Carbon Mitigation for Industrial Sectors in the Jing-Jin-Ji Urban Agglomeration, China

Abstract

:1. Introduction

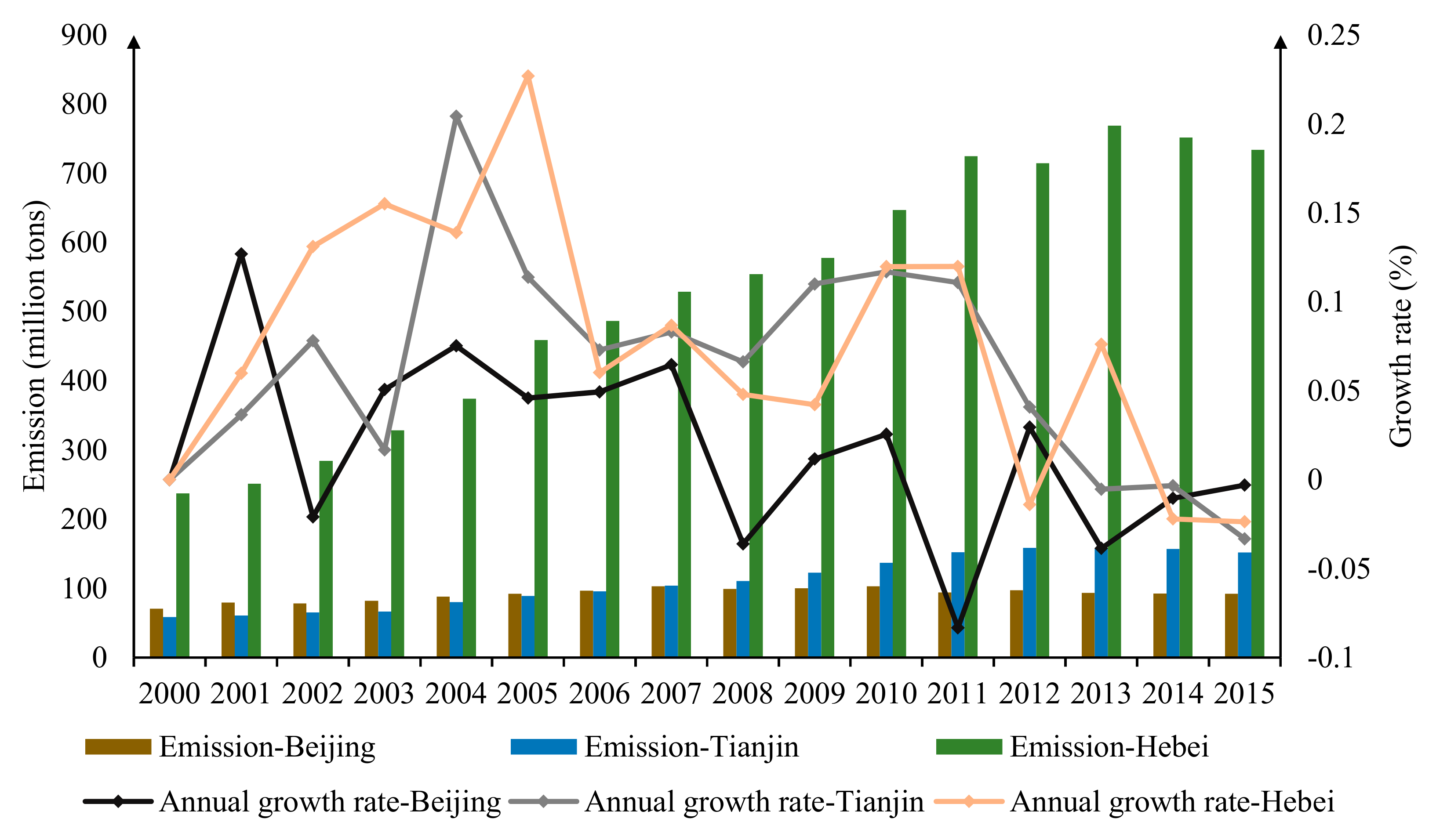

2. Overview of Carbon Emissions in the Jing-Jin-Ji Urban Agglomeration

3. Theories and Methodologies

3.1. Data

3.2. Carbon Emissions and Intensities in 2030

3.3. Nonlinear Quota Allocation Modeling

4. Results and Discussion

4.1. Carbon Mitigation at the City Level

4.2. Industrial Sectors’ Carbon Emissions in 2030

4.3. Carbon Mitigation for Industrial Sectors

4.4. Policy Implications

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Akinyele, D.O.; Rayudu, R.K.; Nair, N.K.C.; Seah, W.K.G. Clean development mechanism projects for developing countries: Potential for carbon emissions mitigation and sustainable development. In Proceedings of the Power Systems Conference, Guwahati, India, 18–20 December 2014; IEEE: Piscataway, NJ, USA, 2015. [Google Scholar] [CrossRef]

