1. Introduction

There are many elements that promote local development, and these are also strongly related to the endogenous resources available in a territory. This concept is defined by The United Nations Development Program as a place in which the interests, the identity and culture of a community converge, i.e., a place where actions and economic relations take place [

1,

2]. However, the strategies for the local economic development [

3,

4] consider a territory to be an agent for social transformation, and not only as a place where its social, cultural, and historical features are important aspects.

Technological progress, as an agent of change towards social and economic development [

4], is of great importance to local development. Moreover, nine categories are usually used to define synergetic capital [

5] (economic, human, cognitive, symbolic, cultural, institutional, social, psychosocial, and civic capital). These elements and their coordinated action within the public and private sectors are also referred to as local development enhancers [

6].

Regarding the globalization process, local society has delayed in adapting to recent leading processes and transformations. Based on their intrinsic social, economic, and political territorial features, some initiatives have been proposed [

7]. All this relies on the concept of development, which has been evolving over time, to the point of being part of theories that will be presented here, together with some perspectives related to this study. Nonetheless, choosing local development requires achieving consolidation of leading nations and communities. In this regard, some investigations have claimed that progress does not follow a linear relation, since it relies upon the historical moment and the perception of reality. Therefore, people might appeal to the exploitation of endogenous resources through the creation of inclusive production chains with clear goals toward local development [

8]. In addition, other authors refer to local development as a system constituted by actors (men and women) with specific roles and features that develop interrelated and interdependent activities surrounding the evolution of a product, from its production to its consumption, to further local development [

9]. To do this, a series of development strategies that contemplate economic and non-economic dimensions [

10] must be established. Considering the aforementioned, local development can be understood as a set of actions that, taken from inside the territory, improve the incomes, the employment opportunities, and the quality of life of its inhabitants [

11].

Nowadays, several products are submitted to drying processes for volume/weight reduction or for preservation purposes [

12]. The latter is essential to ensure high-quality products for international markets, although non-traditional drying processes are preferred. This is because when food is exposed to drying processes, its nutritional properties tend to be reduced. This is especially true for fruits whose organoleptic properties (color, flavor, smell, and texture) can be lost easily [

13]. In fact, the lyophilization technique is the most viable method for this purpose, but it significantly increases the production costs [

14]. On the other hand, it has been proven that industrial development based on agricultural activity plays a crucial role in the economic development of a country [

15]. In fact, several agricultural industries have accelerated their growth by directing their production towards exportation. This creates employment opportunities for rural and urban inhabitants [

16], including non-agricultural activities such as processing, handling, packaging, among others [

17,

18]. Hence, the industrial development based on agricultural activities has a significant impact on the economic development of urban communities, especially rural ones [

16].

Regarding the lucuma fruit, it is originally from the Peruvian Andean valleys, having as its main features a delicious flavor and a wealth of vitamins. In addition, chroniclers and historians have reported the abundance of lucuma in ancient Peru, finding evidence of its cultivation in clay-shaped representations from the Mochica civilization (2nd to 7th century). This clearly shows how important the fruit was in the diets of ancient inhabitants from the coast and Andean regions of Peru. Within a recent context [

19], it has been mentioned that outside Peru, lucuma is not well-known, and has a low demand. This is reflected in the current exportation rates. For example, in 2017, US

$1,241,267 worth of lucuma was exported, which represents a slight increase from the US

$1,186,022 worth exported in 2016. Here, the United States is the country with the highest demand for the fruit, followed by the United Kingdom, Portugal, Germany, the Netherlands and Australia [

20]. This fact clearly shows the lack of exportable product volume and the standardization of competitive prices to identify international markets that need, accept and demand the fruit.

Within the regional context, the production status of lucuma is bleak, since farmers have not been sowing this fruit, restricting this activity to the regions of Lima, Ica, Arequipa and La Libertad, where production is mainly for exportation as fruit or frozen pulp. Besides this fact, lucuma production is still considered scarce due to the lack of an advertisement and especially for not giving it an added value to increase its value both in domestic and international markets. Moreover, there are several deficiencies in most of the regions where this fruit is sown, including poor land management by local, regional, and federal authorities, and alternative use of land such as the extraction of soil to fabricate bricks.

Socio-economic development is framed as what is known as sustainable development. This socio-economics paradigm relies on the basics of economic activities that seek to overcome the basic economic problem, i.e., the scarcity of resources against growing societal needs. Thus, it is desirable to stimulate the creation of companies that satisfy the criteria of sustainability. Moreover, local development is defined as a process of economic, social, and environmental improvement of a region, starting from the employment of endogenous resources to improve the quality of life of the population [

21]. To date, several proposals for sustainable cities have been made [

22], as well as referential initiatives that generate sustainable impacts on farmers [

23], which reinforces the idea of betting on sustainable production.

In fact, the low lucuma production is not enough to supply the increasing international demand, which seeks the fruit in its dehydrated form and with high standards of quality.

The present study seeks to spotlight the current production and commercialization indices of a native Peruvian fruit, the lucuma (Pouteria Lucuma), which has an increasing international demand. For this purpose, the production records of the last twelve years were used, paying special attention to the economic impact over the producer population and the hypothetical impact if measures redirected to provide value are adopted. To do that, some factors, such as an increase in sowing and the implementation of an innovative and sustainable production system, were analyzed; a set of strategies to involve Peruvian farmers in the recovery of the sowing activities of lucuma were also implemented, as well as novel innovative ideas to generate sustainable business development, and consequently, consolidate their products in international markets. In addition, we proposed the use of an innovative system for solar dehydration, able to preserve the organoleptic properties of lucuma and significantly lessen the production costs, while implementing the use of clean technologies.

