A Systematic Disturbance Analysis Method for Resilience Evaluation: A Case Study in Material Handling Systems

Abstract

1. Introduction

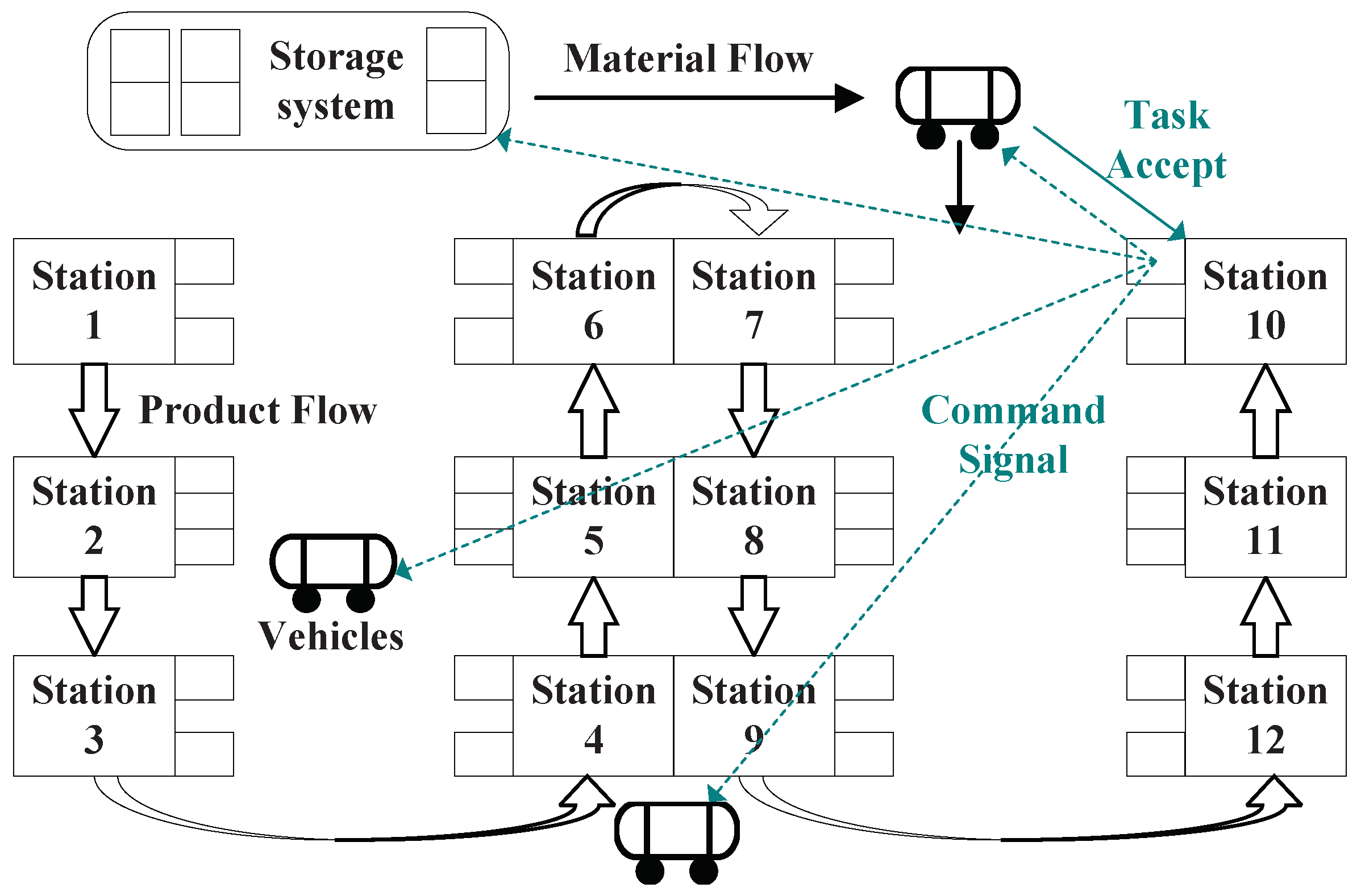

2. Problem Description

- The equipment and caches in the system have a limited capacity.

- Disturbances that occur to the MHS are independent.

3. Disturbance Analysis Method: DMEA

- Function and structure analysis of the system. The indenture levels of the system are specified on the basis of a function and structure analysis. Here, the indenture levels are used to identify or describe the relative complexity of the system. Typical indenture levels include the system level, subsystem level, unit level, and part level. We need to choose the indenture levels appropriately because an insufficient analysis may result in missing some critical disturbance modes, and an excessive analysis may cause resource waste.

- Disturbance identification and effects analysis. As a bottom-up method, the analysis begins at the lowest indenture level and continues upward. At each indenture level, all possible disturbances, their occurrence probabilities, the performances that may be affected, and the degradation and recovery behaviors are identified, as shown in Table 1. The information obtained from a lower level can be used further during the analysis of a higher level.

- Continuous curve

- Linear model. System performance linearly declines from the normal value to the lowest value after the disturbance, or the performance linearly recovers from back to by taking some recovery actions, as shown in Figure 2a.

- Nonlinear model. As shown in Figure 2b, system performance continuously declines from normal to the degraded state or restores to its normal state, and the speed of the performance degradation or recovery is not constant.

- Discrete curve

- In this model, system performance is defined within a limited number of states. After the disturbance, system performance is gradually reduced and then gradually restored, as shown in Figure 2c.

