Analysis of Environmental Productivity on Fossil Fuel Power Plants in the U.S.

Abstract

:1. Introduction

2. Literature Review

2.1. U.S. Environmental Regulations and Related Research

2.2. Environmental Performance Assessment

2.3. Research on the Environmental Performance of Fossil Fuel Power Plants

3. Methodology

3.1. Metafrontier and Distance Function

3.2. Generalized Metafrontier Malmquist Productivity Index

3.3. Model Specification

3.4. Data Source and Variable Construction

4. Empirical Analysis

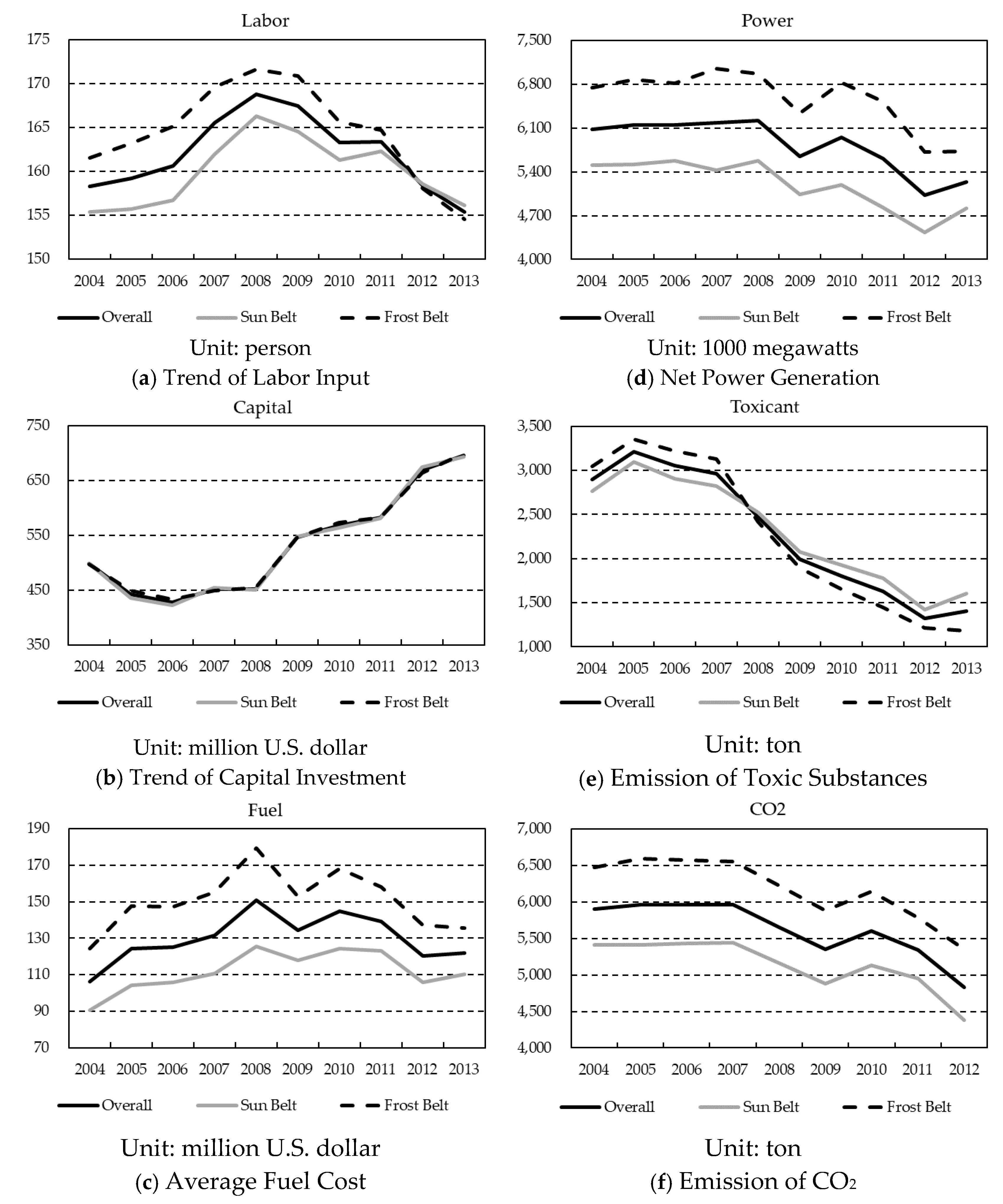

4.1. Overview of the Variables

4.2. Estimating Environmental Performance

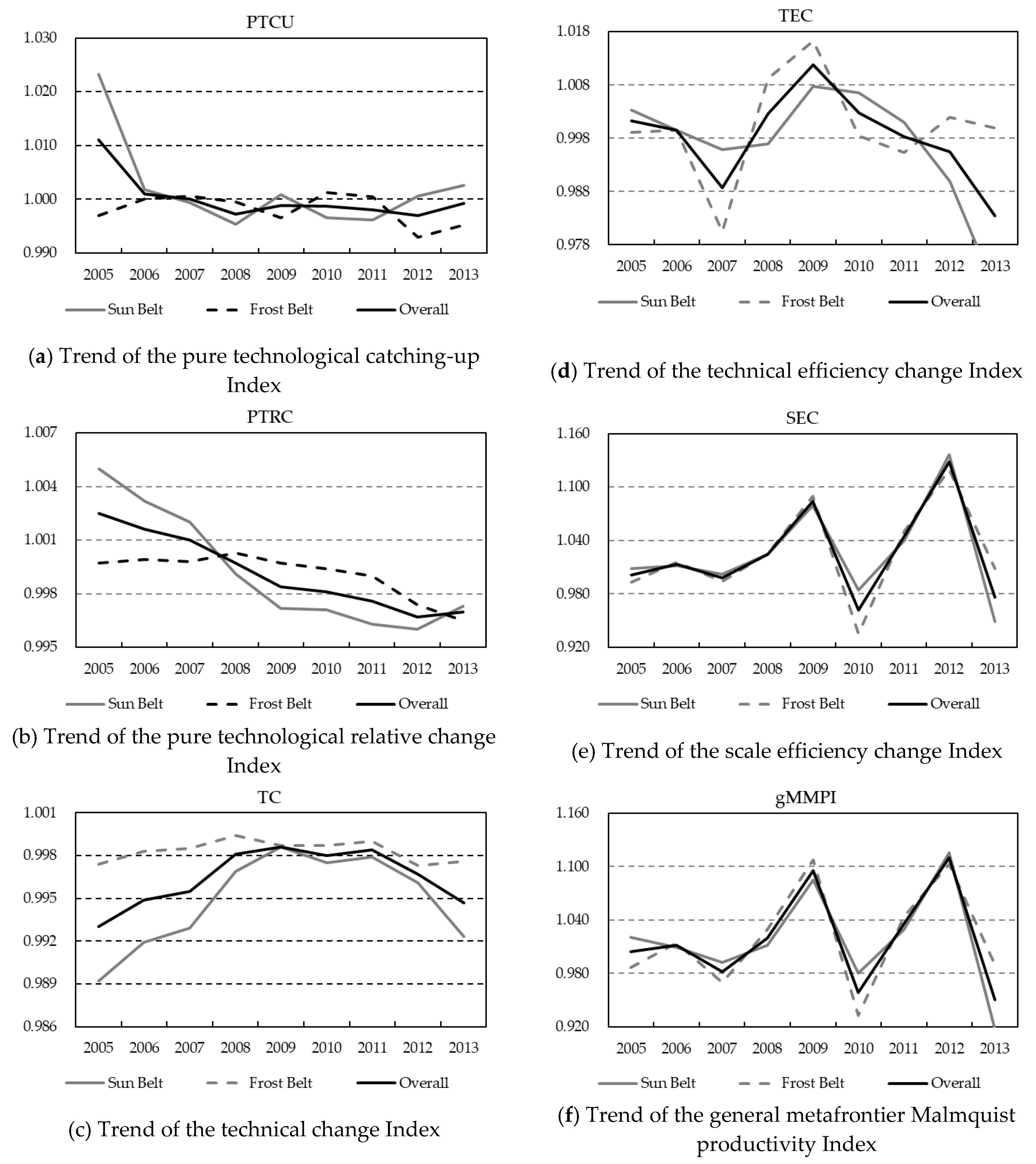

4.3. Measuring Environmental Performance

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Variables\Numbers of the Variables a | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0. Net Power Generation | 1.00 | ||||||||||||||

| 1. Labor | 0.74 | 1.00 | |||||||||||||

| 2. Capital | 0.66 | 0.60 | 1.00 | ||||||||||||

| 3. Fuel Expenditure | 0.85 | 0.59 | 0.62 | 1.00 | |||||||||||

| 4. Toxic Emission | 0.57 | 0.41 | 0.27 | 0.38 | 1.00 | ||||||||||

| 5. CO2 | 0.96 | 0.68 | 0.63 | 0.78 | 0.56 | 1.00 | |||||||||

| 6. Plant Age | −0.29 | −0.11 | −0.27 | −0.29 | −0.03 | −0.27 | 1.00 | ||||||||

| 7. Use of Natural Gas | −0.24 | −0.22 | −0.13 | −0.07 | −0.25 | −0.30 | 0.01 | 1.00 | |||||||

| 8. Coal Ratio | 0.08 | 0.20 | 0.04 | −0.14 | 0.20 | 0.18 | 0.15 | −0.54 | 1.00 | ||||||

