Abstract

Biodiesel is a potentially low-carbon, renewable alternative fuel to diesel, sharing similar chemical and physical properties to diesel. There have been significant efforts in introducing primarily bioethanol and some biodiesel to the road transport sector, with varying levels of success. However, the rail sector has not seen as large an effort in introducing biodiesel. This paper summarizes the literature on the introduction of biodiesel (bioethanol was a relevant fuel) in order to learn lessons, which can be applied to the rail transport sector. A decision-making framework PESTLE (Political/Policies, Economic, Social, Technological, Legal, and Environmental) is used to analyze these lessons, and their relevance (or not) to the rail sector. While introduction of biodiesel in the rail sector has some inherent advantages, such as fewer refueling points, customers and manufacturers compared to the road sector, it also faces some challenges, especially in the context of the longer life of locomotives, making fleet turnover and potential transition to 100% biodiesel slow. Additionally, maintenance costs are still uncertain.

1. Introduction

The transport sector is the largest user of liquid petroleum fuel in the world. It accounted for 49.5 million barrels per day (mb/d) of crude oil in 2014 totaling 54.6% of world use. This figure is set to increase to 60.4 mb/d by 2040 [1]. While liquid petroleum products have advantages over other fuels for transport (high volume in mass energy density), there are serious questions about its longer-term sustainability. In 2015, the transport sector accounted for 23% of all carbon emissions [2], this exacerbates global warming concerns.

It is important to reduce the amount of oil used in the transport sector. There are different options to reduce carbon emissions for transport, for example, switching to public transport, increasing the efficiency of vehicles and reducing the carbon intensity of fuels. Large reductions in emissions, however, will likely require reducing the carbon intensity of fuel [3,4]: Possible options being renewable energy or alternate energy carriers such as electricity or fuels such as compressed natural gas or biofuels. Of these, biofuels have received significant attention from researchers and policy makers for several reasons [5,6]: Energy security can be improved because of the large choice of feedstock available [7]; a biofuel’s lifecycle emissions are lower than crude oil-based fuels if harvested efficiently [8,9]; biofuels are renewable [10]; it can promote economic development in rural areas [11,12]; and the environmental effects of the use of competing fuels, such as air pollution and oil spills, can be reduced. Most importantly the energy in volume in biofuels such as biodiesel are similar to that of liquid petroleum fuels, making them nearly similar replacements.

While all modes of transport have some potential for using biofuel, the primary user has so far been the road transport sector [10]. Other modes have received much less attention but could be equally important, especially in the particular context of specific countries: For example, in a country like India, where the rail sector is often referred to as a lifeline and is responsible for transporting 15% of passengers and 30% of freight [13]. The sector is still dominated by diesel and electricity. However, the rail sector could also benefit from the same advantages of biofuels, as in the road sector, and it is therefore important for the rail sector to learn lessons from the successes and failures in using biofuels in the road transport sector.

Background to World Biofuels

The two most popular biofuels are biodiesel and bio-alcohol. Biodiesel is used in diesel engines and is produced from high oil content crops such as sunflowers and rapeseed, waste vegetable oils such as cooking oil and animal fats such as tallow [10,11,14]. Bioethanol is the most favored bio-alcohol, and is used in SI (Spark Ignition) engines. It is produced from a variety of feedstocks including, sugarcane, corn, wheat, and sugar beet [15,16].

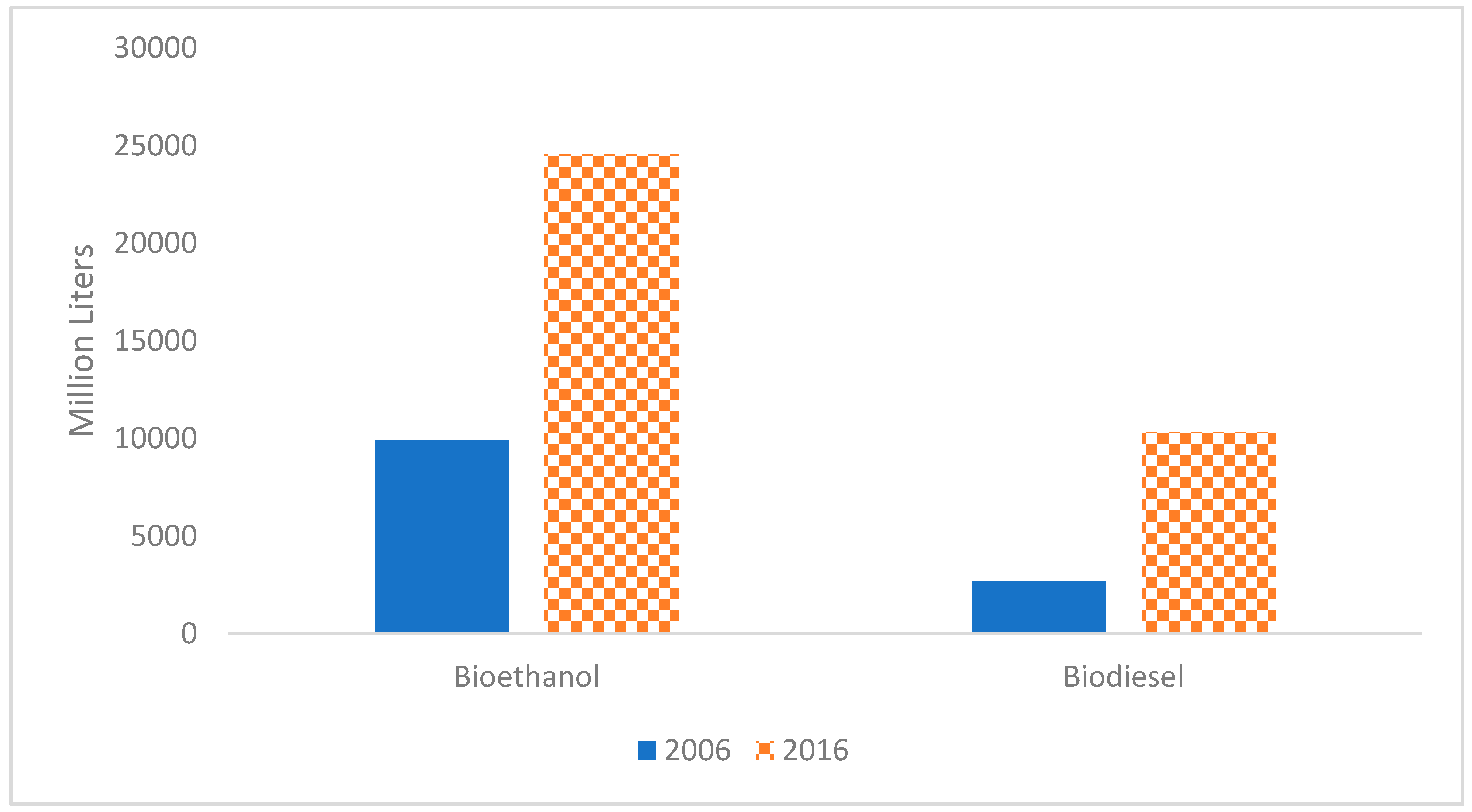

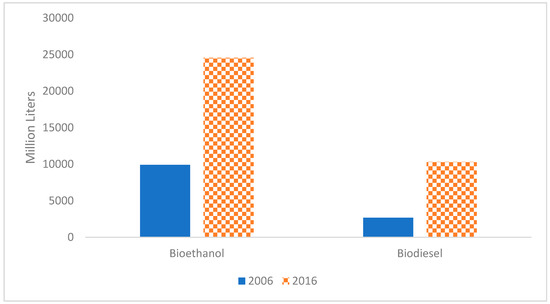

Figure 1 shows the growth in worldwide biodiesel and bioethanol production in 2006 and 2016. During this period bioethanol experienced roughly a 140% increase, whereas biodiesel experienced a 300% increase. The increase for bioethanol has mainly been driven by North, South, and Central America. The geographical areas pursuing a biodiesel route are primarily Europe and Eurasia. Future biodiesel growth is forecasted to be around 3% over the next five years. This growth is expected to come from mainly Latin American and non-OECD Asian countries. The forecast for the European Union (EU) and the United States (US) is lower [17]. Even with a high increase in biodiesel production, biodiesel is still lagging behind bioethanol.

Figure 1.

World biodiesel and bioethanol production, adapted from BP Global [no date] [18].

Diesel dominates the rail sector unlike the road sector where both diesel and petrol have large shares. The equivalent biofuel for diesel is biodiesel and the equivalent biofuel for petrol is bioethanol due to their similar physical and chemical properties. While bioethanol could be used in a diesel engine, it would only be as an oxygen booster and not as an alternative to diesel [19]. This does not mean that bioethanol should be disregarded from this paper because there may be lessons learned from the bioethanol industry despite the fact it is not a direct substitute for diesel. Therefore, the rail sector has an advantage over the road sector in that lessons can be learned from not only the biodiesel industry, but also the bioethanol industry. If this information can be harnessed, analyzed, and applied to rail, then it could help a smoother introduction of biodiesel to the rail sector.

From the need to reduce petroleum liquid in the transport sector to the wealth of research in alternative fuel, i.e., biofuels for the road transport sector and limited research in the rail transport sector and the objectives of this paper are:

- To organize the lessons learned from the road sector using a decision-making framework.

- To gain understanding of the successes and failures experienced in the road sector from introducing biodiesel.

- To analyze if and how the lessons can be applied to the rail sector.

2. The Framework of the Study

In order to capture multiple perspectives of the lessons learnt, a PESTLE framework is followed in this study. PESTLE is a decision-making technique that analyses the political, environmental, social, technological, legal and economic aspects of a new project. This method was used instead of SWOT (Strengths Weaknesses, Opportunities, and Threats) because it is focused on the issues that are of interest to policymakers and developers [20]. PESTLE highlights the categories that need to be considered when introducing new concepts within, for example, the renewable energy sector. It has been used in the UK to assess the risk involved in the tidal industry [21]. In Malawi, PESTLE was used when investigating the development of renewable energy [20].

