A Pilot Study on the Sound Absorption Characteristics of Chicken Feathers as an Alternative Sustainable Acoustical Material

Abstract

1. Introduction

2. Experiments

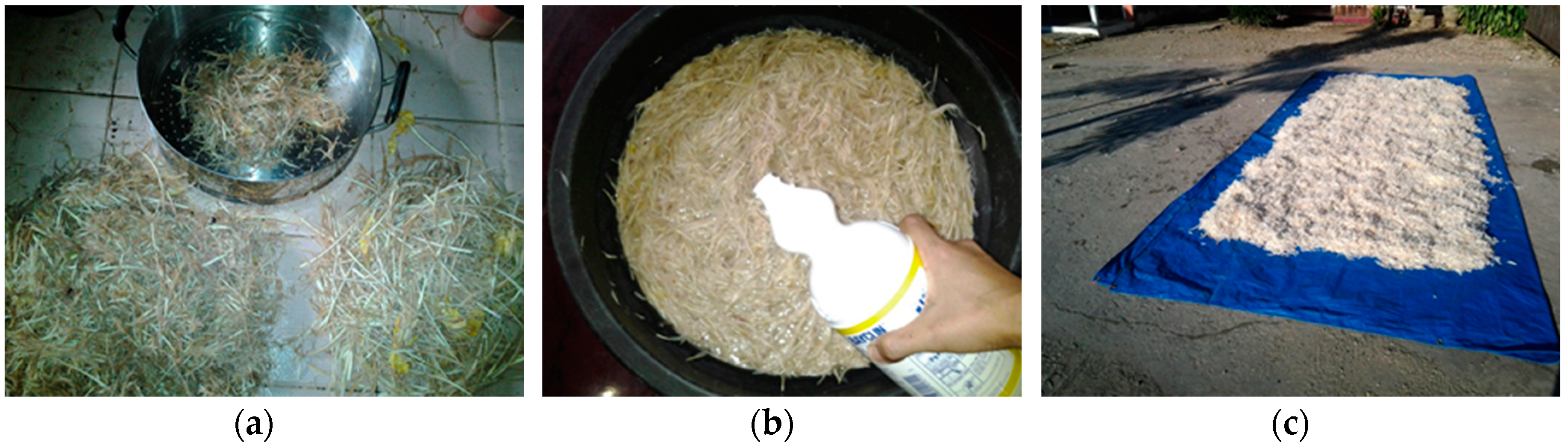

2.1. Materials and Preparation of the Test Specimens

2.2. Experimental Method

3. Results and Discussion

3.1. Absorption Coefficients of Chicken Feathers

3.2. Flow Resistivity of Chicken Feather

4. Concluding Remarks

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sato, H.; Morimoto, M.; Wada, M. Relationship between listening difficulty rating and objective measures in reverberant and noisy sound fields for young adults and elderly persons. J. Acoust. Soc. Am. 2012, 131, 4596–4605. [Google Scholar] [CrossRef] [PubMed]

- Hothersall, D.C.; Horoshenkov, K.V.; Mercy, S.E. Numerical modelling of the sound field near a tall building with balconies near a road. J. Sound Vib. 1996, 198, 507–515. [Google Scholar] [CrossRef]

- Fuchs, H.V. Alternative fibreglass absorbers—New tools and materials for noise control and acoustic comfort. Acust. Acta Acust. 2001, 87, 414–422. [Google Scholar]

- Arenas, J.P.; Crocker, M.J. Recent trend in porous sound-absorbing materials. Sound Vib. 2010, 44, 12–17. [Google Scholar]

- Herrin, D.; Liu, J.; Seybert, A. Properties and applications of microperforated panels. Sound Vib. 2011, 45, 6–9. [Google Scholar]

- Asdrubali, F. Green and sustainable materials for noise control in buildings. In Proceedings of the 19th International Congress on Acoustics, Madrid, Spain, 2–7 September 2007. [Google Scholar]