2. Materials and Methods

This study contains several strategies and methods to address the past/current status of the sowing of lucuma (

Pouteria Lucuma), whose activity has been losing relevance despite its nutritional properties and excellent flavor. Currently, the fruit is well-received in Europe and Asia [

24], which clearly spotlights its high demand. However, only a few regions in Peru grow this fruit. Considering this, it is important to increase farmer’s awareness with respect to the recovery and transformation of the lucuma and, subsequently, give it added value. The transformation of the product relies on the process of dehydration, which would be aided by the innovative and sustainable process that is proposed in this study. The dehydration equipment allows the production of high-quality products while preserving their organoleptic properties (color, flavor, smell, and texture). Moreover, because keeping a product under conditions of minimal moisture can greatly increase its lifetime, foreign companies are primarily interested in dehydrated products [

25]. This fact motivates the redirection of the products to the international market, permitting sustainable development and, consequently, the improvement of the social and economic status of the producers.

Based on the available data from the Peruvian Ministry of Agriculture and Irrigation (MINAGRI, its acronym in Spanish) and the National Institute of Statistics and Informatics (INEI, for its acronym in Spanish) [

26], the trend for the fruit’s scarcity in the face of high international demand has been identified. Therefore, stimulating its recovery requires the establishment of a series of strategies that consider different product sales scenarios, the use of available technology to dry the fruits, and their corresponding economic viability and sustainability. To this end, a multi-criteria methodology (TEFESAL) is employed. This evaluates, simultaneously, alternatives with respect to their degree of success for each established objective as a function of weighted criteria. Their results highlight technological proposals characterized as being innovative for the export market [

27]. The export-related projection used the sensitivity analysis approach, which considers the following variables: production growth, processing costs, manpower, and taxes, among others, which clearly highlights the real context and current trends analyzed by our model. The model also provides information regarding the set of strategies a Peruvian producer must follow to achieve profitability.

2.1. Techniques and Tools

2.2. Methods

2.2.1. Multi-Criteria Approach. TEFESAL Analysis

As previously mentioned, the multi-criteria approach enables us to simultaneously evaluate alternatives considered in the study as a function of the degree of success and their established objectives. This is achieved by quantifying a function through a specific weight, and the ordering of the considered options.

The method consists of the following: “A”, being the axiomatic set of options to consider:

and “C”, being the axiomatic set of evaluation criteria:

Each evaluation criterion possesses a field (numeric, i.e., from 0 to 100; ordinals, i.e., 1st, 2nd, 3rd, etc.).

If an application of the set “A” is done in

, it is possible to assign the evaluation

of the alternative

to the criteria

, and obtain a matrix with the following form:

| | | | |

| | | |

| … | … | … | … |

| … | … | … |

During the process of multi-criteria analysis, four phases can be distinguished: (a) definition of axiomatic set of alternatives, (b) setting of objectives, criteria and indices, (c) partial evaluation of each alternative as a function of each criterion, (d) adding of the partial evaluations as a function of the previously weighted criteria.

In this study, we use the criteria (T) = Technical, (E) = Economic, (F) = Financial, (E) = Environmental, (S) = Social, (A) = Administrative, and (L) = Legal, which form the abbreviation “TEFESAL”, in which the most viable option is assigned for the highest obtained punctuation, whose weights and results are shown in

Table 1 and

Table 2.