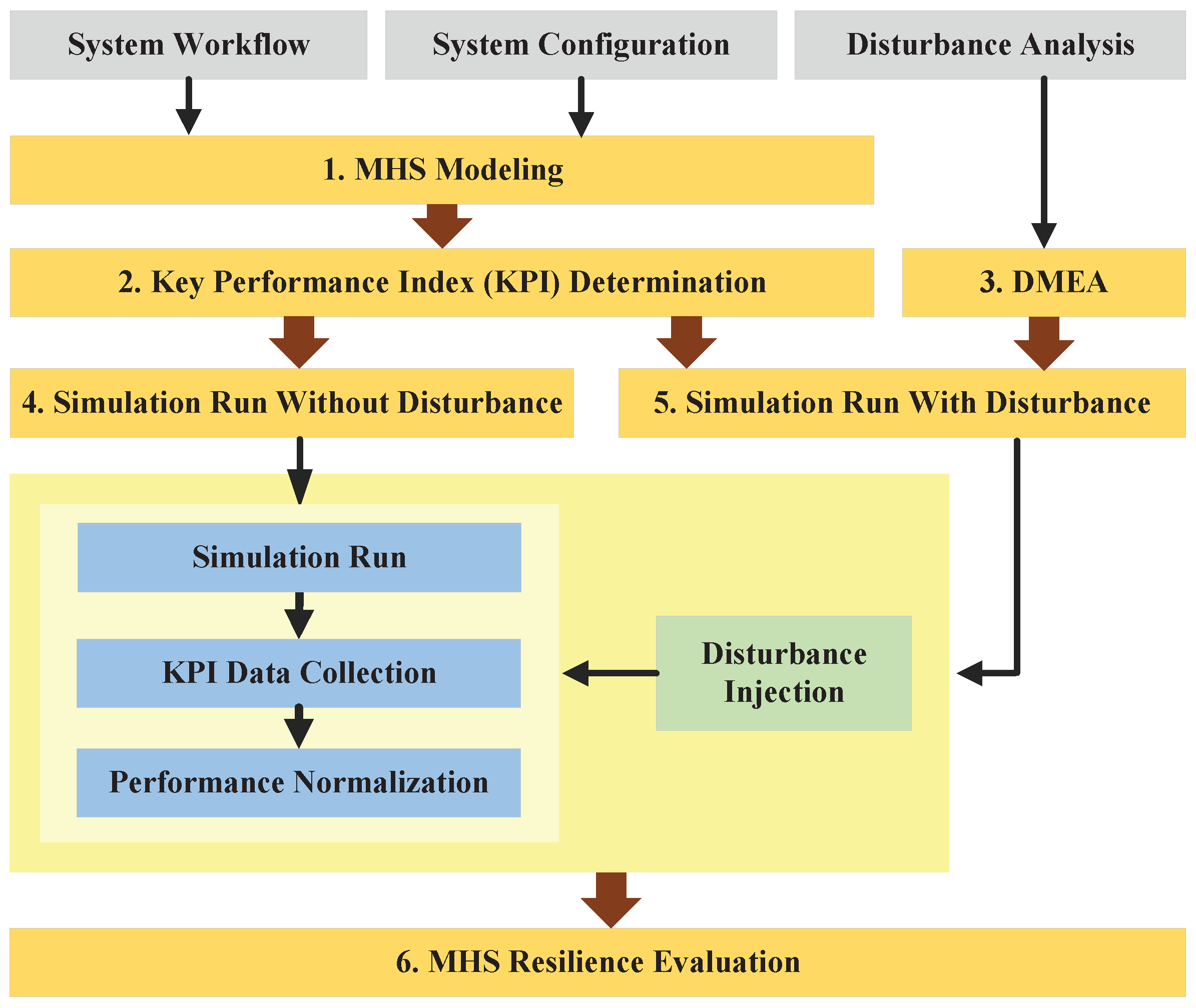

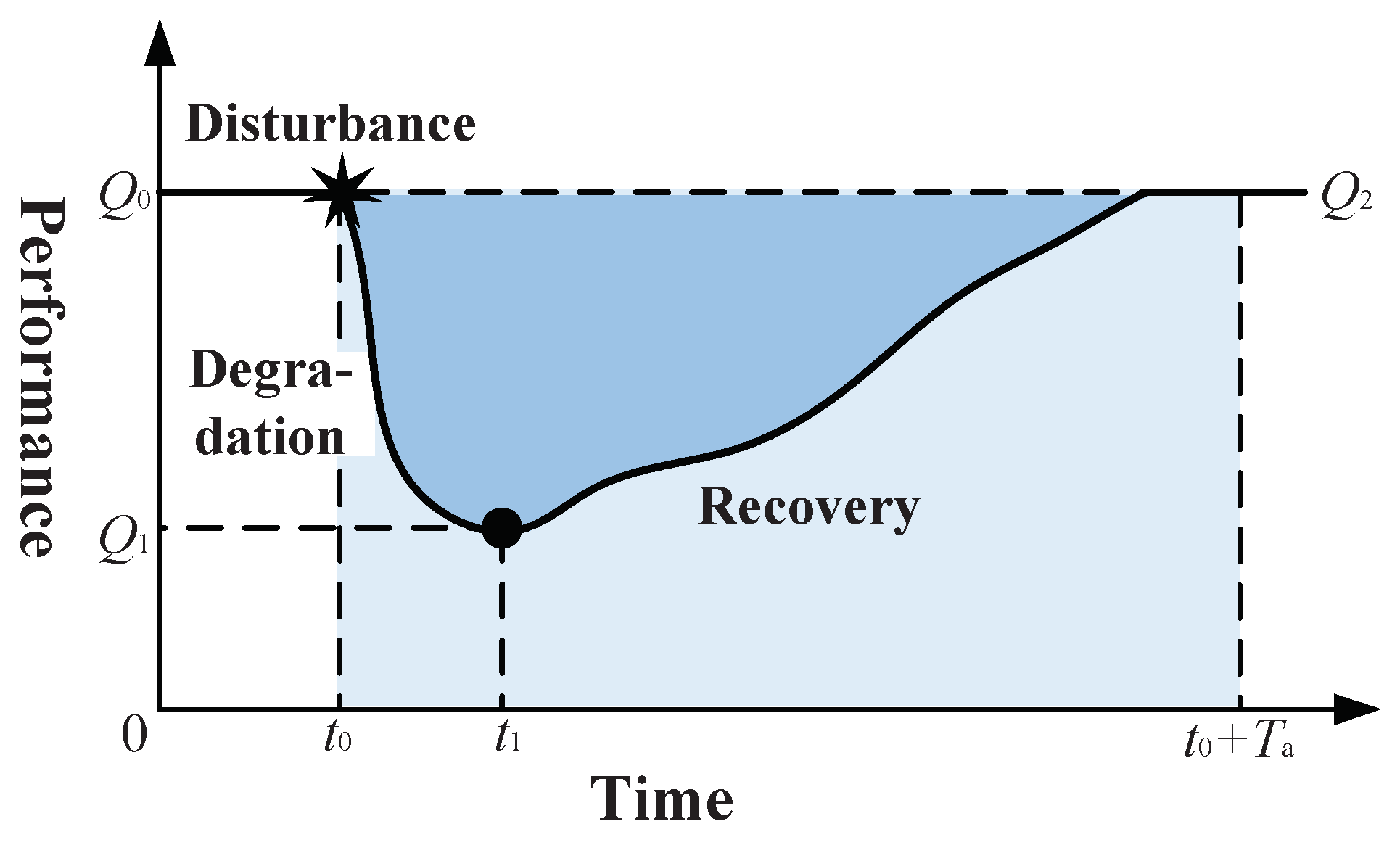

4. Resilience Evaluation Based on DMEA

4.1. MHS Modeling

- System configuration data, such as system composition, equipment layout parameters (e.g., the position, length, width, and height of the equipment), and equipment functional parameters (e.g., velocity, acceleration, operation time, and transport time of the equipment).

- Simulation-related data, such as the iteration number, time duration, and granularity of the simulation.

- Disturbance-related data, such as the minimum acceptable value of the resilience, the disturbance probability, the performance degradation curve, and the recovery curve. See Section 4.3 for details.

4.2. Key Performance Index Determination

4.3. DMEA

- For a continuous linear curve, the following data are required:

- the system’s lowest performance value after the disturbance () and its distribution;

- the time duration of the performance degradation () and its distribution;

- the performance after recovery () and its distribution;

- the time duration of the performance recovery () and its distribution.

- For a continuous nonlinear curve, data are required as follows:

- the system’s lowest performance value after the disturbance () and its distribution;

- the performance function of the degradation process;

- the performance after recovery () and its distribution;

- the performance function of the recovery process.

- For a discrete curve, the following data are needed:

- performance values of all possible states;

- the system’s lowest performance value after the disturbance () and its distribution;

- the time duration and its distribution at each state during system degradation and recovery, respectively.

