CODAS HFLTS Method to Appraise Organizational Culture of Innovation and Complex Technological Changes Environments

Abstract

1. Introduction

- How can the MCDM tool be used to identify the relevant factors?

- How is it possible to use an equation to calculate the weighting values for each criterion incorporating the acquired knowledge and the expert judgment evaluation?

- Can the results obtained be considered reliable and aligned to other ways to calculate weighting values?

2. Literature Review

2.1. Definition of Organizational Culture

2.2. Organizational Culture in Innovation and Sustainable Development

2.2.1. Knowledge Management

2.2.2. Financial Management

2.2.3. Organizational Management

2.2.4. Process Management

2.2.5. Intellectual Property Management

2.2.6. Technology Management

2.3. Definition of Multi-Criteria Decision Making (MCDM) Problem

2.3.1. Analytic Hierarchy Process (AHP)

2.3.2. Combinative Distance-based Assessment (CODAS)

- Step 1.

- Construction of the decision matrix as shown below.where , shows the value of the alternative in the criterion , and .

- Step 2.

- Calculate the normalized decision matrix.where y are a set of significant dimensional criteria.

- Step 3.

- Calculate the normalized weight in the decision matrix with the following formula:where is the weight value of the criterion , with and .

- Step 4.

- Determining the ideal negative solution:

- Step 5.

- Calculate the Euclidean distance and Taxicab distance of the negative idea solution alternatives:

- Step 6.

- Preparation of the relative evaluation matrix:where and shows a threshold function to recognize the equality of the distances of the two alternatives defined by:The value of can be set by the decision maker, with a parameter range between 0.01 and 0.05. The Taxicab distance calculation formula can be used to compare the difference between distances. For the purposes of the present study .

- Step 7.

- Determination of the evaluation of the score of each alternative:

- Step 8.

- Classify the alternatives according to the decreasing values of the evaluation score . The alternative with the highest value of is the best choice among the alternatives.

2.3.3. Hesitant Fuzzy Linguistic Term Sets (HFLTS)

3. Methodology and analysis

3.1. Aggregated Matrix and Ideal Negative Vector

3.2. Weight Calculation

3.2.1. Weight Based on Acquired Knowledge (WAK)

3.2.2. Weight Based on AHP

3.2.3. Weight Based on Ambiguity Reduction (WAHP-AK)

3.3. Normalized Weighted Matrix

3.4. Euclidean and Taxicab Distances, Score and Ranking

3.5. Sensitivity Analysis

4. Discussion

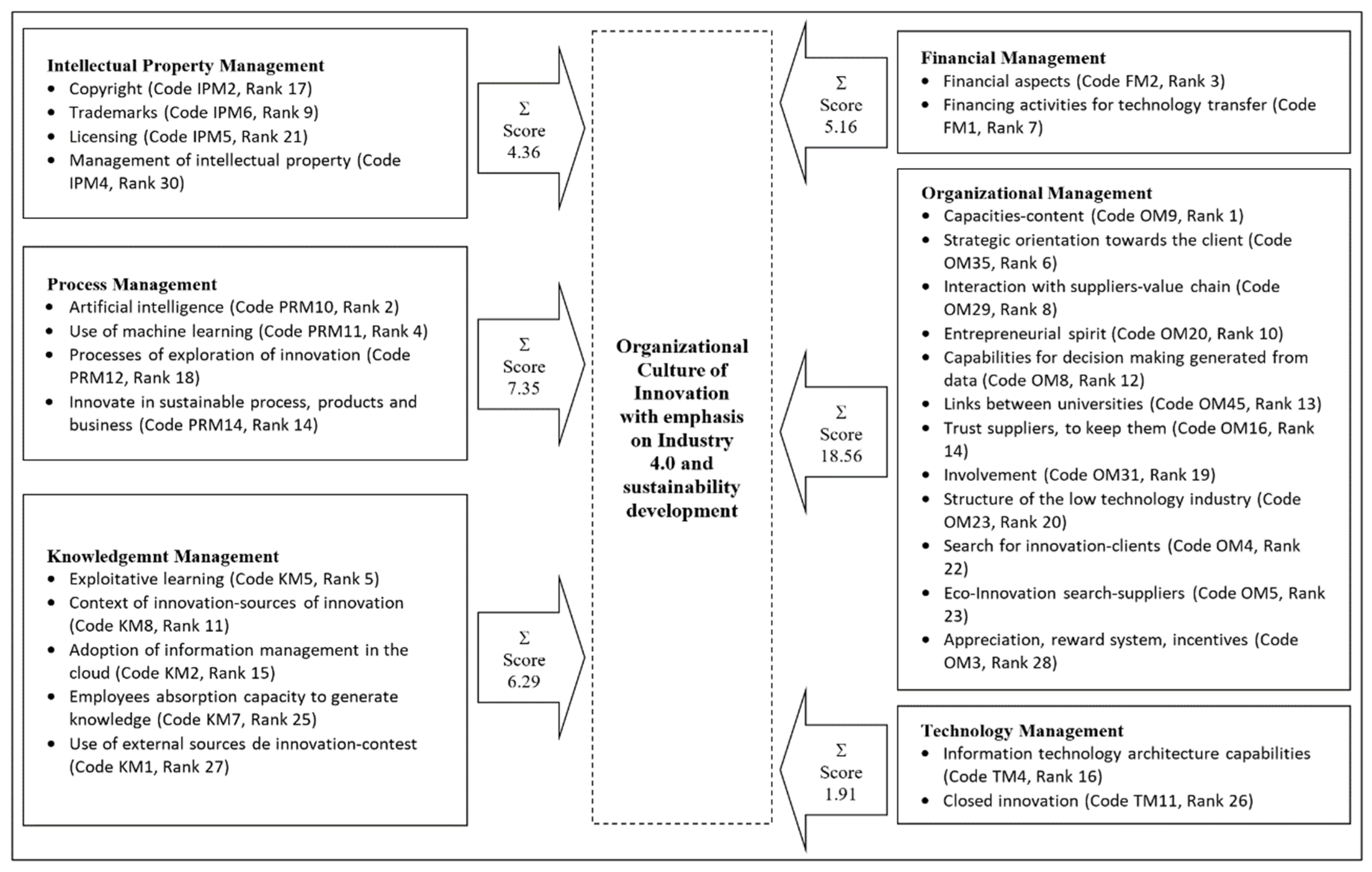

4.1. Organizational Management

- Capacities-content [23,48], score 3.53, allows the organization to establish or consider basic aspects related to what and how to produce in a complex context derived from hyperconnectivity and digitalization, as well as to the speed with which products must be modified or the new products presented for marketing, according the customer requirements.

- Strategic orientation towards the client [16], score 2.13, establishes that the focus in the new environment is towards the client, unlike the past decades, with the starting point for the generation of innovation in the production of new products services or business models and developing and managing a company green image [24], which allow their competitiveness.

- Interaction with suppliers-value chain [67], score 1.94. In the value chain, it is important to be well integrated with suppliers, so that there are no deficiencies, no aspects of raw material specifications that can delay the innovation process, alerts about future changes that may allow to modify processes, products can be generated with higher quality, better supply conditions can be obtained, lower failures in the provision of the elements occur and a reduction of the use of natural resources in production.

- Entrepreneurial spirit [16], score 1.54, allows companies to consider incremental or radical changes within the organization and focus on clean production as a generator of environmental and economic benefits for companies and consumers.

- Links between universities [74], score 1.42. Linking allows generating research and development activities for new products, processes and product improvements in environments where universities provide new solutions to traditional methods or processes followed by organizations.

- Trust suppliers [39], score 1.38. This is a strategic aspect that is possibly not often considered in organizations, but relevant in innovation, since the perception of lack of trust can generate unfinished innovation projects when related to licensing and issues of intellectual property, which can interfere with innovation and the management.

- Structure of the low technology industry [31], score 1.06. High technology is related to economic resources, which are often limited; innovation is not necessarily related to disruptive technological changes, but to the proper use of them.

- Search for innovation-clients [47], score 0.89. The relevance of this factor lies in the search and use of information to generate innovation in new products, when existing products do not meet the functionality expectations specified by customers. It also applies to manufacturing processes, when the existing ones do not present added value in compliance with the process or product specifications.

- Eco-innovation search-suppliers [25], score 0.83, promote the search and development of production equipment suppliers to generate opportunities in process innovation with emphasis in sustainable development.

- Appreciation, reward system and incentives [39], score 0.66. This element establishes reward plans for recognition of employee achievements as an incentive for innovation.

- Structure for innovation [19], score 0.6, involves establishing the conditions to operate in the new environment of digitalization and hyperconnection.

4.2. Process Management

- Artificial intelligence [22], score 3.22, allows the simulation of the most precise production processes, to establish product life cycles, to identify periods of failures, make adaptations in virtual fields before being manufactured or marketed and to carry out product innovations existing or generate new products.

- Use of machine learning [22], score 2.20, provides more information for the development of innovation by integrating it with mathematical algorithms.

- Processes of exploration of innovation [84], score 1.10, strengthens the company’s position in terms of competitiveness by establishing search processes and innovation analysis.

4.3. Knowledge Management

- Context of innovation-sources of innovation [14], score 1.50. The sources of innovation derived from competitions allow companies to get new ideas from the prototypes generated in a particular topic for innovation.