| 9. Content of Sulfate | 0.04 | 0.05 | −0.05 | 0.00 | −0.20 | 0.10 | 0.00 | −0.11 | 0.21 | 1.00 | |||||

| 10. Plant Scale | 0.88 | 0.69 | 0.71 | 0.78 | 0.51 | 0.73 | −0.27 | −0.04 | −0.11 | −0.10 | 1.00 | ||||

| 11. Process Control | 0.20 | 0.21 | 0.11 | 0.17 | 0.06 | 0.22 | −0.06 | −0.03 | −0.04 | 0.08 | 0.16 | 1.00 | |||

| 12. Process Improvement | 0.20 | 0.23 | −0.04 | 0.15 | −0.02 | 0.23 | −0.04 | −0.03 | −0.01 | −0.08 | 0.13 | 0.21 | 1.00 | ||

| 13. Beginning Process Control | −0.07 | 0.00 | 0.19 | 0.02 | −0.22 | −0.08 | 0.13 | 0.06 | −0.03 | 0.01 | 0.02 | −0.04 | −0.01 | 1.00 | |

| 14. Process Control Enhancement | −0.07 | −0.02 | 0.18 | −0.01 | −0.18 | −0.08 | 0.12 | 0.06 | −0.04 | 0.00 | 0.01 | −0.06 | −0.01 | 0.65 | 1.00 |

References

- Mills-Knapp, S.; Traore, K.; Ericson, B.; Keith, J.; Hanrahan, D.; Caravanos, J. The World’s Worst Pollution Problems: Assessing Health Risks at Hazardous Waste Sites; Blacksmith Institute: New York, NY, USA, 2012. [Google Scholar]

- Hart, S.L. Beyond Greening: Strategies for a Sustainable World. Harv. Bus. Rev. 1997, 75, 66–77. [Google Scholar]

- Gao, H.; Yang, W.; Yang, Y.; Yuan, G. Analysis of the Air Quality and the Effect of Governance Policies in China’s Pearl River Delta, 2015–2018. Atmosphere 2019, 10, 412. [Google Scholar] [CrossRef] [Green Version]

- Statistics, I.E.A. CO2 Emissions from Fuel Combustion Highlights; IEA: Paris, France, 2011; Available online: http://www.iea.org/co2highlights/co2highlights.pdf (accessed on 31 July 2014).

