Abstract

This paper addresses the connection between circular building design and residential health and well-being. The general research objective is to determine assessment criteria for the performance of indoor partitioning products in a circular model. The overarching aim is to establish a more integrated and inclusive approach to the transition from linear to circular built environments. This ties in with recent calls for a more comprehensive evidence-base to better inform the policy debate, in the light of interrelated Sustainable Development Goals. The paper emphasises the operational level, looking closer at the actual performance of circular economy implementation, providing more grip on performance indicators of infill components in circular applications, specifically partition walls. Next to partitioning one can think of other components in the infill domain, such as kitchens, bathrooms and mechanical, electrical, plumbing installations. After a brief background sketch, a literature review is reported regarding indoor environmental quality and indoor air quality in general and the linkage with circular and flexible building (products) in particular. Next, an analysis is made of three assessment schemes that address the operational level. Subsequently, several criteria are synthesized and tested. It was shown that the assessment schemes have overlapping and complementary features that, in unison, provide a solid basis for an integrated assessment of circularity potential and health impact of infill products. The test-case helped to pinpoint generic, as well as case-specific, learning points. The interface between product performance and building performance over time remains a grey zone, insufficiently covered by current criteria. More stringent coordination efforts are essential to safeguard circularity potential and healthy living environments pre-use, post-use and not least in-use.

1. Introduction

Circular Building is an approach that has gained considerable traction during the past decade, not least in the Netherlands. Related to concepts such as Circular Economy, Cradle-to-Cradle®, Blue Economy and Regenerative Design, circular building (CB) accentuates the closing and coupling of material flows in order to establish effective and efficient resource cycles. CB inherently adheres to a systemic, holistic worldview, incorporating multiple flows and-social, ecological, economic-values [1]. It implies that buildings and building components are designed to retain value over time, tailor-made for their specific service lives and responsive to potential disruptions. This way, wasting of buildings and building components can be reduced or avoided altogether. This touches upon a myriad of aspects, such as design, asset management, stakeholder integration, user behaviour, legal framework, procurement and reverse logistics. Many of the associated data are not available yet or only on a level that insufficiently addresses circular performance in use and operation [2]. Moreover, if social aspects are considered within the applied guidelines, they are usually not addressing specific benefits for end-users. Without integrating this user domain, replicability of circular building concepts on the larger scale is thought to hamper true sustainable development [3].

This paper addresses research gaps concerning the linkage between resident health and well-being on the one hand and circular and flexible (Circ-Flex) product performance on the other. Circ-Flex can be understood as a systems approach rooted in the synergistic liaison between circular and flexible characteristics, as defined by Geldermans et al. [3]. Circular characteristics concern the dynamic total of associated processes, materials and stakeholders that accommodate renewable flows of building materials and products at optimal rates and utilities. Flexible characteristics concern those aspects that allow easy rearrangement of building components, whilst accommodating changing needs of occupants. Geldermans et al. integrated three domains: circularity capacity, flexibility capacity and user capacity, in order to extend the CB discourse to the domain of the end-user. They tested this on the design and operation of non-bearing indoor partition wall schemes, that are likely to change over time due to new functions or different user requirements. That same product-an indoor partitioning wall-is at the heart of underlying study.

The general research objective is to determine assessment criteria for the performance of indoor partitioning products in a circular model, internalizing residential health & well-being as well as operational processes. The overarching aim is to establish a more integrated and inclusive approach to the transition from linear to circular built environments. This ties in with recent calls for a more comprehensive evidence-base to better inform the policy debate, in the light of interrelated Sustainable Development Goals, as communicated by the World Health Organization Regional Office for Europe [4]. Results from this analysis lead to specific areas of intervention concerning the partitioning product in the test-case, and, more importantly, generic lessons about integrated performance indicators of infill components in Circ-Flex applications. Next to partition walls one can think of other components in the infill domain, such as kitchens, bathrooms and service-mechanical, electrical, plumbing-installations.

The paper is structured as follows. After a brief background sketch from the perspective of interior partitioning, as one of the main aspects of infill and its relation to user benefits and circular material flows, the research design is explained. This includes a literature review regarding indoor environmental quality and indoor air quality in general and the relation with circular and flexible building (products) in particular (Section 3), an analysis and synthesis of three assessment schemes aiming at the operational level (Section 4) and the validation of synthesized criteria on a test-case (Section 5). Finally, in Section 6, the results are discussed from various vantage points, incorporating notions of: validity, data availability, stakeholder engagement, contextual conditions, supply and demand patterns and regulatory framework.

Background Sketch

In Western societies, we usually spend 80–90% of our daily lives indoors, which necessitates an appropriate management of the indoor environment “so that we feel comfortable and healthy” [5]. What’s more, we tend to modify our indoor environment to meet new requirements, following private considerations or from a regulatory point of view. However, in the design and management of residential buildings, modifications are usually not factored in. This is the case for many typologies and in many countries, not least the multi-family homes that form a large part of the building stock in the Netherlands [3]. One of the reasons is that the shortage of housing after the 2nd world war induced a massive building production against low costs. Comfort, health and well-being of the residents was addressed but primarily in the sense of minimum size standards and functional basics, not taking into consideration important factors such as diversity and change (e.g., [6,7,8,9,10,11]). Diversity and change, however, are factors that define the sustainability of the housing stock, both from a social and from a real estate perspective. Habraken’s Open Building concept and Brand’s shearing layers of change are rooted in that notion [11,12]. The former introduced the division between support (structural aspects of a building aimed at collective use and usually for long periods of time) and infill (the individual fit-out on a household level, usually with shorter use cycles). This notion of short-cycle functions has a material consequence and, as such, a strong connection with circular, renewable material and product flows [13,14].

2. Methods

First, in Section 3, a brief literature review is reported regarding indoor environmental quality (IEQ) and indoor air quality (IAQ) in general and the connection with Circ-Flex in particular. The emphasis is on residents’ health & well-being in relation to circular building assessments. Multiple search terms were used in various combinations, in English as well as in the Dutch translation, using multiple-academic and general-search engines. The variation in search engines was deemed important, not least given the significance of circular building developments outside of the academic realm [15]. The consulted literature during the first iteration contributed to additional key terms, subsequently leading to a set of 26 terms, see Table 1. Although there are certainly other terms that represent thematic overlaps, it was estimated that aforementioned approach established a comprehensive and workable framework. Given that CB is still in its initial stage, particularly with regard to a sound scientific and practical evidence-base, other terms (such as ‘sustainable’ and ‘green’) were applied instead of ‘circular’ in a secondary query.

Table 1.

Search terms applied in various combinations, in English and Dutch translation.

Subsequently, in Section 4, the link between IAQ and circularity is further explored with regard to assessment tools and guidelines that focus on the product and operational level. Because tools and guidelines with that specific aim are rare, several instruments with an overlapping scope are explored, either concerning material circularity or concerning indoor air quality within sustainable building frameworks. Three schemes are scrutinized in more detail: Cradle to Cradle Certified™ (version 3.1), the Pre-Returnable Procurement® tool (version 3.1) and the WELL Building Standard™ (version 2). The former two show overlaps in their focus on human health and circularity, albeit with different objectives and approaches. The latter one does not focus on circularity but puts an accent on human health in the overall performance of a building during its service life, including the building products. Based on these schemes, criteria are synthesized. Several embodied impacts are included to underscore systemic relevance and interrelations between factors. The aim is thus not to compare existing tools but to analyse, prioritize and synthesize criteria matching the study’s specific objective.

Next, in Section 5, the synthesized criteria are applied to an indoor partitioning product, comprising of a solid, modular prefab wall panel. The aim of this step is twofold: (1) to validate the criteria and test the workability, shedding a light on the level of detail required to assess the product and operational level, including the entire process from harvesting and/or extraction of resources and all people involved in that process, up to use and reuse and (2) to detect specific points of intervention regarding the product and operation under scrutiny. Several industry partners contributed to this assessment stage, providing data on product properties, production processes, (reverse) supply chain logistics and waste treatment.

