Strength, Carbon Footprint and Cost Considerations of Mortar Blends with High Volume Ground Granulated Blast Furnace Slag

Abstract

:1. Introduction

2. Experimental Program

2.1. Materials

2.2. Procedure

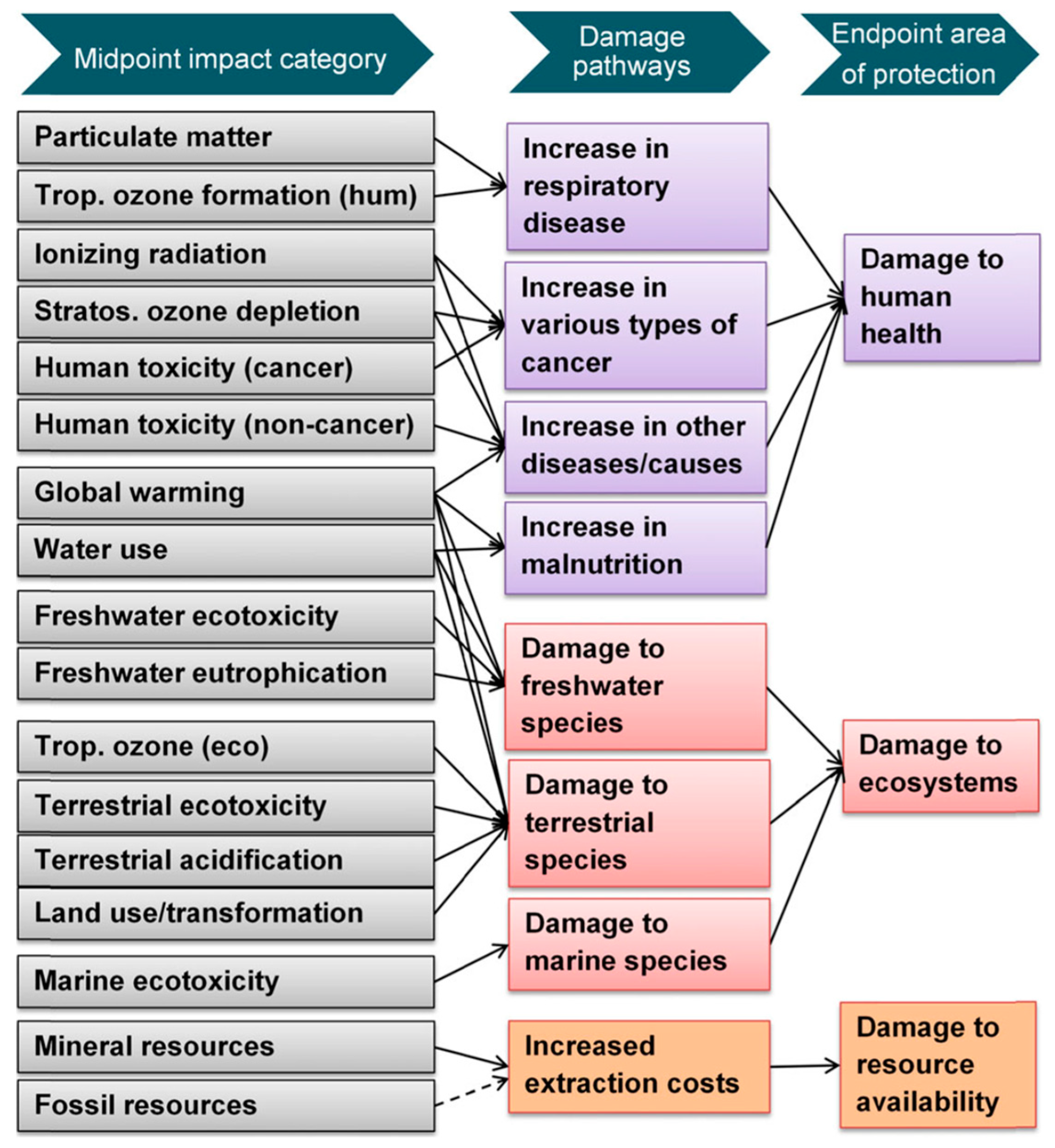

3. Environmental Life Cycle Assessment (eLCA)

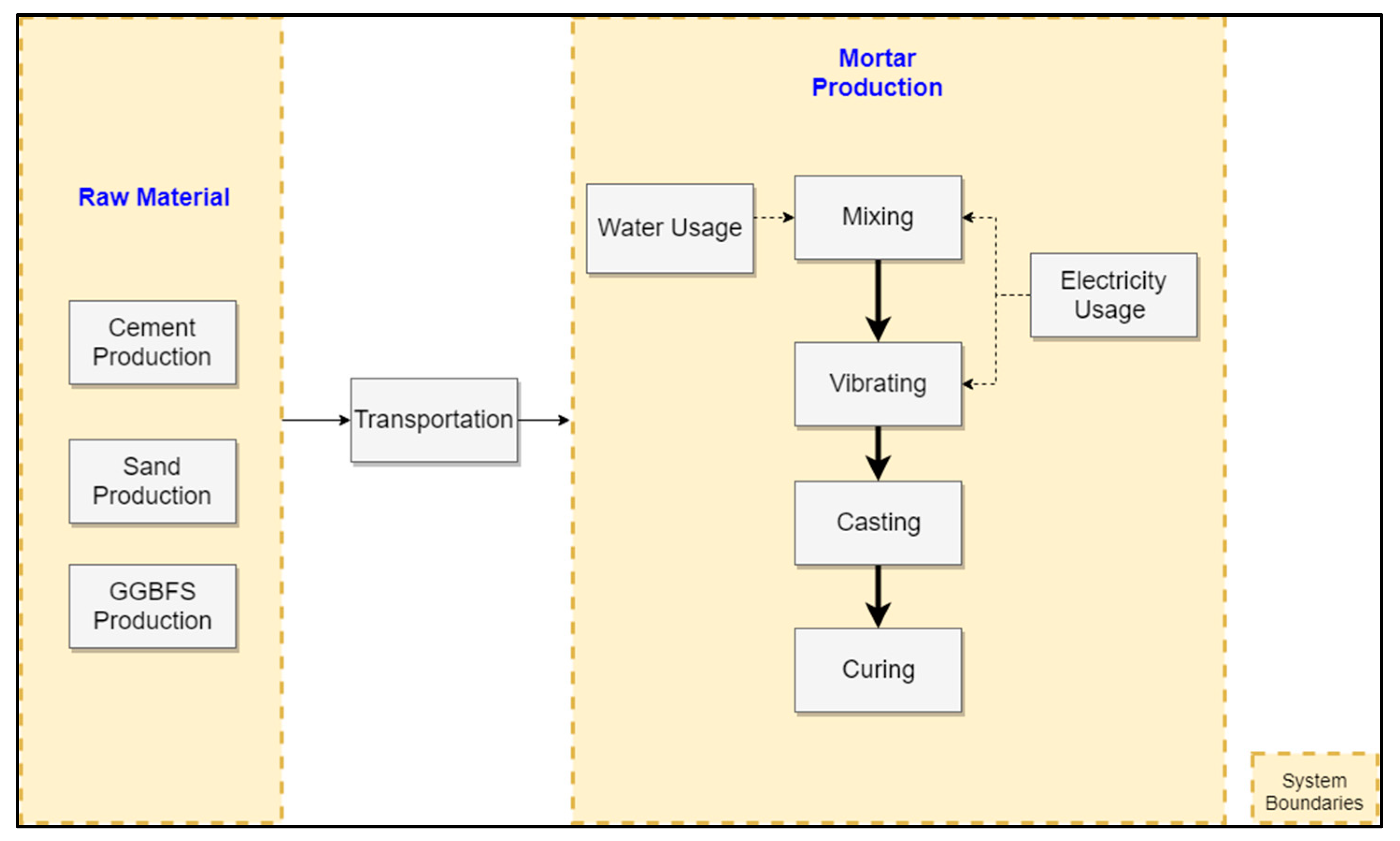

3.1. System Boundary

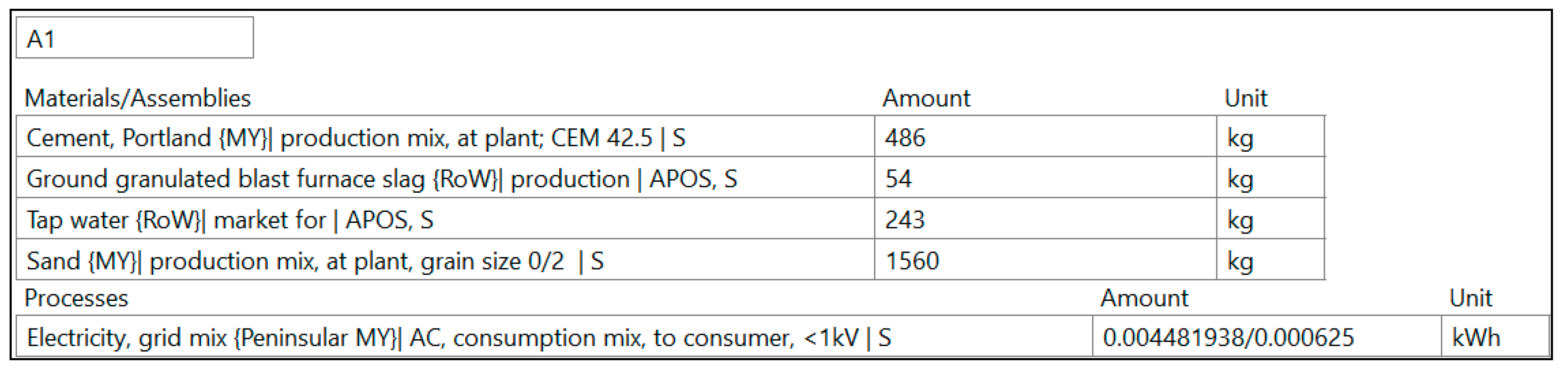

