Optimal Logistics Control of an Omnichannel Supply Chain

Abstract

:1. Introduction

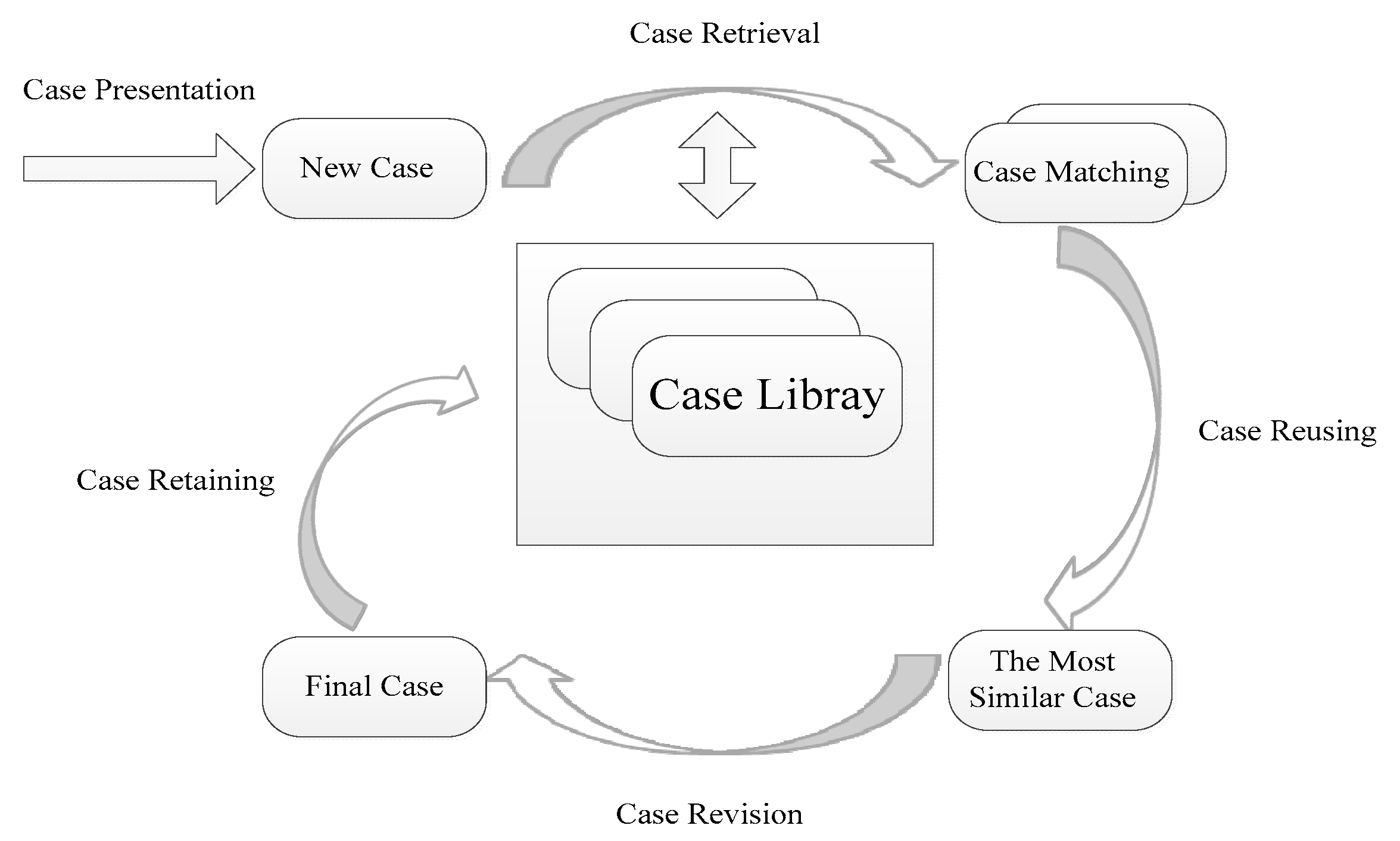

2. The Case Adjustment of the Case Library in CBR of the OSC

2.1. Combined Feedback Model

2.2. Optimal Control Solution

2.2.1. Solution of the Optimal Control Curve

2.2.2. Solution of Endpoint Value

- (1)