3. Literature Review

3.1. Assessing Indoor Environmental Quality

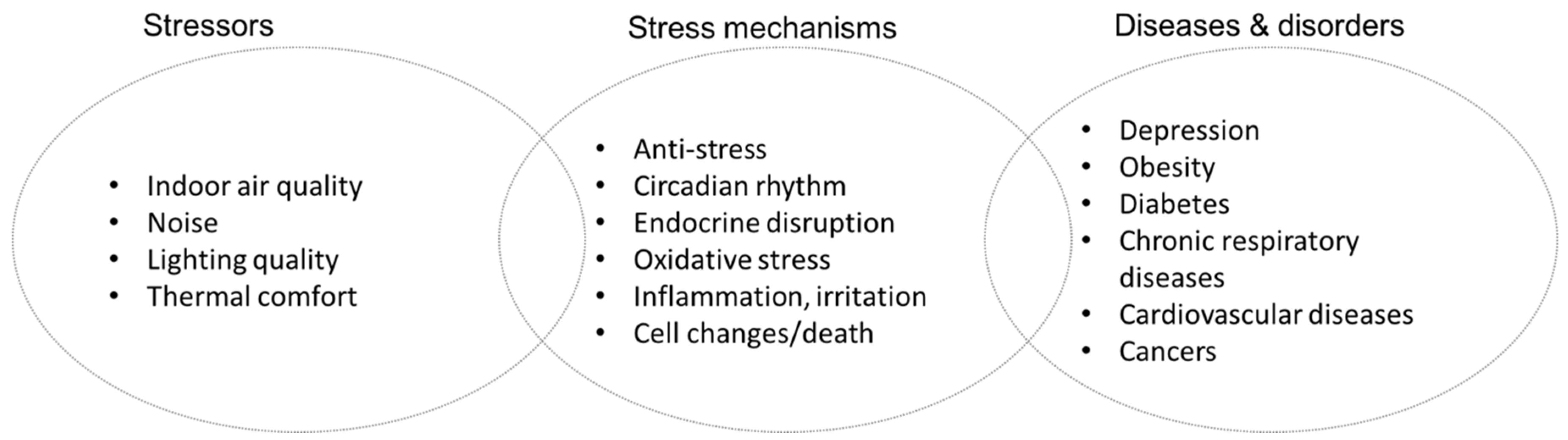

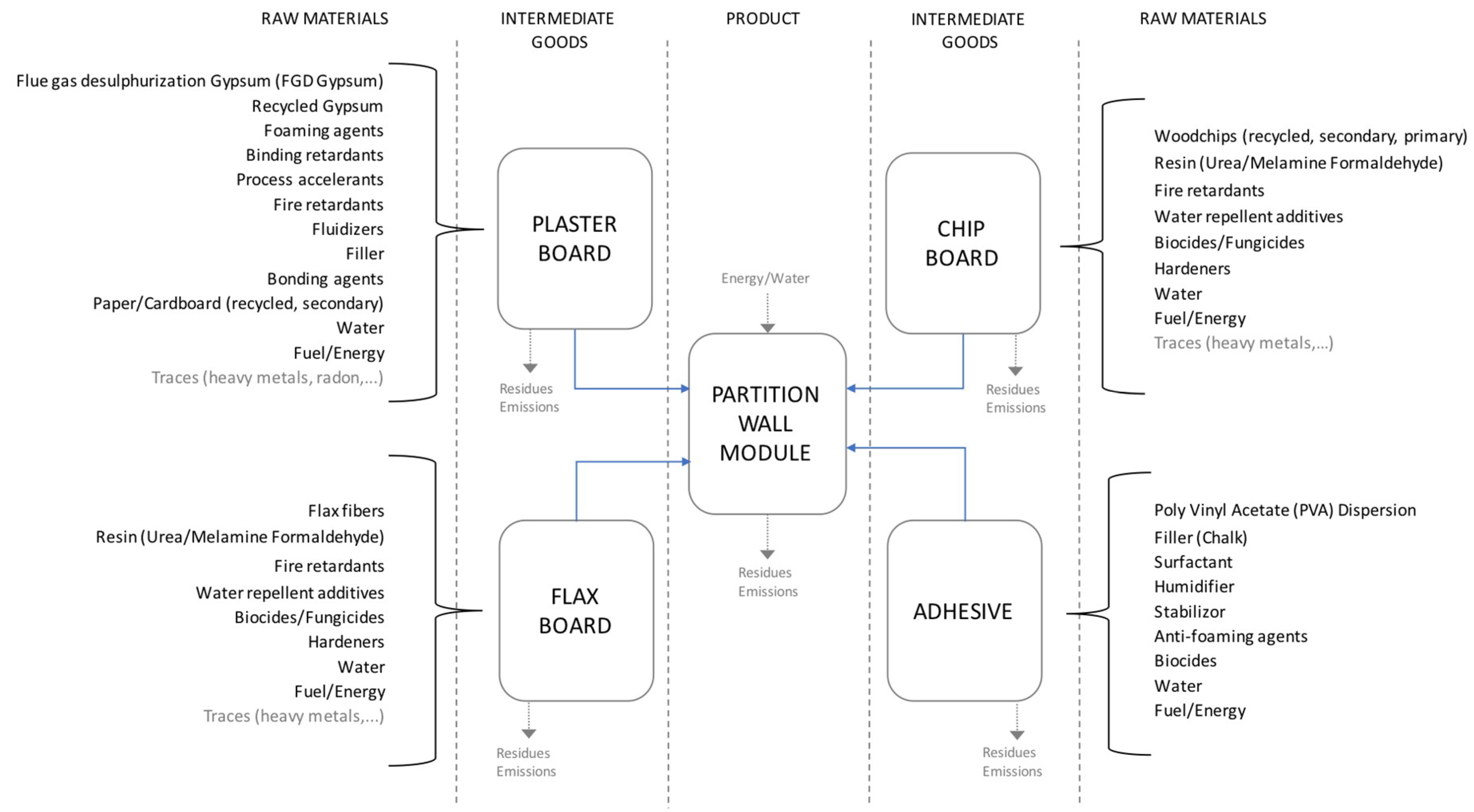

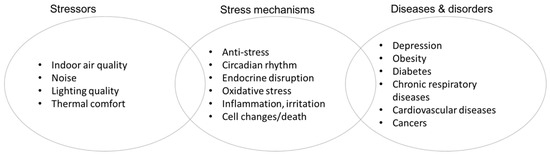

Indoor Environmental quality (IEQ) can be described by a variety of aspects (or stressors), such as: odour, air pollution, fresh air supply, air velocity, moisture, temperature, noise, vibrations, illuminance levels, luminance ratios, reflection, tactility and appearance [5,16,17]. From those aspects, a range of categories can be derived: from indoor air quality, thermal comfort, acoustics and visual or lighting quality, to aesthetic quality, spatial quality, tactile quality and ergonomic quality. All related to the human senses. Potential stress factors concern all three systems of the human body (nervous system, immune system, endocrine system) and can result in both mental and physical effects [5]. It is estimated that one in six Europeans live in unhealthy buildings [18]. Bluyssen (2013) states that major health effects seem to be associated with more than one stressor, whilst taking account of previous and future exposures, as well as duration and combination of exposures [19]. Figure 1 lists several associated stressors, stress mechanisms and diseases & disorders.

Figure 1.

Stressors, stress mechanisms, diseases & disorders associated with indoor environmental quality [19].

Internal partitioning can have an impact on all subsets of IEQ. Most of the subsets are also addressed in the European standards, albeit on a basic level. The complexity that resonates in Figure 1 has not yet found its way to standardization schemes in line with end-user needs [19,20,21]. There is ongoing debate about control measures, assessment methods, indicators and interactions between factors. With regard to indoor air quality (IAQ), the Scientific Committee on Health and Environmental Risks (SCHER) states that over 900 chemicals, particles and biological materials are associated with health effects and the database for indoor air risk assessment is limited [22]. Multiple factors determine the IAQ, such as quality of the surrounding outdoor air, ventilation and indoor sources of pollution. For this study, the focus is on indoor sources, specifically building products and finishing materials associated with the function of partitioning. Products and materials used in indoor partitioning may release physical, chemical or biological emissions that can have adverse health effects. Primary emissions are those substances released directly, as an inherent characteristic of the material or product in question, whereas secondary emissions are those substances that are released through actions on the materials [23]. Emissions can take place during or shortly after construction as well as in the long-term use stage and during deconstruction at the end of a material or product service life. Adverse effects for the residents are dependent on exposure, dose and response over time.

McDonough and Braungart [24] stated that none of the materials used in contemporary buildings are specifically designed to be healthy to people. This statement underscored the fact that materials, products and buildings have become more and more heterogeneous, introducing multiple substances-and synthetics-that pose potential threats to human health. Building standards regarding health and safety have difficulties to keep up with this development [25]. In their article, McDonough and Braungart mention, amongst others, plasticizers in Poly Vinyl Chloride (PVC) that may disrupt human endocrine systems. Furthermore, they refer to the use of heavy metals such as lead (that have neurotoxic properties) and cadmium (classified as carcinogenic). Last but not least, they mention volatile organic compounds (VOC, suspected carcinogens and immune system disruptors) released from, for example, particle boards, paints and adhesives. The list of harmful substances is long and risk assessments are up for debate but the statement of McDonough and Braungart remains valid. Even if some potentially harming chemicals are being phased out, others emerge, in response to ever changing market and regulatory dynamics. Think of additives to enhance fire safety, for example. What’s more, the heavy accent on energy efficiency measures in buildings like airtightness, as a consequence of climate and resource policies, may make matters worse, because such measures inherently imply an increased need for ventilation to avoid accumulation of air-contaminants, amongst others [19].

A study by Steinemann et al. [26] on the focus on indoor air quality of green buildings—and associated certifications–points out that IAQ is not yet fully integrated in the assessment methodologies. They observe that “green” certification schemes may provide inadequate inherent incentive for improving IAQ and that “green practices and products could actually impair IAQ.” An important factor in this respect is the large focus on ventilation for IAQ control, rather than on source control and exposure reduction [26]. Multiple other studies and policy documents in this or related fields indicate that there is or should be an increased attention for IAQ in the current (European) building practice, beyond energy performance and global climate concerns alone [19,25,27,28,29,30,31,32,33,34,35,36]. An important step in securing such attention on the operational side is the recently revised Energy Performance of Buildings Directive (EU) 2018/844 of The European Commission (EC) which puts more emphasis on human health and well-being [37]. With regard to the regulatory framework, a brief study of the literature reveals significant differences between scope, threshold levels, methods and (European Union (EU) member) states [19,21,38]. The debate is ongoing between academia, industry and authorities regarding objectives and legally binding restrictions. Not only due to varying interests and interpretations of available data but also linked to the fact that assessments are difficult because indoor air can contain a mixture of many different pollutants [22]. Important are the complex interrelations between various factors, that can have a significant effect on the IAQ. An example is the relation between formaldehyde emissions, room temperature, relative humidity and air circulation rates [39,40,41,42]. EU regulations in this respect tend to aim at single products rather than accumulated exposure. Moreover, with regard to the Netherlands, mechanisms of monitoring and law-enforcement are missing [21].

3.2. The Operational Level

This section aims to establish a more integrated approach to indoor environmental quality by coupling user benefits to circularity and flexibility. Specific attention thus goes to the relation between the three aspects: user health aspects associated with partition materials; flexibility of partitioning schemes; and circularity of applied materials and products. The objective is to rate the potential impact on residents’ health, well-being and comfort concerning, both, the intrinsic material properties of the wall-components (are there reasons for concern regarding the applied materials on the shorter or longer term?) and the related construction & deconstruction properties (can the components be placed and reutilized easily?). Simultaneously, the circularity factor dictates that the whole-reverse-supply chain needs to be taken into account, in order to facilitate material cycles beyond the housing unit. Combined, those points increase the complexity of an assessment, not least regarding the availability of specific data.

Aforementioned complexity is one of the reasons why assessment tools that aim to measure circularity are often rated sub-optimal [43,44,45,46,47,48,49,50]. Such tools simplify the complexity that is inherently part of circular product and material systems, failing to take account of a “specific or detailed level (...) to further focus on the very core and essence of circular economy, which is the circulation and recirculation of products and materials in (open or closed) loops” [44]. Saidani et al. introduce an operational and product level, which they refer to as ‘nano-level,’ next to the macro (city, region or country), meso (sector or inter-firm) and micro (single company) levels that are the commonly applied scale-levels in approaches to measure circularity [44,51,52]. The argument for a shift of focus to the nano-level is that this operational level essentially binds the various scale levels, whilst looking closer at the actual, effective performance of circular economy implementation [44].

The reality of extracting detailed data from, for example, suppliers and manufacturers, however, is more often than not disproportionately complicated or labour-intensive, if the data are available at all. In its elaboration on barriers for the CE, Nguyen et al. identify three barriers that stop companies from shifting from linear to circular resource use with regard to their products. First, the extensive supply and manufacturing footprint that companies have created, leading to geographic dispersion of parts, even for simple products [53]. Second, the sheer complexity and proliferation of modern product formulations, rarely labelled or made public, hence difficult to identify, even for manufacturers themselves [53]. And third, the difficulty of ingrained habits, linked to decisions made a long time ago [53]. It is thus unsurprising that, to date, there is no recognized, evidence-based way to assess how effective a building product or service truly is in making the transition from a linear to a circular mode of operation [54,55,56]. WBMCD states that companies are shaping and framing the concept of CE based on how it is most material to their core business, which leads to a lack of consensus regarding measuring circularity [56].

Saidani et al. identified three tools that particularly focus on product and operational circularity: Material Circularity Indicator (MCI, Ellen MacArthur Foundation, 2015), Circular Economy Toolkit (CET, University of Cambridge, 2013) and Circular Economy Indicator Prototype (CEIP, Cayzer et al., 2017) [44]. An assessment of these tools revealed substantial room for improvement with regard to, most notably, operational value. Each tool shows a lack of data-construction support and practical guidance. As described above, such operational aspects are crucial in the context of this paper. Moreover, those tools do not distinguish different renewability routes, nor do they connect substantially with social factors that are intertwined within the sustainable development goals (SDG), put forward by the United Nations [57]. For example, with regard to clean water (SDG6), clean energy (SDG7), decent work (SDG8), reduced inequalities (SDG10) and so forth.

