1. Introduction

Industries around the world have implemented various policies and systems to cope with recent environmental impacts such as global warming [

1,

2]. The Fifth Assessment Report of the Intergovernmental Panel on Climate Change places a high responsibility on the construction industry to reduce their environmental footprint, which has led to the application of direct and indirect regulations [

3,

4]. Accordingly, systems to certify that high-performance building materials have reduced environmental impacts and costs are needed.

To reduce the environmental impacts of buildings, many countries are introducing and revising their certification standards for eco-friendly materials, such as the Environmental Profiles of Construction Products in the U.K., the Environmental Product Declaration in Sweden, and the Environmental Declaration of Construction Products in Germany [

5]. In South Korea, certification systems for eco-friendly construction materials are managed by the Ministry of Environment (ME) and include the Environmental Product Declaration (EPD) certification, which evaluates the top seven environmental impacts from a lifecycle perspective, the low-carbon certification, the carbon-footprint certification, and the Korea Eco-Label certification, which evaluates improvements in environmental performance. Certification systems managed by the Ministry of Trade and Industry (MTI) include the Good Recycled (GR) certification, which evaluates the quality of recycled products [

6,

7,

8,

9,

10,

11].

South Korea’s policies for the use of green building materials are continuously emphasized through reinforcement of local government laws, the implementation, and amendment of various building certification systems, and the strengthening of environmental impact assessments for buildings. Accordingly, moves to obtain eco-friendly certification for various products are underway. For example, concrete is used in various structures and packaging materials and is very important because it makes up a large part of construction costs and environmental impacts. As a result, demand for eco-friendly concrete is increasing, and many concrete producers have recently acquired EPD, low-carbon, and carbon-footprint certifications. To be competitive, concrete producers must now identify trends in green building materials at construction sites and select more effective green building materials [

12,

13,

14].

The challenge for increasing the use of eco-friendly construction materials is that each material is managed individually by different operation and management institutions, making it difficult for building owners, architects, and construction companies (hereafter referred to as “construction-related entities”) to access detailed information about the types, prices, standards, and environmental impacts of products certified as green building materials. Consequently, construction-related entities must directly request information from the manufacturer or use products that can be researched easily using the manufacturer’s website [

15,

16]. This not only reduces the work efficiency of many construction projects that use multiple products, but also increases the construction costs, due to a lack of available information regarding potentially cheaper or more eco-friendly products.

Therefore, this study aims to build a green building materials integrated platform (GIP) that will provide information about selected certification systems related to a wide range of eco-friendly materials in South Korea. Moreover, this GIP is intended to support the evaluation of materials and resources criteria in Green Standard for Energy and Environmental Design (G-SEED), through the development of a green building materials database that includes product prices. This GIP will enable construction-related entities to perform efficient comparisons and analyses of products during the design stage and contribute to optimized decision making through knowledge of product prices and environmental impacts.

