Prospective Life Cycle Assessment of a Structural Battery

Abstract

:1. Introduction

2. Materials and Methods

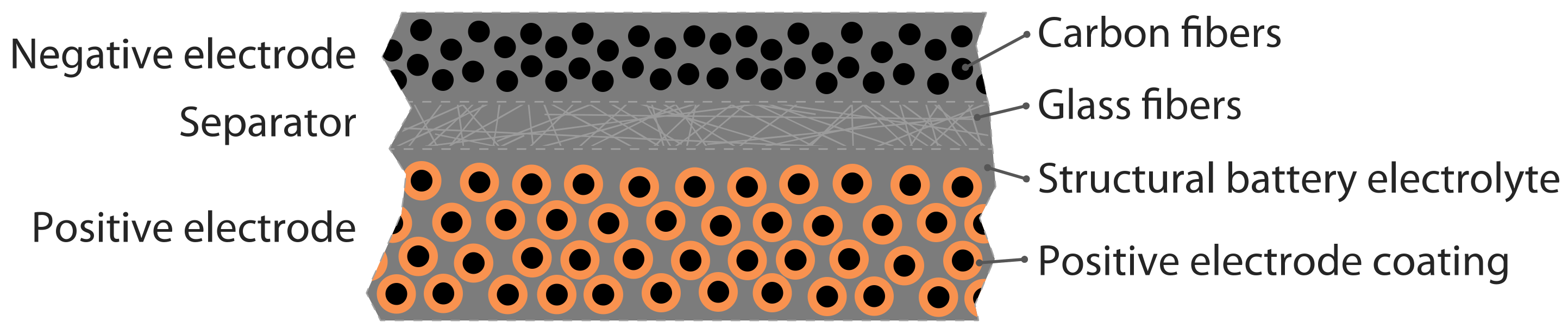

2.1. Structural Battery Design

2.2. Life Cycle Assessment

2.2.1. Electricity

2.2.2. Production of Original Traction Battery and Steel Roof

2.2.3. Production of the Structural Battery

2.2.4. Use Phase

2.2.5. Recycling

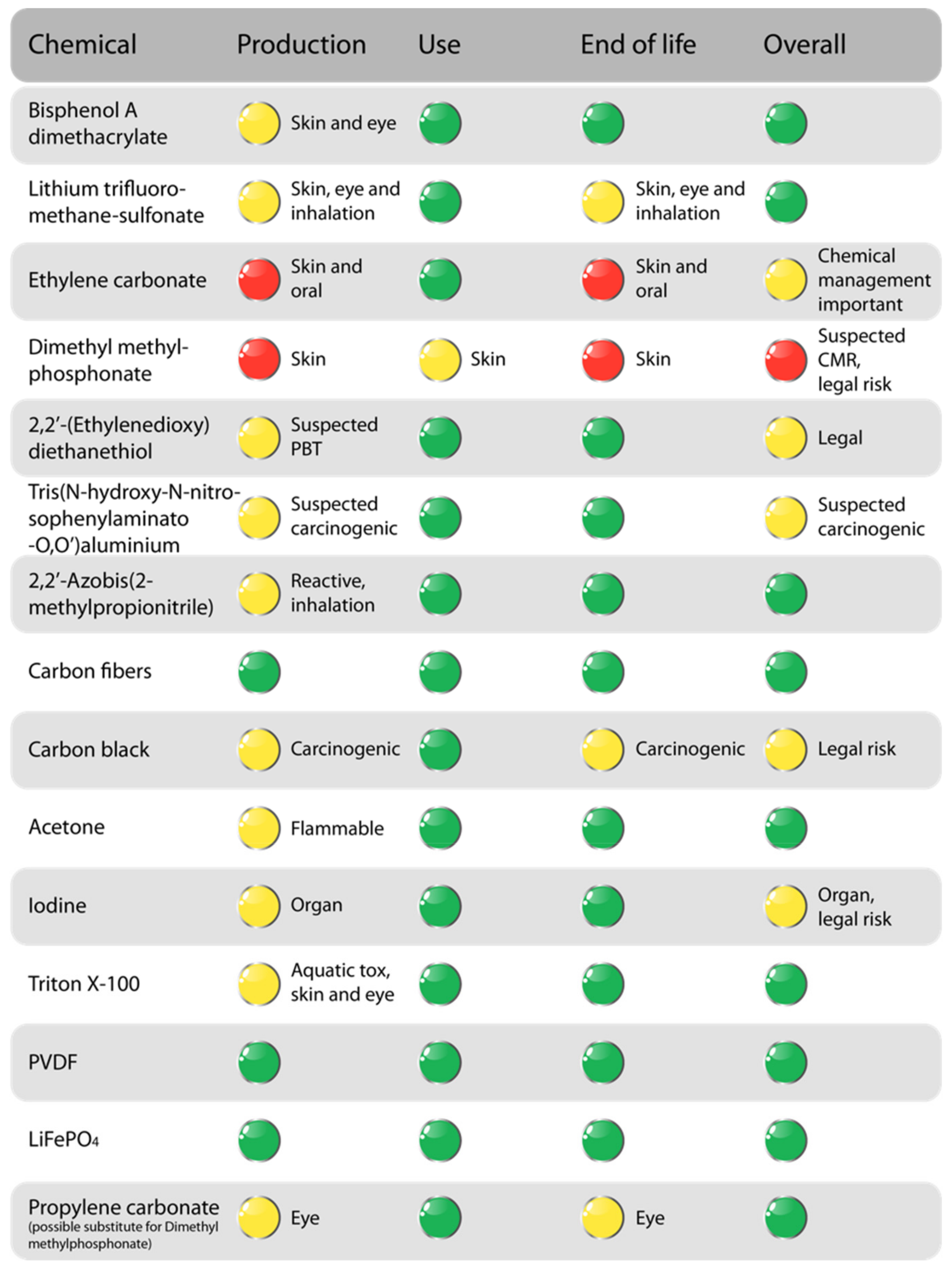

2.3. Chemical Risk Assessment from a Life Cycle Perspective

- Collection of safety data sheets (SDS), retrieved from the chemical suppliers.

- Identification of hazard statements of the chemical mixture as well as the individual components from the SDS, according to CLP. In addition, the chemical abstract service (CAS) registry number for classified individual components are listed.

- In order to identify any legal requirements, restrictions, or unharmonized classifications, the CAS numbers are investigated through the European Chemical Agency (ECHA) database [36].

- Evaluation of risk in each life cycle phase according to criteria in Table S7.