Furthermore, the Circular Building Assessment scheme (CBA) deserves mentioning, which is currently being developed within the framework of the European Horizon 2020 project Buildings as Material Banks (BAMB). CBA brings together four years of study and practical experience regarding, most prominently, reversible building design and material passports. However, at the moment of writing, this instrument is still in the development stage. Moreover, although CBA is designed as a modular tool and thus allows for extensions in the future, its scope does not (yet) include health data in relation to end-users of buildings [58,59].

From the viewpoint of building-occupants’ health related to material use, there are few assessment schemes on the market that prioritize this domain [3,26]. However, the WELL Building Standard, launched in 2014, has been identified as a meaningful framework in this context, as it focuses explicitly on health & well-being of building occupants.

Moreover, the Cradle to Cradle® Product Standardization scheme (C2C Certified™) offers a matching approach, revolving around material health and material reutilization. Lastly, Dutch firm Rendemint developed the Pre-Returnable Procurement® circular purchasing tool (PRP®), which is gradually gaining ground in The Netherlands. PRP® aims at whole value chains, tracking and tracing resource use and preservation, as well as social fairness. WELL Certified™, C2C Certified™ and PRP® are further introduced in Section 4.

4. Analysis and Synthesis of Three Assessment Schemes

Three schemes mentioned at the end of Section 3 are further introduced below. Together they provide the basis for a set of criteria and assessment guidelines.

4.1. Cradle to Cradle Certified™

With regard to the relation of IAQ and circular building principles, the Cradle to Cradle concept–philosophy and certification–(C2C®) deserves recognition. As of the 1990s, C2C® has been dedicated to removing potentially dangerous chemicals from current life cycles, with particular attention for human exposure in the built environment. The C2C Certified™ program was launched in 2005 by McDonough Braungart Design Chemistry (MBDC). It focuses predominantly on the product level [60]. In 2010, a scale-up of C2C Certified™ took place, executed by the newly founded Cradle to Cradle Products Innovation Institute. The C2C Certified™ scheme includes five assessment categories: Material Health, Material Reutilization, Renewable Energy, Water Stewardship and Social Fairness. Thirty-nine (39) standard requirements are distributed over these five categories. Furthermore, Certified™ has five certification levels: Basic, Bronze, Silver, Gold, Platinum, which reflect the level of accomplishment. The standard requirements relate to one or more of the certification levels. C2C Certified™ guides and controls the assessment trajectory of products and processes, accentuating the necessity to submit evidence-based documents and to gradually improve.

4.2. WELL Certified™

The WELL Building Standard was launched by the International WELL Building Institute in 2014, seeking to implement, validate and measure features that support and advance human health and well-being of building occupants [61]. WELL approaches human health as a state of being free of disease and “the enjoyment of productive lives from which we derive happiness and satisfaction” [62]. The Standard’s performance metrics are based on a review of the existing research on the effects of indoor spaces on individuals and has been advanced through a peer reviewed process. The certification procedure includes submission of evidence-based documents as well as a performance evaluation. The focus is on the following categories: Air, Water, Nourishment, Light, Movement, Thermal Comfort, Sound, Materials, Mind and Community. Within these categories, WELL distinguishes twenty-three (23) preconditions and ninety-four (94) optimizations [62]. For each certification level (Silver, Gold and Platinum), 100% of the preconditions must be met. Furthermore, between 20% and 80% of the optimizations must be met, 20% for Silver and 80% for Platinum [63].

4.3. Pre-Returnable Procurement®

The Pre-Returnable Procurement® tool was first described by Rendemint in 2009 and is available as a software tool since 2011. PRP® is designed to analyse, measure and compare a reported end-result (project, process, product), based on ‘circularity potential.’ This circularity potential is defined as the provable preserved resources throughout the whole value chain, from resource to resource, realized in accordance with international human rights and relative to ‘absolute circularity’ [64]. ‘Absolute circularity,’ in the definition of Rendemint, means: zero resource loss and zero human rights violation. PRP® measures and compares the preservation in quality, quantity, non-toxicity and human rights of initial and end-weight (in kg) to (1) achieve an end-result, (2) maintain and reuse that end-result and (3) break the end-result down again to the resource level. PRP® provides an integrated assessment method, intentionally avoiding a scoring system based on selected criteria. To structure and manage the data-collection and registration process, PRP® applies a division in three entry levels: Items, Materials and Resources. Each level distinguishes the categories ‘Product,’ ‘Extraction,’ ‘Social fairness,’ ‘Toxicity’ and ‘Reutilization.’ Data need to be based on verifiable evidence regarding the whole chain of custody.

4.4. Complementary and Overlapping Aspects of the Selected Schemes

The three aforementioned schemes enter the realm of material use, as well as performance over time, whilst addressing the health and engagement of stakeholders. Given their differentiated objectives, the schemes cannot be compared but they comprise overlapping and complementary attributes. Table 2 lists several characteristics per scheme and indicates the connection with the core focus of this paper, that is, the relation between (1) user health, (2) circularity and (3) flexibility.

Table 2.

Characteristics of three schemes: Cradle to Cradle (C2C) Certified™, WELL Certified™ and PRP®.

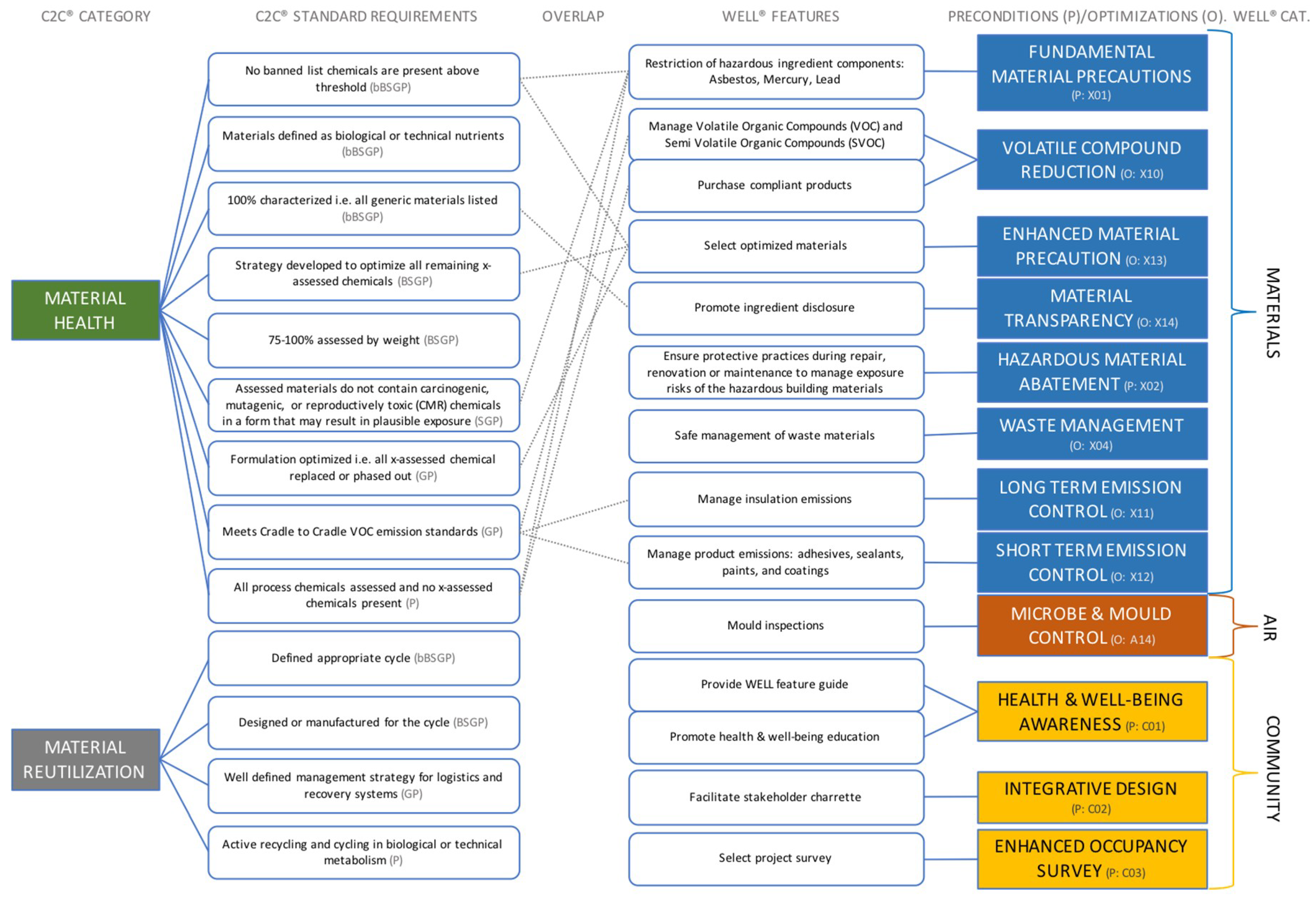

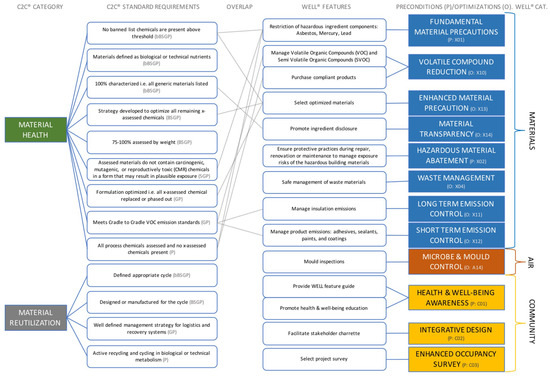

From C2C Certified™, the categories ‘Material Health’ and ‘Material reutilization’ have principal relevance for underlying study, representing the ultimate goals for all products to be manufactured using “only those materials that have been optimized and do not contain any materials/chemicals from the banned list” [60] and for industry to “eliminate the concept of ‘waste’ by designing products with materials that may be perpetually cycled to retain their value” [Ibid.].

From WELL Certified™ the aspects (concepts) Materials, Air and Community are especially relevant in this context, due to their direct relationship with material performance and stakeholder engagement. The first one-Materials-aims to reduce human exposure to hazardous building material ingredients through the restriction or elimination of compounds or products known to be toxic and the promotion of safer replacements. The second one-Air- aims to ensure high levels of indoor air quality across a building’s lifetime through diverse strategies, of which only ‘source elimination’ is considered in this study. The third one-Community-is selected given its adherence to participatory design approaches that address the physical determinants of health and well-being. It is within the concept of ‘Community’ where aspects of user-feedback loops reside.

The integrated PRP® approach opposes a straightforward division and selection of criteria, as all levels-Items, Materials, Resources-and categories-‘Product,’ ‘Extraction,’ ‘Social fairness,’ ‘Toxicity’ and ‘Reutilization-contribute equally to one unambiguous result. These aspects overlap with many of the C2C Certified™ and WELL Certified™ features, whilst adding a certain rigor with respect to completeness: all resources need to be accounted for throughout the whole project’s duration. In such as system, every modification will come to the foreground and the circularity potential can be measured in real-time, relative to the initial, baseline assessment.