4.4. Simulation Run without/with Disturbance

4.4.1. Disturbance Injection

4.4.2. Simulation Run and KPI Data Collection

4.4.3. Performance Normalization

4.5. MHS Resilience Evaluation

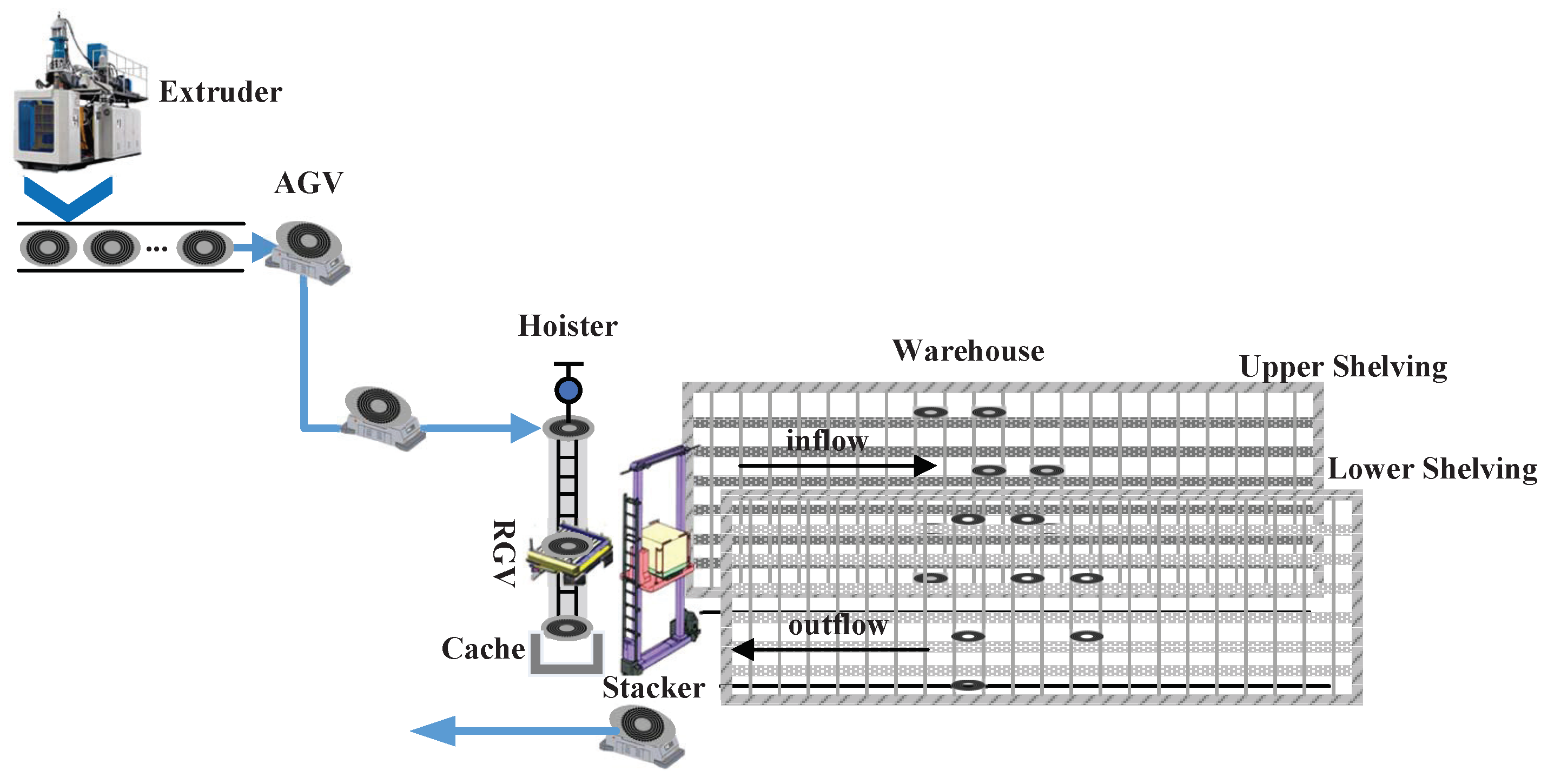

5. Case Study

5.1. Case Overview

5.2. Disturbance Analysis and Resilience Evaluation

5.2.1. DMEA

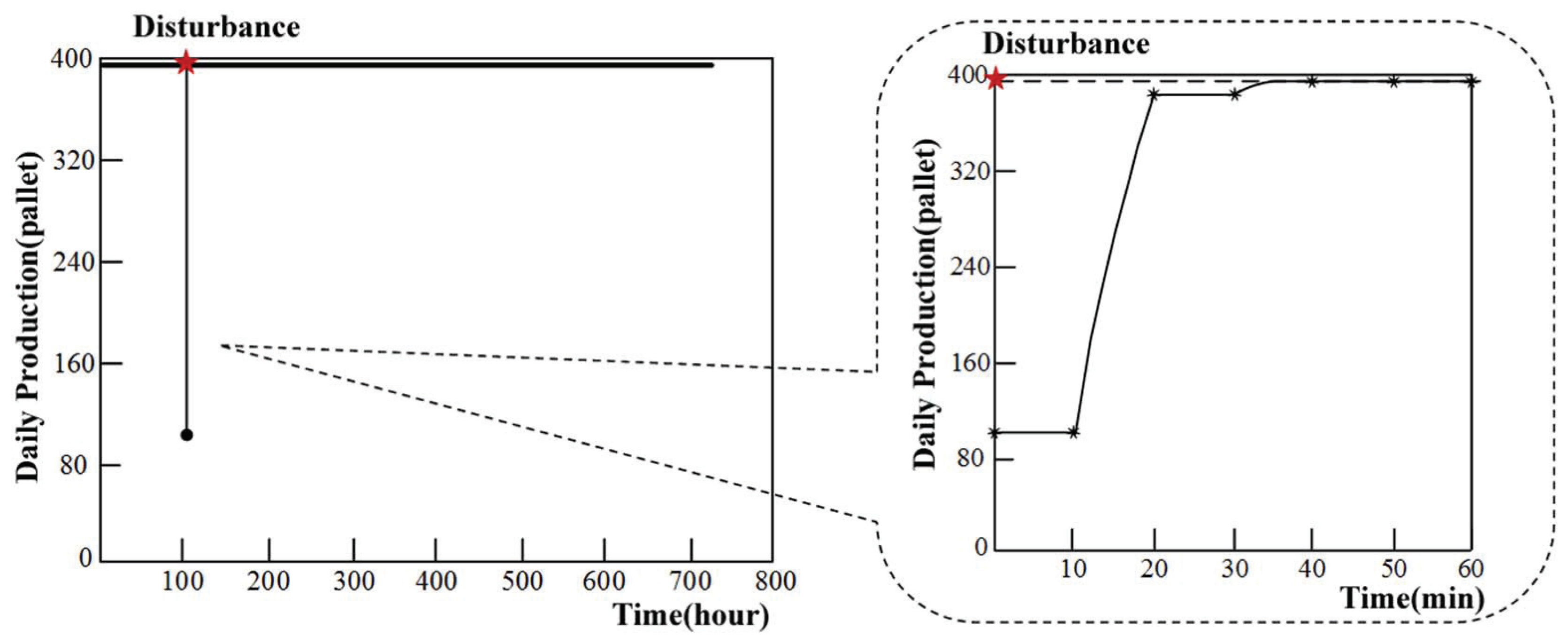

5.2.2. Resilience Evaluation

5.3. Error Analysis

5.4. Results and Discussion

5.4.1. System Resilience Enhancement Methods

5.4.2. Sustainability Analysis

- (1)

- A more resilient tire tread handling system represents more advanced technology. The trade-off between cost and production can be better determined by adding resilience as an additional constraint. Resilience can effectively describe the continuous performance change process of the system after the disturbance and is more advanced than the previous two-state (i.e., the system is either normal or faulty) or discrete multistate methods.

- (2)

- As resilience can describe the feature of continuous changes in system performance, it is very useful in performance management. The deterministic resilience measure in Equation (2) characterizes the average performance of the system over a period of time after the disturbance. For a given disturbance, a resilient strategy can be generated according to the performance level of the system after the disturbance, and then the average performance of the system when responding to the disturbance can be improved. For random disturbances, we can analyze the resilience behavior of the system with different disturbances according to the DMEA method in this paper, and we can then find a way to improve the average resilience of the system to these disturbances.