3.2. Life Cycle Inventory

4. Results and Discussion

4.1. Compressive Strength

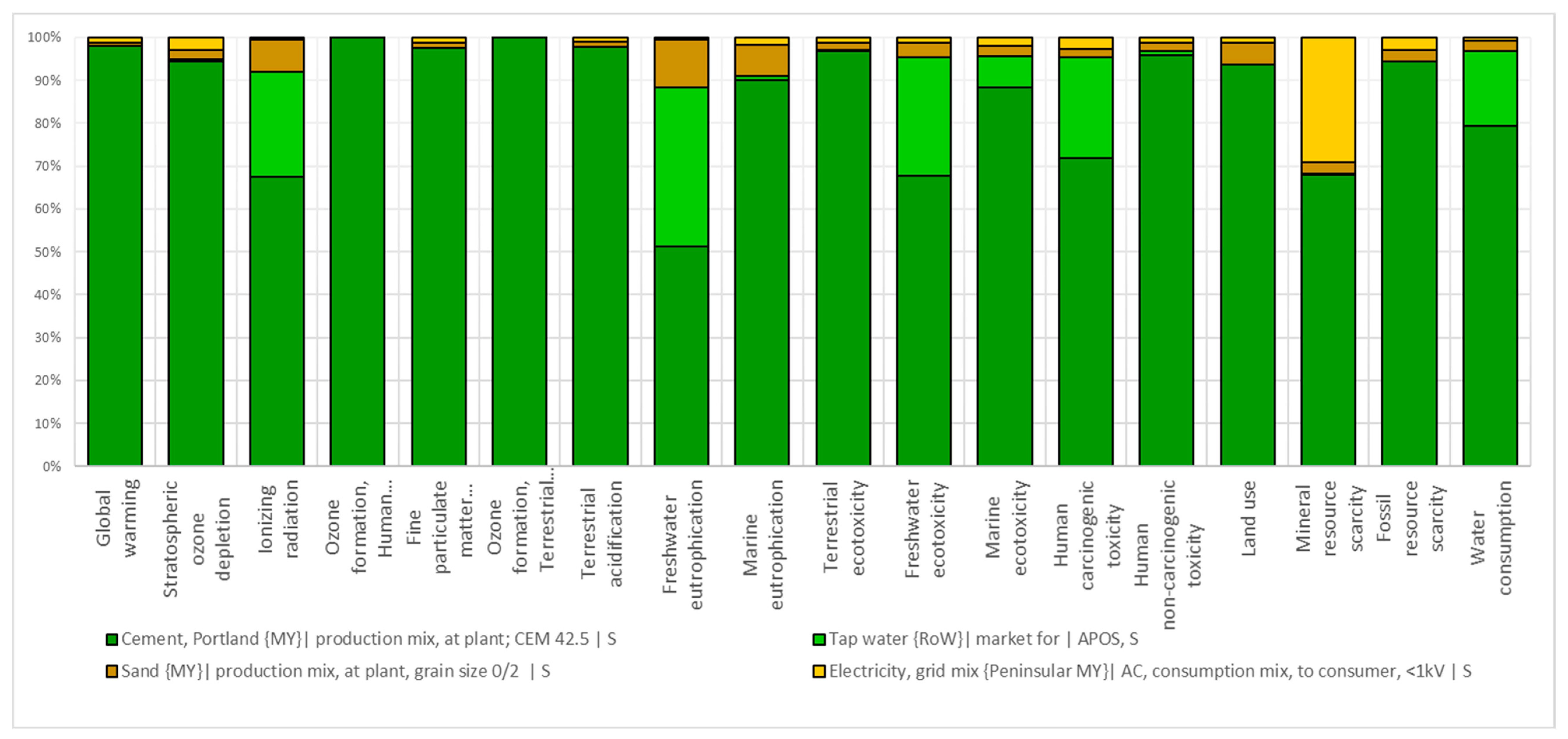

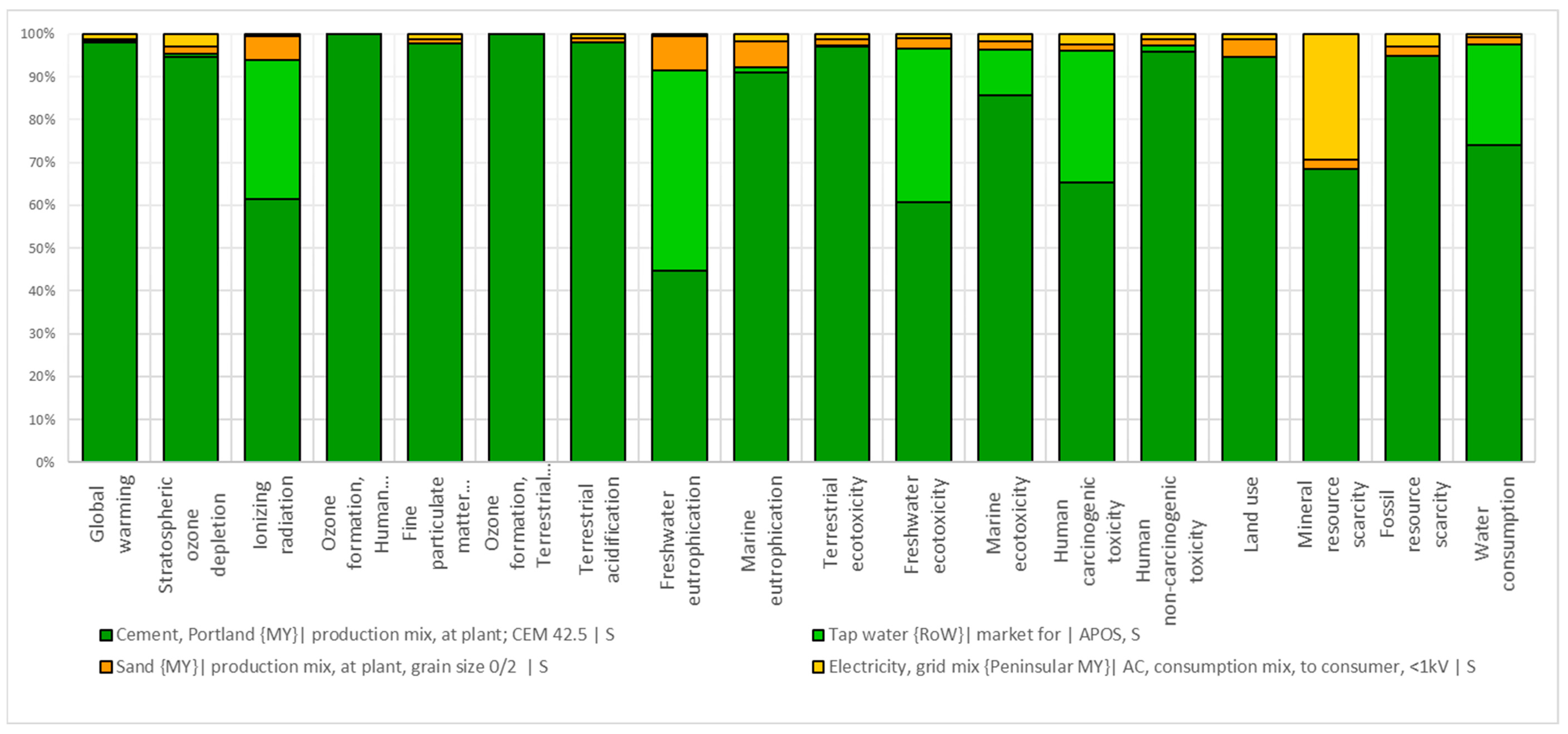

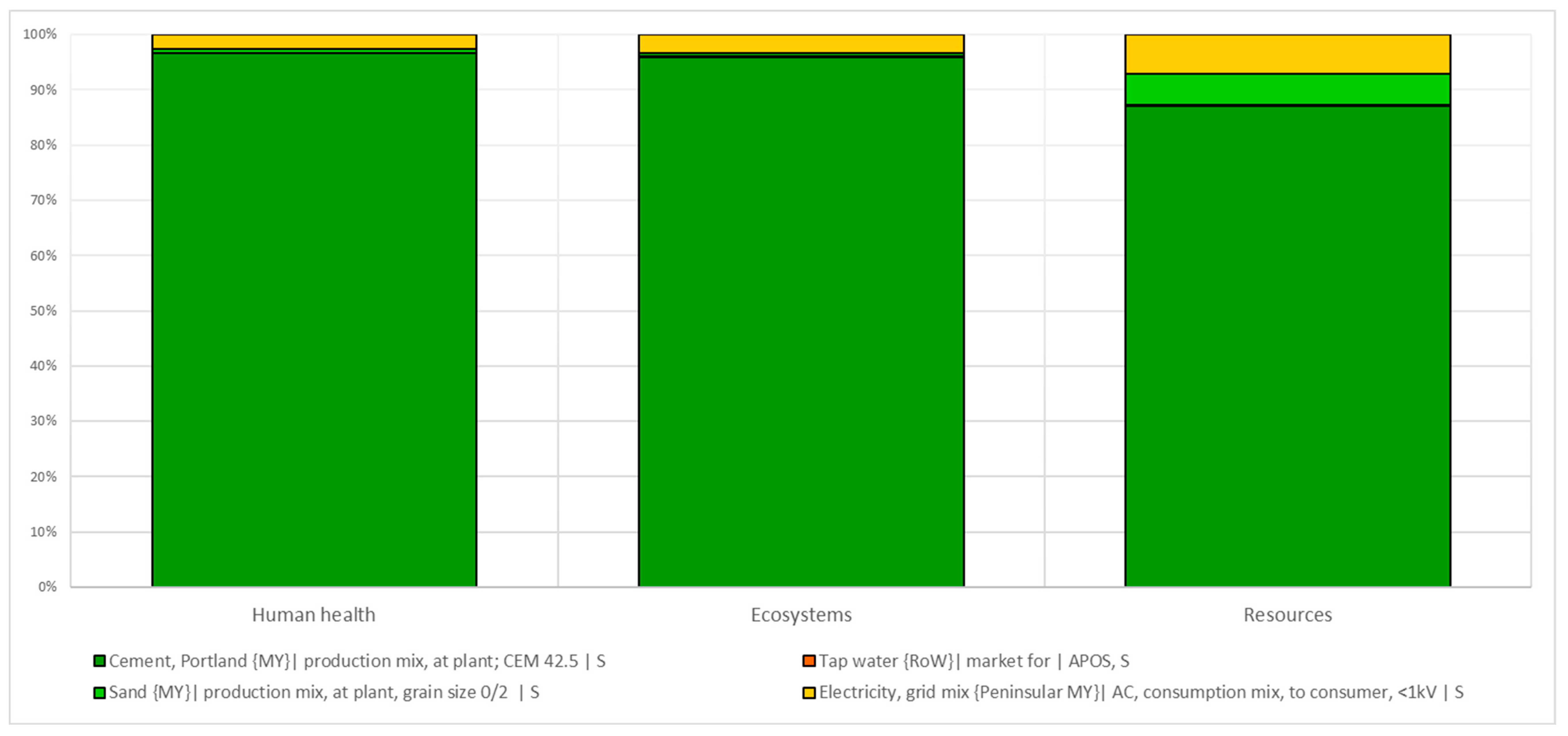

