1. Introduction

Plastic packaging boxes or trays for storing products are highly practical, economical, and convenient, and their demand in the food industry is increasing rapidly. Recently, plastic trays have been increasingly used as a packaging material for food containers or gift sets. However, most of these packaging materials are injection-molded, extruded, and thermoformed petroleum-based synthetic resins, e.g., polypropylene and polyethylene. These petroleum-based plastic materials are convenient to use, but they are causing serious environmental pollution, e.g., environmental hormone leakage due to incineration or landfill disposal, creation of toxic dioxins, and air pollution caused by incomplete combustion of waste.

To solve these serious environmental pollution problems, research and development on sustainable and environmentally friendly materials is actively being carried out. These materials can be used as easily as conventional plastic. If they are discarded, however, they are biodegraded by microorganisms in the soil and contribute to natural circulation, thereby minimizing the environmental pollution. Bio-based plastics are a category of bio-plastics, which accelerate the plastic decomposition rate by adding biomass to the plastic.

In developed countries, e.g., Germany, Italy, and the United States, regulations and laws for environmental protection have been strengthened, and food packaging, shopping bags, and plastic containers are gradually being replaced by biodegradable materials. Disposable containers and envelopes made of biodegradable plastics have been increasing in usage each year, due to the changes in people’s perception of the environment and the government’s guidelines. However, they are still inadequate compared with advanced countries.

Eco-friendly plastics, which have been developed in recent years, are mainly composed of photodegradable plastics, which are degraded by light (mainly ultraviolet rays), and biodegradable plastics, which are degraded by microorganisms. Examples of developed biodegradable polymers include the following.

Biodegradable polymers derived from natural products include starch, cellulose, chitin, chitosan, natural rubber, pulp, and the like.

Biodegradable polymers derived from microorganisms include PHB (polyhydroxybutyrate), PHV (polyhydroxyvalerate), pullulan, curdlan, xanthan gum, alginate, polyamino acids (polyglutamic acid, polylactic acid), and the like.

Biodegradable polymers derived from chemical synthesis include PLA (polylactic acid), PCL (polycaprolactone), polyorthoester, phosphagen, and diol/diacid aliphatic polyester [

1,

2,

3,

4,

5,

6,

7,

8,

9].

However, since most of the raw materials used for synthesizing these biodegradable polymers are expensive, the cost of the product is increased, thereby increasing the burden on consumers. Even after considerable effort, the process and production costs of the developed biodegradable resin need further consideration for the resin to be actually used as a viable material.

As a practical alternative for these materials, compositions and manufacturing techniques for bio-based plastics utilizing biomass, a natural material, have been developed [

10,

11,

12]. In this study, wheat bran was selected as a biomass and mixed with polypropylene (PP) to develop a bio-based plastic–foam cushion. Wheat bran (WB) is produced by separating flour and the embryo from milled wheat. It is thought to be advantageous for the foaming process because there are many viscous polymeric materials available, e.g., cellulose, hemicellulose, and pentanoic acid. The amount of additional wheat bran could control the biodegradation rate and vary the content in terms of flavor, aroma, color expression, and texture expression.

However, it is not easy to uniformly mix thermoplastic resin, polypropylene, and wheat bran. When kneading and foaming in an extruder, the wheat bran is pyrolyzed, due to the high-temperature environment inside the barrel, which may cause carbonization. Therefore, in this study, a water-blowing process using water vaporization and an exclusive screw for natural materials, e.g., biomass, were developed. We also tried to induce high-expansion foaming by designing the shape to improve the pressure gradient of the die. Therefore, a cushioning material that maximizes the volume expansion through a low density and high foaming ratio was prepared.