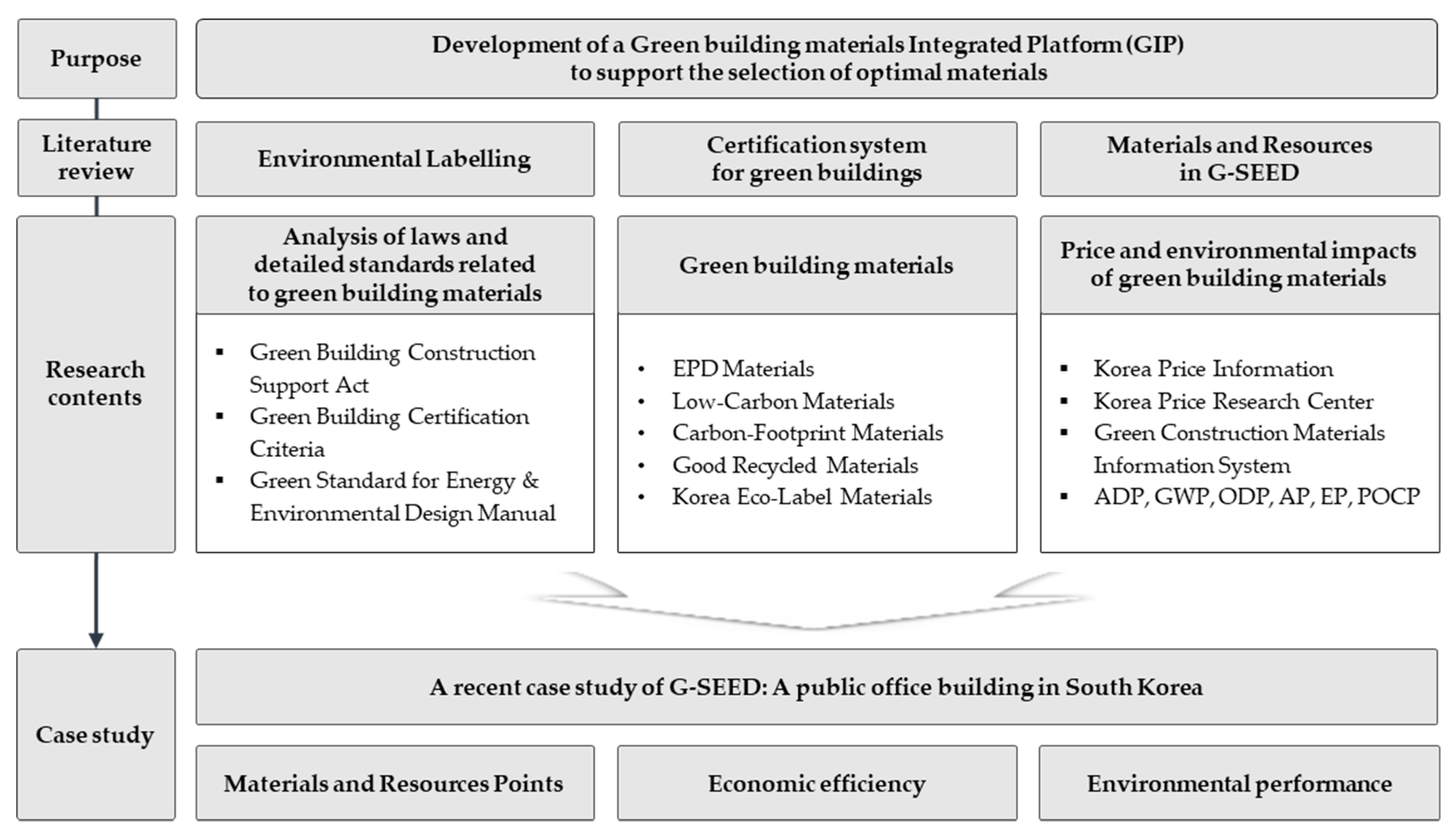

Figure 1 shows the complete flowchart of this study.

2. Background

2.1. Environmental Labelling

Eco-friendly materials are one of the means to show better environmental performance in this market than other products. Environmental labeling is information that helps consumers identify and select products that have superior environmental performance compared to other products for the same purpose. By introducing information on the environmental performance of the product, it enables consumers to select and use eco-friendly products while inducing companies to develop and produce eco-friendly products [

17,

18]. Since 1993, the International Standardization Organization (ISO) has established the Technical Committee (TC) 207 to develop international standards for environmental management. This is achieved by analyzing subjects such as environmental management system, environmental review, environmental labeling, environmental performance evaluation, and life cycle evaluation. The establishment of international standards for the system is completed [

19,

20]. The ISO international standard for environmental labeling is shown in

Table 1 [

17].

Type I Environmental Labels is where a third-party certification body evaluates the environmental impacts over the life-cycle, including the production, distribution, consumption, and disposal of a product. In this instance, this is at the voluntary application of a company and certifies that it is an eco-friendly product. It is also called multi-issue labeling because it considers the various environmental aspects of the product. The Blue Angel, which was implemented in Germany in 1979, was the first use of this concept and was later introduced in developed countries such as Japan, the United States, and the EU. Currently in operation in 47 countries around the world (as of the end of 2015), institutional agencies in each country formed the Global Ecolabeling Network (GEN) in 1994 to promote information exchange and mutual recognition agreements among member countries. In addition, the government is seeking to promote cooperation among countries by striving to promote international standardization of national certification standards for major trade items going forward [

21,

22].

