Reclaimed Polymers as Asphalt Binder Modifiers for More Sustainable Roads: A Review

Abstract

1. Introduction

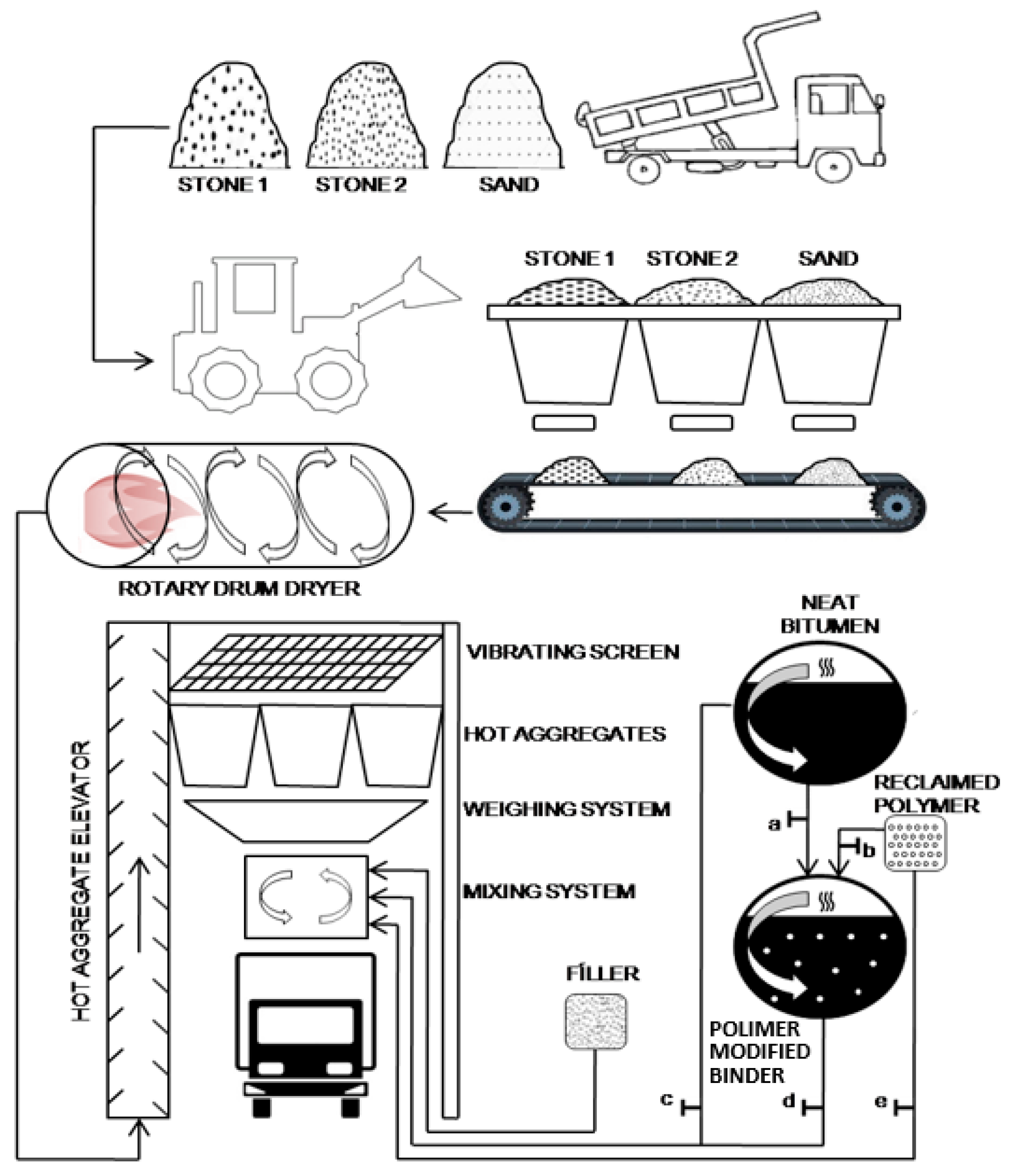

2. Effect of Reclaimed Polymers

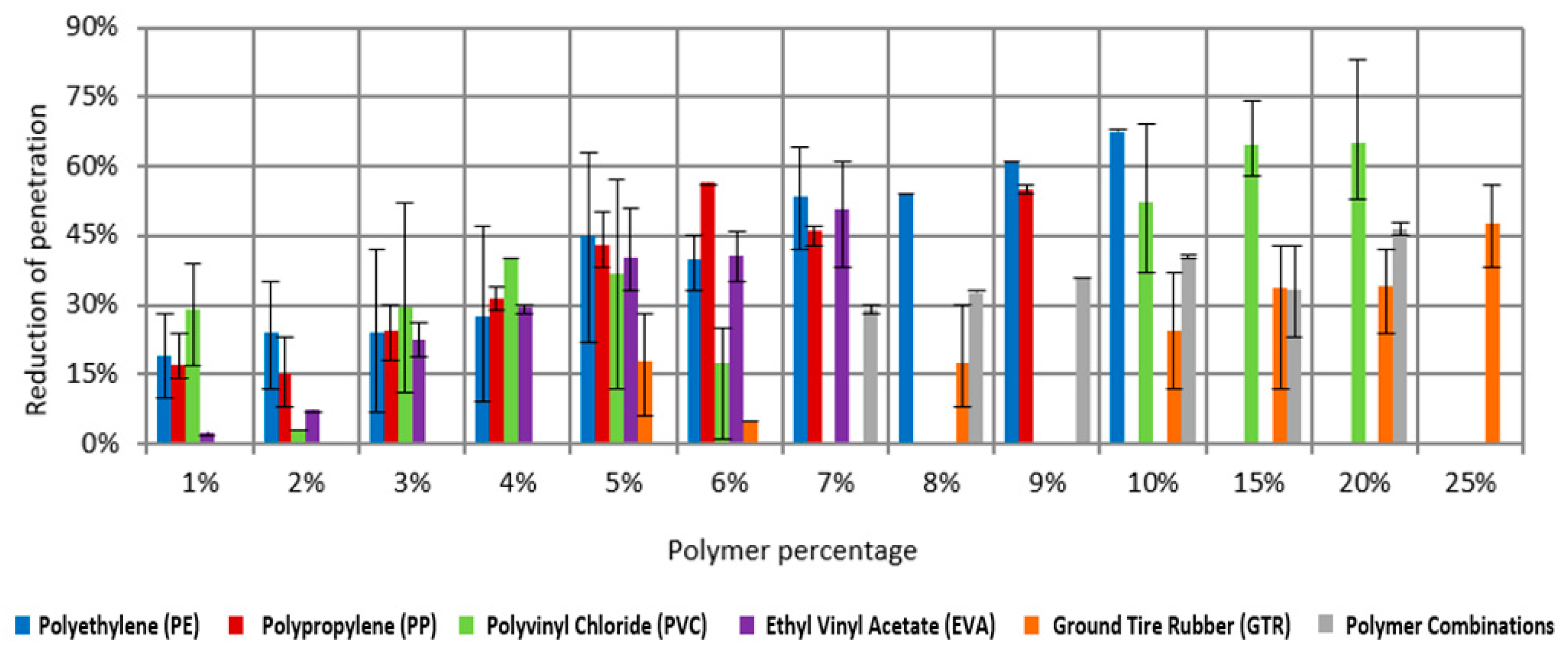

2.1. Polyethylene (PE)

2.2. Polypropylene (PP)

2.3. Polyvinyl Chloride (PVC)

2.4. Ethyl Vinyl Acetate (EVA)

2.5. Ground Tire Rubber (GTR)

3. Effect of Reclaimed Polymer Combinations

4. Discussion

5. Conclusions

- Recycled PE, PP, PVC, EVA, and GTR can be used as binder modifiers, since they have melting points that are lower than the mixing temperature, whereas PET, despite its high availability, is rejected on account of its high melting point.

- The mixing temperatures are often fixed around 160–165 °C for plastomers and 180 °C for the most common percentages of crumb rubber (GTR), whilst digestion time ranges vary from one polymer to another, with polyethylene (PE), polypropylene (PP), and ground tire rubber (GTR) being those with narrower ranges of time.

- The mixing speeds used present a large variation and are related to other factors, such as type of mixer, the amount of polymer added, and mixing temperature, making it difficult to establish a correlation.

- The characteristics of the original binders appear to influence less than the mixing conditions or the kind and amount of polymer added. Nevertheless, a comparative rheological analysis, including specific evaluation of the effect of the polymer added, is needed to fully understand the influence of the neat bitumen.

- Both plastomers and elastomers increase the softening point temperature, viscosity, and complex modulus at high temperatures, whilst reducing penetration and phase angle values. This helps to improve the resistance to permanent deformations, increasing the service life of the pavements.

- Crumb rubber present lower values of complex modulus at low temperatures, reducing the risk of cracking and improving the pavement performance and its durability. In this way, its addition will enhance the elasticity and fatigue performance of the mixture.

- Polyethylene and EVA are the only plastomers (up to 5% of polymer by weight of binder) that present storage stability without the use of additives. Additives such as maleic anhydride could raise the amount of polymer added, increasing the stiffness but improving the ductility of the resulting binder; however, it also increases its cost, limiting the economic benefits of recycled polymers but not the environmental ones.

- Due to their availability and stability, polyethylene, in its different typologies, and crumb rubber are the most promising recycled polymers for binder modification. Their joint use enhances rutting resistance at high temperatures, due to the plastomer, and improves fatigue resistance and low temperature cracking resistance owing to the elastomer, increasing the service life of the mixture that incorporates them. The high viscosity of these materials could also allow for the use of higher contents of bitumen and reduce the propagation of fissures, a common problem in pavements.

