2–160 [42] | 2–20 [40] ≤75 [10] 0.05–100 [43] 1–200 [44] | av. 3.8 [45] av. 11.5 [46] ≤45 [16,47] | 0.3–2 [40] av. 0.1 [48] <1 [49] | ≤70 [22,50] ≤90 [24] av. 45 [51,52] | 0.1–200 [41,53] | |

| SiO2 | 20–22 | 50–68 | 38–46 | 75–91 | 85–97 | 64–72 | 34–42 |

| Al2O3 | 4.0–6.0 | 17–28 | 16–22 | 0–3.9 | 0.2–1.1 | 1.0–10 | 7–16 |

| Fe2O3 | 2.4–3.5 | 4–14 | 6–14 | 0.1–1.1 | 0.4–2.0 | 0.1–1.6 | 0.3–1.5 |

| CaO | 61–65 | 1.6–9.3 | 19–25 | 0.5–3.8 | 0.3–0.7 | 8.5–15 | 32–45 |

| Na2O | 0.1–0.4 | 0.1–1.6 | 0.03–1.6 | 0.1–1.1 | 0.1–0.7 | 12–18 | 0.2–0.4 |

| K2O | 0–0.9 | 0.4–2.6 | 0.2–1.4 | 1.0–3.8 | 0.3–1.3 | 0.4–1.6 | 0–0.8 |

| TiO2 | 0–0.24 | 1.4–1.6 | 0–0.1 | 0–0.1 | 0–1.0 | ||

| MgO | 1.0–2.6 | 1–5.2 | 3–7.8 | 0.2–0.8 | 0.0–1.6 | 0.9–3.9 | 3.2–15 |

| P2O5 | 0–0.9 | 0.4–1.5 | 0.5–2.1 | 0–0.1 | 0–0.7 | ||

| SO3 | 2.0–4.7 | 0.2–2.0 | 1.6–3.3 | 0–1.2 | 0.0–1.3 | 0.1–0.4 | 0.01–1.0 |

| MnO | 0.1 | 0-0.7 | 0–1.0 | ||||

| Loss of ignition (LOI) | 0.1–2.4 | 0.3–3.9 | 0.2–1.3 | 1.8–8.6 | 0.0–2.8 | 0.8 | 0.04–0.3 |

| References for chemical compounds | [8,9,23,41,45,51,54,55,56,57,58,59] | [8,9,11,40,55,60,61,62,63] | [9,11,40,63] | [12,16,17,45,56,57,64,65,66,67,68,69,70] | [17,49,71,72,73] | [22,23,24,50,51,52] | [39,41,53,58,59,74,75,76] |

| Material | Main Microscopic Feature | Reference for SEM Images |

|---|---|---|

| FA | Most of particles have spherical shapes | [40] |

| RHA | Particles have irregular shapes with many micro-pores. This can explain the higher porosity of this material | [70] |

| SF | Particles are found smaller than FA and RHA in most of the reviewed cases, they can rarely be found at bigger sizes | [43] |

| GGBFS | Particles are angular in shape, and their surfaces are rough | [75] |

| WG | Particles appear to have angular shapes with narrow sizes | [50] |

| P | Particles are heterogenous in shapes and textures | [77] |

| w/b | Cement Content (kg/m3) | Reference Compressive Strength at Different Ages (fc’reference) (MPa) | Substitution Ratio of Cement (%) | Substitution Content (kg/m3) | fc’with substitutes/fc’reference | ||||

|---|---|---|---|---|---|---|---|---|---|

| 7 | 28 | 90 | 7 | 28 | 90 | ||||

| 0.25 | 400 | 86.0 | 92.0 | 91.5 | 8 | 32 | 1.02 | 1.05 | 1.08 |

| 15 | 60 | 0.97 | 1.10 | 1.13 | |||||

| 0.35 | 64.0 | 66.0 | 79.0 | 8 | 32 | 0.97 | 1.14 | 1.14 | |

| 15 | 60 | 0.94 | 1.19 | 1.18 | |||||

| 0.40 | 352 | 33.2 | 47.5 | 55.1 | 20 | 70 | 0.91 | 1.03 | 1.08 |

| 30 | 106 | 0.91 | 0.95 | 1.00 | |||||

| 0.28 | 500 | 66.8 | 81.1 | 50 | 250 | 0.52 | 0.67 | ||

| w/b | Cement Content (kg/m3) | Reference Compressive Strength (fc’reference) (MPa) | Substitution Ratio of Cement (%) | Substitution Content (kg/m3) | fc’with substitutes/fc’reference |

|---|---|---|---|---|---|

| 0.53 | 383 | 37.0 | 5 | 19 | 1.05 |

| 10 | 38 | 1.16 | |||

| 15 | 57 | 1.26 | |||

| 20 | 77 | 1.08 | |||

| 25 | 96 | 1.04 | |||

| 30 | 115 | 1.00 | |||

| 35 | 134 | 0.97 | |||

| 0.35 | 571 | 56.0 | 10 | 57 | 1.09 |

| 20 | 114 | 1.07 | |||

| 30 | 171 | 0.96 | |||

| 0.30 | 550 | 63.5 | 10 | 55 | 1.15 |

| 15 | 82 | 1.18 | |||

| 20 | 110 | 1.23 |

| w/b | Cement Content (kg/m3) | Reference Compressive Strength at Different Ages (fc’reference) (MPa) | Substitution Ratio of Cement (%) | Substitution Content (kg/m3) | fc’with substitutes/fc’reference | ||||