Type II environmental labeling as defined in ISO 14021 refers to the use of labels, signs, and symbols that indicate that the company believes its products are eco-friendly without third-party verification. Companies in many countries are already using shapes and phrases that suggest environmentally friendly products in their advertising and product appearance, and they are most actively used for corporate green marketing. Type II environmental labeling is the environmental labeling system that consumers most frequently encounter in the market, in contrast to other environmental labeling systems that undergo third-party verification. Therefore, many countries have adopted guidelines for Type II environmental labeling in order to regulate them. This has resulted in the formulation of ISO 14021 being adopted by many countries. Governments in the United States, Canada, Japan, and Europe have established regulatory standards for Type II environmental labeling in order to regulate self-assertion by companies in the form of false and exaggerated advertising [

21,

23].

Type III environmental labeling is environmental labeling in which a company voluntarily discloses the environmental impact of the entire product as it is and discloses information without judging whether it is eco-friendly or not. It is verified by a third-party whether the published information is correct. Type III environmental labeling has been implemented in eight countries, including South Korea, Sweden, and Japan, since it was first introduced in 1992 by the Scientific Certification System, a private US organization. It is only deployed in some developed countries because it requires a complex analytical method called life cycle assessment (LCA). Type III environmental labeling requires ordinary consumers to interpret the information and determine whether it is eco-friendly, which is a disadvantage over Type I environmental labeling. In order to solve this problem, Global Type III Environmental Product Declarations Network (GEDnet) was formed in 1998 to support the international standardization work of ISO 14025. More recently, discussions on how to comply with these written guidelines among countries implementing the system are ongoing in order to assist consumers to purchase eco-friendly products [

17,

18,

24].

2.2. Environmental Labelling in South Korea

South Korea uses Type I and III environmental labeling systems. Type I examples include the Good Recycled certification system operated by the government Ministry of Trade and Industry and the Environmental Mark certification system operated by the Ministry of Environment. Type III examples include the environmental labeling system and carbon labeling system operated by the Ministry of Environment.

The Good Recycled certification system (Type I) was established in 1997 as the “Product Standards and Quality Certification Standards” to grant Good Recycled certification for recycled products with excellent quality, performance, and environmental friendliness throughout the product life cycle. Recycling products such as waste glass, waste wood, waste plastic, and waste rubber are applied to governmental, construction and civil engineering materials. As of the end of October 2019, Good Recycled materials have 200 companies and 1696 certified products [

11].

The Environmental Mark certification system (Type I) has been in force since June 1992, and its legal basis was established in December 1994 in the Environmental Technology and Environmental Industry Support Act. In the case of Korea Eco-Label materials, four items, including recycled paper and recycled toilet paper were selected in 1992, the first year of introduction, and as of the end of October 2019, it has been expanded to 4201 companies and 87,590 certified products [

10].

Environmental labeling system (Type III) has been in operation since February 2001 under the management of the Ministry of Environment, which is responsible for the certification of environmental labeling, the development of guidelines, and the operation of the information network at the Korea Environmental Industry and Technology Institute. To revitalize the environmental labeling system, a completely revised ‘Environmental Labeling Target Products and Preparation Guidelines’ was issued in June 2013. Through this, the system of guidelines for individual products was unified into a single system, and the verification system for environmental label products was introduced. Environmental Product Declaration materials have 623 cumulative certified products as of the end of October 2019 [

7,

17,

24].

In the carbon labeling system (Type III), carbon reduction and sustainable development are already a global problem. In May 2013, the international standard ISO/TS 14067 (carbon footprint of products) was enacted so that the world’s greenhouse gas emissions were calculated based on the same methodology. Accordingly, 12 countries, including the UK, France, Japan, and China are implementing carbon labeling. South Korea also introduced a carbon labeling system as one of its environmental labeling systems in February 2009 and changed its name to Carbon-footprint in January 2017. Carbon-footprint materials started with 111 product certifications in 2009, and 2203 products have been certified as of the end of October 2019 [

9].