6. Future Recommendations

Author Contributions

Conflicts of Interest

References

- Gogoi, R.; Biligiri, K.P.; Das, N.C. Performance prediction analyses of styrenebutadiene rubber and crumb rubber materials in asphalt road applications. Mater. Struct. 2016, 49, 3479–3493. [Google Scholar] [CrossRef]

- Nguyen, Q.T.; Di Benedetto, H.; Sauzéat, C. Linear and nonlinear viscoelastic behaviour of bituminous mixtures. Mater. Struct. 2014, 48, 2339–2351. [Google Scholar] [CrossRef]

- Moreno-Navarro, F.; Rubio-Gámez, M.C. A review of fatigue damage in bituminous mixtures: Understanding the phenomenon from a new perspective. Constr. Build. Mater. 2016, 113, 927–938. [Google Scholar] [CrossRef]

- Polacco, G.; Stastna, J.; Biondi, D.; Zanzotto, L. Relation between polymer architecture and nonlinear viscoelastic behavior of modified asphalts. Curr. Opin. Colloid Interface Sci. 2006, 11, 230–245. [Google Scholar] [CrossRef]

- García-Travé, G.; Tauste, R.; Moreno-Navarro, F.; Sol-Sánchez, M.; Rubio-Gámez, M.C. Use of Reclaimed Geomembranes for Modification of Mechanical Performance of Bituminous Binders. J. Mater. Civ. Eng. 2016, 28, 04016021. [Google Scholar] [CrossRef]

- Polacco, G.; Stastna, J.; Biondi, D.; Antonelli, F.; Vlachovicova, Z.; Zanzotto, L. Rheology of asphalts modified with glycidylmethacrylate functionalized polymers. J. Colloid Interface Sci. 2004, 280, 366–373. [Google Scholar] [CrossRef] [PubMed]

- Moreno-Navarro, F.; Sol-Sánchez, M.; Rubio-Gámez, M.C. Structural analysis of polymer modified bituminous materials in the rehabilitation of light-medium traffic volume roads. Constr. Build. Mater. 2017, 156, 621–631. [Google Scholar] [CrossRef]

- Plastics Europe. Plastics the Facts-2016: An Analysis of European Plastics Production, Demand and Waste Data; Plastic Europe: Brussels, Belgium, 2016. [Google Scholar]

- Nuñez, J.Y.M.; Domingos, M.D.I.; Faxina, A.L. Susceptibility of low-density polyethylene and polyphosphoric acid-modified asphalt binders to rutting and fatigue cracking. Constr. Build. Mater. 2014, 73, 509–514. [Google Scholar] [CrossRef]

- Yan, K.; Xu, H.; You, L. Rheological properties of asphalts modified by waste tire rubber and reclaimed low density polyethylene. Constr. Build. Mater. 2015, 83, 143–149. [Google Scholar] [CrossRef]

- Wong, S.F.; Htwe, A.A.; Oh, S.H.; Leo, T.Y.; Cheng, J.; Tay, B.K. Utilization of Waste Plastics in Stone Mastic Asphalt for Infrastructural Applications. Mater. Sci. Forum 2017, 902, 55–59. [Google Scholar] [CrossRef]

- Modarres, A.; Hamedi, H. Effect of Waste Plastic Bottles on the Stiffness and Fatigue Properties of Modified Asphalt Mixes. Mater. Des. 2014, 61, 8–15. [Google Scholar] [CrossRef]

- Earnest, M.D. Performance Characteristics of Polyethylene Terephthalate (PET) Modified Asphalt. Electronic Dissertations M.S. Thesis, Georgia Southern University, Statesboro, GA, USA, 2015; p. 1260. Available online: https://digitalcommons.georgiasouthern.edu/cgi/viewcontent.cgi?article=2328&context=etd (accessed on 25 January 2019).

- Cao, W. Study on properties of recycled tire rubber modified asphalt mixtures using dry process. Constr. Build. Mater. 2016, 21, 1011–1015. [Google Scholar] [CrossRef]

- Lastra-González, P.; Calzada-Pérez, M.A.; Castro-Fresno, D.; Vega-Zamanillo, Á.; Indacoechea-Vega, I. Comparative analysis of the performance of asphalt concretes modified by dry way with polymeric waste. Constr. Build. Mater. 2016, 112, 1133–1140. [Google Scholar] [CrossRef]

- Kalantar, Z.N.; Karim, M.R.; Mahrez, A. A review of using waste and virgin polymer in pavement. Constr. Build. Mater. 2012, 33, 55–62. [Google Scholar] [CrossRef]

- González, E.; Costa, L.M.B.; Silva, H.M.R.D.; Hilliou, L. Rheological characterization of EVA and HDPE polymer modified bitumens under large deformation at 20 °C. Constr. Build. Mater. 2016, 112, 756–764. [Google Scholar] [CrossRef]

- Polacco, G.; Berlincioni, S.; Biondi, D.; Stastna, J.; Zanzotto, L. Asphalt modification with different polyethylene-based polymers. Eur. Polym. J. 2005, 41, 2831–2844. [Google Scholar] [CrossRef]

- Yu, R.; Fang, C.; Liu, P.; Liu, X.; Li, Y. Storage stability and rheological properties of asphalt modified with waste packing polyethylene and organic montmorillonite. Appl. Clay Sci. 2015, 104, 1–7. [Google Scholar] [CrossRef]

- Becker, Y.; Méndez, M.P.; Rodríguez, Y. Polymer modified asphalt. Vis. Tecnol. 2001, 9, 39–50. [Google Scholar]