- The atmospheric pressure, a driving force of siphonage, was compared to the emergency level in the OSC material balance. Considering the positive correlation between the pressure and flow rate, the emergency level was assumed to be positively proportional to the inventory coordination speed between multiple channels.

- (2)

- The gravitational acceleration, another driver of liquid flow in siphonage, was compared to the logistics speed in the OSC material balance. The speed was assumed to be fixed under the same conditions, as the gravitational acceleration is stabilized at 9.8.

- (3)

- The liquid density, a determinant of flow rate in siphonage, was compared to the material price in the OSC material balance. The price was assumed to be positively proportional to the level of care and negatively to logistics speed, in light of the relationship between liquid density and flow rate.

- (4)

- The height difference in siphonage, a source of liquid pressure, was compared to the difference in material state in the OSC material balance. The relationship between material state and balance was assumed according to the negative correlation between the height of liquid level and the flow rate.

2.3. Saving as Images

3. Case Description and Matching in CBR of the OSC

3.1. Feature Extraction

3.1.1. Extraction of Intrinsic Features

- (1)

- It is easy to add and modify images through the modular structure of GoogLeNet.

- (2)

- The fully-connected layer is replaced with average pooling, pushing up the accuracy by 0.6%.

- (3)

- Despite the removal of the fully-connected layer, the concept of dropout is retained in the network.

- (4)

- Two additional modules are added to prevent gradient disappearance.

