Digestion Procedure and Determination of Heavy Metals in Sewage Sludge—An Analytical Problem

Abstract

:1. Introduction

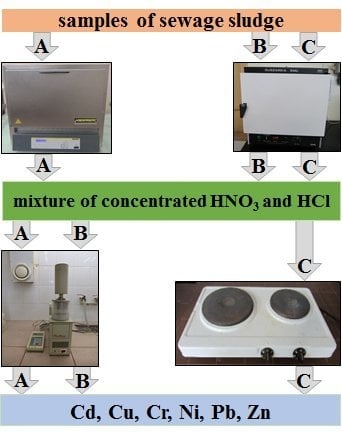

2. Materials and Methods

| heating time [min] | pressure [atm] | power [%] | |

| Step 1 | 5 | 17–20 | 60 |

| Step 2 | 10 | 24–27 | 80 |

| Step 3 | 10 | 27–30 | 100 |

| Cd | Cr | Cu | Ni | Pb | Zn | |

| Lamp current [mA] | 4 | 7 | 4 | 4 | 10 | 5 |

| Slit [nm] | 0.5 | 0.2 | 0.5 | 0.2 | 1.0 | 1.0 |

| Wavelength [nm] | 228.8 | 357.9 | 324.7 | 232.0 | 217.0 | 213.9 |

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Fytili, D.; Zabaniotou, A. Utilization of sewage sludge in EU application of old and new methods—A review. Renew. Sustain. Energy Rev. 2008, 12, 116–140. [Google Scholar] [CrossRef]

- Neczaj, E.; Grosser, A. Circular Economy in Wastewater Treatment Plant—Challenges and Barriers. Proceedings 2018, 2, 614. [Google Scholar] [CrossRef]

- Healy, M.G.; Clarke, R.; Peyton, D.; Cummins, E.; Moynihan, E.L.; Martins, A.; Béraud, P.; Fenton, O. Resource recovery from sewage sludge. In Sewage Treatment Plants: Economic Evaluation of Innovative Technologies for Energy Efficiency; Stamatelatou, K., Tsagarakis, K.P., Eds.; IWA Publishers: London, UK, 2015; pp. 139–162. ISBN 9781780405025. [Google Scholar]

- Zhang, X.; Wang, X.; Wang, D. Immobilization of Heavy Metals in Sewage Sludge during Land Application Process in China: A Review. Sustainability 2017, 9, 2020. [Google Scholar] [CrossRef]

- Paukov, A.; Magaril, R.; Magaril, E. An Investigation of the Feasibility of the Organic Municipal Solid Waste Processing by Coking. Sustainability 2019, 11, 389–401. [Google Scholar] [CrossRef]

- Cieślik, B.M.; Namieśnik, J.; Konieczka, P. Review of sewage sludge management: Standards, regulations and analytical methods. J. Clean. Prod. 2015, 90, 1–15. [Google Scholar] [CrossRef]

- Carabassa, V.; Ortiz, O.; Alcañiz, J.M. Sewage sludge as an organic amendment for quarry restoration: Effects on soil and vegetation. Land Degrad. Dev. 2018, 29, 2568–2574. [Google Scholar] [CrossRef]

- Fijałkowski, K.; Rorat, A.; Grobelak, A.; Kacprzak, M.J. The presence of contaminations in sewage sludge—The current situation. J. Environ. Manag. 2017, 203, 1126–1136. [Google Scholar] [CrossRef]

- Wiechmann, B.; Dienemann, C.; Kabbe, C.; Brandt, S.; Vogel, I.; Roskosch, A. Sewage Sludge Management in German; Umweltbundesamt: Dessau-Rosslau, Germany, 2015; Available online: https://www.umweltbundesamt.de/en/publikationen/sewage-sludge-management-in-germany (accessed on 5 February 2019).

- Kacprzak, M.; Neczaj, E.; Fijałkowski, K.; Grobelak, A.; Grosser, A.; Worwag, M.; Rorat, A.; Brattebo, H.; Almås, Å.; Singh, B.R. Sewage sludge disposal strategies for sustainable development. Environ. Res. 2017, 156, 39–46. [Google Scholar] [CrossRef] [PubMed]

- Statistical Yearbook of the Republic of Poland; Central Statistical Office: Warsaw, Poland, 2015; p. 106. Available online: https://stat.gov.pl/obszary-tematyczne/roczniki-statystyczne/roczniki-statystyczne/rocznik-statystyczny-rzeczypospolitej-polskiej-2015,2,10.html (accessed on 5 February 2019).