- Fang, C.; Wu, C.; Hu, J.; Yu, R.; Zhang, Z.; Nie, L. Pavement properties of asphalt modified with packaging-waste polyethylene. J. Vinyl Addit. Technol. 2014, 20, 31–35. [Google Scholar] [CrossRef]

- Casey, D.; Mcnally, C.; Gibney, A.; Gilchrist, M.D. Development of a recycled polymer modified binder for use in stone mastic asphalt. Resour. Conserv. Recycl. 2008, 52, 1167–1174. [Google Scholar] [CrossRef]

- Jun, L.; Yuxia, Z.; Yuzhen, Z. The research of GMA-g-LDPE modified Qinhuangdao bitumen. Constr. Build. Mater. 2018, 22, 1067–1073. [Google Scholar] [CrossRef]

- Al-Hadidy, A.I.; Yi-Qiu, T. Effect of polyethylene on life of flexible pavements. Constr. Build. Mater. 2009, 23, 1456–1464. [Google Scholar] [CrossRef]

- Vargas, M.A.; Sánchez-Sólis, A.; Manero, O. Asphalt/polyethylene blends: Rheological properties, microstructure and viscosity modeling. Constr. Build. Mater. 2013, 45, 243–250. [Google Scholar] [CrossRef]

- Roman, C.; Cuadri, A.A.; Liashenko, I.; García-Morales, M.; Partal, P. Linear and non-linear viscoelastic behavior of SBS and LDPE modified bituminous mastics. Constr. Build. Mater. 2016, 123, 464–472. [Google Scholar] [CrossRef]

- Attaelmanan, M.; Feng, C.P.; Al-Hadidy, A.I. Laboratory evaluation of HMA with high density polyethylene as a modifier. Constr. Build. Mater. 2011, 25, 2764–2770. [Google Scholar] [CrossRef]

- Fernandes, S.; Costa, L.; Silva, H.; Oliveira, J. Effect of incorporating different waste materials in bitumen. Ciência Tecnol. Mater. 2017, 29, e204–e209. [Google Scholar] [CrossRef]

- Ahmedzade, P.; Fainleib, A.; Günay, T.; Grygoryeva, O. Modification of bitumen by electron beam irradiated recycled low density polyethylene. Constr. Build. Mater. 2014, 69, 1–9. [Google Scholar] [CrossRef]

- Hu, J.; Fang, C.; Zhou, S.; Jiao, L.; Zhang, M.; Wu, D. Rheological properties of packaging-waste-polyethylene-modified asphalt. J. Vinyl Addit. Technol. 2014, 21, 215–219. [Google Scholar] [CrossRef]

- Ma, D.; Zhao, D.; Zhao, J.; Du, S.; Pang, J.; Wang, W.; Fan, C. Functionalization of reclaimed polyethylene with maleic anhydride and its application in improving the high temperature stability of asphalt mixtures. Constr. Build. Mater. 2016, 113, 596–602. [Google Scholar] [CrossRef]

- Costa, L.; Fernandes, S.; Silva, H.; Oliveira, J. Study of the interaction between asphalt and recycled plastics in new polymer modified binders (PMB). Ciência Tecnol. Mater. 2017, 29, e192–e197. [Google Scholar] [CrossRef]

- Hinislioğlua, S.; Ağar, E. Use of waste high density polyethylene as bitumen modifier in asphalt concrete mix. Mater. Lett. 2004, 58, 267–271. [Google Scholar] [CrossRef]

- Napiah, M.; Habib, N.Z.; Kamaruddin, I. Creep Behavior of Polyethylene Modified Bituminous Mixture. APCBEE Proc. 2014, 9, 202–206. [Google Scholar] [CrossRef]

- Baumgardner, G.; Masson, J.F.; Hardee, J.; Menapace, A.; Williams, A. Polyphosphoric acid modified asphalt: Proposed mechanisms. J. Assoc. Asphalt Paving Technol. 2005, 74, 283–305. [Google Scholar]

- Ahmadinia, E.; Zargar, M.; Karim, M.R.; Abdelaziz, M. Performance evaluation of utilization of waste Polyethylene Terephthalate (PET) in stone mastic asphalt. Constr. Build. Mater. 2012, 36, 984–989. [Google Scholar] [CrossRef]

- Moghaddam, T.B.; Soltani, M.; Karim, M.R.; Baaj, H. Optimization of asphalt and modifier contents for polyethylene terephthalate modified asphalt mixtures using response surface methodology. Measurement 2015, 74, 159–169. [Google Scholar] [CrossRef]

- Sojobi, A.O.; Nwobodo, S.E.; Aladegboye, O.J. Recycling of polyethylene terephthalate (PET) plastic bottle wastes in bituminous asphaltic concrete. Cogent Eng. 2016, 3, 1133480. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Al-Hadidy, A.I.; Yi-Qiu, T. New Technical Method for Production Homogenous and Storage Stable Polymer Modified Asphalt. In Plan, Build, and Manage Transportation Infrastructures in China Congress (ISSTP), Proceedings of the Seventh International Conference of Chinese Transportation Professionals Congress (ICCTP), Shanghai, China, 21–22 May 2007; ASCE: Reston, VA, USA, 2007. [Google Scholar]