Figure 2 displays the selected aspects from C2C Certified™ and WELL Certified™ standardization, as a step up to a synthesis. C2C Certified™ aspects are on the left of Figure 2, with 2 main categories and 13 selected standard requirements. WELL Certified™ aspects are on the right, following 3 categories, 12 preconditions/optimizations and 14 features. In brackets, references to the WELL Certified™ arrangement are added to the preconditions and optimizations. For C2C Certified™, references are added in brackets concerning the standard requirements’ validity for one or more certification levels, following the hierarchy: Basic (b), Bronze (B), Silver (S), Gold (G), Platinum (P). The overlap with PRP® is further addressed in subsequent sections.

Figure 2.

Selected aspects from C2C Certified™ (left) and WELL Certified™ (right), with interlinks.

4.5. Additional Features: Embodied Impacts of the Value Chain

Thus far, the focus has been on residents’ direct health and well-being in conjunction with material use and material reutilization associated with indoor partitioning. But there are impacts elsewhere in the system as well. Although those impacts are not at the core of this paper, we prefer to integrate some of them to illustrate the necessity of a systemic perspective. For this, we adhere to two aspects in the C2C Certified™ and PRP® schemes: social fairness and energy management. Concerning the former: in shifting the attention of circular building concepts to the health and well-being of residents, the social aspect of circular building is highlighted. This can never be done in any meaningful way if the health and well-being of workers in the supply chain is not addressed. Concerning the latter: currently there is growing attention in the Netherlands, as well as on EU level, about the relation between circularity, energy and climate, whilst acknowledging the significance of an integrated scope [65,66,67,68,69]. This necessitates a link between materials and energy, looking at resource use-including energy carriers and other materials.

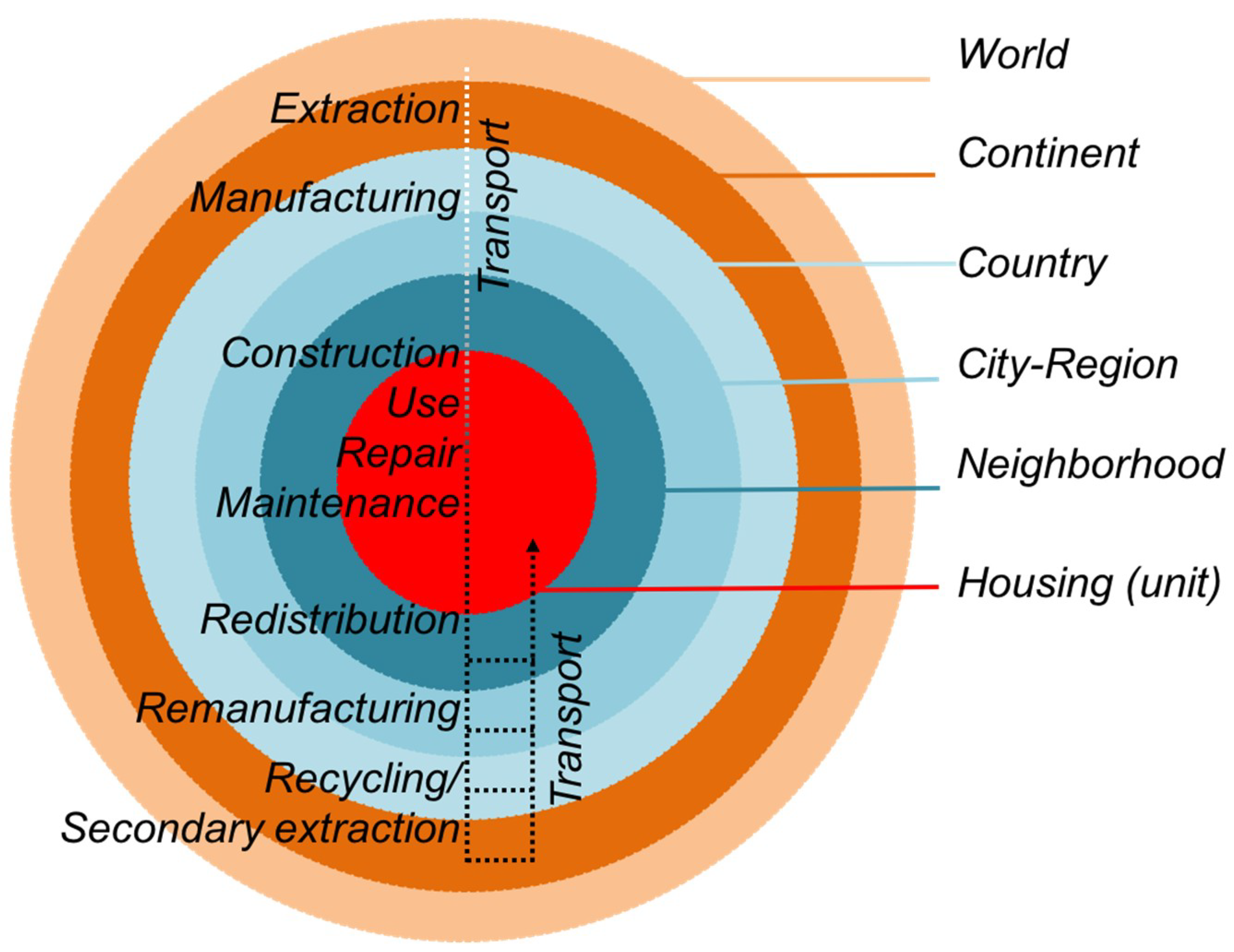

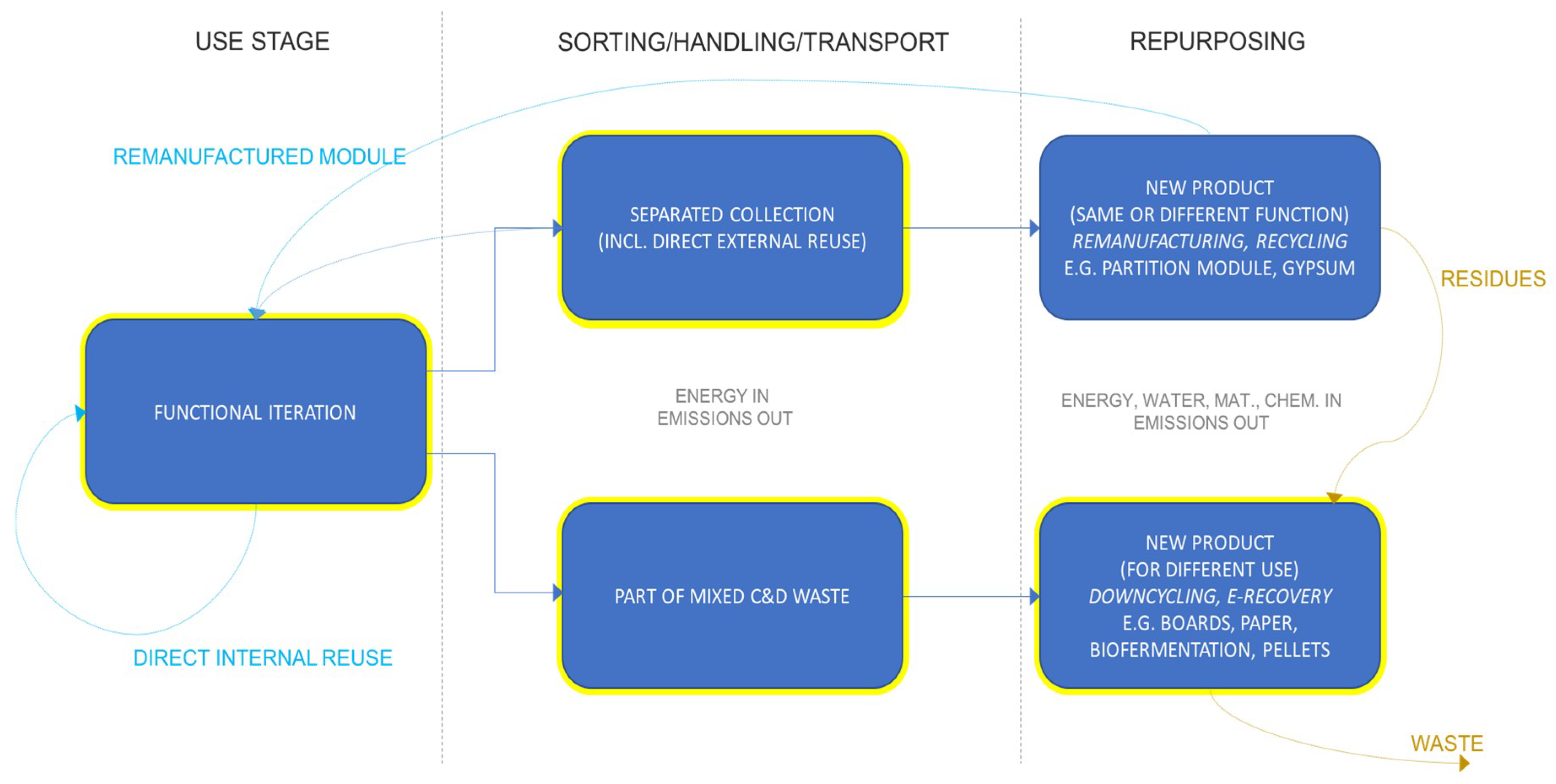

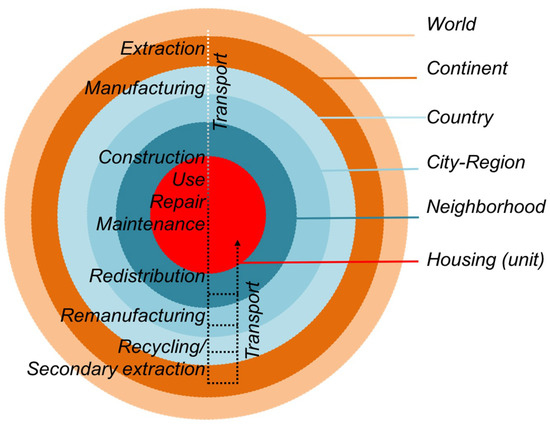

The expanded system boundary for indoor partitioning is illustrated in Figure 3, taking account of the whole value chain, including ‘reverse supply.’ Various spatial scale levels are distinguished associated with the flow and temporary storage of resources. Furthermore, various supply-chain stages are displayed. The figure reflects the assumption that in a circular economy reverse supply chain logistics will increase, whilst limiting the dispersion of resources on a global market. At least, this can be assumed for the (re/de)-materialization of interior partitioning.

Figure 3.

Systemic impact building components through spatial scale levels.