- Ni, L.; Zhu, D. Study on impacts of population, consumption and technology on carbon emission in China (1990–2008) based on STIRPAT model. In Proceedings of the International Conference on Service Systems & Service Management, Tianjin, China, 25–27 June 2011; IEEE: Piscataway, NJ, USA, 2011. [Google Scholar] [CrossRef]

- Guo, X.; Ren, D.; Shi, J. Carbon emissions, logistics volume and GDP in China: Empirical analysis based on panel data model. Environ. Sci. Pollut. Res. 2016, 23, 1–10. [Google Scholar] [CrossRef]

- Luo, T.; Wang, N. Analysis of carbon emission reduction potential by clean coal technology in China. Appl. Mech. Mater. 2015, 737, 935–940. [Google Scholar] [CrossRef]

- United Nations Framework Convention on Climate Change. CO2 Emissions from Fuel Combustion, 2009th ed.; IEA: Paris, France, 2009. [Google Scholar]

- Wang, S.; Fang, C.; Sun, L.; Su, Y.; Chen, X.; Zhou, C.; Feng, K.; Hubacek, K. Decarbonizing China’s urban agglomerations. Ann. Assoc. Am. Geogr. 2019, 109, 266–285. [Google Scholar] [CrossRef]

- Park, J.W.; Kim, C.U.; Iscard, W. Permit allocation in emission trading using the Boltzmann distribution. Physics A 2012, 391, 4883–4890. [Google Scholar] [CrossRef]

- Pang, R.Z.; Deng, Z.Q.; Chiu, Y.H. Pareto improvement through a reallocation of carbon emission quotas. Renew. Sust. Energy Rev. 2015, 50, 419–430. [Google Scholar] [CrossRef]

- Liu, H.; Lin, B. Cost-based modelling of optimal emission quota allocation. J. Clean. Prod. 2017, 149, 472–484. [Google Scholar] [CrossRef]

- Wei, C.; Ni, J.; Du, L. Regional allocation of carbon dioxide abatement in China. China Econ. Rev. 2012, 23, 552–565. [Google Scholar] [CrossRef]

- Yu, S.; Wei, Y.M.; Wang, K. Provincial allocation of carbon emission reduction targets in China: An approach based on improved fuzzy cluster and shapley value decomposition. Energy Policy 2014, 66, 630–644. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, X.; Wei, Y.; Yu, S. Regional allocation of CO2 emissions allowance over provinces in China by 2020. Energy Policy 2013, 54, 214–229. [Google Scholar] [CrossRef]

- Han, R.; Tang, B.; Fan, J.; Liu, L.; Wei, Y. Integrated weighting approach to carbon emission quotas: An application case of Beijing-Tianjin-Hebei region. J. Clean. Prod. 2016, 131, 448–459. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, A.; Da, Y. Regional allocation of carbon emission quotas in China: Evidence from the Shapley value method. Energy Policy 2014, 74, 454–464. [Google Scholar] [CrossRef]

- Han, R.; Yu, B.; Tang, B.; Liao, H.; Wei, Y. Carbon emissions quotas in the Chinese road transport sector: A carbon trading perspective. Energy Policy 2017, 106, 298–309. [Google Scholar] [CrossRef]

- Zhao, R.; Min, N.; Geng, Y.; He, Y. Allocation of carbon emissions among industries/sectors: An emissions intensity reduction constrained approach. J. Clean. Prod. 2016, 142, 3083–3094. [Google Scholar] [CrossRef]

- Chen, W.; He, Q. Intersectoral burden sharing of CO2 mitigation in China in 2020. Mitig. Adapt. Strateg. Glob. Chang. 2014, 21, 1–14. [Google Scholar] [CrossRef]

- Zhang, Y.; Hao, J. Carbon emission quota allocation among China’s industrial sectors based on the equity and efficiency principles. Ann. Oper. Res. 2017, 255, 117–140. [Google Scholar] [CrossRef]

- The State Council. The 12th Five-Year Plan Program on Curbing Greenhouse Gases Emission. Available online: http://www.gov.cn/xxgk/pub/govpublic/mrlm/201201/t20120113_64719.html (accessed on 24 June 2019).