- Ragazzi, M.; Rada, E.C.; Ferrentino, R. Analysis of real-scale experiences of novel sewage sludge treatments in an Italian pilot region. Desalin. Water Treat. 2015, 55, 783–790. [Google Scholar] [CrossRef]

- Grobelak, A.; Grosser, A.; Kacprzak, M.; Kamizela, T. Sewage sludge processing and management in small and medium-sized municipal wastewater treatment plant—New technical solution. J. Environ. Manag. 2019, 234, 90–96. [Google Scholar] [CrossRef] [PubMed]

- Council Directive of 12th June 1986 on the Protection of the Environment, and in Particular of the Soil, When Sewage Sludge is used in Agriculture (86/278/EEC). Official Journal of the European Communities No L 181/6. Available online: https://publications.europa.eu/en/publication-detail/-/publication/2b059f2b-6a6d-4596-bf1a-3f02ad970026/language-en (accessed on 5 February 2019).

- Raboni, M.; Torretta, V.; Urbini, G. Influence of Strong Diurnal Variations in Sewage Quality on the Performance of Biological Denitrification in Small Community Wastewater Treatment Plants (WWTPs). Sustainability 2013, 5, 3679–3689. [Google Scholar] [CrossRef]

- Heavy Metals (Trace Elements) and Organic Matter Content of European Soils—A Feasibility Study; European Soil Bureau Scientific Committee: Ispra, Italy, 1999; Available online: http://ec.europa.eu/environment/archives/waste/sludge/pdf/heavy_metals_feasibility_study.pdf (accessed on 5 February 2019).

- Przewrocki, P.; Kulczycka, J.; Wzorek, Z.; Kowalski, Z.; Gorazda, K.; Jodko, M. Risk Analysis of Sewage Sludge – Poland and EU Comparative Approach. Pol. J. Environ. Stud. 2004, 2, 237–244. Available online: http://www.pjoes.com/Issue-2-2004,3793 (accessed on 5 February 2019).

- Borgulat, J.; Mętrak, M.; Staszewski, T.; Wiłkomirski, B.; Suska-Malawska, M. Heavy Metals Accumulation in Soil and Plants of Polish Peat Bogs. Pol. J. Environ. Stud. 2018, 27, 537–544. [Google Scholar] [CrossRef]

- Rosik-Dulewska, C. Impact of Municipal Wastewater Treatment and Processing Technologies on the Total Content of Trace Metals and Their Fractions in Sewage Sludge. Ecol. Chem. Eng. 2003, 10, 427–436. [Google Scholar]

- The Environment Protection Act. Journal of Law of 2001, No. 62, Item 627. Available online: http://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20010620627 (accessed on 5 February 2019).

- The Act on Waste. Journal of Law of 2013, Item 21. Available online: http://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20130000021 (accessed on 5 February 2019).

- Regulation of the Minister of the Environment of 6 February 2015 on Municipal Sewage Sludge. Journal of Law of 2015, Item 257. Available online: http://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20150000257 (accessed on 5 February 2019).

- Pathak, A.; Dastidar, M.G.; Sreekrishnan, T.R. Bioleaching of heavy metals from sewage sludge: A review. J. Environ. Manag. 2009, 90, 2343–2353. [Google Scholar] [CrossRef]

- Tytła, M.; Widziewicz, K.; Zielewicz, E. Heavy metals and its chemical speciation in sewage sludge at different stages of processing. Environ. Technol. 2016, 37, 899–908. [Google Scholar] [CrossRef]

- Spanos, T.; Ene, A.; Karadiova, I.B. Assessment of Toxic Elements Cu, Cr, Ni, Pb, Cd, Hg, Zn, As and Hexavalent Chromium in Sewage Sludge from Municipal Wastewater Treatment Plants by Combined Spectroscopic Techniques. Rom. J. Phys. 2015, 60, 237–245. [Google Scholar]

