Current Status, Emerging Challenges, and Future Prospects of Industrial Symbiosis in Portugal

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Industrial Symbiosis in Portugal

3.1.1. Current Status

3.1.2. Portuguese Legislative Context Related to Industrial Symbiosis

3.1.3. Industrial Symbiosis Networks in Portugal

3.2. Current Development, Challenges, and Future Prospects

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Papetti, A.; Menghi, R.; Di Domizio, G.; Germani, M.; Marconi, M. Resources value mapping: A method to assess the resource efficiency of manufacturing systems. Appl. Energy 2019, 249, 326–342. [Google Scholar] [CrossRef]

- González-Val, R.; Pueyo, F. Natural resources, economic growth and geography. Econ. Modell. 2019. [Google Scholar] [CrossRef]

- Liu, X.; Bae, J. Urbanization and industrialization impact of CO2 emissions in China. J. Clean. Prod. 2018, 172, 178–186. [Google Scholar] [CrossRef]

- Li, K.; Lin, B. Impacts of urbanization and industrialization on energy consumption/CO2 emissions: Does the level of development matter? Renew Sust. Energ. Rev. 2015, 52, 1107–1122. [Google Scholar] [CrossRef]

- Dong, F.; Wang, Y.; Su, B.; Hua, Y.; Zhang, Y. The process of peak CO2 emissions in developed economies: A perspective of industrialization and urbanization. Resour. Conserv. Recy. 2019, 141, 61–75. [Google Scholar] [CrossRef]

- De Abreu, M.C.S.; Ceglia, D. On the implementation of a circular economy: The role of institutional capacity-building through industrial symbiosis. Resour. Conserv. Recy. 2018, 138, 99–109. [Google Scholar] [CrossRef]

- Shi, X.; Li, X. A symbiosis-based life cycle management approach for sustainable resource flows of industrial ecosystem. J. Clean. Prod. 2019, 226, 324–335. [Google Scholar] [CrossRef]

- Lowe, E.A.; Evans, L.K. Industrial ecology and industrial ecosystems. J. Clean. Prod. 1995, 3, 47–53. [Google Scholar] [CrossRef]

- Ehrenfeld, J.R. Would Industrial Ecology Exist without Sustainability in the Background? J. Ind. Ecol. 2007, 11, 73–84. [Google Scholar] [CrossRef]

- Frosch, R.A.; Gallopoulos, N.E. Strategies for Manufacturing. SA 1989, 261, 144–153. [Google Scholar] [CrossRef]

- Zhang, B.; Du, Z.; Wang, Z. Carbon reduction from sustainable consumption of waste resources: An optimal model for collaboration in an industrial symbiotic network. J. Clean. Prod. 2018, 196, 821–828. [Google Scholar] [CrossRef]

- Cui, H.; Liu, C.; Côté, R.; Liu, W. Understanding the Evolution of Industrial Symbiosis with a System Dynamics Model: A Case Study of Hai Hua Industrial Symbiosis, China. Sustainability 2018, 10, 3873. [Google Scholar] [CrossRef]

- Park, J.; Park, J.-M.; Park, H.-S. Scaling-Up of Industrial Symbiosis in the Korean National Eco-Industrial Park Program: Examining Its Evolution over the 10 Years between 2005–2014. J. Ind. Ecol. 2019, 23, 197–207. [Google Scholar] [CrossRef]

- Morales, M.; Diemer, A. Industrial Symbiosis Dynamics, a Strategy to Accomplish Complex Analysis: The Dunkirk Case Study. Sustainability 2019, 11, 1971. [Google Scholar] [CrossRef]

- Chertow, M.R. Industrial Symbiosis: Literature and Taxonomy. Annu. Rev. Energy. Environ. 2000, 25, 313–337. [Google Scholar] [CrossRef]

- Chertow, M.R.; Ashton, W.S.; Espinosa, J.C. Industrial Symbiosis in Puerto Rico: Environmentally Related Agglomeration Economies. Reg. Stud. 2008, 42, 1299–1312. [Google Scholar] [CrossRef]

- Valentine, S.V. Kalundborg Symbiosis: Fostering progressive innovation in environmental networks. J. Clean. Prod. 2016, 118, 65–77. [Google Scholar] [CrossRef]

- Zhang, X.; Chai, L. Structural features and evolutionary mechanisms of industrial symbiosis networks: Comparable analyses of two different cases. J. Clean. Prod. 2019, 213, 528–539. [Google Scholar] [CrossRef]

- Velenturf, A.P.M. Promoting industrial symbiosis: Empirical observations of low-carbon innovations in the Humber region, UK. J. Clean. Prod. 2016, 128, 116–130. [Google Scholar] [CrossRef]

- Mirata, M. Experiences from early stages of a national industrial symbiosis programme in the UK: Determinants and coordination challenges. J. Clean. Prod. 2004, 12, 967–983. [Google Scholar] [CrossRef]

- Paquin, R.L.; Howard-Grenville, J. The Evolution of Facilitated Industrial Symbiosis. J. Ind. Ecol. 2012, 16, 83–93. [Google Scholar] [CrossRef] [Green Version]

- Harris, S.; Pritchard, C. Industrial Ecology as a learning process in business strategy. PIE 2004, 1, 89. [Google Scholar] [CrossRef]

- Martin, M. Quantifying the environmental performance of an industrial symbiosis network of biofuel producers. J. Clean. Prod. 2015, 102, 202–212. [Google Scholar] [CrossRef]