- Environmental Protection Agency. 2012 Toxics Release Inventory National Analysis Overview 2014. Available online: http://www2.epa.gov/toxics-release-inventory-tri-program/2012-tri-national-analysis (accessed on 13 March 2015).

- Sueyoshi, T.; Goto, M. Should the US Clean Air Act Include CO2 Emission Control? Examination by Data Envelopment Analysis. Energy Policy 2010, 38, 5902–5911. [Google Scholar] [CrossRef]

- Kumar, S.; Managi, S. Sulfur Dioxide Allowances: Trading and Technological Progress. Ecol. Econ. 2010, 69, 623–631. [Google Scholar] [CrossRef]

- Yang, W.; Yuan, G.; Han, J. Is China’s Air Pollution Control Policy Effective? Evidence from Yangtze River Delta Cities. J. Clean. Prod. 2019, 220, 110–133. [Google Scholar] [CrossRef]

- Yang, W.; Li, L. Efficiency Evaluation of Industrial Waste Gas Control in China: A Study Based on Data Envelopment Analysis (DEA) Model. J. Clean. Prod. 2018, 179, 1–11. [Google Scholar] [CrossRef]

- Yuan, G.; Yang, W. Evaluating China’s Air Pollution Control Policy with Extended AQI Indicator System: Example of the Beijing-Tianjin-Hebei Region. Sustainability 2019, 11, 939. [Google Scholar] [CrossRef] [Green Version]

- Hu, H.; Jin, Q.; Kavan, P. A Study of Heavy Metal Pollution in China: Current Status, Pollution-Control Policies and Countermeasures. Sustainability 2014, 6, 5820–5838. [Google Scholar] [CrossRef] [Green Version]

- Pettersson, M.; Söderholm, P. Industrial Pollution Control and Efficient Licensing Processes: The Case of Swedish Regulatory Design. Sustainability 2014, 6, 5401–5422. [Google Scholar] [CrossRef] [Green Version]

- Zhang, N.; Kong, F.; Choi, Y.; Zhou, P. The Effect of Size-Control Policy on Unified Energy and Carbon Efficiency for Chinese Fossil Fuel Power Plants. Energy Policy 2014, 70, 193–200. [Google Scholar] [CrossRef]

- Zhang, N.; Choi, Y. Total-Factor Carbon Emission Performance of Fossil Fuel Power Plants in China: A Metafrontier Non-Radial Malmquist Index Analysis. Energy Econ. 2013, 40, 549–559. [Google Scholar] [CrossRef]

- Zhang, N.; Zhou, P.; Choi, Y. Energy Efficiency, CO2 Emission Performance and Technology Gaps in Fossil Fuel Electricity Generation in Korea: A Meta-Frontier Non-Radial Directional Distance Function Analysis. Energy Policy 2013, 56, 653–662. [Google Scholar] [CrossRef]

- Sueyoshi, T.; Goto, M. DEA Radial Measurement for Environmental Assessment and Planning: Desirable Procedures to Evaluate Fossil Fuel Power Plants. Energy Policy 2012, 41, 422–432. [Google Scholar] [CrossRef]

- Chung, Y.H.; Färe, R.; Grosskopf, S. Productivity and Undesirable Outputs: A Directional Distance Function Approach. J. Environ. Manag. 1997, 51, 229–240. [Google Scholar] [CrossRef] [Green Version]

- Zhang, N.; Choi, Y. A Comparative Study of Dynamic Changes in CO2 Emission Performance of Fossil Fuel Power Plants in China and Korea. Energy Policy 2013, 62, 324–332. [Google Scholar] [CrossRef]

- Sueyoshi, T.; Goto, M. Returns to Scale vs. Damages to Scale in Data Envelopment Analysis: An Impact of US Clean Air Act on Coal-Fired Power Plants. Omega 2013, 41, 164–175. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S. New Directions: Efficiency and Productivity; Kluwer Academic Publishers: Boston, MA, USA, 2004. [Google Scholar]

- Shephard, R.W. Theory of Cost and Production Functions; Princeton University Press: Princeton, NJ, USA, 1970. [Google Scholar]

- Cuesta, R.A.; Zofio, J.L. Hyperbolic Efficiency and Parametric Distance Functions: With Application to Spanish Savings Banks. J. Prod. Anal. 2005, 24, 31–48. [Google Scholar] [CrossRef]

- Cuesta, R.A.; Lovell, C.K.; Zofio, J.L. Environmental Efficiency Measurement with Translog Distance Functions: A Parametric Approach. Ecol. Econ. 2009, 68, 2232–2242. [Google Scholar] [CrossRef]

- Crandall, R.W. Clean Air and Regional Protectionism. Brook. Rev. 1983, 2, 17–20. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S.; Pasurka, C.A., Jr. Accounting for Air Pollution Emissions in Measures of State Manufacturing Productivity Growth. J. Reg. Sci. 2001, 41, 381–409. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S.; Pasurka, C.A., Jr. Toxic Releases: An Environmental Performance Index for Coal-Fired Power Plants. Energy Econ. 2010, 32, 158–165. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S.; Pasurka, C.A., Jr. Social Responsibility: US Power Plants 1985–1998. J. Prod. Anal. 2006, 26, 259–267. [Google Scholar] [CrossRef]

- Battese, G.E.; Rao, D.P.; O’Donnell, C.J. A Metafrontier Production Function for Estimation of Technical Efficiencies and Technology Gaps for Firms Operating under Different Technologies. J. Prod. Anal. 2004, 21, 91–103. [Google Scholar] [CrossRef]

- Huang, C.J.; Huang, T.H.; Liu, N.H. A New Approach to Estimating the Metafrontier Production Function Based on a Stochastic Frontier Framework. J. Prod. Anal. 2014, 42, 241–254. [Google Scholar] [CrossRef]

- Environmental Protection Agency. Cleaner Power Plant 2015. Available online: https://archive.epa.gov/epa/cleanpowerplan/fact-sheet-overview-clean-power-plan.html (accessed on 29 April 2017).