- Asdrubali, F. Survey on the acoustical properties of new sustainable materials for noise control. In Proceedings of the Euronoise 2016, Tampere, Finland, 30 May–1 June 2006; pp. 1–10. [Google Scholar]

- Fouladi, M.H.; Ayub, M.; Nor, M.J.M. Analysis of coir fiber acoustical characteristics. Appl. Acoust. 2011, 72, 35–42. [Google Scholar] [CrossRef]

- Lima, Z.Y.; Putra, A.; Nora, M.J.M.; Yaakob, M.Y. Sound absorption performance of natural kenaf fibres. Appl. Acoust. 2018, 118, 107–114. [Google Scholar] [CrossRef]

- Chin, D.D.V.S.; Yahya, M.N.B.; Din, N.B.C.; Ong, P. Acoustic properties of biodegradable composite micro-perforated panel (BC-MPP) made from kenaf fibre and polyactic acid (PLA). Appl. Acoust. 2018, 138, 179–187. [Google Scholar] [CrossRef]

- Koizumi, T.; Tsujiuchi, N.; Adachi, A. The development of sound absorbing materials using natural bamboo fibers. High performance structures and composites. WIT Trans. Built Environ. 2002, 59, 157–166. [Google Scholar]

- Adams, T. Sound Materials: A Compendium of Sound Absorbing Materials for Architecture and Design; Frame Publishers: New York, NY, USA, 2017. [Google Scholar]

- Berardi, U.; Iannace, G. Acoustic characterization of natural fibers for sound absorption applications. Build. Environ. 2015, 94, 84–852. [Google Scholar] [CrossRef]

- Wang, Y.X.; Cao, X.J. Extracting keratin from chicken feathers by using a hydrophobic ionic liquid. Process Biochem. 2012, 47, 896–899. [Google Scholar] [CrossRef]

- Jimenez-Cervantes Amieva, E.; Fuentes-Ramirez, R.; Martinez-Hernandez, A.L.; Millan-Chiu, B.; Lopez-Marin, L.M.; Castaño, V.M.; Velasco-Santos, C. Graphene oxide and reduced graphene oxide modification with polypeptide chains from chicken feather keratin. J. Alloys Compd. 2015, 643, 137–148. [Google Scholar] [CrossRef]

- Wang, Q.; Cao, Q.; Wang, X.; Jing, B.; Kuang, H.; Zhou, L. A high-capacity carbon prepared from renewable chicken feather biopolymer for supercapacitors. J. Power Sour. 2013, 225, 101–107. [Google Scholar] [CrossRef]

- Reddy, N.; Jiang, Q.; Jin, E.; Shi, Z.; Hou, X.; Yang, Y. Bio-thermoplastics from grafted chicken feathers for potential biomedical applications. Colloids Surf. B Biointerfaces 2013, 110, 51–58. [Google Scholar] [CrossRef] [PubMed]

- Reddy, N.; Hu, C.; Yan, K.; Yang, Y. Thermoplastic films from cyanoethylated chicken feathers. Mater. Sci. Eng. C 2011, 31, 1706–1710. [Google Scholar] [CrossRef]

- Forgács, G.; Alinezhad, S.; Mirabdollah, A.; Feuk-Lagerstedt, E.; Horváth, I.S. Biological treatment of chicken feather waste for improved biogas production. J. Environ. Sci. 2011, 23, 1747–1753. [Google Scholar] [CrossRef]

- Huda, S.; Yang, Y. Composites from ground chicken quill and polypropylene. Compos. Sci. Technol. 2008, 68, 790–798. [Google Scholar] [CrossRef]

- Sun, X.; Liang, W. Cellular structure control and sound absorption of polyolefin microlayer sheets. Compos. Part B Eng. 2016, 87, 21–26. [Google Scholar] [CrossRef]

- Dragonetti, R.; Romano, R. Considerations on the sound absorption of non locally reacting porous layers. Appl. Acoust. 2015, 87, 46–56. [Google Scholar] [CrossRef]

- Binici, H.; Aksogan, O.; Demirhan, C. Mechanical, thermal and acoustical characterizations of an insulation composite made of bio-based materials. Sustain. Cities Soc. 2016, 20, 17–26. [Google Scholar] [CrossRef]