- Adoption of information management in the cloud [22], score 1.22, recognizes that information is an intangible asset that produces great changes in organizations, in the new context of digitalization, this promotes more agile processes and more information to gain competitive advantage over aspects, characteristics, problems, improvements etc., which lead to information and for the generation of innovation.

- Employees absorption capacity to generate knowledge [27,28], score 0.77. This is an intangible asset in companies and is difficult to measure. It allows the organization to implement, adapt and decode tacit knowledge to make it explicit, with the intention of transferring it into innovative products and processes and developing a corporate environmental culture.

4.4. Financial Management

- Financial aspects [19,33,34,35,36,37,38,39,40,41], score 3.08, include resources that are involved in innovation, costs related to training, updates, payments to professionals for legal aspects related to patenting, licensing, registration and the investment in contributions to sustainable development, as well as those related to human capital.

- Financing activities for technology transfer [19,37,40], score 2.08, refers to significant activities in strategic planning and involves the allocation of financial resources to carry out the generation and implementation of innovation by transferring additional technology to equipment or machinery, including transport and complementary costs for such transfers.

4.5. Intellectual Property Management

- Copyright [33], score 1.17, corresponds to the legal value of the reserved rights that protect ideas for innovation and part of the competitiveness of companies.

- Management of intellectual property [27,33], score 0.61, involves the legal aspects related to intellectual property rights, licensing and trademark registration, or the use of intellectual property by third parties. As a complement to innovations generated in the organization, this allows to protect the innovation and above all to commercialize the products.

4.6. Technology management

- Information technology architecture capabilities [80], score 1.17, includes the capabilities in the management of information technologies, hardware management for information storage, data synchronization programming and simulation capabilities for the virtual creation of innovation, for its subsequent development of physical way, such as business strategies.

- Closed innovation [74], score 0.74, uses the resources available within the organization, human and technological, to carry out innovative research and development activities.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Piccarozzi, M.; Aquilani, B.; Gatti, C. Industry 4.0 in management studies: A systematic literature review. Sustainability 2018, 10, 3821. [Google Scholar] [CrossRef]

- Adamik, A.; Nowicki, M. Pathologies and paradoxes of co-creation: A contribution to the discussion about corporate social responsibility in building a competitive advantage in the age of Industry 4.0. Sustainability 2019, 11, 4954. [Google Scholar] [CrossRef]

- Müller, J.M. Antecedents to digital platform usage in Industry 4.0 by established manufacturers. Sustainability 2019, 11, 1121. [Google Scholar] [CrossRef]

- Birkel, H.S.; Veile, J.W.; Müller, J.M.; Hartmann, E.; Voigt, K.I. Development of a Risk Framework for Industry 4.0 in the Context of Sustainability for Established Manufacturers. Sustainability 2019, 11, 384. [Google Scholar] [CrossRef]

- Li, Z.; Liu, L.; Barenji, A.V.; Wang, W. Cloud-based manufacturing blockchain: Secure knowledge sharing for injection mold redesign. Procedia CIRP 2018, 72, 961–966. [Google Scholar] [CrossRef]

- Orive, M.P. La gestión de la cadena de suministro en la era de la Industria 4.0, caso práctico: El sector cárnico. CEL 2017, 1, 49–52. [Google Scholar]

- Braccini, A.M.; Margherita, E.G. Exploring Organizational Sustainability of Industry 4.0 under the triple bottom line: The case of a manufacturing company. Sustainability 2019, 11, 36. [Google Scholar] [CrossRef]

- Raoufi, K.; Haapala, K.R.; Jackson, K.L.; Kim, K.Y.; Okudan, G.E.; Psenka, C.E. Enabling non-expert sustainable manufacturing process and supply chain analysis during the early product design phase. Procedia Manuf. 2017, 10, 1097–1108. [Google Scholar] [CrossRef]

- Shrivastava, P. The role of corporations in achieving ecological sustainability. Acad. Manag. Rev. 1995, 20, 936–960. [Google Scholar] [CrossRef]

- Denison, D. Cultura Corporativa y Productividad Organizacional; Legis: Santa Fe de Bogota, Colombia, 1991. [Google Scholar]

- Labuschagne, C.; Brent, A.C. Sustainable project life cycle management: The need to integrate life cycles in the manufacturing sector. Int. J. Proj. Manag. 2005, 23, 159–168. [Google Scholar] [CrossRef]

- Rodríguez, R.G. La cultura organizacional: Un potencial activo estratégico desde la perspectiva de la administración. Inventio 2009, 12, 67–92. [Google Scholar]

- Martínez, M.E.A. Relaciones entre cultura y desempeño organizacional en una muestra de empresas colombianas: Reflexiones sobre la utilización del modelo de Denison. Cuad. Admin. 2010, 23, 163–190. [Google Scholar]

- Hartmann, A. The role of organizational culture in motivating innovative behavior in construction firms. Constr. Innov. 2006, 6, 159–172. [Google Scholar] [CrossRef]

- Vyatkin, V.; Salcic, Z.; Roop, P.S.; Fitzgerald, J. Now that’s smart. IEEE Ind. Electron. Mag. 2007, 1, 17–29. [Google Scholar] [CrossRef]

- Naranjo, J.C.; Calderón, G. Construyendo una cultura de innovación: Una propuesta de transformación cultural. Estud. Gerenc. 2015, 31, 223–236. [Google Scholar] [CrossRef]

- Kraśnicka, T.; Głód, W.; Wronka, M. Management innovation, pro-innovation organizational culture and enterprise performance: Testing the mediation effect. Rev. Manag. Sci. 2018, 12, 737–769. [Google Scholar] [CrossRef]

- Vlaicu, L.F.; Neagoe, A.; Tîru, L.G.; Otovescu, A. The organizational culture of a major social work Institution in Romania: A sociological analysis. Sustainability 2019, 11, 3587. [Google Scholar] [CrossRef]

- Gault, F. Defining and measuring innovation in all sectors of the economy. Res. Policy 2018, 47, 617–622. [Google Scholar] [CrossRef]

- Burmeister, C.; Luettgens, D.; Piller, F.T. Business model innovation for Industrie 4.0: Why the industrial internet mandates a new perspective on innovation. Die Unternehm. 2016, 2, 124–152. [Google Scholar] [CrossRef]

- García-Piqueres, G.; Serrano-Bedia, A.M.; Pérez-Pérez, M. Knowledge management practices and innovation outcomes: The moderating role of risk-taking and proactiveness. Adm. Sci. 2019, 9, 75. [Google Scholar] [CrossRef]

- Gerbert, P.; Lorenz, M.; Rüßmann, M.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M. Industry 4.0: The Future of Productivity and Growth in Manufacturing; Boston Consulting Group: Boston, MA, USA, 2015; Available online: https://www.zvw.de/media.media.72e472fb-1698-4a15-8858-344351c8902f.original.pdf (accessed on 1 November 2019).

- Brettel, M.; Friederichsen, N.; Keller, M.; Rosenberg, M. How virtualization, decentralization and network building change the manufacturing landscape: An Industry 4.0 perspective. Int. J. Mech. Aerosp. Ind. Mechatron. Eng. 2014, 8, 37–44. [Google Scholar]

- Dangelico, R.M. Green product innovation: Where we are and where we are going. Bus. Strategy Environ. 2016, 25, 560–576. [Google Scholar] [CrossRef]

- West, J.; Bogers, M. Leveraging external sources of innovation: A review of research on open innovation. J. Prod. Innov. Manag. Forthcom. 2014, 31, 814–831. [Google Scholar] [CrossRef]

- Torres, A.; Dutrénit, G.; Becerra, N.; Sampedro, J.L. Patrones de vinculación academia-industria: Factores determinantes en el caso de México. In 4º Congreso Internacional de Sistemas de Innovación Para la Competitividad; Universidad Iberoamericana de Leon: Leon, Guanajuato, Mexico, 2009; pp. 1–16. [Google Scholar]

- Contreras, O.F.; Carrillo, J.; Alonso, J. Local entrepreneurship within global value chains: A case study in the Mexican automotive industry. World Dev. 2012, 40, 1013–1023. [Google Scholar] [CrossRef]

- Chiavenato, I. Administración de Recursos Humanos: El Capital Humano de las Organizaciones; McGraw Hill: Ciudad de México, México, 2007. [Google Scholar]

- Chesbrough, H. Business model innovation: It’s not just about technology anymore. Strategy Leadersh. 2007, 35, 12–17. [Google Scholar] [CrossRef]

- Baden, C.; Haefliger, S. Business models and technological innovation. Long Range Plan. 2003, 46, 419–426. [Google Scholar] [CrossRef]

- Pisano, G. Profiting from innovation and the intellectual property revolution. Res. Policy 2006, 35, 1122–1130. [Google Scholar] [CrossRef]

- Conley, J.G.; Bican, P.M.; Ernst, H. A framework for the strategic management of intellectual property. Calif. Manag. Rev. 2013, 55, 102–120. [Google Scholar] [CrossRef]

- Hsieh, C.H. Patent value assessment and commercialization strategy. Technol. Soc. Chang. 2013, 80, 307–319. [Google Scholar] [CrossRef]

- Binney, D. The knowledge management spectrum–understanding the KM landscape. J. Knowl. Manag. 2001, 5, 33–42. [Google Scholar] [CrossRef]