- Ahmedzade, P.; Demirelli, K.; Günay, T.; Biryan, F.; Alqudah, O. Effects of Waste Polypropylene Additive on the Properties of Bituminous Binder. Procedia Manuf. 2015, 2, 165–170. [Google Scholar] [CrossRef]

- Wahhab, H.I.A.; Dalhat, M.A.; Habib, M.A. Storage stability and high-temperature performance of asphalt binder modified with recycled plastic. Road Mater. Pavement 2016, 18, 1117–1134. [Google Scholar] [CrossRef]

- Habib, N.Z.; Kamaruddin, I.; Napiah, M.; Tan, I.M. Rheological Properties of Polyethylene and Polypropylene Modified Bitumen. Int. J. Sci. Appl. Technol. 2010, 4, 381–385. [Google Scholar]

- Yeh, P.-H.; Nien, Y.-H.; Chen, J.-H.; Chen, W.-C.; Chen, J.-S. Thermal and Rheological Properties of Maleated Polypropylene Modified Asphalt. Polym. Eng. Sci. 2005, 45, 1152–1158. [Google Scholar] [CrossRef]

- Nien, Y.-H.; Yeh, P.-H.; Chen, W.-C.; Liu, W.-T.; Chen, J.-H. Investigation of Flow Properties of Asphalt Binders Containing Polymer Modifiers. Polym. Compos. 2008, 29, 518–524. [Google Scholar] [CrossRef]

- Dalhat, M.A.; Al-Abdul Wahhab, H.I. Performance of recycled plastic waste modified asphalt binder in Saudi Arabia. Int. J. Pavement Eng. 2015, 18, 349–357. [Google Scholar] [CrossRef]

- Al-Hadidy, A.I.; Yi-Qiu, T. Mechanistic approach for polypropylene-modified flexible pavements. Mater. Des. 2009, 30, 1133–1140. [Google Scholar] [CrossRef]

- Giavarini, C.; Filippis, P.; de Santarelli, M.L.; Scarsella, M. Production of stable polypropylene-modified bitumens. Fuel 1996, 75, 681–686. [Google Scholar] [CrossRef]

- Abdel-Goad, M.A.-H. Waste Polyvinyl Chloride-Modified Bitumen. J. Appl. Polym. Sci. 2006, 101, 1501–1505. [Google Scholar] [CrossRef]

- Behl, A.; Sharma, G.; Kumar, G. A sustainable approach: Utilization of waste PVC in asphalting of roads. Constr. Build. Mater. 2014, 54, 113–117. [Google Scholar] [CrossRef]

- Köfteci, S.; Ahmedzade, P.; Kultayev, B. Performance evaluation of bitumen modified by various types of waste plastics. Constr. Build. Mater. 2014, 73, 592–602. [Google Scholar] [CrossRef]

- Rahman, M.N.; Ahmeduzzaman, M.; Sobhan, M.A.; Ahmed, T.U. Performance evaluation of waste polyethylene and PVC on hot asphalt mixtures. Am. J. Civ. Eng. Arch. 2013, 1, 97–102. [Google Scholar]

- Ghani, U.; Tanoli, W.A. Performance evaluation of waste PVC modified bitumen. Int. J. Adv. Struct. Geotech. Eng. 2015, 04, 207–210. [Google Scholar]

- Abd-Allah, A.M.; El-Sharkawi Attia, M.I.; Abd-Elmaksoud Khamis, M.F.; Deef-Allah, E.M.M. Effect of Using Polymers on Bituminous Mixtures Characteristics in Egypt. IOSR-JMCE 2014, 11, 54–63. [Google Scholar] [CrossRef]

- Fang, C.; Liu, X.; Yu, R.; Liu, P.; Lei, W. Preparation and Properties of Asphalt Modified with a Composite Composed of Waste Package Poly (vinyl chloride) and Organic Montmorillonite. J. Mater. Sci. Technol. 2014, 30, 1304–1310. [Google Scholar] [CrossRef]

- Sureshkumar, A.S.; Filippi, S.; Polacco, G.; Kazatchkov, I.; Stastna, J.; Zanzotto, L. Internal structure and linear viscoelastic properties of EVA/asphalt nanocomposites. Eur. Polym. J. 2010, 46, 621–633. [Google Scholar] [CrossRef]

- El-Rahman, A.M.M.A.; El-Shafie, M.; Mohammedy, M.M.; Abo-Shanab, Z.L. Enhancing the performance of blown asphalt binder using waste EVA copolymer (WEVA). Egypt. J. Petrol. 2017. [Google Scholar] [CrossRef]

- Stark, W.; Jaunich, M. Investigation of Ethylene/Vinyl Acetate Copolymer (EVA) by thermal analysis DSC and DMA. Polym. Test. 2011, 30, 236–242. [Google Scholar] [CrossRef]

- Alataş, T.; Yilmaz, M. Effects of different polymers on mechanical properties of bituminous binders and hot mixtures. Constr. Build. Mater. 2013, 42, 161–167. [Google Scholar] [CrossRef]