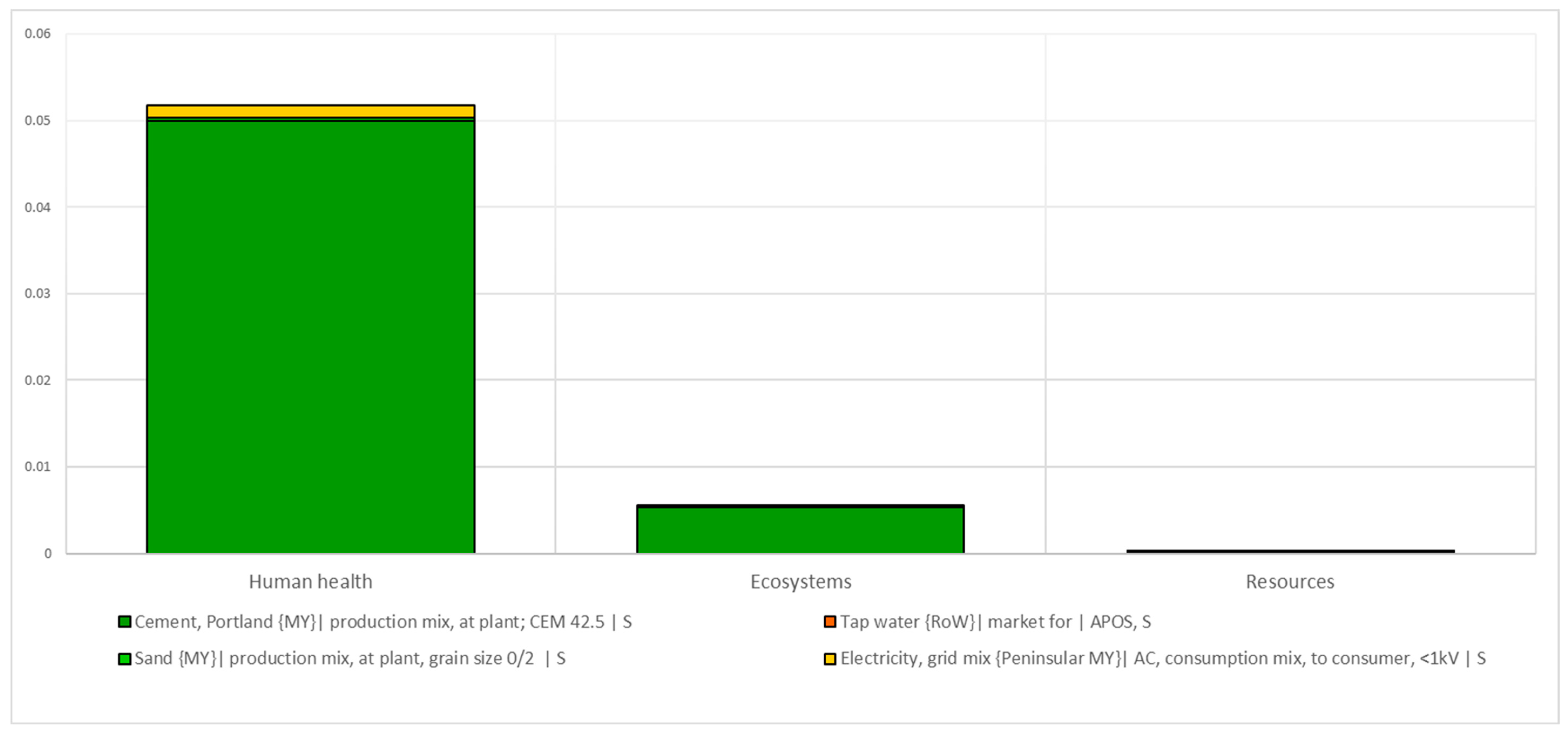

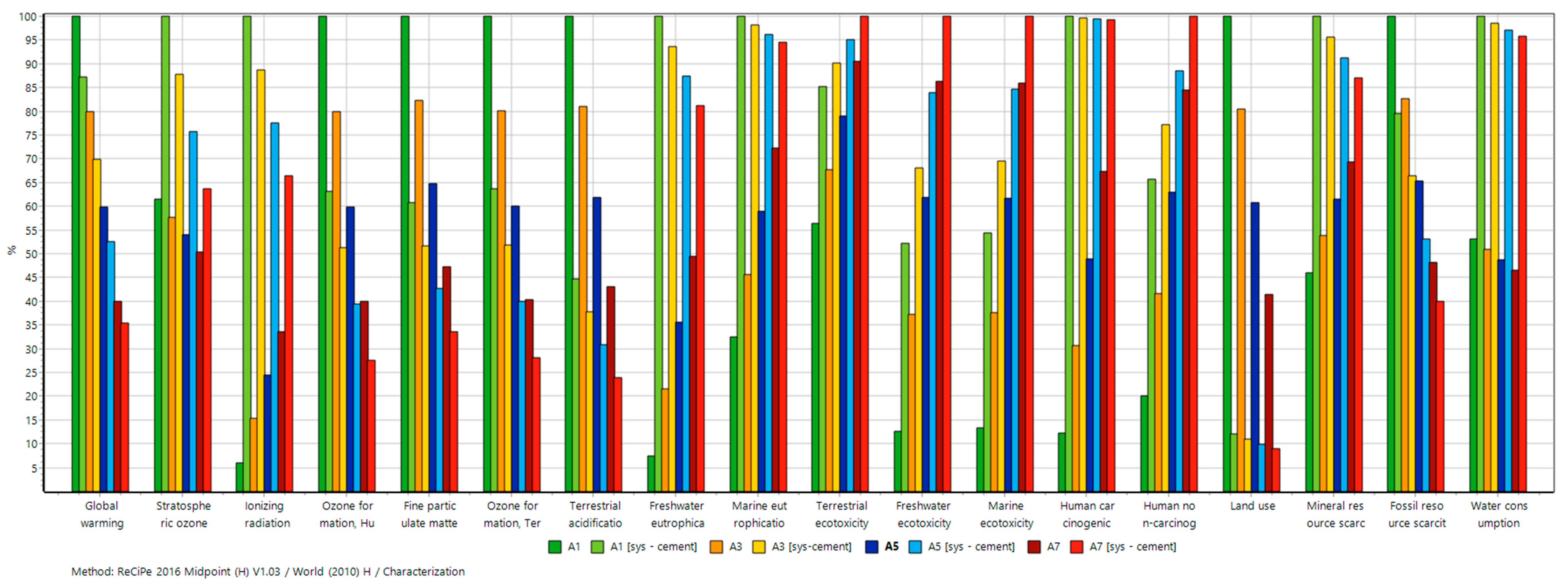

4.2. Life Cycle Impact Assessment

4.3. Sensitivity Analysis

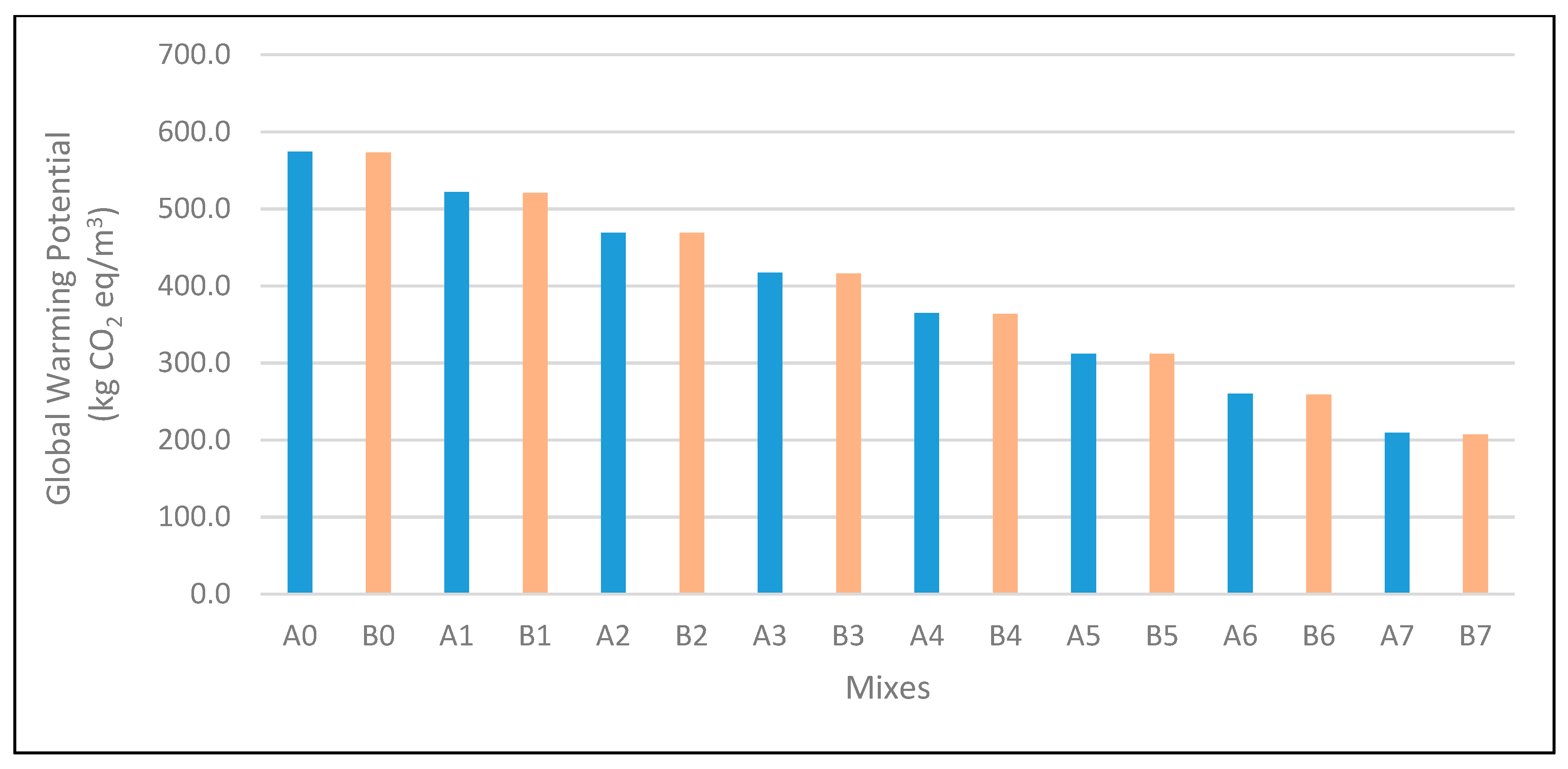