- Patricio, J.; Axelsson, L.; Blomé, S.; Rosado, L. Enabling industrial symbiosis collaborations between SMEs from a regional perspective. J. Clean. Prod. 2018, 202, 1120–1130. [Google Scholar] [CrossRef]

- Røyne, F.; Hackl, R.; Ringström, E.; Berlin, J. Environmental Evaluation of Industry Cluster Strategies with a Life Cycle Perspective: Replacing Fossil Feedstock with Forest-Based Feedstock and Increasing Thermal Energy Integration. J. Ind. Ecol. 2018, 22, 694–705. [Google Scholar] [CrossRef]

- Spekkink, W. Building capacity for sustainable regional industrial systems: An event sequence analysis of developments in the Sloe Area and Canal Zone. J. Clean. Prod. 2015, 98, 133–144. [Google Scholar] [CrossRef]

- Baldassarre, B.; Schepers, M.; Bocken, N.; Cuppen, E.; Korevaar, G.; Calabretta, G. Industrial Symbiosis: Towards a design process for eco-industrial clusters by integrating Circular Economy and Industrial Ecology perspectives. J. Clean. Prod. 2019, 216, 446–460. [Google Scholar] [CrossRef]

- Schieb, P.-A.; Lescieux-Katir, H.; Thénot, M.; Clément-Larosière, B. Industrial Symbiosis at the Bazancourt-Pomacle Biorefinery. In Biorefinery 2030: Future Prospects for the Bioeconomy; Schieb, P.-A., Lescieux-Katir, H., Thénot, M., Clément-Larosière, B., Eds.; Springer: Berlin/Heidelberg, Germany, 2015; pp. 67–80. ISBN 978-3-662-47374-0. [Google Scholar]

- Sokka, L.; Pakarinen, S.; Melanen, M. Industrial symbiosis contributing to more sustainable energy use—An example from the forest industry in Kymenlaakso, Finland. J. Clean. Prod. 2011, 19, 285–293. [Google Scholar] [CrossRef]

- Sokka, L.; Lehtoranta, S.; Nissinen, A.; Melanen, M. Analyzing the Environmental Benefits of Industrial Symbiosis: Life Cycle Assessment Applied to a Finnish Forest Industry Complex. J. Ind. Ecol. 2011, 15, 137–155. [Google Scholar] [CrossRef]

- Daddi, T.; Nucci, B.; Iraldo, F. Using Life Cycle Assessment (LCA) to measure the environmental benefits of industrial symbiosis in an industrial cluster of SMEs. J. Clean. Prod. 2017, 147, 157–164. [Google Scholar] [CrossRef]

- Taddeo, R.; Simboli, A.; Morgante, A.; Erkman, S. The Development of Industrial Symbiosis in Existing Contexts. Experiences from Three Italian Clusters. Ecol. Econ. 2017, 139, 55–67. [Google Scholar] [CrossRef]

- Neves, A.; Godina, R.; Carvalho, H.; Azevedo, S.G.; Matias, J.C. Industrial Symbiosis Initiatives in United States of America and Canada: Current Status and Challenges. In Proceedings of the 2019 8th International Conference on Industrial Technology and Management (ICITM), Institute of Electrical and Electronics Engineers (IEEE), Cambridge, UK; 2019; pp. 247–251. [Google Scholar]

- Shi, L. Marian Chertow Organizational Boundary Change in Industrial Symbiosis: Revisiting the Guitang Group in China. Sustainability 2017, 9, 1085. [Google Scholar]

- Song, X.; Geng, Y.; Dong, H.; Chen, W. Social network analysis on industrial symbiosis: A case of Gujiao eco-industrial park. J. Clean. Prod. 2018, 193, 414–423. [Google Scholar] [CrossRef]

- Park, H.-S.; Behera, S.K. Methodological aspects of applying eco-efficiency indicators to industrial symbiosis networks. J. Clean. Prod. 2014, 64, 478–485. [Google Scholar] [CrossRef]

- Kim, H.-W.; Ohnishi, S.; Fujii, M.; Fujita, T.; Park, H.-S. Evaluation and Allocation of Greenhouse Gas Reductions in Industrial Symbiosis. J. Ind. Ecol. 2018, 22, 275–287. [Google Scholar] [CrossRef]

- Chen, X.; Fujita, T.; Ohnishi, S.; Fujii, M.; Geng, Y. The Impact of Scale, Recycling Boundary, and Type of Waste on Symbiosis and Recycling: An Empirical Study of Japanese Eco-Towns. J. Ind. Ecol. 2012, 16, 129–141. [Google Scholar] [CrossRef]

- Ohnishi, S.; Dong, H.; Geng, Y.; Fujii, M.; Fujita, T. A comprehensive evaluation on industrial & urban symbiosis by combining MFA, carbon footprint and emergy methods—Case of Kawasaki, Japan. Ecol. Indic. 2017, 73, 513–524. [Google Scholar]

- Van Berkel, R.; Fujita, T.; Hashimoto, S.; Geng, Y. Industrial and urban symbiosis in Japan: Analysis of the Eco-Town program 1997–2006. J. Environ. Manag. 2009, 90, 1544–1556. [Google Scholar] [CrossRef]

- Krones, J.S. Industrial Symbiosis in the Upper Valley: A Study of the Casella-Hypertherm Recycling Partnership. Sustainability 2017, 9, 806. [Google Scholar] [CrossRef]