3. Results and Discussion

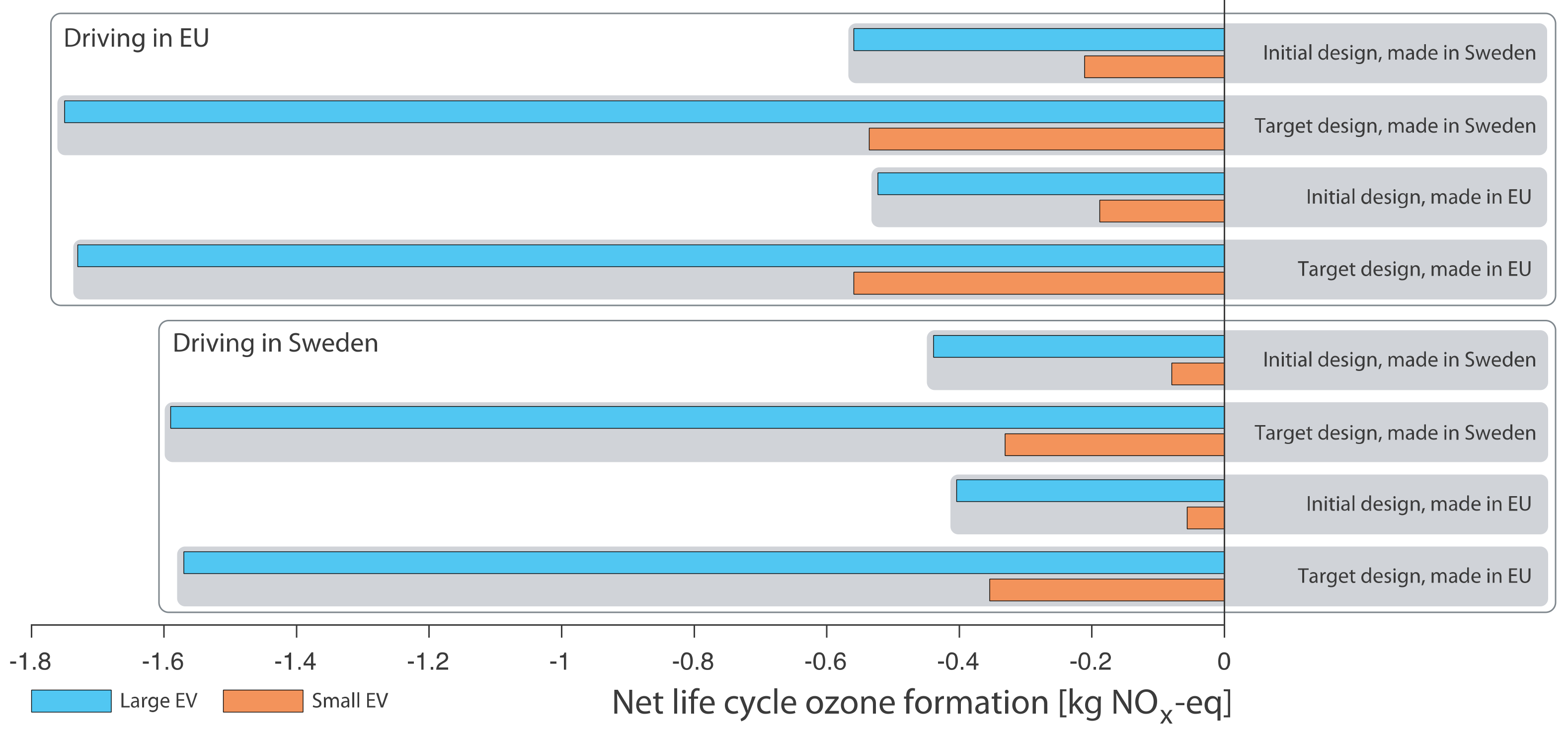

3.1. Life Cycle Assessment

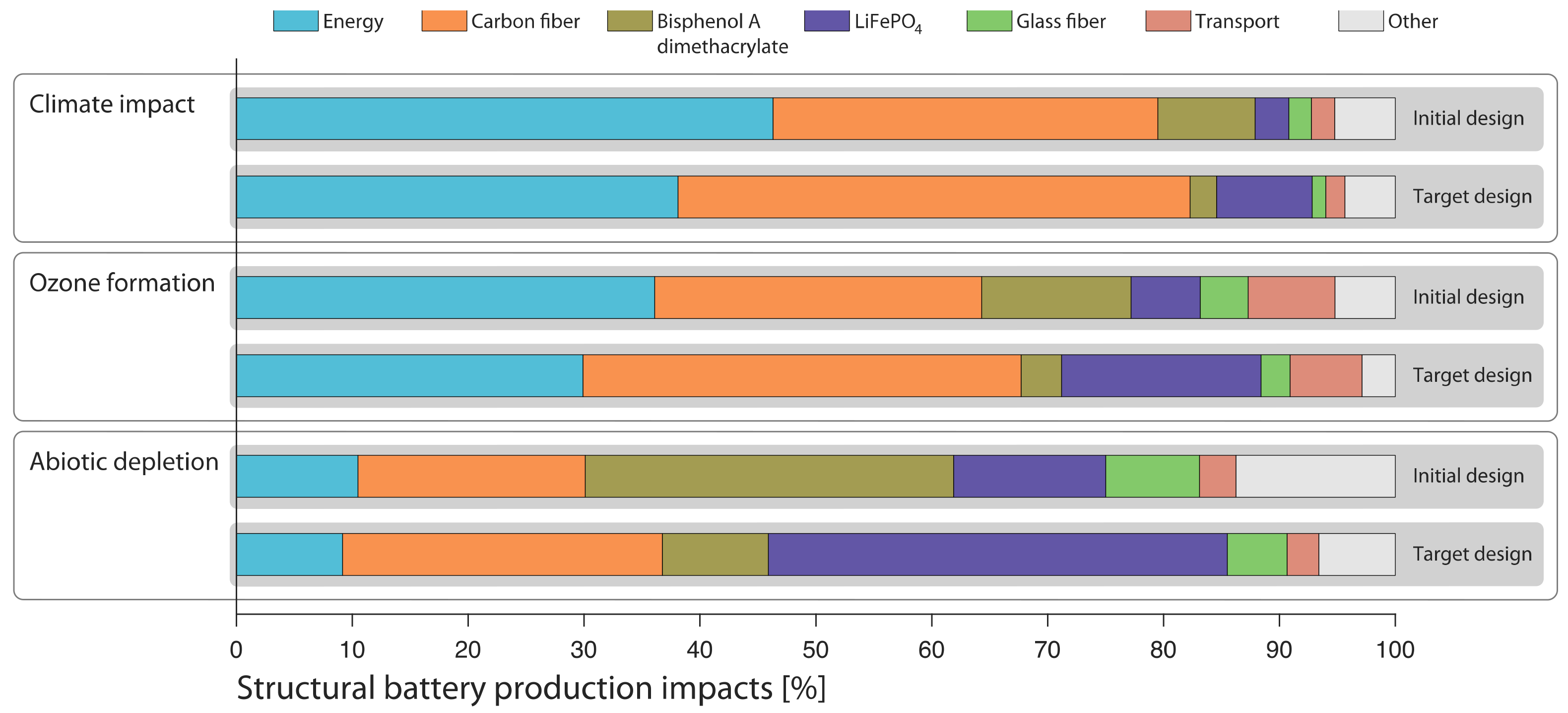

Environmental Impact of Structural Battery Production

3.2. LCA Results in Perspective

3.3. Chemical Risk Assessment from a Life Cycle Perspective

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kim, H.C.; Wallington, T.J.; Arsenault, R.; Bae, C.; Ahn, S.; Lee, J. Cradle-to-Gate Emissions from a Commercial Electric Vehicle Li-Ion Battery: A Comparative Analysis. Environ. Sci. Technol. 2016, 50, 7715–7722. [Google Scholar] [CrossRef] [PubMed]

- Ellingsen, L.A.; Singh, B.; Strømman, A.H. The size and range effect: lifecycle greenhouse gas emissions of electric vehicles. Environ. Res. Lett. 2016, 11, 054010. [Google Scholar] [CrossRef]

- Cox, B.; Mutel, C.L.; Bauer, C.; Beltran, A.M.; Van Vuuren, D.P. Uncertain Environmental Footprint of Current and Future Battery Electric Vehicles. Environ. Sci. Technol. 2018, 52, 4989–4995. [Google Scholar] [CrossRef] [PubMed]