- China Statistics Bureau. China Statistical Yearbook; China Statistics Press: Beijing, China, 2018. [Google Scholar]

- Sun, W.; Mao, L.; Tang, Z. Research on the non-capital function decentralization sequence based on the sensitivity model. Geogr. Res. 2016, 35, 1819–1830. [Google Scholar] [CrossRef]

- Liu, H.; Lin, M.; Li, G. Spatial-temporal evolution pattern of unbalanced economic development in Beijing-Tianjin-Hebei region since the 1990s. Geogr. Res. 2016, 35, 471–481. [Google Scholar] [CrossRef]

- CEADs. National Emission Inventory 2000–2015. Available online: http://www.ceads.net/data/inventory-by-sectoral-approach/ (accessed on 20 June 2019).

- Wang, X.; Cai, Y.; Xu, Y.; Zhao, H.; Chen, J. Optimal strategies for carbon reduction at dual levels in china based on a hybrid nonlinear grey-prediction and quota-allocation model. J. Clean. Prod. 2014, 83, 185–193. [Google Scholar] [CrossRef]

- Ellerman, D.; Decaux, A. Analysis of Post-Kyoto CO2 Emissions Trading Using Marginal Abatement Curves; MIT Joint Program on the Science and Policy of Global Change, Report 40; MIT: Cambridge, MA, USA, 1998. [Google Scholar]

- Nordhuas, W.D. The cost of slowing climate change: A survey. Energy 1991, 12, 37–66. [Google Scholar] [CrossRef]

- Zhu, L.; Zhang, X.B.; Fan, Y. A non-linear model for estimating the cost of achieving emission reduction targets: The case of the U.S. China and India. J. Syst. Sci. Syst. Eng. 2012, 21, 297–315. [Google Scholar] [CrossRef]

- Mustafa, H.B.; John, M.; Reilly, M.M.; Richard, S.E.; Ian, S.W.; Robert, C.H. The MIT Emissions Prediction and Policy Analysis (EPPA) Model: Revisions, Sensitivities, and Comparisons of Results. Available online: https://dspace.mit.edu/bitstream/handle/1721.1/3574/MITJPSPGC_Rpt71.pdf?sequence=1 (accessed on 11 June 2019).

- Xin, T.; Xuesen, L.; Lin, T. Gray correlative empirical research on carbon emissions and influencing factors in Hebei Province. In Proceedings of the 29th Chinese Control and Decision Conference (CCDC), Chongqing, China, 28–30 May 2017; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, L. Delinking indicators on regional industry development and carbon emissions: Beijing–Tianjin–Hebei economic band case. Ecol. Indic. 2015, 48, 41–48. [Google Scholar] [CrossRef]

- Wang, D.; Guo, H. A study on development policy of low-carbon city. Appl. Mech. Mater. 2014, 641-642, 1058–1061. [Google Scholar] [CrossRef]

- Wu, Y. Energy intensity and its determinants in China’s regional economies. Energy Policy 2012, 41, 703–711. [Google Scholar] [CrossRef]

- Li, K.; Lin, B. The nonlinear impacts of industrial structure on China’s energy intensity. Energy 2014, 69, 258–265. [Google Scholar] [CrossRef]

- Mi, Z.; Pan, S.; Yu, H.; Wei, Y. Potential impacts of industrial structure on energy consumption and CO2 emission: A case study of Beijing. J. Clean. Prod. 2015, 103, 455–462. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Liu, Z.; Zhang, H.; Tan, T.D. The impact of economic growth, industrial structure and urbanization on carbon emission intensity in China. Nat. Hazards 2014, 73, 579–595. [Google Scholar] [CrossRef]

- Yan, Q.; Wang, Y.; Baležentis, T.; Sun, Y.; Streimikiene, D. Energy-related CO2 emission in China’s provincial thermal electricity generation: Driving factors and possibilities for abatement. Energies 2018, 11, 1096. [Google Scholar] [CrossRef]

- Lin, B.; Tan, R. Ecological total-factor energy efficiency of China’s energy intensive industries. Ecol. Indic. 2016, 70, 480–497. [Google Scholar] [CrossRef]

- Cao, H.; Du, Y.; Chen, Y. Exploring a new low-carbon development paradigm for China’s future manufacturing sectors. J. Sci. Technol. Policy China 2012, 2, 159–170. [Google Scholar] [CrossRef]

- Lin, Y.; Yao, Y.; Zhang, J.; Xian, Z.; Mcalinden, K.J. A CGE analysis of carbon market impact on CO2 emission reduction in China: A technology-led approach. Nat. Hazards 2016, 81, 1107–1128. [Google Scholar] [CrossRef]

- The State Council. Beijing-Tianjin-Hebei and its Surrounding Areas Industrial Resources Comprehensive Utilization Industry Coordinated Development Action Plan (2015–2017). Available online: http://www.scio.gov.cn/xwfbh/xwbfbh/wqfbh/33978/34204/xgzc34210/Document/1469694/1469694.htm (accessed on 29 June 2019).