- Gonela, V.; Zhang, J.; Osmani, A. Stochastic optimization of sustainable industrial symbiosis based hybrid generation bioethanol supply chains. Comput. Ind. Eng. 2015, 87, 40–65. [Google Scholar] [CrossRef]

- Bansal, P.; McKnight, B. Looking forward, pushing back and peering sideways: Analyzing the sustainability of industrial symbiosis. J. Supply Chain Manag. 2009, 45, 26–37. [Google Scholar] [CrossRef]

- Freitas, L.A.R.U.; Magrini, A. Waste Management in Industrial Construction: Investigating Contributions from Industrial Ecology. Sustainability 2017, 9, 1251. [Google Scholar] [CrossRef]

- Golev, A.; Corder, G.D.; Giurco, D.P. Industrial symbiosis in Gladstone: A decade of progress and future development. J. Clean. Prod. 2014, 84, 421–429. [Google Scholar] [CrossRef]

- Golev, A.; Corder, G.D.; Giurco, D.P. Barriers to Industrial Symbiosis: Insights from the Use of a Maturity Grid. J. Ind. Ecol. 2015, 19, 141–153. [Google Scholar] [CrossRef]

- Cerceau, J.; Mat, N.; Junqua, G.; Lin, L.; Laforest, V.; Gonzalez, C. Implementing industrial ecology in port cities: International overview of case studies and cross-case analysis. J. Clean. Prod. 2014, 74, 1–16. [Google Scholar] [CrossRef]

- Jacobsen, N.B. Industrial Symbiosis in Kalundborg, Denmark: A Quantitative Assessment of Economic and Environmental Aspects. J. Ind. Ecol. 2008, 10, 239–255. [Google Scholar] [CrossRef]

- Dong, L.; Zhang, H.; Fujita, T.; Ohnishi, S.; Li, H.; Fujii, M.; Dong, H. Environmental and economic gains of industrial symbiosis for Chinese iron/steel industry: Kawasaki’s experience and practice in Liuzhou and Jinan. J. Clean. Prod. 2013, 59, 226–238. [Google Scholar] [CrossRef]

- Park, J.; Duque-Hernández, J.; Díaz-Posada, N. Facilitating Business Collaborations for Industrial Symbiosis: The Pilot Experience of the Sustainable Industrial Network Program in Colombia. Sustainability 2018, 10, 3637. [Google Scholar] [CrossRef]

- Walls, J.L.; Paquin, R.L. Organizational Perspectives of Industrial Symbiosis: A Review and Synthesis. O&E 2015, 28, 32–53. [Google Scholar]

- Yu, F.; Han, F.; Cui, Z. Evolution of industrial symbiosis in an eco-industrial park in China. J. Clean. Prod. 2015, 87, 339–347. [Google Scholar] [CrossRef]

- Wu, J.; Qi, H.; Wang, R. Insight into industrial symbiosis and carbon metabolism from the evolution of iron and steel industrial network. J. Clean. Prod. 2016, 135, 251–262. [Google Scholar] [CrossRef]

- Morales, E.M.; Diemer, A.; Cervantes, G.; Carrillo-González, G. “By-product synergy” changes in the industrial symbiosis dynamics at the Altamira-Tampico industrial corridor: 20 Years of industrial ecology in Mexico. Resour. Conserv. Recycl. 2019, 140, 235–245. [Google Scholar] [CrossRef]

- Fang, K.; Dong, L.; Ren, J.; Zhang, Q.; Han, L.; Fu, H. Carbon footprints of urban transition: Tracking circular economy promotions in Guiyang, China. Ecol. Model. 2017, 365, 30–44. [Google Scholar] [CrossRef]

- Wang, Q.; Deutz, P.; Chen, Y. Building institutional capacity for industrial symbiosis development: A case study of an industrial symbiosis coordination network in China. J. Clean. Prod. 2017, 142, 1571–1582. [Google Scholar] [CrossRef]

- Dong, H.; Ohnishi, S.; Fujita, T.; Geng, Y.; Fujii, M.; Dong, L. Achieving carbon emission reduction through industrial & urban symbiosis: A case of Kawasaki. Energy 2014, 64, 277–286. [Google Scholar]

- Behera, S.K.; Kim, J.-H.; Lee, S.-Y.; Suh, S.; Park, H.-S. Evolution of ‘designed’ industrial symbiosis networks in the Ulsan Eco-industrial Park: ‘research and development into business’ as the enabling framework. J. Clean. Prod. 2012, 29, 103–112. [Google Scholar] [CrossRef]

- Fraccascia, L.; Giannoccaro, I.; Albino, V. Business models for industrial symbiosis: A taxonomy focused on the form of governance. Resour. Conserv. Recycl. 2019, 146, 114–126. [Google Scholar] [CrossRef]

- Tao, Y.; Evans, S.; Wen, Z.; Ma, M. The influence of policy on industrial symbiosis from the Firm’s perspective: A framework. J. Clean. Prod. 2019, 213, 1172–1187. [Google Scholar] [CrossRef]

- Fraccascia, L.; Giannoccaro, I.; Albino, V. Efficacy of Landfill Tax and Subsidy Policies for the Emergence of Industrial Symbiosis Networks: An Agent-Based Simulation Study. Sustainability 2017, 9, 521. [Google Scholar] [CrossRef]

- Sun, L.; Spekkink, W.; Cuppen, E.; Korevaar, G. Coordination of Industrial Symbiosis through Anchoring. Sustainability 2017, 9, 549. [Google Scholar] [CrossRef]