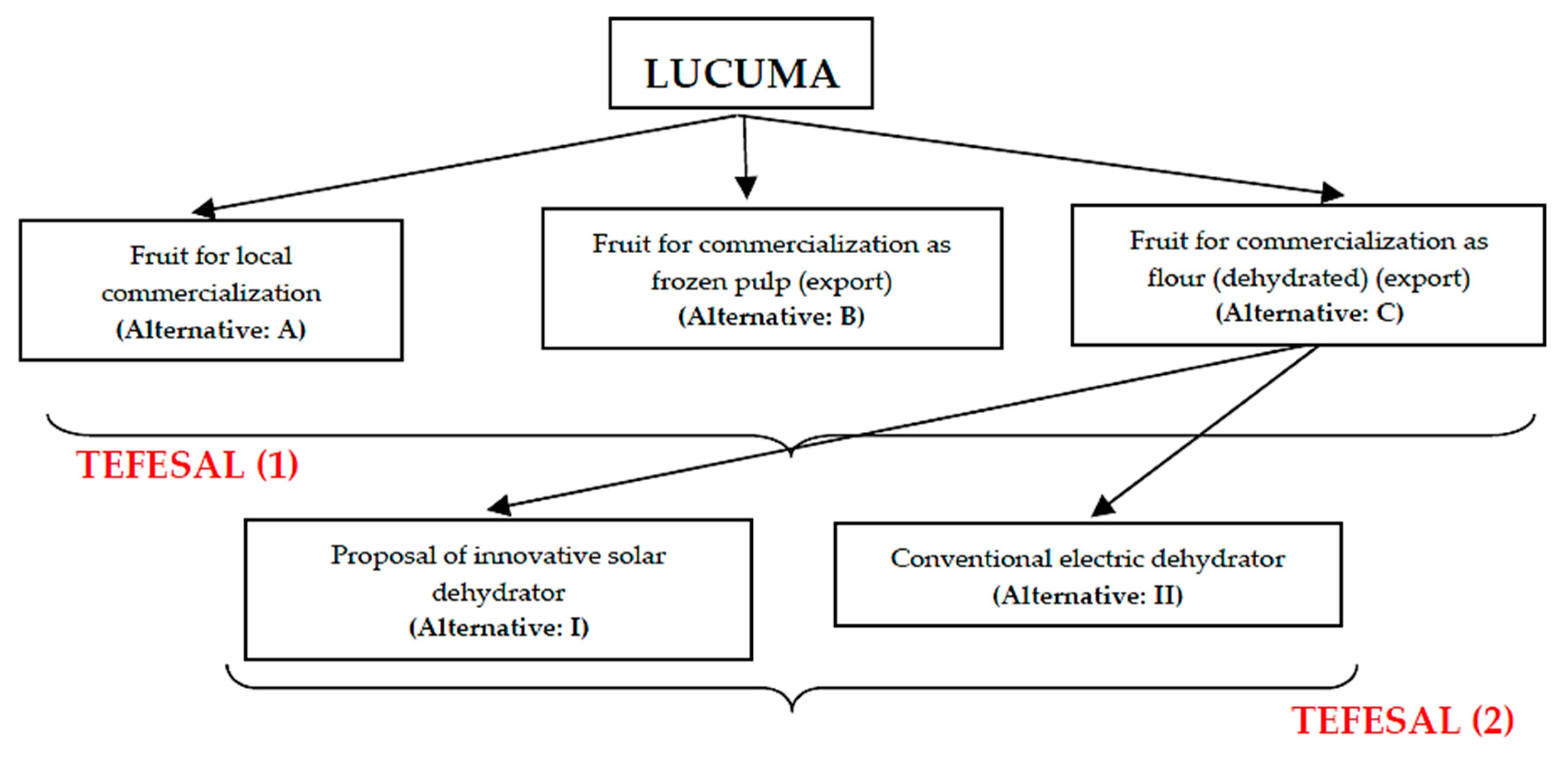

In the present work, following the scheme below, two fundamental characteristics are analyzed (see

Figure 1):

2.2.2. Sensitivity Analysis Approach

Sensitivity analysis is the first step taken to identify eventual uncertainties. This is crucial, since we are interested in exploring how the change in one variable might affect the overall result. Additionally, one can identify the most critical variables or build possible scenarios that enable the analysis of the results under different assumptions [

29]. In short, the sensitivity analysis allows us to measure the change in a result, given a change in a set of variables, both in relative and absolute terms. It also improves the quality of the information so that, for instance, an investor possesses additional tools that take into account risks and possible profits to better decide whether or not to invest in a project [

27].

The importance of this approach relies on the fact that it provides a referential scenario that can be used to compare future alternatives based on different strategies for energetic and agro-export policies related to lucuma and its transformation into flour for export. Therefore, the model seeks to predict the profitability of the production process of lucuma flour, as well as to evaluate the uncertainties related to the model to guarantee its reliability and identify eventual variabilities in the model. To do so, we considered input parameters, some of them quite variable, such as the number of trees sown as a function of lucuma production. We also consider fixed and variable costs in the productive system (previously identified).

The analysis was carried out using the centered finite difference scheme. Thus, the initial values (the most likely or frequent) are set up to later introduce parameters based on averaged statistical data according to each particular case. Moreover, each input parameter is subject to minor changes, while other input parameters remain constant to their nominal values. Any change in the output is used to compute the sensitivity coefficients, represented by partial derivatives of the output with respect to the input parameters around their nominal values. For a model with “m” input parameters and only one output, the sensitivity coefficients can be computed as:

where “y” is the output variable, “kj” is j-th input parameter and (kj + Δkj) and (kj − Δkj) represent the value “y” when the input parameter “kj” changes in “Δkj”. The precision of the computed sensitivities depends on the change “Δkj”. In this study, we consider one input parameter (m = 1) and seven output variables to map out the increase in profitability of the operation. The standardized sensitivity coefficients (Sj) are computed to ensure that the sensitivity results are independent of the model’s units as well as to enable the comparison between the effects of different input parameters. The “Sj” represent the percentage rate of the most sensitive variables (seven variables) as a consequence of the percentage rate in the input parameters that oscillate from ±20% to ±50%, depending on the standard deviations of the statistical sample. Microsoft Excel was used to analyze these parameters.

3. Results

This section is divided in three parts: In the first one, we deal with the statistical data treatment, paying attention to the current circumstances of the fruit, especially in its production and current market cost. The second part is based on the results collected from the multi-criteria approach TEFESAL (1–2). There, it is proposed to transform the fruit into a dehydrated product, by using innovative solar dehydration equipment that preserves its organoleptic properties. Finally, we analyze the viability of exporting the dehydrated product by means of the sensitivity analysis approach, which considers production indices, fixed and variable costs, and logistics costs, among other things.