The results from the PESTLE analysis will be discussed on how and if they could be applied to the rail. The opposite also needs to be considered; the lessons that cannot be used on rail and why it is not possible. This section will also highlight what the rail industry needs to consider that is not necessarily applicable for the road.

To ensure that appropriate literature has been consulted, the following keywords have been used when researching the lessons learned from the road transport sector and applied to rail when introducing biodiesel; biodiesel, lessons learned, rail, road, policies, environmental, legislation, and mechanics. These keywords were combined is different variations and entered into google scholar and web of science to produce research on this topic in journals, books, and government documents. As well as using these search engines, government websites were investigated directly where the country has attempted to introduce biodiesel. There are many sources that could feed into this paper, but it was important to recognize the key sources. Key sources included using the most up to date research and working backwards, countries where biodiesel has had a significant impact in the transport sector such as the US, Europe, and Malaysia and only using key literature that involves the countries that have used bioethanol and finally the sources that fed directly into the aspects within PESTLE.

3. The Lessons Learned from Road Transport

3.1. Regulating the Introduction of Biodiesel

Policies, the political system, and regulating enforcement (laws) cannot be easily separated so they have been combined in this section. Policies play a key role when introducing biodiesel to transport and legislation help implement them. Introducing biodiesel policies is complex because of the multiple stages of the supply chain and would likely need specific policies applied at each stage, as well as an overarching policy framework [22]. The policy instruments used can include tax exemptions and mandates. However, setting the policies is not difficult, the challenge lies with understanding the consequences [23].

3.1.1. Enforcing Tax Exemptions

Tax exemptions are where the consumer or producer of biodiesel receives a reduced or complete removal of tax when using or producing biodiesel. In 1999, Germany began its transition to alternative fuels through the introduction of an Eco-Tax to help reduce fossil fuel consumption. Further, 2002 biofuels were exempt from tax [24,25]. Due to a combined Eco-Tax on crude oil based fuels and tax exemptions on biodiesel at the pumps, the price of biodiesel fell below that of diesel [26]. At the same time, the infrastructure of the biodiesel network helped ensure higher blends that could be used. This was achieved by the government demanding fuel stations to convert the pumps to handle up to 100% biodiesel [27].

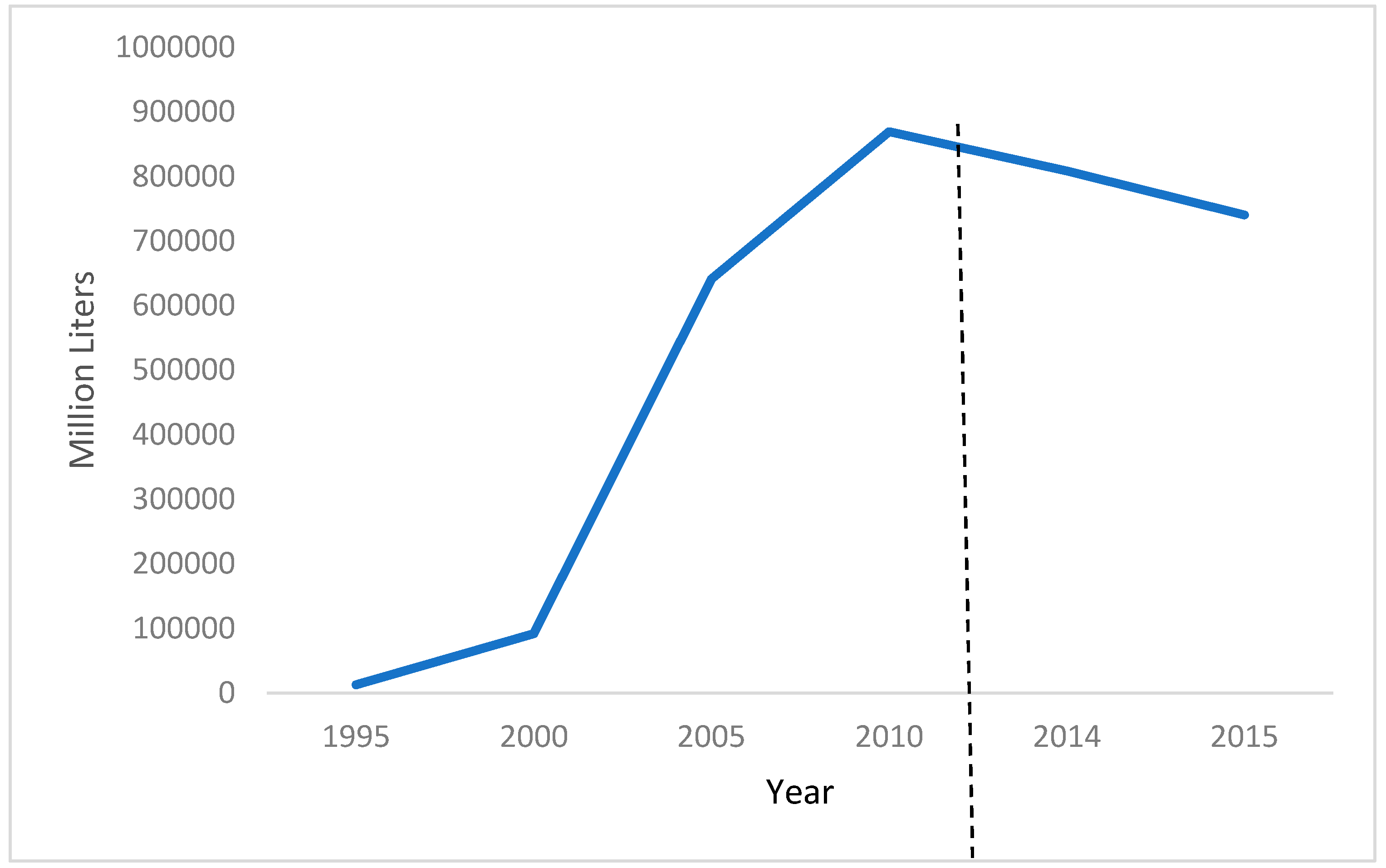

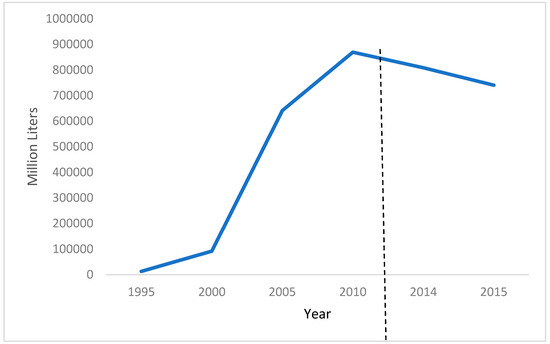

Figure 2 [28] shows Germany’s consumption of biodiesel between 1995 and 2015. There was a consistent increase in the consumption of biodiesel in Germany from 1995 to around 2010/2011. From 2002, there was a steep increase in consumption over the next five years. An existing tax exemption was slowly being replaced with a blending mandate from 2006 [29] and was completely abolished in 2012, as indicated by the dashed line. A drop in consumption is seen in 2010 where the likely increased price of biodiesel is exceeding consumers’ willingness to pay. The tax exemption was replaced with fuel supplier mandates. In this instance a mandate refers to a certain level of biofuel that fuel suppliers had to blend or sell. The mandate in Germany was that 5.75% of fuel suppliers’ sales had to be biodiesel [24]. Despite the mandate in place, consumption was still decreasing. There was no legislation stating that the biodiesel had to be used in a domestic capacity, and since 2012, exports of biodiesel from Germany has been increasing [30]. An alternative to giving tax incentives to consumers is to give it to the producers of biodiesel. This is the approach that the United States (US) took.

Figure 2.

Consumption of biodiesel in Germany 1995–2015, adapted from Statistica 2018 [28].