Within the C2C Certified™ framework, the focus is on a “future in which industry and commerce positively impact the energy supply, ecosystem balance and community” [60]. Hence, their focus is on renewable energy and carbon management, ultimately phasing out any use of fossil fuels, whilst managing emissions that do occur as biological nutrients. The requirements for organizations striving for certification of a product become more stringent with every hierarchical step (from basic to bronze, silver, gold and platinum). The platinum scheme includes energy use and greenhouse gas (GHG) emissions associated with the product from Cradle to Gate. This means, from a circularity-or continuous flow-perspective, that a significant part of potential embodied energy and carbon impact is not accounted for, namely from Gate all the way to-the next-Cradle. It is easy to understand why these cut-offs are applied when practicality and allocation issues are taken into account. However, for this study, we adhere to the whole value chain from one iteration to the next, as anticipated by the PRP® method. Embodied energy is defined as: the total primary energy demand for extraction, processing, manufacturing, construction, use, deconstruction and reprocessing to secondary materials associated with the partitioning components, including transport (see Figure 3). Embodied carbon signifies the related CO2 emissions.

With regard to social fairness, C2C Certified™ and PRP® bring up human rights for all stakeholders in the value chain. Both schemes refer to acknowledged social responsibility programs as a benchmark, dependent on the organization, product or project in question.

4.6. Synthesis of Criteria

Several key categories can be distinguished that in unison cover the pillars at the heart of underlying study: ‘user health,’ ‘flexibility’ and ‘circularity.’ C2C Certified™ and PRP® specifically address (1) ‘material health’ & ‘material transparency’ (due to the interlinks, sub-categories are combined into one category) and (2) ‘material reutilization.’ WELL Certified™ also focuses on material health & transparency but has no focus on the reutilization aspect. Furthermore, WELL Certified™ adds a specific criterion concerning (3) ‘microbe & mould control’ to the equation. This category is estimated to have particular relevance for this study, concerning inherent material-selection and handling-properties in relation to moisture conditions and mould growth. Moreover, WELL Certified™ introduces notions of (4) ‘health & well-being awareness,’ (5) ‘integrative design’ and (6) ‘perceived performance.’ All of which are regarded relevant in relation to product performance, notably concerning valuable feedback loops throughout supply, use and reuse chain. Finally, ‘embodied impact’ is represented by (7) ‘embodied energy’ and (8) ‘social fairness,’ which are included in C2C Certified™ as well as PRP®.

Table 3 displays a synthesized set of criteria and assessment guidelines. It concerns a total of eighteen criteria, divided over the eight aforementioned categories, derived from the assessment schemes analysed in Section 4. The term ‘Criteria’ is applied in order to relate to the requirements of C2C Certified™ as well as features, preconditions and optimizations of WELL Certified™ and integrated aspects of PRP®. Criteria are either directly transferred from their original framework or slightly adapted. The latter is the case when aspects from one source are merged, multiple sources overlap or when aspects are applied to the specific perspective of underlying study. This is indicated in brackets behind the criteria. Each criterion is accompanied by potential assessment guidelines. Where applicable, references are made to current European performance requirements for internal partitioning, as part of the European Technical Approval Guideline, ETAG 003 [70].

Table 3.

Synthesized set of criteria and assessment guidelines, including European Technical Approval Guidance (ETAG) reference.

C2C Certified™ developed an elaborate set of guidelines regarding problematic substances and threshold levels. Concerning Category 1 of Table 3, the C2C Certified™ “x-listed” classification is followed, adhering to the most ambitious level (Platinum). This includes, what C2C Certified™ refers to as, ‘banned’ list and ‘grey’ (lack of data) chemicals. Within WELL Certified™, many of those x-listed materials and chemicals are present as well, albeit distributed over multiple requirements (preconditions and optimizations), in function of its focus on in-use building performance. In most cases, WELL Certified™ refers to relevant external sources for specific standards and guidelines. PRP® does not work with precautionary lists but in providing a full account of all resources used, potentially problematic aspects, such as toxicity, will arise. In this respect, PRP® refers to external standards, such as the regulatory framework REACH of the European Chemical Agency [71]. Reutilization criteria, Category 2 of Table 3, are derived from C2C Certified™. These largely overlap with the scope of PRP®. Categories 3, 4, 5 and 6 are adapted from WELL Certified™. Category 3, regarding mould control, inherently relates to PRP® as well, being inextricably linked to the-changing-quality of the item/material/resource. Moreover, the potential addition of (treatment) substances or the devaluation of quality due to mould will also need to be reported in the PRP® framework. Category 4 concerns the importance of awareness-creation regarding the relation between buildings and health, particularly aimed at residents. Category 5 addresses the notion of co-design towards better buildings by integrating feedback loops across the value chain. This category overlaps with PRP® in case modifications to the initial materialization, on the level of item, material or resource, are concerned. Category 6 specifically zooms into the performance as perceived-and fed back-by the occupants. Lastly, in categories 7 and 8 PRP® is guiding, due to its whole-systems scope, integrating associated pre-use, use and post use processes. These two categories have an overlap with C2C Certified™.

5. Application of the Criteria to a Partitioning Product

5.1. Introduction

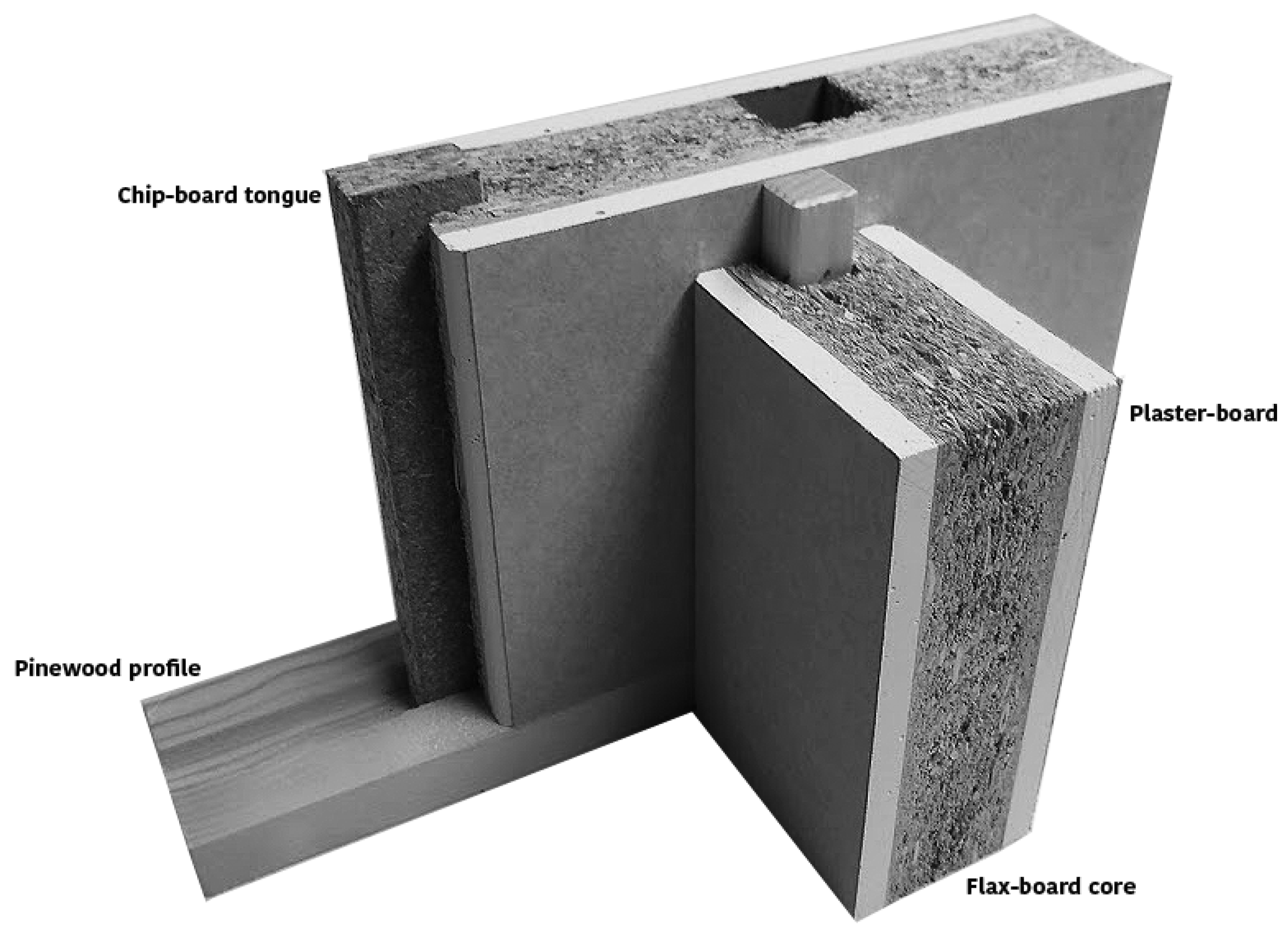

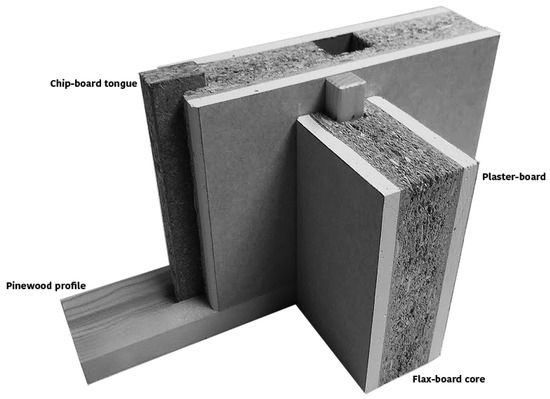

The product in focus is a solid prefab wall module, used in basic partitioning schemes for commercial and residential purposes. The core of this module is flax-board. Flax is grown for the production of linen yarns. Flax fibres are primarily meant for the textile industry but are also used in insulation materials for the building industry and in the paper industry. The seed of the plant is used for the production of linseed oil. At the end of the chain the remaining woody materials (stalk parts and roots) are used for the manufacturing of flax-boards. At the manufactory, cable-ducts are cut out and the flax-boards are bonded together with plasterboard, before being cut to standard size modules. During assembly on site, chipboard elements (“tongues”) are utilized to keep the wall modules in place and timber (pinewood) studs are applied as ceiling and floor profiles (as well as posts). Furthermore, foam is placed in floor and ceiling cavities and MDF or Meranti is applied for skirting. The thickness of the total module is approximately 54 mm: 34 mm for the flax core and 2 × 10 mm plasterboard. Figure 4 below is a sketch of the wall module and its main components.

Figure 4.

Wall module with main components.

5.2. Assessment of Product Performance

Virtual starting point: for the renovation of a multi-family apartment block in the Netherlands, the owner (for example a housing corporation) aims to meet residents’ desires for reconfiguration of the spatial layout. For the assessment, only the new materialization is taken into account, not the removal of any existing components. However, future change/removal is factored into the scope. A standard ‘fitness for use’ is assumed, following the European standard: the product complies with all requirements in that respect. Moreover, the manufacturer has a proactive stance with regard to sustainability performance of their products. This resonates, amongst others, in the ambition to adhere to circularity and flexibility principles, both concerning material performance and-reverse-logistics. The product has a C2C® certification: Basic. Finishing layers (any type of coating) are not part of the core assessment but are expected to occur at least once during functional iterations.