Low-carbon certification is granted to products that are below the average carbon emission of similar products and have reduced greenhouse gas emissions by 4.24% (based on the carbon reduction rate) by applying low carbon technology. As of the end of October 2019, 531 low-carbon materials were certified [

8].

2.3. Green Building Certification Systems in South Korea

The Type I and III environmental labeling system is used in five items of materials and resources in Green Standard for Energy and Environmental Design (G-SEED), a green building certification system in South Korea.

G-SEED started in 2002 and is now actively operated. G-SEED consists of evaluations of materials and resources (18%), land use and transport (10%), energy and pollution (25%), water (10%), management (7%), ecology (10%), and indoor environment quality (20%). The evaluation criteria for the materials and resources evaluation in G-SEED consists of six items (3.1 to 3.6), which are classified into four grades according to the respective evaluation criteria. For items 3.1, 3.2, 3.3, and 3.4, the grade and score depend on the applied number of green building materials corresponding to each item. Item 3.5 is scored by the ratio of the applied cost of green building materials in items 3.1 to 3.4, relative to the total construction cost. Item 3.6 verifies the installation of recyclable household waste storage facilities and waste sorting bins. This is excluded from the scope of this study because it is unrelated to green building materials. The life cycle assessment (LCA), an additional item of the materials and resources category in G-SEED, evaluates the environmental impact of the total lifecycle of buildings.

The evaluation criteria for items 3.1 to 3.4 relate to the use of certified products. However, products unrelated to construction, portable products, and consumables cannot be recognized even if they have certificates.

Table 2 lists the evaluation criteria and points for each grade of materials and resources addressed in this study [

25,

26].

3. Materials and Methods

Green building materials database was constructed in G-SEED as Type I and III environmental labeling materials that can be used in the five materials and resources evaluation items [

25]. A GIP aims to facilitate decision-making related to the best product alternatives, according to economic efficiency and environmental performance, by providing product price and environmental impact information. Through this, GIP are able to predict and evaluate economic efficiency and environmental performance at the building level rather than at the material level.

Figure 2 shows the conceptual diagram of GIP development.

3.1. Construction of Green Building Materials Database

3.1.1. Target Green Building Materials

Type III green building materials targets are Environmental Product Declaration materials and carbon-footprint materials in item 3.1 and low-carbon materials in item 3.2. Type I green building materials targets are good recycled in item 3.3 and Korea Eco-Label materials in item 3.4 in materials and resources in G-SEED.

Detailed information about green building materials is provided by the Korea Environmental Industry and Technology Institute, an agency under the Ministry of Environment, for Environmental Product Declaration, low-carbon, carbon-footprint, and Korea Eco-Label materials. The Good Recycled Products Information System of the Resources Circulation Industry Certification Institute, an agency under the Ministry of Trade and Industry, for good recycled materials. However, these data include certified products from all industries and not only construction. To construct the green materials database, the selected products were classified based on the middle category items used in Korea Eco-Label materials [

10]. Of the 23 middle category items, the selected items were EL241–EL259 other materials; EL721–EL727 plastic, rubber, and wood materials; EL741–EL746 metal, inorganic, and ceramic materials. Among the 17 criteria for certification of Korea Eco-Label materials, improved resource circulation and reduced harmful substances were selected, excluding portable products and consumable products, in accordance with the detailed guidelines for G-SEED. Selected product groups include bricks, stones, tiles, adhesives, wood, earth, blocks, waterproofing, roofing and gutters, plaster, windows, glass, paints, insulation etc.