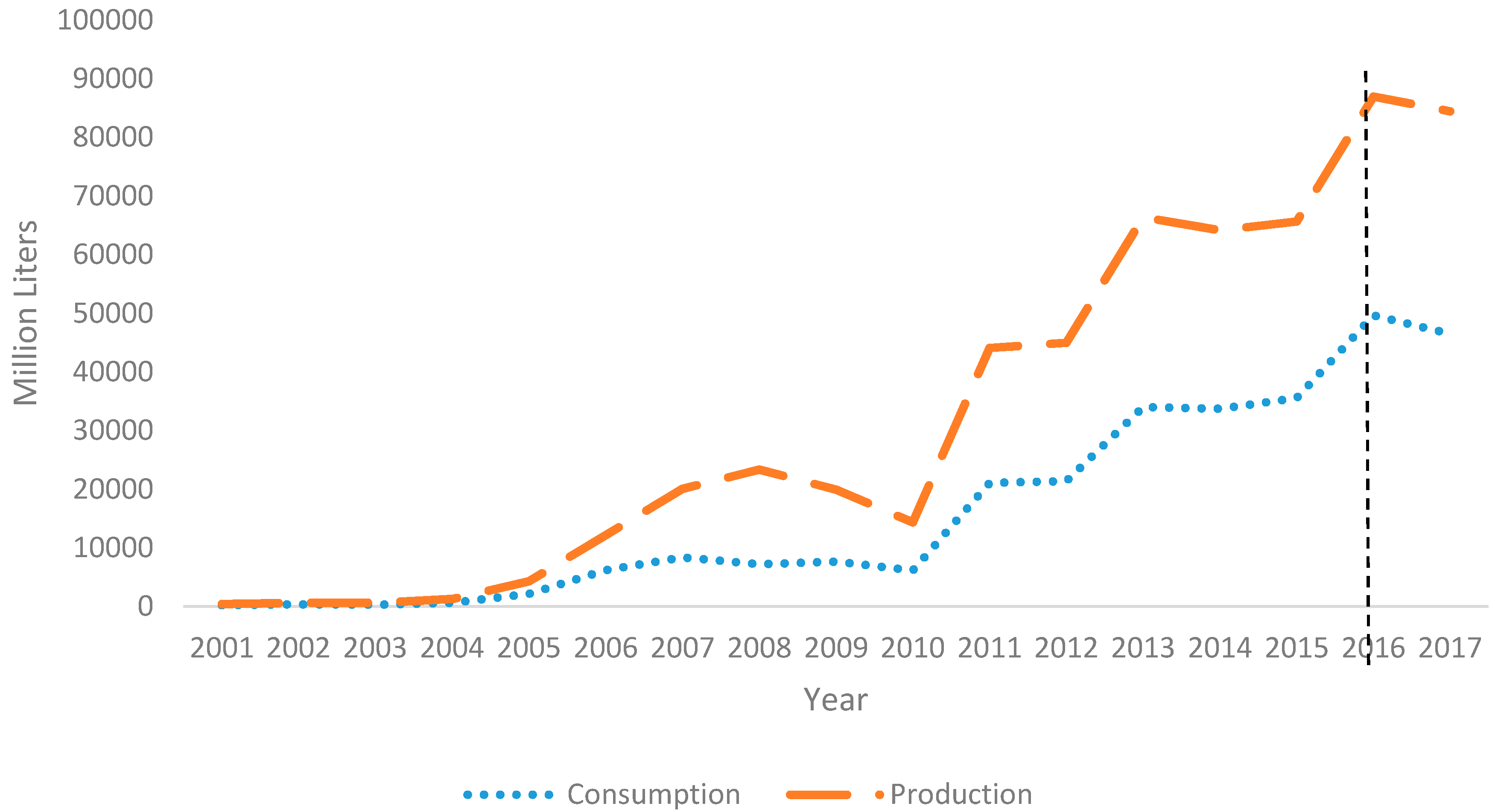

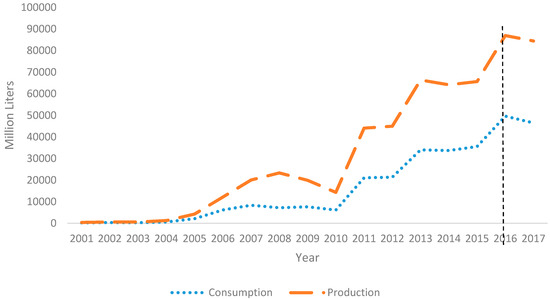

Figure 3 shows the US’ production and consumption of biodiesel between 2001 and 2017. Production began to increase more noticeably from 2005. During this time, a tax relief was present for the production of biodiesel and this encouraged production [31]. However, there were few incentives for consumers. Instead of selling to the domestic market, the US began exporting more biodiesel [32]. The tax relief was abolished in 2016 and there was a slight decrease in production, as indicated by the dashed line. When the tax relief was abolished, there was no replacement or alternative introduced. From the evidence of production dropping when there is no tax relief present, the US was set to reinstate the tax relief mid-2017 [33].

Figure 3.

US Production and Consumption of Biodiesel between 2001–2017, adapted from BP Global (no date) [18].

In Germany, the tax incentives were for the consumers, however, in the US, tax incentives were for the producers of biodiesel. When tax incentives were abolished for consumers in Germany, demand for biodiesel decreased. When tax incentives were abolished for producers in the US, the supply of biodiesel decreased. This indicates that tax incentives influence the demand and supply of biodiesel. The consequences of using a tax exemption are dependent on other factors, such as whether the price of crude oil-based fuels is consistent. There is limited research in this area, especially with biodiesel, but some research has been conducted on the possible consequences of using bioethanol [23]—this is explained in Section 4 of this paper.

3.1.2. Mandates Issued Due to Legislation

An alternative to using tax exemptions is to use a mandate. Malaysia used mandates to ensure the consumption of biodiesel. Before 2010, Malaysia’s consumption of biodiesel was zero. It exported all its biodiesel. When the Government of Malaysia was originally setting the blend level, there was a debate on what it should be. A blend is any concentration of biodiesel mixed with diesel, e.g., 5% biodiesel with 95% diesel is called B5. Initially, a blend of 5% was established, but with high palm oil costs, the government would have to supply large subsidies to compensate for this [34]. The 5% was reduced to 3%, but this was met with opposition because producing such a small amount would not be economically prudent. The government reverted back to 5%, but was delayed and only applied to certain regions. At the same time, pumps at petrol stations were adapted to handle higher blends [35]. In 2015, after delays, B7 was introduced and consumption started to increase very slowly. The government of Malaysia imposed a B10 mandate at the end of 2016, but there has been resistance from car manufacturers who claim that engine damage is inevitable if the blend goes above 7% [34].

In the US, there are federal policies that promote the use of biodiesel, but Minnesota was the first state to introduce compulsory biodiesel blending in 2002. In 2013, B10 was meant to be introduced, but was delayed until 2014 because of a lack of blending infrastructure and inadequate regulatory measures. This shows that having ancillary polices supporting the technical side of introducing biodiesel is important for it to be successful. B10 is only applicable during the summer months because the fuel in the winter months causes solidifying problems. The mandate reverts to B5 during the winter months [36].

3.1.3. The Importance of Legislation and Political Structure in Introducing Biodiesel to Road Transport

Policies have been further strengthened by legislation. For example, in Brazil, that is one of the most successful countries in the world in introducing biofuel, the Alcohol Programme was partly successful because of the laws and decreases that had been introduced at the beginning of 1975. These held industry accountable by law to the commitments of introducing bioethanol.

- On 14 November 1975, The National Alcohol Programme was established through parliament [37], which outlined the objectives and financing of the programme.

- In the early 1990s, the ethanol program was under threat because of declining oil prices. People were reverting to using petrol as it was becoming cheaper once again. On 28 October 1993, legislation was passed that stated a 22% ethanol blend was to be used across the country [37].

The effectiveness and ease of using policies and laws partly depends on the political structure of a country. For example, during the OPEC oil crisis, Brazil was under a military dictatorship. During this time, economic growth was made a priority [38]. To meet the targets, President Geisel was prepared to further the country’s debt through foreign loans—he was more liberal in allowing foreign investment compared with his predecessors [39]. This, in turn, would lead to Brazil being able to finance infrastructure projects. After reviewing what turned out to be implausible strategies such as further exploration for Brazilian oil because reserves were less than previously thought and nuclear where the time frame for implementation was too long, and therefore, biofuel was the favorable option to reduce the importation of oil [40]. For this project to succeed, this required tools that Brazil already had, including the ability to control oil prices because of the monopoly state-owned Petrobras [1] and Brazil was able to finance the project because of Geisel’s liberal view of allowing foreign investment.

Unlike Brazil, the EU consists of member states/countries and therefore has approached the introduction of biofuel in a different format. The EU issues targets and individual countries, then have the flexibility to meet the targets in an approach that is fitting to their resources [41]. To achieve these targets, each member state has their own Energy Action Plan [42] with sections specific towards biofuels in general and not only biodiesel. Compared to Brazil, the EU appears to have more flexibility in their approach. Thus, even though it may be an option to use Brazil’s approach in introducing biofuel, it may not be possible, because of the political structures within countries. Each country is different and will always have varying levels of success.

3.2. The Economics of Using Biodiesel

Policy instruments can influence the production and consumption of biodiesel to the transport sector, but this can result in a cost to the government, transport companies, the biodiesel industry, and consumers. It is essential to establish the costs before embarking on such a venture to assess whether the introduction of biodiesel to transport is beneficial in monetary terms.

3.2.1. The Costs of Using Tax Exemptions and Mandates

Tax incentives can result in a loss of revenue for the government. In 2005, Germany had a loss of €1.14 billion (US $1.3 billion) due to a reduction in fuel taxes on biodiesel. In total, the support for biofuels costs the EU around €3.7 billion (US $4.22 billion) per annum, split between bioethanol at €1.3 billion (US $1.48 billion) and biodiesel at €2.4 billion (US $2.74 billion) [26]. The US has experienced similar results and it has been estimated that B20 could cost around US $0.68–0.9/L more for producer than the cost of unblended diesel [43]. To help compensate these losses, foreign or private investment is often encouraged and promoted. As Malaysia emerged as a world player in biodiesel production, foreign investments have been injected into the industry. Yanmar, a Japanese diesel engine manufacturer, opened a biodiesel research facility. Additionally, Middle East Dubai Group invested US $49.5 million in Global Biodiesel, a Malaysian biodiesel producer [35]. This shows that not all costs fall to the taxpayer or consumer.

When there is a loss of revenue for the government, funds may have to be reallocated or reduced in other areas of government spending; thus, the government faces an opportunity cost. To avoid the drop in expenditure in other areas of the economy, the government may have to consider measures such as a rise in taxes elsewhere. Politicians are often against raising the taxes due to the possibility of voters turning against them. Governments need to assess the risk and sacrifice they are willing to make in order to introduce biodiesel.

When a mandate is issued, there will likely be an increase in the cost of the fuel, which will likely fall upon the fuel supplier. The fuel supplier has to make a decision on what to do with the extra costs, either to absorb them or pass them onto the consumers [44]. There are variables that could influence the decision on which option the fuel supplier would choose. However, more often than not, the consumer will usually bear the increased cost [45]. If competitors absorb the costs, then other fuel suppliers who do not could be pushed out of the market. Governments could put price caps on fuels, so it is not possible to shift the cost to fuel supplier’s customer. However, if the fuel supplier is a private company, the passing of the cost onto the consumer is more likely in order to maximize their profits.

3.2.2. The Price of Ethanol and Economies of Scale

In the long term, costs may reduce with the introduction of bulk producing and the learning curve. A new project or venture can often have high initial costs through the possibly of using new technologies and producing a new product. With time, as the process and technology becomes more advanced and efficient, the marginal cost will reduce. This was experienced by Brazil. Brazil is a prime example of a nation which has demonstrated the interdependent links between policy, the market, and economics when trying to increase the use of biofuel [46]. Through the use of policies such as mandates, tax exemptions, and investment, along the bioethanol supply chain [47], Brazilian bioethanol has become competitive against gasoline.