- (3)

- Under a given disturbance, a resilient system can be restored faster. Fast recovery increases system production by consuming maintenance resources. In Table 8, one can see that a more resilient recovery strategy significantly decreases the total expense (i.e., the sum of the maintenance cost and the economic loss caused by the decrease in production). For example, Case 1 has a total expense of 24,070 Yuan at a resilience level of 0.9099, while the total expense in Case 2 decreases to 10,903 Yuan at a high resilience level of 0.9958. A highly resilient manufacturing process realizes global economic savings, avoids overtime work, and prevents additional resource consumption, thus promoting sustainable manufacturing. Exceptions may exist when the failure is so severe that only an overhaul or even replacement can bring the broken component back into use, as in Case 8. In this case, high resilience is obtained by direct replacement of a part.

- (4)

- The recovery strategy, which is determined with the consideration of resilience, helps increase the average production of the tire tread handling system after the disturbance. This means that the factory emissions per product can be reduced and that the resilient system is environmentally friendly. Moreover, the recovery strategy for multi-failure conditions affects production continuity a lot and determines the additional effort hours and resources, and this topic is closely linked with resource consumption and environmental pressure, on which sustainability has primarily focused [51]. Research concentrating on the optimal recovery strategy will be conducted in the future.

- (5)

- Because the resilience can improve the average performance of the system after the disturbance, it is beneficial to manufacture more products facing the same situation. The richness of commodities attracts customers and is conducive to improvement in social well-being.

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yuan, C.; Zhai, Q.; Dornfeld, D. A three dimensional system approach for environmentally sustainable manufacturing. CIRP Ann.-Manuf. Technol. 2012, 61, 39–42. [Google Scholar] [CrossRef]

- Murino, T.; Romano, E.; Santillo, L.C. Supply chain performance sustainability through resilience function. In Proceedings of the 2011 Winter Simulation Conference (WSC), Phoenix, AZ, USA, 11–14 December 2011; pp. 1600–1611. [Google Scholar]

- Rajesh, R. On sustainability, resilience, and the sustainable-resilient supply networks. Sustain. Prod. Consum. 2018, 15, 74–88. [Google Scholar] [CrossRef]

- Pope, J.; Bond, A.; Morrison-Saunders, A. A conceptual framework for sustainability assessment. In Handbook of Sustainability Assessment; Edward Elgar Publishing: Cheltenham, UK; Northampton, MA, USA, 2015; pp. 20–42. [Google Scholar]

- Jayal, A.D.; Badurdeen, F.; Dillon, O.W.; Jawahir, J.I.S. Sustainable manufacturing: Modeling and optimization challenges at the product, process and system levels. CIRP J. Manuf. Sci. Technol. 2010, 2, 144–152. [Google Scholar] [CrossRef]

- Nakano, M. A conceptual framework for sustainable manufacturing by focusing on risks in supply chains. In Proceedings of the IFIP International Conference on Advances in Production Management Systems, Bordeaux, France, 21–23 September 2009; pp. 160–167. [Google Scholar]

- Thomas, A.; Byard, P.; Francis, M.; Fisher, R.; White, G.R. Profiling the resiliency and sustainability of UK manufacturing companies. J. Manuf. Technol. Manag. 2016, 27, 82–99. [Google Scholar] [CrossRef]

- Lin, J.T.; Wang, F.K.; Yen, P.Y. Simulation analysis of dispatching rules for an automated interbay material handling system in wafer fab. Int. J. Prod. Res. 2001, 39, 1221–1238. [Google Scholar] [CrossRef]

- Wu, L.H.; Mok, P.Y.; Zhang, J. An adaptive multi-parameter based dispatching strategy for single-loop interbay material handling systems. Comput. Ind. 2011, 62, 175–186. [Google Scholar] [CrossRef]

- Wang, C.N.; Lee, Y.H.; Hsu, H.P.; Nguyen, D.H. The heuristic preemptive dispatching method for convey-based automated material handling system of 450 mm wafer fabrication. Comput. Ind. Eng. 2016, 96, 52–60. [Google Scholar] [CrossRef]

- Lau, H.Y.K.; Woo, S.O. An agent-based dynamic routing strategy for automated material handling systems. Int. J. Comput. Integr. Manuf. 2008, 21, 269–288. [Google Scholar] [CrossRef]

- Chien, C.F.; Chou, C.W.; Yu, H.C. A novel route selection and resource allocation approach to improve the efficiency of manual material handling system in 200-mm wafer fabs for Industry 3.5. IEEE Trans. Autom. Sci. Eng. 2016, 13, 1567–1580. [Google Scholar] [CrossRef]

- Fang, Z.; Mao, J. Energy-efficient elevating transfer vehicle routing for automated multi-level material handling systems. In Proceedings of the 13th IEEE Conference on Automation Science and EngineeringAutomation Science and Engineering, Xi’an, China, 20–23 August 2017; pp. 249–254. [Google Scholar]

- Tavana, M.; Fazlollahtabar, H.; Hassanzadeh, R. A bi-objective stochastic programming model for optimising automated material handling systems with reliability considerations. Int. J. Prod. Res. 2014, 52, 5597–5610. [Google Scholar] [CrossRef]

- Karimi, B.; Niaki, S.T.A.; Haleh, H.; Naderi, B. Bi-Objective optimization of a job shop with two types of failures for the operating machines that use automated guided vehicles. Reliab. Eng. Syst. Saf. 2018, 175, 92–104. [Google Scholar] [CrossRef]

- Beschorner, A.; Glüer, D. MaxFlow theory for availability calculation of automated material handling systems. Robot. Comput. Integr. Manuf. 2003, 19, 141–145. [Google Scholar] [CrossRef]