- Jiao, W.; Boons, F. Toward a research agenda for policy intervention and facilitation to enhance industrial symbiosis based on a comprehensive literature review. J. Clean. Prod. 2014, 67, 14–25. [Google Scholar] [CrossRef]

- Van Beers, D.; Bossilkov, A.; Lund, C. Development of large scale reuses of inorganic by-products in Australia: The case study of Kwinana, Western Australia. Resour. Conserv. Recycl. 2009, 53, 365–378. [Google Scholar] [CrossRef]

- Simboli, A.; Taddeo, R.; Morgante, A. The potential of Industrial Ecology in agri-food clusters (AFCs): A case study based on valorisation of auxiliary materials. Ecol. Econ. 2015, 111, 65–75. [Google Scholar] [CrossRef]

- Mortensen, L.; Kørnøv, L. Critical factors for industrial symbiosis emergence process. J. Clean. Prod. 2019, 212, 56–69. [Google Scholar] [CrossRef]

- Ramsheva, Y.K.; Prosman, E.J.; Wæhrens, B.V. Dare to make investments in industrial symbiosis? A conceptual framework and research agenda for developing trust. J. Clean. Prod. 2019, 223, 989–997. [Google Scholar] [CrossRef]

- Costa, I.; Ferrão, P. A case study of industrial symbiosis development using a middle-out approach. J. Clean. Prod. 2010, 18, 984–992. [Google Scholar] [CrossRef]

- Patrício, J.; Costa, I.; Niza, S. Urban material cycle closing—Assessment of industrial waste management in Lisbon region. J. Clean. Prod. 2015, 106, 389–399. [Google Scholar] [CrossRef]

- Ferreira, I.D.A.; Fraga, M.D.C.; Godina, R.; Barreiros, M.S.; Carvalho, H. A Proposed Index of the Implementation and Maturity of Circular Economy Practices—The Case of the Pulp and Paper Industries of Portugal and Spain. Sustainability 2019, 11, 1722. [Google Scholar] [CrossRef]

- Ferreira, I.A.; Barreiros, M.S.; Carvalho, H. The industrial symbiosis network of the biomass fluidized bed boiler sand—Mapping its value network. Resour. Conserv. Recy. 2019, 149, 595–604. [Google Scholar] [CrossRef]

- Kokoulina, L.; Ermolaeva, L.; Patala, S.; Ritala, P. Championing processes and the emergence of industrial symbiosis. Reg. Stud. 2019, 53, 528–539. [Google Scholar] [CrossRef]

- Grant, G.B.; Seager, T.P.; Massard, G.; Nies, L. Information and Communication Technology for Industrial Symbiosis. J. Ind. Ecol. 2010, 14, 740–753. [Google Scholar] [CrossRef]

- Eurostat, Statistical Office of the European Communities Greenhouse Gas Emissions, Base Year 1990. Available online: https://ec.europa.eu/eurostat/tgm/table.do?tab=table&init=1&plugin=0&language=en&pcode=t2020_30&tableSelection=1 (accessed on 9 August 2019).

- Presidência do Conselho de Ministros Resolução do Conselho de Ministros n.o 190-A/2017. 2017, p. 6584. Available online: https://dre.pt/home/-/dre/114337039/details/maximized (accessed on 20 July 2019).

- Eurostat, Statistical Office of the European Communities Resource Productivity Statistics. 31 July 2019. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=File:Resource_productivity_statistics_31July2019.xlsx (accessed on 1 August 2019).

- INE, Instituto Nacional de Estatística INE, Instituto Nacional de Estatística. 2017, Industria e Energia. Available online: https://www.ine.pt/xportal/xmain?xpgid=ine_tema&xpid=INE&tema_cod=1611 (accessed on 20 June 2019).

- Eurostat, Statistical Office of the European Communities Waste Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Waste_statistics (accessed on 1 August 2019).

- European Parliament, Council of the European Union. Directive 2018/851 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2008/98/EC on Waste. 2018, p. 109. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32018L0851 (accessed on 20 July 2019).

- European Commission Closing the Loop—An EU Action Plan for the Circular Economy; COM(2015) 614 Final. 2015. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52015DC0614 (accessed on 20 July 2019).

- Ministério do Ambiente e do Ordenamento do Território Decreto-Lei n.o 73/2011. 2011, p. 3251. Available online: https://dre.pt/pesquisa/-/search/670034/details/maximized (accessed on 20 July 2019).

- European Parliament, Council of the European Union. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste. 2008. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32008L0098 (accessed on 20 July 2019).

- Agência Portuguesa do Ambiente. Desclassificação de Resíduos, Resíduos. Available online: http://apambiente.pt/index.php?ref=16&subref=84&sub2ref=957&sub3ref=958 (accessed on 5 June 2019).

- Presidência do Conselho de Ministros Resolução do Conselho de Ministros n.o 38/2016. 2016, p. 2484. Available online: https://dre.pt/home/-/dre/75060358/details/maximized?p_auth=Qimw5Qgh (accessed on 20 July 2019).

- Presidência do Conselho de Ministros Resolução do Conselho de Ministros n.o 11-C/2015. 2015, p. 1610. Available online: https://dre.pt/home/-/dre/66762671/details/maximized (accessed on 20 July 2019).

- Presidência do Conselho de Ministros Resolução do Conselho de Ministros n.o 107/2019. 2019, p. 3208. Available online: https://dre.pt/home/-/dre/122777644/details/maximized (accessed on 20 July 2019).