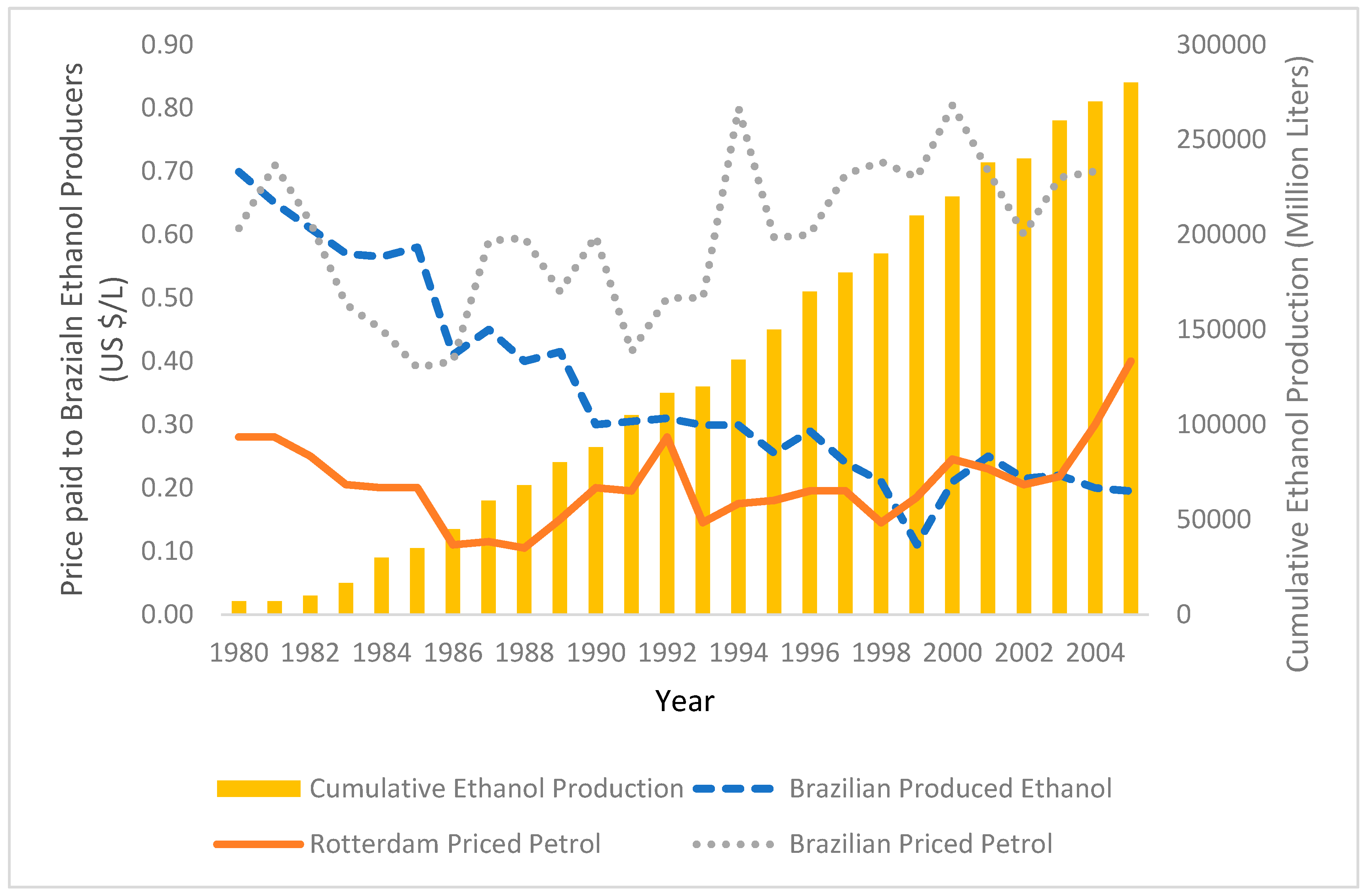

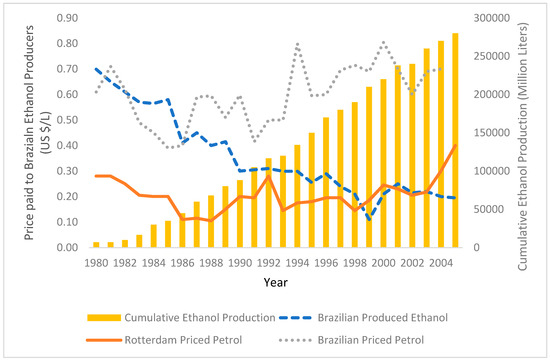

Figure 4 shows the production of ethanol in Brazil and the prices of Brazilian ethanol, international gasoline/petrol, and Brazilian gasoline from 1980–2005. In 1980, the price paid for Brazilian ethanol was more than double that of international gasoline, even though subsidies were being given to ethanol production. From 1990, subsidies were slowly removed as ethanol became more competitive with Brazilian gasoline. From 2002 to 2005, Brazilian produced bioethanol had a slow decreasing price, whereas international gasoline had a sharper increase in price—thus making ethanol cheaper than petrol by around US $0.22/L. During this time, all subsidies were removed from the production of ethanol making, and it is competitive with international gasoline without the need for government intervention. By 2005, bioethanol was 60%–70% of the price of international gasoline [48,49,50]. Brazil is a good example in that with a supportive structure and framework in place it is possible for biodiesel to become successful. The price of ethanol is decreasing as ethanol production increases. This shows the link between the price of ethanol and scale of production, i.e., the larger the production the lower the marginal cost.

Figure 4.

The production of ethanol in Brazil and the prices of Brazilian ethanol, international gasoline/petrol and Brazilian petrol from 1980–2005, adapted from Goldemberg et al. (2004) [48].

3.2.3. The Costs of Maintaining Vehicles Using Biodiesel

Apart from the price of biodiesel for the consumer being often more expensive than diesel, other factors could also affect the costs to the consumer. Table 1 shows two studies of maintenance costs when using B20 in buses compared with diesel. Even though the studies are independent of one another, the results could be considered as quite similar.

Table 1.

Comparison of fuel efficiency and maintenance costs from two bus studies investigating the use of biodiesel, adapted from Barnitt et al. (2006) [51] and Barnitt et al. (2008) [52].

Table 1 compares the fuel efficiency and maintenance costs from two separate bus studies. Fuel efficiency is approximately the same or slightly increased for biodiesel. There is little difference in the overall maintenance costs, but in study A, diesel was the more expensive because of high costs for transmission repairs. The monthly running maintenance costs are higher for biodiesel. Study A reports a fourfold difference between biodiesel and diesel at US $0.08/km and biodiesel at US $0.02/km. Study B, however, shows that biodiesel is 50% more expensive than diesel. Overall, the bus maintenance costs are similar for diesel and biodiesel, but the engine and fuel maintenance costs are higher for biodiesel. However, when the blend increases to above 20%, it is recommended that fuel filters are changed more frequently, and when above 80%, manufacturers recommend an extra oil change per year [53]. This shows that, when using biodiesel, consumers can expect little change in the costs of maintaining their vehicle if the blend is 20% or below.

3.2.4. The Cost of Feedstock

The choice of feedstock has an influence on the overall production cost of biodiesel and thus the price the consumer pays. Biodiesel production costs can be up to three times more than that of petroleum diesel [54].

Table 2 shows a comparison of diesel and biodiesel produced from a variety of feedstock. Biodiesel made from peanut butter oil is the most expensive at US $0.52/L, which is more than diesel. The feedstock derived from waste in general is the cheapest out of the feedstock, including diesel with tallow being US $0.36/L less than diesel, although this varies. This is positive because it eliminates the food versus fuel debate; the competition of land between feedstock grown for food or fuel. Edible feedstock has a large range, from the most expensive of US $0.52/L more expensive than diesel to the cheapest of soybean, which is US $0.05/L cheaper than diesel. The non-edible feedstock (jatropha) is more expensive than diesel at US $0.20/L. These are guidelines of biodiesel prices produced from various feedstock pertaining to the parameters mentioned above. Policy instruments, including tax exemptions, have been used to help reduce the price of biodiesel, but it is not successful for all. From 2004 to 2013, the US saw the cost of biodiesel produced from soybean and yellow grease increase in cost from US $0.56/L to US $0.62/L and US $0.31/L to US $0.34/L, respectively, based on a production of 909.2 million liters. The cost of producing petroleum during the same period varies from US $0.15/L to US $0.17/L [43]. With these costs, biodiesel is not economically feasible from a monetary perspective. Were externality costs to be included in this estimate, then the opposite may be true, but research is limited in this specific area. When choosing to introduce biodiesel, the choice of feedstock is important because this will affect the costs and prices along the supply chain and the burden the government accepts from applying policy instruments such as tax exemptions.

Table 2.

Comparison of diesel and biodiesel produced from a variety of feedstock.

3.3. Social Implications and Acceptance of Introducing Biodiesel to Transport

Social implications and acceptance of biodiesel are important because it can affect the overall welfare of a country. By demonstrating that welfare can be increased with the introduction of biodiesel, this may lead to social acceptance and thus support for current and future energy schemes. Over time, the introduction of the Brazilian Alcohol Program was welcomed by the people because it has enabled around 700,000 jobs to be created across the entire supply chain, mainly in rural areas [60]. While creating these jobs may initially be costly, in the long term, it would likely benefit the economy by having higher employment, higher wages, and a higher standard of living [44]. For those not directly involved in the programme, it was important for the government to gain support from the people in the use of bioethanol. With this, they provided incentives such as Value Added Tax (VAT) reductions [54] to switch to ethanol-fuelled cars. Other than Brazil, there is little information on how people are given incentives to choose biodiesel for their cars. The policies used can also have an influence over social welfare. As mentioned previously with a mandate, for example, oil companies would have to provide a certain percentage of biofuels, which are usually more expensive. This extra cost could be passed on to the end user [26].

3.4. A Technological Perspective

While there is a lot of literature about how biodiesel affects engines, there are also several studies that have investigated the performance of biodiesel in locomotives. Areas include the effects on fuel consumption, different blend levels and the materials in the engine.