3.1. Recovering the Traditional Cultivation of Lucuma

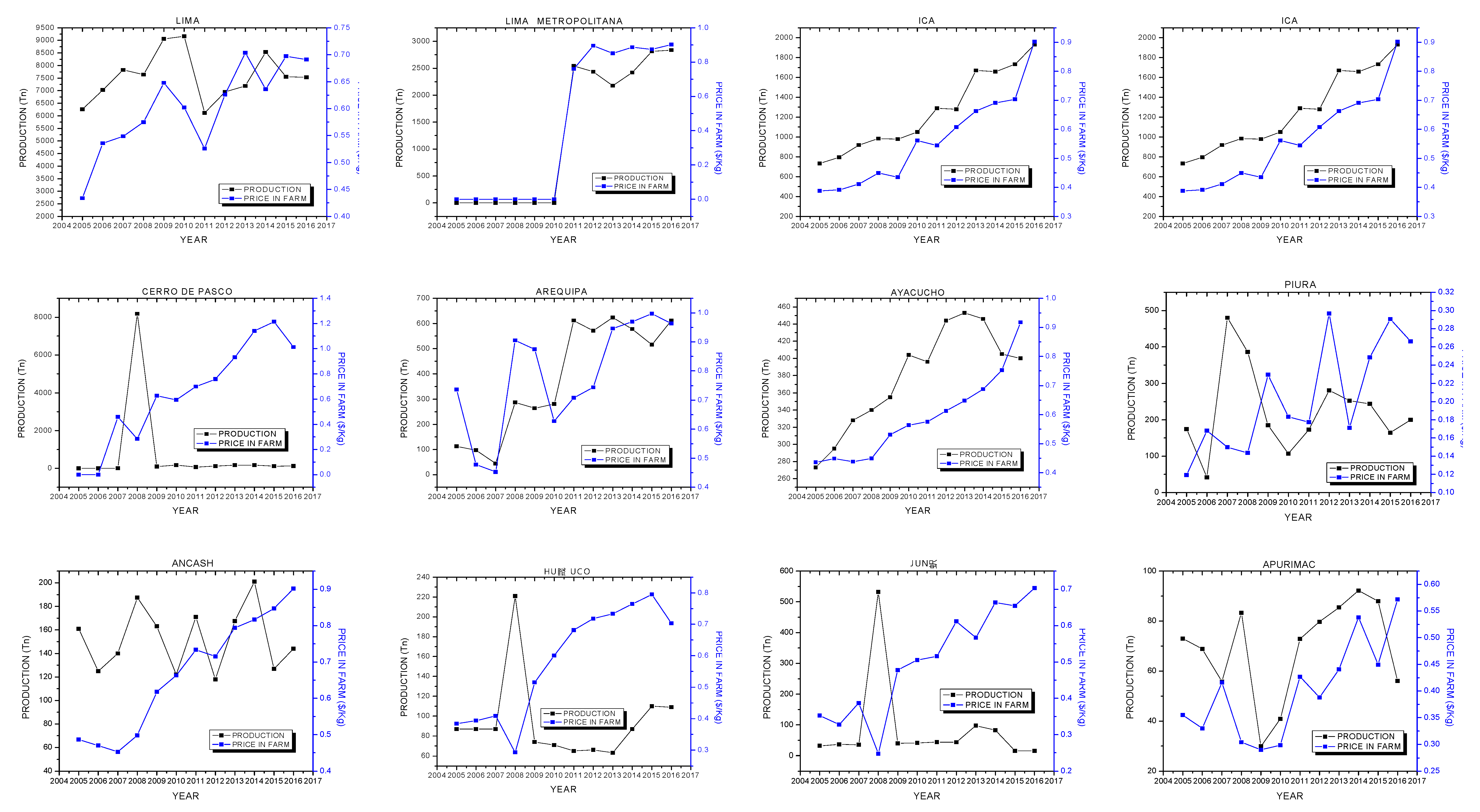

To date, the production of Lucuma has been restricted to seventeen Peruvian regions (of the twenty-four in total), with the Lima region being responsible for the highest production. In addition to this, in recent years, Lima’s annual production has decreased, while other regions have reported slow growth over the past fourteen years. Utilizing the data from the Peruvian department of agriculture and irrigation, we created graphics of the annual variation of production as a function of the sales price for the twelve biggest lucuma producing regions (

Figure 2).

According the Ministry of Agriculture and Irrigation (MINAGRI), in the last twelve years, Peru has produced, on average, 12,637.33 TN of lucuma, which corresponds to a harvested area of 1453.25 ha (representing 0.020% of the national agricultural area).

Considering the vast amount of agricultural land intended for other crops (99.98% of the national agricultural area), and the deficient production of lucuma, here we propose using the available areas between cultivation fields. Therefore, we estimated through the Google Earth measurement tools, the total perimeter length of cultivation fields in the regions dedicated exclusively to crops, obtaining a value of 2,047,321.56 meters, with 0.1% margin of error. Our proposal is based on the fact that each tree must have a distance of 4 meters with respect to its neighbor, having an additional zigzag distribution. This is suggested to guarantee the appropriate solar exposition and root distribution.

In addition, according the data of MINAGRI, each lucuma tree produces, on average, 500 fruits per year (between January and May), which is proportionally equivalent to producing 100 fruits per month. Also, through the produced net mass data (12,637.33 Tn, and the average mass of a single fruit), we estimate the number of lucuma trees currently existing, obtaining 84,249.

Considering the current production data for lucuma (mass in TN), we performed a comparative analysis of the first three situations considered in the TEFESAL approach. Thus, we refer to the following possibilities:

Multi-Criteria Analysis-TEFESAL (1)

- ➢

ALTERNATIVE A: Use of the fruit for commercialization in local markets.