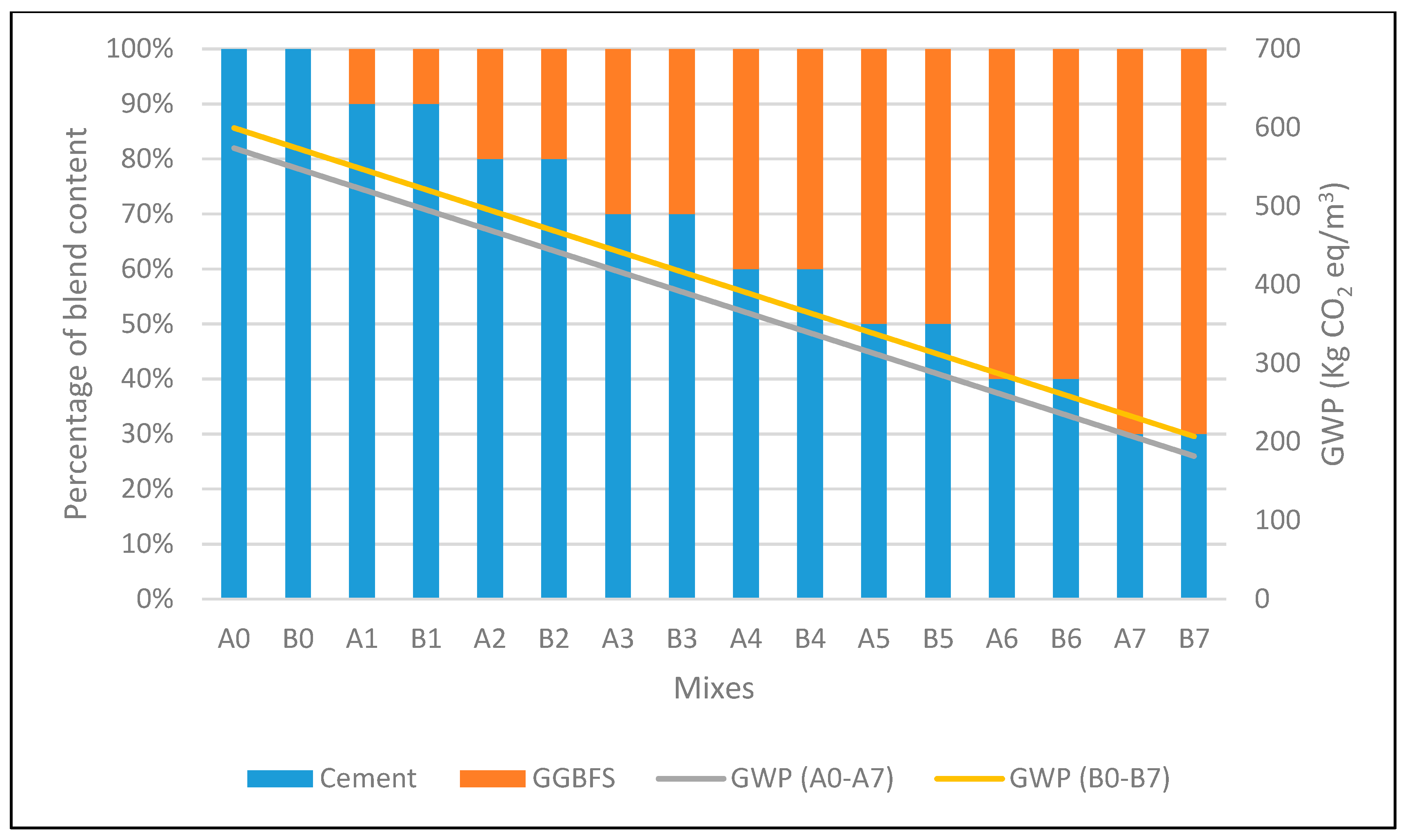

4.4. Carbon Footprint Performance

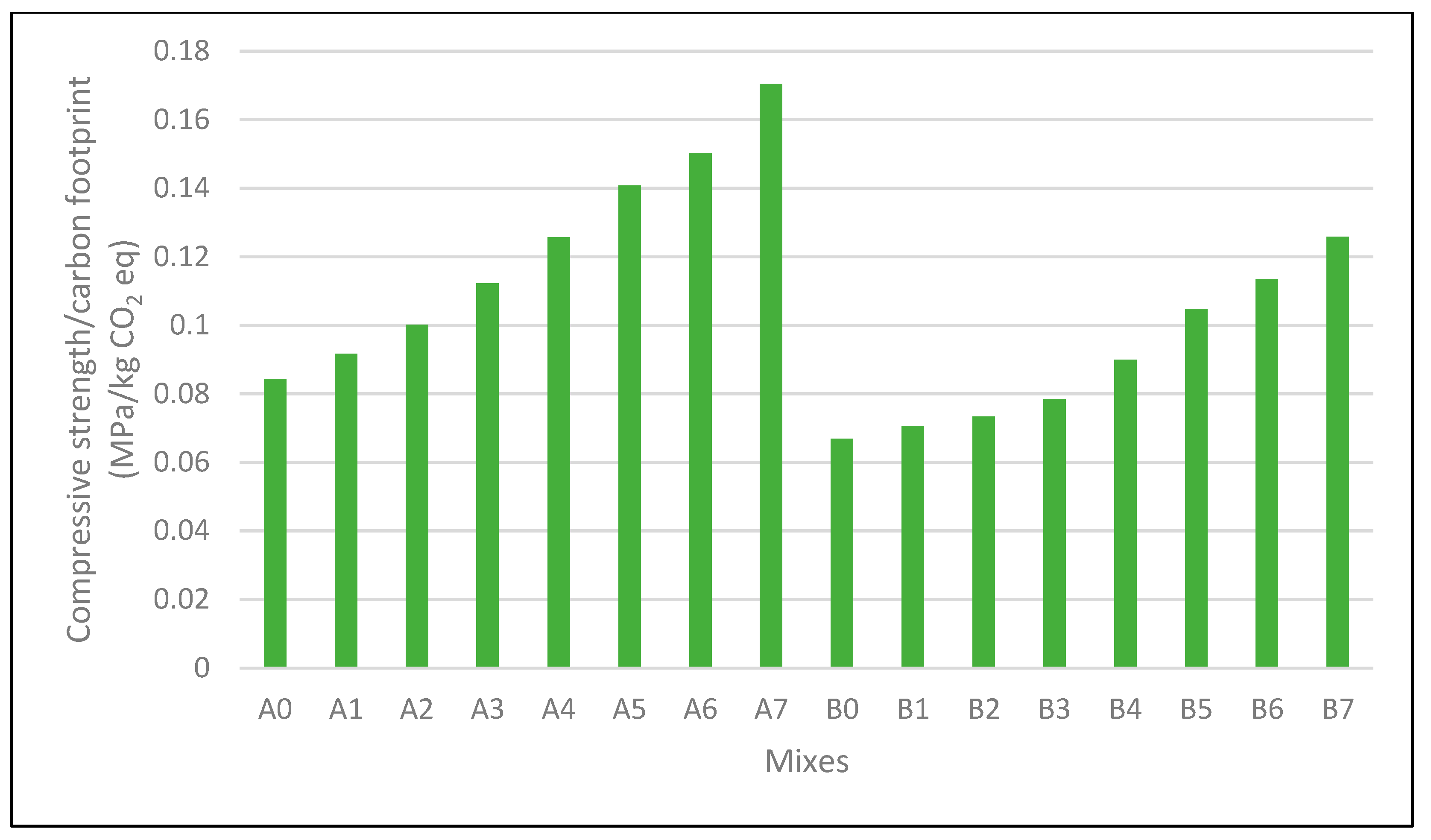

4.5. Compressive Strength/Carbon Footrpint Analysis

4.6. Cost Efficiency

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Crossin, E. The greenhouse gas implications of using ground granulated blast furnace slag as a cement substitute. J. Clean. Prod. 2015, 95, 101–108. [Google Scholar] [CrossRef]