- Rubin, E.S.; Taylor, M.R.; Yeh, S.; Hounshell, D.A. Learning Curves for Environmental Technology and Their Importance for Climate Policy Analysis. Energy 2004, 29, 1551–1559. [Google Scholar] [CrossRef] [Green Version]

- Adair, S.K.; Hoppock, D.C.; Monast, J.J. New Source Review and Coal Plant Efficiency Gains: How New and Forthcoming Air Regulations Affect Outcomes. Energy Policy 2014, 70, 183–192. [Google Scholar] [CrossRef]

- Fleishman, R.; Alexander, R.; Bretschneider, S.; Popp, D. Does Regulation Stimulate Productivity? The Effect of Air Quality Policies on the Efficiency of US Power Plants. Energy Policy 2009, 37, 4574–4582. [Google Scholar] [CrossRef]

- Klassen, R.; McLaughlin, C. The Impact of Environmental Management on Firm Performance. Manag. Sci. 1996, 42, 1199–1214. [Google Scholar] [CrossRef]

- Keffer, C.; Shimp, R.; Lehni, M. Eco-Efficiency Indicators and Reporting; World Business Council for Sustainable Development (WBCSD): London, UK, 1999. [Google Scholar]

- Verfaillie, H.A.; Bidwell, R. Measuring Eco-efficiency: A Guide to Reporting Company Performance. World Business Council for Sustainable Development (WBCSD). 2000. Available online: https://www.gdrc.org/sustbiz/measuring.pdf (accessed on 3 December 2019).

- Färe, R.; Grosskopf, S.; Lovell, C.K.; Pasurka, C. Multilateral Productivity Comparisons When Some Outputs Are Undesirable: A Nonparametric Approach. Rev. Econ. Stat. 1989, 75, 90–98. [Google Scholar] [CrossRef]

- Murty, M.N.; Kummer, S.; Dhavala, K.K. Measuring Environmental Efficiency of Industry: A Case Study of Thermal Power Generation in India. Environ. Resour. Econ. 2007, 38, 31–50. [Google Scholar] [CrossRef]

- Khanna, M.; Kummer, S. Corporate Environmental Management and Environmental Efficiency. Environ. Resour. Econ. 2011, 50, 227–242. [Google Scholar] [CrossRef]

- Lin, Y.Y.; Chen, P.Y.; Chen, C.C. Measuring the Environmental Efficiency of Countries: A Directional Distance Function Metafrontier Approach. J. Environ. Manag. 2013, 119, 134–142. [Google Scholar]

- Wei, C.; Loschel, A.; Liu, B. An Empirical Analysis of the CO2 Shadow Price in Chinese Thermal Power Plant. Energy Econ. 2013, 40, 22–31. [Google Scholar] [CrossRef]

- Dong, F.; Li, X.; Liu, X. Regional Carbon Emission Performance in China According to a Stochastic Frontier Model. Renew. Sustain. Energy Rev. 2013, 28, 525–530. [Google Scholar] [CrossRef]

- Ramanathan, R. An Analysis of Energy Consumption and Carbon Dioxide Emissions in Countries of the Middle East and North Africa. Energy 2005, 30, 2831–2842. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S.; Noh, D.W.; Weber, W.L. Characteristics of a Polluting Technology: Theory and Practice. J. Econom. 2005, 126, 469–492. [Google Scholar] [CrossRef]

- Managi, S.; Kumar, S. Trade-Induced Technological Change: Analyzing Economic and Environmental Outcomes. Econ. Model. 2009, 26, 721–732. [Google Scholar] [CrossRef]

- Yang, M.; Yang, F.X.; Chen, X.P. Effects of Substituting Energy with Capital on China’s Aggregated Energy and Environmental Efficiency. Energy Policy 2011, 39, 6065–6072. [Google Scholar] [CrossRef]

- Lee, M. The Shadow Price of Substitutable Sulfur in the US Electric Power Plant: A Distance Function Approach. J. Environ. Manag. 2005, 77, 104–110. [Google Scholar] [CrossRef]

- Mekaroonreung, M.; Johnson, A. Estimating Efficiency of U.S. Oil Refineries Under Varying Assumptions Regarding Disposability of Bad Outputs. Int. J. Energy Sect. Manag. 2009, 4, 356–398. [Google Scholar] [CrossRef] [Green Version]

- Sueyoshi, T.; Goto, M. DEA Approach for Unified Efficiency Measurement: Assessment of Japanese Fossil Fuel Power Generation. Energy Econ. 2011, 33, 292–303. [Google Scholar] [CrossRef]

- GAO, U. Environmental Protection: More Consistency Needed Among EPA Regions in Approach to Enforcement; General Accounting Office: Washington, DC, USA, 2000. [Google Scholar]

- Zwickl, K.; Ash, M.; Boyce, J.K. Regional Variation in Environmental Inequality: Industrial Air Toxics Exposure in US Cities. Ecol. Econ. 2014, 107, 494–509. [Google Scholar] [CrossRef] [Green Version]

- Lau, L.J.; Yotopoulos, P.A. The Meta-Production Function Approach to Technological Change in World Agriculture. J. Dev. Econ. 1989, 31, 241–269. [Google Scholar] [CrossRef]

- Battese, G.E.; Rao, D.P. Technology Gap, Efficiency, and a Stochastic Metafrontier Function. Int. J. Bus. Econ. 2002, 1, 87–93. [Google Scholar]

- Oh, D.H. A Metafrontier Approach for Measuring an Environmentally Sensitive Productivity Growth Index. Energy Econ. 2010, 32, 146–157. [Google Scholar] [CrossRef]

- Chiu, C.R.; Liou, J.L.; Wu, P.I.; Fang, C.L. Decomposition of the Environmental Inefficiency of the Meta-Frontier with Undesirable Output. Energy Econ. 2012, 34, 1392–1399. [Google Scholar] [CrossRef]

- Yaisawarng, S.; Klein, J.D. The Effects of Sulfur Dioxide Controls on Productivity Change in the US Electric Power Industry. Rev. Econ. Stat. 1994, 76, 447–460. [Google Scholar] [CrossRef]