The foaming process using starch has been continuously studied [

13]. Previous studies have examined the effect of foaming by improving the mechanical properties of foams using additives [

14,

15,

16] or reinforcing fibers [

17] or by blending between materials [

18,

19]. There have also been studies investigating the effect of foam through chemical modification of natural materials [

20,

21], or approaching from a process perspective, using supercritical fluid [

22] as a foaming agent or applying a compression process [

23]. These studies utilize a wide variety of starches and commonly carry out the foaming process by inducing gelatinization, which is a unique characteristic of starch.

However, wheat bran is a biomass that can be used directly as feed for livestock but not for human consumption. In addition to the recycling of such materials, it is possible to produce high-expansion foams because it can induce the effect of gelatinization using starch components contained in wheat bran. This study is an eco-friendly process using vaporization of water, so it does not use inert gas such as CO2, N2, or chemical foaming agents harmful to the environment, and does not require any additional equipment. From this point of view, this study can bring various advantages in terms of ethical and economic aspects. This study aims to develop a more environmentally friendly product by reducing the amount of plastic-based petroleum resin, which is difficult to decompose. We expect that the foaming materials of this study will be applied to diverse fields, e.g., food and industrial packing materials, by producing them in sheet form.

2. Experiments

2.1. Materials

Polypropylene (PP, LOTTE Chemical Corp., Seoul, Korea, Grade No. SEP-550H, melt index = 30 g/10 min, density = 0.91 g/cm3, impact strength (at 23 °C) = 54 J/m, melting point = 167 °C), a thermoplastic, was used as the matrix material in this study. Polypropylene resin is an olefinic polymer, widely used because of its excellent formability, and a material that can be easily found in our living environment. It is also widely used as a safe plastic food container material, which has excellent high gloss, high flowability, impact resistance, and no detectable environmental hormones (bisphenol A (BPA)). The natural materials used in this study were milled wheat by-products and free-flowing fiber flakes (Ben Furney Flour Mills Pty., Ltd., Dubbo, Australia; Product Name: PURASTOCK Wheat Bran; ingredient information: Protein 10%, minimum crude fat 5%, moisture 7.2%, minimum dietary fiber 36%). The materials are derived from the first protective layer of wheat grains.