- Glüer, D. Optimization of automated material handling systems regarding robustness and delivery time. In Proceedings of the 2003 IEEEI/SEMI Advanced Semiconductor Manufacturing Conference and Workshop, Munich, Germany, 31 March–1 April 2003; pp. 96–100. [Google Scholar]

- Mital, P.; Goetschalckx, M.; Huang, E. Robust material handling system design with standard deviation, variance and downside risk as risk measures. Int. J. Prod. Econ. 2015, 170, 815–824. [Google Scholar] [CrossRef]

- Chen, W.; Wang, Z.; Chan, F.T.S. Robust production capacity planning under uncertain wafer lots transfer probabilities for semiconductor automated material handling systems. Eur. J. Oper. Res. 2017, 261, 929–940. [Google Scholar] [CrossRef]

- Gu, X.; Jin, X.; Ni, J. Resilience measures of manufacturing systems under disruptions. In Proceedings of the ASME 2014 International Manufacturing Science and Engineering Conference, Detroit, MI, USA, 9–13 June 2014; pp. 1–10. [Google Scholar]

- Gu, X.; Jin, X.; Ni, J.; Koren, Y. Manufacturing system design for resilience. Procedia CIRP 2015, 36, 135–140. [Google Scholar] [CrossRef]

- Fisher, O.; Watson, N.; Porcu, L.; Bacon, D.; Rigley, M.; Gomes, R.L. Cloud manufacturing as a sustainable process manufacturing route. J. Manuf. Syst. 2018, 47, 53–68. [Google Scholar] [CrossRef]

- Brandon-Jones, E.; Squire, B.; Autry, C.; Petersen, K.J. A contingent resource-based perspective of supply chain resilience and robustness. J. Supply Chain Manag. 2014, 50, 55–73. [Google Scholar] [CrossRef]

- Li, R.; Dong, Q.; Jin, C.; Kang, R. A new resilience measure for supply chain networks. Sustainability 2017, 9, 144. [Google Scholar] [CrossRef]

- Adams, T.; Bekkem, K.; Bier, V. Operational Resiliency of Beloit-Hudson Interstate Highway Corridor; Technical Report; University of Wisconsin: Madison, WI, USA, 2010. [Google Scholar]

- Marousek, R.; Novotny, P. The FMEA exploitation in supply chain resilience evaluation. In Proceedings of the 23rd International Conference on Metallurgy and Materials, Brno, Czech Republic, 21–23 May 2014; pp. 1–6. [Google Scholar]

- Mock, R.G.; de Obeso Luis, L.; Zipper, C.; Schönenberger, M. Resilience assessment of internet of things: A case study on smart buildings. In Risk, Reliability and Safety: Innovating Theory and Practice; Walls, L., Revie, M., Bedford, T., Eds.; Taylor & Francis: Glasgow, UK, 2016; pp. 2260–2267. [Google Scholar]

- Bruelheide, H.; Luginbühl, U. Peeking at ecosystem stability: Making use of a natural disturbance experiment to analyze resistance and resilience. Ecology 2009, 90, 1314–1325. [Google Scholar] [CrossRef]

- Ledger, M.E.; Harris, R.M.L.; Armitage, P.D.; Milner, A.M. Climate change impacts on community resilience: Evidence from a drought disturbance experiment. Adv. Ecol. Res. 2012, 46, 211–258. [Google Scholar]

- Pascale, F.D.; Bernardo, M.; Muto, F.; Matteo, D.D.; Dattilo, V. Resilience and seismic risk perception at school: A geoethical experiment in Aiello Calabro, southern Italy. Nat. Hazards 2017, 86, 569–586. [Google Scholar] [CrossRef]

- Shirali, G.A.; Mohammadfam, I.; Ebrahimipour, V. A new method for quantitative assessment of resilience engineering by PCA and NT approach: A case study in a process industry. Reliab. Eng. Syst. Saf. 2013, 119, 88–94. [Google Scholar] [CrossRef]

- Azadeh, A.; Asadzadeh, S.M.; Tanhaeean, M. A consensus-based AHP for improved assessment of resilience engineering in maintenance organizations. J. Loss Prev. Process Ind. 2017, 47, 151–160. [Google Scholar] [CrossRef]

- Azadeh, A.; Salehi, V.; Kianpour, M. Performance evaluation of rail transportation systems by considering resilience engineering factors: Tehran railway electrification system. Transp. Lett. 2018, 10, 12–25. [Google Scholar] [CrossRef]

- Almeida, R.; Vieira, M. Benchmarking the resilience of self-adaptive software systems: perspectives and challenges. In Proceedings of the 6th International Symposium on Software Engineering for Adaptive and Self-Managing Systems, Waikiki, HI, USA, 23–24 May 2011; pp. 190–195. [Google Scholar]

- Pradhan, S.; Dubey, A.; Levendovszky, T.; Kumar, P.S.; Emfinger, W.A.; Balasubramanian, D.; Otte, W.; Karsai, G. Achieving resilience in distributed software systems via self-reconfiguration. J. Syst. Softw. 2016, 122, 344–363. [Google Scholar] [CrossRef]

- Ma, W.; Li, R.; Jin, C.; Kang, R. Resilience test and evaluation of networked control systems for given disturbances. In Proceedings of the 2nd International Conference on Reliability Systems Engineering, Beijing, China, 10–12 July 2017; p. R043. [Google Scholar]

- Tran, H.T.; Balchanos, M.; Domerçant, J.C.; Mavris, D.N. A framework for the quantitative assessment of performance-based system resilience. Reliab. Eng. Syst. Saf. 2017, 158, 73–84. [Google Scholar] [CrossRef]