3.4.1. Storage, Engine and Fuel Performance

The length of storage of biodiesel without affecting the use varies depending on the blend. B100 should be used within one year and requires regular monitoring, B20 can span longer and B5 can remain stable for the longest [61]. Additionally, due to the increased density of B100 compared to lower blends, the risk of sediments settling to the bottom of the tank is higher, and therefore, proper mixing may be needed in the engine tank or fueling system before use. Biodiesel can be mixed by the fuel supplier before being dispatched to the consumer or it will be mixed while putting it into the tank. Biodiesel has a higher pour point temperature than diesel [57] and solidifies at a higher temperature, and therefore, cannot be used in winter months. Thus, biodiesel may not be feasible to use in countries with colder climates. As mentioned above, Minnesota only allowed the use of biodiesel in engines during the summer months, because of the physical properties of biodiesel.

The higher the blend, the lower the energy content, but the change is insignificant for B5 [62]. Biodiesel is a good solvent and can dissolve varnish and gums, which, along with wax formed in lower temperatures, can cause the clogging of filters. There are also concerns that a blend higher than 80% biodiesel could potentially damage the engine and cause other engineering problems [63,64]. When B100 is used, certain metals can be degraded such as bronze, tin, zinc, and lead, so should not be used in the engine [65]. These problems have led to vehicle manufacturers, invalidating warranties when biodiesel is used. For example, France wanted to increase their compulsory blending from 7% to 8%, but faced objections from automobile manufacturers, who state that the warranties on vehicles would become invalid if an 8% blend is used [66]. Germany has been able to use B100 because the government and organizations that promote the use of biodiesel have worked closely with automobile manufacturers and have established the following conditions in which B100 can be used in certain vehicles [67,68]:

- Fuel had to comply with DIN EN 14214 standards.

- A certificate must accompany each supply of fuel ensuring that it meets the required conditions. Any additives added to the fuel must be included in the certificate.

- Tanks must be emptied and cleaned when switching from summer to winter fuel.

- When a warranty claim is issued the manufacturer must have proof of the fuel’s origin.

These guidelines were established after rigorous tests, including different climate situations, the usage, chemical observations, and mechanical contingencies.

3.4.2. Blending Diesel and Biodiesel

Biodiesel can be blended at refineries, which are already producing and supplying diesel. For low blends such as B7 used in the UK, there is no need to change the pumps at fuel stations. Some countries such as Brazil, Germany, and Malaysia converted their pumps at refueling stations for distributing pre-mixed high blend fuels. Apart from blending at refineries, it is possible to load biodiesel and diesel separately directly into the fuel tank. There are two methods for this:

- Splash blending. This is widely available, but the least effective. First, the diesel is loaded into the tank followed by the biodiesel being pumped on top

- In-line blending. Warm biodiesel is pumped into an already running stream of diesel as it is loaded into the tank. It is thoroughly mixed through the turbulent movement of the fuel [69,70]. Even though this is the most efficient and reliable method, it is also more expensive than splash blending.

This shows that there are different methods to mix biodiesel and diesel so there is a flexibility for a country or mode of transport to choose the method that is most beneficial for them.

3.5. Environmental Effects of Using Biodiesel in Automotive Vehicles

The use of biodiesel can help reduce Greenhouse Gases (GHGs) and pollutants (e.g., NOx and SOx), generally the higher the blend, the larger the reduction. GHGs are important to observe because they contribute to global warming, which can lead to severe weather and rising sea levels. During the production and combustion of biodiesel CO2 is released, but it is absorbed by the crops [71]. To account for this absorption back into the supply chain, it is often assumed that CO2 exhaust emissions are neutral. Pollutants can affect people’s health, especially the respiratory system. A lot of research on emissions from biodiesel has been conducted and reported, the table below shows a snapshot of such studies.

Table 3 shows the change in emission levels of using up to B100 compared with conventional diesel. B20 made from soya bean has a reduction in PM, HC, and CO (10.1%, 21.1%, and 11% respectively), whereas NOx emissions increase by 2% when compared to B0 [72]. Regardless of the feedstock used, there is a reduction in HC, CO, PM, and SO2. When using B100, the majority of researchers believe that NOx increases by up to 14% compared to B0 [73,74,75,76,77]. There have been attempts to reduce NOx emissions by improving the cetane number. These tests did not result in much improvement and proved to be expensive [78]. Additionally, there have been attempts to help reduce NOx by up to 15% by lowering the levels of oxygen in the system, but once again, this is expensive and with biodiesel being more expensive than diesel already, this is not possible to use at present, unless the social costs heavily outweighed the private costs. Other studies have seen that it is possible to reduce NOx emissions through modifications in the engine [64,79,80] because NOx appears to be the emission that is most sensitive to driving conditions. Other possible solutions for reducing the NOx emissions include changing the initial chemical composition of the feedstock [78]. There are significantly more studies that show an increase, but it is difficult to ascertain how exactly NOx emissions are measured and that is a possible reason why there is a range of levels, both positive and negative [78,81].

Table 3.

The change in exhaust emission levels of up to B100 compared with conventional diesel.

4. A Discussion on the Transition to Biodiesel Used in Locomotives and the Lessons Learned from the Road Sector

There are many influencing factors that contribute to the success or failure during a transition to biodiesel as an alternative fuel. By assessing the successes and failures, it is possible to establish the areas for further development and risk factors of introducing biodiesel to the rail sector. Table 4 is a summary of the lessons learnt from the road transport sector. Each lesson is categorized in whether it was successful, unsuccessful or partially successful. A brief explanation is given to describe this decision, and finally, the consequences of applying the lesson to the rail sector.

Table 4.

A breakdown of the lessons learnt from the road sector and how they apply to rail.

4.1. The Political and Policy Side of Introducing Biodiesel to Rail

There are two sides to the “P” of the PESTLE framework the policy side and the political side, bust are closely linked. Both play a key role in introducing biodiesel to road, and consequently, rail. Policies have an influence across the areas of the PESTLE framework. This is a key lesson for rail, that the wider affects and consequences, both direct and indirect, need to be considered when issuing policies. Biofuels need to be understood in their historical socio-economic contexts [85]. Policy makers prefer to use a combination of mandate and tax credits in conjunction [23]. However, this is not always the best approach, there are other considerations that can influence the outcome of such measures and will be explained in further detail in this section:

- The political set up of a country

- The elasticities of the biofuel and fossil fuel

- Whether the fossil fuel price is endogenous or exogenous

- If a mandate is binding or non-binding

These variables add an uncertainty on whether to enter to biofuel market [72]. Another aspect that can lead to uncertainty is the political structure of a country because it could have a number of influences. There was a military rule in Brazil during the bioethanol programme. When the country had control over the gasoline and ethanol, growth and uptake of the ethanol was largely successful. Even though the government had control over ethanol production and the state owned oil company, there was a degree of flexibility that allowed for high uncertainties in the industry. It also took into account the demographic of the country, whereby they issued varying federal and state taxes, and they did not take a one size fits all approach [86]. This approach shows that, when introducing a new fuel to a market, policies are important flexibility within those policies that are just as important. Just because a country industry is heavily state owned, this does not mean that introducing biodiesel will automatically be successful. For example, the Indian government wanted to introduce a 20% biofuel usage target by 2017 [22], this target has fallen short, partly because of the lack of clarity and consequences of the government policies. There was confusion in understanding the policies [87], in that farmers claim that the government is unclear about the price of seeds, where to grow the crops and the type of crops that should be grown [88]. This shows that, even though the government may have large controlling power over the industry, the programme can still fail.

There are two possible contentious areas, the first is the relationship between politics and the corporate sector [85], and how much of an influence does the corporate sector have over politicians? This brings us to the second area, the reasoning of promoting biodiesel initially. Often, the main reason is to reduce GHGs and reliance on fossil fuels, however a government needs to decide how much they are willing to sacrifice in order to achieve this. For example, biofuels are often more expensive than fossil fuels, so the cost of a blend (if desired) will be more expensive than an unblended fossil fuel. Either this cost is passed on to the consumer or the government absorbs it, but GHGs will likely be reduced. The government needs to decide the cost it is willing to pay for lower GHGs.

Regulating policies can be strengthened through the use of legislation, which is mandatory [89]. Different legislation in different countries has been used when attempting to introduce biodiesel to road. In the EU legislation about biofuels is generalized. The EU issues directives, such as the Renewable Energy Directive [90], which promotes the production and promotion of renewable energy, and each member state enacts their own legislation. This may not be as effective and thorough as some focused and specific legislation. For example, Brazil was clear in its in plans of setting targets and had a structure in how they would achieve their goals. The success of Brazil passing legislation could be partly due to the political structure of the country. The military government had few opponents to object to their ethanol plans. In a democracy, it could be seen as more difficult to pass legislation because of the opposition. Nevertheless, legislation can only strengthen the introduction of biodiesel to rail.

4.2. The Economics of the Policy Instruments Used and Their Application to Rail

While it is easy to set a policy, understanding the consequences of the policy is not. Policies have a direct impact on the entire economy. Mandates and tax exemptions can be standalone or used in conjunction with one another. A mandate can lead to modest gains in biofuel production, exports and reduction in GHGs [91]. Tax money is not used to foot the bill of a mandate, instead consumers pay with higher prices at the pump [23]. A mandate can be binding or non-binding. Binding means the fuel suppliers are forced to supply more biofuel than they would otherwise, non-binding means they are already supplying more than the mandate states [92]. A high gasoline price means that a non-bound mandate will leave little impact on the market [41]. This is because the oil companies are already using more biofuel than is being asked of them, so a high gasoline price would have little impact on the amount of biofuel being used.

With a tax exemption, the question that is always asked is who pays? Whilst it has been seen by Germany and the US that tax exemptions increase the use biofuel, policy of makers need to be careful that the fuel price is not so low that the consumption of fuel begins to increase with the consequence of higher GHGs [41]. On the opposite side to this, abolishing tax exemptions can lead to consumers reverting to fossil fuels which would likely be once again cheaper than its biofuel counterpart. This would likely lead to increased GHGs. There is a trade off in that society has a cleaner environment at the expense of higher fuel prices [86]. This once again highlights politicians and also the rail sector need to understand and clarify the reasoning behind their choice to use biodiesel.