- Liang, M.; Ren, S.; Fan, W.; Xin, X.; Shi, J.; Luo, H. Rheological property and stability of polymer modified asphalt: Effect of various vinyl-acetate structures in EVA copolymers. Constr. Build. Mater. 2017, 137, 367–380. [Google Scholar] [CrossRef]

- Haddadi, S.; Ghorbel, E.; Laradi, N. Effects of the manufacturing process on the performances of the bituminous binders modified with EVA. Constr. Build. Mater. 2008, 22, 1212–1219. [Google Scholar] [CrossRef]

- Luo, W.; Chen, J. Preparation and properties of bitumen modified by EVA graft copolymer. Constr. Build. Mater. 2011, 25, 1830–1835. [Google Scholar] [CrossRef]

- Yuliestyan, A.; Cuadri, A.A.; García-Morales, M.; Partal, P. Binder Design for Asphalt Mixes with Reduced Temperature: EVA Modified Bitumen and its Emulsions. Transp. Res. Proc. 2016, 14, 3512–3518. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J.; Chen, R.; Cai, J.; Xi, Z.; Xie, H. Ethylene vinyl acetate copolymer modified epoxy asphalt binders: Phase separation evolution and mechanical properties. Constr. Build. Mater. 2017, 137, 55–65. [Google Scholar] [CrossRef]

- Saboo, N.; Kumar, P. A study on creep and recovery behavior of asphalt binders. Constr. Build. Mater. 2015, 96, 632–640. [Google Scholar] [CrossRef]

- Saboo, N.; Kumar, P. Optimum blending requirements for EVA modified binder. Transp. Res. Proc. 2016, 17, 98–106. [Google Scholar] [CrossRef]

- WBCSD (World Business Council for Sustainable Development). End-of-Live Tires: A Framework for Effective Management Systems 2010. Available online: http://www.etrma.org/uploads/Moduluss/Documentsmanager/a-framework-for-effective-elt-management-systems-final-25.6.10.pdf (accessed on 1 February 2018).

- Lo Presti, D. Recycled tire rubber modified bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Cheovits, J.G.; Dunning, R.L.; Morris, G.R. Characteristics of asphalt-rubber by the slide plate microviscometer. Assoc. Asph. Paving Technol. 1982, 51, 240–261. [Google Scholar]

- Lee, S.J.; Akisetty, C.K.; Amirkhanian, S.N. The effect of crumb rubber modifier (CRM) on the performance properties of rubberized binders in HMA pavements. Constr. Build. Mater. 2008, 22, 1368–1376. [Google Scholar] [CrossRef]

- Celauro, B.; Celauro, C.; Lo Presti, D.; Bevilacqua, A. Definition of a laboratory optimization protocol for road bitumen improved with recycled tire rubber. Constr. Build. Mater. 2012, 37, 562–572. [Google Scholar] [CrossRef]

- Barco-Carrión, A.J.; del García-Travé, G.; Moreno-Navarro, F.; Martínez-Montes, G.; Rubio-Gámez, M.C. Comparison of the effect of recycled crumb rubber and polymer concentration on the performance of binders for asphalt mixtures. Mater. Constr. 2016, 66, e090. [Google Scholar] [CrossRef]

- Moreno, F.; Sol, M.; Martín, J.; Pérez, M.; Rubio, M.C. The effect of crumb rubber modifier on the resistance of asphalt mixes to plastic deformation. Mater. Des. 2013, 47, 274–280. [Google Scholar] [CrossRef]

- Moreno-Navarro, F.; Sol-Sánchez, M.; Rubio-Gámez, M.C.; Segarra-Martínez, M. The use of additives for the improvement of the mechanical behavior of high modulus asphalt mixes. Constr. Build. Mater. 2014, 70, 65–70. [Google Scholar] [CrossRef]

- Shen, J.; Li, B.; Xie, Z. Interaction between crumb rubber modifier (CRM) and asphalt binder in dry process. Constr. Build. Mater. 2017, 149, 202–206. [Google Scholar] [CrossRef]

- Nejad, F.M.; Aghajani, P.; Modarres, A.; Firoozifar, H. Investigating the properties of crumb rubber modified bitumen using classic and SHRP testing methods. Constr. Build. Mater. 2012, 26, 481–489. [Google Scholar] [CrossRef]

- Ge, D.; Yan, K.; You, Z.; Xu, H. Modification mechanism of asphalt binder with waste tire rubber and recycled polyethylene. Constr. Build. Mater. 2016, 126, 66–76. [Google Scholar] [CrossRef]

- Navarro, F.J.; Partal, P.; Martınez-Boza, F.; Gallegos, C. Thermo-rheological behaviour and storage stability of ground tire rubber-modified bitumens. Fuel 2004, 83, 2041–2049. [Google Scholar] [CrossRef]

- Diab, A.; You, Z. Small and large strain rheological characterizations of polymer- and crumb rubber-modified asphalt binders. Constr. Build. Mater. 2017, 144, 168–177. [Google Scholar] [CrossRef]

- Xu, O.; Rangaraju, P.R.; Wang, S.; Xiao, F. Comparison of rheological properties and hot storage characteristics of asphalt binders modified with devulcanized ground tire rubber and other modifiers. Constr. Build. Mater. 2017, 154, 841–848. [Google Scholar] [CrossRef]