3.1.2. Law and Detailed Standards Related to Green Building Materials

The laws related to materials and resources in G-SEED include the “Green Building Construction Support Act,” “Enforcement Decree of the Green Building Construction Support Act,” “Seoul Green Building Design Standard,” “Gyeonggi-do Green Building Design Standard,” “Recycled Building Materials Utilization Standard,” and “Green Building Certification Regulation.” Detailed standards related to the evaluation of materials and resources include the “EPD Standard,” “Low-Carbon Standard,” “Carbon-Footprint Standard,” “Korea Eco-Label Standard,” “GR Standard,” “G-SEED Standard,” “G-SEED Regulation,” “G-SEED Operation Rules,” and “Standard Construction Cost for Overpopulation Fee.” The final targets for building the green building materials database were selected according to the relevant laws and regulations.

Table 3 lists the Korean laws and provisions related to the materials and resources category in G-SEED [

7,

8,

9,

10,

11,

25,

26,

27,

28,

29,

30,

31,

32,

33,

34,

35,

36].

3.1.3. Product Price and Environmental Impact

Product prices are required in item 3.5 of G-SEED and can be calculated using the values provided by the Korea Price Information and the Korea Price Research Center, in accordance with the detailed guidelines of G-SEED [

25]. Price data provided by the KPI and the Green Construction Materials Information System of KPRC [

34,

35] were input to G-SEED. If the product certification standard units differed from those of the price standard, the product price standard unit was converted to the certification standard by the method shown in

Table 4.

For the environmental impact, emission factor data (Type III) derived in accordance with the environmental impact measurement method for certified products of Korea Environmental Industry and Technology Institute (KEITI) were used for Environmental Product Declaration (EPD), low-carbon and carbon-footprint materials [

7,

8,

9]. The data for EPD materials include six key environmental impact indexes: The global warming potential (GWP), abiotic depletion potential (ADP), acidification potential (AP), eutrophication potential (EP), ozone depletion potential (ODP), and photochemical oxidant creation potential (POCP), whereas the data for low-carbon and carbon-footprint materials include only the GWP.

Table 5 shows an example of the composition of the green building materials database with environmental impacts.

3.1.4. Results of the Green Building Materials Database

The green building materials database was compiled using 12,636 data points found through an analysis of laws and standards related to green building materials, selection of target green building materials, acquisition of product price information and unit conversion, and analysis of environmental impact data. The database consists of 21 EPD materials and 166 carbon-footprint materials, which are required in item 3.1 of G-SEED; 34 low-carbon materials, required in item 3.2; 640 GR materials in item 3.3; and 11,775 Korea Eco-Label materials required for item 3.4. These products all include the information required for the evaluation of G-SEED, i.e., manufacturer, product name, specifications, valid term, and unit price. The EPD, low-carbon, and carbon-footprint materials also include environmental impact data.

Table 6 shows the results of the green building materials database [

37,

38].

3.2. Development of Green Building Materials Integrated Platform (GIP)

Based on the constructed green building materials database, an Excel-based GIP was developed to improve the accessibility and efficiency of construction-related entities. The GIP was composed of four steps: Input sheet, select sheet, analysis sheet, and database sheet.

In the input sheet (Step 1), a brief business overview for using the GIP is entered, including the project name, region, and G-SEED target grade. The gross area of the project is also required to evaluate item 3.5. The construction cost is calculated by multiplying the gross area by the standard construction cost for 2019 (USD 1584.67) [

33]. In the select sheet (Step 2), a product is selected for each item of the materials and resources categories in G-SEED. This is linked to the database sheet corresponding to each item, so that only the corresponding data in the database appears. The convenience of product selection was improved by using the filter feature of Excel. For the selected product, the manufacturer, product name, available term, and unit price are loaded. If there are duplicate certified products with other items, they are displayed as a note. In the analysis sheet (Step 3), the products selected from items 3.1 to 3.4 in the select sheet are automatically loaded. Then, the cost of green building materials is calculated when the quantity of each product is entered. Duplicate calculation of duplicate products is prevented through the conditional format feature of Excel. The database sheet consists of four sheets from item 3.1 to 3.4. It includes the manufacturer, product name, specifications, available term, unit price, and code for future data management. The green building materials, by product type, consist of 21 EPD materials, 166 carbon-footprint materials, 34 low-carbon materials, 640 GR materials, and 11,775 Korea Eco-Label materials. Furthermore, the EPD, low-carbon, and carbon-footprint materials certified for environmental impacts include the six key environmental impact indexes (ADP, GWP, ODP, AP, EP, and POCP) (

Table 6).