A combined approach of using a mandate and tax incentive is often advised [23,93]. The use of biofuels in the road transport sector already has experience in initiating such policies, and as a result, has discovered that a combined approach will likely provide the most positive results. This may also increase demand above the required mandates when demand for biofuel is high, especially during times of higher oil prices [94]. However, the tax exemptions can offset the increased price of the mandate [41] and using a tax exemption on a binding mandate contradicts the biofuel policy [23]. The tax would be acting as a subsidy, leading to a likely increase in both biofuel and fossil fuel consumption, which leads to increased GHGs [91]. This section does not recommend a particular policy that rail should adopt were it to introduce biodiesel, but an awareness that understanding the consequences of a policy is a complex issue.

4.3. Social Implications and Acceptance of Using Biodiesel in the Rail Sector

Biofuels can result in rural economic development through more people being employed across the supply chain. This would likely lead to having a higher standard of living, however this could once again depend on the policies chosen. Assuming a mandate would lead to increased costs on the fuel, society would pay the marginal difference. The increased wages from the workers would pay towards this extra cost. However, this could once again be outweighed by some of the benefits that biofuels bring specifically lower GHGs and pollutants [86], but is not always the case as some policies can lead to increased GHGs and thus lowering social welfare [91]. There aresome statistics showing an increase in jobs in Brazil, but at the same time, Brazil has been criticized by rural development movements for labor exploitation [85]. This highlights the issue that clarity and transparency are vital when introducing such a scheme, and all aspects along the supply chain need to be considered by governments.

The rail sector and rail companies need to understand the benefits of using biodiesel. They should be educated in not only the engineering, practical side of using biodiesel, but also from a cost and social impact perspective. Companies need to be educated about the benefits of using biodiesel and how to make that marketable to their consumers. It may be difficult for customers who use rail to switch between brands of train due to the structure of the rail network in most countries, but it is possible to change the mode of transport—to reflect their support for the most carbon-friendly means of transport. This is a positive point that encourages the introduction of biodiesel to road and rail, and they need to work together to avoid a negative modal shift.

4.4. The Technological Aspects of Using Biodiesel in Locomotives

While the basic principle of both a locomotive and road vehicle (diesel powered) is the same (compression ignition engine), the maintenance needs may be different. For example, the distance travelled and the age of vehicles (locomotives may be older because of their lifespan).

- Considering the lifespan of a locomotive there may be materials in older models, such as metals, that would be degraded if biodiesel were to be used. It may take longer to use biodiesel in the rail sector because the frequency of replacing locomotives is less than road transport. However, until rolling stock is replaced, it may be possible to work with manufacturers to establish the maximum blends they will allow when certain conditions are met. When locomotives need replacing, the rail companies must work with the manufacturers to help increase the possibility of using higher blends in the engine. If the government or biodiesel advocates help fund the development of biodiesel, in rail and in a partnership with engine manufacturers, the chances of using higher blends could become higher.

- This in turn may affect the cost of the overall maintenance. While the under-investigated understanding is that there are few changes in maintenance costs, it may differ for rail. Therefore this is the benchmark for maintenance costs, but checks and pilot tests would need to take place to assess if there is a similar trend to that of road.

4.5. Environmental Consequences of Using Biodiesel in the Rail Sector

Pollutants could be reduced by 1%–7% by using B20 [73,95,96] and 10%–30% by B100 in comparison to conventional diesel. Significant reductions of both HC and CO were observed, B20 could reduce HC and CO emissions by 21% and 17%, while B100 could reduce HC and CO emissions by 24% and 34%, respectively. However, there are debates on HC and PM emissions for B20 blend wherein some believe this should be a lot lower [95]. Tests have indicated that there is an increase of NOx, HC and CO emissions when the locomotive is in an idle state while using B20 [97]. Were the use of biodiesel to increase, then these emissions would also increase, putting human health at risk. GHGs are reduced in the rail sector when introducing biodiesel with a reduction of 70% for B100 over the lifecycle of producing biodiesel [98,99].

Another aspect other than the technological side that can affect, the environmental effects of using biodiesel is the policy side. As discussed above, if, for example, the tax exemptions are too high and this could lead to an increase in fuel consumption, thus resulting in a possible increase in emissions. Once again, this highlights the importance of understanding the consequences of policies.

5. Conclusions

The road transport sector is rich in research and experience of introducing biodiesel. This experience is varied, ranging from successes to failures. The relevant lessons for rail are:

- Using biodiesel can reduce most GHGs and most pollutant emissions, with potential health benefits.

- Tax incentives and mandates have promoted the production and consumption of biodiesel. Such incentives will likely be required for all rail sector, too

- The cost of producing biodiesel is larger than fossil fuels, with the price of feedstock an important constituent. These extra costs will likely be absorbed by the consumer or taxpayer. The cost competitiveness of biodiesel fuel depends on global oil prices too.

- Maintenance costs are perhaps more difficult to determine for rail due to the differences between the vehicles. This highlights the importance of working with locomotive manufacturers and train operators to determine these costs.

- The use of biodiesel as small blends may not require any modification to existing locomotives. However, warranties of locomotives for biodiesel blends is an important area requiring consultation.

- Longer life of rail locomotives compared to vehicles may be a barrier to rapid adoption of higher blends of biodiesel.

- Suitability of existing infrastructure and required modifications play a key role in introducing biodiesel into the market. This may be easier for rail compared to road due to fewer fueling stations.

- Policies and governance structure have an important role in the biofuel transition. A study of the political economy of transitions in the road sector will be useful for rail.

Author Contributions

C.S. gathered the information and wrote the article. Z.W. conducted major reviews, edits and wrote the abstract. C.N. advised on structural changes and the economic section as well as reviewing the article. H.L. input on the technological section.

Funding

C.S. Stead is grateful to EPRSC Centre for Doctoral Training in Bioenergy (Grant number: EP/L014912/1) for the award of a postgraduate studentship.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- International Energy Agency (IEA). World energy outlook 2015. In Organization for Economic Co-Operation and Development (OECD/IEA); IEA: Paris, France, 2015; Available online: https://www.iea.org/publications/freepublications/publication/WEO2015.pdf (accessed on 12 June 2017).

- International Energy Agency (IEA). Tracking Progress: Transport. 2017. Available online: https://www.iea.org/etp/tracking2017/transport/ (accessed on 11 December 2018).

- Yin, X.; Chen, W.; Eom, J.; Clarke, L.E.; Kim, S.H.; Patel, P.L.; Yu, S.; Kyle, G.P. China’s transportation energy consumption and CO2 emissions from a global perspective. Energy Policy 2015, 82, 233–248. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, X.; Shao, S. Decoupling CO2 emissions and industrial growth in China over 1993–2013: The role of investment. Energy Econ. 2016, 60, 275–292. [Google Scholar] [CrossRef]

- Azad, A.K.; Al, E. Prospect of biofuels as an alternative transport fuel in Australia. Renew. Sustain. Energy Rev. 2015, 43, 331–351. [Google Scholar] [CrossRef]

- Kim, I.; Ismai, M. Growing Demand for Biofuel and its Impact on Sustainable Rural Development in Nigeria. Economy 2014, 1, 1–4. [Google Scholar]

- Papong, S.; Chom-In, T.; Noksa-nga, S.; Malakul, P. Life cycle energy efficiency and potentials of biodiesel production from palm oil in Thailand. Energy Policy 2010, 38, 226–233. [Google Scholar] [CrossRef]

- de Souza, S.P.; Pacca, S.; de Ávila, M.T.; Borges, J.L.B. Greenhouse gas emissions and energy balance of palm oil biofuel. Renew. Energy 2010, 35, 2552–2561. [Google Scholar] [CrossRef]

- Eshton, B.; Katima, J.H.Y.; Kituyi, E. Greenhouse gas emissions and energy balances of jatropha biodiesel as an alternative fuel in Tanzania. Biomass Bioenergy 2013, 58, 95–103. [Google Scholar] [CrossRef]

- Ong, H.C.; Mahlia, T.M.I.; Masjuki, H.H.; Norhasyima, R.S. Comparison of palm oil, Jatropha curcas and Calophyllum inophyllum for biodiesel: A review. Renew. Sustain. Energy Rev. 2011, 15, 3501–3515. [Google Scholar] [CrossRef]

- Akbar, E.; Yaakob, Z.; Kamarudin, S.K.; Ismail, M.; Salimon, J. Characteristic and Composition of Jatropha Curcas Oil Seed from Malaysia and its Potential as Biodiesel Feedstock Feedstock. Eur. J. Sci. Res. 2009, 29, 396–403. [Google Scholar] [CrossRef]

- Altenburg, T.; Dietz, H.; Hahl, M.; Nikolidakis, N.; Rosendahl, C.; Seelige, K. Biodiesel in India: Value Chain Organisation and Policy Options for Rural Development; Deutsches Institut für Entwicklungspolitik gGmbH: Bonn, Germany, 2009; ISBN 9783889853790. [Google Scholar]

- Atsushi, I.; Martin, H.R.; Yonas, E.M. Modal Choice between Rail and Road Transportation Evidence from Tanzania. 2017. Available online: http://hdl.handle.net/10986/28349 (accessed on 2 February 2018).

- Silalertruksa, T.; Bonnet, S.; Gheewala, S.H. Life cycle costing and externalities of palm oil biodiesel in Thailand. J. Clean. Prod. 2012, 28, 225–232. [Google Scholar] [CrossRef]

- Demirbas, A. Biofuels securing the planet’s future energy needs. Energy Convers. Manag. 2009, 50, 2239–2249. [Google Scholar] [CrossRef]

- Black, G.; Curran, H.J.; Pichon, S.; Simmie, J.M.; Zhukov, V. Bio-butanol: Combustion properties and detailed chemical kinetic model. Combust. Flame 2010, 157, 363–373. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Global Biofuels Production. 2018. Available online: https://www.iea.org/tcep/transport/biofuels/ (accessed on 22 October 2018).