- Ferrão, P.; Lorena, A.; Ribeiro, P. Industrial Ecology and Portugal’s National Waste Plans. In Taking Stock of Industrial Ecology; Clift, R., Druckman, A., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 275–289. ISBN 978-3-319-20571-7. [Google Scholar]

- Magalhães, B.; Cruz, V.F.; Ascenço, C. Relatório de Boas Práticas de Utilização Eficiente de Recursos e Valorização de Resíduos e Subprodutos; ISQ, Universidade de Évora, Equiporave: Évora, Portugal, 2018; p. 80. Available online: http://alentejocircular.uevora.pt/?publicacao=2014 (accessed on 20 July 2019).

- BCSD. Portugal Business Council for Sustainable Development Portugal (Conselho Empresarial para o Desenvolvimento Sustentável). Available online: https://www.bcsdportugal.org/ (accessed on 20 July 2019).

- Domenech, T.; Bleischwitz, R.; Doranova, A.; Panayotopoulos, D.; Roman, L. Mapping Industrial Symbiosis Development in Europe_ typologies of networks, characteristics, performance and contribution to the Circular Economy. Resour. Conserv. Recy. 2019, 141, 76–98. [Google Scholar] [CrossRef]

- BCSD. Portugal—Conselho Empresarial para o Desenvolvimento Sustentável Sinergias Circulares—Desafios para Portugal; BCSD: Delmar, NY, USA, 2018; p. 52. [Google Scholar]

- ECO.NOMIA. Available online: https://eco.nomia.pt/ (accessed on 20 July 2019).

- Costa, I.S. The Challenge of Industrial Symbiosis—A Scientific Contribution to the Development of Industrial Symbiosis: A Portuguese Case Study. Ph.D. Thesis, Universidade Técnica de Lisboa—Instituto Superior Técnico, Lisboa, Portugal, 2011. [Google Scholar]

- COTEC Portugal. The Circular Economy—Preserving, Optimising and Ensuring Essential Resources for Our Future; COTEC Portugal: Porto, Portugal, 2016; p. 52. [Google Scholar]

- Van der Ploeg, R.; Withagen, C. Green Growth, Green Paradox and the global economic crisis. Environ. Innov. Soc. Tr. 2013, 6, 116–119. [Google Scholar] [CrossRef]

- Geels, F.W. The impact of the financial–economic crisis on sustainability transitions: Financial investment, governance and public discourse. Environ. Innov. Soc. Tr. 2013, 6, 67–95. [Google Scholar] [CrossRef]

- Prieto-Sandoval, V.; Ormazabal, M.; Jaca, C.; Viles, E. Key elements in assessing circular economy implementation in small and medium-sized enterprises. BSE 2018, 27, 1525–1534. [Google Scholar] [CrossRef]

- Costa, I.; Massard, G.; Agarwal, A. Waste management policies for industrial symbiosis development: Case studies in European countries. J. Clean. Prod. 2010, 18, 815–822. [Google Scholar] [CrossRef]

- Mathews, J.A.; Tan, H. Progress Toward a Circular Economy in China. J. Ind. Ecol. 2011, 15, 435–457. [Google Scholar] [CrossRef]

- Shi, H.; Chertow, M.; Song, Y. Developing country experience with eco-industrial parks: A case study of the Tianjin Economic-Technological Development Area in China. J. Clean. Prod. 2010, 18, 191–199. [Google Scholar] [CrossRef]

- Martin, M.; Harris, S. Prospecting the sustainability implications of an emerging industrial symbiosis network. Resour. Conserv. Recycl. 2018, 138, 246–256. [Google Scholar] [CrossRef]

- Vimal, K.; Rajak, S.; Kandasamy, J. Analysis of network design for a circular production system using multi-objective mixed integer linear programming model. J. Manuf. Technol. Manag. 2019, 30, 628–646. [Google Scholar] [CrossRef]

- Chertow, M.; Miyata, Y. Assessing collective firm behavior: Comparing industrial symbiosis with possible alternatives for individual companies in Oahu, HI. BSE 2011, 20, 266–280. [Google Scholar] [CrossRef]

- Lehtoranta, S.; Nissinen, A.; Mattila, T.; Melanen, M. Industrial symbiosis and the policy instruments of sustainable consumption and production. J. Clean. Prod. 2011, 19, 1865–1875. [Google Scholar] [CrossRef]

- Hashimoto, S.; Fujita, T.; Geng, Y.; Nagasawa, E. Realizing CO2 emission reduction through industrial symbiosis: A cement production case study for Kawasaki. Resour. Conserv. Recycl. 2010, 54, 704–710. [Google Scholar] [CrossRef]

| Location/Region | NE | Activity | Waste/By-Product | Sharing Facilities/Utilities/Services | Publication Year | Refs. |

|---|---|---|---|---|---|---|

| Industrial Symbiosis Networks | ||||||

| Coimbra, I.C. | ||||||

| Souselas | Cement manufacturer | Agricultural, urban, industrial, and construction and demolition wastes | 2018 | [91] | ||

| Leiria, I.C.; West, I.C. and Lisbon, M.A. | ||||||

| Leiria, Alcobaça and Setúbal | Shipyards and cement manufacturers | Steel shot | 2018 | [91] | ||