- Duan, X.H.; Wang, H.Q.; Li, Z.B.; Zhu, L.K.; Chen, R.; Kong, D.Y.; Zhao, Z. Sound absorption of a flexible micro-perforated panel absorber based on PVDF piezoelectric film. Appl. Acoust. 2015, 88, 84–89. [Google Scholar] [CrossRef]

- Mati-Baouche, N.; De Baynast, H.; Lebert, A.; Sun, S.; Lopez-Mingo, C.J.S.; Leclaire, P.; Michaud, P. Mechanical, thermal and acoustical characterizations of an insulating bio-based composite made from sunflower stalks particles and chitosan. Ind. Crops Prod. 2014, 58, 244–250. [Google Scholar] [CrossRef]

- Delany, M.; Bazley, E. Acoustical properties of fibrous absorbent materials. Appl. Acoust. 1970, 3, 105–116. [Google Scholar] [CrossRef]

- Miki, Y. Acoustical properties of porous materials—Generalizations of empirical models. J. Acoust. Soc. Jpn. E 1990, 11, 25–28. [Google Scholar] [CrossRef]

- Miki, Y. Acoustical properties of porous materials—Modifications of Delany-Bazley models. J. Acoust. Soc. Jpn. E 1990, 11, 19–24. [Google Scholar] [CrossRef]

- Allard, J.F.; Atalla, N. Propagation of Sound in Porous Media: Modelling Sound Absorbing Materials, 3rd ed.; Wiley: Hoboken, NJ, USA, 2009. [Google Scholar]

- Maekawa, Z.; Rindel, J.H.; Lord, P. Environmental and Architectural Acoustics; Taylor and Francis: Oxford, UK, 2010. [Google Scholar]

| Density 48 kg/m3 | 25 mm | 50 mm | 75 mm | |

| Specimen 1 | 1004 | 1109 | 439 | |

| Specimen 2 | 797 | 752 | 740 | |

| Specimen 3 | 440 | 1512 | 536 | Total Avg. |

| Average | 747 | 1124 | 572 | 814 (Pa s/m2) |

| Density 60 kg/m3 | 25 mm | 50 mm | 75 mm | |

| Specimen 1 | 1444 | 986 | 1100 | |

| Specimen 2 | 524 | 666 | 1339 | |

| Specimen 3 | 891 | 817 | 1154 | Total Avg. |

| Average | 953 | 823 | 1198 | 991 (Pa s/m2) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kusno, A.; Sakagami, K.; Okuzono, T.; Toyoda, M.; Otsuru, T.; Mulyadi, R.; Kamil, K. A Pilot Study on the Sound Absorption Characteristics of Chicken Feathers as an Alternative Sustainable Acoustical Material. Sustainability 2019, 11, 1476. https://doi.org/10.3390/su11051476

Kusno A, Sakagami K, Okuzono T, Toyoda M, Otsuru T, Mulyadi R, Kamil K. A Pilot Study on the Sound Absorption Characteristics of Chicken Feathers as an Alternative Sustainable Acoustical Material. Sustainability. 2019; 11(5):1476. https://doi.org/10.3390/su11051476

Chicago/Turabian StyleKusno, Asniawaty, Kimihiro Sakagami, Takeshi Okuzono, Masahiro Toyoda, Toru Otsuru, Rosady Mulyadi, and Kusno Kamil. 2019. "A Pilot Study on the Sound Absorption Characteristics of Chicken Feathers as an Alternative Sustainable Acoustical Material" Sustainability 11, no. 5: 1476. https://doi.org/10.3390/su11051476

APA StyleKusno, A., Sakagami, K., Okuzono, T., Toyoda, M., Otsuru, T., Mulyadi, R., & Kamil, K. (2019). A Pilot Study on the Sound Absorption Characteristics of Chicken Feathers as an Alternative Sustainable Acoustical Material. Sustainability, 11(5), 1476. https://doi.org/10.3390/su11051476