- South, J.T.; Carter, R.H.; Snyder, J.F.; Hilton, C.D.; O’Brien, D.J.; Wetzel, E.D. Multifunctional Power-Generating and Energy-Storing Structural Composites for U.S. Army Applications. MRS Proc. 2004, 851, NN4.6. Available online: https://www.cambridge.org/core/journals/mrs-online-proceedings-library-archive/article/multifunctional-powergenerating-and-energystoring-structural-composites-for-us-army-applications/EE493315B815801CD4F5BB1BB97AB64A (accessed on 11 October 2019). [CrossRef]

- Snyder, J.F.; Gienger, E.B.; Wetzel, E.D.; Xu, K.; Curtis, P.T. Multifunctional Structural Composite Batteries. In Proceedings of the Society for the Advancement of Materiel and Process Engineering (SAMPE) 2006 Fall Technical Conference, Dallas, TX, USA, 6–9 November 2010. [Google Scholar]

- Wong, E.L.; Baechle, D.M.; Xu, K.; Carter, R.H.; Snyder, J.F.; Wetzel, E.D. Design and Processing of Structural Composite Batteries. In Proceedings of the Society of Advancement of Material and Process Engineering, Baltimore, MD, USA, 3–7 June 2007. [Google Scholar]

- Kjell, M.H.; Jacques, E.; Zenkert, D.; Behm, M.; Lindbergh, G. PAN-Based Carbon Fiber Negative Electrodes for Structural Lithium-Ion Batteries. J. Electrochem. Soc. 2011, 158, A1455. [Google Scholar] [CrossRef]

- Arvidsson, R.; Janssen, M.; Nordelöf, A. Environmental Assessment of Emerging Technologies Recommendations for Prospective LCA. J. Ind. Ecol. 2017, 22, 1286–1294. [Google Scholar] [CrossRef]

- Nielsen, P.H.; Wenzel, H. Integration of environmental aspects in product development: A Stepwise Procedure Based on Quantitative Life Cycle Assessment. J. Clean. Prod. 2002, 10, 247–257. [Google Scholar] [CrossRef]

- Simon, M.; Poole, S.; Sweatman, A.; Evans, S.; Bhamra, T.; McAloone, T. Environmental Priorities in Strategic Product Development. Bus Strateg. Environ. 2000, 9, 367–377. [Google Scholar] [CrossRef]

- Zackrisson, M. Product Orientation of Environmental Work: Barriers & Incentives; Degree in Licentiate of Engineering, Department of Machine Design, Royal Institute of Technology; KTH: Stockholm, Sweden, 2009; Available online: http://urn.kb.se/resolve?urn=urn:nbn:se:kth:diva-10585 (accessed on 11 October 2019).