- Kök, B.V.; Yilmaz, M.; Geçkil, A. Evaluation of low-temperature and elastic properties of crumb rubber–and SBS-modified bitumen and mixtures. J. Mater. Civ. Eng. 2013, 25, 257–265. [Google Scholar] [CrossRef]

- Cong, P.; Xun, P.; Xing, M.; Chen, S. Investigation of asphalt binder containing various crumb rubbers and asphalts. Constr. Build. Mater. 2013, 40, 632–641. [Google Scholar] [CrossRef]

- Xie, Z.; Shen, J. Effect of cross-linking agent on the properties of asphalt rubber. Constr. Build. Mater. 2014, 67, 234–238. [Google Scholar] [CrossRef]

- Behnood, A.; Olek, J. Rheological properties of asphalt binders modified with styrene-butadiene-styrene (SBS), ground tire rubber (GTR), or polyphosphoric acid (PPA). Constr. Build. Mater. 2017, 151, 464–478. [Google Scholar] [CrossRef]

- Ding, X.; Ma, T.; Zhang, W.; Zhang, D. Experimental study of stable crumb rubber asphalt and asphalt mixture. Constr. Build. Mater. 2017, 157, 975–981. [Google Scholar] [CrossRef]

- Navarro, F.J.; Partal, P.; Martínez-Boza, F.J.; Gallegos, C. Novel recycled polyethylene/ground tire rubber/bitumen blends for use in roofing applications: Thermo-mechanical properties. Polym. Test. 2010, 29, 588–595. [Google Scholar] [CrossRef]

- Han, L.; Zheng, M.; Li, J.; Li, Y.; Zhu, Y.; Ma, Q. Effect of nano silica and pretreated rubber on the properties of terminal blend crumb rubber modified asphalt. Constr. Build. Mater. 2017, 157, 277–291. [Google Scholar] [CrossRef]

- Sienkiewicz, M.; Borzędowska-Labuda, K.; Zalewski, S.; Janik, H. The effect of tire rubber grinding method on the rubber-asphalt binder properties. Constr. Build. Mater. 2017, 154, 144–154. [Google Scholar] [CrossRef]

- Yan, K.; He, W.; Chen, M.; Liu, W. Laboratory investigation of waste tire rubber and amorphous poly alpha olefin modified asphalt. Constr. Build. Mater. 2016, 129, 256–265. [Google Scholar] [CrossRef]

- Zhang, F.; Hu, C. The research for crumb rubber/waste plastic compound modified asphalt. J. Therm. Anal. Calorim. 2016, 124, 729–741. [Google Scholar] [CrossRef]

- Brovelli, C.; Crispino, M.; Pais, J.; Pereira, P. Using polymers to improve the rutting resistance of asphalt concrete. Constr. Build. Mater. 2015, 77, 117–123. [Google Scholar] [CrossRef]

- García-Morales, M.; Partal, P.; Navarro, F.J.; Gallegos, C. Effect of waste polymer addition on the rheology of modified bitumen. Fuel 2006, 85, 936–943. [Google Scholar] [CrossRef]

- Karahrodi, M.H.; Jazani, O.M.; Paran, S.M.R.; Formela, K.; Saeb, M.R. Modification of thermal and rheological characteristics of bitumen by waste PET/GTR blends. Constr. Build. Mater. 2017, 134, 157–166. [Google Scholar] [CrossRef]

- Gibreil, H.A.A.; Feng, C.P. Effects of high-density polyethylene and crumb rubber powder as modifiers on properties of hot mix asphalt. Constr. Build. Mater. 2017, 142, 101–108. [Google Scholar] [CrossRef]

- Fang, C.Q.; Zhang, M.Y.; Yu, R.E.; Liu, X.L. Effect of preparation temperature on the aging properties of waste polyethylene modified asphalt. J. Mater. Sci. Technol. 2015, 31, 320–324. [Google Scholar] [CrossRef]

- Yuan, J.; Wang, J.; Xiao, F.; Amirkhanian, S.; Wang, J.; Xu, Z. Impacts of multiple-polymer components on high temperature performance characteristics of airfield modified binders. Constr. Build. Mater. 2017, 134, 694–702. [Google Scholar] [CrossRef]

- Luo, W.; Zhang, Y.; Cong, P. Investigation on physical and high temperature rheology properties of asphalt binder adding waste oil and polymers. Constr. Build. Mater. 2017, 144, 13–24. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, X.; Cao, D.; Zhang, Y.; He, M. Effect of linear low density polyethylene grafted with maleic anhydride (LLDPE-g-MAH) on properties of high density polyethylene/styrene–butadiene–styrene (HDPE/SBS) modified asphalt. Constr. Build. Mater. 2013, 47, 192–198. [Google Scholar] [CrossRef]

- Swamy, A.K.; Rongali, U.D.; Jain, P.K. Effect of HDPEH polymer on viscoelastic properties of SBS modified asphalt. Constr. Build. Mater. 2017, 136, 230–236. [Google Scholar] [CrossRef]

- Gama, D.A.; Rosa Júnior, J.M.; de Melo, T.J.A.; Rodrigues, J.K.G. Rheological studies of asphalt modified with elastomeric polymer. Constr. Build. Mater. 2016, 106, 290–295. [Google Scholar] [CrossRef]

- Alibaba.com Site. HDPE, LDPE Recycled. Last Consulted: February 2018. Available online: https://spanish.alibaba.com/trade/search?fsb=y&IndexArea=product_en&CatId=&SearchText=hdpe+recycled&viewtype=G (accessed on 1 February 2018).