- Chesbrough, H. Business model innovation: Opportunities and barriers. Long Range Plan. 2010, 43, 354–363. [Google Scholar] [CrossRef]

- Darnley, R.; Diplacido, M.; Kerns, M.; Kim, A. Industry 4.0: Digitization in Danish industry. Interact. Qualif. Proj. 2018, 1, 127–162. [Google Scholar]

- Battistella, C.; De Toni, A.F.; Pillon, R. Inter-organizational technology/knowledge transfer: A framework from critical literature review. J. Technol. Transf. 2016, 41, 1195–1234. [Google Scholar] [CrossRef]

- Carvalho, N.; Chaim, O.; Cazarini, E.; Gerolamo, M. Manufacturing in the fourth industrial revolution: A positive prospect in sustainable manufacturing. Procedia Manuf. 2018, 21, 671–678. [Google Scholar] [CrossRef]

- Hogan, S.J.; Coote, L.V. Organizational culture, innovation, and performance: A test of Schein’s model. J. Bus. Res. 2014, 67, 1609–1621. [Google Scholar] [CrossRef]

- Berry, M. Strategic planning in small high-tech companies. Long Range Plan. 1998, 31, 455–466. [Google Scholar] [CrossRef]

- Plimmer, G.; Bryson, J. Opening the black box: The mediating roles of organizational systems and ambidexterity in the HRM-performance link in public sector organizations. Pers. Rev. 2017, 46, 1434–1451. [Google Scholar] [CrossRef]

- Osterwalder, A.; Pigneur, Y. Business Model Generation: A Handbook for Visionaries, Game Changers, and Challengers; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Camisón;, C.; Villar, A. Organizational innovation as an enabler of technological innovation capabilities and firm performance. J. Bus. Res. 2014, 67, 2891–2902. [Google Scholar] [CrossRef]

- Shrivastava, P. Greening business: Profiting the Corporation and the Environment; Thompson Executive Press: Cincinnati, OH, USA, 1995. [Google Scholar] [CrossRef]

- Ferro-Soto, C.; Macías-Quintana, L.; Vázquez-Rodríguez, P. Effect of stakeholders-oriented behavior on the performance of sustainable business. Sustainability 2018, 10, 4724. [Google Scholar] [CrossRef]

- Schiederig, T.; Tietze, F.; Herstatt, C. Green innovation in technology and innovation management—An exploratory literature review. RD Manag. 2012, 42, 180–192. [Google Scholar] [CrossRef]

- Gassmann, O.; Frankenberger, K.; Sauer, R. Exploring the Field of Business Model Innovation: New Theoretical Perspectives; Palgrave Macmillan: New York, NY, USA, 2016. [Google Scholar]

- Ochoa, O. Modelos de madurez digital: En qué consisten y qué podemos aprender de ellos? Boletín De Estud. Económicos 2016, 71, 573–590. [Google Scholar]

- Amabile, T. A model of creativity and innovation in organizations. Res. Organ. Behav. 1988, 10, 123–167. [Google Scholar]

- Binnewies, C.; Ohly, S.; Sonnentag, S. Taking personal initiative and communicating about ideas: What is important for the creative process and for idea creativity? Eur. J. Work Organ. Psychol. 2007, 16, 432–455. [Google Scholar] [CrossRef]

- Caldwell, D.F.; O’Reilly, C.A. The determinants of team-based innovation in organizations: The role of social influence. Small Group Res. 2003, 34, 497–517. [Google Scholar] [CrossRef]

- García, V.J.; Matías, F.; Verdú, A. Influence of internal communication on technological proactivity, organizational learning and organizational innovation in the pharmaceutical sector. J. Commun. 2011, 61, 150–177. [Google Scholar] [CrossRef]

- Moorman, C.; Miner, A.S. The impact of organizational memory on new product performance and creativity. J. Mark. Res. 1997, 34, 91–107. [Google Scholar] [CrossRef]

- Sonnentag, S.; Volmer, J. Individual-level predictors of task-related teamwork processes: The role of expertise and self-efficacy in team meetings. Group Organ. Manag. 2009, 34, 37–66. [Google Scholar] [CrossRef]

- Abbey, A.; Dickson, J.W. R&D work climate and innovation in semiconductors. Acad. Manag. J. 1983, 26, 362–368. [Google Scholar] [CrossRef]

- Baker, N.R.; Freeland, J.R. Structuring information flow to enhance innovation. Manag. Sci. 1972, 19, 105–116. [Google Scholar] [CrossRef]

- De Clercq, S.; Menguc, B.; Auh, S. Unpacking the relationship between an innovation strategy and firm performance: The role of task conflict and political activity. J. Bus. Res. 2009, 62, 1046–1053. [Google Scholar] [CrossRef]

- Song, M.; Swink, M. Marketing—Manufacturing integration across stages of new product development: Effects on the success of high-and low-innovativeness products. IEEE Trans. Eng. Manag. 2009, 56, 31–44. [Google Scholar] [CrossRef]

- Subramaniam, M.; Youndt, M.A. Capabilities, the influences of intellectual capital on the types of innovative. Acad. Manag. J. 2005, 48, 450–463. [Google Scholar] [CrossRef]

- Sung, T.K.; Gibson, D.V. Knowledge and technology transfer: Levels and key factors. In Proceedings of the 4th International Conference on Technology Policy and Innovation, Curitiba, Brazil, 28–31 August 2000; pp. 441–449. [Google Scholar]

- Amabile, T.M.; Conti, R.; Coon, H.; Lazenby, J.; Herron, M. Assessing the work environment for creativity. Acad. Manag. J. 1996, 39, 1154–1184. [Google Scholar] [CrossRef]

- Gumusluoglu, L.; Ilsev, A. Transformational leadership, creativity and organizational innovation. J. Bus. Res. 2009, 62, 461–473. [Google Scholar] [CrossRef]

- Khazanchi, S.; Lewis, M.W.; Boyer, K.K. Innovation-supportive culture: The impact of organizational values on process innovation. J. Oper. Manag. 2007, 25, 871–884. [Google Scholar] [CrossRef]

- Mumford, M.D.; Scott, G.M.; Gaddis, B.; Strange, J.M. Leading creative people: Orchestrating expertise and relationships. Leadersh. Q. 2002, 13, 705–750. [Google Scholar] [CrossRef]

- Sethi, R.; Smith, D.C.; Whan Park, C. Cross-functional product development teams, creativity, and the innovativeness of new consumer products. J. Mark. Res. 2001, 38, 73–85. [Google Scholar] [CrossRef]

- West, M.A. Sparkling fountains or stagnant ponds: An integrative model of creativity and innovation implementation in work. Appl. Psychol. 2002, 51, 355–387. [Google Scholar] [CrossRef]

- Teece, D.J. The foundations of enterprise performance: Dynamic and ordinary capabilities in an (economic) theory of firms. Acad. Manag. Perspect. 2014, 28, 328–352. [Google Scholar] [CrossRef]

- Carro, J.; Sarmiento, S. Organizational culture and its influence in business sustainability. Estud. Gerenc. 2017, 33, 352–365. [Google Scholar] [CrossRef]

- Lukoto, K.; Chan, K.Y. The perception of innovative organizational culture and its influence on employee innovative work behavior. PICMET 2016, 972–977. [Google Scholar] [CrossRef]

- Dewett, T. Creativity and strategic management: Individual and group considerations concerning decision alternatives in the top management teams. J. Manag. Psychol. 2004, 19, 156–169. [Google Scholar] [CrossRef]

- Tellis, G.J.; Prabhu, J.C.; Chandy, R.K. Radical innovation across nations: The preeminence of corporate culture. J. Mark. 2009, 73, 3–23. [Google Scholar] [CrossRef]

- Tatikonda, M.V.; Stock, G.N. Product technology transfer in the upstream supply chain. J. Prod. Innov. Manag. 2003, 20, 444–467. [Google Scholar] [CrossRef]

- Dutrénit, G.; Arza, V. Channels and benefits of interactions between public research organizations and industry: Comparing four Latin American countries. Sci. Public Policy 2010, 37, 541–553. [Google Scholar] [CrossRef]

- Lavrynenko, A.; Shmatko, N.; Meissner, D. Managing skills for open innovation: The case of biotechnology. Manag. Decis. 2018, 56, 1336–1347. [Google Scholar] [CrossRef]

- Pérez, M.N.; Bustinza, F.; Barrales, V. Exploring the relationship between information technology competence and quality management. BRQ Bus. Res. Q. 2015, 18, 4–17. [Google Scholar] [CrossRef]

- De Fuentes, C.; Dutrénit, G. Best channels of academia-industry interaction for long-term benefit. Res. Policy 2012, 41, 1666–1682. [Google Scholar] [CrossRef]

- Del Val Román, J.L. Industria 4.0: La Transformación Digital de la Industria; Facultad de Ingeniería de la Universidad de Deusto: Bilbo, Spain, 2016; pp. 3–13. Available online: http://coddii.org/wp-content/uploads/2016/10/Informe-CODDII-Industria-4.0.pdf (accessed on 1 November 2019).