- Johannisson, W.; Zenkert, D.; Lindbergh, G. Model of a structural battery and its potential for system level mass savings. Multifunct. Mater. 2019, 2, 035002. [Google Scholar] [CrossRef]

- Jacques, E.; Kjell, M.H.; Zenkert, D.; Lindbergh, G.; Behm, M.; Willgert, M. Impact of electrochemical cycling on the tensile properties of carbon fibres for structural lithium-ion composite batteries. Compos. Sci. Technol. 2012, 72, 792–798. [Google Scholar] [CrossRef] [Green Version]

- Jacques, E.H.; Kjell, M.; Zenkert, D.; Lindbergh, G. The effect of lithium-intercalation on the mechanical properties of carbon fibres. Carbon N. Y. 2014, 68, 725–733. [Google Scholar] [CrossRef]

- Hagberg, J.; Maples, H.A.; Alvim, K.S.P.; Xu, J.; Johannisson, W.; Bismarck, A.; Zenkert, D.; Lindbergh, G. Lithium iron phosphate coated carbon fiber electrodes for structural lithium ion batteries. Compos. Sci. Technol. 2018, 162, 235–243. [Google Scholar] [CrossRef] [Green Version]

- Zackrisson, M.; Fransson, K.; Hildenbrand, J.; Lampic, G.; O’Dwyer, C. Life cycle assessment of lithium-air battery cells. J. Clean. Prod. 2016, 135, 299–311. [Google Scholar] [CrossRef]

- European Commission. Energy Roadmap 2050; Publications Office of the European Union: Luxembourg, 2012. [Google Scholar]

- Das, S. Life cycle assessment of carbon fiber-reinforced polymer composites. Int. J. Life Cycle Assess. 2011, 16, 268–282. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Dunn, J.B.; Gaines, L.; Sullivan, J.; Wang, M.Q. Impact of recycling on cradle-to-gate energy consumption and greenhouse gas emissions of automotive lithium-ion batteries. Environ. Sci. Technol. 2012, 46, 12704–12710. [Google Scholar] [CrossRef]

- Zackrisson, M.; Avellán, L.; Orlenius, J. Life cycle assessment of lithium-ion batteries for plug-in hybrid electric vehicles-Critical issues. J. Clean. Prod. 2010, 18, 1517–1527. [Google Scholar] [CrossRef]

- Dunn, J.B.; Gaines, L.; Kelly, J.C.; James, C.; Gallagher, K.G. The significance of Li-ion batteries in electric vehicle life-cycle energy and emissions and recycling’s role in its reduction. Energy Environ. Sci. 2014, 8, 158–168. [Google Scholar] [CrossRef]

- Matheys, J.; Van Autenboer, W.; Van Mierlo, J. Subat: Sustainable Batteries. Work Package 5: Overall Assessment; Final Public Report; Vrije Universiteit Brussels-ETEC: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Forell, A.; Busa, A.; Wilbert, G. Advanced High Volume Affordable Lightweighting for Future Electric Vehicles; Thinkstep AG: Wolfsburg, Germany, 2016. [Google Scholar]

- Cullbrand, F.K.; Fråne, A.; Jensen, C. Utökad demontering av personbilar; IVL Svenska Miljöinstitutet: Stockholm, Sweden, 2015. [Google Scholar]

- Ec. Directive 200053EC of the European Parliament and of the Council on end-of Life Vehicles. Off. J. Eur. Communities 2000, 1–15. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32000L0053 (accessed on 11 October 2019).