The set of criteria and assessment guidelines introduced in the former sections (culminating in Table 3) form the backbone of this assessment. The product is explored and assessed following eight categories with eighteen features, applying both quantitative and qualitative elements. This concerns an explorative assessment to reveal if-and to what extent-the product complies with the given criteria and which stakeholders are or need to be involved. Where applicable, the functional unit is: 1 m2 of partitioning wall. Concerning materials, the main focus is on: plasterboard, flax-board, chipboard and adhesives (bonding agent between flax-board and plasterboard). The anticipated cycle is from cradle to cradle: starting from extraction of resources and processing of the parts, to construction, use, dismantling and repurposing routes (in low or high-grade applications) whilst accounting for transport in-between. Functional cycles for residential use are estimated to be on average 15–20 years but the product has a potential service life that is much longer. All stages of the supply-use-reuse iteration are taken into account as the product’s operational model for assessment.

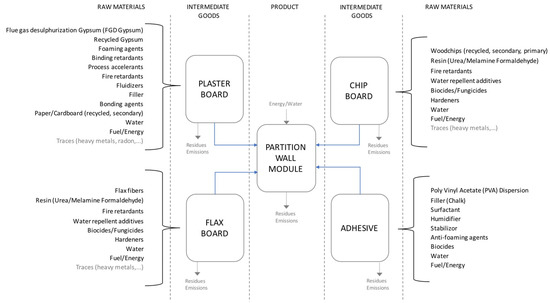

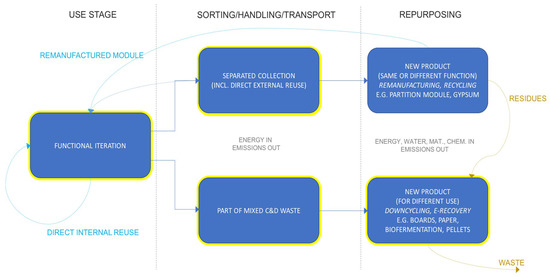

Figure 5 visualizes supply flows towards the final product. In the far left and right, a (non-exhaustive) list of most probable raw materials and resources is given. This includes additives, water and energy, as well as trace elements that may be part of the intermediate goods, albeit in small quantities. The ‘intermediate goods’ section includes residues that emerge in the manufacturing process. The same goes for the final product, which also requires the input of resources such as energy and water. Figure 6 displays end-of-service-life processes, including two scenarios: one towards down-cycling purposes, gradually reducing the value represented by the product and one towards higher-grade repurposing, maintaining or adding value. As yet, the former, low-grade, route is dominant practice in the Netherlands.

Figure 5.

From raw materials via intermediate goods to final product.

Figure 6.

From product in use to repurposing routes and final wasting. Most common processes highlighted yellow.

Table 4 lists observations and notes with regard to each of the 18 features. This is not so much a score card to pinpoint good and bad performance aspects but first and foremost a validation of the synthesized set of criteria. It objectively reflects on the status quo in relation to Circ-Flex ambitions focus on mental and physical health of residents during use.

Table 4.

Test-case assessment of partitioning product following synthesized set of criteria.

6. Discussion of the Results

After a reflection on the overall research context, particularly in relation to Dutch and EU standards, the selected criteria are discussed. Each category is briefly reflected upon, from multiple perspectives relevant for the category in question, with particular attention for operational impact. Finally, specific results are discussed in relation to the test-case.

6.1. Standardization and Assessment Context

In the Netherlands and the EU, the current regulatory framework does not yet address circularity performance of products. Occupants health, on the other hand, is part of the scope, albeit with difficulties to keep up with market dynamics as well as societal and scientific developments, as discussed in Section 3. Current approval guidelines, such as the ETAG, that each EU member state has to comply with, have limitations in that respect. Implementation of those guidelines differs greatly per member state and so does associated law-enforcement. Although-harmonization of-regulations have improved the overall quality of construction works across Europe in the last decades, it is not self-evident that this has led to inherently healthy buildings. Quality issues remain an issue in that respect. Poignant examples of poor indoor air conditions related to, for example, moisture, mould and formaldehyde problems, are still occurring throughout Europe, The Netherlands included [74]. Against this backdrop, an exploration was carried out into applicable assessment schemes with an explicit aim for occupant health and material circularity. It was found that three assessment schemes were particularly eligible with regard to aforementioned task. This is not to say that other schemes completely omit the mentioned aspects. At the contrary, many instruments on the market show thematic overlaps. However, end-user health and/or operational product performance is not commonly addressed, certainly not in an uncompromising manner. This led to the selection of C2C Certified™, WELL Certified™ and PRP®. These schemes provided a comprehensive framework in response to set task and form the basis for criteria and assessment guidelines to determine a product’s performance relating circularity, flexibility and user benefits. Other aspects, such as costs, are beyond the scope.

6.2. Reflection on the Synthesized Criteria

The synthesized set of criteria comprises eight categories. The first Category, ‘Material Health & Transparency,’ represents eight criteria that integrate all aspects deemed essential. Starting from a thorough ‘material passport,’ up to the chemical level and with specific mention of problematic substances in product or associated processes. This is, although data-heavy and potentially data-sensitive, estimated to be crucial in regard of the materialization complexity we face in our built environment, as mentioned in Section 4. In the case of C2C Certified™, this is safeguarded on the platinum level in particular, less so-or not-on lower standardization levels. The PRP® approach can be complementary in that respect. PRP® does not apply a point-based standardization hierarchy but aims at one score: the circularity potential. This score has the ability to unambiguously reveal the compliance with or deviation from full circularity, as well as where in the value chain challenges reside (both relating-data concerning-resources and human rights). Woven into the PRP® approach is the intention to engage all key stakeholders in the value network, in order to effectively source data and create awareness. At this moment in time, one could expect barriers to emerge, relating availability and accessibility of data. This touches upon several interrelated issues, concerning, for example, material complexity and ingrained habits relating decision-making processes, as addressed in Section 3.2. Next to that, a point-based scoring system is more familiar to most and the associated certificates are internalized in market mechanisms. However, such a code of conduct does not mean that circularity-as an inherently systemic phenomenon-is always facilitated. On the contrary, one could argue. As long as incentives lack to thoroughly relate individual operations to overarching systems performance, circularity will never take off. In that respect, creating awareness and engagement across the chain of custody is an essential step in the transition from linear to circular systems.

Regarding Category 1, the notions of progress and time are addressed by the inclusion of optimization strategies and anticipation of repair and maintenance cycles. Those aspects underscore the necessity to integrate learning loops and operational-primarily short-cyclic-interventions associated with the product. C2C Certified™, with its focus on designers and manufacturers, emphasizes learning loops for product optimization, whereas WELL Certified™ has specific attention for interventions in the use-stage. The hazardous materials-Asbestos, Lead and PCBs–part of this WELL Certified™ feature will not be part of new C2C Certified™ products (given the banned list, in alignment with the Living Building Challenge Red List [75]) and will thus not end up in the materialization. However, this does not address other aspects that concern product-interventions in the use stage and its impact on health and/or circularity potential. This will be addressed under Category 4. Lastly, the criteria on long-term and short-term emission control, derived from WELL Certified™ in overlap with C2C Certified™, are explicitly distinguished, given their relevance for the scope of this study, that is, infill product performance and functional iterations. Such products can emit VOCs, either in the short run or over a longer period. It was stated in Section 3 that norms tend to focus on products rather than accumulated exposure. This underscores the urge for more integrated approaches. The difficulty to address this in single product assessments reveals the necessity for stronger communication between scale levels and during multiple temporal intervals. In that respect, there is currently no attention for the question: how many qualified products can safely accumulate in relation to VOC emissions and for how long, in a residential space?

In Category 2, the reutilization of materials in cyclic models is addressed through defining and designing products and processes appropriately, as well as achieving operational strategies and execution management. Especially the latter is thought to be important for bridging the gap between theory and practice. From that viewpoint, PRP® has developed its model for enforcement of agreements between clients and suppliers, most notably concerning take-back models and reverse logistics. This proposition concerns legally binding contracts that might be challenging for some organizations but is estimated to be instrumental in mobilizing the market and creating new potential for safeguarding actual material circulation in the future. What happens in-use, between supply and reverse supply, is decisive in this respect.

Category 3, regarding mould, has been included in order to anticipate problems that can emerge over time as a result of product behaviour, either intrinsically or in relation to contextual conditions. This indicates, again, the fine line between product and building scales. The main concern is the role a product has in the possible creation of mould growth. This is usually related to moisture conditions but has also strong connotations with applied coatings. It can be expected that products themselves are in line with the required norms, which shifts the attention to the way products are transported, stored and treated. Key aspects are, amongst others, storage off the floor and away from weather exposure; dry and ventilated installation area; wicking prevention; and clear communication regarding wall finishing and wall treatment. Appropriate guidelines and agreements are thus required, as well as multiple inspections, taking account of the fact that it takes several days for mould and mildew to develop [76,77].

Category 4, on health & well-being information of products, is estimated to be a key aspect of extended stewardship, in which the use and reuse stages are internalized effectively. This criterion is specifically aimed at increasing the awareness of-and feedback loops from-building users regarding the relation between health, buildings and materials. Anticipation of interventions that affect the product quality is important, as it inevitably impacts the performance in terms of health, flexibility, and/or circularity. WELL Certified™ introduces a wider interpretation of health and well-being, from the viewpoint of happiness and sense-making, as addressed in Section 3 and Section 4. Within the current criteria such perspectives are addressed implicitly, needing further elaboration.

Categories 5 and 6 have close ties with aspects of co-design and feedback loops. Category 5 hints at a specific part of the WELL Certified™ precondition ‘Integrative Design.’ Although WELL Certified™ concerns the whole building scale, the integration of stakeholders, such as owners, occupants, architects, engineers and managers, during the establishment of a project, is thought no less relevant with regard to specific infill products. Particular emphasis is put on engaging those stakeholders that are usually kept out of the realization process or those only concerned with fragments of it. This taps into the notion of interrelated (sub)systems that-in unison-define the quality of a whole building. This has clear links with factors such as diversity and change, as put forward in Section 3 but also with more straightforward aspects of logical sequences in which construction takes place. Category 6, on the other hand, specifically addresses the need for increased monitoring of a product-and building’s-performance beyond energy efficiency and thermal comfort. Underlying study points at aspects of materialization, tying into health, well-being and flexibility potential. Post occupancy surveys may be appropriate tools for this task.