Figure 3 shows the configuration GIP.

4. Case Study

An actual building that was evaluated by G-SEED was analyzed in this study to determine the economic efficiency and environmental performance of using the GIP. The target building was a public office facility in South Korea (

Table 7) that was evaluated based on the latest G-SEED version implemented on 1 September 2018. For this case study, the economic efficiency and environmental performance of the products used to evaluate items 3.1 and 3.2 of the materials and resources category in G-SEED were compared with those of the alternative products proposed as a result of applying the GIP. The proposed alternative products were divided into Case 1, which was focused on the product price, and Case 2, which was focused on the product GWP emission factor.

4.1. Economic Efficiency Analysis

To analyze the economic efficiency, the material costs saved by using the alternative products proposed by the GIP and by using the products applied to the target building were compared. The total cost of green building materials in the evaluated building accounted for approximately 4.49% (USD 210,380) of the total costs and corresponded to grade 3 and 2.4 points in item 3.5.

In Case 1, the cost was reduced by 16.87% (USD 35,483). The reduction rate was the highest for the floor materials, representing a saving of 69.43% (USD 27,833), followed by ceiling and structure materials. In Case 2, the cost was reduced by 7.89% (USD 16,609). The reduction rate was the highest for the floor materials, representing a saving of 53.01% (USD 21,253). However, structure and ceiling have rather increased costs, because Case 2 products are focused on eco-friendly. Specifically, ready-mixed-concrete accounted for approximately 90% of the cost of green building materials and corresponded to grade 3 and 2.4 points in item 3.5 for just the one product. This is because it is an important and costly structural component used in large quantities.

Table 8,

Figure 4, and

Figure 5 show the results of the economic efficiency analysis of the alternative products proposed by the GIP.

4.2. Analysis of Environmental Performance

To analyze the environmental performance of the products, six IPCC-defined greenhouse gases emitted during material production were converted to GWP and evaluated. The total GWP in the target building was 6.61 × 10

5 (kg CO

2). In Case 1, the GWP was reduced by 9.82% (6.49 × 10

4 kg CO

2). The reduction rate was the highest in the floor materials, which was reduced by 39.82% (3.43 × 10

3 kg CO

2), followed by structure and ceiling materials. In Case 2, the GWP was reduced by 20.89% (1.38 × 10

5 kg CO

2). The reduction rate was the highest in the floor materials, which was reduced by 66.32% (5.71 × 10

3 kg CO

2), followed by ceiling and structure materials. This is because the types of floor materials are diverse and the GWP emissions factor varies greatly depending on the material type and properties. Specifically, the ready-mixed-concrete was shown to be an important material from an environmental perspective because it accounted for approximately 99% of the total GWP. Again, this is because ready-mixed-concrete is a major structural member with a high GWP due to its large quantities.

Table 9,

Figure 6, and

Figure 7 show the results of the environmental performance analysis of the alternative products proposed by the GIP.

5. Discussion

The major green building certification systems of environmentally developed countries are managed in an integrated manner through a classification system linked with eco-friendly materials. However, in South Korea, eco-friendly materials are managed separately by various manufacturers, making it difficult for construction-related entities to make informed product choices. As a result, even though effective products exist, they may not be selected during the construction of green buildings, due to a lack of detailed product information and accessibility. Consequently, this study developed an Excel-based GIP that integrates various product-related laws and certification systems in South Korea.