- Zackrisson, M.; Jönsson, C.; Olsson, E. Life Cycle Assessment and Life Cycle Cost of Waste Management—Plastic Cable Waste. Adv. Chem. Eng. Sci. 2014, 4, 221–232. [Google Scholar] [CrossRef]

- Hagnell, M.K.; Åkermo, M. The economic and mechanical potential of closed loop material usage and recycling of fibre-reinforced composite materials. J. Clean. Prod. 2019, 223, 957–968. [Google Scholar] [CrossRef]

- RECHARGE. PEFCR—Product Environmental Footprint Category Rules for High Specific Energy Rechargeable Batteries for Mobile Applications; The Advanced Rechargeable & Lithium Batteries Association: Brussels, Belgium, 2018. [Google Scholar]

- Ellingsen, L.A.; Majeau-bettez, G.; Singh, B.; Srivastava, A.K.; Valøen, L.O.; Strømman, A.H. Life Cycle Assessment of a Lithium-Ion Battery Vehicle Pack. J. Ind. Ecol. 2013, 18, 113–124. [Google Scholar] [CrossRef] [Green Version]

- Askham, C.; Gade, A.L.; Hanssen, O.J. Linking chemical risk information with life cycle assessment in product development. J. Clean. Prod. 2013, 51, 196–204. [Google Scholar] [CrossRef]

- Barberio, G.; Scalbi, S.; Buttol, P.; Masoni, P.; Righi, S. Combining life cycle assessment and qualitative risk assessment: The case study of alumina nanofluid production. Sci. Total Environ. 2014, 496, 122–131. [Google Scholar] [CrossRef] [PubMed]

- Harmon, J.P.; Otter, R. Green Chemistry and the Search for New Plasticizers. ACS Sustain. Chem. Eng. 2018, 6, 2078–2085. [Google Scholar] [CrossRef]

- Jacobs, M.M.; Malloy, T.F.; Tickner, J.A.; Edwards, S. Alternatives assessment frameworks: Research needs for the informed substitution of hazardous chemicals. Environ. Health Perspect. 2016, 124, 265–280. [Google Scholar] [CrossRef]

- European Commission. Regulation (EC) No 1272/2008 of the European Parliament and of the Council of 16 December 2008 on Classification Labelling and Packaging of Substances and Mixtures, Amending and Repealing Directives 67/548/EEC and 1999/45/EC, and Amending Regulation (EC); Publications Office of the European Union: Luxembourg, 2008. [Google Scholar]

- ECHA. European Chemicals Agency, Chemical Database. 2019. Available online: https://echa.europa.eu/sv/home (accessed on 27 may 2019).

- European Commission. Regulation (EC) No 1907/2006 of the European Parliament and of the Council of 18 December 2006 Concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH); Publications Office of the European Union: Luxembourg, 2006. [Google Scholar]

- EU; European Commission. Regulation (EC) No 850/2004 of the European Parliament and of the Council of 29 April 2004 on Persistent Organic Pollutants and Amending Directive 79/117/EEC; Publications Office of the European Union: Luxembourg, 2004. [Google Scholar]

- Bauer, C. Ökobilanz Von Lithium-Ionen Batterien; Paul Scherrer Institut: Villigen, Switzerland, 2010. [Google Scholar]

- Peters, J.; Weil, M. A Critical Assessment of the Resource Depletion Potential of Current and Future Lithium-Ion Batteries. Resources 2016, 5, 46. [Google Scholar] [CrossRef]

- Klinglmair, M.; Sala, S.; Brandão, M. Assessing resource depletion in LCA: A review of methods and methodological issues. Int. J. Life Cycle Assess. 2014, 19, 580–592. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zackrisson, M.; Jönsson, C.; Johannisson, W.; Fransson, K.; Posner, S.; Zenkert, D.; Lindbergh, G. Prospective Life Cycle Assessment of a Structural Battery. Sustainability 2019, 11, 5679. https://doi.org/10.3390/su11205679

Zackrisson M, Jönsson C, Johannisson W, Fransson K, Posner S, Zenkert D, Lindbergh G. Prospective Life Cycle Assessment of a Structural Battery. Sustainability. 2019; 11(20):5679. https://doi.org/10.3390/su11205679

Chicago/Turabian StyleZackrisson, Mats, Christina Jönsson, Wilhelm Johannisson, Kristin Fransson, Stefan Posner, Dan Zenkert, and Göran Lindbergh. 2019. "Prospective Life Cycle Assessment of a Structural Battery" Sustainability 11, no. 20: 5679. https://doi.org/10.3390/su11205679

APA StyleZackrisson, M., Jönsson, C., Johannisson, W., Fransson, K., Posner, S., Zenkert, D., & Lindbergh, G. (2019). Prospective Life Cycle Assessment of a Structural Battery. Sustainability, 11(20), 5679. https://doi.org/10.3390/su11205679