Where the current lucuma sale price per kilogram is about US$0.80 (Ministry of Agriculture and Irrigation (MINAGRI), (2018). Statistical data of production and sales prices in Peru). Assuming a total mass of 12,637,330 kg, we obtain a total sale amount of US$10,109,864.

Based on these results, we noted that if a farmer currently sells a product to local markets, they may receive a gross annual income (total gross sale or annual gross income. This refers to the net income without excluding the production costs) of US$10,109,864, during a productive year (7 remaining months after the harvest). This would mean an average monthly income of US$1,444,266.29. Please note that this income does not belong to a single population, it is the net income applicable at the level of the 17 regions that produce this fruit.

- ➢

ALTERNATIVE “B”: Use of the fruit for commercialization as frozen pulp abroad (exportation).

Where the current lucuma pulp sales price per kilogram is about US

$4.51 (Foreign import company: “El Inti, the Peruvienne boutique”. (

www.boutique-peruvienne.com)). For a total mass of 12,637,330 kg, we obtain a total sale amount of US

$56,994,358.3.

In this case, the increase in the gross total of alternative “A” by 5.63 times is noticeable. Nevertheless, we should mention that the production cost to process the fruit using this approach is relatively high, since refrigeration equipment is used. One should also consider the fixed and variable costs that this approach implies. As in the previous case, this net value does not apply to one person, but a set of people whose total production reaches the calculated value.

- ➢

ALTERNATIVE “C”: Use of the fruit for commercialization as flour abroad (dehydrated) (export).

The current sale price per kilogram of lucuma flour is US

$18 (Foreign import company from Spain,

http://www.naturitas.es (Retrieved on: 12 November 2018)). Nonetheless, one must consider the net mass, which can be estimated by knowing that the mass reduction is 61.1%, due to the moisture removal of the product. With that in mind, this results in a net mass of 5,042,294.7 kg, which represents total gross sales of US

$90,761,305.

For this alternative, the production costs are much lower than in case “B”, due to the fact that the solar equipment does not demand expensive initial costs, although another production cost exists that will be described later. In addition to that, we compare the gross sales, obtaining an increase by 1.59 times with respect to case “B” and 8.97 times compared to case “A”. This clearly highlights the benefits of alternative “C”.

By employing adapted data for the multi-criteria analysis TEFESAL (I), in

Table 1, we show the computed results for each case. Use of the fruit for its commercialization as flour (dehydrated) for export was the chosen alternative (highest score).

Option “C” generates different opportunities for use with this kind of merchandise, which possesses similar conditions to the merchandise currently commercialized and with only slightly less desirable physical characteristics.

Considering the costs and profitability, we can select this alternative as the most viable, since it permits a reduction in costs and environmental impact which certainly improves local development.

3.2. INNOVATION: Solar Dehydration of Lucuma

By taking advantage of Peru’s solar potential, we propose an innovative solar dehydration model that generates a product of high quality that adheres to export standards (certified by Codex Alimentarius) and, at the same time, is able to reduce costs and environmental impact.

Several studies have demonstrated that use of conventional models of dryers and solar dehydrators adversely affects the product’s taste and vitamin quantity, a fact that motivates the novel proposal of innovative solar dehydrator systems.