- Alibaba.com Site. PP Recycled. Last Consulted: February 2018. Available online: https://spanish.alibaba.com/trade/search?fsb=y&IndexArea=product_en&CatId=&SearchText=pp+recycled&viewtype=G (accessed on 1 February 2018).

- Alibaba.com Site. PVC Recycled. Last Consulted: February 2018. Available online: https://spanish.alibaba.com/trade/search?fsb=y&IndexArea=product_en&CatId=&SearchText=pvc+recycled&viewtype=G (accessed on 1 February 2018).

- Alibaba.com Site. Tyre Recycle Rubber. Last Consulted: February 2018. Available online: https://spanish.alibaba.com/trade/search?IndexArea=product_en&CatId=&fsb=y&SearchText=tyre+recycle+rubber (accessed on 1 February 2018).

- Rowe, G.M.; King, G.; Anderson, M. The influence of binder rheology on the cracking of asphalt mixes in airport and highway projects. J. Test. Eval. 2014, 42, 1063–1072. [Google Scholar] [CrossRef]

- D’Angelo, J.; Dongre, R. Practical use of the MSCR test: Characterization of SBS dispersion and other additives in PMA binders. Transp. Res. Rec. 2009, 2126, 73–82. [Google Scholar] [CrossRef]

- Harrigan, E.T.; Leahy, R.B.; Youtcheff, J.S. The Superpave Mix Design System Manual of Specifications, Test Methods and Practices; SHRP-A-379, Strategic Highway Research Program; National Research Council: Washington, DC, USA, 1994. [Google Scholar]

- Alibaba.com Site. SBS Bitumen Modifier. Last Consulted: February 2018. Available online: https://spanish.alibaba.com/trade/search?fsb=y&IndexArea=products&CatId=&SearchText=SBS+bitumen+modifier&selectedTab=products (accessed on 1 February 2018).

| Mixture Characteristics | Polyethylene (PE) | Polypropylene (PP) | Polyvinyl Chloride (PVC) | Ethyl Vinyl Acetate (EVA) | Ground Tire Rubber (GTR) |

|---|---|---|---|---|---|

| Amount of polymer most commonly used (%) | 3–5 | 3–5 | 5 | 5 | 10 |

| Mixture temperature (°C) | 163–180 | 160–180 | 165–180 | 170–180 | 180 |

| Digestion time (minutes) | 60–150 | 60–-90 | 20–180 | 40–240 | 90–140 |

| Mixing speed (rpm) | 1300–5000 | 120–1200 | 1300–2000 | 300–3000 | 800–5000 |

| Penetration reduction (%) | 33–59 | 23–82 | 46–57 | 33–51 | 16–30 |

| Softening point temperature increase (%) | 11–92 | 30–44 | 6–29 | 22–53 | 9–19 |

| Use of compatibilizer/dispersant/agglutinantadditives | No—up to 3% PE; Yes—4–5% PE, (MA 0.87–5% by weight of PE) | Yes (MA 0.91% by weight of PP) | Yes (dispersant) | No—up to 5% EVA Yes—(MA 2% by weight EVA) | No—up to 5% GTR Yes—(TOR 3–6% by weight of binder) |

| Polymer approximate cost (€/t) | 378.00–1261.00 [101] | 461.00–1261.00 [102] | 424.00–1051.00 [103] | - | 336.00–1177.00 [104] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brasileiro, L.; Moreno-Navarro, F.; Tauste-Martínez, R.; Matos, J.; Rubio-Gámez, M.d.C. Reclaimed Polymers as Asphalt Binder Modifiers for More Sustainable Roads: A Review. Sustainability 2019, 11, 646. https://doi.org/10.3390/su11030646

Brasileiro L, Moreno-Navarro F, Tauste-Martínez R, Matos J, Rubio-Gámez MdC. Reclaimed Polymers as Asphalt Binder Modifiers for More Sustainable Roads: A Review. Sustainability. 2019; 11(3):646. https://doi.org/10.3390/su11030646

Chicago/Turabian StyleBrasileiro, Luzana, Fernando Moreno-Navarro, Raúl Tauste-Martínez, Jose Matos, and Maria del Carmen Rubio-Gámez. 2019. "Reclaimed Polymers as Asphalt Binder Modifiers for More Sustainable Roads: A Review" Sustainability 11, no. 3: 646. https://doi.org/10.3390/su11030646

APA StyleBrasileiro, L., Moreno-Navarro, F., Tauste-Martínez, R., Matos, J., & Rubio-Gámez, M. d. C. (2019). Reclaimed Polymers as Asphalt Binder Modifiers for More Sustainable Roads: A Review. Sustainability, 11(3), 646. https://doi.org/10.3390/su11030646