- Miller, S.A.; Horvath, A.; Monteiro, P.J.M.; Ostertag, C.P. Greenhouse gas emissions from concrete can be reduced by using mix proportions, geometric aspects, and age as design. Environ. Res. Lett. 2015, 10, 114017. [Google Scholar] [CrossRef] [Green Version]

- Li, G.; Zhao, X. Properties of concrete incorporating fly ash and ground granulated blast-furnace slag. Cem. Concr. Compos. 2003, 25, 293–299. [Google Scholar] [CrossRef]

- Higgins, D. Briefing: GGBS and sustainability. Proc. Inst. Civ. Eng. Constr. Mater. 2007, 160, 99–101. [Google Scholar] [CrossRef]

- Beushausen, H.; Alexander, M.; Ballim, Y. Early-age properties, strength development and heat of hydration of concrete containing various South African slags at different replacement ratios. Constr. Build. Mater. 2012, 29, 533–540. [Google Scholar] [CrossRef]

- Siddique, R.; Bennacer, R. Use of iron and steel industry by-products (GGBS) in cement paste and mortar. Res. Conserv. Recyc. 2012, 69, 29–34. [Google Scholar] [CrossRef]

- Ling, T.-C.; Poon, C.-S. Feasible use of large volumes of GGBS in 100% recycled glass architectural mortar. Cem. Concr. Compos. 2014, 53, 350–356. [Google Scholar] [CrossRef]

- Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z.; Liu, M.Y.J. Contribution of acrylic fibre addition and ground granulated blast furnace slag on the properties of lightweight concrete. Constr. Build. Mater. 2015, 95, 686–695. [Google Scholar] [CrossRef]

- Hannesson, G.; Kuder, K.; Shogren, R.; Lehman, D. The influence of high volume of fly ash and slag on the compressive strength of self-consolidating concrete. Constr. Build. Mater. 2012, 30, 161–168. [Google Scholar] [CrossRef]

- Chao-Lung, H.; Anh-Tuan, B.L.; Chun-Tsun, C. Effect of rice husk ash on the strength and durability characteristics of concrete. Constr. Build. Mater. 2011, 25, 3768–3772. [Google Scholar] [CrossRef]

- Mo, K.H.; Mohd Anor, F.A.; Alengaram, U.J.; Jumaat, M.Z.; Rao, K.J. Properties of metakaolin-blended oil palm shell lightweight concrete. Eur. J. Env. Civ. Eng. 2018, 22, 852–868. [Google Scholar] [CrossRef]

- Muller, H.S.; Haist, M.; Vogel, M. Assessment of the sustainability potential of concrete and concrete structures considering their environmental impact, performance and lifetime. Constr. Build. Mater. 2014, 67, 321–337. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, J.; Luo, W.; Wang, J.; Shi, J.; Zhang, H.; Wang, Y. Effect of compressive strength and chloride diffusion on life cycle CO2 assessment of concrete containing supplementary cementitious materials. J. Clean. Prod. 2019, 218, 450–458. [Google Scholar] [CrossRef]

- Onn, C.C.; Yusoff, S. The formulation of life cycle impact assessment framework for Malaysia using Eco-indicator. Int. J. LCA 2010, 15, 985–993. [Google Scholar] [CrossRef]

- Babu, K.G.; Kumar, V.S.R. Efficiency of GGBS in concrete. Cem. Concr. Res. 2000, 30, 1031–1036. [Google Scholar] [CrossRef]

- Samad, S.; Shah, A.; Limbachiya, M. Strength development characteristics of concrete produced with blended cement using ground granulated blast furnace slag (GGBS) under various curing conditions. Sadhana 2017, 42, 1203–1213. [Google Scholar] [CrossRef] [Green Version]

- Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z. Utilization of ground granulated blast furnace slag as partial cement replacement in lightweight oil palm shell concrete. Mater. Struct. 2015, 48, 2545–2556. [Google Scholar] [CrossRef]

- Kim, T.; Tae, S.; Chae, S.U. Analysis of Environmental Impact for Concrete Using LCA by Varying the Recycling Components, the Compressive Strength and the Admixture Material Mixing. Sustainability 2016, 8, 389. [Google Scholar] [CrossRef] [Green Version]

- Miller, S.A.; Monteiro, P.J.M.; Ostertag, C.P.; Horvath, A. Concrete mixture proportioning for desired strength and reduced global warming potential. Constr. Build. Mater. 2016, 128, 410–421. [Google Scholar] [CrossRef]

- Tait, M.W.; Cheung, W.M. A comparative cradle-to-gate life cycle assessment of three concrete mix designs. Int. J. LCA 2016, 21, 847–860. [Google Scholar] [CrossRef] [Green Version]

- Choong, J.E.; Onn, C.C.; Yusoff, S.; Mohd, N.S. Life Cycle Assessment of Waste-to-Energy: Energy Recovery from Wood Waste in Malaysia. Pol. J. Environ. Stud. 2019, 28, 2593–2602. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Zhou, X.; Slater, J.R.; Wavell, S.E.; Oladiran, O. Effects of PFA and GGBS on early-ages engineering properties of Portland cement systems. J. Adv. Concr. Tech. 2012, 10, 74–85. [Google Scholar] [CrossRef] [Green Version]

- Gholampour, A.; Ozbakkaloglu, T. Performance of sustainable concretes containing very high volume Class-F fly ash and ground granulated blast furnace slag. J. Clean. Prod. 2017, 162, 1407–1417. [Google Scholar] [CrossRef]

- Mehmeti, A.; Angelis-Dimakis, A.; Arampatzis, G.; McPhail, S.J.; Ulgiati, S. Life Cycle Assessment and Water Footprint of Hydrogen Production Methods: From Conventional to Emerging Technologies. Environments 2018, 5, 24. [Google Scholar] [CrossRef] [Green Version]

- Sameer, H.; Weber, V.; Mostert, C.; Bringezu, S.; Fehling, E.; Wetzel, A. Environmental Assessment of Ultra-High-Performance Concrete Using Carbon, Material, and Water Footprint. Materials 2019, 12, 851. [Google Scholar] [CrossRef] [Green Version]