- Lombardero, L. Trabajar en la era Digital: Tecnología y Competencias Para la Transformación Digital; LID Editorial Empresarial: Madrid, España, 2015. [Google Scholar]

- Ynzunza, C.B.; Izar, J.M.; Bocarando, J.G.; Aguilar, F.; Larios, M. El entorno de la Industria 4.0: Implicaciones y perspectivas futuras. Concienc. Tecnológica 2017, 54, 33–45. [Google Scholar]

- Korhonen, J.J.; Gill, A.Q. Digital capability dissected. In Proceedings of the Australasian Conference on Information Systems, Sydney, Australia, 3–5 December 2018; pp. 1–12. [Google Scholar]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Teece, D.J. Profiting from technological innovation: Implications for integration, collaboration, licensing and public policy. Res. Policy 1986, 15, 285–305. [Google Scholar] [CrossRef]

- Dutrénit, G.; Nuñez Jover, J. Vinculación Universidad-Sector Productivo Para Fortalecer los Sistemas Nacionales de Innovación: Experiencia de Cuba, México y Costa Rica; Universidad de La Habana: La Habana, Cuba, 2017. [Google Scholar]

- Stoffels, M.; Leker, J. The impact of its assets on innovation performance—The mediating role of developmental culture and absorptive capacity. Int. J. Innov. Manag. 2018, 22, 1840011. [Google Scholar] [CrossRef]

- Nouiri, M.; Trentesaux, D.; Bekrar, A. Towards energy efficient scheduling of manufacturing systems through collaboration between cyber physical production and energy systems. Energies 2019, 12, 4448. [Google Scholar] [CrossRef]

- Moreno, A.; Lara, A. Instituciones de Metrología en el Sector Automotriz. El caso Cenam y Volkswagen. Sistemas de Innovación en México. Regiones, Redes y Sectores; Plaza y Valdés Editores: Ciudad de México, México, 2010. [Google Scholar]

- García, V.; Sánchez, J.S.; Marqués, A.I. Synergetic application of multi-criteria decision-making models to credit granting decision problems. Appl. Sci. 2019, 9, 5052. [Google Scholar] [CrossRef]

- Vivas, R.; Sant’anna, Â.; Esquerre, K.; Freires, F. Measuring sustainability performance with multi criteria model: A case study. Sustainability 2019, 11, 6113. [Google Scholar] [CrossRef]

- Villa Silva, A.J.; Pérez Dominguez, L.A.; Martínez Gómez, E.; Alvarado-Iniesta, A.; Pérez Olguín, I.J.C. Dimensional analysis under pythagorean fuzzy approach for supplier selection. Symmetry 2019, 11, 336. [Google Scholar] [CrossRef]

- Yalçın, N.; Yapıcı Pehlivan, N. Application of the fuzzy CODAS method based on fuzzy envelopes for hesitant fuzzy linguistic term sets: A case study on a personnel selection problem. Symmetry 2019, 11, 493. [Google Scholar] [CrossRef]

- Wind, Y.; Saaty, T.L. Marketing applications of the analytic hierarchy process. Manag. Sci. 1980, 26, 641–658. [Google Scholar] [CrossRef]

- Ghorabaee, M.K.; Amiri, M.; Zavadskas, E.K.; Hooshmand, R.; Antucheviciene, J. Fuzzy extension of the CODAS method for multi-criteria market segment evaluation. J. Bus. Econ. Manag. 2017, 18, 1–19. [Google Scholar] [CrossRef]

- Ghorabaee, M.; Zavadskas, E.; Turskis, Z.; Antucheviciene, J. A new combinative distance-based assessment (CODAS) method for multi-criteria decision-making. Econ. Comput. Econ. Cybern. Stud. Res. 2016, 50, 25–44. [Google Scholar]

- Rodriguez, R.M.; Martinez, L.; Herrera, F. Hesitant fuzzy linguistic term sets for decision making. IEEE Trans. Fuzzy Syst. 2012, 20, 109–119. [Google Scholar] [CrossRef]

- Chandio, I.; Matori, A.N.; WanYusof, K.; Hussain Talput, M.A. Validation of Multi-Criteria Decision Analysis Model of Land Suitability Analysis for Sustainable Hillside Development. Eur. J. Sci. Res. 2013, 109, 342–349. [Google Scholar]

- Wu, J.Z.; Zhang, Q. Multicriteria decision making method based on intuitionistic fuzzy weighted entropy. Expert Syst. Appl. 2011, 38, 916–922. [Google Scholar] [CrossRef]

- Riosvelasco-Monroy, G.E.; Flores-Amador, J.; Pérez-Olguín, I.J.C. Gestión del conocimiento a través de la colaboración horizontal en el clúster MACH. Rev. Int. Investig. E Innov. Tecnol. 2019, 7, 1–22. [Google Scholar]

- Sanches Rodrigues, V.; Harris, I.; Mason, R. Horizontal logistic collaboration for enhanced supply chain performance: An international retail perspective. Supply Chain Manag. 2015, 20, 631–647. [Google Scholar] [CrossRef]

- Ghadimi, P.; Wang, C.; Lim, M.K.; Heavey, C. Intelligent sustainable supplier selection using multi-agent technology: Theory and application for Industry 4.0 supply chains. Comput. Ind. Eng. 2019, 127, 588–600. [Google Scholar] [CrossRef]

- Balzer, W.K.; Brodke, M.H.; Kizhakethalackal, E.T. Lean higher education: Successes, challenges and realizing potential. Int. J. Qual. Reliab. Manag. 2015, 32, 924–933. [Google Scholar] [CrossRef]

| Code | Knowledge Management Items |

|---|---|

| KM01 | Use external sources innovation-contest [25]. |

| KM02 | Adoption of information management in the cloud [22]. |

| KM03 | Continuous learning [16,22]. |

| KM04 | Exploratory learning [20,26]. |

| KM05 | Exploitative learning [20,26]. |

| KM06 | Search for innovation in universities [14]. |

| KM07 | Employees absorption capacity to generate knowledge [27,28]. |

| KM08 | Context of innovation-sources of innovation [14]. |

| KM09 | Value creation [29,30,31,32]. |

| KM10 | Creativity, initiative [16]. |

| KM11 | Generation of patents [33]. |

| KM12 | Knowledge skills encoded in technology [19]. |

| KM13 | Value capture [31,34,35]. |

| Code | Financing Management Items |

|---|---|

| FM01 | Financing activities for technology transfer [19,37,40]. |

| FM02 | Financial aspects [19,33,34,35,40,41]. |

| FM03 | Financing activities for innovation [14]. |

| Code | Organizational Management Items |

|---|---|

| OM01 | Structure of the high technology industry [19]. |

| OM02 | Structure for innovation [19]. |

| OM03 | Appreciation, reward system, incentives [39]. |

| OM04 | Search for innovation-clients [47]. |

| OM05 | Eco-innovation search-suppliers [25]. |

| OM06 | Search for innovation-competitors [25]. |

| OM07 | External capacities (relations and negotiation) [39]. |

| OM08 | Capabilities for decision making generated from data [23,36,48]. |

| OM09 | Capacities-content [23,48]. |

| OM10 | Training [29,35]. |

| OM11 | Competence and professionalism [39]. |

| OM12 | Commitment to innovation [19]. |

| OM13 | External communication-interaction other media virtual connections [16,17]. |

| OM14 | Internal communication [39,49,50,51,52,53,54]. |

| OM15 | Communication [35]. |

| OM16 | Trust suppliers, to keep them [39]. |

| OM17 | Cooperation between functions [39,51,55,56,57,58]. |

| OM18 | Development of human talent [39,49,54,59]. |

| OM19 | Market focus [25,60]. |

| OM20 | Entrepreneurial spirit [16]. |

| OM21 | Establishment of innovation/eco-innovations policies [19]. |

| OM22 | Innovation strategy generation of spin off [35]. |

| OM23 | Structure of the low technology industry [31]. |

| OM24 | Structure of the media technology industry [31]. |

| OM25 | Success-orientation to achievement [39,55,61,62,63,64,65,66]. |

| OM26 | Ways to access the markets [39]. |

| OM27 | Innovation management [27]. |

| OM28 | Identification of tacit needs online customers [48]. |

| OM29 | Interaction with suppliers-value chain [67]. |

| OM30 | Interaction with customers-value chain [31]. |

| OM31 | Involvement [10,68]. |

| OM32 | Loyalty [39]. |

| OM33 | Freedom autonomy [16,69]. |

| OM34 | Level of education of the personnel [19]. |

| OM35 | Strategic orientation towards the client [16]. |

| OM36 | Participation of the workers [16]. |

| OM37 | Responsibility [39,50,51,64]. |

| OM38 | Sufficiency of resources [16]. |

| OM39 | Decision making [31]. |

| OM40 | Risk aversion to new projects, acquisition and development of new technology [39] |