| Lisbon, M.A. | ||||||

| Lisbon Metropolitan Area | 44 | Manufacturer of paper pulp; repair and maintenance of ships and boats; construction of railways and underground railways; wholesale of waste and scrap; manufacturer of doors and windows of metal; manufacturer of other fabricated metal products; shaping and processing of flat glass; production of electricity; logging; manufacturer of cement; manufacturer of concrete products; manufacturer of household and sanitary goods and of toilet requisites; aluminum production; manufacturer of plastic plates, sheets, tubes, and profiles; manufacturer of basic iron and steel and of ferro-alloys; and manufacture of flat glass | Waste bark and wood, bottom ash, slag, boiler dust, sludge, plastics, rubber, waste blasting material, paper, cardboard, aluminum, ferrous metals, waste glass, waste concrete, concrete sludge, mixtures of concrete and bricks and ceramics, linings, refractories, welding waste, and lime mud waste | 2015 | [69] | |

| Lisbon | Restaurants, coffee shops, and mushroom producer | Coffee grounds | 2019 | [92] | ||

| Alentejo Litoral, I.C. | ||||||

| Sines | Oil refinery; manufacturers of fertilizers, paper, and sulphuric acid; microalgae production; and manufacturer of plastics in primary forms | Sulphur, industrial gases (CO2), hydrogen, liquefied petroleum gas, fuel, and others fuels (naphtha) | 2011 | [93] | ||

| Sines | Power plant and cement manufacturer | Ashes | 2011 | [93] | ||

| Sines | Recovery of sorted materials (tyres), power plant, chemical industry; and cement/concrete/construction materials manufacturer | Waste tyres and gypsum | 2011 | [93] | ||

| Lezíria do Tejo, I.C. | ||||||

| Chamusca | >16 | Integrated recovery, treatment and elimination center for hazardous wastes, municipal waste management, wastewater treatment facilities, container refurbishment, battery recycler, paper pulp producer, plastic recycler, end of life vehicles disassemblers, aluminum slag processor, biomass processers, fertilizer producers, and local farms | Containers, acids, biomass, plastics, ferrous metals, batteries and oil filters, ash, food waste, and sludge | 2010 | [68] | |

| Rio Maior | 2 | Furniture manufacturer and mixed farming | Wood shavings | 2011 | [93] | |

| Salvaterra de Magos and Rio Maior | 2 | Carpentry and pig farm | Wood shavings | 2011 | [93] | |

| Benavente and Rio Maior | 2 | Fruit processer and wholesale of grain | Unsuitable fruit materials | 2011 | [93] | |

| Santarém | 2 | Pig farm and agricultural production | Manure | 2011 | [93] | |

| Santarém | 2 | Stone quarry and mechanical repair | Oils | 2011 | [93] | |

| Santarém | 2 | Sewerage and agricultural products | Wastewater sludge | 2011 | [93] | |

| Santarém | 2 | Furniture manufacturer and ceramics manufacturer | Wood shavings | 2011 | [93] | |

| Santarém | 2 | Olive oil production | Washing sludge | 2011 | [93] | |

| Santarém | 3 | Stone quarries and stone cutting and shaping | Excavation wastes, stone cutting wastes, and freshwater drilling muds | 2011 | [93] | |

| Santarém and Benavente | 3 | Meat processer, paper products manufacturer, and printing | Paper/cardboard | 2011 | [93] | |

| Santarém and Alpiarça | 3 | Brewery, raising of farm animals, and agricultural production | Biomass and sludges | 2011 | [93] | |

| Santarém, Almeirim and Alpiarça | 3 | Vineyards and distiller | Unsuitable beverage materials and washing/mechanical process wastes | 2011 | [93] | |

| Santarém and Cartaxo | 3 | Manufacturer of wires, chains, and springs; hardware retailer; and cold forming or folding | Ferrous metal dust and particles and ferrous metal fillings | 2011 | [93] | |

| Chamusca | 2 | Winery and mixed farming | Washing/mechanical process wastes | 2011 | [93] | |

| Chamusca and Azambuja | 2 | Aviary and recovery of sorted materials | Discarded electronic equipment | 2011 | [93] | |

| Azambuja | 2 | Veneer sheets and wood panels manufacturer and agricultural products retailer | Wood shavings | 2011 | [93] | |

| Azambuja and Coruche | 5 | Manufacturer of parts for motor vehicles, recovery of sorted materials, car manufacturer, and construction | Steel mill scales and lead batteries | 2011 | [93] | |

| Benavente and Cartaxo | 2 | Manufacturer of medical products and manufacturer of steel drums | Metal containers | 2011 | [93] | |

| Cartaxo | 2 | Juice manufacturer and post-harvest crop activities | Washing/mechanical process wastes | 2011 | [93] | |

| Cartaxo | 2 | Stone cutting and shaping and construction | Stone cutting wastes | 2011 | [93] | |

| Cartaxo | 2 | Manufacturer of parts for motor vehicles and manufacturer of wires, chains, and springs | Ferrous metal fillings | 2011 | [93] | |

| Cartaxo | 2 | Printing and school | Paper/cardboard packaging | 2011 | [93] | |

| Alentejo | ||||||

| Alentejo | Olive oil and wine industries, paper mill, and poultry farmer | Olive lump, by-products of pruning of vines and olive trees, stalks, sludge from wastewater treatment plants of paper mill, and poultry manure | Infrastructures, human resources, waste management (with a common waste park and wastewater treatment plant), and equipment | 2018 | [88] | |

| Alentejo | 2 | Wine, olive oil, and pig farmers | Swine effluent | Facilities and human resources | 2018 | [88] |