Categories 4, 5 and 6 unveil a challenge, relating the interface between product and building scopes. For example, regarding the question how far a product supplier’s responsibility stretches, beyond providing guidelines and professional narratives. What type of monitoring schemes are appropriate? And who coordinates alignment between the stakeholders in this stage? For the most part, this remains a grey zone. Knowing that Category 2 primarily hints at material recovery and reutilization after- not the influencing factors during- a functional iteration, this question relates mainly to the realm of Categories 4, 5 and 6. Feedback loops and data-sharing between stakeholders could inform maintenance, repair, reuse and upgrade cycles. However, it does not say a lot about actual operational performance, defining and securing the required mechanisms at the right moment by the right stakeholder. Guidelines, contracts, (dynamic) bills of materials and software could be instrumental here, much in the way PRP® anticipates. In a PRP® trajectory, each intervention or mutation needs to be registered, be it on the entry level of Item, Material or Resource (see Section 4.3). The impact on health and circularity potential-relative to a baseline analysis-can thus be assessed in real-time. This requires consistent coordination efforts, most likely conducted by a housing or facility manager, in close conjunction with residents, suppliers and (maintenance) contractors. Although first initiatives in this direction have started, more experience to build on is needed, particularly regarding residential settings. It has to be seen which models and methods would succeed in Dutch housing. The building sector in the Netherlands is different from, for example, the Japanese one, where lifelong contractual relationships between stakeholders, such as housing suppliers, owners and users, are more common [Geldermans, 2009]. Further research in that field should, amongst others, deepen the link between business models from the supply side and value as perceived by the user. These considerations also touch upon the application of ICT in homes. Attention for smart technology and building-information-modelling is increasing but innovations have a long way to go, certainly concerning stakeholder-integration in the residential sector [78,79,80].

Finally, embodied aspects resonate in Categories 7 and 8. This was not part of the core scope but integrated to address systemic relevance and threats of burden-shifting. Of course, many other embodied aspects would apply here as well. A key challenge is related to whole-systems-quantification regarding embodied energy and carbon: getting the functional unit and system boundaries right, agreeing upon appropriate cut-offs. This will come back briefly in reflection on the test-case.

6.3. Lessons from the Test-Case

The test-case was focused on a relatively straightforward infill product. Closer examination, however, paints a more complex picture. Following one product back to its intermediate goods and subsequent raw materials shows an exponential increase in applied resources. And that is not the end-or beginning-of the line, as most of those resources originate elsewhere. Confidentiality issues, unknowns, as well as cultural barriers or ingrained habits pop up in this respect, as addressed in Section 3. The C2C certified™ scheme offers a system to deal with this but this is not applicable to the basic certification level that the given product complies with. That said, a generic characterization is already valuable, pinpointing potential weak spots with regard to health issues or Circ-Flex potential. In this case one can think of formaldehyde content and product composition. Regarding the former, the product complies with all relevant norms, as indicated in Section 6.2. In accordance with the regulatory framework, this does not take into consideration potential accumulated exposure. The latter aspect (product composition) relates to the fact that it concerns a composite product, in which the constituent materials together achieve new properties. Those properties reflect the core functional aspects: room dividing, robust, low-weight, cost-effective, modular and such. The product is not designed for circularity but is compatible with product and operational models that aim at longevity and short reuse cycles: the product could be reused multiple times in similar applications. The manufacturer mentions a predicted service life of 75 years but there is no evidence for this available yet. Whether or not reuse actually happens is currently beyond the scope of the manufacturer and depends greatly on what happens in between. How is the product treated? What finishing layers or jointing products are used? This confirms the remark in Section 6.2 on the grey zone between the scopes of product and building performance. Also with regard to mould issues, the application of coatings are decisive factors. This needs to be internalized one way or another, in order to capitalize on the circularity, flexibility and health potential. Finally, at the very end of its functional life, the product can be downcycled. Being a composite product makes it impossible to do so in a high-grade, renewable manner.

Concerning Categories 3–6, the product does not comply in the way that is intended in this research or lack of data inhibits a proper assessment. This is in line with the regulatory framework and organisational culture in the sector. Being engaged in the circular building discourse, however, the supplier explores ways for improvement. This greatly correlates with and depends on shared efforts between value chain partners, willing to play a pioneering role. At this moment in time, developments in this direction are in their infancy. Lastly, it could be advocated that inherent benefits of the product-and the supplier’s agility-are related with Categories 5 and 6. Particularly in regard of the assembly and disassembly speed and a certain dimensional modularity flexibility.

Taking a brief look into the supply-chain learns that the companies that provide intermediate goods are generally willing to think along with envisioned changes in the end-product’s performance. However, they are bound by their own business models and internal processes. A peek into the world of gypsum, for example, immediately shows the complexity here. Gypsum can be recycled over and over again, only losing fractions of its initial quality along the way. In the test-case product, recycled gypsum as well as flue gas desulphurization (FGD) gypsum replace virgin, natural gypsum for 100%. FGD, coming from coal-fired power plants in Germany and the Netherlands, currently takes up 90% of the share. Coal-fired power plants are gradually phased out between now and 2035. This necessitates the exploration of new sourcing options, unavoidably also leading to virgin gypsum, to be shipped in from farther away locations. This is but one example of interdependencies within a complex system, touching upon (embodied) energy and climate, as well as circularity considerations.

7. Conclusions

Against the background of discussions around sustainability in the built environment, emerged the concept of circular building. Circular building accentuates the closing and coupling of material flows in order to establish effective and efficient resource cycles but can–in fact: should-not be isolated from topics such as energy, climate, biodiversity, water use, social fairness, air emissions and health. In that respect, the sustainable development goals, as developed by the United Nations, need to be approached holistically [57].

The current traction of CB comes at a cost, namely that the market moves faster than science, leading to a lack of evidence based knowledge and an overflow of interpretations and assessment methods. Understandably, most of those assessment methods narrow down the scope to manageable sizes, inherently simplifying the complexity. Among the aspects that are often underrepresented in those methods are: actual performance on the product and operational level and the impact on-and role of-residents. This paper took those two vantage points to explore the state of affairs and integrate criteria that better reflect the needs in this respect, specifically aimed at Circ-Flex infill products and health. This led to the prioritization and synthesis of criteria from three different assessment schemes. The purpose of this exercise was not to compare existing tools but to synergize. It was shown that these schemes have overlapping and complementary features that, in unison, provide a solid basis for an integrated assessment of circularity potential and health impact of infill products. In total, eight categories were defined, comprising eighteen criteria, that were tested on a non-bearing partitioning product. This helped to validate the set of criteria, while simultaneously pinpointing specific areas of intervention to match the product’s performance with Circ-Flex requirements. With regard to the generic criteria, main insights that came to the foreground were related to the connection between product performance and building performance over time. Specifically concerning orphan operational processes, that is, those processes that are likely to play a decisive role but are insufficiently addressed in current assessment methods. New mind-sets are required in the building and housing sector to implement design and monitoring systems that integrate this grey zone. Product suppliers need to internalize the use and reutilization stage or have it outsourced to another party, such as a housing corporation or facility manager. Either way, it must become part of the client-supplier negotiation. This ties into material composition and health aspects much more than is currently the case. Detailed-up to date-material and product data are pre-conditional to unlock flexibility and circularity capacity. And potentially damaging emissions associated with building products are inextricably linked to this. Design, maintenance and upgrade cycles will thus get a different status in such a model and the role of the building occupants will also change. Safeguarding a healthy interior over time, whilst securing circularity potential in the future, necessitates reshuffling of value models and value chains, including the binding agreements and multi-criteria learning loops that feed them.

Author Contributions

Conceptualization, B.G. and M.T.; Data curation, B.G.; Formal analysis, B.G.; Investigation, B.G.; Methodology, B.G., M.T. and P.L.; Supervision, M.T. and P.L.

Funding

This research received no external funding.

Acknowledgments

This study has benefitted from the kind information input of the following companies: Faay Vianen B.V.; Intercol Kleefstoffen B.V.; Blok Plaatmateriaal; Siniat/Etex B.V.; Knauf B.V.; BAM Bouw & Vastgoed Nederland B.V.; Beelen Groep B.V.; Rendemint B.V. No dependencies, financial or otherwise, exist between the authors and those companies.

Conflicts of Interest

The authors declare no conflict of interest

References

- Van Dijk, S.; Tenpierik, M.; van den Dobbelsteen, A. Continuing the building’s cycles: A literature review and analysis of current systems theories in comparison with the theory of Cradle to Cradle. Resour. Conserv. Recycl. 2014, 82, 21–34. [Google Scholar] [CrossRef]

- Den Hollander, M.C.; Bakker, C.A.; Hultink, E.J. Product design in a circular economy development of a typology of key concepts and terms. J. Ind. Ecol. 2017, 21, 515–527. [Google Scholar] [CrossRef]

- Geldermans, B.; Tenpierik, M.; Luscuere, P. Circular and flexible infill concepts: Integration of the residential user perspective. Sustainability 2019, 11, 261. [Google Scholar] [CrossRef]

- World Health Organization. Circular Economy and Health: Opportunities and Risks; World Health Organization Regional Office for Europe: Copenhagen, Denmark, 2018; ISBN 9789289053341. [Google Scholar]

- Bluyssen, P.M. The Indoor Environment Handbook: How to Make Buildings Healthy and Comfortable; Earthscan: London, UK, 2009. [Google Scholar]

- Leupen, B. The frame and the generic space, a new way of looking to flexibility. In Proceedings of the Open Building and Sustainable Environment Conference, Paris, France, 20–22 September 2004. [Google Scholar]

- Houben, J.M.J.F. Kwaliteitsbeleid Voor de Nederlandse Woningvoorraad-Historie, Methodiek, Toepassingen, Beleidsopties. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 1989. [Google Scholar]

- Thijssen, C.C.F.; Meijer, C.J. Bouwconstructieve Analyse van Naoorlogse Meergezinshuizen in de Non-Profit Huursector 1946–1965; Delft University Press, Delft University of Technology: Delft, The Netherlands, 1988. [Google Scholar]

- Van der Schaar, J. Groei en Bloei van Het Nederlandse Volkshuisvestingsbeleid. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 1987. [Google Scholar]

- Priemus, H. Volkshuisvesting in de Vuurlinie; Delft University Press, Delft University of Technology: Delft, The Netherlands, 1983; ISBN 90-6275-120-2. [Google Scholar]

- Habraken, N.J. De Dragers en de Mensen—Het Einde van de Massawoningbouw; Scheltema & Holkema: Amsterdam, The Netherlands, 1961. [Google Scholar]

- Brand, S. How Buildings Learn; Viking: New York, NY, USA, 1994; ISBN 9780670835157. [Google Scholar]

- Geldermans, R.J. Cradle-to-Cradibility: Two Material Cycles and the Challenges of Closed Loops in Construction. Master’s Thesis, Delft University of Technology and Leiden University, Leiden, The Netherlands, 2009. [Google Scholar]

- Geldermans, R.J. Design for change and circularity: Accommodating circular material & product flows in construction. Energy Procedia 2016, 96, 301–311. [Google Scholar]

- Korhonen, J.; Honskalo, A.; Seppala, J. Circular economy: The concept and its limitations. J. Clean. Prod. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Pallasmaa, J. The Eyes of the Skin, Architecture and the Senses; Wiley Academy: Chichester, UK, 2005. [Google Scholar]

- Fanger, P.O. What is IAQ? Indoor Air 2006, 16, 328–334. [Google Scholar] [CrossRef]