- Gaber, S.E.; Rizk, M.S.; Yehia, M.M. Extraction of certain heavy metals from sewage sludge using different types of acids. Biokemistri 2011, 23, 41–48. [Google Scholar]

- Feng, J.J.; Jia, L.; Liu, Q.Z.; Chen, X.L.; Cheng, J.P. Source identification of heavy metals in sewage sludge and the effect of influent characteristics: A case of study China. Urban Water J. 2018, 15, 381–387. [Google Scholar] [CrossRef]

- Patorczyk-Pytlik, B.; Gediga, K. BCR method in assessing alterations of copper forms in sludge composed according to different methods. Environ. Prot. Eng. 2009, 35, 89–94. [Google Scholar]

- Characterization of Sludge—Determination of Trace Elements and Phosphorus—Aqua Regia Extraction Methods; Polish Standard, PN-EN 13346:2002; Polish Committee of the Standardization: Warsaw, Poland, 2002.

- Kalisz, L.A.; Nechay, A.; Kaźmierczuk, M.; Sałbut, J.; Szyprowska, E.; Gierczak, A.; Kostrzewa-Szulc, J. Physico-Chemical and Biological Reference Methods of Municipal Sewage Sludge Investigation; Inspectorate of Environmental Protection: Warsaw, Poland, 2003. (In Polish) [Google Scholar]

- Jakubus, M.; Czekała, J. Heavy Metal Speciation in Sewage Sludge. Pol. J. Environ. Stud. 2001, 10, 245–250. Available online: http://www.pjoes.com/Heavy-metal-speciation-in-sewage-sludge,87379,0,2.html (accessed on 5 February 2019).

- Bezak-Mazur, E.; Dąbek, L.; Gawdzik, J. Influence of Mineralization and Analysis Technique on the Results of Determination of Iron and Nickel in Industrial Wastes. Pol. J. Environ. Stud. 2001, 10, 63–66. Available online: http://www.pjoes.com/Influence-of-mineralization-and-analysis-technique-on-the-results-of-determination,87354,0,2.html (accessed on 5 February 2019).

- Adamczyk-Szabela, D.; Anielak, P.; Wolf, M.W. Influence of Digestion Procedure and Residual Carbon on Manganese, Copper, and Zinc Determination in Herbal Matrices by Atomic Absorption Spectrometry. J. Anal. Methods Chem. 2017, 2017, 6947376. [Google Scholar] [CrossRef]

- Ishak, I.; Rosli, F.D.; Mohamed, J.; Ismail, M.F.M. Comparison of Digestion Methods for the Determination of Trace Elements and Heavy Metals in Human Hair and Nails, Malays. J. Med. Sci. 2015, 22, 11–20. Available online: http://www.mjms.usm.my/default.asp?tag=14&kod_volume=87 (accessed on 5 February 2019).

- Cristache, C.; Comero, S.; Locoro, G.; Fissiaux, I.; Ruiz, A.A.; Tóth, G.; Gawlik, B.M. Comparative Study on Open System Digestion vs. Microwave-Assisted Digestion Methods for Trace Element Analysis in Agricultural Soils; JRC Technical Reports; Publications Office of the European Union: Luxembourg, 2014. [Google Scholar]

- Nemati, K.; Abu Bakar, N.K.; Bin Abas, M.R.; Sobhanzadeh, E.; Low, K.H. Comparative study on open system digestion and microwave assisted digestion methods for metal determination in shrimp sludge compost. J. Hazard. Mater. 2010, 182, 453–459. [Google Scholar] [CrossRef] [PubMed]

- Abbruzzini, T.F.; Silva, C.A.; de Andrade, D.A.; de Oliveira Carneiro, W.J. Influence of Digestion Methods on the Recovery of Iron, Zinc, Nickel, Chromium, Cadmium and Lead Contents in 11 Organic Residues. Rev. Bras. Cieñc. Solo 2014, 38, 166–176. [Google Scholar] [CrossRef]

- Water Quality—Sampling—Part 15: Guidance on Preservation and Handling of Sludge and Sediment Samples; Polish Standard PN-ISO 5667-15; Polish Committee of the Standardization: Warsaw, Poland, 2004.