3.1.2. Extraction of Texture Features

3.2. Feature Matching

3.2.1. Cloud Model Method

3.2.2. Modification of Cloud Model Method

4. Experiments

4.1. Comparison between Different Feedback Devices

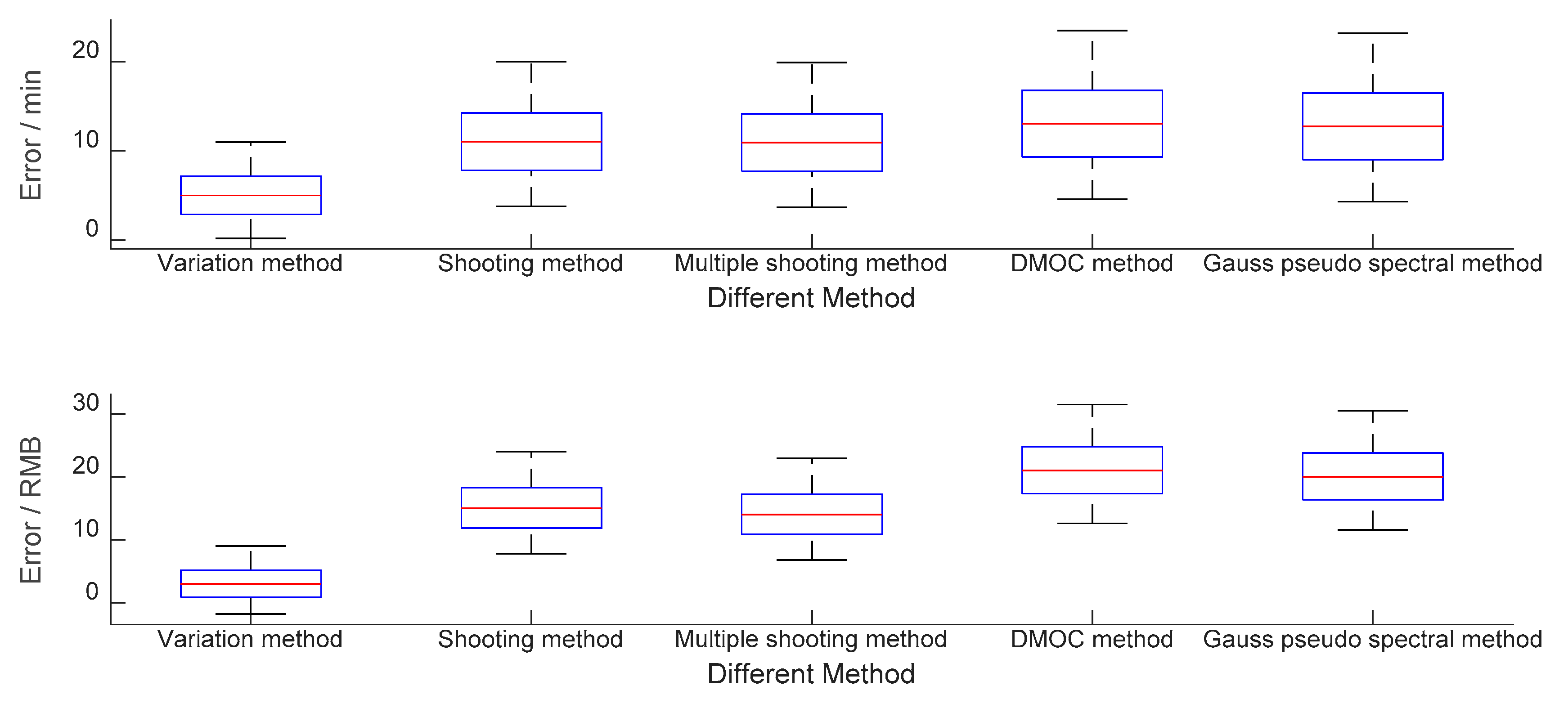

4.2. Comparison between Different Solutions to the Optimal Control Curve

4.3. Comparison between Different Image Formats

4.4. Comparison with Single Feature Extraction Methods

4.5. Comparison with Hybrid Feature Extraction Methods

4.6. Comparison between Case Matching Methods

5. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Xue, H.; Lin, Y. The omni-channel consumer segmentation method based on consumption data stream mining. In Proceedings of the 2017 IEEE 2nd International Conference on Big Data Analysis (ICBDA), Beijing, China, 10–12 March 2017. [Google Scholar]

- Du, S.; Wang, L.; Hu, L. Omnichannel management with consumer disappointment aversion. Int. J. Prod. Econ. 2019, 215, 84–101. [Google Scholar] [CrossRef]

- Gupta, V.K.; Ting, Q.; Tiwari, M.K. Multi-period price optimization problem for omnichannel retailers accounting for customer heterogeneity. Int. J. Prod. Econ. 2019, 212, 155–167. [Google Scholar] [CrossRef]

- Xue, H.; Yuan, Y.; Lin, Y.; Cai, J. Early warning decision-making system based on cloud computing technology for retail supply chain unconventional emergency. In Proceedings of the 2017 IEEE 2nd International Conference on Cloud Computing and Big Data Analysis (ICCCBDA), Chengdu, China, 28–30 April 2017. [Google Scholar]

- Xue, H.; Cai, J.; Yuan, Y.; Lin, Y. The collaborative decision of profit distribution in retail supply chain under emergency. In Proceedings of the 2017 29th Chinese Control and Decision Conference (CCDC), Chongqing, China, 28–30 May 2017. [Google Scholar]

- Alfares, H.K.; Attia, A.M. A supply chain model with vendor-managed inventory, consignment, and quality inspection errors. Int. J. Prod. Res. 2017, 55, 5706–5727. [Google Scholar] [CrossRef]

- Sarkar, M.; Hur, S.; Sarkar, B. Effects of Variable Production Rate and Time-Dependent Holding Cost for Complementary Products in Supply Chain Model. Math. Probl. Eng. 2017, 2017, 1–13. [Google Scholar] [CrossRef]