- Huang, T.H.; Chiang, D.L.; Tsai, C.M. Applying the New Metafrontier Directional Distance Function to Compare Banking Efficiencies in Central and Eastern European Countries. Econ. Model. 2015, 44, 188–199. [Google Scholar] [CrossRef]

- Battese, G.E.; Coelli, T.J. A Model for Technical Inefficiency Effects in a Stochastic Frontier Production Function for Panel Data. Empir. Econ. 1995, 20, 325–332. [Google Scholar] [CrossRef] [Green Version]

- Caves, D.W.; Christensen, L.R.; Diewert, W.E. The Economic Theory of Index Numbers and the Measurement of Input, Output, and Productivity. Econometrica 1982, 50, 1393–1414. [Google Scholar] [CrossRef]

- Caves, D.W.; Christensen, L.R.; Diewert, W.E. Multilateral Comparisons of Output, Input, and Productivity Using Superlative Index Numbers. Econ. J. 1982, 92, 73–86. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S.; Norris, M.; Zhang, Z. Productivity Growth, Technical Progress, and Efficiency Change in Industrialized Countries. Am. Econ. Rev. 1994, 84, 66–83. [Google Scholar]

- Rao, D.S.P. Metafrontier Frameworks for the Study on Firm-Level Efficiencies and Technology Gaps. In Proceedings of the 2006 Productivity and Efficiency Seminar, Taipei, Taiwan, 10 March 2006. [Google Scholar]

- Campisi, D.; Mancuso, P.; Mastrodonato, S.; Morea, D. Efficiency Assessment of Knowledge Intensive Business Services Industry in Italy: Data Envelopment Analysis (DEA) and Financial Ratio Analysis. Meas. Bus. Excell. 2019, 23, 484–495. [Google Scholar] [CrossRef]

- Diewert, W.E. Exact and Superlative Index Numbers. J. Econom. 1976, 4, 115–145. [Google Scholar] [CrossRef]

- Färe, R.; Primont, D. Measuring the Efficiency of Multiunit Banking: An Activity Analysis Approach. J. Bank. Financ. 1993, 17, 539–544. [Google Scholar] [CrossRef]

- Lovell, C.K.; Travers, P.; Richardson, S.; Wood, L. Resources and Functionings: A New View of Inequality in Australia. In Models and Measurement of Welfare and Inequality; Springer: Heidelberg/Berlin, Germany, 1994; pp. 787–807. [Google Scholar]

- Färe, R.; Grosskopf, S.; Pasurka, C.A., Jr. Environmental Production Functions and Environment Directional Distance Functions. Energy 2007, 32, 1055–1066. [Google Scholar] [CrossRef]

- Sueyoshi, T.; Goto, M.; Sugiyama, M. DEA Window Analysis for Environmental Assessment in a Dynamic Time Shift: Performance Assessment of U.S. Coal-Fired Power Plants. Energy Econ. 2013, 40, 845–857. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S.; Pasurka, C.A., Jr. Potential Gains from Trading Bad Outputs: The Case of US Electric Power Plants. Resour. Energy Econ. 2014, 36, 99–112. [Google Scholar] [CrossRef]

- Yang, H.; Pollitt, M. Incorporating both Undesirable Outputs and Uncontrollable Variables into DEA: The Performance of Chinese Coal-Fired Power Plants. Eur. J. Oper. Res. 2009, 197, 1095–1105. [Google Scholar] [CrossRef] [Green Version]

- Pollitt, M.G. Ownership and Efficiency in Nuclear Power Production. Oxf. Econ. Pap. 1996, 48, 342–360. [Google Scholar] [CrossRef]

- Chang, D.S.; Chen, Y.T.; Chen, W.D. The Exogenous Factors Affecting the Cost Efficiency of Power Generation. Energy Policy 2009, 37, 5540–5545. [Google Scholar] [CrossRef]

- Sarıca, K.; Or, I. Efficiency Assessment of Turkish Power Plants Using Data Envelopment Analysis. Energy 2007, 32, 1484–1499. [Google Scholar] [CrossRef]

- Lam, P.L.; Shiu, A. A Data Envelopment Analysis of the Efficiency of China’s Thermal Power Generation. Util. Policy 2001, 10, 75–83. [Google Scholar] [CrossRef]

- See, K.F.; Coelli, T. An Analysis of Factors That Influence the Technical Efficiency of Malaysian Thermal Power Plants. Energy Econ. 2012, 34, 677–685. [Google Scholar] [CrossRef]

| Name of the Variable | Measurement | Literature |

|---|---|---|

| Inputs | ||

| Labor (L) | Number of employees in each year. (Unit: person) | Färe et al. [67]; Sueyoshi and Goto [6]; Sueyoshi et al. [68] |

| Capital (K) | Sum of equipment costs, structural costs and depreciation costs for each year, adjusted with purchasing power parity (unit: million US dollar). | Färe et al. [67]; Sueyoshi and Goto [6]; Sueyoshi et al. [68]; Färe et al. [69] |

| Fuel Expenditure (E) | Product of maximum thermal energy output per unit of fuel, total fuel consumption by the power plant, and unit thermal energy cost, also adjust with purchasing power parity (unit: million US dollar). | Färe et al. [67]; Sueyoshi and Goto [6]; Färe et al. [69] |

| Desirable Output | ||

| Net Power Generation (P) | Difference between the actual total power generated by the plant and the power consumed by the plant itself (unit: MWh). | Sueyoshi and Goto [6]; Sueyoshi et al. [68]; Färe et al. [69] |

| Undesirable Output | ||

| Toxic Emission (T) | Toxic materials listed in Toxics Release Inventory database (unit: ton). | Mekaroonreung and Johnson [48] |

| CO2 (C) | Actual CO2 emissions by the power plants (unit: ton). | Sueyoshi and Goto [6]; Färe et al. [69] |