| OM41 | Risk taking [16,39,51,65,70,71]. |

| OM42 | Teamwork [16,39,51,52,53,54,55,56,57,58]. |

| OM43 | Linking private research and development agencies [72,73] |

| OM44 | Linking public research and development agencies [69] |

| OM45 | Links between universities [74] |

| OM46 | The coalignment between TQM and research and development [75,76]. |

| Code | Processes Management Items |

|---|---|

| PM01 | Adaptability flexibility for new sustainable processes [39]. |

| PM02 | Capacities-automation [80]. |

| PM03 | Capacities-connectivity [80]. |

| PM04 | Technological capabilities for process automation [67,81,82]. |

| PM05 | Technological capabilities use of the cloud [81,83]. |

| PM06 | Technological capabilities data mining [22]. |

| PM07 | Programing and software development [22]. |

| PM08 | Digital marketing and design [22]. |

| PM09 | Human digital physical interaction [81]. |

| PM10 | Artificial intelligence [22]. |

| PM11 | Machine learning [22]. |

| PM12 | Process of exploration of innovation [84]. |

| PM13 | Generation of innovation [35]. |

| PM14 | Innovate in sustainable processes, products, business [31,33]. |

| PM15 | Robotics [22]. |

| PM16 | Process of exploitation of innovation [32]. |

| Code | Intellectual Property Management Items |

|---|---|

| IPM01 | Acquisition of patents [35]. |

| IPM02 | Copyright [33]. |

| IPM03 | Innovation strategy-sale of intellectual property rights [33]. |

| IPM04 | Management of intellectual property [27,33]. |

| IPM05 | Licensing [32,33]. |

| IPM06 | Trademarks [32,33]. |

| Code | Technology Management Items |

|---|---|

| TM01 | Acquisition of complementary assets [25,37]. |

| TM02 | Ambidexterity (move to radical innovation or disruptive innovation) [84]. |