|---|---|---|---|---|---|---|---|---|---|

| 7 | 28 | 90 | 7 | 28 | 90 | ||||

| 0.43 | 440 | 45 | 4.5 | 20 | 1.13 | ||||

| 9 | 40 | 1.09 | |||||||

| 0.23 | 980 | 82 | 10 | 88 | 1.21 | ||||

| 20 | 160 | 1.23 | |||||||

| 30 | 219 | 1.15 | |||||||

| 0.35 | 425 | 57 | 65 | 74 | 10 | 45 | 1.23 | 1.48 | 1.27 |

| w/c | Cement Content (kg/m3) | Coarse Aggregates Content (kg/m3) | Reference Compressive Strength (fc’reference) (MPa) | Substitution Ratio of Coarse Aggregates (%) | Substitution Content (kg/m3) | fc’with substitutes/fc’reference |

|---|---|---|---|---|---|---|

| 0.43 | 430 | 1295 | 35.9 | 30 | 374 | 0.95 |

| 50 | 609 | 0.82 | ||||

| 70 | 832 | 0.84 | ||||

| 100 | 1149 | 0.74 | ||||

| 0.4 | 300 | 1366 | 34.8 | 25 | 290 | 0.95 |

| 50 | 570 | 0.92 | ||||

| 100 | 1150 | 0.84 | ||||

| 0.5 | 300 | 1314 | 35.8 | 25 | 280 | 0.97 |

| 50 | 550 | 0.92 | ||||

| 100 | 1100 | 0.84 | ||||

| 0.4 | 450 | 1179 | 52.8 | 25 | 250 | 0.95 |

| 50 | 500 | 0.89 | ||||

| 100 | 990 | 0.81 | ||||

| 0.5 | 450 | 1100 | 41.5 | 25 | 230 | 0.97 |

| 50 | 460 | 0.92 | ||||

| 100 | 920 | 0.83 | ||||

| 0.55 | 298 | 1361 | 34.6 | 100 | 1361 | 0.76 |

| w/b | Cement Content (kg/m3) | Reference Compressive Strength at Different Ages (fc’reference) (MPa) | Substitution Ratio of Cement (%) | Substitution Content (kg/m3) | fc’with substitutes/fc’reference | ||||

|---|---|---|---|---|---|---|---|---|---|

| 7 | 28 | 90 | 7 | 28 | 90 | ||||

| 0.3 | 400 | 73.8 | 80.7 | 85.2 | 20 | 80 | 0.93 | 1.01 | 1.06 |

| 40 | 160 | 0.87 | 1.02 | 1.04 | |||||

| 60 | 240 | 0.79 | 0.96 | 0.93 | |||||

| 80 | 320 | 0.66 | 0.84 | 0.89 | |||||

| 0.4 | 400 | 53.7 | 63.9 | 67.9 | 20 | 80 | 0.96 | 1.03 | 1.07 |

| 40 | 160 | 0.94 | 1.05 | 1.15 | |||||

| 60 | 240 | 0.85 | 0.96 | 1.11 | |||||

| 80 | 320 | 0.72 | 0.83 | 0.84 | |||||

| 0.5 | 400 | 34.9 | 51.4 | 56.8 | 20 | 80 | 0.98 | 1.02 | 1.08 |

| 40 | 160 | 0.82 | 1.00 | 1.02 | |||||

| 60 | 240 | 0.68 | 0.78 | 0.87 | |||||

| 80 | 320 | 0.54 | 0.49 | 0.56 | |||||

| 0.56 | 415 | 27.0 | 37.0 | 30 | 146 | 0.89 | 1.05 | ||

| 70 | 319 | 0.81 | 1.01 | ||||||

| w/b | Cement Content (kg/m3) | Reference Compressive Strength (fc’reference) (MPa) | Substitution Ratio of Cement (%) | Substitution Content (kg/m3) | fc’with substitutes/fc’reference |

|---|---|---|---|---|---|

| 0.500 | 350 | 32.20 | 5 | 17.5 | 1.05 |

| 10 | 35.0 | 1.00 | |||

| 15 | 52.0 | 0.91 | |||

| 20 | 70.0 | 0.87 | |||

| 25 | 87.5 | 0.85 | |||

| 0.350 | 450 | 44.32 | 5 | 22.5 | 1.02 |

| 10 | 45.0 | 1.05 | |||

| 15 | 67.5 | 0.91 | |||

| 20 | 90.0 | 0.89 | |||

| 25 | 112.5 | 0.86 | |||

| 0.485 | 300 | 43.00 | 10 | 30.0 | 0.93 |

| 15 | 45.0 | 0.88 | |||

| 20 | 60.0 | 0.85 | |||

| 25 | 75.0 | 0.80 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Mansour, A.; Chow, C.L.; Feo, L.; Penna, R.; Lau, D. Green Concrete: By-Products Utilization and Advanced Approaches. Sustainability 2019, 11, 5145. https://doi.org/10.3390/su11195145

Al-Mansour A, Chow CL, Feo L, Penna R, Lau D. Green Concrete: By-Products Utilization and Advanced Approaches. Sustainability. 2019; 11(19):5145. https://doi.org/10.3390/su11195145

Chicago/Turabian StyleAl-Mansour, Ahmed, Cheuk Lun Chow, Luciano Feo, Rosa Penna, and Denvid Lau. 2019. "Green Concrete: By-Products Utilization and Advanced Approaches" Sustainability 11, no. 19: 5145. https://doi.org/10.3390/su11195145

APA StyleAl-Mansour, A., Chow, C. L., Feo, L., Penna, R., & Lau, D. (2019). Green Concrete: By-Products Utilization and Advanced Approaches. Sustainability, 11(19), 5145. https://doi.org/10.3390/su11195145