| Environment Variable | Definition and Measurement |

|---|---|

| Firm-Level | |

| Plant Age | Difference between study year and plant establishment year. (Unit: year) |

| Use of Natural Gas | Dummy variable: 1 if using natural gas, 0 otherwise. |

| Coal Ratio | Coal-fired power to total power by the plant (Unit: %) |

| Content of Sulfate | Dummy variable: 1 if using sub-bituminous coal, 0 otherwise. |

| Plant Scale | Power capacity (Unit: 1000 megawatts) |

| Process Control | Number of reports on process control. (Unit: number) |

| Process Improvement | Number of reports on process improvement. (Unit: number) |

| Industry-Level | |

| Beginning Process Control | Dummy variable: 1 for year after 2008, 0 otherwise. |

| Process Control Enhancement | Dummy variable: 1 for year after 2010, 0 otherwise. |

| Variables | Overall | Sun Belt | Frost Belt | Diff. F Test (Sun Belt vs. Frost Belt) a | |

|---|---|---|---|---|---|

| L | 162.024 | 159.880 | 164.479 | 0.55 | |

| (113.160) | (96.033) | (130.069) | |||

| K | 533.44 | 532.20 | 534.85 | 0.014 | |

| (414.20) | (443.41) | (378.36) | |||

| F | 129.89 | 111.85 | 150.54 | 38.64 | *** |

| (114.830) | (90.16) | (134.90) | |||

| P | 5828.094 | 5189.99 | 6558.82 | 28.05 | *** |

| (4749.74) | (4347.58) | (5077.91) | |||

| T | 2275.12 | 2291.92 | 2255.89 | 0.048 | |

| (2980.24) | (2897.32) | (3074.69) | |||

| C | 5553.82 | 5089.85 | 6085.13 | 16.86 | *** |

| (4435.40) | (4124.66) | (4713.98) | |||

| Plant Age | 39.856 | 42.99 | 36.27 | 69.41 | *** |

| (15.056) | (15.79) | (13.30) | |||

| Use of Natural Gas | 0.25 | 0.21 | 0.30 | 14.91 | *** |

| (0.44) | (0.41) | (0.46) | |||

| Coal Ratio | 0.972 | 0.976 | 0.968 | 0.26 | |

| (0.082) | (0.072) | (0.094) | |||

| Content of Sulfate | 0.43 | 0.52 | 0.32 | 57.19 | *** |

| (0.50) | (0.50) | (0.47) | |||

| Plant Scale | 1.14 | 1.04 | 1.26 | 26.26 | *** |

| (0.79) | (0.72) | (0.84) | |||

| Process Control | 0.48 | 0.50 | 0.47 | 0.057 | |

| (2.68) | (2.96) | (2.32) | |||

| Process Improvement | 0.25 | 0.001 | 0.55 | 13.47 | *** |

| (2.71) | (0.038) | (3.95) | |||

| Beginning Process Control | 0.60 | 0.60 | 0.60 | 0.00 | |

| (0.49) | (0.49) | (0.49) | |||

| Process Control Enhancement | 0.40 | 0.40 | 0.40 | 0.00 | |

| (0.49) | (0.49) | (0.49) | |||

| Variables | Sun Belt frontier | Frost Belt frontier | Metafrontier | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Constant | 1.16 | *** | (0.45) | 1.79 | *** | (0.30) | 2.0037 | *** | (0.0818) |

| lnL | 0.10 | (0.18) | −0.43 | *** | (0.10) | −0.312 | *** | (0.025) | |

| lnK | −0.25 | ** | (0.11) | −0.510 | *** | (0.053) | −0.471 | *** | (0.016) |

| lnE | −0.20 | ** | (0.10) | 0.372 | *** | (0.073) | 0.133 | *** | (0.021) |

| lnT’ | −0.120 | *** | (0.047) | −0.102 | *** | (0.024) | −0.1041 | *** | (0.0061) |

| lnC’ | −0.389 | *** | (0.062) | −0.403 | *** | (0.051) | −0.402 | *** | (0.013) |

| lnL2 | −0.057 | (0.041) | −0.033 | (0.025) | −0.0587 | *** | (0.0067) | ||

| lnK2 | −0.024 | (0.026) | −0.0011 | (0.0016) | −0.00312 | *** | (0.00061) | ||

| lnE2 | −0.023 | (0.024) | −0.0453 | *** | (0.0077) | −0.0298 | *** | (0.0027) | |

| lnT’2 | −0.0259 | *** | (0.0048) | −0.0069 | *** | (0.0011) | −0.00692 | *** | (0.00033 |

| lnC’2 | −0.0802 | *** | (0.0041) | −0.0826 | *** | (0.0016) | −0.08024 | *** | (0.00052) |

| lnL x lnK | 0.0012 | (0.0241) | 0.025 | ** | (0.011) | 0.0071 | ** | (0.0033) | |

| lnL x lnE | −0.00030 | (0.04051) | −0.139 | *** | (0.022) | −0.1286 | *** | (0.0054) | |

| lnK x lnE | −0.050 | ** | (0.025) | −0.130 | *** | (0.014) | −0.0874 | *** | (0.0036) |

| lnT x lnC’ | 0.0412 | *** | (0.0062) | 0.0169 | *** | (0.0031) | 0.01733 | *** | (0.00082) |

| lnL x lnT’ | 0.00071 | (0.01030) | −0.0155 | *** | (0.0061) | −0.0094 | *** | (0.0017) | |

| lnK x lnT’ | −0.0212 | ** | (0.0093) | −0.0025 | (0.0047) | −0.0069 | *** | (0.0015) | |

| lnE x lnT’ | −0.0179 | * | (0.0097) | −0.0038 | (0.0045) | −0.0058 | *** | (0.0012) | |

| lnL x lnC’ | 0.012 | (0.023) | 0.079 | *** | (0.014) | 0.0776 | *** | (0.0034) | |

| lnK x lnC’ | 0.052 | *** | (0.013) | 0.0583 | *** | (0.0095) | 0.0533 | *** | (0.0025) |