- White, A.S.; Censlive, M. Control system analysis of labour supply flows in production systems. J. Manuf. Syst. 2015, 37, 316–327. [Google Scholar] [CrossRef]

- Chang, J.S.; Chang, C.; Shi, M. A market-based martingale valuation approach to optimum inventory control in a doubly stochastic jump-diffusion economy. J. Oper. Res. Soc. 2015, 66, 405–420. [Google Scholar] [CrossRef]

- Sadeghi, J.; Mousavi, S.M.; Niaki, S.T.A.; Sadeghi, S. Optimizing a bi-objective inventory model of a three-echelon supply chain using a tuned hybrid bat algorithm. Transp. Res. Part E: Logist. Transp. Rev. 2014, 70, 274–292. [Google Scholar] [CrossRef]

- Pedrosa, A.D.M.; Näslund, D.; Jasmand, C. Logistics case study based research: towards higher quality. Int. J. Phys. Distrib. Logist. Manag. 2012, 42, 275–295. [Google Scholar] [CrossRef]

- Zhao, K.; Yu, X. A case based reasoning approach on supplier selection in petroleum enterprises. Expert Syst. Appl. 2011, 38, 6839–6847. [Google Scholar] [CrossRef]

- Germani, M.; Mandolini, M.; Mengoni, M.; Peruzzini, M. Platform to support dynamic collaborative design processes in virtual enterprises. Int. J. Comput. Integr. Manuf. 2013, 26, 1003–1020. [Google Scholar] [CrossRef]

- Poon, T.; Choy, K.L.T.; Chow, H.K.; Lau, H.C.; Chan, F.T.; Ho, K. A RFID case-based logistics resource management system for managing order-picking operations in warehouses. Expert Syst. Appl. 2009, 36, 8277–8301. [Google Scholar] [CrossRef]

- Lao, S.; Choy, K.L.T.; Ho, G.; Tsim, Y.; Poon, T.; Cheng, C. A real-time food safety management system for receiving operations in distribution centers. Expert Syst. Appl. 2012, 39, 2532–2548. [Google Scholar] [CrossRef]

- Lam, H.; Choy, K.L.T.; Ho, G.; Kwong, C.; Lee, C. A real-time risk control and monitoring system for incident handling in wine storage. Expert Syst. Appl. 2013, 40, 3665–3678. [Google Scholar] [CrossRef]

- Choy, K.L.; Chow, K.H.; Moon, K.L.; Zeng, X.; Lau, H.C.; Chan, F.T.; Ho, G.T. A RFID-case-based sample management system for fashion product development. Eng. Appl. Artif. Intell. 2009, 22, 882–896. [Google Scholar] [CrossRef]

- Lim, S.F.W.; Srai, J.S. Examining the anatomy of last-mile distribution in e-commerce omnichannel retailing: A supply network configuration approach. Int. J. Oper. Prod. Manag. 2018, 38, 1735–1764. [Google Scholar] [CrossRef]

- Schank, R.C. Dynamic Memory: A Theory of Reminding and Learning in Computers and People; Cambridge University Press: New York, NY, USA, 1983. [Google Scholar]

- Martinez, A.J.P.; Stapleton, O.; Van Wassenhove, L.N. Field vehicle fleet management in humanitarian operations: A case-based approach. J. Oper. Manag. 2011, 29, 404–421. [Google Scholar] [CrossRef]

- Wang, X.F.; Zhu, W.D. Design and Stability Analysis of an Integral Time-Delay Feedback Control Combined with an Open-Loop Control for an Infinitely Variable Transmission System. J. Dyn. Syst. Meas. Control 2018, 140, 011007. [Google Scholar] [CrossRef]

- Sun, G.; Ma, P.; Ren, J.; Zhang, A.; Jia, X. A stability constrained adaptive alpha for gravitational search algorithm. Knowl.-Based Syst. 2018, 139, 200–213. [Google Scholar] [CrossRef]