2.2. Equipment

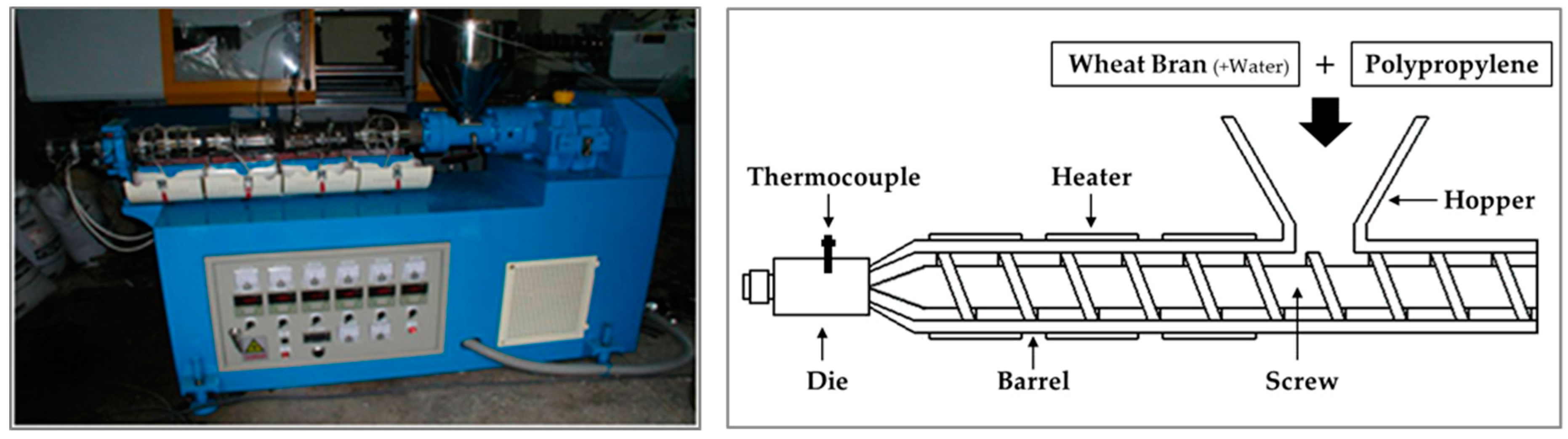

The extruder used in this study was a 40-mm small extruder (output = 7.5 kW, maximum revolutions per minute (RPM) = 1740, Yonsei University, Seoul, Korea) (

Figure 1). It was necessary to design a screw to generate a pressure profile capable of uniform mixing and metering between materials. Additionally, it was necessary to create natural materials with a low viscosity and to increase the pressure-drop rate. Thus, we designed a special screw for extruding the natural material to match the material characteristics of this study (

Figure 2). The viscosity of a natural material can be controlled by changing the amount of water. Because the viscosity of a resin is generally low, a low-viscosity resin was assumed for the design. A mixing zone was not needed because the material was pre-mixed before being barreled. For general polymer-forming screws, compression ratios of 2:1 to 4:1 are used. However, in this study, the compression ratio was designed to be 4:1 to 5:1 to induce high-expansion foaming by the pressure drop.

The detailed design plan of the screw used in this study is as follows. The feeding zone occupies 10–20% of the total length and has dimensions of 140–280 mm, which is a solid conveying zone. The pre-mixing zone for the natural materials is designed to be short because a long feeding zone is not necessary. The compressing zone occupies more than 50% of the total length, and is designed twice over the compressing zone by distributing the discrete compressing zone, considering the motor torque and natural carbonization. The mixing zone is supplied with pre-mixed natural material, thus, it does not need a mixing feature. However, it is designed with an Egan-type mixer, which is a simple feature considering the dispersion and distribution of water and natural materials. Finally, the channel depth is designed to be small and constant, so the plasticized resin can pass through the die.

The process conditions, e.g., the die temperature, barrel temperature, foaming agent, and gas input amount, affect the foaming ratio when the extruder performs the foaming process, however, the die shape of the extruder has the greatest influence on the foaming ratio. The die is designed according to the basic material properties, e.g., the viscosity. For this study, the die should be designed to maximize the pressure drop rate, considering the viscosity of the composite materials for wheat bran and PP, to obtain a high-expansion foam. Generally, when designing a die, it is necessary to uniformly form the molten resin that has been kneaded in a barrel. If possible, it should not be affected by the fluidity of the resin. Additionally, the temperature must be controllable.

Figure 3 shows a photograph and a drawing of the die used in this study. The die consists of three parts, as shown in

Figure 4.

Figure 4A shows the basic die connected to the barrel,

Figure 4B shows the adapter that connects the basic die and the designed die, and

Figure 4C shows a drawing of the core die designed in this study, which corresponds to the discharging part. The diameter of the designed die was 1 mm, and the length was 3 mm, which maximized the pressure drop. The viscosity of the bio-based plastic was expected to decrease.

2.3. Method

The process conditions of this study should be considered, together with the induction of the water vaporization in the extruder barrel, the prevention of carbonization caused by deteriorating natural materials, and the melting point of the matrix PP. Therefore, a preliminary experiment was conducted to investigate the correct process temperature (

Figure 5). This preliminary experiment did not induce foaming, as no water was added. It investigated only the PP70 and WB30 mixed condition to check whether the discharge proceeded normally from the extruder die. The mixing ratio was based on the inclusion criteria of domestic and foreign bio-based plastics (more than 20% in Europe, more than 25% in the USA, Japan, and Korea) [

24].