| lnE x lnT’ | 0.0534 | *** | (0.0096) | 0.0765 | *** | (0.0046) | 0.0721 | *** | (0.0013) |

| t | −0.162 | *** | (0.023) | −0.070 | *** | (0.013) | −0.0897 | ** | (0.0035) |

| t2 | 0.00082 | (0.00113) | 0.00031 | (0.00072) | 0.00091 | *** | (0.00023) | ||

| lnL x t | −0.0015 | (0.0041) | 0.0075 | *** | (0.0023) | 0.00611 | *** | (0.00073) | |

| lnK x t | 0.0059 | * | (0.0031) | 0.0048 | *** | (0.0017) | 0.00533 | *** | (0.00052) |

| lnE x t | −0.0448 | *** | (0.0057) | −0.0137 | *** | (0.0026) | −0.02364 | *** | (0.00083) |

| lnT’ x t | 0.0013 | (0.0014) | 0.00243 | *** | (0.00081) | 0.00254 | *** | (0.00032) | |

| lnC’ x t | 0.0191 | *** | (0.0031) | 0.0019 | (0.0015) | 0.00580 | *** | (0.00054) | |

| Plant Age | 0.0065 | *** | (0.0011) | −0.0051 | *** | (0.0013) | - | ||

| Use of Natural Gas | 0.019 | (0.027) | −0.489 | *** | (0.043) | - | |||

| Coal Ratio | −0.952 | *** | (0.071) | −1.59 | *** | (0.13) | - | ||

| Content of Sulfate | −0.224 | *** | (0.042) | −0.228 | *** | (0.077) | - | ||

| Plant Scale | −0.415 | *** | (0.046) | −0.272 | *** | (0.021) | - | ||

| Process Control | −0.0073 | (0.0168) | −0.0387 | *** | (0.0041) | - | |||

| Process Improvement | −1.079 | *** | (0.087) | −0.0084 | *** | (0.0015) | - | ||