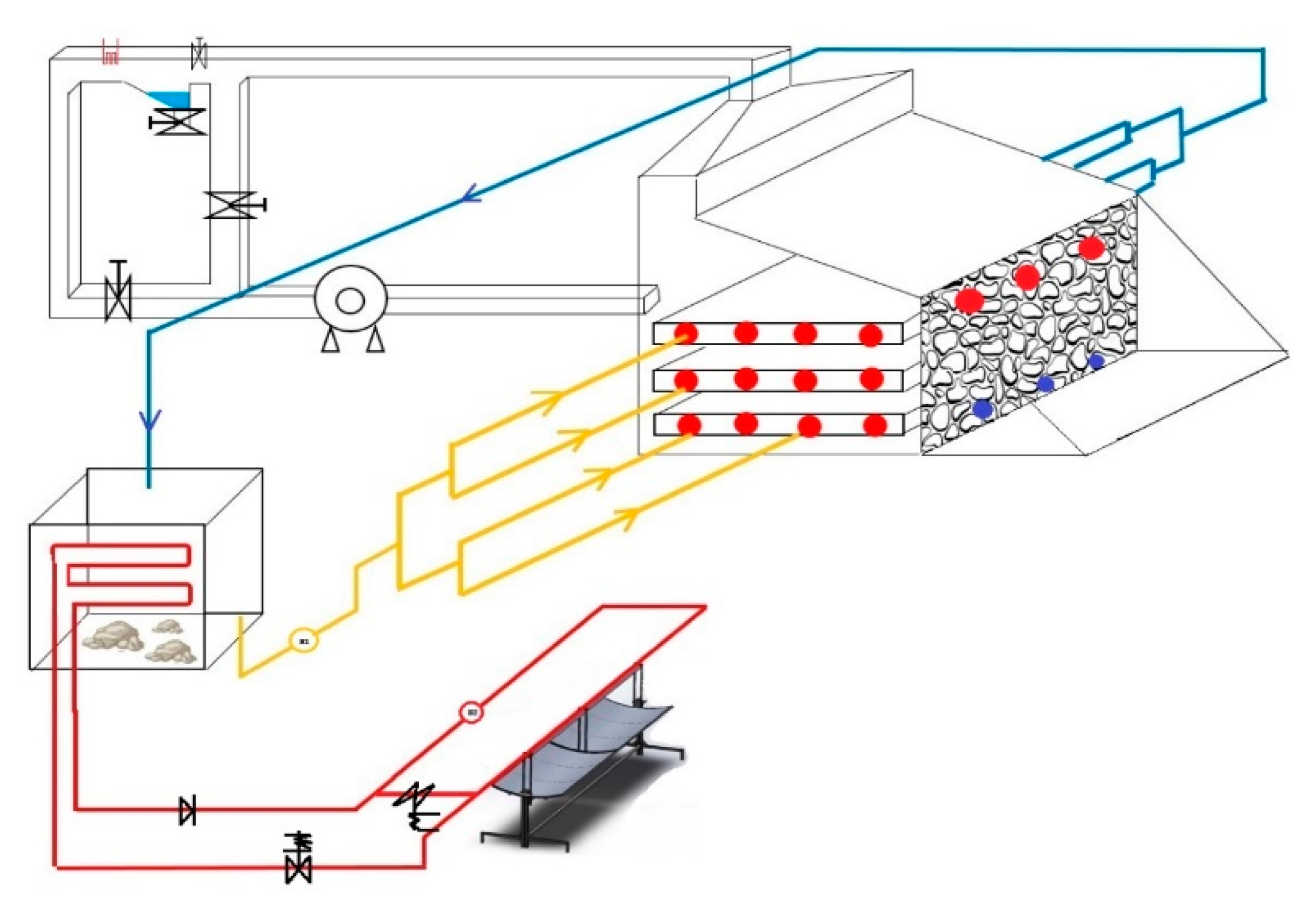

3.2.1. Proposal for an Innovative Solar Dehydrator Model

We propose a solar system that dehydrates the lucuma while keeping its organoleptic properties (texture, color, flavor and smell) [

13], which are in demand in international markets, almost intact.

Through a physical study, we developed a novel system (Patent number N° P201731235) that increases the productivity levels of dehydrated fruits and uses calorific energy by means of a cylindrical parabolic collector (CPC) and a Trombe wall. The latter has the capability to heat a wall of stones that acts as a battery of thermal energy, a phenomenon similar to the greenhouse effect. The wall of stones, when heated, emits infrared radiation to the internal air medium. Since this kind of radiation transmits only low-energy rates, it is mainly accumulated in the internal region of the chamber (since it does not have enough energy to be transmitted through the walls), and as a consequence, the heat increases and can be stored to later be released to the dehydration chamber.

To obtain a quality product, we incorporate a “Thermobank”, which stores the calorific energy emitted by the CPC, and thus provides a controlled temperature of 60 °C to the dehydrated chamber, allowing gradual dehydration. Later, the lucuma’s pellets start to release their moisture, which is then redirected to a controlled condensation system. The Trombe wall process is performed several times during a day, as it works as a calorific energy source. Since the wall of stones emits calorific energy continuously during the drying process, the product is able to preserve its organoleptic properties. This process is monitored through temperature and humidity sensors (

Figure 3).

On the basis of thermodynamics, we are able to get the amount of calorific energy, in watts/hour, that each system obtains. The Trombe wall emits 420 W/h and the CPC a total of 202.22 W/h. These results will be used later to analyze the production viability further.

It should be noted that the calculations presupposed a system working eight hours a day for seven months (number of months where there is no production). Thus, a total of 182 production days were estimated for the transformation process (June–December, excluding weekends which are non-working days according to Peruvian legislation).

Considering the average production for five months (January–May) over the last twelve years, i.e., 12,637.33 Tn (12,637,330 kg), and considering that during the dehydration process, the fruit would lose up to 60.1% of its mass as moisture, the estimated net mass is 5,042,294.67 kg (lucuma flour), which represents the quantity used for commercialization purposes. In what follows, we detail some calculations to estimate the number of solar dehydrators needed to process the current amount of lucuma that is mass produced in Peru. Computation of the energy necessary to obtain 5,042,294.67 kg.

However, the proposed equipment provides a net energy rate of 622.22 watts/h; using this data, the total number of solar dehydrator units is estimated to be 18,986. Hence, to dehydrate the 12,637,330 kg of lucuma produced annually might require 18,986 solar dehydrator units (distributed in the 17 regions of Peru where the fruit is produced). In this way, 5,042,294.67 kg of lucuma flour mass can be produced in eight workday hours over a productive cycle of seven months. Expressing the results in monthly production, one estimates 720,327.81 kg.

3.2.2. Analysis of Two Models for Dehydration

Multi-Criteria Analysis—TEFESAL (2)

Currently, there are several types of electric dehydration equipment on the market that ensure quality products. Nevertheless, due to electricity consumption, as well as preventive and corrective maintenance, those units increase production costs. To reduce costs and ensure a quality product, we propose the usage of an innovative piece of solar dehydrator equipment whose viability, with respect to technological, energetic, and other relevant factors, is tested by the multi-criteria TEFESAL analysis. In what follows, two options are analyzed: ALTERNATIVE “I”: Innovative solar dehydrator; and ALTERNATIVE “II”: Electric dehydrator.

After analyzing the two options, and considering the data related to the following characteristics: Technological, Economic, Financial, Environmental, Social, Administrative and Legal, we obtained the proper weights, whose scores are detailed in

Table 2.