| Alentejo | Cooperatives and producers | Organic matter | 2018 | [88] | ||

| Alentejo | Olive oil farmers and poultry farmer | Olive lump | 2018 | [88] | ||

| Alentejo | Pig farmers and farmers | Liquid and solid effluents | 2018 | [88] | ||

| Undefined region | ||||||

| Paper and pulp industry and mortar producer | Aggregate (sand) re-used from fluidized bed boilers | 2016 | [94] | |||

| Paper pulp producer and sustainable forest management company | Organic waste | 2018 | [91] | |||

| Electricity producer, distributor and trader, and international companies | Coal slag | 2018 | [91] | |||

| Pulp and paper industries, ceramic, cement, and other industries | Waste and by-products from pulp and paper industries | 2019 | [70] | |||

| Potential industrial symbiosis network | ||||||

| Alentejo Litoral, I.C. | ||||||

| Sines | Refinery and cement industry | Used catalyst and hydrocarbon sludge | 2018 | [91,94] | ||

| Undefined region | ||||||

| Pulp and paper plants, sand producers, and mortars producers | Fluidized bed sands | 2019 | [71] | |||

| Categories | Main Challenges and Future Prospects |

|---|---|

| Political | Establishment of policies and strategies by national and European institutions that effectively promote sustainable growth and support companies Definition of a concerted action plan tailored to the reality of small- and medium-sized enterprises Increased waste disposal taxes Creation of dissemination and encouragement mechanisms for companies Tax reduction for companies that adopt more sustainable waste treatment practices Creation of funds specially designed to increase industrial symbiosis Promotion of legislative changes, such as streamlining and reducing bureaucracy in the application for by-product classification |

| Organizational | Existence of a facilitator who promotes industrial symbiosis relations between companies |