Upon examining the extruded composite molten PP–WB materials at the 160–170 °C of condition 1, the mixture failed to reach the melting point of the PP matrix. Thus, the flowability was poor, due to the low viscosity, and the discharge was poor. Condition 2 set the temperature of the barrel including the die to 160 to 180 °C. The discharge of the extruded composite molten material was somewhat improved over the previous experimental conditions, but was still discontinuous. As shown in condition 2 of

Figure 5, discontinuously discharged strands can be identified, as the melt was not complete and the flowability was low. In condition 3, a stable discharge was confirmed with the smoothest flow among the experimental conditions of

Table 1. From condition 4, carbonization started with the higher temperature and was discontinuously discharged in the form of moss. Based on the results of this preliminary experiment, the experiment was conducted with the extruder process temperature condition set to 190 °C.

In addition, prior to the foaming process according to the PP and WB mixing ratio, experiments were conducted to investigate the proper content of water as a foaming agent. Water was added in amounts of 15 to 45 PHR (parts per hundred resin) at a content ratio of 100, which is the sum of the PP and WB contents. At the beginning of each experimental condition, after confirming that the discharge was smooth, the discharge rate was gradually increased for high-volume foaming. This induced foaming by a pressure drop in the die to vaporize the water inside the barrel. During the foaming process, the maximum RPM of the extruder motor was 1500, and the RPM of the screw was 100.

Based on the process conditions investigated in this series of preliminary experiments, foamed cushioning material specimens were prepared and the foaming rate was measured. The measurement of the foaming ratio was averaged after measuring five specimens. In addition, an evaluation based on ASTM (American Society for Testing and Materials) D 3332 [

25] was carried out to evaluate the dynamic cushioning properties of the cushioning materials developed in this study. This is a method of measuring the acceleration by dropping a 1 kg plate-shaped object free from a height of 50 cm, placing the developed buffer material between the plate-shaped object and the floor, and measuring the change in acceleration. Based on the measured acceleration values, dynamic cushioning properties including the impact amount and the maximum acceleration value according to the product of the development cushioning material can be derived. In this experiment, a 3-axis accelerometer was used by itself as a lab scale, and its acceleration value was calculated in units of 1000 Hz and 1 ms.

3. Results and Discussion

To satisfy the basic content condition of domestic and foreign bio-based plastics, the experiment was carried out with 20% or more of wheat bran. However, when the bran content reached 80%, carbonization occurred, too much steam was generated, and the extrusion process could not be controlled due to the rapid discharge (

Figure 6). Therefore, in this study, the experimental results of the foam test of bio-based plastics using PP as a matrix were summarized for the condition when the bran content is in the range of 20–70% (

Figure 7).

In the PP80/WB20 condition, the highest density, low volume expansion ratio, and low foaming ratio were observed under experimental conditions. The best result was obtained with the PP50/WB50 condition. According to

Figure 7 and

Figure 8, the PP and WB mixing ratios for forming high-expansion foam materials show the best volume-expansion ratio and foaming ratio at 40 and 50% wheat bran content. Particularly, PP50/WB50 showed a 50-times volume-expansion ratio and a 98.4% foaming ratio. The density of the high-expansion ratio and the foaming ratio was 0.021 g/cm

3 in the experimental condition, which was the maximum value. It is considered that high-expansion foaming occurred because the PP density is generally about 0.9 g/cm

3. Moreover, when the mixing ratio of PP50/WB50 was fixed and the water content was varied, the high-expansion ratio was 62 times, the foaming ratio was 98.8% at 25 PHR, and the density was 0.017 g/cm

3 (

Figure 9 and

Figure 10). It is considered that there is a mixing ratio and water content between the materials to induce a suitable foam as a cushioning material. It is also necessary to increase the viscosity and to induce gelatinization of the starch component by examining the appropriate water content to maximize the volume expansion ratio. The micelle structure is loosened due to the optimization of the starch component, so that the water penetrates and swells, and water is vaporized at a high temperature to form cells of independent spaces. A scanning election microscope (JEOL Ltd., Product No. 7001F, Tokyo, Japan) observation was carried out to confirm the morphology of the foamed cushioning material of this study (

Figure 11 and

Figure 12). The cell showed an angled vinyl shape, unlike the cell of the usual foamed polymer resin, and the cell wall was relatively thin. The cell-morphology observation showed that the foaming process was carried out properly, however, additional studies on the durability and restoration characteristics of the material should be performed concurrently. The addition of a physical reinforcing agent should also be considered, depending on the application of the cushioning material.