| Regions | Emissions in 2030 (106 ton) | Emission Intensity in 2030 (ton/104 RMB) | Target Reduction | Target Reduction for the Secondary Industry | ||

|---|---|---|---|---|---|---|

| 60% (104 ton) | 65% (104 ton) | 60% (104 ton) | 65% (104 ton) | |||

| Beijing | 152.41 | 0.68 | 482.59 | 1046.75 | 229.42 | 497.63 |

| Tianjin | 251.19 | 1.01 | 1184.67 | 2569.58 | 986.40 | 2139.52 |

| Hebei | 1213.86 | 2.58 | 14,605.65 | 31,680.13 | 13,257.59 | 28,756.14 |

| Year | United States | United Kingdom | Japan | Beijing | Tianjin | Hebei |

|---|---|---|---|---|---|---|

| 2005 | 22.00 | 26.20 | 30.20 | 64.70 | 80.90 | 90.40 |

| 2010 | 21.40 | 21.10 | 28.00 | 54.90 | 82.70 | 90.90 |

| 2015 | 20.70 | 16.80 | 26.90 | 42.60 | 81.90 | 89.40 |

| Industrial Sectors | Abbreviation | Classification |

|---|---|---|

| Coal Mining and Dressing | S1 | Energy production |

| Petroleum and Natural Gas Extraction | S2 | Energy production |

| Ferrous Metals Mining and Dressing | S3 | Heavy manufacturing |

| Nonmetal Minerals Mining and Dressing | S4 | Heavy manufacturing |

| Food Processing | S5 | Light manufacturing |

| Food Production | S6 | Light manufacturing |

| Beverage Production | S7 | Light manufacturing |

| Tobacco Processing | S8 | Light manufacturing |

| Textile Industry | S9 | Light manufacturing |

| Garments and Other Fiber Products | S10 | Light manufacturing |

| Leather, Furs, Down, and Related Products | S11 | Light manufacturing |

| Timber Processing, Bamboo, Cane, Palm Fiber, and Straw Products | S12 | Light manufacturing |

| Furniture Manufacturing | S13 | Light manufacturing |

| Papermaking and Paper Products | S14 | Light manufacturing |

| Printing and Record Medium Reproduction | S15 | Light manufacturing |

| Cultural, Educational, and Sports Articles | S16 | Light manufacturing |

| Petroleum Processing and Coking | S17 | Energy production |

| Raw Chemical Materials and Chemical Products | S18 | Heavy manufacturing |

| Medical and Pharmaceutical Products | S19 | Light manufacturing |

| Chemical Fiber | S20 | Heavy manufacturing |

| Rubber Products | S21 | Heavy manufacturing |

| Plastic Products | S22 | Heavy manufacturing |

| Nonmetal Mineral Products | S23 | Heavy manufacturing |

| Smelting and Pressing of Ferrous Metals | S24 | Heavy manufacturing |

| Smelting and Pressing of Nonferrous Metals | S25 | Heavy manufacturing |

| Metal Products | S26 | Heavy manufacturing |

| Ordinary Machinery | S27 | Heavy manufacturing |

| Equipment for Special Purposes | S28 | Heavy manufacturing |

| Transportation Equipment | S29 | Heavy manufacturing |

| Electric Equipment and Machinery | S30 | High-tech industry |

| Electronic and Telecommunications Equipment | S31 | High-tech industry |

| Instruments, Meters, Cultural, and Office Machinery | S32 | High-tech industry |

| Other Manufacturing Industry | S33 | High-tech industry |

| Scrap and waste | S34 | High-tech industry |

| Production and Supply of Electric Power, Steam, and Hot Water | S35 | Energy production |

| Production and Supply of Gas | S36 | Energy production |

| Production and Supply of Tap Water | S37 | Heavy manufacturing |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Wang, Y.; Hou, X. Carbon Mitigation for Industrial Sectors in the Jing-Jin-Ji Urban Agglomeration, China. Sustainability 2019, 11, 6383. https://doi.org/10.3390/su11226383

Zhang Y, Wang Y, Hou X. Carbon Mitigation for Industrial Sectors in the Jing-Jin-Ji Urban Agglomeration, China. Sustainability. 2019; 11(22):6383. https://doi.org/10.3390/su11226383

Chicago/Turabian StyleZhang, Yali, Yihan Wang, and Xiaoshu Hou. 2019. "Carbon Mitigation for Industrial Sectors in the Jing-Jin-Ji Urban Agglomeration, China" Sustainability 11, no. 22: 6383. https://doi.org/10.3390/su11226383

APA StyleZhang, Y., Wang, Y., & Hou, X. (2019). Carbon Mitigation for Industrial Sectors in the Jing-Jin-Ji Urban Agglomeration, China. Sustainability, 11(22), 6383. https://doi.org/10.3390/su11226383