After the analysis, the chosen alternative is the use of an “Innovative solar dehydrator”, since it produces different opportunities for use, reduces costs, and increases profitability; features that qualify the equipment as viable while also generating low environmental impact.

3.3. VIABILITY ANALYSIS: Lucuma Flour Exportation

Based on the results regarding the annual production of the fruit (gross mass, net mass, international sale price of lucuma flour), obtained through the setting of parameters previously defined, we estimate that there should be 18,986 solar dehydration units (SDU)—distributed throughout the seventeen Peruvian regions where lucuma is produced—to transform and add value to current production. This involves conducting a general analysis in which each family that grows lucuma is assigned one SDU [

30,

31,

32,

33].

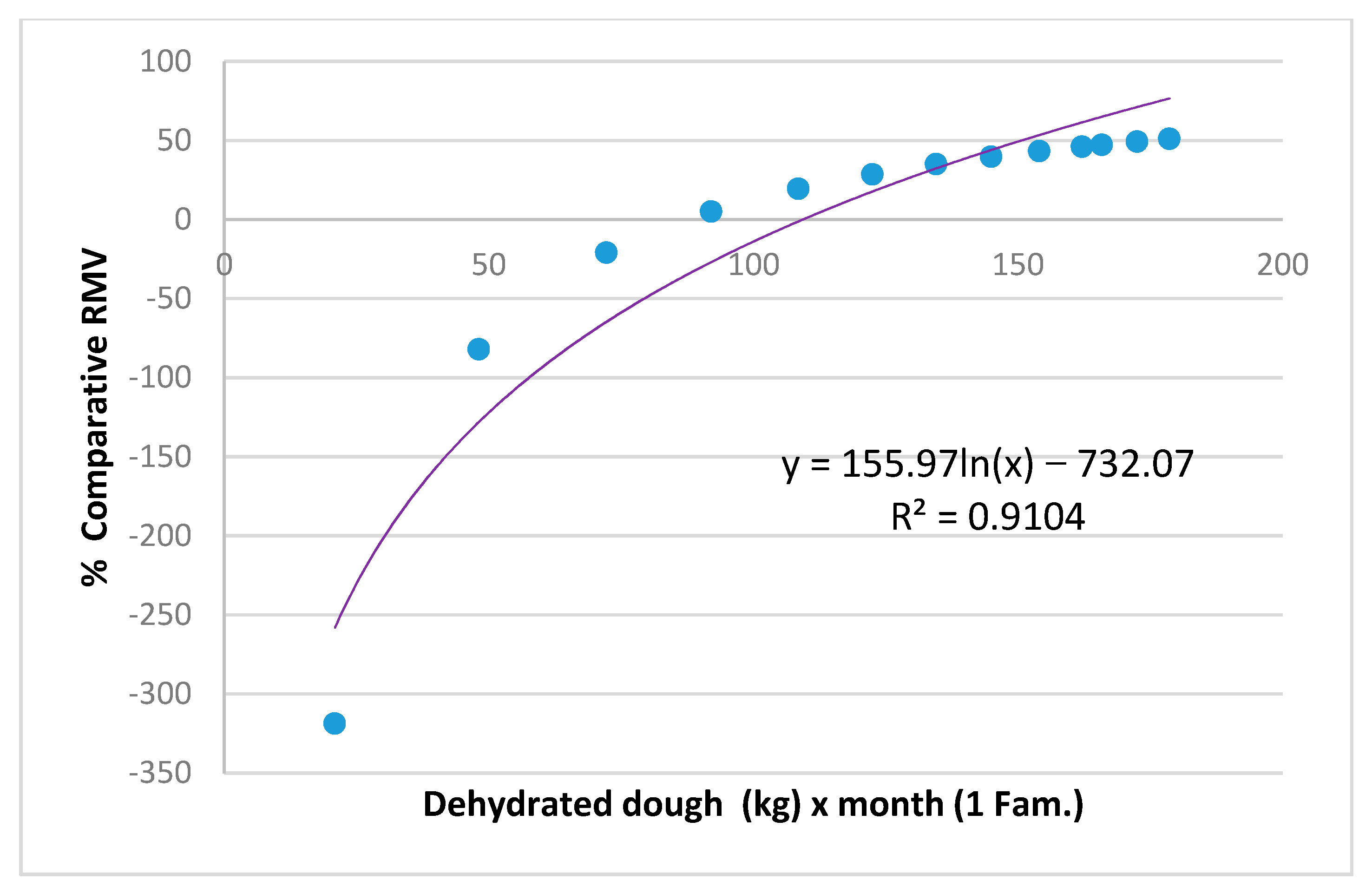

In addition, considering the sales and production of dehydrated net mass, we estimated an income of US$90,761,305.00. In this case, the annual and monthly incomes of the 18,986 families (who would each possess a SDU) with a gross income per family per year of US$4780.43 (US$398.36 per month). Please note that the latter is gross income, which means that fixed and variable costs need to be subtracted from it. This calculation will be done in detail by using the sensitivity analysis approach.