| TM03 | Internal research and development capabilities [31,82]. |

| TM04 | Information technology architecture capabilities [80]. |

| TM05 | External research and development capabilities [31]. |

| TM06 | Technological capabilities [37,80]. |

| TM07 | Capacities-information technology [37,80]. |

| TM08 | Focus on incremental innovation [29]. |

| TM09 | Flexibility to the production of new methodologies [16,29]. |

| TM10 | Open innovation [74]. |

| TM11 | Closed innovation [74]. |

| TM12 | External laboratories [86]. |

| TM13 | Internal laboratories [73]. |

| TM14 | Surveillance of innovation-life cycles of technology [84]. |

| TM15 | Use external sources innovation-open source software [25,26]. |

| Dimensional Criterions | ||||||

|---|---|---|---|---|---|---|

| Alternatives | ||||||

| Linguistic Terms | Code | Value |

|---|---|---|

| Excellent | L8 | 8 |

| Very strong | L7 | 7 |

| Strong | L6 | 6 |

| Fine | L5 | 5 |

| Middle good | L4 | 4 |

| Unbiased | L3 | 3 |

| Medium insignificant | L2 | 2 |

| Insignificant | L1 | 1 |

| Null | L0 | 0 |

| ID | CODE | R&D | P | Q | M | O | F |

|---|---|---|---|---|---|---|---|

| 1 | KM01 | L8 | L2 | L5 | L3 | L6 | L6 |

| 2 | KM02 | L6 | L8 | L6 | L6 | L5 | L4 |

| 3 | KM03 | L8 | L7 | L5 | L5 | L7 | L2 |

| 4 | KM04 | L8 | L4 | L5 | L3 | L6 | L4 |

| 5 | KM05 | L4 | L6 | L1 | L2 | L8 | L5 |

| 6 | KM06 | L8 | L5 | L5 | L3 | L8 | L3 |

| 7 | KM07 | L6 | L6 | L5 | L6 | L8 | L6 |

| 8 | KM08 | L8 | L4 | L2 | L1 | L1 | L2 |

| 9 | KM09 | L8 | L7 | L6 | L6 | L7 | L6 |

| 10 | KM10 | L8 | L8 | L8 | L6 | L6 | L5 |

| 11 | KM11 | L8 | L6 | L3 | L6 | L6 | L6 |

| 12 | KM12 | L8 | L6 | L6 | L6 | L8 | L4 |

| 13 | KM13 | L8 | L8 | L8 | L8 | L6 | L5 |

| 14 | FM01 | L6 | L6 | L5 | L4 | L5 | L8 |

| 15 | FM02 | L6 | L4 | L4 | L4 | L4 | L8 |

| 16 | FM03 | L7 | L7 | L8 | L6 | L6 | L8 |

| 17 | OM01 | L7 | L4 | L5 | L2 | L8 | L7 |

| 18 | OM02 | L7 | L4 | L2 | L4 | L8 | L3 |

| 19 | OM03 | L5 | L8 | L7 | L3 | L8 | L8 |

| 20 | OM04 | L6 | L6 | L3 | L5 | L8 | L2 |

| 21 | OM05 | L6 | L5 | L7 | L8 | L8 | L2 |

| 22 | OM06 | L7 | L6 | L6 | L5 | L8 | L4 |

| 23 | OM07 | L8 | L6 | L6 | L6 | L8 | L2 |

| 24 | OM08 | L5 | L8 | L8 | L1 | L6 | L8 |

| 25 | OM09 | L3 | L8 | L8 | L1 | L2 | L7 |

| 26 | OM10 | L8 | L8 | L8 | L8 | L8 | L8 |

| 27 | OM11 | L8 | L8 | L7 | L6 | L8 | L6 |

| 28 | OM12 | L8 | L7 | L8 | L6 | L8 | L7 |

| 29 | OM13 | L8 | L8 | L8 | L6 | L6 | L1 |

| 30 | OM14 | L8 | L8 | L8 | L8 | L7 | L8 |

| 31 | OM15 | L8 | L8 | L8 | L8 | L8 | L8 |

| 32 | OM16 | L2 | L8 | L8 | L5 | L8 | L1 |

| 33 | OM17 | L8 | L8 | L8 | L8 | L8 | L7 |

| 34 | OM18 | L8 | L8 | L4 | L5 | L5 | L2 |

| 35 | OM19 | L8 | L8 | L4 | L4 | L4 | L7 |

| 36 | OM20 | L6 | L1 | L2 | L8 | L8 | L4 |

| 37 | OM21 | L8 | L8 | L4 | L2 | L7 | L1 |

| 38 | OM22 | L8 | L7 | L5 | L4 | L4 | L4 |

| 39 | OM23 | L5 | L7 | L5 | L6 | L8 | L7 |

| 40 | OM24 | L6 | L7 | L5 | L5 | L8 | L8 |

| 41 | OM25 | L8 | L8 | L8 | L8 | L8 | L5 |

| 42 | OM26 | L8 | L2 | L7 | L8 | L8 | L6 |

| 43 | OM27 | L8 | L8 | L5 | L6 | L3 | L2 |

| 44 | OM28 | L8 | L2 | L4 | L8 | L8 | L4 |

| 45 | OM29 | L4 | L6 | L5 | L4 | L8 | L8 |

| 46 | OM30 | L8 | L6 | L4 | L5 | L8 | L2 |

| 47 | OM31 | L4 | L8 | L7 | L4 | L8 | L6 |

| 48 | OM32 | L7 | L6 | L6 | L7 | L8 | L1 |

| 49 | OM33 | L8 | L2 | L8 | L8 | L8 | L8 |

| 50 | OM34 | L8 | L8 | L8 | L8 | L8 | L5 |

| 51 | OM35 | L5 | L8 | L8 | L8 | L3 | L3 |

| 52 | OM36 | L8 | L8 | L8 | L5 | L8 | L3 |

| 53 | OM37 | L8 | L8 | L8 | L8 | L8 | L8 |

| 54 | OM38 | L8 | L7 | L4 | L2 | L8 | L8 |

| 55 | OM39 | L8 | L4 | L4 | L8 | L8 | L5 |

| 56 | OM40 | L8 | L8 | L8 | L1 | L8 | L5 |

| 57 | OM41 | L8 | L5 | L7 | L4 | L8 | L2 |

| 58 | OM42 | L8 | L8 | L8 | L8 | L8 | L7 |

| 59 | OM43 | L8 | L2 | L6 | L2 | L8 | L3 |

| 60 | OM44 | L8 | L2 | L4 | L4 | L8 | L7 |

| 61 | OM45 | L8 | L3 | L3 | L3 | L3 | L6 |

| 62 | OM46 | L8 | L7 | L8 | L4 | L5 | L1 |

| 63 | PM01 | L8 | L8 | L8 | L1 | L8 | L4 |

| 64 | PM02 | L8 | L8 | L8 | L4 | L5 | L3 |

| 65 | PM03 | L8 | L8 | L8 | L5 | L8 | L4 |

| 66 | PM04 | L8 | L8 | L8 | L4 | L7 | L4 |

| 67 | IPM5 | L8 | L4 | L2 | L7 | L4 | L2 |

| 68 | IPM6 | L8 | L2 | L5 | L3 | L1 | L8 |

| 69 | TM01 | L8 | L8 | L8 | L6 | L8 | L7 |

| 70 | TM02 | L8 | L7 | L8 | L4 | L3 | L7 |

| 71 | TM03 | L8 | L8 | L3 | L3 | L3 | L3 |

| 72 | TM04 | L6 | L8 | L8 | L1 | L5 | L7 |

| 73 | TM05 | L8 | L6 | L4 | L4 | L7 | L3 |

| 74 | TM06 | L8 | L8 | L8 | L2 | L3 | L2 |

| 75 | TM07 | L8 | L8 | L8 | L6 | L6 | L2 |

| 76 | TM08 | L8 | L8 | L8 | L8 | L6 | L3 |

| 77 | TM09 | L8 | L6 | L7 | L6 | L7 | L4 |

| 78 | TM10 | L8 | L5 | L8 | L3 | L5 | L7 |

| 79 | TM11 | L8 | L5 | L6 | L3 | L4 | L7 |

| 80 | TM12 | L8 | L8 | L8 | L4 | L7 | L8 |

| 81 | TM13 | L8 | L8 | L8 | L5 | L7 | L2 |

| 82 | TM14 | L8 | L5 | L5 | L4 | L6 | L4 |

| 83 | TM15 | L8 | L2 | L3 | L2 | L8 | L8 |

| 84 | PM05 | L8 | L8 | L8 | L6 | L5 | L7 |

| 85 | PM06 | L8 | L8 | L8 | L5 | L8 | L8 |

| 86 | PM07 | L8 | L8 | L8 | L5 | L7 | L7 |

| 87 | PM08 | L8 | L8 | L8 | L5 | L5 | L6 |

| 88 | PM09 | L8 | L8 | L8 | L7 | L5 | L1 |

| 89 | PM10 | L5 | L6 | L7 | L7 | L3 | L1 |

| 90 | PM11 | L7 | L8 | L5 | L4 | L2 | L3 |

| 91 | PM12 | L7 | L5 | L6 | L2 | L1 | L1 |

| 92 | PM13 | L8 | L8 | L4 | L3 | L4 | L3 |

| 93 | PM14 | L8 | L4 | L5 | L8 | L4 | L2 |

| 94 | PM15 | L8 | L5 | L1 | L2 | L8 | L2 |

| 95 | PM16 | L8 | L5 | L8 | L8 | L5 | L3 |

| 96 | IPM1 | L8 | L8 | L1 | L2 | L1 | L7 |

| 97 | IPM2 | L8 | L3 | L2 | L6 | L4 | L4 |

| 98 | IPM3 | L8 | L7 | L5 | L8 | L8 | L5 |

| 99 | IPM4 | L8 | L6 | L4 | L2 | L4 | L1 |

| General Factors | Dimensions | |||||

|---|---|---|---|---|---|---|

| R&D | P | Q | M | O | F | |

| Knowledge | 9 | 7 | 0 | 3 | 2 | 3 |

| Financial | 1 | 1 | 0 | 0 | 0 | 0 |

| Organizational | 11 | 17 | 14 | 9 | 34 | 9 |

| Process | 4 | 12 | 2 | 2 | 0 | 2 |

| Intellectual property | 4 | 2 | 0 | 2 | 0 | 2 |

| Technology | 24 | 12 | 4 | 1 | 16 | 1 |

| WAK | 0.2677 | 0.2576 | 0.1010 | 0.0859 | 0.2626 | 0.0253 |

| Dimension | Saaty Judgment Scale |

|---|---|

| R&D | 1 |

| O | 3 |

| P | 5 |

| F | 6 |

| Q | 7 |

| M | 8 |

| Dimension | Ahp Weight |

|---|---|

| R&D | 0.4596 |

| O | 0.2010 |

| P | 0.1576 |

| F | 0.0833 |

| Q | 0.0654 |

| M | 0.0331 |

| Dimensions | WAHP-AK Weight |

|---|---|

| R&D | 0.3637 |

| O | 0.2318 |

| P | 0.2076 |

| F | 0.0292 |

| Q | 0.0922 |

| M | 0.0757 |

| ID | CODE | R&D | P | Q | M | O | F |

|---|---|---|---|---|---|---|---|

| 1 | KM01 | 2.9092 | 0.4152 | 0.4608 | 0.2269 | 1.3908 | 0.1751 |

| 2 | KM02 | 2.1819 | 1.6606 | 0.5530 | 0.4539 | 1.1590 | 0.1167 |

| 3 | KM03 | 2.9092 | 1.4530 | 0.4608 | 0.3782 | 1.6226 | 0.0584 |

| 4 | KM04 | 2.9092 | 0.8303 | 0.4608 | 0.2269 | 1.3908 | 0.1167 |