PP/WB foam composites exhibited different volume expansion ratios depending on the mixing ratio between the materials. The content of 50/50 showed the highest value and was considered to be suitable as cushioning material. In addition, the sense of touch was different according to the content ratio. When the content of PP is high, the foam is hard, while when the content of WB is high, the foam is felt to be somewhat brittle.

Table 2 compares the dynamic cushioning properties of PP50/WB50 cushioning materials prepared in this study. The maximum acceleration value of the conventional commercial product is 1.018 G, and the developed cushioning material is 1.006 G, which has a lower maximum acceleration than the commercial cushioning material. This means that the developed cushioning material receives less force when it collides. In the measurement results of the impulse, the commercial product was 2.810 kg∙m/s while the cushioning material of this study was 2.530 kg∙m/s. The measurement results suggest the possibility of commercialization of cushioning materials in this study.

4. Conclusions

This study investigated polypropylene cushion materials foamed through the phase-change characteristics of water using natural by-product wheat bran. The results can be summarized as follows: It was possible to prepare a bio-based plastic cushion containing more than 50% wheat bran, by inducing a foaming ratio over 95%, it was possible to achieve a volume-expansion ratio from 16 times to over 62 times. In addition, PP and wheat bran bio-based plastics had an optimum mixing ratio of PP50/WB50 for high-expansion foaming, and the water content of the foaming agent was 25 PHR.

In response to the global demands for environmentally friendly products, this study aimed to reduce the use of plastics and develop eco-friendly foaming processes. The following conditions were implemented to meet these requirements:

- (1)

The bran content, which is a natural byproduct, was maximized to 50% or more.

- (2)

The study avoided the use of chemical additives that are harmful to the environment.

- (3)

The foaming process was simple, using only the phase change of water.

The results of this study have several advantages, as follows.

First, polypropylene is attempting to replace polystyrene, polyethylene, and polyurethane foams, because of its high tensile modulus, high melting point, excellent chemical stability, and excellent recyclability. However, its low melt tension and relatively narrow foaming temperature range make it difficult to induce high-expansion foaming. However, in this study, it was confirmed that high-expansion foaming is possible using a polypropylene matrix. Secondly, the foaming process of this study can be easily implemented using existing extrusion equipment and the existing process system.

Third, this technology maximizes eco-friendliness. Compared with conventional foaming technology (supercritical fluid, chemical foaming agent), it only uses the phase change of water, maximizes the natural-material content, and avoids the use of chemical additives. In addition, since the product has a human affinity (light yellow color, baking odor, and naturally soft touch), consumers who use the product can easily recognize that it is an eco-friendly product through their five senses. As described above, in this study, by maximizing the content of biomass byproducts, a highly expanded bio-based plastic foam was induced to provide an environmentally friendly product.

In the future, our additional study will highlight the product design elements through modifying the die shape, and we expect consumers who use environmentally friendly products to naturally recognize the green materials. Natural color and texture mean that when a consumer touches a product, it is difficult to feel the conventional plastic, due to the effect of the high-expansion foaming.

A product of this study is expected to replace existing EPS (Styrofoam) and PE foam as a carbon-saving eco-friendly product, which reduces the amount of plastic used. In addition, it can be applied to various applications through the production of a high-expansion foam sheet. Major expected applications include industrial cushioning packaging, shipping cold-storage and cushioning packaging, gift packaging, agricultural and marine packaging, electronics packaging, etc.