For sensitivity analysis, we considered the variation of the planting of lucuma trees, which involves making estimates using proportionality rules, the gross mass (non-dehydrated), net mass (dehydrated), the perimeter length of the cultivation area (in meters), the number of SDU assigned to each family, the gross sale income of lucuma flour in Europe (Spain) (the sale price for 1kg is taken as reference. Lucuma flour = US

$18 (Spain, 2018)), and the expenditures (fixed and variable production cost and the corresponding export taxes). The National Minimum Wage (NMW) of 2018 was taken as a reference for our analysis. In

Table 3, the NMW percentage variation is shown, which begins from rates below the NMW until reaching the target rate, i.e., those in which the families devoted to exporting lucuma flour obtain a profit of 50% above the NMW.

Please note that the NMW in Peru has increased by 7.82% on average annually. This is a consequence of the sustained development of the country in recent years, which indirectly denotes a better scenario for the consolidation of local development projects spread across the country. The NMW data covers a range of time from 2000 to 2018. In its last revision (2018), it was fixed at US

$281.43. Our analysis considers the current Peruvian situation, where annual production is estimated to be 12,637,350 kg, as shown in

Table 3. On the basis of our model, this implies that 336,992 m are used for sowing and 18,988 farming families (who would each have a SDU) may be involved. The results indicate that 37.9 kg of lucuma flour can be produced, leaving a profit of US

$143.4 (this includes tax retentions and production costs). This income is compared to the NMW, yielding a negative rate (−98.3%) which indicates that the income is below the NMW. This means that currently, for a farmer, it is not worth it to transform the fruit for export purposes. Nevertheless, since our aim is to increase production and, consequently, the number of families involved in this activity, we systematically increase the number of planted trees, so we consider it a fundamental variable for simulation purposes. In

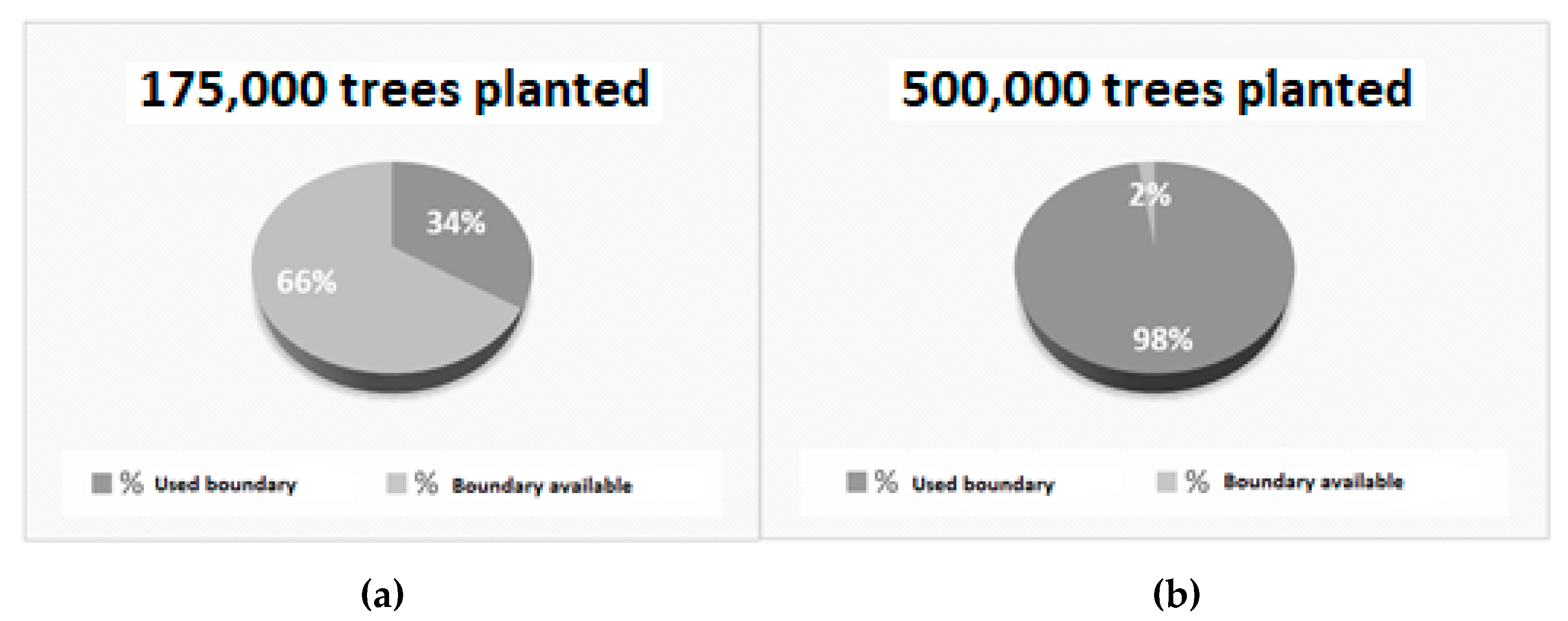

Table 3, we show the variation of the number of planted trees and the corresponding production indices. For the sake of completeness, in

Figure 4, the increase in the number of trees is shown, but from the perspective of the lucuma flour mass obtained, which clearly reflects its growth. Our results show that by sowing 175,000 trees, a relative income of +4.5% above the NMW can be achieved. Surprisingly, by increasing the number of trees planted to 500,000, a relative income of +66.6% above the NMW is reached, involving 18,996 families with a profit of US

$850.70 monthly. To achieve such profit, 1,999,996 meters of cultivated perimeter length is required, which represents 97.69% of the total perimeter length available in the seventeen regions (from a total of 24) of Peru that produce the fruit (see

Figure 5).