- Mckinley, J.D.; Thomas, H.R.; Williams, K.P.; Reed, J.R. Chemical aspects of the strengthening of contaminated material using lime. In Geoenvironmental Engineering: Ground Contamination: Pollutant Management and Remediation, 1st ed.; Yong, R.N., Thomas, H.R., Eds.; Thomas Telford Ltd.: Great Britain, UK, 1999; p. 289. ISBN 9780727747518. [Google Scholar]

- Riaz, U.; Murtaza, G.; Saifullah; Farooq, M. Influence of different sewage sludges and composts on growth, yield, and trace elements accumulation in rice and wheat. Land Degrad. Dev. 2018, 29, 1343–1352. [Google Scholar] [CrossRef]

- Długosz, J.; Gawdzik, J. The content of heavy metals in sewage sludge conditioned CaO. Arch. Waste Manag. Environ. Prot. 2014, 16, 49–56. Available online: http://awmep.org/?journal=ago&page=article&op=view&path%5B%5D=366 (accessed on 5 February 2019).

- Bacon, J.R.; Butler, O.T.; Cairns, W.R.L.; Cook, J.M.; Mertz-Kraus, R.; Tyson, J.F. Atomic Spectrometry Update—A review of advances in environmental analysis. J. Anal. Atomic Spectrom. 2019, 34, 9–58. [Google Scholar] [CrossRef]

- Spanos, T.; Ene, A.; Styliani Patronidou, C.; Xatzixristou, C. Temporal variability of sewage sludge heavy metal content from Geek wastewater treatment plants. Ecol. Chem. Eng. S 2016, 23, 271–283. [Google Scholar] [CrossRef]

- Sánchez, C.H.; Gutiérrez, Á.; Galindo, J.M.; González-Weller, D.; Rubio, C.; Revert, C.; Burgos, A.; Hardisson, A. Heavy Metal Content in Sewage Sludge: A Management Strategy for an Ocean Island. Rev. Salud Ambient. 2017, 17, 3–9. Available online: http://www.ojs.diffundit.com/index.php/rsa/article/viewFile/758/798 (accessed on 5 February 2019).

- Li, J.; Luo, G.; Gao, J.; Yuan, S.; Du, J.; Wang, Z. Quantitative evaluation of potential ecological risk of heavy metals in sewage sludge from three wastewater treatment plants in the main urban area of Wuxi China. Chem. Ecol. 2014, 31, 235–251. [Google Scholar] [CrossRef]

| Sludge | Content [mg/kg] | ||||||

|---|---|---|---|---|---|---|---|

| Cd | Cr | Cu | Ni | Pb | Zn | ||

| Method A | |||||||

| raw | range median | 3.7–4.4 3.85 | 9.0–11.6 10.20 | 126.9–143.5 132.55 | 12.7–22.7 15.80 | 27.6–35.7 31.85 | 843.1–986.5 875.55 |

| stabilized | range median | 5.1–8.4 5.25 | 4.1–9.1 7.00 | 85.2–143.5 106.45 | 17.9–29.2 19.90 | 37.2–69.1 42.10 | 547.8–869.2 681.35 |

| Method B | |||||||

| raw | range median | 3.0–3.8 3.60 | 10.8–14.8 11.85 | 121.2–136.9 124.50 | 14.6–27.9 20.30 | 30.7–34.1 32.15 | 836.7–1010.7 886.6 |

| stabilized | range median | 5.0–7.7 5.20 | 8.5–11.2 9.45 | 86.1–121.7 100.80 | 19.5–71.3 21.60 | 47.3–82.0 50.50 | 575.0–898.3 704.05 |

| Method C | |||||||

| raw | range median | 2.3–3.5 2.55 | 9.9–12.7 10.70 | 108.0–122.1 111.90 | 12.6–13.8 13.15 | 29.1–32.5 30.75 | 780.4–907.9 792.2 |

| stabilized | range median | 9.9–12.7 10.70 | 7.1–8.9 8.40 | 69.3–104.2 86.80 | 15.7–23.7 16.90 | 36.3–55.8 39.75 | 487.2–761.5 601.2 |

| Method A | ||||||

| Sample no. 3 | Cd | Cr | Cu | Ni | Pb | Zn |

| confidence interval for the mean [mg/kg] | 4.44 ± 0.77 | 11.04 ± 2.39 | 137.68 ± 4.51 | 22.68 ± 5.52 | 27.60 ± 9.73 | 879.56 ± 107.34 |