- Almajali, A.; Viswanathan, A.; Neuman, C. Resilience evaluation of demand response as spinning reserve under cyber-physical threats. Electronics 2017, 6, 2. [Google Scholar] [CrossRef]

- Liu, X.; Jiang, W.; Li, J.; Wang, W. Evaluation of the vegetation coverage resilience in areas damaged by the Wenchuan earthquake based on MODIS-EVI data. Sensors 2017, 17, 259. [Google Scholar] [CrossRef]

- Zio, E.; Piccinelli, R. Randomized flow model and centrality measure for electrical power transmission network analysis. Reliab. Eng. Syst. Saf. 2010, 95, 379–385. [Google Scholar] [CrossRef]

- O’Sullivan, D. Material Transport Systems. Available online: http://www.nuigalway.ie/staff-sites/david_osullivan/documents/unit_8_material_transport_systems.pdf (accessed on 8 March 2019).

- Hao, Q.; Shen, W. Implementing a hybrid simulation model for a Kanban-based material handling system. Robot. Comput.-Integr. Manuf. 2008, 24, 635–646. [Google Scholar] [CrossRef]

- Strigini, L. Fault tolerance and resilience: meanings, measures and assessment. In Resilience Assessment and Evaluation of Computing Systems; Springer: Berlin/Heidelberg, Germany, 2012; pp. 3–24. [Google Scholar]

- Bruneau, M.; Chang, S.E.; Eguchi, R.T.; Lee, G.C.; O’Rourke, T.D.; Reinhorn, A.M.; Shinozuka, M.; Tierney, K.; Wallace, W.A.; von Winterfeldti, D. A framework to quantitatively assess and enhance the seismic resilience of communities. Earthq. Spectra 2003, 19, 733–752. [Google Scholar] [CrossRef]

- Zobel, C.W. Representing perceived tradeoffs in defining disaster resilience. Decis. Support Syst. 2011, 50, 394–403. [Google Scholar] [CrossRef]

- Ouyang, M.; Dueñas Osorio, L.; Min, X. A three-stage resilience analysis framework for urban infrastructure systems. Struct. Saf. 2012, 36–37, 23–31. [Google Scholar] [CrossRef]

- Chang, S.E.; Shinozuka, M. Measuring improvements in the disaster resilience of communities. Earthq. Spectra 2004, 20, 739–755. [Google Scholar] [CrossRef]

- Cimellaro, G.P.; Reinhorn, A.M.; MichelBruneau, M. Seismic resilience of a hospital system. Struct. Infrastruct. Eng. 2010, 6, 127–144. [Google Scholar] [CrossRef]

- Henry, D.; Ramirez-Marquez, J.E. Generic metrics and quantitative approaches for system resilience as a function of time. Reliab. Eng. Syst. Saf. 2012, 99, 114–122. [Google Scholar] [CrossRef]

- Joung, C.B.; Carrell, J.; Sarkar, P.; Feng, S.C. Categorization of indicators for sustainable manufacturing. Ecol. Indicat. 2013, 24, 148–157. [Google Scholar] [CrossRef]

- Garetti, M.; Mummolo, G.; Taisch, M. Special issue on “sustainable manufacturing”. Prod. Plan. Control 2012, 23, 79–82. [Google Scholar] [CrossRef]

- Lee, J.; Ghaffari, M.; Elmeligy, S. Self-maintenance and engineering immune systems: Towards smarter machines and manufacturing systems. Annu. Rev. Control 2011, 35, 111–122. [Google Scholar] [CrossRef]

| No. | Part Name | Function | Disturbance Modes | Disturbance Causes | Occurrence Probability | Disturbance Effects | |

|---|---|---|---|---|---|---|---|

| Performance Affected | Performance Degradation and Recovery | ||||||

| Parameter | Value | Parameter | Value | ||

|---|---|---|---|---|---|

| Discharge time interval of the extruder | 221.4 s/pallet | Hoister | Material pick-up duration () | 8 s | |

| Maximum allowable recovery time | 4 h | Material drop-off duration () | 1 s | ||

| Transport duration from extruder to the AGV pick-up location () | 45 s | Transport duration from the AGV drop off location to hoister cache () | 17.5 s | ||

| AGV | Forward velocity () | 1.33 m/s | RGV | Duration of vehicle go () | 12 s |

| Turn velocity () | 0.5 m/s | Duration of vehicle return () | 11 s | ||

| Acceleration () | 0.2 m/s | Material drop-off duration () | 2 s | ||

| U-turn duration () | 25 s | Stacker | Material pick-up/drop-off duration () | 22 s | |

| Material pick-up/drop-off duration () | 15 s | Lift velocity () | 0.67 m/s | ||

| Straight path length of AGV go | 35.6 m | Walk velocity () | 2.67 m/s | ||

| Straight path length of AGV return | 36.9 m | Acceleration () | 0.5 m/s | ||

| Turning path length of AGV go | 7.4 m | Shelving | Number of floors | 7 | |

| Turning path length of AGV return | 10.3 m | Number of upper horizontal storage units | 24 | ||

| U-turn times of AGV go | 0 | Number of lower horizontal storage units | 25 | ||

| Turn times of AGV go | 1 | Width of the storage unit | 1.47 m | ||

| U-turn times of AGV return | 1 | Height of the storage unit | 2.325∼2.425 m | ||

| Turn times of AGV return | 1 | ||||

| No. | Part Name | Function | Disturbance Modes | Disturbance Causes | Occurrence Probability | Disturbance Effects | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Performance Affected | ||||||||||

| 1 | AGV | take tire treads | drive unit fails | drive unit design | ∼ | 1,0.8,1 | 0 | 1,10,10 | ||