- BP Global. Biofuels Production. Available online: https://www.bp.com/en/global/corporate/energy-economics/statistical-review-of-world-energy/renewable-energy/biofuels-production.html (accessed on 15 May 2018).

- Nagy, G.; Marsi, G.; Hancsók, J. Study on Stability of Ethanol/Diesel Fuel Blend. In Proceedings of the European Congress of Chemical Engineering (ECCE-6), Copenhagen, Denmark, 16–20 September 2007; pp. 1–12. Available online: http://folk.ntnu.no/skoge/prost/proceedings/ecce6_sep07/upload/1036.pdf (accessed on 1 June 2018).

- Zalengera, C.; Blanchard, R.E.; Eames, P.C.; Juma, A.M.; Chitawo, M.L.; Gondwe, K.T. Overview of the Malawi energy situation and A PESTLE analysis for sustainable development of renewable energy. Renew. Sustain. Energy Rev. 2014, 38, 335–347. [Google Scholar] [CrossRef]

- Kolios, A.; Read, G. A Political, economic, social, technology, legal and environmental (PESTLE) approach for risk identification of the tidal industry in the United Kingdom. Energies 2013, 6, 5023–5045. [Google Scholar] [CrossRef]

- Basavaraj, G.; Parthasarathy Rao, P.; Ravinder Reddy, C.; Ashok Kumar, A.; Srinivasa Rao, P.; Reddy, B. A Review of the National Biofuel Policy in India: A Critique of the Need to Promote Alternative Feedstocks. 2012. Available online: http://oar.icrisat.org/6520/1/WPS_34.pdf (accessed on 9 April 2017).

- de Gorter, H.; Just, D.R. The social costs and benefits of biofuels: The intersection of environmental, energy and agricultural policy. Appl. Econ. Perspect. Policy 2010, 32, 4–32. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Eco-Tax Reform. 2012. Available online: https://www.iea.org/policiesandmeasures/pams/germany/name-22079-en.php (accessed on 22 October 2018).

- Henke, J.M.; Klepper, G.; Schmitz, N. Tax exemption for biofuels in Germany: Is bio-ethanol really an option for climate policy? Energy 2005, 30, 2617–2635. [Google Scholar] [CrossRef]

- Wiesenthal, T.; Leduc, G.; Christidis, P.; Schade, B.; Pelkmans, L.; Govaerts, L.; Georgopoulos, P. Biofuel support policies in Europe: Lessons learnt for the long way ahead. Renew. Sustain. Energy Rev. 2009, 13, 789–800. [Google Scholar] [CrossRef]

- Bomb, C.; McCormick, K.; Deurwaarder, E.; Kåberger, T. Biofuels for transport in Europe: Lessons from Germany and the UK. Energy Policy 2007, 35, 2256–2267. [Google Scholar] [CrossRef]

- Statistica. Volume of Biodiesel Fuel Consumed in the Transport Sector in Germany from 1995 to 2016 (In Kilotons of Oil Equivalent). 2018. Available online: https://www.statista.com/statistics/489476/volume-of-biodiesel-fuel-consumed-in-transport-in-germany/ (accessed on 30 June 2018).

- Raunch, A.; Thone, M.; FiFo Institute. Biofuels—At What Cost? Mandating Ethanol and Biodiesel Consumption in the United Kingdom; International Institute for Sustainable Development: Winnipeg, MB, Canada, 2012; pp. 1–60. Available online: http://www.iisd.org/gsi/sites/default/files/bf_awc_germany.pdf (accessed on 15 September 2018).

- Union Zur Forderung von Oel- und Proteinpflanzen E.V. (UFOP). Report on the Current Situation and Prospects—Extract from the UFOP Annual Report. 2016. Available online: https://www.ufop.de/files/9314/5372/7521/WEB_Auszug_Biodiesel_2015_EN.pdf (accessed on 19 March 2018).

- Rusco, F. Biofuels Infrastructure in the United States: Current Status and Future Challenges. 2012. Available online: https://www.oecd.org/futures/Biofuels%20Infrastructure%20in%20the%20United%20States%20Current%20Status%20and%20Future%20Challenges.pdf (accessed on 1 December 2017).

- Energy Information Administration (EIA). Petroleum and Other Liquids. Available online: https://www.eia.gov/dnav/pet/pet_move_expc_a_EPOORDB_EEX_mbbl_m.htm (accessed on 8 December 2018).

- Energy Information Administration (EIA). U.S. Biodiesel Production Still Increasing Despite Expiration of Tax Credit. 2017. Available online: https://www.eia.gov/todayinenergy/detail.php?id=34152 (accessed on 23 December 2018).

- Chin, M. Biofuels in Malaysia: An Analysis of the Legal and Institutional Framework. 2011. Available online: https://hdl.handle.net/10568/20808 (accessed on 14 September 2018).

- Lim, S.; Teong, L.K. Recent trends, opportunities and challenges of biodiesel in Malaysia: An overview. Renew. Sustain. Energy Rev. 2010, 14, 938–954. [Google Scholar] [CrossRef]

- Minnesota Department of Agriculture. About the Minnesota Biodiesel Program. Available online: http://www.mda.state.mn.us/renewable/biodiesel/aboutbiodiesel.aspx (accessed on 5 January 2017).

- Colares, J.F. A Brief History of Brazilian Biofuels Legislation. SSRN. 2008. Available online: https://scholarlycommons.law.case.edu/cgi/viewcontent.cgi?article=1169&context=faculty_publications (accessed on 15 May 2017).

- Nass, L.L.; Pereira, P.A.A.; Ellis, D. Biofuels in Brazil: An overview. Crop Sci. 2007, 47, 2228–2237. [Google Scholar] [CrossRef]

- Skidmore, T.E. The Politics of Military Rule in Brazil 1964-85; Oxford University Press: New York, NY, USA, 1989. [Google Scholar]

- Hira, A.; de Oliveira, L.G. No substitute for oil? How Brazil developed its ethanol industry. Energy Policy 2009, 37, 2450–2456. [Google Scholar] [CrossRef]

- Ziolkowska, J.; Meyers, W.; Meyer, S.; Binfield, J. Targets and Mandates: Lessons Learned from EU and US Biofuels Policy Mechanisms. AgBioForum 2010, 13, 398–412. [Google Scholar] [CrossRef]

- European Commision. National Action Plans. Available online: https://ec.europa.eu/energy/en/topics/renewable-energy/national-action-plans (accessed on 19 December 2018).

- Bozbas, K. Biodiesel as an alternative motor fuel: Production and policies in the European Union. Renew. Sustain. Energy Rev. 2008, 12, 542–552. [Google Scholar] [CrossRef]

- Gheewala, S.H.; Damen, B.; Shi, X. Biofuels: Economic, environmental and social benefits and costs for developing countries in Asia. Wiley Interdiscip. Rev. Clim. Chang. 2013, 4, 497–511. [Google Scholar] [CrossRef]

- Charles, C.; Gerasimchuk, I.; Bridle, R.; Moerenhout, T.; Asmelash, E.; Laan, T. A Review of Costs and Benefits of o f EU Biofuel Policies; International Institute for Sustainable Development: Winnipeg, MB, Canada, 2013; pp. 23–25. [Google Scholar]

- Gee, S.; McMeekin, A. Eco-Innovation Systems and Problem Sequences: The Contrasting Cases of US and Brazilian Biofuels. Ind. Innov. 2011, 18, 301–315. [Google Scholar] [CrossRef]

- Zapata, C.; Nieuwenhuis, P. Driving on liquid sunshine—The brazilian biofuel experience: A policy driven analysis. Bus. Strateg. Environ. 2009, 18, 528–541. [Google Scholar] [CrossRef]

- Goldemberg, J.; Coelho, S.T.; Nastari, P.M.; Lucon, O. Ethanol learning curve—The Brazilian experience. Biomass Bioenergy 2004, 26, 301–304. [Google Scholar] [CrossRef]

- Solomon, B.D.; Krishna, K. The coming sustainable energy transition: History, strategies, and outlook. Energy Policy 2011, 39, 7422–7431. [Google Scholar] [CrossRef]

- Lehtonen, M. Social sustainability of the Brazilian bioethanol: Power relations in a centre-periphery perspective. Biomass Bioenergy 2011, 35, 2425–2434. [Google Scholar] [CrossRef]

- Proc, K.; Barnitt, R.; Hayes, R.R.; Ratcliff, M.; McCormick, R.L. 100,000-Mile Evaluation of Transit Buses Operated on Biodiesel Blends (B20); SAE Technical Paper; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Barnitt, R.; McCormick, R.; Lammert, M. St. Louis Metro Biodiesel (B20) Transit Bus Evaluation. 2008. Available online: https://www.nrel.gov/docs/fy08osti/43486.pdf (accessed on 13 April 2017).

- Greater London Authority The Mayor’s Biodiesel Programme. 2015. Available online: https://www.london.gov.uk/sites/default/files/gla_-_biodiesel_operational_note_june_2015_0.pdf (accessed on 19 December 2017).

- Gaeta-Bernardi, A.; Parente, V. Organic municipal solid waste (MSW) as feedstock for biodiesel production: A fi nancial feasibility analysis. Renew. Energy 2016, 86, 1422–1432. [Google Scholar] [CrossRef]

- Balat, M. Potential alternatives to edible oils for biodiesel production—A review of current work. Energy Convers. Manag. 2011, 52, 1479–1492. [Google Scholar] [CrossRef]

- Canakci, M.; Sanli, H. Biodiesel production from various feedstocks and their effects on the fuel properties. J. Ind. Microbiol. Biotechnol. 2008, 35, 431–441. [Google Scholar] [CrossRef] [PubMed]

- Gui, M.M.; Lee, K.T.; Bhatia, S. Feasibility of edible oil vs. non-edible oil vs. waste edible oil as biodiesel feedstock. Energy 2008, 33, 1646–1653. [Google Scholar] [CrossRef]

- Karmee, S.K.; Patria, R.D.; Sze, C.; Lin, K. Techno-Economic Evaluation of Biodiesel Production from Waste Cooking Oil—A Case Study of Hong Kong. Int. J. Mol. Sci. 2015, 16, 4362–4371. [Google Scholar] [CrossRef]

- Barnwal, B.K.; Sharma, M.P. Prospects of biodiesel production from vegetable oils in India. Renew. Sustain. Energy Rev. 2005, 9, 363–378. [Google Scholar] [CrossRef]

- Coelho, S.T.; Goldemberg, J.; Lucon, O.; Guardabassi, P. Brazilian sugarcane ethanol: Lessons learned. Energy Sustain. Dev. 2006, 10, 26–39. [Google Scholar] [CrossRef]

- Christensen, E.; McCormick, R.L. Long-term storage stability of biodiesel and biodiesel blends. Fuel Process. Technol. 2014, 128, 339–348. [Google Scholar] [CrossRef]

- SAE. Biodiesel in Automotive Application. Lessons Learned. 2014. Available online: https://global.ihs.com/doc_detail.cfm?item_s_key=00640279 (accessed on 9 January 2017).