| standard deviation [mg/kg] | 0.54 | 1.68 | 3.17 | 3.88 | 6.84 | 75.43 |

| RSD [%] | 12.16 | 15.22 | 2.30 | 17.11 | 24.78 | 8.58 |

| Sample no. 4 | Cd | Cr | Cu | Ni | Pb | Zn |

| confidence interval for the mean [mg/kg] | 8.44 ± 1.14 | 4.10 ± 1.10 | 85.20 ± 3.70 | 29.24 ± 2.29 | 69.14 ± 10.73 | 547.76 ± 57.75 |

| standard deviation [mg/kg] | 0.80 | 0.77 | 2.60 | 1.61 | 7.54 | 40.58 |

| RSD [%] | 9.48 | 18.78 | 3.05 | 5.51 | 10.91 | 7.41 |

| Method B | ||||||

| Sample no. 3 | Cd | Cr | Cu | Ni | Pb | Zn |

| confidence interval for the mean [mg/kg] | 3.50 ± 0.31 | 11.94 ± 2.26 | 127.14 ± 1.39 | 27.90 ± 0.97 | 32.86 ± 0.84 | 913.00 ± 22.84 |

| standard deviation [mg/kg] | 0.22 | 1.59 | 0.98 | 0.68 | 0.59 | 16.05 |

| RSD [%] | 6.11 | 13.32 | 0.77 | 2.44 | 1.80 | 1.76 |

| Sample no. 4 | Cd | Cr | Cu | Ni | Pb | Zn |

| confidence interval for the mean [mg/kg] | 7.72 ± 0.81 | 11.22 ± 1.28 | 86.14 ± 0.51 | 71.26 ± 6.25 | 81.98 ± 0.83 | 575.08 ± 9.43 |

| standard deviation [mg/kg] | 0.57 | 0.90 | 0.36 | 4.39 | 0.58 | 6.63 |

| RSD [%] | 7.38 | 8.02 | 0.42 | 6.16 | 0.71 | 1.15 |

| Method C | ||||||

| Sample no. 3 | Cd | Cr | Cu | Ni | Pb | Zn |

| confidence interval for the mean [mg/kg] | 2.32 ± 0.26 | 11.04 ± 0.78 | 110.78 ± 2.11 | 13.22 ± 0.44 | 30.02 ± 1.05 | 797.54 ± 17.00 |

| standard deviation [mg/kg] | 0.18 | 0.55 | 1.48 | 0.31 | 0.74 | 11.95 |

| RSD [%] | 7.76 | 4.98 | 1.34 | 2.34 | 2.47 | 1.50 |

| Sample no. 4 | Cd | Cr | Cu | Ni | Pb | Zn |

| confidence interval for the mean [mg/kg] | 6.02 ± 0.37 | 8.84 ± 1.04 | 69.32 ± 2.03 | 23.70 ± 0.85 | 55.84 ± 3.09 | 487.20 ± 7.68 |

| standard deviation [mg/kg] | 0.26 | 0.73 | 1.43 | 0.60 | 2.17 | 5.40 |

| RSD [%] | 4.32 | 8.26 | 2.06 | 2.53 | 3.89 | 1.11 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Turek, A.; Wieczorek, K.; Wolf, W.M. Digestion Procedure and Determination of Heavy Metals in Sewage Sludge—An Analytical Problem. Sustainability 2019, 11, 1753. https://doi.org/10.3390/su11061753

Turek A, Wieczorek K, Wolf WM. Digestion Procedure and Determination of Heavy Metals in Sewage Sludge—An Analytical Problem. Sustainability. 2019; 11(6):1753. https://doi.org/10.3390/su11061753

Chicago/Turabian StyleTurek, Anna, Kinga Wieczorek, and Wojciech M. Wolf. 2019. "Digestion Procedure and Determination of Heavy Metals in Sewage Sludge—An Analytical Problem" Sustainability 11, no. 6: 1753. https://doi.org/10.3390/su11061753

APA StyleTurek, A., Wieczorek, K., & Wolf, W. M. (2019). Digestion Procedure and Determination of Heavy Metals in Sewage Sludge—An Analytical Problem. Sustainability, 11(6), 1753. https://doi.org/10.3390/su11061753