| 5 | KM05 | 1.4546 | 1.2454 | 0.0922 | 0.1513 | 1.8544 | 0.1460 |

| 6 | KM06 | 2.9092 | 1.0379 | 0.4608 | 0.2269 | 1.8544 | 0.0876 |

| 7 | KM07 | 2.1819 | 1.2454 | 0.4608 | 0.4539 | 1.8544 | 0.1751 |

| 8 | KM08 | 2.9092 | 0.8303 | 0.1843 | 0.0756 | 0.2318 | 0.0584 |

| 9 | KM09 | 2.9092 | 1.4530 | 0.5530 | 0.4539 | 1.6226 | 0.1751 |

| 10 | KM10 | 2.9092 | 1.6606 | 0.7373 | 0.4539 | 1.3908 | 0.1459 |

| 11 | KM11 | 2.9092 | 1.2454 | 0.2765 | 0.4539 | 1.3908 | 0.1751 |

| 12 | KM12 | 2.9092 | 1.2454 | 0.5530 | 0.4539 | 1.8544 | 0.1167 |

| 13 | KM13 | 2.9092 | 1.6606 | 0.7373 | 0.6051 | 1.3908 | 0.1459 |

| 14 | FM01 | 2.1819 | 1.2454 | 0.4608 | 0.3026 | 1.1590 | 0.2335 |

| 15 | FM02 | 2.1819 | 0.8303 | 0.3686 | 0.3026 | 0.9272 | 0.2335 |

| 16 | FM03 | 2.5455 | 1.4530 | 0.7373 | 0.4536 | 1.3908 | 0.2335 |

| 17 | OM01 | 2.5455 | 0.8303 | 0.4608 | 0.1513 | 1.8544 | 0.2043 |

| 18 | OM02 | 2.5455 | 0.8303 | 0.1843 | 0.3026 | 1.8544 | 0.0876 |

| 19 | OM03 | 1.8182 | 1.6606 | 0.6451 | 0.2269 | 1.8544 | 0.2335 |

| 20 | OM04 | 2.1819 | 1.2454 | 0.2765 | 0.3782 | 1.8544 | 0.0584 |

| 21 | OM05 | 2.1819 | 1.0379 | 0.6451 | 0.6051 | 1.8544 | 0.0584 |

| 22 | OM06 | 2.5455 | 1.2454 | 0.5530 | 0.3782 | 1.8544 | 0.1167 |

| 23 | OM07 | 2.9092 | 1.2454 | 0.5530 | 0.4539 | 1.8544 | 0.0584 |

| 24 | OM08 | 1.8182 | 1.6606 | 0.7373 | 0.0756 | 1.3908 | 0.2335 |

| 25 | OM09 | 1.0909 | 1.6606 | 0.7373 | 0.0756 | 0.4636 | 0.2043 |

| 26 | OM10 | 2.9092 | 1.6606 | 0.7373 | 0.6051 | 1.8544 | 0.2335 |

| 27 | OM11 | 2.9092 | 1.6606 | 0.6451 | 0.4539 | 1.8544 | 0.1751 |

| 28 | OM12 | 2.9092 | 1.4530 | 0.7373 | 0.4539 | 1.8544 | 0.2043 |

| 29 | OM13 | 2.9092 | 1.6606 | 0.7373 | 0.4539 | 1.3908 | 0.0292 |

| 30 | OM14 | 2.9092 | 1.6606 | 0.7373 | 0.6051 | 1.6226 | 0.2335 |

| 31 | OM15 | 2.9092 | 1.6606 | 0.7373 | 0.6051 | 1.8544 | 0.2335 |

| 32 | OM16 | 0.7273 | 1.6606 | 0.7373 | 0.3782 | 1.8544 | 0.0292 |

| 33 | OM17 | 2.9092 | 1.6606 | 0.7373 | 0.6051 | 1.8544 | 0.2043 |

| 34 | OM18 | 2.9092 | 1.6606 | 0.3687 | 0.3782 | 1.1590 | 0.0584 |

| 35 | OM19 | 2.9092 | 1.6606 | 0.3687 | 0.3026 | 0.9272 | 0.2043 |

| 36 | OM20 | 2.1819 | 0.2076 | 0.1843 | 0.6051 | 1.8544 | 0.1167 |

| 37 | OM21 | 2.9092 | 1.6606 | 0.3686 | 0.1513 | 1.6226 | 0.0292 |

| 38 | OM22 | 2.9092 | 1.4530 | 0.4608 | 0.3026 | 0.9272 | 0.1167 |

| 39 | OM23 | 1.8182 | 1.4530 | 0.4608 | 0.4539 | 1.8544 | 0.2043 |

| 40 | OM24 | 2.1819 | 1.4530 | 0.4608 | 0.3782 | 1.8544 | 0.2335 |

| 41 | OM25 | 2.9092 | 1.6606 | 0.7373 | 0.6051 | 1.8544 | 0.1459 |

| 42 | OM26 | 2.9092 | 0.4152 | 0.6451 | 0.6051 | 1.8544 | 0.1751 |

| 43 | OM27 | 2.9092 | 1.6606 | 0.4608 | 0.4539 | 0.6954 | 0.0584 |

| 44 | OM28 | 2.9092 | 0.4152 | 0.3686 | 0.6051 | 1.8544 | 0.1167 |

| 45 | OM29 | 1.4546 | 1.2454 | 0.4608 | 0.3026 | 1.8544 | 0.2335 |

| 46 | OM30 | 2.9092 | 1.2454 | 0.3686 | 0.3782 | 1.8544 | 0.0584 |

| 47 | OM31 | 1.4546 | 1.6606 | 0.6451 | 0.3026 | 1.8544 | 0.1751 |

| 48 | OM32 | 2.5455 | 1.2454 | 0.5530 | 0.5295 | 1.8544 | 0.0292 |

| 49 | OM33 | 2.9092 | 0.4152 | 0.7373 | 0.6051 | 1.8544 | 0.2335 |

| 50 | OM34 | 2.9092 | 1.6606 | 0.7373 | 0.6051 | 1.8544 | 0.1459 |

| 51 | OM35 | 1.8182 | 1.6606 | 0.7373 | 0.6051 | 0.6954 | 0.0876 |

| 52 | OM36 | 2.9092 | 1.6606 | 0.7373 | 0.3782 | 1.8544 | 0.0876 |

| 53 | OM37 | 2.9092 | 1.6606 | 0.7373 | 0.6051 | 1.8544 | 0.2335 |

| 54 | OM38 | 2.9092 | 1.4530 | 0.3686 | 0.1513 | 1.8544 | 0.2335 |

| 55 | OM39 | 2.9092 | 0.8303 | 0.3686 | 0.6051 | 1.8544 | 0.1459 |

| 56 | OM40 | 2.9092 | 1.6606 | 0.7373 | 0.0756 | 1.8544 | 0.1459 |

| 57 | OM41 | 2.9092 | 1.0379 | 0.6451 | 0.3026 | 1.8544 | 0.0584 |

| 58 | OM42 | 2.9092 | 1.6606 | 0.7373 | 0.6051 | 1.8544 | 0.2043 |

| 59 | OM43 | 2.9092 | 0.4152 | 0.5530 | 0.1513 | 1.8544 | 0.0876 |

| 60 | OM44 | 2.9092 | 0.4152 | 0.3686 | 0.3026 | 1.8544 | 0.2043 |

| 61 | OM45 | 2.9092 | 0.6227 | 0.2765 | 0.2269 | 0.6954 | 0.1751 |

| 62 | OM46 | 2.9092 | 2.5455 | 2.9092 | 1.4546 | 1.8182 | 0.3637 |

| 63 | PM01 | 2.9092 | 2.9092 | 2.9092 | 0.3637 | 2.9092 | 1.4546 |

| 64 | PM02 | 2.9092 | 2.9092 | 2.9092 | 1.4546 | 1.8182 | 1.0909 |

| 65 | PM03 | 2.9092 | 2.9092 | 2.9092 | 1.8182 | 2.9092 | 1.4546 |

| 66 | PM04 | 2.9092 | 2.9092 | 2.9092 | 1.4546 | 2.5455 | 1.4546 |

| 67 | PM05 | 2.9092 | 2.9092 | 2.9092 | 2.1819 | 1.8182 | 2.5455 |

| 68 | PM06 | 2.9092 | 2.9092 | 2.9092 | 1.8182 | 2.9092 | 2.9092 |

| 69 | PM07 | 2.9092 | 2.9092 | 2.9092 | 1.8182 | 2.5455 | 2.5455 |

| 70 | PM08 | 2.9092 | 2.9092 | 2.9092 | 1.8182 | 1.8182 | 2.1819 |

| 71 | PM09 | 2.9092 | 2.9092 | 2.9092 | 2.5455 | 1.8182 | 0.3637 |

| 72 | PM10 | 1.8182 | 2.1819 | 2.5455 | 2.5455 | 1.0909 | 0.3637 |

| 73 | PM11 | 2.5455 | 2.9092 | 1.8182 | 1.4546 | 0.7273 | 1.0909 |

| 74 | PM12 | 2.5455 | 1.8182 | 2.1819 | 0.7273 | 0.3637 | 0.3637 |

| 75 | PM13 | 2.9092 | 2.9092 | 1.4546 | 1.0909 | 1.4546 | 1.0909 |

| 76 | PM14 | 2.9092 | 1.4546 | 1.8182 | 2.9092 | 1.4546 | 0.7273 |

| 77 | PM15 | 2.9092 | 1.8182 | 0.3637 | 0.7273 | 2.9092 | 0.7273 |

| 78 | PM16 | 2.9092 | 1.8182 | 2.9092 | 2.9092 | 1.8182 | 1.0909 |

| 79 | IPM01 | 2.9092 | 2.9092 | 0.3637 | 0.7273 | 0.3637 | 2.5455 |

| 80 | IPM02 | 2.9092 | 1.0909 | 0.7273 | 2.1819 | 1.4546 | 1.4546 |

| 81 | IPM03 | 2.9092 | 2.5455 | 1.8182 | 2.9092 | 2.9092 | 1.8182 |

| 82 | IPM04 | 2.9092 | 2.1819 | 1.4546 | 0.7273 | 1.4546 | 0.3637 |

| 83 | IPM05 | 2.9092 | 1.4546 | 0.7273 | 2.5455 | 1.4546 | 0.7273 |

| 84 | IPM06 | 2.9092 | 0.7273 | 1.8182 | 1.0909 | 0.3637 | 2.9092 |

| 85 | TM01 | 2.9092 | 2.9092 | 2.9092 | 2.1819 | 2.9092 | 2.5455 |

| 86 | TM02 | 2.9092 | 2.5455 | 2.9092 | 1.4546 | 1.0909 | 2.5455 |

| 87 | TM03 | 2.9092 | 2.9092 | 1.0909 | 1.0909 | 1.0909 | 1.0909 |

| 88 | TM04 | 2.1819 | 2.9092 | 2.9092 | 0.3637 | 1.8182 | 2.5455 |

| 89 | TM05 | 2.9092 | 2.1819 | 1.4546 | 1.4546 | 2.5455 | 1.0909 |

| 90 | TM06 | 2.9092 | 2.9092 | 2.9092 | 0.7273 | 1.0909 | 0.7273 |

| 91 | TM07 | 2.9092 | 2.9092 | 2.9092 | 2.1819 | 2.1819 | 0.7273 |

| 92 | TM08 | 2.9092 | 2.9092 | 2.9092 | 2.9092 | 2.1819 | 1.0909 |

| 93 | TM09 | 2.9092 | 2.1819 | 2.5455 | 2.1819 | 2.5455 | 1.4546 |

| 94 | TM10 | 2.9092 | 1.8182 | 2.9092 | 1.0909 | 1.8182 | 2.5455 |

| 95 | TM11 | 2.9092 | 1.8182 | 2.1819 | 1.0909 | 1.4546 | 2.5455 |

| 96 | TM12 | 2.9092 | 2.9092 | 2.9092 | 1.4546 | 2.5455 | 2.9092 |

| 97 | TM13 | 2.9092 | 2.9092 | 2.9092 | 1.8182 | 2.5455 | 0.7273 |

| 98 | TM14 | 2.9092 | 1.8182 | 1.8182 | 1.4546 | 2.1819 | 1.4546 |

| 99 | TM15 | 2.9092 | 1.8182 | 1.8182 | 1.4546 | 2.1819 | 1.4546 |

| Negative Vector | 0.7273 | 0.2076 | 0.0922 | 0.0756 | 0.2318 | 0.0292 | |

| ID | CODE | Ei = Euclidean Distance | Ti = Taxicab Distance | Assessment Weight | |