- Ebadollahi, S.; Saki, S. Wind turbine torque oscillation reduction using soft switching multiple model predictive control based on the gap metric and kalman filter estimator. IEEE Trans. Ind. Electron. 2017, 65, 3890–3898. [Google Scholar] [CrossRef]

- Bitew, W.T.; Grabovsky, Y. Higher regularity of uniform local minimizers in Calculus of Variations. Proc. Am. Math. Soc. 2017, 145, 5215–5222. [Google Scholar] [CrossRef] [Green Version]

- March, R.; Riey, G. Analysis of a variational model for motion compensated inpainting. Inverse Probl. Imaging 2017, 11, 997–1025. [Google Scholar] [CrossRef]

- Bélaise, C.; Dal Maso, F.; Michaud, B.; Mombaur, K.; Begon, M. An EMG-marker tracking optimisation method for estimating muscle forces. Multibody Syst. Dyn. 2018, 42, 119–143. [Google Scholar] [CrossRef]

- Blonigan, P.J.; Wang, Q. Multiple shooting shadowing for sensitivity analysis of chaotic dynamical systems. J. Comput. Phys. 2018, 354, 447–475. [Google Scholar] [CrossRef] [Green Version]

- Moore, A.; Ober-Blöbaum, S.; Marsden, J.E. Trajectory Design Combining Invariant Manifolds with Discrete Mechanics and Optimal Control. J. Guid. Control. Dyn. 2012, 35, 1507–1525. [Google Scholar] [CrossRef] [Green Version]

- Shareef, Z.; Trächtler, A. Simultaneous path planning and trajectory optimization for robotic manipulators using discrete mechanics and optimal control. Robotica 2016, 34, 1322–1334. [Google Scholar] [CrossRef]

- Zaky, M.; Machado, J.T.; Zaky, M. On the formulation and numerical simulation of distributed-order fractional optimal control problems. Commun. Nonlinear Sci. Numer. Simul. 2017, 52, 177–189. [Google Scholar] [CrossRef]

- Williams, T.; Taroyan, Y. Formation of a Dense Flux Rope by a Siphon Flow. Astrophys. J. 2018, 852, 77. [Google Scholar] [CrossRef]

- Chen, R.; Imani, F.; Reutzel, E.; Yang, H. From Design Complexity to Build Quality in Additive Manufacturing—A Sensor-Based Perspective. IEEE Sens. Lett. 2018, 3, 1–4. [Google Scholar] [CrossRef]

- Kan, C.; Chen, R.; Yang, H. Image-guided Quality Control of Biomanufacturing Process. Procedia CIRP 2017, 65, 168–174. [Google Scholar] [CrossRef]

- Imani, F.; Cheng, C.; Chen, R.; Yang, H. Nested gaussian process modeling for high-dimensional data imputation in healthcare systems. In Proceedings of the 2018 Institute of Industrial and Systems Engineers Annual Conference and Expo, IISE, Orlando, FL, USA, 19–22 May 2018. [Google Scholar]

- Imani, F.; Chen, R.; Diewald, E.; Reutzel, E.; Yang, H. Image-guided Variant Shape Analysis of Layerwise Build Quality in Additive Manufacturing. In Proceedings of the International Manufacturing Science and Engineering Conference, ASME, Erie, PA, USA, 10–14 June 2019. [Google Scholar]

- Scott, G.J.; England, M.R.; Starms, W.A.; Marcum, R.A.; Davis, C.H. Training Deep Convolutional Neural Networks for Land-Cover Classification of High-Resolution Imagery. IEEE Geosci. Remote Sens. Lett. 2017, 14, 549–553. [Google Scholar] [CrossRef]