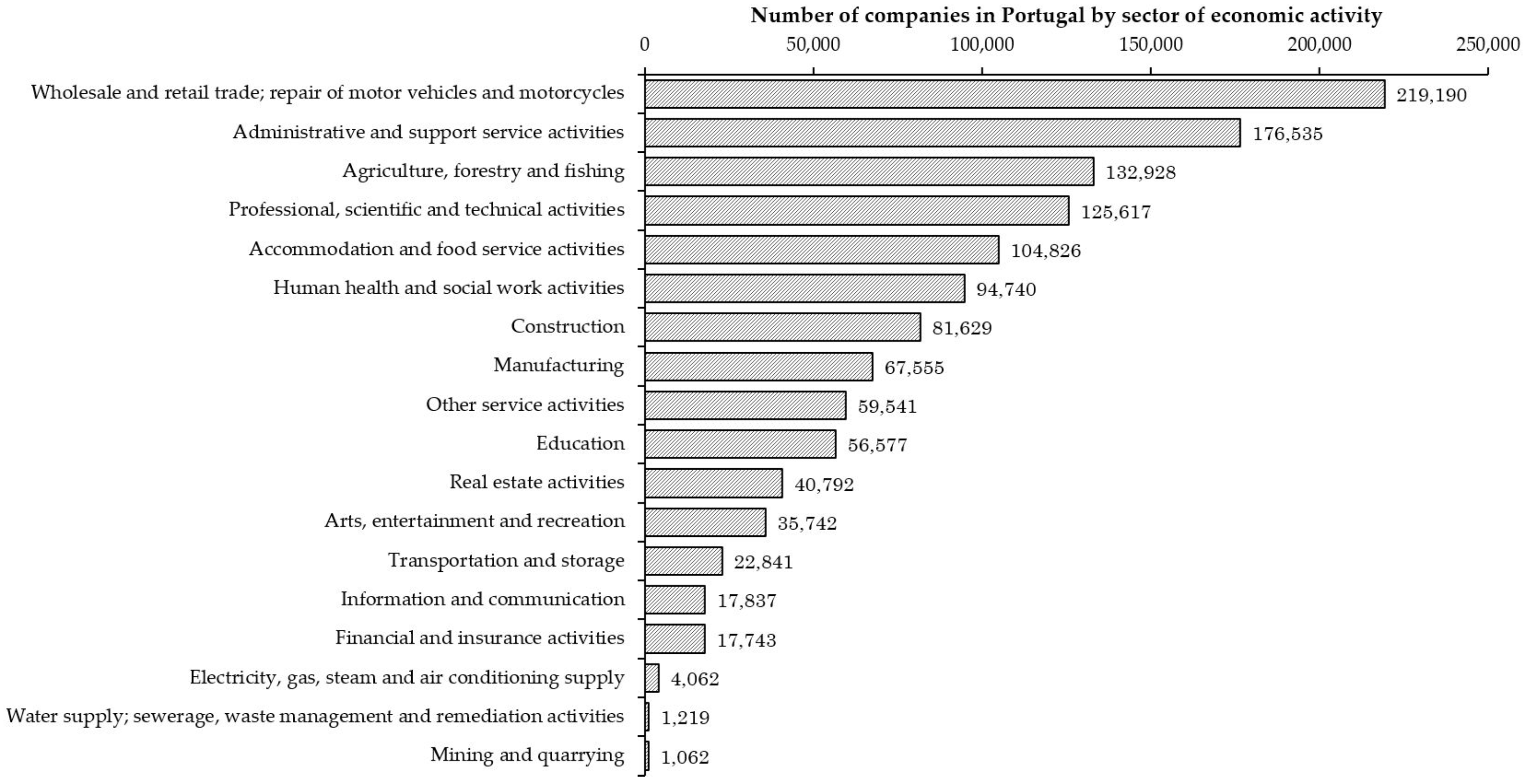

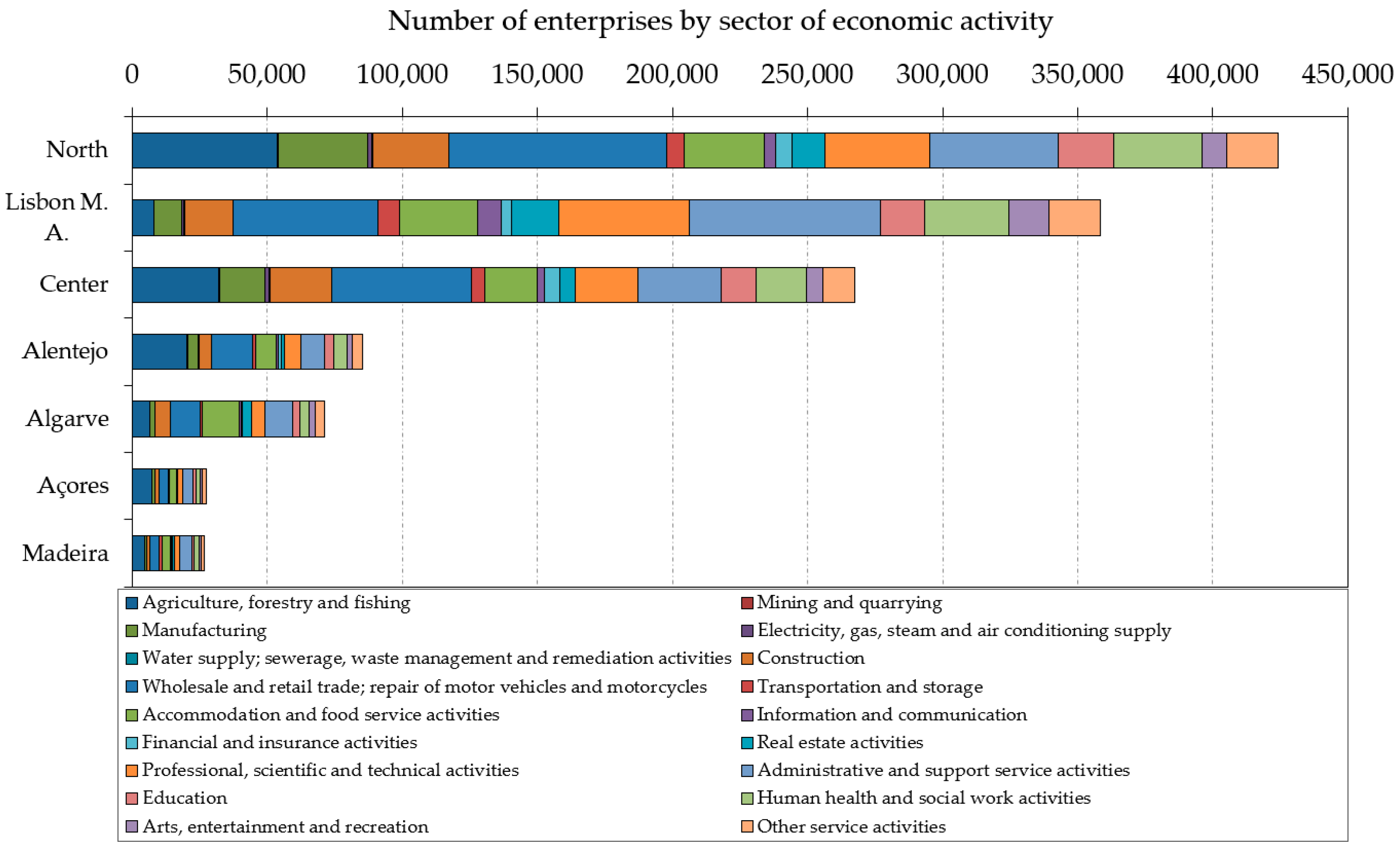

| Technical | Industrial symbiosis between manufacturing and agriculture, forestry, and fishing companies Promoting symbiosis relationships with more representative and waste-generating industries such as the paper industry and the manufacturing industry of basic metals and fabricated metal products Boost symbiosis by using larger companies that are already present in industrial symbiosis networks, acting as anchor tenants Promotion of infrastructure sharing and joint provision of services |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Neves, A.; Godina, R.; G. Azevedo, S.; C. O. Matias, J. Current Status, Emerging Challenges, and Future Prospects of Industrial Symbiosis in Portugal. Sustainability 2019, 11, 5497. https://doi.org/10.3390/su11195497

Neves A, Godina R, G. Azevedo S, C. O. Matias J. Current Status, Emerging Challenges, and Future Prospects of Industrial Symbiosis in Portugal. Sustainability. 2019; 11(19):5497. https://doi.org/10.3390/su11195497

Chicago/Turabian StyleNeves, Angela, Radu Godina, Susana G. Azevedo, and João C. O. Matias. 2019. "Current Status, Emerging Challenges, and Future Prospects of Industrial Symbiosis in Portugal" Sustainability 11, no. 19: 5497. https://doi.org/10.3390/su11195497

APA StyleNeves, A., Godina, R., G. Azevedo, S., & C. O. Matias, J. (2019). Current Status, Emerging Challenges, and Future Prospects of Industrial Symbiosis in Portugal. Sustainability, 11(19), 5497. https://doi.org/10.3390/su11195497