- Kurad, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Effect of incorporation of high volume or recycled concrete aggregates and fly ash on the strength and global warming potential of concrete. J. Clean. Prod. 2017, 166, 485–502. [Google Scholar] [CrossRef]

| Oxide | CaO | Al2O3 | SiO2 | K2O | Na2O | MgO | TiO2 | LOI |

|---|---|---|---|---|---|---|---|---|

| % | 43.3 | 11.9 | 34.6 | 0.39 | 0.19 | 5.2 | 0.46 | 1.6 |

| Blend | Content (kg/m3) | |||

|---|---|---|---|---|

| Cement | GGBFS | Sand | Water | |

| A0 | 540 | 0 | 1560 | 243 |

| A1 | 486 | 54 | 1560 | 243 |

| A2 | 432 | 108 | 1560 | 243 |

| A3 | 378 | 162 | 1560 | 243 |

| A4 | 324 | 216 | 1560 | 243 |

| A5 | 270 | 270 | 1560 | 243 |

| A6 | 216 | 324 | 1560 | 243 |

| A7 | 162 | 378 | 1560 | 243 |

| B0 | 540 | 0 | 1270 | 351 |

| B1 | 486 | 54 | 1270 | 351 |

| B2 | 432 | 108 | 1270 | 351 |

| B3 | 378 | 162 | 1270 | 351 |

| B4 | 324 | 216 | 1270 | 351 |

| B5 | 270 | 270 | 1270 | 351 |

| B6 | 216 | 324 | 1270 | 351 |

| B7 | 162 | 378 | 1270 | 351 |

| Inventory | Reference Database | Geographical Representativeness | |

|---|---|---|---|

| Raw Material | Cement, CEM I 42.5 | MY-LCID | Malaysia |

| GGBS | Ecoinvent | Rest of the World | |

| Water | Ecoinvent | Rest of the World | |

| Sand, 0/2 | MY-LCID | Malaysia | |

| Energy | Electricity, PM | MY-LCID | Malaysia |

| Impact Category | Unit | A0 | B0 |

|---|---|---|---|

| Global warming potential | kg CO2 eq | 574.033 | 573.209 |

| Stratospheric ozone depletion | kg CFC11 eq | 2.65 × 10−5 | 2.65 × 10−5 |

| Ionizing radiation | kBq Co-60 eq | 0.050 | 0.055 |

| Ozone formation, Human health | kg NOx eq | 1.255 | 1.255 |

| Fine particulate matter formation | kg PM2.5 eq | 0.535 | 0.534 |

| Ozone formation, Terrestrial ecosystems | kg NOx eq | 1.258 | 1.258 |

| Terrestrial acidification | kg SO2 eq | 1.770 | 1.767 |

| Freshwater eutrophication | kg P eq | 2.10 × 10−4 | 2.41 × 10−4 |

| Marine eutrophication | kg N eq | 7.04 × 10−4 | 6.97 × 10−4 |

| Terrestrial ecotoxicity | kg 1,4-DCB | 147.647 | 147.289 |

| Freshwater ecotoxicity | kg 1,4-DCB | 0.017 | 0.019 |

| Marine ecotoxicity | kg 1,4-DCB | 0.087 | 0.090 |

| Human carcinogenic toxicity | kg 1,4-DCB | 0.135 | 0.149 |

| Human non-carcinogenic toxicity | kg 1,4-DCB | 10.932 | 10.938 |

| Land use | m2a crop eq | 21.138 | 20.939 |

| Mineral resource scarcity | kg Cu eq | 1.181 | 1.175 |

| Fossil resource scarcity | kg oil eq | 56.203 | 55.958 |

| Water consumption | m3 | 1.391 | 1.494 |

| Impact Category | Damage Assessment | Normalization | |||

|---|---|---|---|---|---|

| Unit | A0 | B0 | A0 | B0 | |

| Human health | DALY | 1.23 × 10−3 | 1.23 × 10−3 | 0.052 | 0.052 |

| Ecosystems | species.yr | 4.02 × 10−6 | 4.02 × 10−6 | 0.006 | 0.006 |

| Resources | USD2013 | 6.918 | 6.835 | 0.000 | 0.000 |

| Blend | Cost/m3 (MYR) | 28 Day Compressive Strength (Mpa) | Cost Efficiency (MPa/MYR m−3) |

|---|---|---|---|

| A0 | 184.20 | 48.41 | 0.2628 |

| A1 | 182.04 | 47.87 | 0.2630 |

| A2 | 179.88 | 46.98 | 0.2612 |

| A3 | 177.72 | 46.78 | 0.2632 |

| A4 | 175.56 | 45.86 | 0.2612 |

| A5 | 173.40 | 43.92 | 0.2533 |

| A6 | 171.24 | 39.07 | 0.2281 |

| A7 | 169.08 | 35.61 | 0.2106 |

| B0 | 174.05 | 38.29 | 0.2200 |

| B1 | 171.89 | 36.80 | 0.2141 |

| B2 | 169.73 | 34.36 | 0.2024 |

| B3 | 167.57 | 32.56 | 0.1943 |

| B4 | 165.41 | 32.71 | 0.1977 |

| B5 | 163.25 | 32.70 | 0.2003 |

| B6 | 161.09 | 29.39 | 0.1824 |

| B7 | 158.93 | 26.05 | 0.1639 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Onn, C.C.; Mo, K.H.; Radwan, M.K.H.; Liew, W.H.; Ng, C.G.; Yusoff, S. Strength, Carbon Footprint and Cost Considerations of Mortar Blends with High Volume Ground Granulated Blast Furnace Slag. Sustainability 2019, 11, 7194. https://doi.org/10.3390/su11247194

Onn CC, Mo KH, Radwan MKH, Liew WH, Ng CG, Yusoff S. Strength, Carbon Footprint and Cost Considerations of Mortar Blends with High Volume Ground Granulated Blast Furnace Slag. Sustainability. 2019; 11(24):7194. https://doi.org/10.3390/su11247194

Chicago/Turabian StyleOnn, Chiu Chuen, Kim Hung Mo, Mohammed K. H. Radwan, Wen Hong Liew, Chee Guan Ng, and Sumiani Yusoff. 2019. "Strength, Carbon Footprint and Cost Considerations of Mortar Blends with High Volume Ground Granulated Blast Furnace Slag" Sustainability 11, no. 24: 7194. https://doi.org/10.3390/su11247194

APA StyleOnn, C. C., Mo, K. H., Radwan, M. K. H., Liew, W. H., Ng, C. G., & Yusoff, S. (2019). Strength, Carbon Footprint and Cost Considerations of Mortar Blends with High Volume Ground Granulated Blast Furnace Slag. Sustainability, 11(24), 7194. https://doi.org/10.3390/su11247194