- Zhao, G.; Ahonen, T.; Matas, J.; Pietikainen, M. Rotation-Invariant Image and Video Description with Local Binary Pattern Features. IEEE Trans. Image Process. 2011, 21, 1465–1477. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Dawson, D.; Sarasua, W.A.; Birchfield, S.T. Automated traffic surveillance system with aerial camera arrays imagery: Macroscopic data collection with vehicle tracking. J. Comput. Civ. Eng. 2016, 31, 04016072. [Google Scholar] [CrossRef]

- Hu, Y.; Li, L. 3D reconstruction of end-effector in autonomous positioning process using depth imaging device. Math. Probl. Eng. 2016, 2016, 8972764. [Google Scholar] [CrossRef]

| No. | Name | PC | Mobile | Physical | |||

|---|---|---|---|---|---|---|---|

| Time (min) | Energy (¥) | Time (min) | Energy (¥) | Time (min) | Energy (¥) | ||

| 1 | Combined feedback | 417.6 | 786.12 | 439.4 | 841.62 | 449.1 | 879.14 |

| 2 | Linear feedback | 462.5 | 854.69 | 501.2 | 984.26 | 523.7 | 1021.36 |

| 3 | Nonlinear feedback | 437.8 | 814.97 | 482.3 | 953.67 | 489.4 | 979.41 |

| No. | Name | Operation Time (s) | Time (min) | Energy (¥) |

|---|---|---|---|---|

| 1 | Variational method | 30.2 | 423.6 | 833.66 |

| 2 | Shooting method | 22.3 | 429.6 | 845.68 |

| 3 | Multiple shooting method | 23.5 | 428.9 | 844.72 |

| 4 | DMOC method | 24.6 | 432.1 | 851.17 |

| 5 | Gauss pseudo spectral method | 25.1 | 431.9 | 850.34 |

| No. | Data Format | Data Duration | File Size | .Rar Compress |

|---|---|---|---|---|

| 1 | .mat | 10s | 604MB | 312 MB |

| 2 | .csv | 10s | 451MB | 229 MB |

| 3 | .xlsx | 10s | 367MB | 190 MB |

| 4 | .jpg | 10s | 16.6KB | 8.9 KB |

| No. | Name | Surf | GoogLeNet | Surf–GoogLeNet |

|---|---|---|---|---|

| 1 | correct number | 1798 | 1876 | 1986 |

| 2 | correct rate | 83.24% | 86.85% | 91.94% |

| No. | Name | DFT | IVT | CT | DLT | Surf–GoogLeNet |

|---|---|---|---|---|---|---|

| 1 | correct number | 1924 | 1911 | 1934 | 1958 | 1986 |

| 2 | correct rate | 89.07% | 88.47% | 89.54% | 90.65 | 91.94% |

| No. | Name | Gray-Cloud | KNN | Gray | Cloud | BP |

|---|---|---|---|---|---|---|

| 1 | correct number | 1986 | 1949 | 1945 | 1961 | 1959 |

| 2 | correct rate | 91.94% | 90.23% | 90.05% | 90.79% | 90.69% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhuang, Y.; Zhang, N.; Wang, S.; Hu, Y. Optimal Logistics Control of an Omnichannel Supply Chain. Sustainability 2019, 11, 6014. https://doi.org/10.3390/su11216014

Zhuang Y, Zhang N, Wang S, Hu Y. Optimal Logistics Control of an Omnichannel Supply Chain. Sustainability. 2019; 11(21):6014. https://doi.org/10.3390/su11216014

Chicago/Turabian StyleZhuang, Yufeng, Ningxi Zhang, Song Wang, and Yanzhu Hu. 2019. "Optimal Logistics Control of an Omnichannel Supply Chain" Sustainability 11, no. 21: 6014. https://doi.org/10.3390/su11216014

APA StyleZhuang, Y., Zhang, N., Wang, S., & Hu, Y. (2019). Optimal Logistics Control of an Omnichannel Supply Chain. Sustainability, 11(21), 6014. https://doi.org/10.3390/su11216014