| 2 | to the warehouse | circuit connection fails | process problem | ∼ | 6,[0.5,0.8],[0.2,0.8] | 0 | 1,20,20 | |||

| 3 | entrance | control system fails | external interference | ∼ | 6,[0.5,0.8],[0.2,0.8] | 0 | 1,30,30 | |||

| … | … | … | … | … | … | … | … | … | … | … |

| 84 | stacker | carry tire | tire treads exceed on the left | bias of the pallet | ∼ | 6,[0,0.5,0.8],[0.5,0.3,0.2] | 0 | 4,2.678,0.265 | ||

| 85 | treads to the | tire treads exceed on the right | bias of the pallet | ∼ | 6,[0,0.5,0.8],[0.5,0.3,0.2] | 0 | 4,2.632,0.248 | |||

| 86 | storage unit | task execution timeout | network interruption | ∼ | 6,[0,0.5,0.8],[0.5,0.3,0.2] | 0 | 4,2.732,0.314 | |||

| Distribution Type | Distribution Type No. | Characteristic Parameters | |

|---|---|---|---|

| 1 | 2 | ||

| Uniform distribution | 1 | a | b |

| Exponential distribution | 2 | - | |

| Normal distribution | 3 | ||

| Log–normal distribution | 4 | ||

| Log-logistic distribution | 5 | s | |

| Discrete distribution | 6 | ||

| No. | Number of Iterations | Error | Duration (s) |

|---|---|---|---|

| 1 | 500 | 0.006131 | 52.6959 |

| 2 | 1000 | 0.003437 | 89.2595 |

| 3 | 1500 | 0.003306 | 127.169 |

| 4 | 2000 | 0.003197 | 178.013 |

| 5 | 2500 | 0.002938 | 200.445 |

| 6 | 3000 | 0.002747 | 279.122 |

| 7 | 3500 | 0.002564 | 283.232 |

| 8 | 4000 | 0.002430 | 327.458 |

| 9 | 4500 | 0.002291 | 368.282 |

| 10 | 5000 | 0.002077 | 509.328 |

| Equipment | Acquisition Cost (Yuan/Unit) | Operation Cost (Yuan/Unit Year) | Maintenance Cost | |

|---|---|---|---|---|

| Hardware | Manpower (Yuan/Hour) | |||

| AGV | 900,000 | 10,000 | Determined by the disturbance mode | 500 |

| Hoister | 150,000 | 1000 | ||

| RGV | 200,000 | 1000 | ||

| Stacker | 1,000,000 | 10,000 | ||

| Cache | 100,000 | - | - | - |

| Storage Unit | 2700 | - | - | - |

| Case No. | Number of | Cost (Yuan) | Daily Production (Pallet) | Resilience | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| AGV | Hoister | RGV | Cache | Acquisition | Operation | Maintenance | Total | |||

| 1 | 1 | 1 | 1 | 1 | 3,276,100 | 22,000 | 95,000 | 3,393,100 | 390 | 0.9565 |

| 2 | 2 | 1 | 1 | 1 | 4,176,100 | 32,000 | 173,000 | 4,381,100 | 390 | 0.9867 |

| 3 | 1 | 2 | 1 | 1 | 3,426,100 | 23,000 | 102,000 | 3,551,100 | 390 | 0.9716 |

| 4 | 1 | 1 | 2 | 1 | 3,476,100 | 23,000 | 107,000 | 3,606,100 | 390 | 0.9700 |

| 5 | 1 | 1 | 1 | 2 | 3,376,100 | 22,000 | 95,000 | 3,493,100 | 390 | 0.9720 |

| Case No. | Disrupted Equipment | Maintenance Cost (Yuan) | Resilience | Production Loss (Pallets) | Economic Loss (Yuan) | ||

|---|---|---|---|---|---|---|---|

| Manpower | Hardware | Total | |||||

| 1 | AGV | 500 | 6000 | 6500 | 0.9099 | 35.14 | 17,570 |

| 2 | 83 | 10,000 | 10,083 | 0.9958 | 1.64 | 820 | |

| 3 | Hoister | 750 | 10,000 | 10,750 | 0.9792 | 8.11 | 4055 |

| 4 | 750 | 10,000 | 10,750 | 0.9968 | 1.25 | 625 | |

| 5 | RGV | 500 | 600 | 1100 | 0.976 | 9.36 | 4680 |

| 6 | 83 | 1000 | 1083 | 0.9919 | 3.16 | 1580 | |

| 7 | Stacker | 103.7 | 3000 | 3103.7 | 0.9792 | 8.11 | 4055 |

| 8 | 70 | 20,000 | 20,070 | 0.9932 | 2.65 | 1325 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, R.; Tian, X.; Yu, L.; Kang, R. A Systematic Disturbance Analysis Method for Resilience Evaluation: A Case Study in Material Handling Systems. Sustainability 2019, 11, 1447. https://doi.org/10.3390/su11051447

Li R, Tian X, Yu L, Kang R. A Systematic Disturbance Analysis Method for Resilience Evaluation: A Case Study in Material Handling Systems. Sustainability. 2019; 11(5):1447. https://doi.org/10.3390/su11051447

Chicago/Turabian StyleLi, Ruiying, Xiaoyu Tian, Li Yu, and Rui Kang. 2019. "A Systematic Disturbance Analysis Method for Resilience Evaluation: A Case Study in Material Handling Systems" Sustainability 11, no. 5: 1447. https://doi.org/10.3390/su11051447

APA StyleLi, R., Tian, X., Yu, L., & Kang, R. (2019). A Systematic Disturbance Analysis Method for Resilience Evaluation: A Case Study in Material Handling Systems. Sustainability, 11(5), 1447. https://doi.org/10.3390/su11051447