| Beginning Process Control | - | - | - | - | 0.139 | *** | (0.019) | ||

| Process Control Enhancement | - | - | - | - | 0.234 | *** | (0.025) | ||

| δ | 0.31 | *** | (0.12) | 0.966 | *** | (0.062) | −1.4196 | *** | (0.1715) |

| σ2 | 0.0453 | (0.0027) | 0.0591 | *** | (0.0085) | 0.0269 | *** | (0.0032) | |

| γ | 0.9336 | (0.0085) | 0.9849 | (0.0031) | 0.9929 | *** | (0.0013) | ||

| Adjusted R2 | 0.54 | 0.47 | 0.81 | ||||||

| λ | 325.91 *** | - | |||||||

| Group | Year | GTE a | TGR b | MTE c | |||

|---|---|---|---|---|---|---|---|

| Mean | (Std. Dev.) | Mean | (Std. Dev.) | Mean | (Std. Dev.) | ||

| Sun Belt | 2004 | 0.956 | (0.049) | 0.966 | (0.052) | 0.924 | (0.065) |

| 2005 | 0.957 | (0.008) | 0.986 | (0.026) | 0.944 | (0.025) | |

| 2006 | 0.956 | (0.007) | 0.988 | (0.028) | 0.945 | (0.027) | |

| 2007 | 0.952 | (0.012) | 0.987 | (0.033) | 0.940 | (0.034) | |

| 2008 | 0.948 | (0.015) | 0.983 | (0.037) | 0.932 | (0.040) | |

| 2009 | 0.958 | (0.013) | 0.984 | (0.035) | 0.942 | (0.039) | |

| 2010 | 0.961 | (0.020) | 0.980 | (0.030) | 0.942 | (0.036) | |

| 2011 | 0.961 | (0.020) | 0.976 | (0.031) | 0.939 | (0.038) | |

| 2012 | 0.953 | (0.016) | 0.977 | (0.047) | 0.931 | (0.050) | |

| 2013 | 0.924 | (0.018) | 0.979 | (0.130) | 0.905 | (0.129) | |

| Average | 0.953 | (0.018) | 0.981 | (0.045) | 0.934 | (0.048) | |

| FrostBelt | 2004 | 0.960 | (0.017) | 0.983 | (0.027) | 0.944 | (0.032) |

| 2005 | 0.959 | (0.020) | 0.980 | (0.041) | 0.940 | (0.046) | |

| 2006 | 0.958 | (0.018) | 0.980 | (0.043) | 0.939 | (0.047) | |

| 2007 | 0.941 | (0.016) | 0.981 | (0.094) | 0.922 | (0.093) | |

| 2008 | 0.937 | (0.016) | 0.980 | (0.062) | 0.918 | (0.063) | |

| 2009 | 0.949 | (0.026) | 0.977 | (0.064) | 0.928 | (0.071) | |

| 2010 | 0.950 | (0.014) | 0.980 | (0.063) | 0.931 | (0.062) | |

| 2011 | 0.944 | (0.013) | 0.981 | (0.077) | 0.926 | (0.077) | |

| 2012 | 0.944 | (0.020) | 0.978 | (0.069) | 0.923 | (0.070) | |

| 2013 | 0.938 | (0.028) | 0.973 | (0.072) | 0.913 | (0.076) | |

| Average | 0.948 | (0.019) | 0.979 | (0.061) | 0.928 | (0.064) | |

| Overall | 2004 | 0.958 | (0.039) | 0.974 | (0.042) | 0.933 | (0.053) |

| 2005 | 0.958 | (0.015) | 0.983 | (0.034) | 0.942 | (0.036) | |

| 2006 | 0.957 | (0.014) | 0.984 | (0.036) | 0.942 | (0.038) | |

| 2007 | 0.947 | (0.014) | 0.984 | (0.068) | 0.932 | (0.068) | |

| 2008 | 0.943 | (0.016) | 0.982 | (0.051) | 0.926 | (0.052) | |

| 2009 | 0.954 | (0.020) | 0.981 | (0.051) | 0.935 | (0.057) | |

| 2010 | 0.956 | (0.017) | 0.980 | (0.048) | 0.937 | (0.050) | |

| 2011 | 0.954 | (0.018) | 0.979 | (0.057) | 0.933 | (0.059) | |

| 2012 | 0.948 | (0.018) | 0.977 | (0.058) | 0.927 | (0.060) | |

| 2013 | 0.930 | (0.023) | 0.976 | (0.107) | 0.908 | (0.108) | |

| Average | 0.950 | (0.039) | 0.980 | (0.042) | 0.932 | (0.053) | |

| Diff. F test (Sun Belt vs. Frost Belt) d | 4.109 | *** | 4.047 | *** | |||

| Years | PTCU b | PTRC c | TC d | TEC e | SEC f | gMMPI a | |

|---|---|---|---|---|---|---|---|

| Sun Belt | 2004–2005 | 1.02320 | 1.00500 | 0.98920 | 1.00330 | 1.00840 | 1.02030 |

| 2005–2006 | 1.00180 | 1.00320 | 0.99190 | 0.99950 | 1.01200 | 1.00930 | |

| 2006–2007 | 0.99940 | 1.00200 | 0.99290 | 0.99590 | 1.00170 | 0.99270 | |

| 2007–2008 | 0.99530 | 0.99910 | 0.99690 | 0.99700 | 1.02430 | 1.01170 | |

| 2008–2009 | 1.00090 | 0.99720 | 0.99860 | 1.00780 | 1.07930 | 1.08520 | |

| 2009–2010 | 0.99650 | 0.99710 | 0.99750 | 1.00650 | 0.98430 | 0.98020 | |

| 2010–2011 | 0.99610 | 0.99630 | 0.99790 | 1.00100 | 1.03950 | 1.02960 | |

| 2011–2012 | 1.00060 | 0.99600 | 0.99610 | 0.98990 | 1.13620 | 1.11560 | |

| 2012–2013 | 1.00260 | 0.99730 | 0.99230 | 0.96970 | 0.94930 | 0.91790 | |

| Average | 1.00180 | 0.99920 | 0.99480 | 0.99670 | 1.02610 | 1.01800 | |

| Frost Belt | 2004–2005 | 0.99690 | 0.99970 | 0.99740 | 0.99910 | 0.99290 | 0.98720 |

| 2005–2006 | 1.00000 | 0.99990 | 0.99830 | 0.99960 | 1.01570 | 1.01390 | |

| 2006–2007 | 1.00060 | 0.99980 | 0.99850 | 0.98050 | 0.99360 | 0.97030 | |

| 2007–2008 | 0.99950 | 1.00030 | 0.99940 | 1.00930 | 1.02560 | 1.02960 | |

| 2008–2009 | 0.99650 | 0.99970 | 0.99870 | 1.01630 | 1.08990 | 1.10730 | |

| 2009–2010 | 1.00120 | 0.99940 | 0.99870 | 0.99850 | 0.93530 | 0.93290 | |

| 2010–2011 | 1.00040 | 0.99900 | 0.99900 | 0.99530 | 1.05030 | 1.04410 | |

| 2011–2012 | 0.99300 | 0.99740 | 0.99730 | 1.00200 | 1.11980 | 1.10310 | |

| 2012–2013 | 0.99520 | 0.99650 | 0.99760 | 1.00000 | 1.00880 | 0.99030 | |

| Average | 0.99810 | 0.99910 | 0.99830 | 1.00010 | 1.02580 | 1.01990 | |

| Overall | 2004–2005 | 1.01100 | 1.00250 | 0.99300 | 1.00130 | 1.00120 | 1.00490 |

| 2005–2006 | 1.00100 | 1.00160 | 0.99490 | 0.99950 | 1.01370 | 1.01140 | |

| 2006–2007 | 1.00000 | 1.00100 | 0.99550 | 0.98870 | 0.99790 | 0.98220 | |

| 2007–2008 | 0.99720 | 0.99970 | 0.99810 | 1.00270 | 1.02490 | 1.02000 | |

| 2008–2009 | 0.99890 | 0.99840 | 0.99860 | 1.01180 | 1.08430 | 1.09560 | |

| 2009–2010 | 0.99870 | 0.99810 | 0.99800 | 1.00280 | 0.96190 | 0.95850 | |

| 2010–2011 | 0.99810 | 0.99760 | 0.99840 | 0.99830 | 1.04450 | 1.03630 | |

| 2011–2012 | 0.99700 | 0.99670 | 0.99670 | 0.99550 | 1.12860 | 1.10970 | |

| 2012–2013 | 0.99930 | 0.99700 | 0.99470 | 0.98340 | 0.97620 | 0.95070 | |

| Average | 1.00010 | 0.99920 | 0.99640 | 0.99820 | 1.02590 | 1.01880 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.-H.; Chen, K.-H.; Cheng, J.-C.; Chen, C.-C.; Li, S.-Y. Analysis of Environmental Productivity on Fossil Fuel Power Plants in the U.S. Sustainability 2019, 11, 6907. https://doi.org/10.3390/su11246907

Lu Y-H, Chen K-H, Cheng J-C, Chen C-C, Li S-Y. Analysis of Environmental Productivity on Fossil Fuel Power Plants in the U.S. Sustainability. 2019; 11(24):6907. https://doi.org/10.3390/su11246907

Chicago/Turabian StyleLu, Yung-Hsiang, Ku-Hsieh Chen, Jen-Chi Cheng, Chih-Chun Chen, and Sian-Yuan Li. 2019. "Analysis of Environmental Productivity on Fossil Fuel Power Plants in the U.S." Sustainability 11, no. 24: 6907. https://doi.org/10.3390/su11246907

APA StyleLu, Y.-H., Chen, K.-H., Cheng, J.-C., Chen, C.-C., & Li, S.-Y. (2019). Analysis of Environmental Productivity on Fossil Fuel Power Plants in the U.S. Sustainability, 11(24), 6907. https://doi.org/10.3390/su11246907