Two G-SEED case studies were performed using the developed GIP, both of which indicated that the economic efficiency and environmental performance of buildings could be improved by using alternative materials and resources proposed by the GIP. Case 1, which focused on economic efficiency, was more effective in terms of G-SEED and construction cost reduction. Case 2 was less effective in terms of construction cost but showed excellent improvements in both environmental performance and economic efficiency relative to the material combination selected in the existing building. The GIP developed in this study can be used to calculate various environmental load emissions and costs of green building materials for each part of a target building. Furthermore, construction-related entities, including architects, can directly participate in the selection of materials based on their environmental performance and economic efficiency. The case study results suggest that replacing concrete in the structure of the building, which has relatively high costs and GWP, is more efficient than changing the finishing material. Furthermore, because the work efficiency was difficult to quantify, a survey was conducted with construction-related entities engaged in actual G-SEED operations. For the target building, the work time spent for the evaluation of materials and resources was 75.5 h. The search for detailed product information—including laws, certified products, certificates, and prices—took 53.5 h, accounting for approximately 71% of the total work time. When GIP was used, the total work time was reduced to 58 h, improving the work efficiency by 23.18%. The search for detailed product information took 36 h, improving the work efficiency by 32.71%. In contrast, the preparation of evidence drawings, which differs for every project, did not show any efficiency improvement when using the GIP.

Figure 8 shows the results of the survey on work efficiency using GIP completed by people in charge of G-SEED.

However, GIP has limitations in data security and maintenance because it is based on Excel. Therefore, the GIP should be improved by developing a Web-based platform in the future. This will protect the data, improve sustainability, and enable construction-related entities to improve accessibility and efficiency. The U.S. and U.K., which are environmentally developed countries, perform LCA using environmental impact data of the materials actually used. However, in South Korea, LCA is performed using the average data of the national LCI Database. Thus, the overall G-SEED grade and specific materials and resources grade, which evaluates the use of green building materials in the building, are unrelated to the LCA result. This problem can be improved by combining the environmental impact data of EPD, low-carbon, and carbon-footprint materials provided by the GIP with the evaluation system for LCA.

6. Conclusions

This study developed a green building materials integrated platform (GIP) to support the evaluation of materials and resources in the G-SEED green building certification system currently used in South Korea. GIP is based on green building materials which are configured by Type I and III environmental labeling materials. Green building materials are the detailed evaluation criteria and guidelines, construction cost criteria, and selection criteria for green building materials were selected from 16 laws and regulations compiled by eight institutions related to the materials and resources evaluation category in G-SEED. The GIP was developed by constructing a green building materials database that includes product prices and environmental impact data to enable construction-related entities such as architects to efficiently compare and analyze materials according to their environmental performance and economic efficiency. The following conclusions were reached.

A green building materials database was constructed, which can be used for the evaluation of materials and resources in G-SEED, encompassing all eco-friendly materials currently used in industries in South Korea. The database comprises 12,636 materials as of 2018, including 221 EPD, low-carbon, and carbon-footprint materials, 640 GR materials, and 11,775 Korea Eco-Label materials. The database also contains product price data and six key environmental impact indexes (ADP, GWP, ODP, AP, EP, POCP) for EPD, low-carbon, and carbon-footprint materials.

To review the applicability of GIP to the evaluation of materials and resources in G-SEED, two case studies were performed that focused on the economic efficiency and environmental performance of materials proposed by the GIP.

As a result of the economic efficiency analysis, Case 1 costs were improved by 16.87% (USD 35,483), relative to the existing alternative materials. In Case 2, costs were improved by 7.89% (USD 16,609). Thus, both cases showed that the GIP can propose more economical combinations of green building materials than the existing system.

As a result of the environmental efficiency analysis, Case 1 impacts were improved by 9.82% (6.49 × 104 kg CO2) relative to the existing alternative materials. In Case 2, impacts were improved by 20.89% (1.38 × 105 kg CO2). Thus, both cases showed that the GIP can propose better combinations of green building materials than the existing system.

The analysis of the environmental performance and economic efficiency of selected eco-friendly materials showed that environmental and economic efficiency improvement among homogeneous products was achieved, especially for finishing materials such as flooring materials at the material level. Changing concrete should be considered the most important action for improved efficiency at the building level. Changing the selection of ready-mixed concrete accounts for about 90% of the economic weight and 99% of the environmental weight.

The GIP proposed in this study is expected to further contribute to the development of a system that can evaluate the environmental impacts of green building materials applied to the materials and resources category in G-SEED, by linking the evaluation system with LCA.