|---|---|---|---|---|---|

| Score | Ranking | ||||

| 1 | KM01 | 0.07899 | 4.21427 | 0.66147 | 27 |

| 2 | KM02 | 0.07331 | 4.76134 | 1.21856 | 15 |

| 3 | KM03 | 0.09142 | 5.51849 | −0.58007 | 67 |

| 4 | KM04 | 0.08103 | 4.57105 | 0.44915 | 33 |

| 5 | KM05 | 0.06480 | 3.58011 | 2.14178 | 5 |

| 6 | KM06 | 0.09017 | 5.21304 | −0.46206 | 62 |

| 7 | KM07 | 0.07773 | 5.00779 | 0.77116 | 25 |

| 8 | KM08 | 0.07132 | 2.92594 | 1.49537 | 11 |

| 9 | KM09 | 0.09222 | 5.80302 | −0.65278 | 68 |

| 10 | KM10 | 0.09309 | 5.93393 | −0.73533 | 72 |

| 11 | KM11 | 0.08531 | 5.08717 | 0.01827 | 44 |

| 12 | KM12 | 0.09334 | 5.76888 | −0.76223 | 74 |

| 13 | KM13 | 0.09382 | 6.08521 | −0.80183 | 77 |

| 14 | FM01 | 0.06498 | 4.21948 | 2.08445 | 7 |

| 15 | FM02 | 0.05580 | 3.48038 | 3.08212 | 3 |

| 16 | FM03 | 0.08190 | 5.45025 | 0.35178 | 35 |

| 17 | OM01 | 0.08006 | 4.68291 | 0.54531 | 31 |

| 18 | OM02 | 0.07938 | 4.44099 | 0.61738 | 29 |

| 19 | OM03 | 0.07885 | 5.07504 | 0.65813 | 28 |

| 20 | OM04 | 0.07662 | 4.63110 | 0.89161 | 22 |

| 21 | OM05 | 0.07708 | 5.01909 | 0.83477 | 23 |

| 22 | OM06 | 0.08501 | 5.32959 | 0.04740 | 42 |

| 23 | OM07 | 0.09330 | 5.71051 | −0.75999 | 73 |

| 24 | OM08 | 0.07094 | 4.55232 | 1.46506 | 12 |

| 25 | OM09 | 0.05202 | 2.86865 | 3.53394 | 1 |

| 26 | OM10 | 0.10051 | 6.63635 | −1.42140 | 97 |

| 27 | OM11 | 0.09918 | 6.33455 | −1.30783 | 88 |

| 28 | OM12 | 0.09697 | 6.24831 | −1.09933 | 85 |

| 29 | OM13 | 0.09302 | 5.81720 | −0.73077 | 71 |

| 30 | OM14 | 0.09702 | 6.40455 | −1.09915 | 84 |

| 31 | OM15 | 0.10051 | 6.63635 | −1.42140 | 97 |

| 32 | OM16 | 0.07197 | 4.02327 | 1.38288 | 14 |

| 33 | OM17 | 0.10045 | 6.60717 | −1.41750 | 95 |

| 34 | OM18 | 0.08827 | 5.17031 | −0.27439 | 54 |

| 35 | OM19 | 0.08608 | 5.00878 | −0.05853 | 48 |

| 36 | OM20 | 0.07054 | 3.78637 | 1.53949 | 10 |

| 37 | OM21 | 0.09362 | 5.37780 | −0.79903 | 76 |

| 38 | OM22 | 0.08303 | 4.80582 | 0.24636 | 38 |

| 39 | OM23 | 0.07487 | 4.88090 | 1.05908 | 20 |

| 40 | OM24 | 0.08049 | 5.19809 | 0.49406 | 32 |

| 41 | OM25 | 0.10037 | 6.54881 | −1.41204 | 93 |

| 42 | OM26 | 0.08907 | 5.24039 | −0.35262 | 56 |

| 43 | OM27 | 0.08523 | 4.87451 | 0.02600 | 43 |

| 44 | OM28 | 0.08771 | 4.90555 | −0.22074 | 53 |

| 45 | OM29 | 0.06638 | 4.18758 | 1.94424 | 8 |

| 46 | OM30 | 0.09230 | 5.45056 | −0.66801 | 69 |

| 47 | OM31 | 0.07466 | 4.72867 | 1.08517 | 19 |

| 48 | OM32 | 0.08562 | 5.39333 | −0.01334 | 45 |

| 49 | OM33 | 0.08979 | 5.39092 | −0.42206 | 59 |

| 50 | OM34 | 0.10037 | 6.54881 | −1.41204 | 93 |

| 51 | OM35 | 0.06448 | 4.24051 | 2.13386 | 6 |

| 52 | OM36 | 0.09939 | 6.26352 | −1.33007 | 89 |

| 53 | OM37 | 0.10051 | 6.63635 | −1.42140 | 97 |

| 54 | OM38 | 0.09457 | 5.60630 | −0.88596 | 78 |

| 55 | OM39 | 0.08966 | 5.34988 | −0.41003 | 58 |

| 56 | OM40 | 0.09898 | 6.01931 | −1.30069 | 87 |

| 57 | OM41 | 0.09124 | 5.44382 | −0.56358 | 66 |

| 58 | OM42 | 0.10045 | 6.60717 | −1.41750 | 95 |

| 59 | OM43 | 0.08690 | 4.60684 | −0.14118 | 52 |

| 60 | OM44 | 0.08655 | 4.69053 | −0.10512 | 50 |

| 61 | OM45 | 0.07179 | 3.54213 | 1.42059 | 13 |

| 62 | OM46 | 0.08680 | 5.22654 | −0.12879 | 51 |

| 63 | PM01 | 0.09895 | 5.99013 | −1.29894 | 86 |

| 64 | PM02 | 0.08994 | 5.49248 | −0.43588 | 60 |

| 65 | PM03 | 0.09941 | 6.29270 | −1.33094 | 90 |

| 66 | PM04 | 0.09567 | 5.98526 | −0.98293 | 79 |

| 67 | PM05 | 0.09059 | 5.76049 | −0.49574 | 64 |

| 68 | PM06 | 0.09958 | 6.40943 | −1.34243 | 91 |

| 69 | PM07 | 0.09600 | 6.14845 | −1.00942 | 82 |

| 70 | PM08 | 0.09026 | 5.65567 | −0.46484 | 63 |

| 71 | PM09 | 0.09077 | 5.66104 | −0.51419 | 65 |

| 72 | PM10 | 0.05434 | 3.59920 | 3.22252 | 2 |

| 73 | PM11 | 0.06446 | 3.18496 | 2.20174 | 4 |

| 74 | PM12 | 0.07472 | 4.15697 | 1.09697 | 18 |

| 75 | PM13 | 0.08576 | 4.81641 | −0.02663 | 46 |

| 76 | PM14 | 0.07724 | 4.42730 | 0.83437 | 24 |

| 77 | PM15 | 0.08932 | 4.73958 | −0.38239 | 57 |

| 78 | PM16 | 0.08314 | 5.17233 | 0.23201 | 39 |

| 79 | IPM01 | 0.08254 | 3.88563 | 0.30416 | 36 |

| 80 | IPM02 | 0.07415 | 3.85034 | 1.16540 | 17 |

| 81 | IPM03 | 0.09615 | 6.06476 | −1.02663 | 83 |

| 82 | IPM04 | 0.07947 | 4.26726 | 0.61212 | 30 |

| 83 | IPM05 | 0.07594 | 4.07519 | 0.97573 | 21 |

| 84 | IPM06 | 0.07025 | 3.11365 | 1.59951 | 9 |

| 85 | TM01 | 0.09978 | 6.45589 | −1.35959 | 92 |

| 86 | TM02 | 0.08323 | 4.93804 | 0.22483 | 40 |

| 87 | TM03 | 0.08395 | 4.49245 | 0.15570 | 41 |

| 88 | TM04 | 0.07387 | 4.65499 | 1.16613 | 16 |

| 89 | TM05 | 0.08829 | 5.17230 | −0.27606 | 55 |

| 90 | TM06 | 0.08606 | 4.84842 | −0.05605 | 47 |

| 91 | TM07 | 0.09303 | 5.84638 | −0.73061 | 70 |

| 92 | TM08 | 0.09377 | 6.02685 | −0.79800 | 75 |

| 93 | TM09 | 0.09008 | 5.62924 | −0.44811 | 61 |

| 94 | TM10 | 0.08177 | 4.91085 | 0.37119 | 34 |

| 95 | TM11 | 0.07819 | 4.49473 | 0.73652 | 26 |

| 96 | TM12 | 0.09585 | 6.10199 | −0.99647 | 80 |

| 97 | TM13 | 0.09584 | 6.00254 | −0.99894 | 81 |

| 98 | TM14 | 0.08302 | 4.85427 | 0.24716 | 37 |

| 99 | TM15 | 0.08611 | 4.47627 | −0.06108 | 49 |

| Omitted Variable | Adjusted Total Mean | Adjusted Total Standard Deviation | Item-Adjusted Total Correlation | Squared Multiple Correlation | Cronbach’s Alpha |

|---|---|---|---|---|---|

| WAHP | 99.90 | 56.10 | 0.9228 | 0.9734 | 0.9574 |

| WAK | 99.90 | 56.91 | 0.8813 | 0.9177 | 0.9870 |

| WAHP-AK | 99.90 | 54.84 | 0.9884 | 0.9864 | 0.9090 |

| WAHP | WAK | WAHP-AK | |

|---|---|---|---|

| WAHP | 1.00 | 0.83 | 0.97 |

| WAK | 0.83 | 1.00 | 0.92 |

| WAHP-AK | 0.97 | 0.92 | 1.00 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sansabas-Villalpando, V.; Pérez-Olguín, I.J.C.; Pérez-Domínguez, L.A.; Rodríguez-Picón, L.A.; Mendez-González, L.C. CODAS HFLTS Method to Appraise Organizational Culture of Innovation and Complex Technological Changes Environments. Sustainability 2019, 11, 7045. https://doi.org/10.3390/su11247045

Sansabas-Villalpando V, Pérez-Olguín IJC, Pérez-Domínguez LA, Rodríguez-Picón LA, Mendez-González LC. CODAS HFLTS Method to Appraise Organizational Culture of Innovation and Complex Technological Changes Environments. Sustainability. 2019; 11(24):7045. https://doi.org/10.3390/su11247045

Chicago/Turabian StyleSansabas-Villalpando, Verónica, Iván Juan Carlos Pérez-Olguín, Luis Asunción Pérez-Domínguez, Luis Alberto Rodríguez-Picón, and Luis Carlos Mendez-González. 2019. "CODAS HFLTS Method to Appraise Organizational Culture of Innovation and Complex Technological Changes Environments" Sustainability 11, no. 24: 7045. https://doi.org/10.3390/su11247045

APA StyleSansabas-Villalpando, V., Pérez-Olguín, I. J. C., Pérez-Domínguez, L. A., Rodríguez-Picón, L. A., & Mendez-González, L. C. (2019). CODAS HFLTS Method to Appraise Organizational Culture of Innovation and Complex Technological Changes Environments. Sustainability, 11(24), 7045. https://doi.org/10.3390/su11247045