- Shahid, E.M.; Jamal, Y. A review of biodiesel as vehicular fuel. Renew. Sustain. Energy Rev. 2008, 12, 2477–2487. [Google Scholar] [CrossRef]

- Mofijur, M.; Masjuki, H.H.; Kalam, M.A.; Hazrat, M.A.; Liaquat, A.M.; Shahabuddin, M.; Varman, M. Prospects of biodiesel from Jatropha in Malaysia. Renew. Sustain. Energy Rev. 2012, 16, 5007–5020. [Google Scholar] [CrossRef]

- Pramanik, K. Properties and use of jatropha curcas oil and diesel fuel blends in compression ignition engine. Renew. Energy 2003, 28, 239–248. [Google Scholar] [CrossRef]

- Lane, J. Biofuels Mandates Around the World: 2016. Available online: http://www.biofuelsdigest.com/bdigest/2016/01/03/biofuels-mandates-around-the-world-2016/ (accessed on 18 December 2016).

- Union Zur Forderung von Oel- und Proteinpflanzen E.V. (UFOP). Commercial vehicle manufacturer approvals on using biodiesel (B100). 2010. Available online: https://www.ufop.de/files/3813/3940/7470/201006_Biodiesel_approvals_B100.pdf (accessed on 21 March 2018).

- Gärtner, S.O.; Reinhardt, G.A. Biodiesel Initiatives in Germany. 2005. Available online: https://www.ifeu.de/landwirtschaft/pdf/premia-biodiesel-germany.pdf (accessed on 16 September 2018).

- Archer Daniels Midland Company. Biodiesel Technical Information; Archer Daniels Midland Company: Chicago, IL, USA, No accurate publication date.

- Scharffbillig, J.; Clark, E. A Biodiesel Blend Handling Guide. Minnesota Biodiesel Technical Cold Weather Issues Team Handling Subcommittee. 2014. Available online: http://www.cleanairchoice.org/pdf/MNBiodieselBlendHandlingGuide.pdf (accessed on 12 December 2017).

- Lam, M.K.; Lee, K.T.; Mohamed, A. Life cycle assessment for the production of biodiesel: A case study in Malaysia for palm oil versus jatropha oil. Biofuels Bioprod. Biorefining 2009, 3, 601–612. [Google Scholar] [CrossRef]

- Markel, E.; Sims, C.; English, B.C. Policy uncertainty and the optimal investment decisions of second-generation biofuel producers. Energy Econ. 2018, 76, 89–100. [Google Scholar] [CrossRef]

- Basha, S.A.; Gopal, K.R.; Jebaraj, S. A review on biodiesel production, combustion, emissions and performance. Renew. Sustain. Energy Rev. 2009, 13, 1628–1634. [Google Scholar] [CrossRef]

- Wang, W.G.; Lyons, D.W.; Clark, N.N.; Gautam, M.; Norton, P.M. Emissions from nine heavy trucks fueled by diesel and biodiesel blend without engine modification. Environ. Sci. Technol. 2000, 34, 933–939. [Google Scholar] [CrossRef]

- Pradeep, V.; Sharma, R.P. Use of HOT EGR for NOx control in a compression ignition engine fuelled with bio-diesel from Jatropha oil. Renew. Energy 2007, 32, 1136–1154. [Google Scholar] [CrossRef]

- Chang, D.Y.Z.; Van Gerpen, J.H.; Lee, I.; Johnson, L.A.; Hammond, E.G.; Marley, S.J. Fuel properties and emissions of soybean oil esters as diesel fuel. JAOCS J. Am. Oil Chem. Soc. 1996, 73, 1549–1555. [Google Scholar] [CrossRef]

- Schumacher, L.; Borgelt, S.; Hires, W.; Wetherell, W.; Nevils, A. 100,000 Miles of Fueling 5.9 L Cummins Engines with 100% Biodiesel; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1996. [Google Scholar]

- Szybist, J.P.; Boehman, A.L.; Taylor, J.D.; McCormick, R.L. Evaluation of formulation strategies to eliminate the biodiesel NO x effect. Fuel Process. Technol. 2005, 86, 1109–1126. [Google Scholar] [CrossRef]

- Peterson, C.L.; Reece, D.L.; Thompson, J.C.; Beck, S.M.; Chase, C. Ethyl ester of rapeseed used as a biodiesel fuel—A case study. Biomass Bioenergy 1996, 10, 331–336. [Google Scholar] [CrossRef]

- McDonald, J.; Purcell, D.; McClure, B.; Kittelson, D. Emissions Characteristics of Soy Methyl Ester Fuels in an IDI Compression Ignition Engine; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1995. [Google Scholar]

- Yusuf, N.N.A.N.; Kamarudin, S.K.; Yaakub, Z. Overview on the current trends in biodiesel production. Energy Convers. Manag. 2011, 52, 2741–2751. [Google Scholar] [CrossRef]

- Li, H.; Song, C.; Lv, G.; Pang, H.; Qiao, Y. Assessment of the impact of post-injection on exhaust pollutantsemitted from a diesel engine fueled with biodiesel. Renew. Energy 2017, 114, 924–933. [Google Scholar] [CrossRef]

- Tan, P.; Hu, Z.; Lou, D.; Li, Z. Exhaust emissions from a light-duty diesel engine with Jatropha biodiesel fuel. Energy 2012, 39, 356–362. [Google Scholar] [CrossRef]

- Osborne, D.; Fritz, S.; Glenn, D. The Effects of Biodiesel Fuel Blends on Exhaust Emissions From a General Electric Tier 2 Line-Haul Locomotive. J. Eng. Gas Turbines Power 2011, 133, 102803. [Google Scholar] [CrossRef]

- de L.T. Oliveira, G.; McKay, B.; Plank, C. How biofuel policies backfire: Misguided goals, inefficient mechanisms, and political-ecological blind spots. Energy Policy 2017, 108, 765–775. [Google Scholar] [CrossRef]

- Nuñez, H.M.; Önal, H. An economic analysis of transportation fuel policies in Brazil: Fuel choice, land use, and environmental impacts. Energy Econ. 2016, 55, 319–331. [Google Scholar] [CrossRef]

- Saravanan, A.P.; Mathimani, T.; Deviram, G.; Rajendran, K.; Pugazhendhi, A. Biofuel policy in India: A review of policy barriers in sustainable marketing of biofuel. J. Clean. Prod. 2018, 193, 734–747. [Google Scholar] [CrossRef]

- Kumar Biswas, P.; Pohit, S. What ails India’s biodiesel programme? Energy Policy 2013, 52, 789–796. [Google Scholar] [CrossRef]

- Han, H.; Zongwei, L.; Fuquan, Z.; Jingzheng, R.; Shiyan, C.; Ke, R.; Jiuyu Dua, E. Biofuel for vehicle use in China: Current status, future potential and policy implications. Renew. Sustain. Energy Rev. 2018, 82, 645–653. [Google Scholar] [CrossRef]

- European Commission. Renewable Energy Directive 2009/28/EC; European Commission: Brussels, Belgium, 2009. [Google Scholar]

- Khanna, M.; Nuñez, H.M.; Zilberman, D. Who pays and who gains from fuel policies in Brazil? Energy Econ. 2016, 54, 133–143. [Google Scholar] [CrossRef]

- Thompson, W.; Whistance, J.; Meyer, S. Effects of US biofuel policies on US and world petroleum product markets with consequences for greenhouse gas emissions. Energy Policy 2011, 39, 5509–5518. [Google Scholar] [CrossRef]

- Lapan, H.; Moschini, G.C. Second-best biofuel policies and the welfare effects of quantity mandates and subsidies. J. Environ. Econ. Manag. 2012, 63, 224–241. [Google Scholar] [CrossRef]

- Babcock, B.A. Mandates, Tax Credits, and Tariffs: Does the U.S. Biofuels Industry Need Them All? 2010. Available online: https://lib.dr.iastate.edu/cgi/viewcontent.cgi?article=1000&context=card_policybriefs (accessed on 2 January 2019).

- Fritz, S.G. Evaluation of Biodiesel Fuel in an EMD GP38-2 Locomotive; National Renewable Energy Laboratory: Golden, CO, USA, 2005.

- Sze, C.; Whinihan, J.; Olson, B.; Schenk, C.; Sobotowski, R. Impact of Test Cycle and Biodiesel Concentration on Emissions; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- Prueksakorn, K.; Gheewala, S.H.; Malakul, P.; Bonnet, S. Energy analysis of Jatropha plantation systems for biodiesel production in Thailand. Energy Sustain. Dev. 2010, 14, 1–5. [Google Scholar] [CrossRef]

- Whitaker, M.; Heath, G. Life Cycle Assessment Comparing the Use of Jatropha Biodiesel in the Indian Road and Rail Sectors Life Cycle Assessment Comparing the Use of Jatropha Biodiesel in the Indian Road and Rail Sectors; National Renewable Energy Laboratory: Golden, CO, USA, 2010; p. 143.

- Sharma, A.; Strezov, V. Life cycle environmental and economic impact assessment of alternative transport fuels and power-train technologies. Energy 2017, 133, 1132–1141. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).