- Klimovich, K.; Anagnostopoulos, F.; de Groote, M.; Staniaszek, D.; Nicolle, R. Building 4 People: People-Centric Buildings for European Citizens; Buildings 2030: Brussels, Belgium, 2017. [Google Scholar]

- Bluyssen, P.M. Understanding the Indoor Environment. Published Inaugural Speech; Delft University of Technology: Delft, The Netherlands, 2013. [Google Scholar]

- Bluyssen, P.M. Management of the Indoor Environment: From a Component Related to an Interactive Top-down Approach. Indoor Built Environ. 2008, 17, 483–495. [Google Scholar] [CrossRef]

- Mathijssen, E.A.M.; Boger, R.P. Regelgeving Stoffen in Het Binnenmilieu in Nederland en Andere eu-Landen-Een Verkennende Studie; RIVM brief-rapport 2016-0112; RIVM: Bilthoven, The Netherlands, 2016. [Google Scholar]

- Scientific Committee on Health and Environmental Risks (SCHER). Opinion on Risk Assessment on Indoor Air Quality; European Commission, Health & Consumer Protection DG: Brussels, Belgium, 2007. [Google Scholar]

- Sundell, J. On the history of indoor air quality and health. Indoor Air 2014, 14, 51–58. [Google Scholar] [CrossRef]

- McDonough, W.; Braungart, M. Towards a sustaining architecture for the 21st century: The promise of cradle-to-cradle design. Ind. Environ. 2003, 26, 13–16. [Google Scholar]

- Yang, F.; Tepfler, S. Prescription for Healthier Building Materials: A Design and Implementation Protocol; AIA/Arup: Washington, DC, USA, 2018. [Google Scholar]

- Steinemann, A.; Wargocki, P.; Richamnchi, B. Ten questions concerning green buildings and indoor air quality. Build. Environ. 2017, 112, 351–358. [Google Scholar] [CrossRef]

- Mulhall, D.; Braungart, M. Cradle to Cradle criteria for the built environment; Duurzaam Gebouwd/CEO Media BV: Nunspeet, The Netherlands, 2010; ISBN 9789491083013. [Google Scholar]

- World Health Organization. Guidelines for Indoor Air Quality: Selected Pollutants; World Health Organization Regional Office for Europe: Copenhagen, Denmark, 2010. [Google Scholar]

- International WELL Building Institute. The WELL Building Standard® Version 1.0; International WELL Building Institute: New York, NY, USA, 2015. [Google Scholar]

- Bluyssen, P.M.; Oostra, M.A.R.; Meertins, D. Understanding the indoor environment: How to assess and improve indoor environmental quality of people? In Proceedings of the CLIMA 2013: 11th REHVA World Congress & 8th International Conference on IAQVEC “Energy Efficient, Smart and Healthy Buildings”, Prague, Czech Republic, 16–19 June 2013. [Google Scholar]

- Wei, W.; Ramalho, O.; Mandin, C. Indoor air quality requirements in green building certifications. Build. Environ. 2015, 92, 10–19. [Google Scholar] [CrossRef]

- Allen, J.G.; MacNaughton, P.; Cedeno Laurent, J.G.; Flanigan, S.S.; Eitland, E.S.; Spengler, J.D. Green buildings and health. Curr. Environ. Health Rep. 2015, 2, 250–258. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Circularity in the Built Environment: A Compilation of Case-Studies from the CE100; Ellen MacArthur Foundation: Cowes, UK, 2016. [Google Scholar]

- Al Horr, Y.; Arif, M.; Katafygiotou, M.; Mazroei, A.; Kaushik, A.; Elsarrag, E. Impact of indoor environmental quality on occupant well-being and comfort: A review of the literature. Int. J. Sustain. Built Environ. 2016, 5, 1–11. [Google Scholar] [CrossRef]

- Levasseur, M.E.; Poulin, P.; Campagna, C.; Leclerc, J.M. Integrated management of residential indoor air quality: A call for stakeholders in a changing climate. Int. J. Environ. Res. Public Health 2017, 14, 1455. [Google Scholar] [CrossRef]

- Pardo, R.; Schweitzer, J.P. A Long-Term Strategy for a European Circular Economy—Setting the Course for Success; Policy Paper produced for the Think2030 Project: Brussels, Belgium, 2018. [Google Scholar]

- European Commission. Directive (EU) 2018/844 of the European parliament and of the council-amending directive 2010/31/EU on the energy performance of buildings and Directive 2012/27/EU on energy efficiency. Off. J. Eur. Union 2018, 156, 75–91. [Google Scholar]

- Dimitrolopoulou, C. Ventilation in European dwellings: A review. Build. Environ. 2012, 47, 109–125. [Google Scholar] [CrossRef]

- Swankie, W. Effects of Temperature on the Emission Rate of Formaldehyde from Medium Density Fiberboard in a Controlled Chamber. Bachelor’s Thesis, University of South Florida, Tampa, FL, USA, 2017. [Google Scholar]

- Abdul–Wahab, S.A.; Chin Fah En, S.; Elkamel, A.; Ahmadi, L.; Yetilmezsoy, K. A review of standards and guidelines set by international bodies for the parameters of indoor air quality. Atmos. Pollut. Res. 2015, 6, 751–767. [Google Scholar] [CrossRef]

- Chin, J.Y.; Godwin, C.; Parker, E.; Robins, T.; Lewis, T.; Harbin, P.; Batterman, S. Levels and sources of volatile organic compounds in homes of children with asthma. Indoor Air 2014, 24, 403–415. [Google Scholar] [CrossRef]

- Mendell, M.J. Indoor residential chemical emissions as risk factors for respiratory and allergic effects in children: A review. Indoor Air 2007, 17, 259–277. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Saidani, M.; Yannou, B.; Cluzel, F. How to assess product performance in the circular economy? Proposed requirements for the design of a circularity measurement framework. Recycling 2017, 2, 6. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Linder, M.; Sarasini, S.; van Loon, P. A metric for quantifying product-level circularity. J. Ind. Ecol. 2017, 21, 545–558. [Google Scholar] [CrossRef]

- Korhonen, J.; Nuur, C.; Feldmann, A.; Birkie, S.E. Circular economy as an essentially contested concept. J. Clean. Prod. 2017, 175, 544–552. [Google Scholar] [CrossRef]

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy–From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2017, 135, 190–201. [Google Scholar] [CrossRef]

- Pomponi, F.; Moncaster, A. Circular economy for the built environment: A research framework. J. Clean. Prod. 2017, 143, 710–718. [Google Scholar] [CrossRef]

- Leising, E.; Quist, J.; Bocken, N. Circular economy in the building sector: Three cases and a collaboration tool. J. Clean. Prod. 2018, 176, 976–989. [Google Scholar] [CrossRef]

- Balanay, R.; Halog, A. Charting policy directions for mining’s sustainability with circular economy. Recycling 2016, 2, 219–231. [Google Scholar] [CrossRef]

- Banaité, D. Towards circular economy: Analysis of indicators in the context of sustainable development. In Proceedings of the International Scientific Conference for Young Researchers, Social Transformations in Contemporary Society, Mykolas Romeris University, Vilnius, Lithuania, 2–3 June 2016. [Google Scholar]

- Nguyen, H.; Stuchtey, M.; Zils, M. Remaking the Industrial Economy. McKinsey Quarterly, February 2014; McKinsey & Company: New York, NY, USA, 2014. [Google Scholar]

- Cayzer, S.; Griffiths, P.; Beghetto, V. Design of indicators for measuring product performance in the circular economy. Int. J. Sustain. Eng. 2017, 10, 289–298. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation and Granta Material Intelligence. Circularity Indicators, An Approach to Measuring Circularity; Ellen MacArthur Foundation: Cowen, UK, 2015. [Google Scholar]

- World Business Council for Sustainable Development. Circular Metrics, Landscape Analysis; WBCSD: Geneva, Switzerland, 2018. [Google Scholar]

- United Nations Development Programme. Sustainable Development Goals; UNDP: New York, NY, USA, 2015. [Google Scholar]

- Luscuere, L. Materials Passports: Optimising value recovery from materials. Waste Resour. Manag. 2017, 170, 25–28. [Google Scholar] [CrossRef]

- Boström, J. Making the right decision for circularity. In Proceedings of the BAMB Final Conference, Brussels, Belgium, 5–7 February 2019. [Google Scholar]

- Cradle to Cradle Products Innovation Institute and McDonough Braungart Design Chemistry. C2C Certified Product Standard V3.1; Cradle to Cradle Products Innovation Institute: Oakland, CA, USA, 2016. [Google Scholar]

- International WELL Building Institute. The WELL Building Standard® v1 with Q1 2018 Addenda; International WELL Building Institute: New York, NY, USA, 2018. [Google Scholar]

- International WELL Building Institute. The WELL Building Standard® v2™ Pilot. Available online: v2.wellcertified.com/v2.1c/cn/overview (accessed on 20 February 2019).

- International WELL Building Institute. The WELL Multifamily Residential Pilot Addendum, Version A; International WELL Building Institute: New York, NY, USA, 2018. [Google Scholar]

- Rendemint. Pre-Returnable e-Procurement Purchasing Tool® V3.1. Licensed; Rendemint: Ridderkerk, The Netherlands, 2019. [Google Scholar]

- Drissen, E.; Vollebergh, H. Kan de Circulaire Economie een Bijdrage Leveren aan de Energietransitie; Planbureau Voor de Leefomgeving: The Hague, The Netherlands, 2018. [Google Scholar]

- Kerkhof, A.; Quant, M.; Srivastav, P.; Neelis, M.; Blok, K. Circular Economy and Environmental Priorities for Business; Ecofys, WBCSD: Geneva, Switzerland, 2017. [Google Scholar]

- Van Exter, P.; Bosch, S.; Schipper, B.; Sprenger, B.; Kleijn, R. Metaalvraag van de Nederlandse Energietransitie-Navigeren in een Complexe Keten; Ministry of Infrastructure and Water Management: The Hague, The Netherlands, 2018. [Google Scholar]

- Material Economics. The Circular Economy: A Powerful Force for Climate Mitigation; Material Economics: Stockholm, Sweden, 2018. [Google Scholar]

- Rietveld, E.; Boonman, H.; van Harmelen, T.; Hauck, M. , Bastein, T. Global Energy Transition and Metal Demand-an Introduction and Circular Economy Perspectives; TNO: The Hague, The Netherlands, 2019. [Google Scholar]

- ETAG 003. Guideline for European Technical Approval for Internal Partition Kits for Use as Non-Loadbearing Walls; European Organisation for Technical Assessment: Brussels, Belgium, 2012. [Google Scholar]

- European Chemicals Agency. Registration, Evaluation, Authorisation & restriction of Chemicals (REACH). Available online: http://ec.europa.eu/environment/chemicals/reach/reach_en.htm (accessed on 24 January 2019).

- Smith, K.; Dooley, D.; Brown, E.J. Standard Method for the Testing and Evaluation of Volatile Organic Chemical Emissions from Indoor Sources Using Environmental Chambers Version 1.2; California Department of Public Health: Sacramento, CA, USA, 2017. [Google Scholar]